Patents

Literature

60results about How to "Raise the finishing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Free-cutting medium-carbon non-quenching and tempering steel for fracture splitting connecting rod and manufacturing method thereof

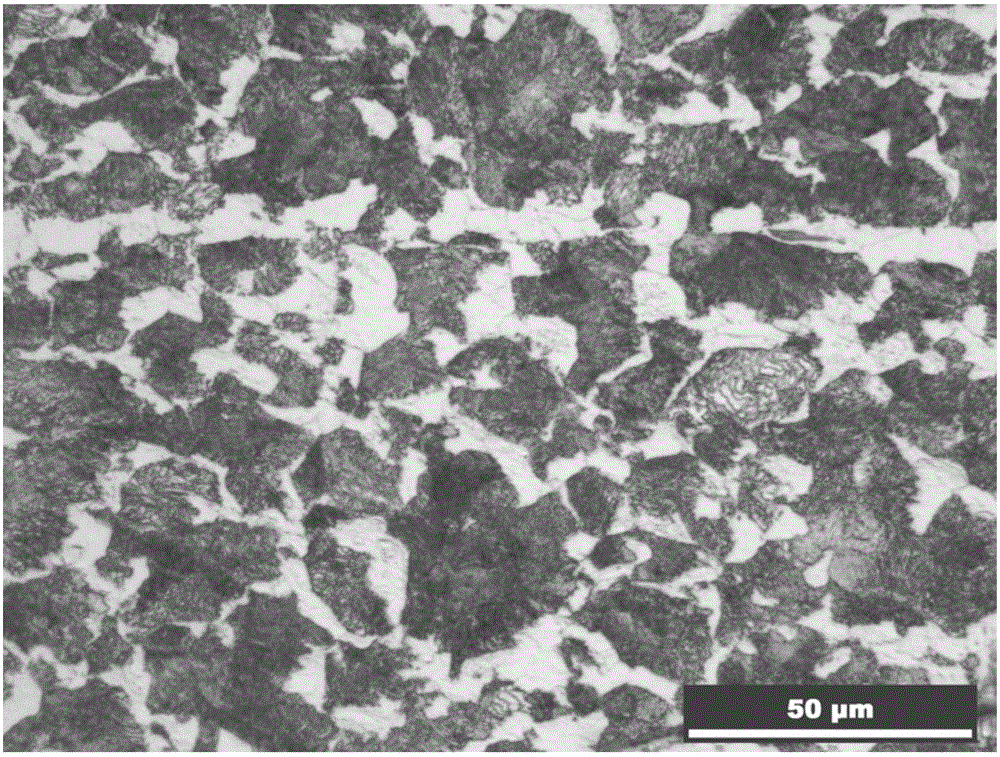

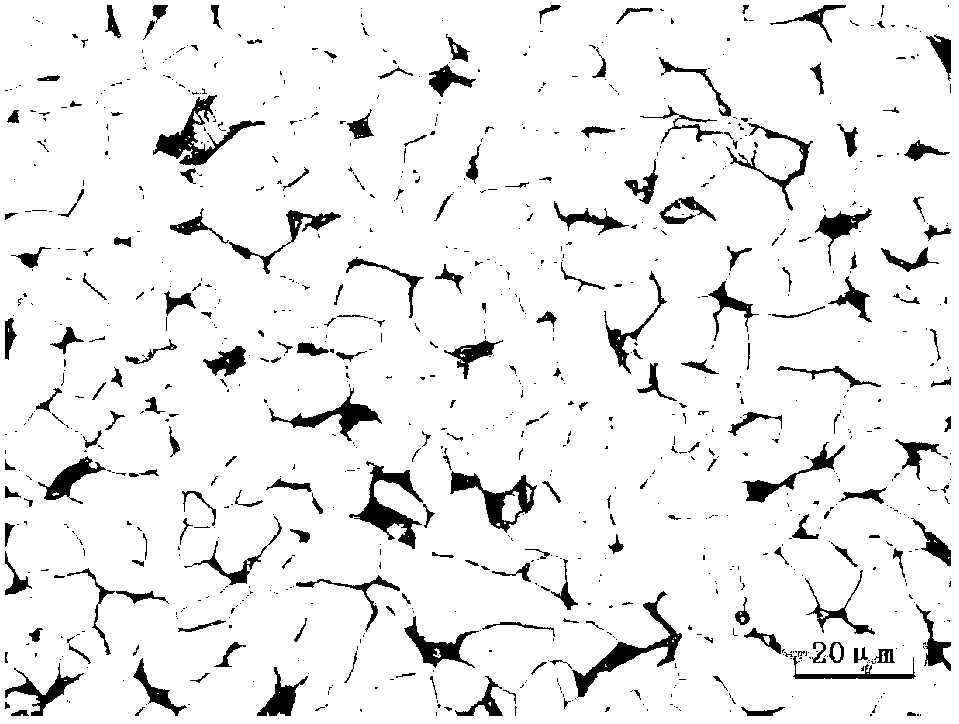

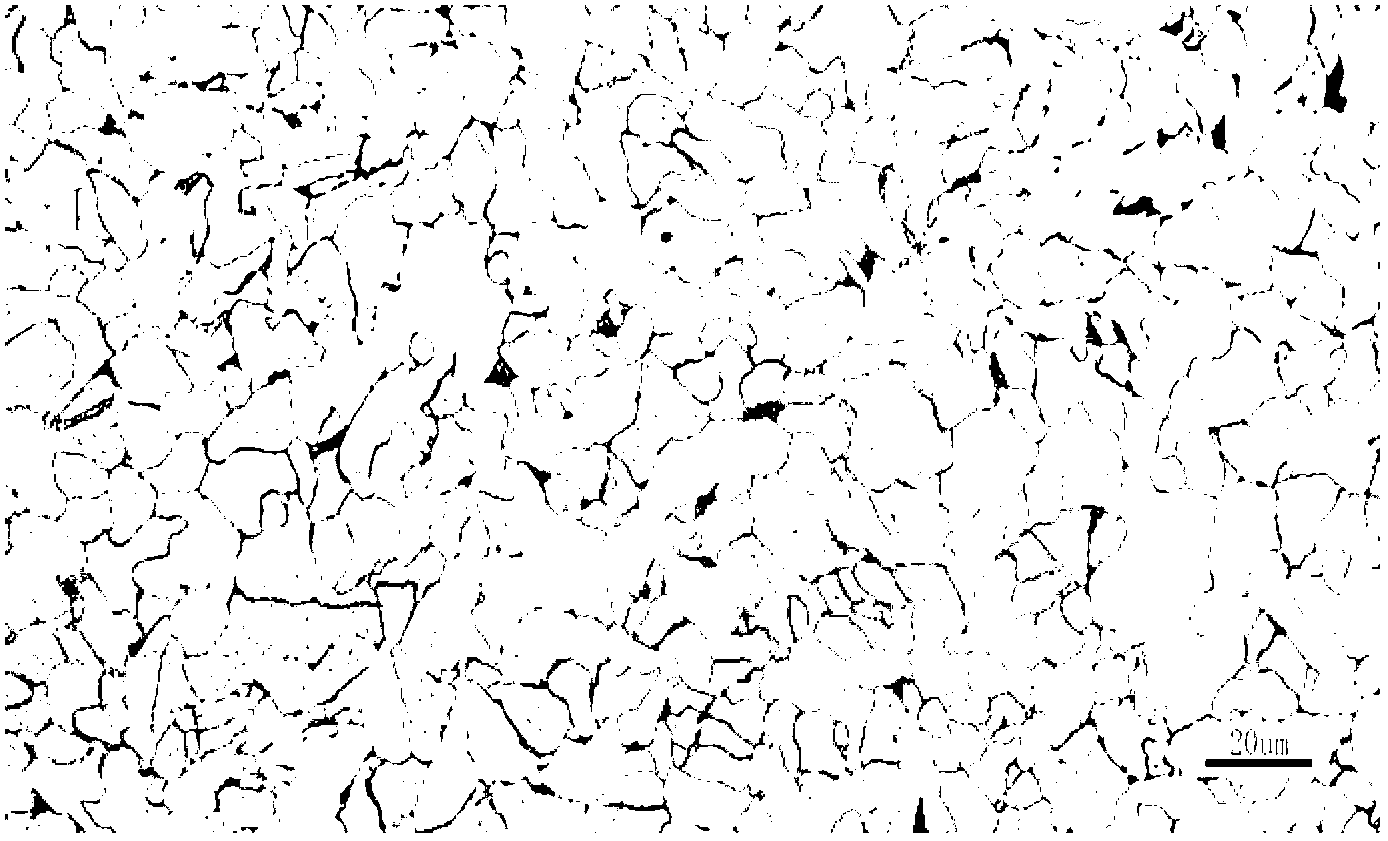

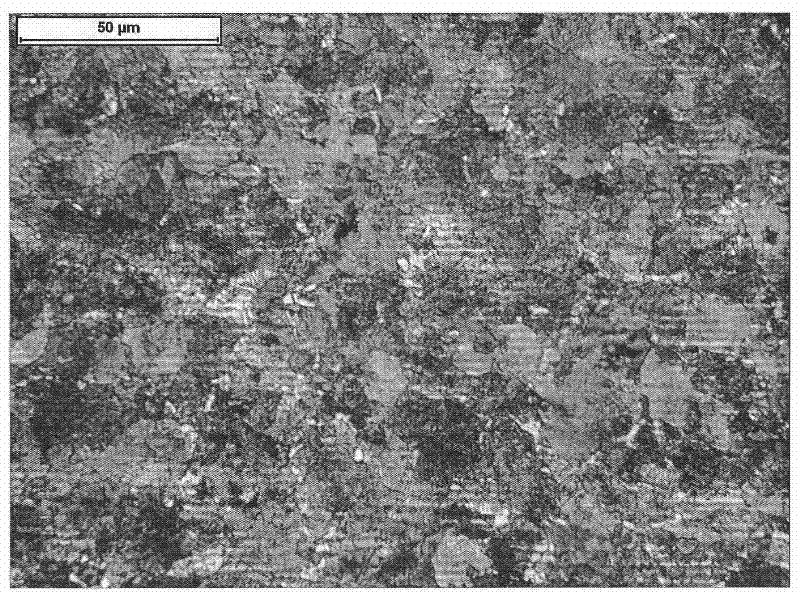

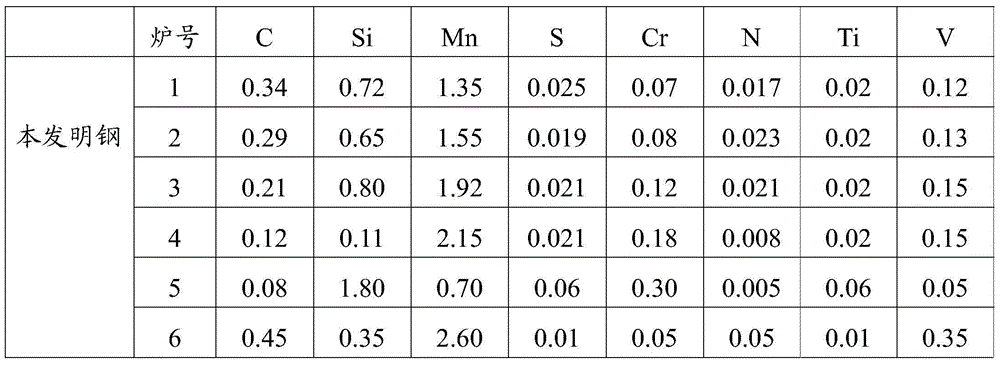

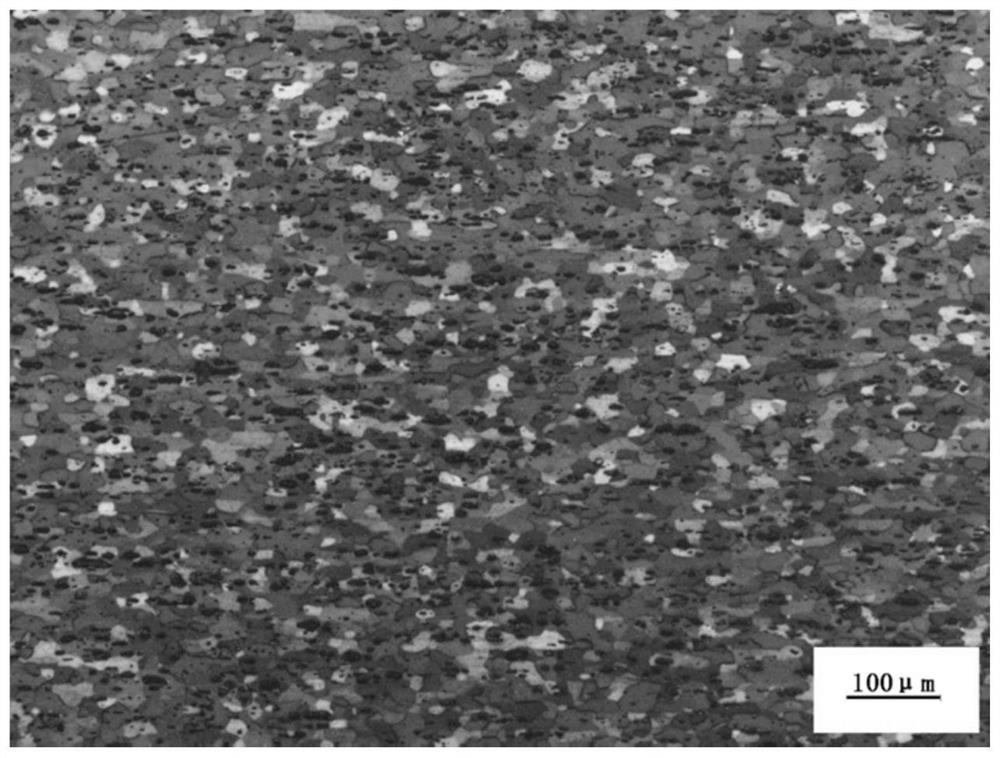

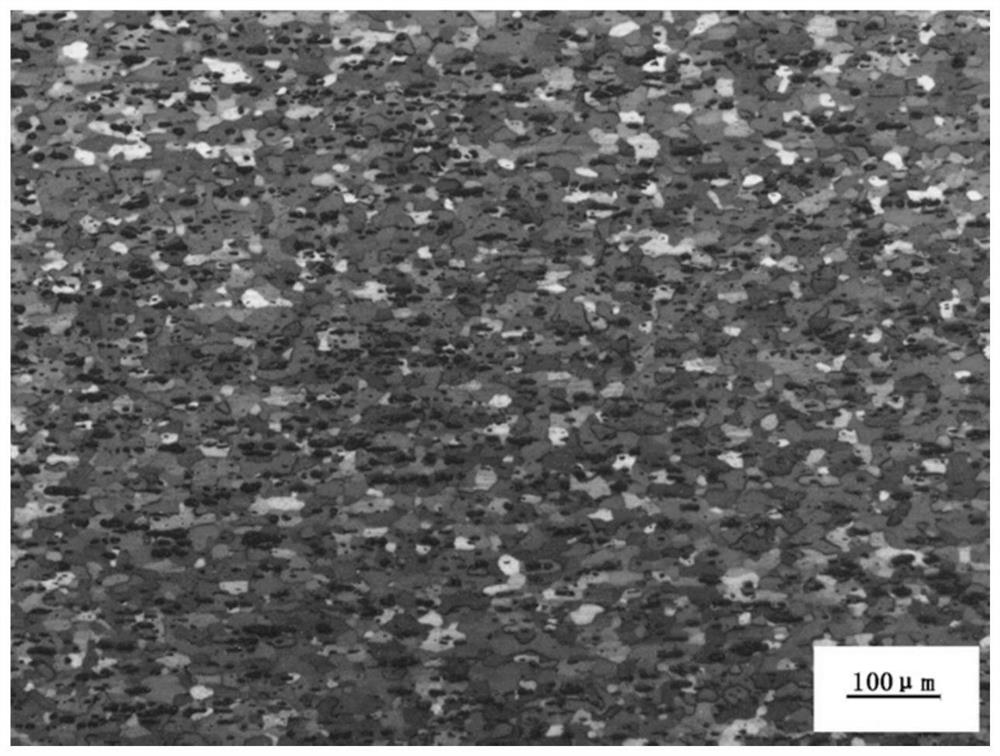

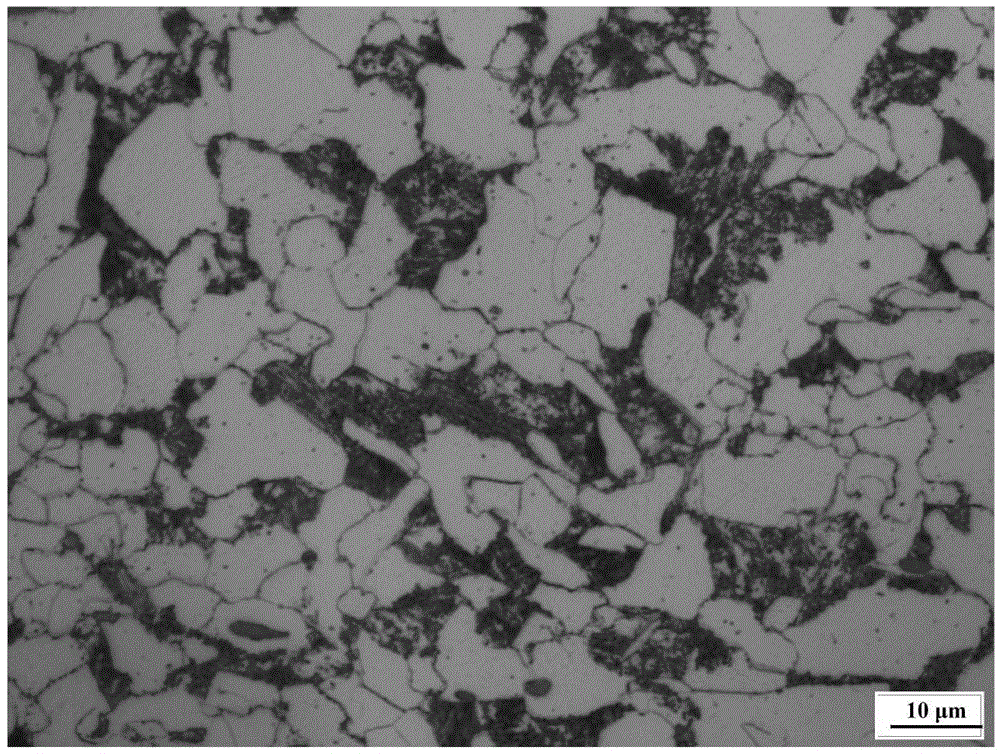

The invention discloses free-cutting medium-carbon non-quenching and tempering steel for a fracture splitting connecting rod. The microstructure of the free-cutting medium-carbon non-quenching and tempering steel comprises ferrite and pearlite; the free-cutting medium-carbon non-quenching and tempering steel for a fracture splitting connecting rod comprises chemical elements according to mass percents: 0.2-0.55 % of C, 0.35-1.00 % of Si, 0.5-1.70 % of Mn, 0.01-0.09 % of S, 0.03-0.15 % of P, 0.05-0.50 % of Cr, 0.05-0.45 % of V, 0.005-0.030% of N, and the balance Fe and other inevitable impurities. The free-cutting medium-carbon non-quenching and tempering steel for a fracture splitting connecting rod has relatively high intensity; in addition, the steel material disclosed by the invention has excellent cutting machinability and good brittleness splitting decomposition performance, and is suitable for a connecting rod processing technology.

Owner:BAOSHAN IRON & STEEL CO LTD

Cooling-after-rolling method of high-weather resistance hot-rolling H-shaped steel with yield strength of 500MPa

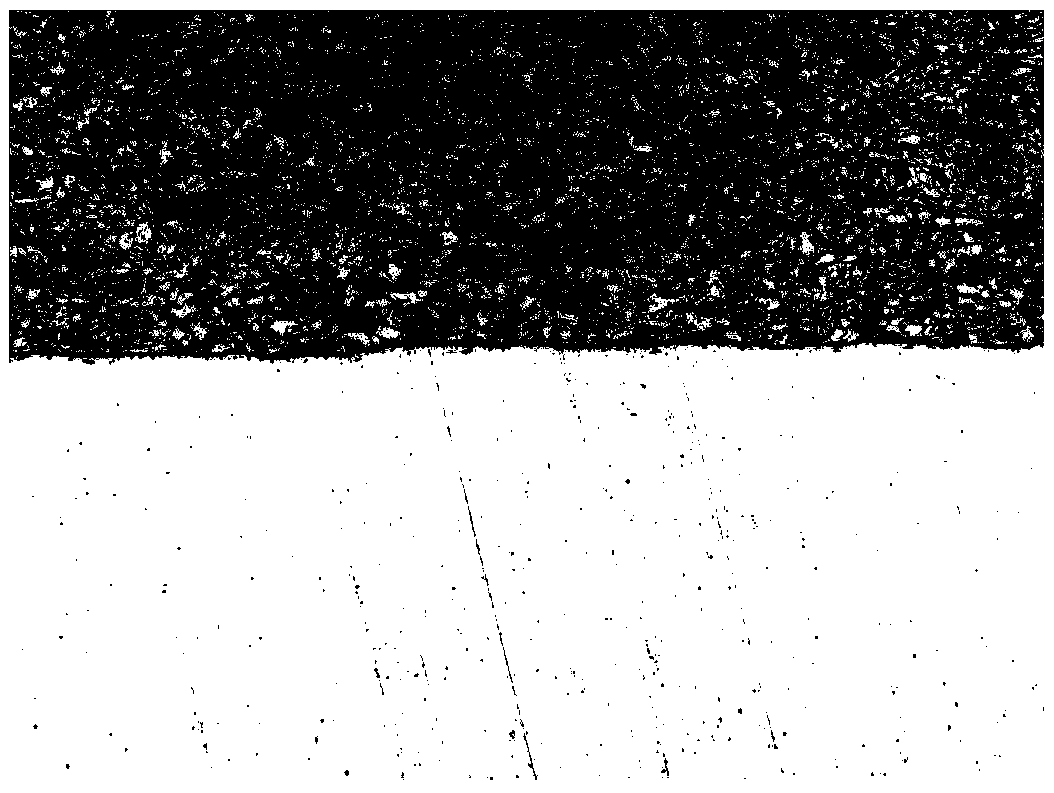

