Low-temperature steel for engineering machinery and production method thereof

A technology for mechanical steel and low-temperature engineering, applied in the direction of temperature control, etc., can solve the problems of difficulty in ensuring the low-temperature impact toughness and welding performance of materials, poor control and rolling effect, and difficulty in ensuring the requirements of plate shape, etc., and achieve good industrial implementation. Feasibility, excellent low temperature impact toughness, the effect of ensuring the quality of the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The specific method of producing 600MPa high-strength engineering machinery steel is as follows: continuous casting of molten steel smelted in a 220-ton converter and refined outside the furnace into billets, rolling in a 2250 hot continuous rolling production line at a heating temperature of 1200-1220 °C, The entrance temperature of finish rolling is 960℃~1000℃, the thickness of intermediate billet is 42mm~54mm, the temperature of final rolling is 810℃~830℃, after rolling, it is cooled to the target coiling temperature of 590℃ by laminar cooling, and bell annealing is carried out after coiling Remove residual stress. The chemical composition of steel produced by the present invention and contrast steel, mechanical property and weldability contrast situation are as shown in table 1:

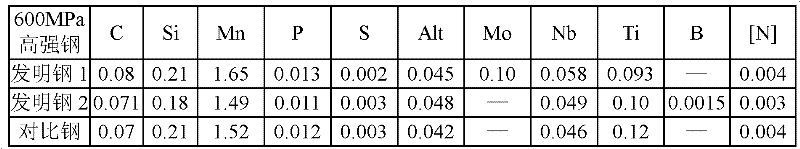

[0047] Table 1 Chemical composition of 600MPa high-strength steel

[0048]

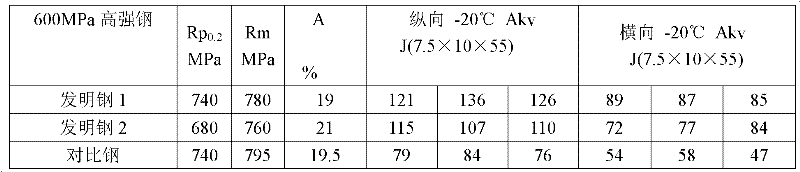

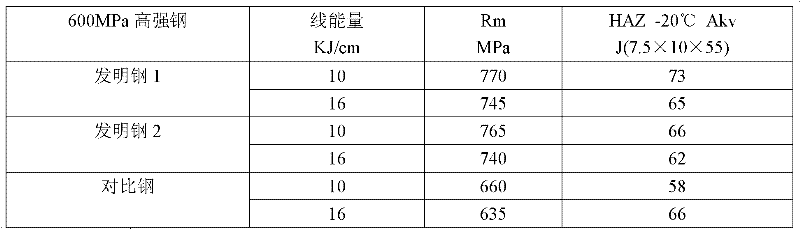

[0049] Table 2 Mechanical properties of base metal of 600MPa grade high strength steel plate

[0050]

...

Embodiment 2

[0055] The specific method of producing 700MPa high-strength engineering machinery steel is as follows: continuous casting of molten steel smelted in a 220-ton converter and refined outside the furnace into slabs, rolling on a 2250 hot continuous rolling production line at a heating temperature of 1200-1220 °C, The entrance temperature of finish rolling is 960℃~1000℃, the thickness of intermediate billet is 42mm~54mm, the temperature of final rolling is 810℃~830℃, after rolling, it is cooled to the target coiling temperature of 590℃ by laminar cooling, and bell annealing is carried out after coiling Remove residual stress. The chemical composition of steel produced by the present invention and contrast steel, mechanical property and weldability contrast situation are as shown in table 1:

[0056] Table 4 Chemical composition of 700MPa high strength steel plate

[0057]

[0058] Table 5 Mechanical properties and welding properties of 700MPa high-strength steel plates

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com