Preparation method of easy welding high strength toughness X80 pipe line steel for magnesium treatment

A pipeline steel and easy-to-weld technology, applied in the field of laboratory preparation of easy-to-weld high-strength and tough X80 pipeline steel, can solve the problems of insufficient welding performance, inability to weld with high line energy (stability), etc. Effect of Line Energy on Welding Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The design composition of the high-strength and high-toughness pipeline steel in this embodiment is: C 0.042, Si 0.18, Mn 1.65, P 0.001, S 0.002, O 0.0015, Al 0.02, Nb 0.045, Ti 0.015, Cr 0.3, Mo 0.22, Ni 0.25, Cu 0.26, Mg 0.005, Ti / Mg=3, the rest are Fe and unavoidable impurities.

[0036] According to the above ingredients, it is smelted in a vacuum induction furnace and cast into a slab of 50Kg; the slab is cut into a riser, and forged into a slab with a thickness of 100mm, a width of 90mm, and a length of 80mm; Heating time 90min; furnace temperature 1170°C, rough rolling start temperature 1150°C, rough rolling finish temperature 990°C; intermediate billet waiting temperature 50mm; finish rolling start temperature 870°C, finish rolling finish temperature 800°C; finish rolling Then quickly enter the ACC controlled cooling, the cooling speed is 20°C / s; the red temperature is 470°C, and the product thickness is 15mm.