ActiveCN102644034AAdd lessReduce manufacturing costMetal rolling arrangementsSurface layerWeather resistance

The invention discloses a cooling-after-rolling method of high-weather resistance hot-rolling H-shaped steel with yield strength of 500MPa. The high-weather resistance hot-rolling H-shaped steel with yield strength of 500MPa comprises the following components in percentage by mass: 0.06-0.12% of C, 0.30-0.60% of Si, 0.80-1.20% of Mn, 0.010-0.030% of P, 0.001-0.015% of S, 0.20-0.35% of Cu, 0.20-0.40% of Cr, 0.15-0.30% of Ni, 0.040-0.060% of Nb, 0.003-0.030% of Als, and the balance of iron and residual trace impurities. The H-shaped steel rolling technology comprises the steps of: heating with a casting blank heating furnace, rolling with a cogging mill, rolling with a universal mill and two-segment quick cooling after the rolling. In the invention, by adopting a two-segment quick cooling method after the hot rolling of the H-shaped steel and by use of a refined crystalline strengthening, precipitation strengthening and phase change strengthening mechanism, the H-shaped steel organization state with single-phase bainite on the surface layer and complex-phase organization inside and with small grains is obtained, the addition of the alloy elements is obviously reduced, the productioncost is lowered, the weather resistance of the H-shaped steel is improved, the welding performance of the steel is enhanced, and the production efficiency is increased.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Method for producing 65Mn hot rolled steel plate

InactiveCN101773930AImprove product qualityUniform tissue performanceMetal rolling arrangementsContinuous rollingSmelting

