Yield strength 690 MPa class steel plate capable of bearing high heat input welding and manufacturing method

A high-energy welding and yield strength technology, applied in the field of low-alloy high-strength steel, can solve the problems of low high-strength steel plate high-energy welding performance, achieve high-energy welding performance, improve strength and toughness and large wire Energy welding performance, the effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

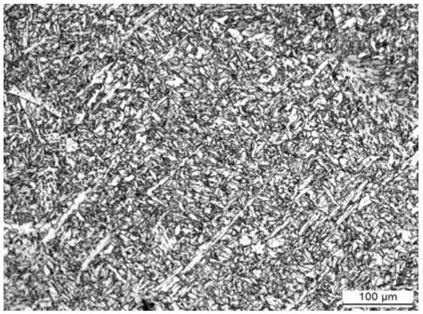

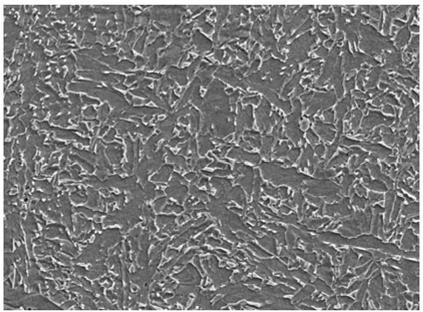

Image

Examples

Embodiment 1

[0025] In this embodiment, the steel plate with a yield strength of 690 MPa that can withstand large heat input welding, its chemical composition includes: C 0.01%, Si 0.2%, Mn 1.9%, Nb 0.02%, V 0.05%, Ti 0.005% , P0.003%, S 0.002%, Cu 0.05%, Ni 0.5%, Cr 0.05%, Mo 0.5%, B 0.0005%, N 0.001%, H 0.0002%, O 0.005%, Al 0.01%, Mg 0.001%, The balance is Fe; among the inclusions with a size of 0.2-3μm in the steel plate, the number of Ti-Mg-O composite inclusions accounts for 50%; the Ti-Mg-O inclusions contain an average of Ti15% by mass fraction; The number of inclusions with a size of 3 μm or more is 30-50 / mm 3 .

[0026]The manufacturing method of the above-mentioned steel plate: the oxygen content at the end of LD converter smelting is 650ppm, the carbon content is 0.05%, and the phosphorus content is 0.003%; RH vacuum decarburization is performed, the carbon content in molten steel is 0.008%, and the oxygen content is 150ppm; The content is 0.002%; RH vacuum degassing treatmen...

Embodiment 2

[0029] In this example, the steel plate with a yield strength of 690 MPa that can withstand large heat input welding, its chemical composition includes: C 0.04%, Si 0.1%, Mn 1.7%, Nb 0.01%, V 0.02%, Ti 0.015% , P0.005%, S 0.005%, Cu 0.5%, Ni 0.4%, Cr 0.45%, Mo 0.15%, B 0.0025%, N 0.005%, H 0.0001%, O 0.004%, Al 0.015%, Ca 0.001%, The balance is Fe; among the inclusions with a size of 0.2-3μm in the steel plate, the number of Ti-Ca-O composite inclusions accounts for 30%; the Ti-Ca-O inclusions contain an average of Ti25% by mass fraction; The number of inclusions with a size of 3 μm or more is 10 to 30 pieces / mm 3 .

[0030] The manufacturing method of the above-mentioned steel plate: the oxygen content at the end of LD converter smelting is 710ppm, the carbon content is 0.04%, and the phosphorus content is 0.005%; RH vacuum decarburization is performed, the carbon content in molten steel is 0.004%, and the oxygen content is 250ppm; content of 0.005%; RH vacuum degassing tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com