High-strength thick steel plate for large heat input welding

A technology for high-intensity welding and thick steel plates, which is applied to the thick steel plate for high-intensity welding and its manufacturing field, and can solve the problem that the adverse effect is not obvious, the weldability of high-intensity energy is unfavorable, and no welding thermal simulation or physical welding is given. Process conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

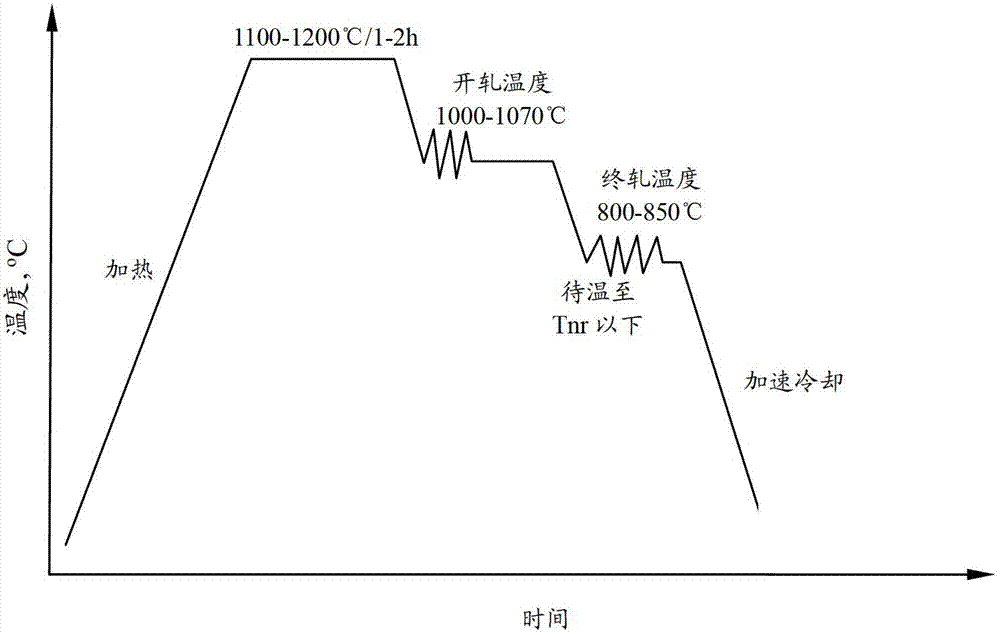

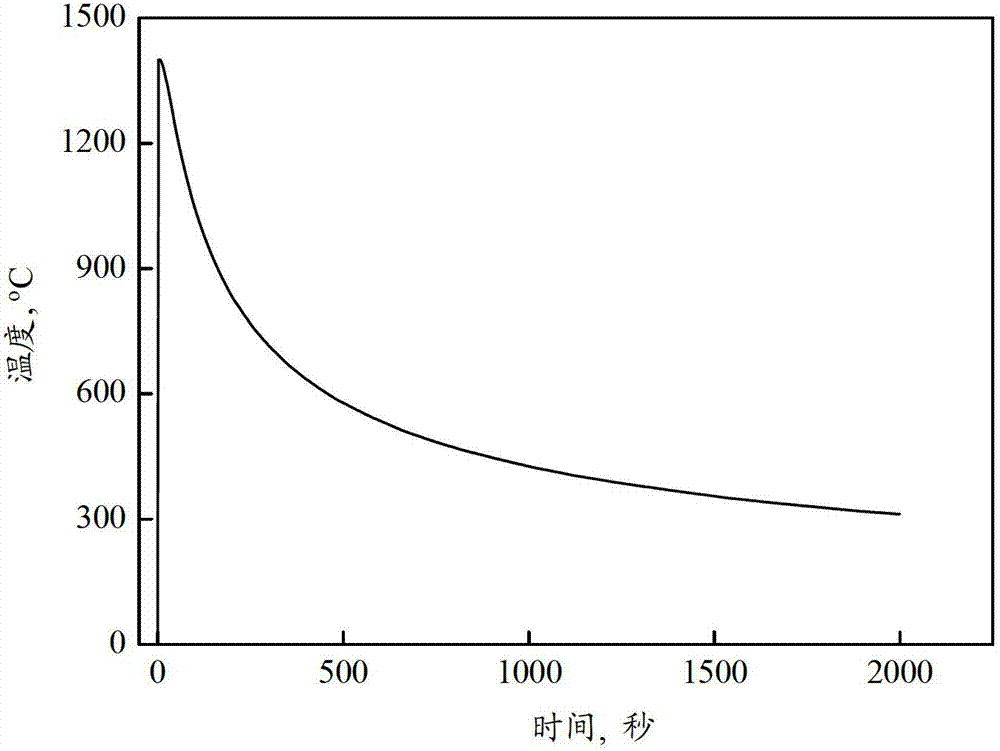

Method used

Image

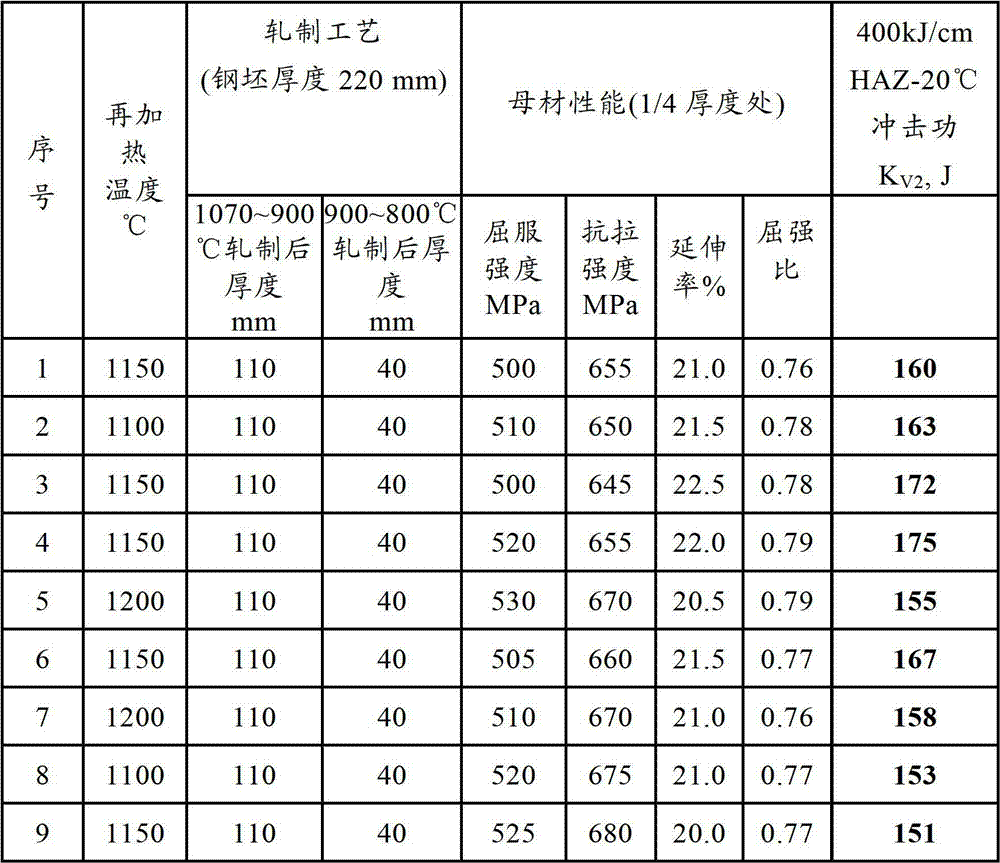

Examples

Embodiment

[0043] Table 1 The chemical composition of the steel plate of the embodiment of the present invention, % by weight

[0044] serial number

C

Si

P

S

mn

Al

N

Ti

Cr

B

1

0.07

0.15

0.0080

0.0031

1.70

0.06

0.009

0.013

0.10

0.0016

2

0.08

0.13

0.0077

0.0042

1.78

0.02

0.006

0.011

0.18

0.0015

[0045] 3

0.08

0.14

0.0075

0.0035

1.51

0.08

0.020

0.012

0.21

0.0023

4

0.09

0.11

0.0076

0.0041

1.55

0.05

0.015

0.009

0.16

0.0018

5

0.10

0.05

0.0085

0.0038

1.61

0.03

0.018

0.006

0.24

0.0024

6

0.08

0.12

0.0084

0.0032

1.79

0.10

0.007

0.005

0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com