The invention discloses a method for producing a 65Mn hot rolled steel plate, which comprises the steps of smelting, refining, thin slab casting, soaking, high pressure water descaling, hot continuous rolling, cooling and reeling based on the process of thin slab casting and rolling. The molten steel superheat temperature is T superheat (30 DEG C <T superheat < / = 45 DEG C), the charging temperature of casting blanks is T charging (900 DEG C < / = T charging < / = 1050 DEG C), the final rolling temperature is T final (850 DEG C < / = T final < / = 950 DEG C), the reeling temperature is T reeling ( 550 DEG C < / = T reeling < / = 650 DEG C), the liquid core pressure of casting blanks is L pressure (2 < / = L pressure < / = 20mm), and the depth of a single-surface decarburized layer is 0.3 to 0.9 percent of the depth of the steel plate. The chemical constitutes of molten steel after being alloyed in a refining process comprise 0.62-0.70 wt.% of C, 0.17-0.37 wt.% of Si, 0.90-1.20 wt.% of Mn, less than or equal to 0.035 wt.% of P, less than or equal to 0.035 wt.% of S, less than or equal to 0.25 wt.% of Cr, less than or equal to 0.25 wt.% of Ni and the balance of Fe and inevitable impurities. The 65Mn hot rolled steel plate produced in the method has the characteristics of uniform structure property, high thermal stability and high strength, and the quality of the 65Mn hot-rolled steel plate is obviously improved.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Method for making easy-to-pickle steel plate

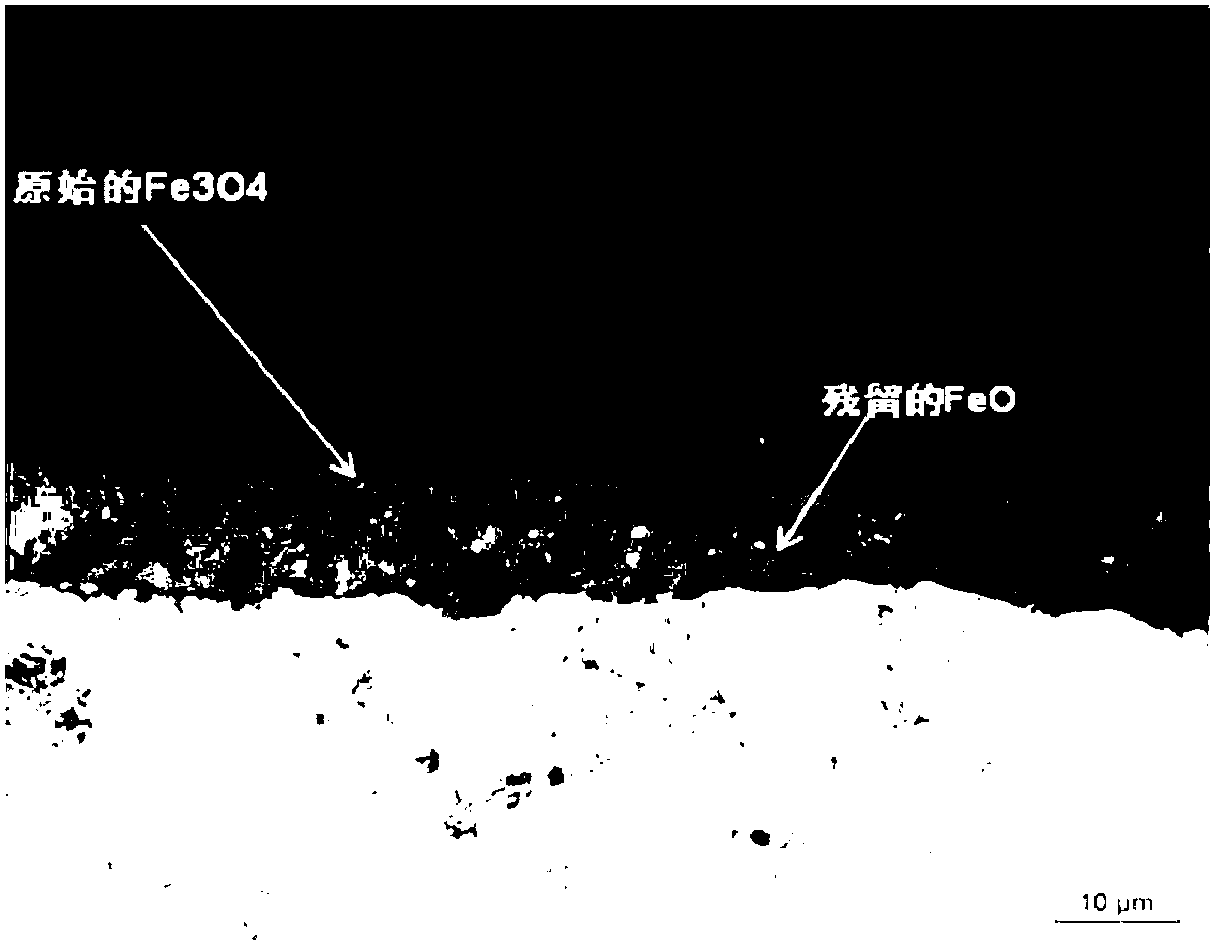

InactiveCN102671992AIncreasing the thicknessImprove lateral uniformityRare end control deviceWork treatment devicesSheet steelStrip steel

The invention provides a method for making an easy-to-pickle steel plate and belongs to the technical field of metallurgy. The method comprises the following steps of: smelting molten steel, and making a plate blank by continuous casting; descaling by using high pressure water, performing rough rolling on the descaled plate blank, performing finish rolling, cooling to the temperature of 500 to 550 DEG C, cooling at the speed of 5 to 10 DEG C per minute to obtain the steel which is easy to pickle and in a hot rolling state and of which the content of FeO is over 25 percent; performing finish rolling, cooling to the temperature of 650 to 700 DEG C at the speed of 1 to 5 DEG C per minute to obtain the steel which is easy to pickle and in a cold rolling state and has a uniform structure and of which the content of iron oxide scale FeO is less than 10 percent. By adopting the method, the thickness of the iron oxide scale is reduced by 20 to 30 percent compared with the conventional process, the pickling speed of the strip steel is increased from 150 to 160 m per minute to 180 to 200 m per minute compared with the conventional process, not only the pickling quality of the steel plate is guaranteed, but also the pickling efficiency is effectively improved.

Owner:NORTHEASTERN UNIV +1

Manufacturing method for easily pickled steel with low yield ratio by thin slab casting and rolling

InactiveCN102699029ALow yield ratioIncrease volume fractionWork treatment devicesRoll mill control devicesSlagThin slab

The invention discloses a manufacturing method for easily pickled steel with a low yield ratio by thin slab casting and rolling. The method comprises the steps of molten iron desulfurizing, converter smelting, refining, thin slab continuous casting, slab soaking, hot continuous rolling, laminar cooling, coiling and air-cooling, wherein the slab soaking temperature is 1160 DEG C to 1200 DEG C; finish rolling is directly carried out for seven times in the hot continuous rolling process, and screw-down rate for the seven times is as follows in sequence: 50-60%, 50-60%, 52-58%, 45-50%, 20-25%, 13-18% and 9-13%; the final rolling temperature is 870 DEG C to 890 DEG C; the temperature after laminar cooling is 580 DEG C to 610 DEG C; and the components of the slag are as follows in percentages by weight: 0.045-0.065% of C, not more than 0.05% of Si, 0.40-0.60% of Mn, not more than 0.015% of P, not more than 0.010% of S, and the balance of iron and inevitable impurities. According to the manufacturing method disclosed by the invention, the yield ratio of the easily pickled steel is effectively reduced without the addition of extra noble alloy elements.

Owner:武汉钢铁有限公司

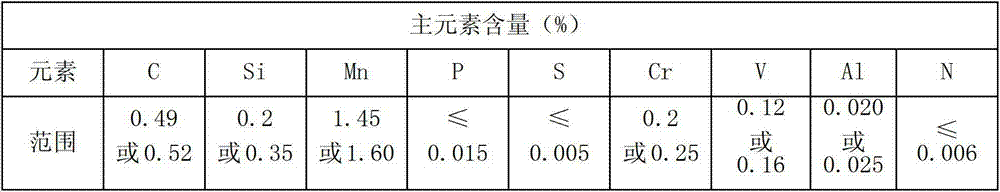

Production method of high-strength saw bit steel coil

ActiveCN103173685AGuaranteed stabilityImproved shape controlTemperature control deviceHeat treatment process controlHardnessSlow cooling

The invention provides a production method of a high-strength saw bit steel coil. The production method is suitable for a rolled steel coil of saw bit or saw blade steel with the thickness of 3.0-14.0mm. The component design comprises 0.49-0.52 of C, 0.2-0.35 of Si, 1.45-1.60 of Mn, less than or equal to 0.015 of P, less than or equal to 0.005 of S, 0.2-0.25 of Cr, 0.12-0.16 of V, 0.020-0.025 of Al and less than or equal to 0.006 of N by weight percent. The production process adopts a converter smelting-LF (ladle furnace) refining-hot continuous rolling process and comprises slab continuous casting and segregation control in saw bit steel production, control of the slab continuous offline slow cooling temperature of the saw bit steel and the control of the roll rolling start temperature, the rolling finished temperature and the coiling temperature. The horizontal yield of the saw bit steel coil is MPa600-750, the horizontal tensile strength is MPa930-1040, the elongation is 19.5-26%, and the hardness of HRC is 20-28.

Owner:XINJIANG BAYI IRON & STEEL

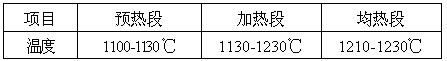

Super duplex stainless steel S32750 medium plate rolling process

ActiveCN103286128AGuaranteed heating timeGuaranteed surface qualityTemperature control deviceMetal rolling arrangementsSheet steelHigh pressure water

The invention discloses a super duplex stainless steel S32750 medium plate rolling process which includes blank selection, heating, high-pressure water descaling, two-roll rough rolling, and four-roll finish rolling. By increasing heating temperature, reducing rolling pass, and increasing finish rolling temperature of steel plates, edge cracks and partial cracks on the surface of the steel plates are reduced, medium plate rejection rate is lowered, rolling yield is increased, and contract fulfillment rate is increased.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