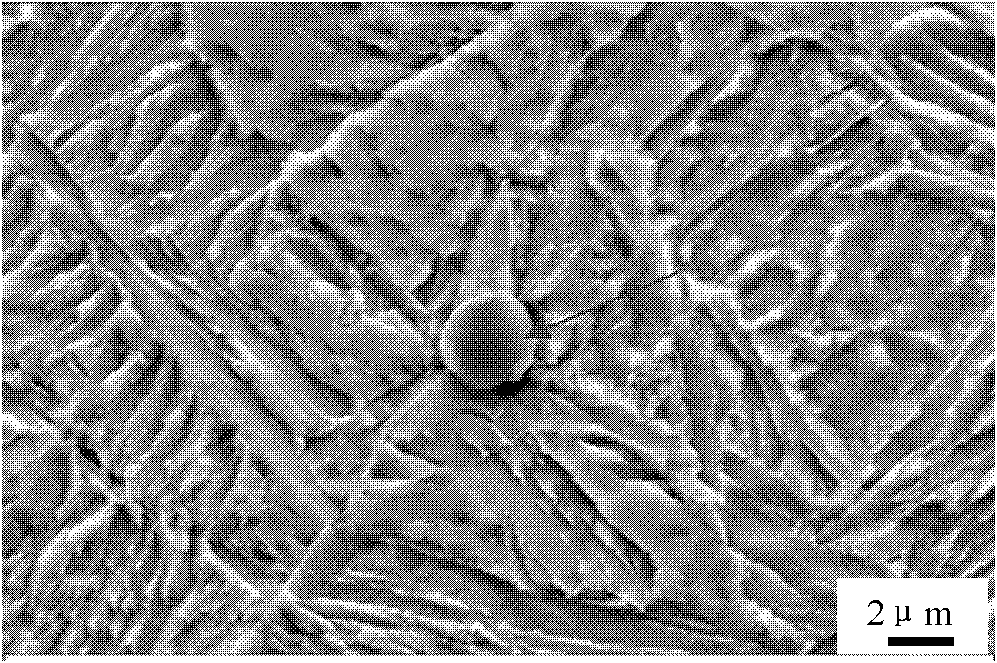

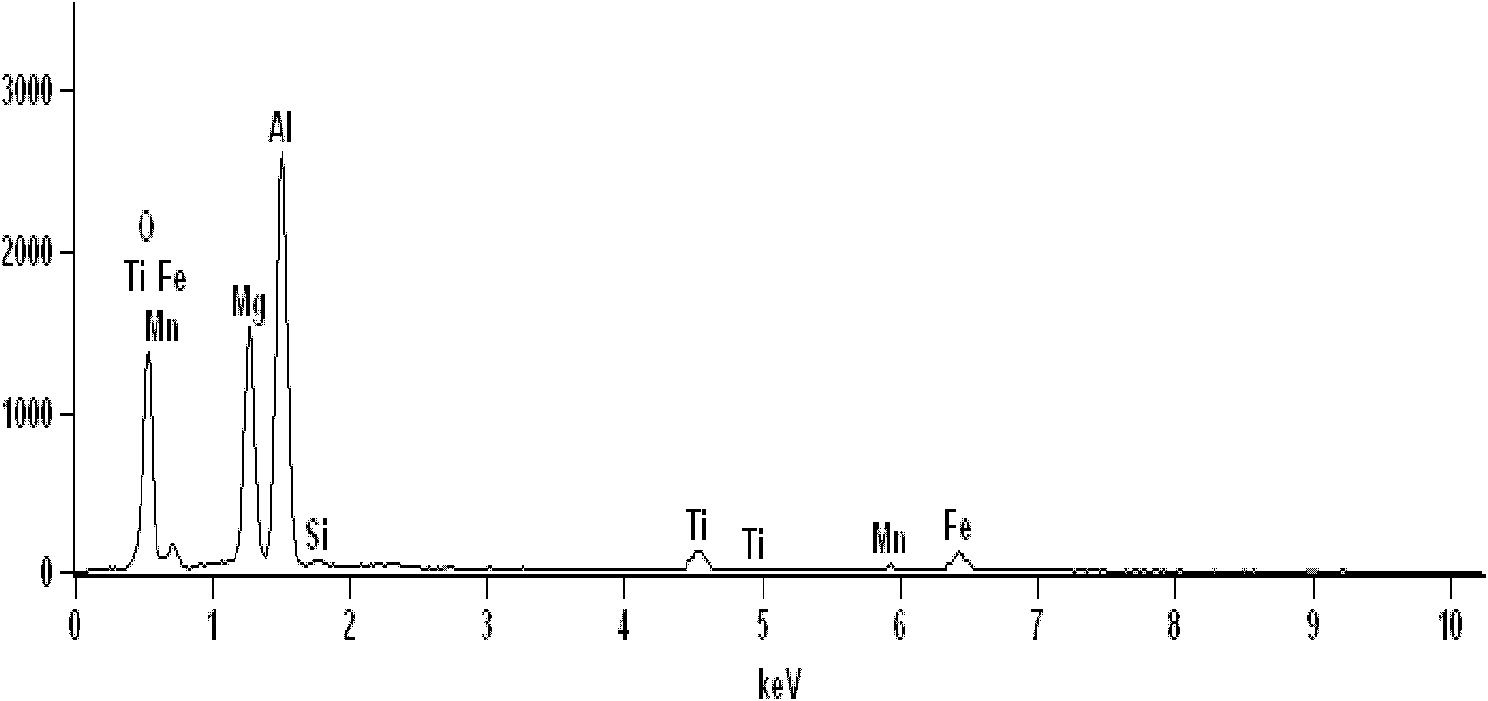

[0037] figure 1 and figure 2 They are the scan...

Embodiment 2

[0039] The design composition of the high-strength and high-toughness pipeline steel in this embodiment is: C 0.041, Si 0.20, Mn 1.70, P 0.001, S 0.002, O 0.0015, Al 0.02, Nb 0.040, Ti 0.025, Cr 0.4, Mo 0.20, Ni 0.24, Cu 0.21, Mg 0.0025, Ti / Mg=10, the rest are Fe and unavoidable impurities.

[0040] According to the above composition, it is smelted in a vacuum induction furnace and cast into a slab of 50Kg; the slab is cut into a riser, and forged into a slab with a thickness of 100mm, a width of 90mm, and a length of 80mm; the slab is sent to the heating furnace, and the heating temperature is 1200°C The heating time is 90 minutes; the furnace temperature is 1180°C, the rough rolling start temperature is 1160°C, the rough rolling finish temperature is 990°C; After rolling, it quickly enters the ACC controlled cooling, the cooling rate is 22°C / s; the red return temperature is 440°C, and the product thickness is 12mm.

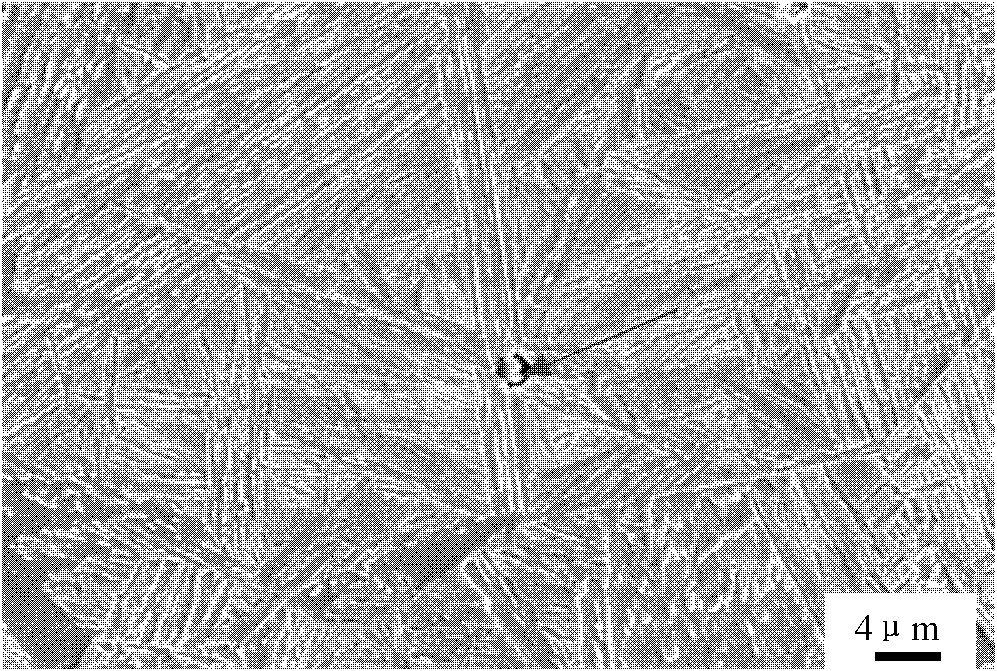

[0041] image 3 and Figure 4 It is the scanned tissue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com