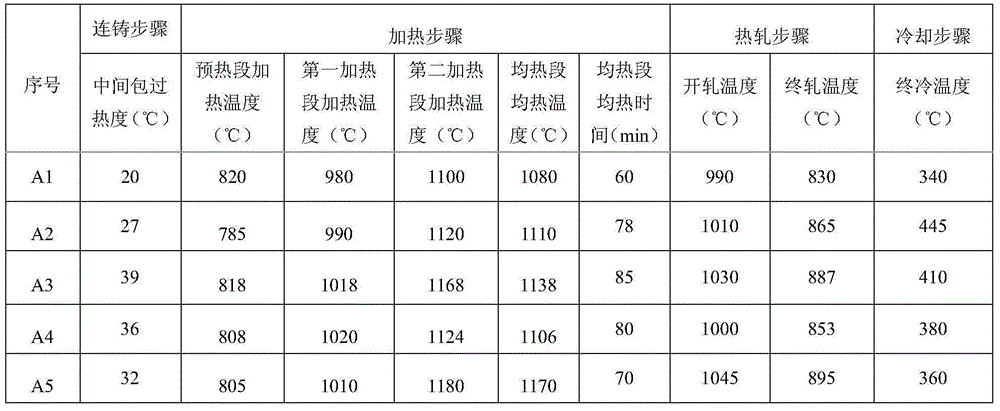

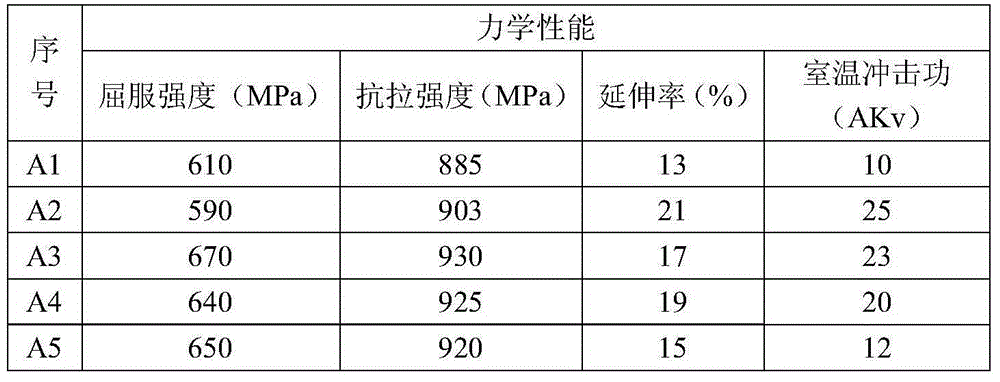

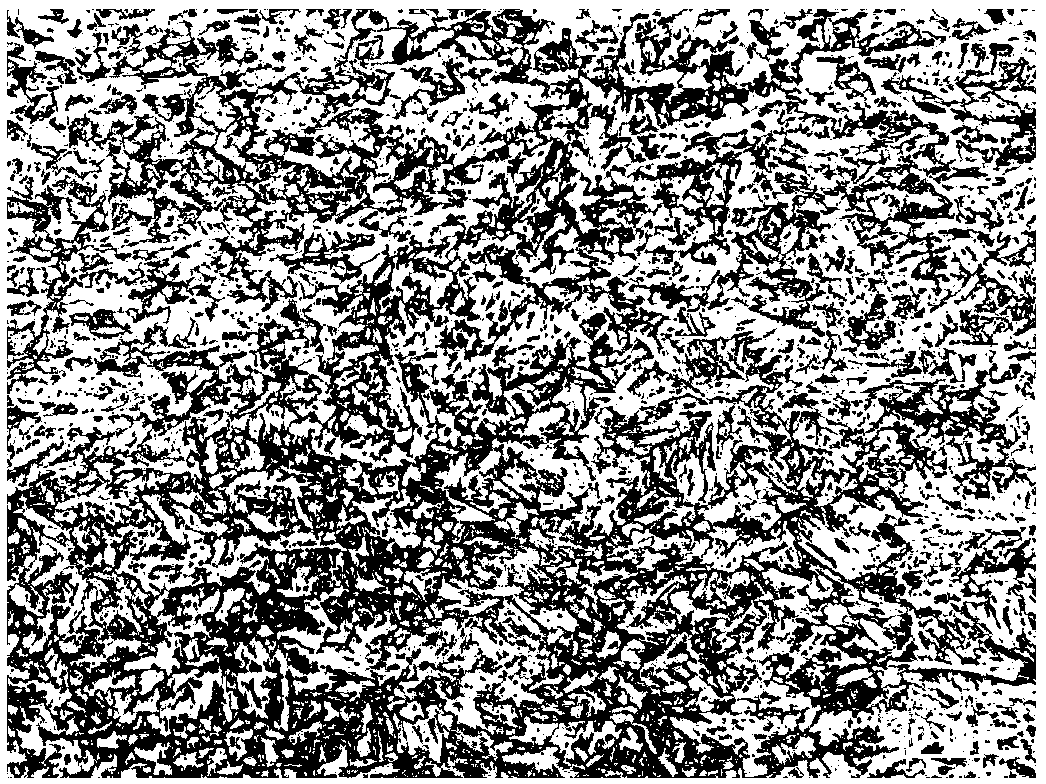

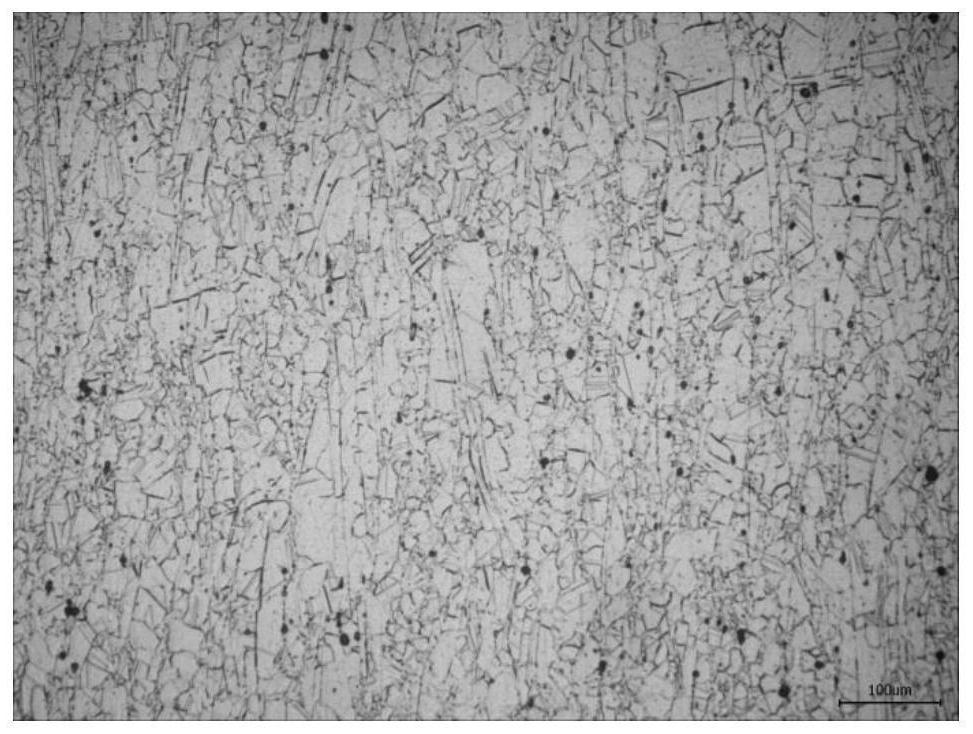

Non-annealed cold forging steel hot-rolled wire rod and production method thereof

The invention discloses a non-annealed cold forging steel hot-rolled wire rod and a production method thereof. The method comprises the steps of continuous casting, heating, rolling, spinning and cooling. The non-annealed cold forging steel hot-rolled wire rod comprises 0.29-0.38wt% of C, 0.15-0.30wt% of Si, 0.70-0.90wt% of Mn, 0.03wt% or less of P, 0.03wt% or less of S, 0.30wt% or less of Cr, 0.0008-0.0050wt% of B, and the balance of Fe and residual elements. In the heating step, continuous cast billets are heated to 1100-1190DEG C; in the rolling step, the initial finish rolling temperature is 965-995DEG C; in the spinning step, the spinning temperature is 960-990DEG C; and in the cooling step, the cooling speed is 0.5-1.5DEG C / s. The method realizes production of the non-annealed cold forging steel hot-rolled wire rod through optimally designing chemical components, controlling the heating temperature, the initial finish rolling temperature, the spinning temperature and the cooling speed and controlling the amount and the grain size of ferrite by using present devices and technologies without increasing investment or production cost, so the non-annealing production and cost reduction demands of downstream users are met, and pollution of annealing to environment is avoided.

Owner:XINGTAI IRON & STEEL

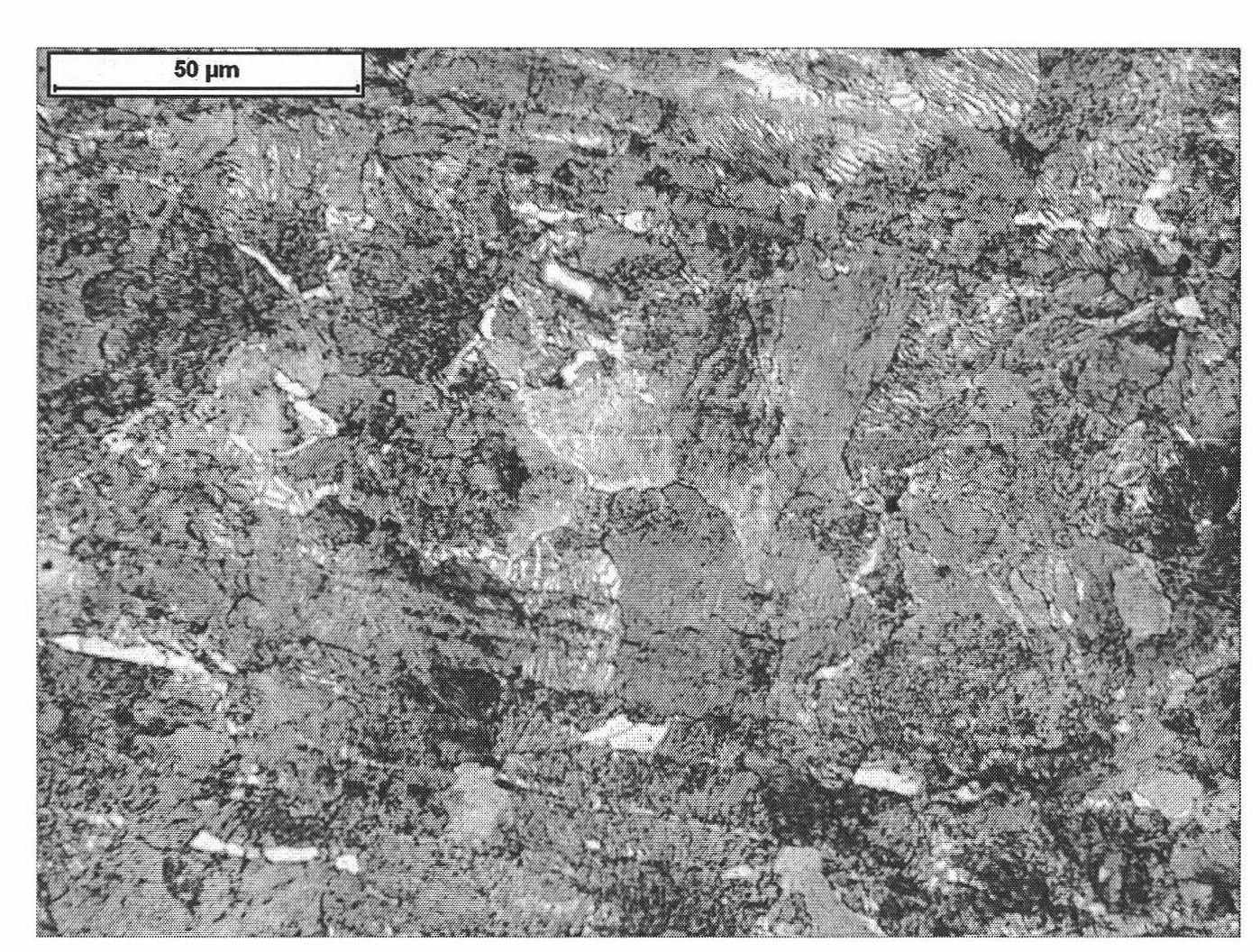

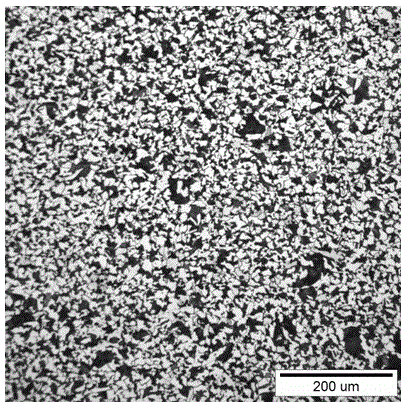

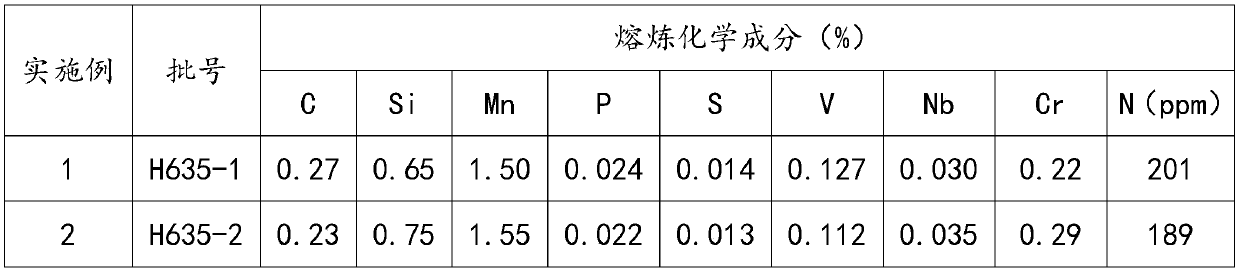

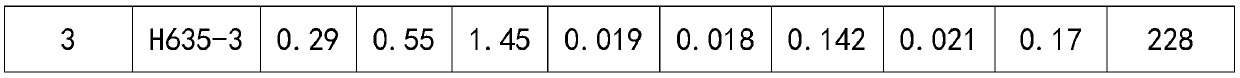

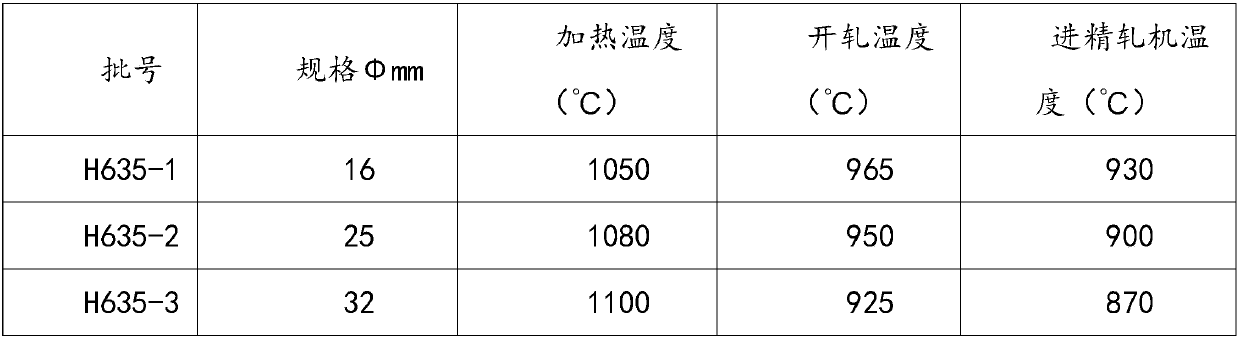

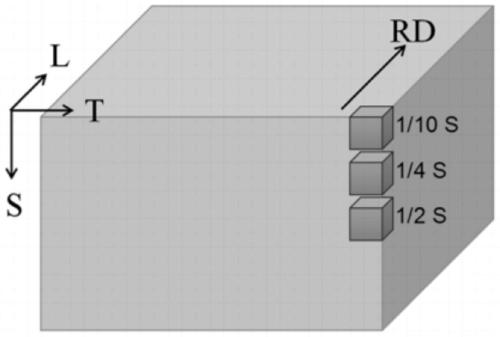

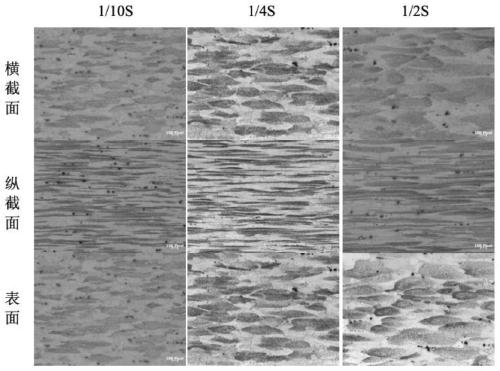

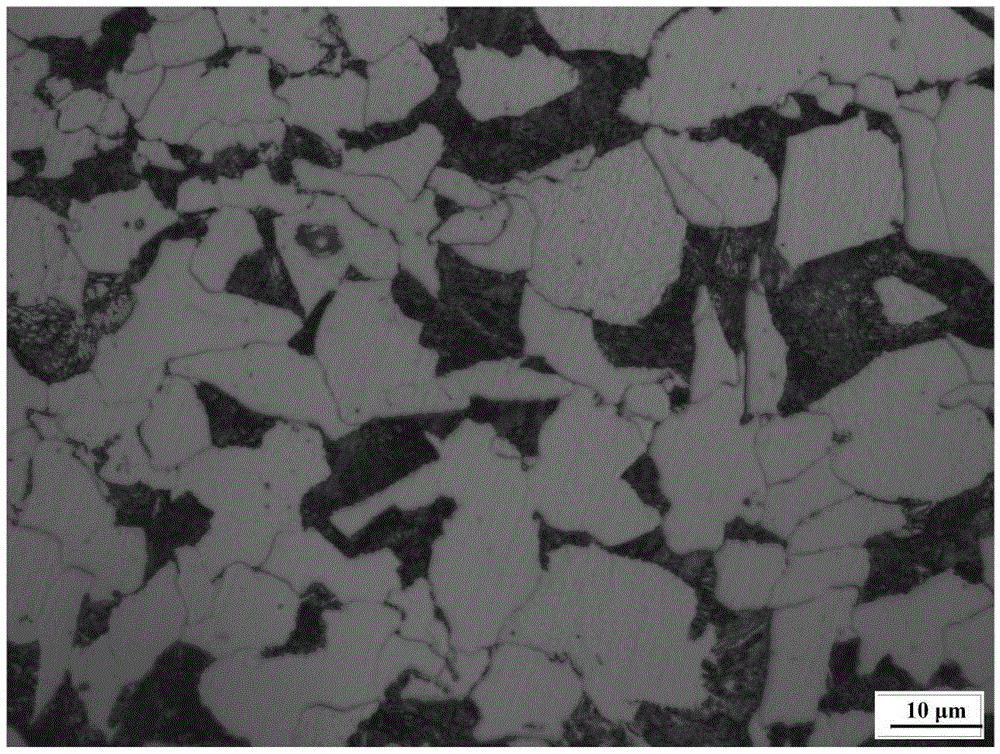

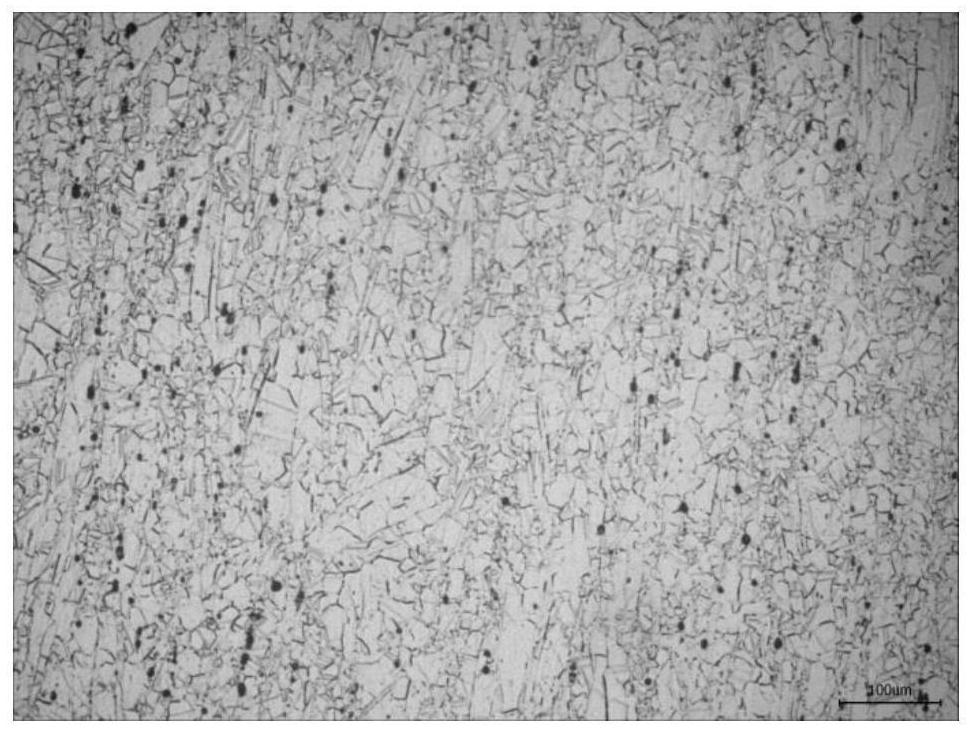

Steel for 635 MPa level high-strength hot-rolled steel bar

The invention relates to the technical field of hot-rolled ribbed steel bars, and discloses steel for a 635 MPa level high-strength hot-rolled steel bar. The steel is prepared from, by weight, 0.22-0.30% of C, 0.50-0.80% of Si, 1.40-1.60% of Mn, not larger than 0.025% of P, not larger than 0.025% of S, 0.015-0.035% of Nb, 0.105-0.145% of V, 0.15-0.35% of Cr, 0.018-0.025% of N and the balance Fe. According to the steel for the 635 MPa level high-strength hot-rolled steel bar and a machining method thereof, by adopting C, C is a cheap element, the strength of the steel can be remarkably improved, the extension performance of the steel can be lowered, meanwhile, the cold brittleness and aging sensitivity of the steel are improved, the integrated ingredients are reasonable, the comprehensive performance of the whole steel is improved, the stability of the steel performance is enhanced, the overall performance of the steel on the aspects of yield strength, tensile strength, the high yield ratio, the percentage elongation after fracture, the total elongation percentage under the maximum force and the like is good, meanwhile, the steel metallographic structure is ferrite+pearlite, the granularity is 11.5, the good fatigue resistance is achieved, the steel is suitable for large-scale industrial production, and benefits are remarkable.

Owner:安徽吾兴新材料有限公司

Blade ring forged piece and fabrication technology thereof

The invention relates to a blade ring forged piece and a fabrication technology thereof. The fabrication technology comprises the following steps: 1, preparing materials; 2, cogging and forging, including heating, forging, and annealing; 3, baiting, and removing head and tail of a steel ingot; 4, molding and forging, including heating, forming, rolling and annealing; 5, carrying out thermal treatment, including normalizing, tempering for the first time, quenching, tempering for the second time, and tempering for the third time; 6, carrying out ultrasonic flaw detection; 7, carrying out physical and chemical testing; 8, carrying out finish machining; 9, packaging products. Thus, the blade ring forged piece obtains a good fine grain microstructure and high-temperature endurance property, and simultaneously has good tensile strength and yield strength.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

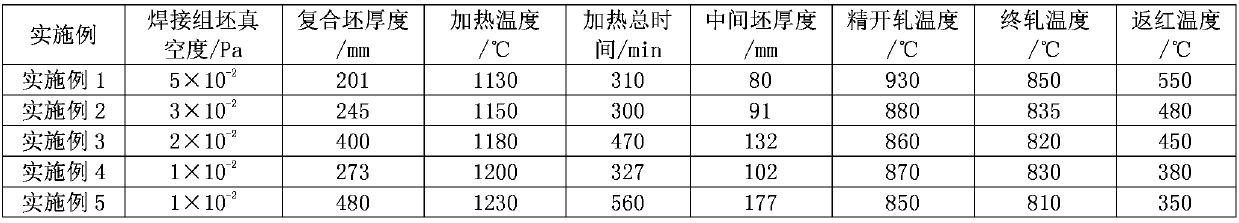

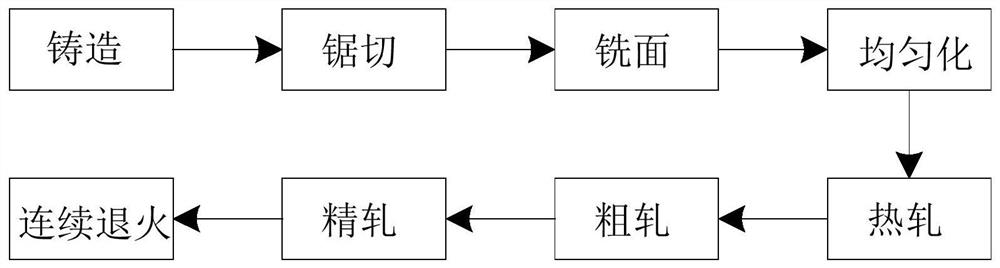

Preparation process of high-strength 7150 aluminum alloy medium plate

The invention belongs to the technical field of aluminum alloy manufacturing, and relates to a preparation process of a high-strength 7150 aluminum alloy medium plate. Raw material ingredients comprise: Si <= 0.50%, Fe <= 0.50%, Cu: 2.10-2.20%, Mn <= 0.01%, Mg: 2.15-2.35%, Cr <= 0.02%, Zn <= 6.65%, Ti <= 0.03%, Zr: 0.10-0.12%, single impurity <= 0.01%, total <= 0.15%, and the balance Al. The product formulation and casting process are optimized, the homogenization system is improved, initial rolling temperature is improved, high rolling-reduction rolling is adopted, the solid solution processis optimized, quenching delay time is strictly controlled, the quenching speed is improved, stretching delay time is strictly controlled, the optimal amount of stretching is selected, the aging process is improved, and finally the 7150 medium plate with excellent properties is obtained.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

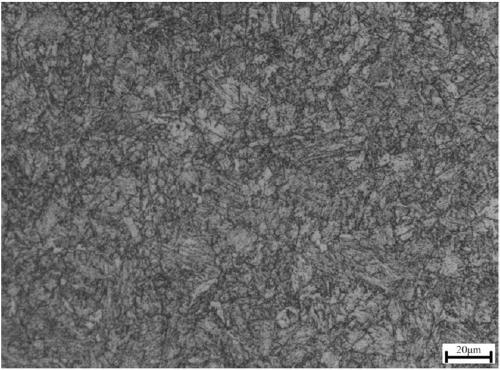

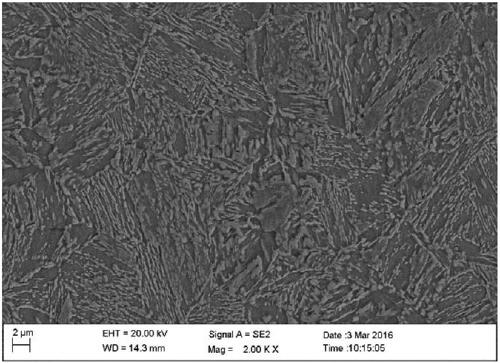

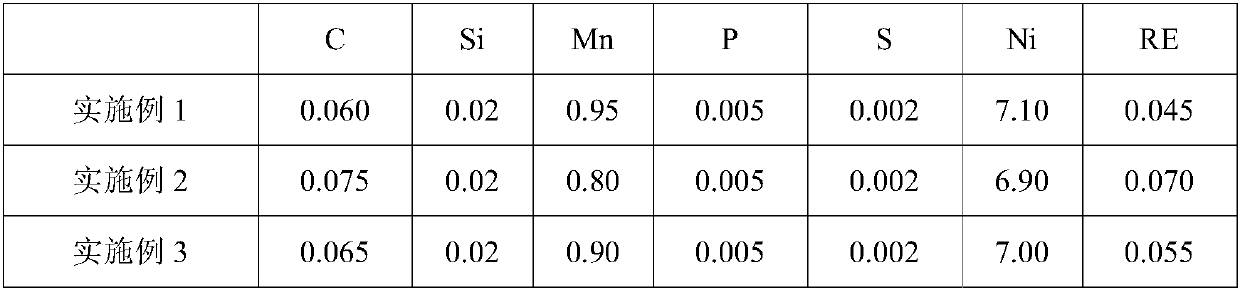

High nickel steel for ultra-low temperature pressure vessel and manufacturing method thereof

The invention provides high nickel steel for an ultra-low temperature pressure vessel and a manufacturing method thereof. The components of a steel plate include, by weight percentage, 0.01-0.10% of C, 0.01-0.10% of Si, 0.50-1.50% of Mn, 6.50-7.50% of Ni, 0.01-0.20% of RE, S which is less than or equal to 0.005%, and P which is less than or equal to 0.008%, with the balance being Fe and inevitableimpurities; and the manufacturing method includes converter smelting, external refining, continuous casting, slow cooling of slabs, rolling and heat treatment. The yield strength of the produced steel plate is greater than or equal to 585 MPa, the tensile strength is greater than or equal to 680 MPa, he elongation rate is greater than or equal to 18%, -196 DEG C V-type impact energy is greater than or equal to 100 J, and the lateral expansion is greater than or equal to 1.0; and therefore, manufacturing costs of the steel for LNG storage tanks can be reduced.

Owner:ANGANG STEEL CO LTD

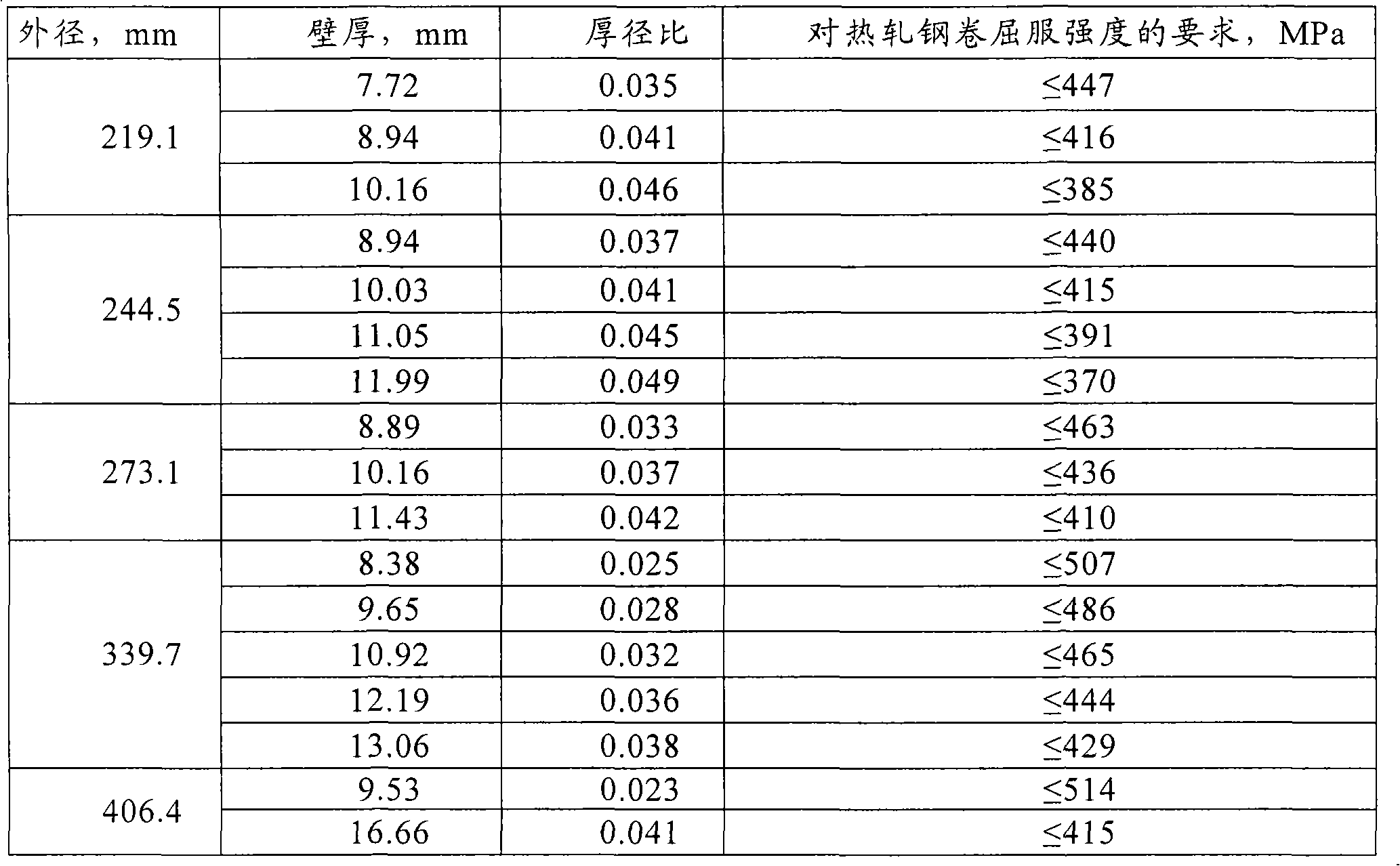

Petroleum sleeve steel and manufacturing method thereof

ActiveCN101845583AReduce formationHigh tensile strengthDrilling rodsTemperature control deviceMolten steelThermal treatment

The invention provides petroleum sleeve steel which comprises the following components in mass percent: 0.31-0.35 of C, 0.1-0.45 of Si, 0.8-1.5 of Mn, not more than 0.02 of P, not more than 0.01 of S, not more than 0.024 of Al, not more than 0.1 of V, not more than 0.35 part of Mo, and the balance Fe and inevitable impurities. The invention further provides a manufacturing method of the petroleum sleeve steel. The manufacturing method comprises the following steps: smelting molten steel by a converter or an electric furnace, and then casting the smelted molten steel into board blank; heating the board blank to the temperature of 1190-1260 DEG C, and then primarily rolling into board bands; conveying the primarily rolled board bands and then finally rolling through a final roller, wherein, the temperature for final rolling is 820-920 DEG C; and cooling the finally rolled board bands, and then rolling up the bands into steel coils at the temperature of not less than 610 DEG C. In the invention, the steel coils produced by the manufacturing method can meet the requirements of the steel with all specifications (i.e. the ratio of radius to thickness is not more than 0.049) for a non-integral pipe thermal-treatment straight welding petroleum sleeve API K55 on the hot-rolled steel coils.

Owner:BAOSHAN IRON & STEEL CO LTD

High-ductility FH500-grade ship plate steel and preparation method thereof

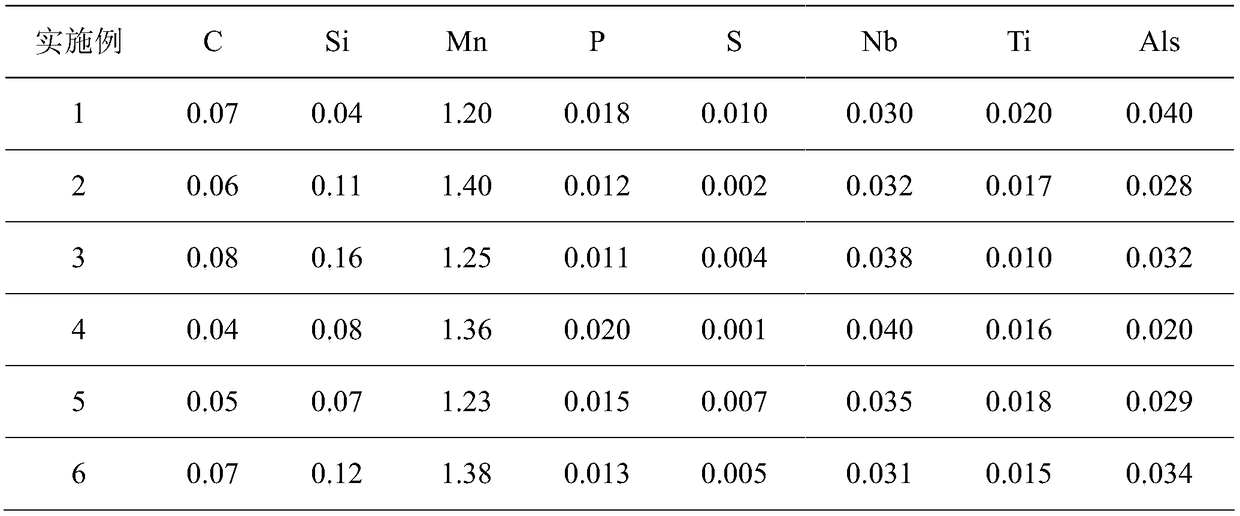

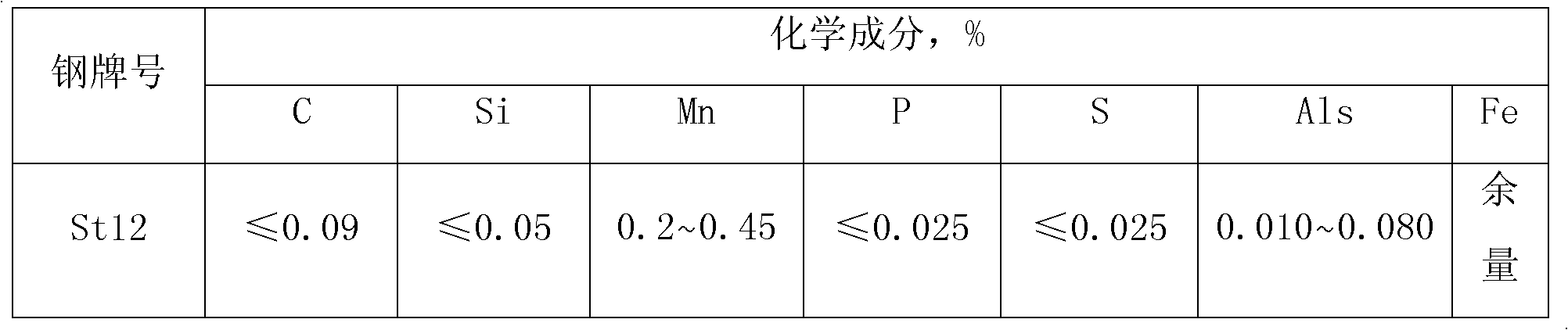

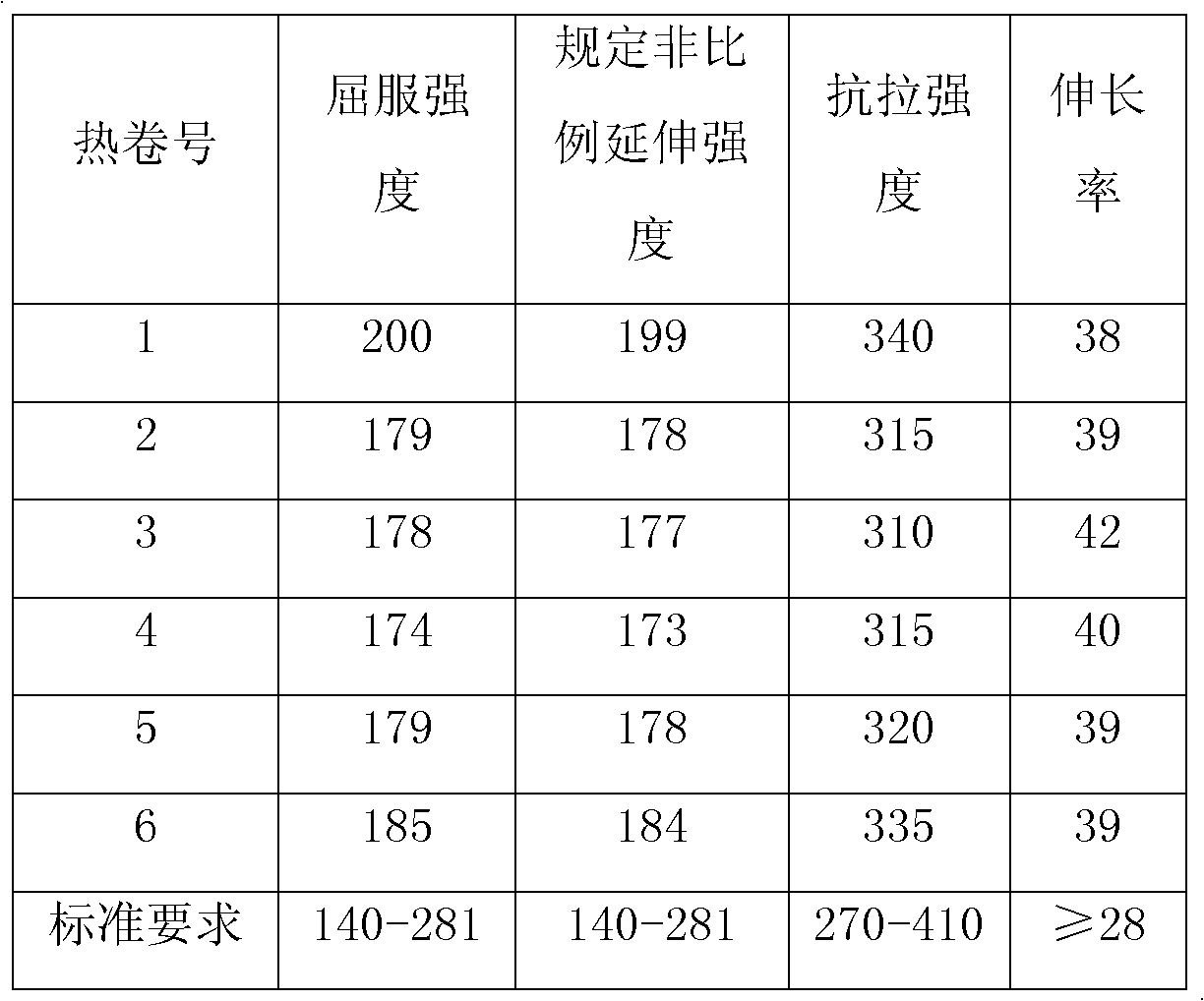

The invention provides high-ductility FH500-grade ship plate steel and a preparation method thereof, and belongs to the technical field of metallurgy. The components of the ship plate steel are as follows in percentage by weight: 0.04-0.08% of C, 0.04-0.16% of Si, 1.20-1.40% of Mn, 0.03-0.04% of Nb, 0.01-0.02% of Ti, 0.02-0.04% of Als, less than or equal to 0.02% of P, less than or equal to 0.01%of S and the balance of Fe and inevitable impurities; the preparation method of the FH500-grade ship plate steel comprises the steps that billet steel with the thickness of 120-140 mm is adopted for being subjected to heating, thermal insulation, rough rolling, finish rolling and cooling to obtain the finished-product ship plate steel. According to the high-ductility FH500-grade ship plate steel and the preparation method thereof, by adopting a controlled rolling and controlled cooling technology, the ship plate steel with the texture including soft-phase ferrite and hard-phase bainite is obtained; moreover, elements such as Cr, Ni and Mo are not added, so that the cost is low; through a fast cooling method, the finishing temperature can be properly improved, the rolling mill load can be reduced, the rolling efficiency can be improved, and production, which is low in cost, easy to conduct rolling and high in efficiency, of the high-ductility FH500-grade ship plate steel is achieved.

Owner:NORTHEASTERN UNIV

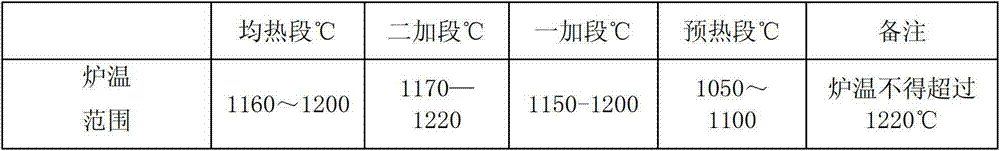

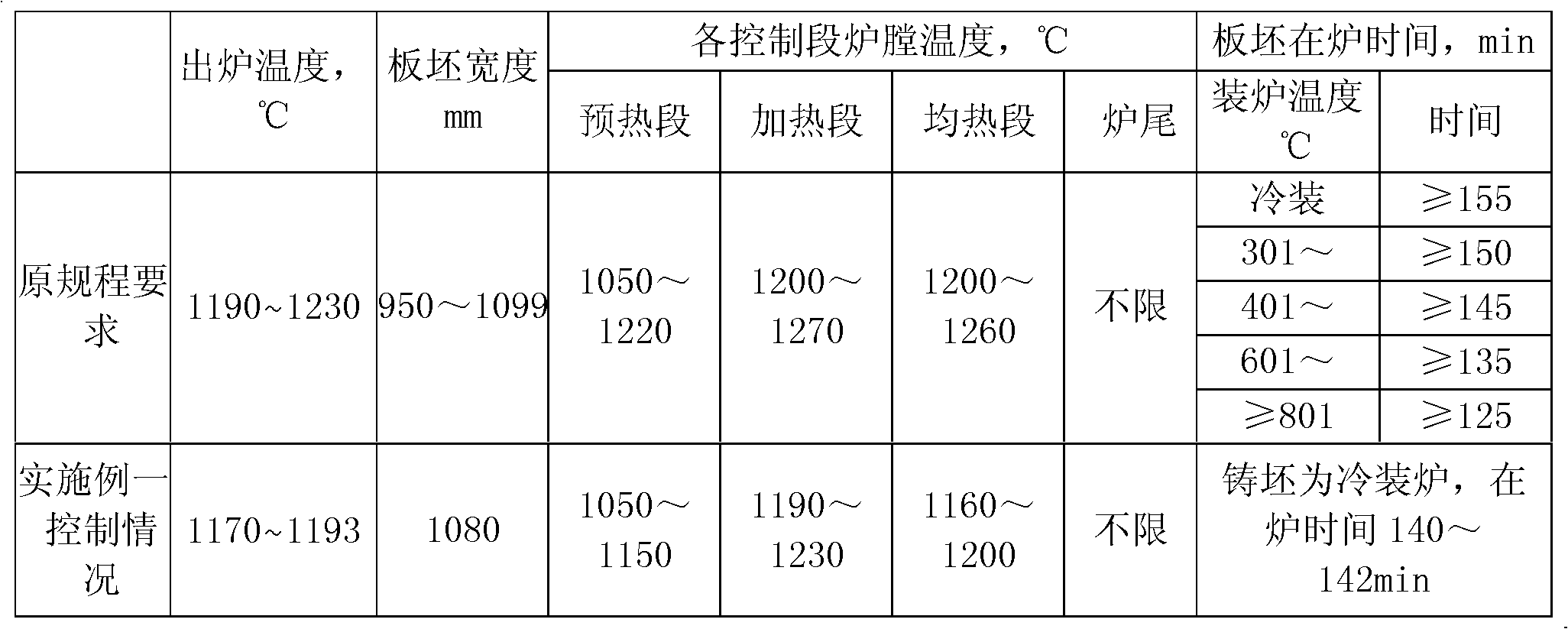

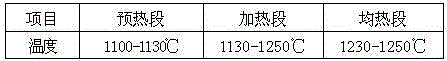

Hot rolling heating method for low-carbon aluminum killed steel casting blank

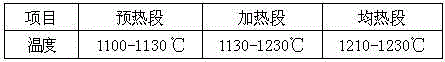

The invention belongs to the technical field of production of hot rolling strip steel, and in particular relates to a hot rolling heating method for a low-carbon aluminum killed steel casting blank. The invention aims to solve the technical problem of providing a hot rolling heating method for the low-carbon aluminum killed steel casting blank, and the hot rolling heating method has low heating temperature and short heating time. To solve the technical problem, the invention uses the technical scheme that the temperature of a preheating section of a heating furnace is 1050-1150 DEG C, the temperature of a heating section is 1185-1230 DEG C, the temperature of a holding section is 1160-1200 DEG C, and the heating time of the heating furnace is 135-147min. By adopting the method of the invention for heating the low-carbon aluminum killed steel casting blank, the uniformity of the heating temperature of the low-carbon aluminum killed steel can be improved, the rolling process requirement is met, the heating temperature of the low-carbon aluminum killed steel casting blank is reduced by 40 DEG C averagely, low temperature heating is realized, the heating time is reduced by 10 minutes averagely, the yield and the heating quality of the heating furnace are improved, the fuel consumption of the heating furnace is reduced, and the comprehensive effects of increasing yield, guaranteeing quality, saving energy and reducing consumption are obtained.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Steel for superhigh-strength hot rolling automobile structure and preparation method thereof

The invention relates to steel for a superhigh-strength hot rolling automobile structure and a preparation method thereof, belonging to the field of alloy steel production processes. The steel comprises the following components: 0.08 percent to 0.12 percent of carbon, 0.10 percent to 0.50 percent of silicon, 1.5 percent to 2.50 percent of manganese, less than 0.02 percent of phosphorus, less than 0.01 percent of sulfur, 0.02 percent to 0.05 percent of aluminum, 0.08 to 0.25 percent of vanadium, 0.03 percent to 0.06 percent of nitrogen and the balance of Fe and other inevitable impurities. The production process comprises the following steps of: converter smelting; external refining; continuous casting; hot rolling and reeling. The main process parameters are as follows: the heating temperature of continuous casting slabs is between 1,150 and 1,220 DEG C, the reeling temperature is between 500 and 650 DEG C, and the hot rolling total reduction ratio is more than 85 percent. According to the steel, vanadium-nitride micro alloying is adopted, vanadium precipitation is promoted by enhancing nitrogen, grains are refined, and precipitation strengthening and fine-grain strengthening are used as main strengthening measures, so that the yield strength is more than 700 MPa, the tensile strength is more than 800 MPa, the total elongation rate after fracture is more than percent, and the steel is used for high-strength automobile structures with high plasticity and good cold bending properties.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for producing 65Mn hot rolled steel plate

InactiveCN101773930BAdd depthImprove billet qualityMetal rolling arrangementsLiquid coreStructure property

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

SPHC cold-rolled edge cracking eliminating method

ActiveCN103480656ACold Rolled Edge Crack EliminationRaise the finishing temperatureTemperature control deviceBand shapeCarbide

The invention provides an SPHC cold-rolled edge cracking eliminating method. By controlling edges of SPHC at hot rolling and precision rolling stages within austenite single-phase rolling range, hot and finish rolling temperature is increased while hot rolling and coiling temperature is decreased. Problems that edge texture of the hot-rolled SPHC is rough, carbide bands seriously exist and crystal is mixed are solved, and cold-rolled edge cracking of the SPHC is eliminated.

Owner:SHOUGANG CORPORATION

Cooling after rolling method for high-weather fastness hot-rolled H-steel with yield strength up to 550MPa

The invention discloses a cooling after rolling method for high-weather fastness hot-rolled H-steel with yield strength up to 550MPa. The high-weather fastness hot-rolled H-steel with the yield strength up to 550MPa comprises the following components in weight percentage: 0.06-0.12 percent of C, 0.30-0.60 percent of Si, 1.25-1.50 percent of Mn, 0.010-0.030 percent of P, 0.001-0.015 percent of S, 0.20-0.35 percent of Cu, 0.20-0.40 percent of Cr, 0.15-0.30 percent of Ni, 0.10-0.12 percent of V, 0.008-0.014 percent of N, 0.003-0.030 percent of Als and the balance of ferrum and residual trace impurities. An H-steel rolling process comprises the following steps of: heating a casting blank in a heating furnace, rolling by a roughing mill, rolling by a universal rolling mill, and performing two-stage rapid cooling after rolling is ended. According to the cooling after rolling method for the high-weather fastness hot-rolled H-steel with the yield strength up to 550MPa, through adopting a two-stage rapid cooling method after hot rolling is performed on the H-steel and by utilizing a refined crystalline strengthening mechanism, a precipitation strengthening mechanism and a phase change strengthening mechanism, an H-steel texture which is provided with single-phase bainite on the surface layer, is of a multiphase structure inside and has fine grains is obtained, thereby, the additive amount of alloying elements is reduced, the production cost is obviously reduced, the welding performance of the steel is improved, and the production efficiency is increased.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Ball stud steel of automobile steering system and manufacturing method thereof

InactiveCN105821348AGuaranteed mechanical propertiesConforming to cold deformation processCompound (substance)Ultimate tensile strength

The invention relates to ball stud steel of an automobile steering system and a manufacturing method thereof. the steel product contains the following chemical components (by weight): 0.08-0.45% of C, 0.35-1.80% of Si, 0.7-2.6% of Mn, 0.01-0.06% of S, P being less than or equal to 0.025%, 0.05-0.30% of Cr, 0.05-0.35% of V, 0.010-0.060% of Ti, 0.005-0.050% of N and the rest of Fe and unavoidable impurities. The steel has moderate strength, good plasticity and good machinability, and can be used in manufacturing ball studs for an automobile steering system of above 900 MPa. In addition, production technology is simple and environmentally friendly, the hot-rolled steel product requires no annealing or quenching-and-tempering heat treatment, energy conservation and emission reduction can be effectively achieved, and manufacturing cost of workpieces can be reduced.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Cooling-after-rolling method of high-weather resistance hot-rolling H-shaped steel with yield strength of 500MPa

ActiveCN102644034BAdd lessReduce manufacturing costMetal rolling arrangementsWeather resistanceSurface layer

The invention discloses a cooling-after-rolling method of high-weather resistance hot-rolling H-shaped steel with yield strength of 500MPa. The high-weather resistance hot-rolling H-shaped steel with yield strength of 500MPa comprises the following components in percentage by mass: 0.06-0.12% of C, 0.30-0.60% of Si, 0.80-1.20% of Mn, 0.010-0.030% of P, 0.001-0.015% of S, 0.20-0.35% of Cu, 0.20-0.40% of Cr, 0.15-0.30% of Ni, 0.040-0.060% of Nb, 0.003-0.030% of Als, and the balance of iron and residual trace impurities. The H-shaped steel rolling technology comprises the steps of: heating with a casting blank heating furnace, rolling with a cogging mill, rolling with a universal mill and two-segment quick cooling after the rolling. In the invention, by adopting a two-segment quick cooling method after the hot rolling of the H-shaped steel and by use of a refined crystalline strengthening, precipitation strengthening and phase change strengthening mechanism, the H-shaped steel organization state with single-phase bainite on the surface layer and complex-phase organization inside and with small grains is obtained, the addition of the alloy elements is obviously reduced, the production cost is lowered, the weather resistance of the H-shaped steel is improved, the welding performance of the steel is enhanced, and the production efficiency is increased.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Large-section H-shaped steel and production process thereof

The invention discloses large-section H-shaped steel and a production process thereof. The large-section H-shaped steel comprises the following chemical components in percentage by mass: 0.08-0.13% ofcarbon, 0.15-0.35% of silicon, 1.25-1.45% of manganese, 0.10-0.20% of vanadium, nitrogen not more than 0.012%, phosphorus not more than 0.01%, sulfur not more than 0.010%, 0.03-0.05% of niobium, 0.03-0.05% of thallium, 0.03-0.05% of polonium, 0.02-0.04% of terbium, 0.01-0.02% of nickel, and the balance of iron and impurity elements. The produced large-section H-shaped steel is lower in alloy content and high in final rolling temperature, reduces the load and the energy consumption of a rolling mill, and improves the production efficiency.

Owner:ANHUI KINGYOUNG STRUCTURAL METAL WORK

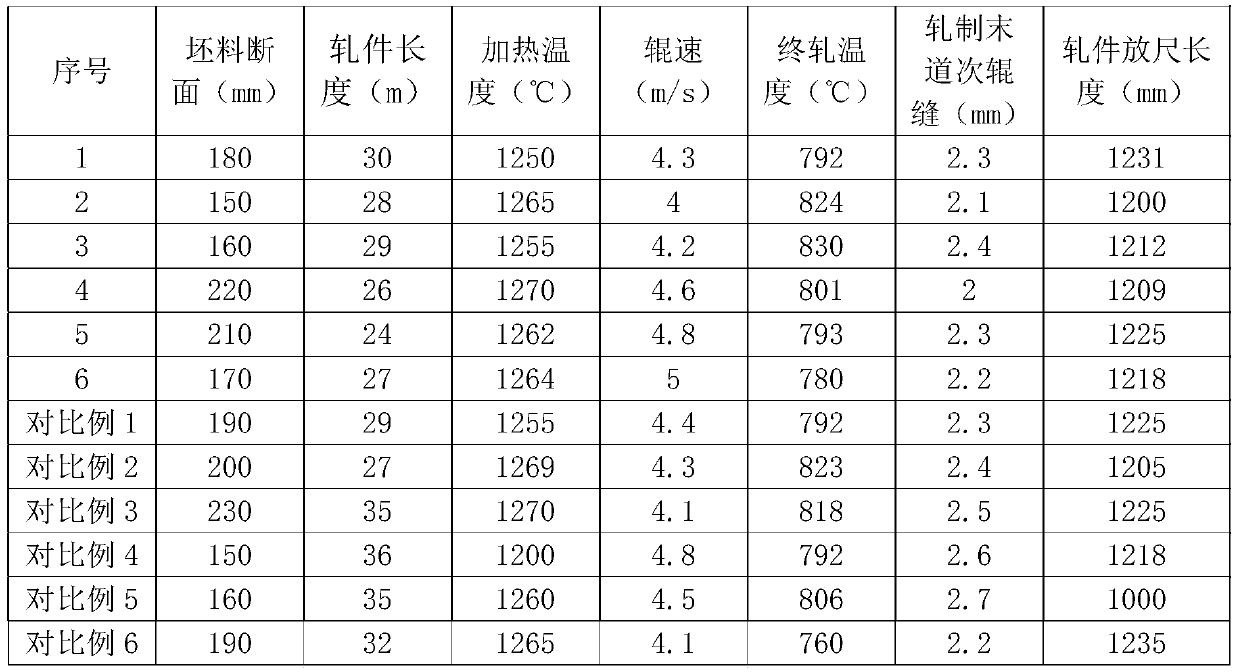

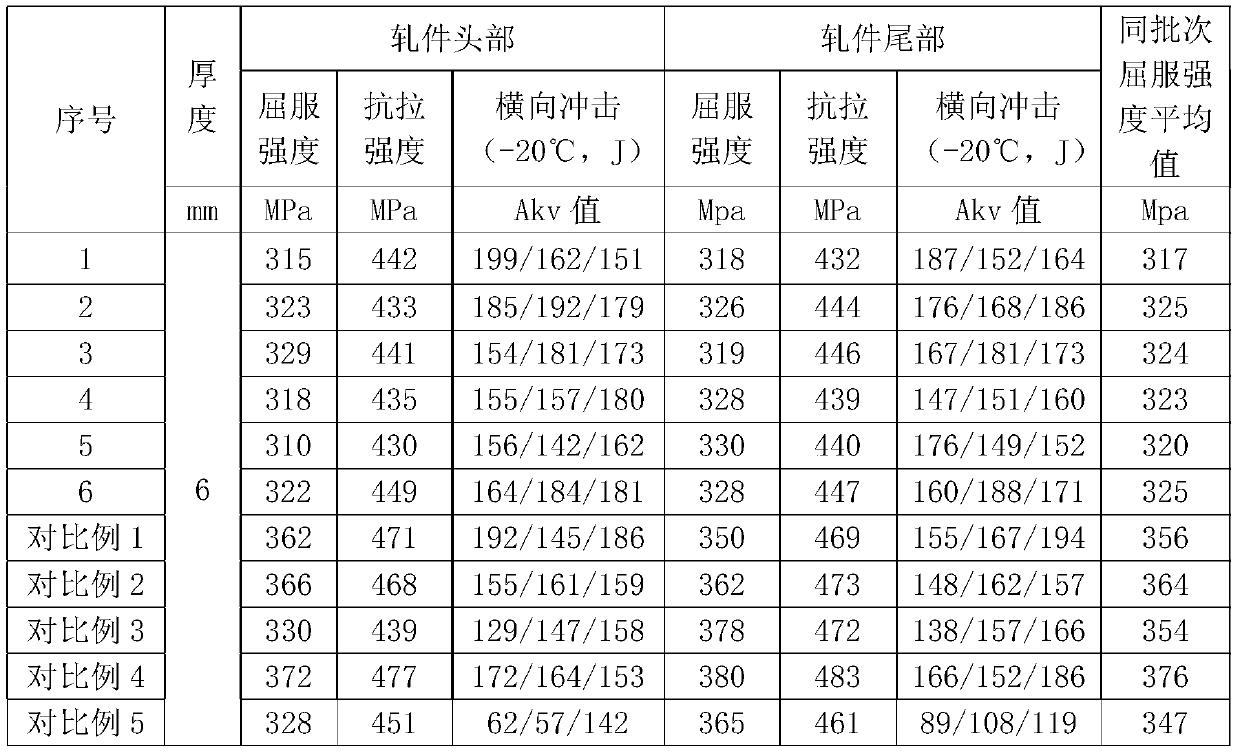

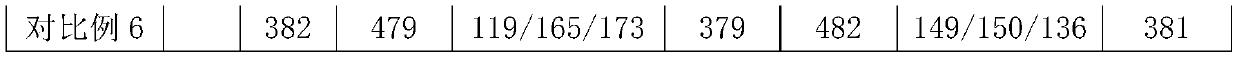

Steel for nuclear-power containment with thickness of 6 mm and manufacturing method of steel

ActiveCN111270153AEnsure yield strength stabilityTaking into account the radiation effectMetal rolling arrangementsNuclear physicsSteel plates

The invention discloses steel for nuclear-power containment with thickness of 6 mm and a manufacturing method of the steel. The low-C and low-Mn composition series design for the steel, extra alloyingcomponents are not added, and an irradiation effect is taken into consideration while yield strength stability is guaranteed. According to the manufacturing method, by means of optimization of blanktype, length of a rolled piece is effectively controlled in a rolling process, and larger temperature fluctuation caused by the too long rolled piece is avoided. With the adoption of superhigh-temperature heating mechanism, higher temperature for blanks is obtained during rolling, and higher final rolling temperature for a steel plate is guaranteed after the rolling is finished. By means of control for the rolling process, temperature drop in the process is reduced, and smaller temperature difference fluctuation of the head and the tail of the rolled piece is guaranteed. The length of the rolled piece is optimized and an area with poorer plate cut is cut off, and performance uniformity of a sampling position is ensured. The 6mm nuclear-power steel produced with the method has the advantages that yield strength is controlled stably, the toughness matching is excellent, and requirements for performance are met completely. The performance qualification rate of production reaches 94%, andthe steel is completely applicable to industrial mass production.

Owner:NANJING IRON & STEEL CO LTD

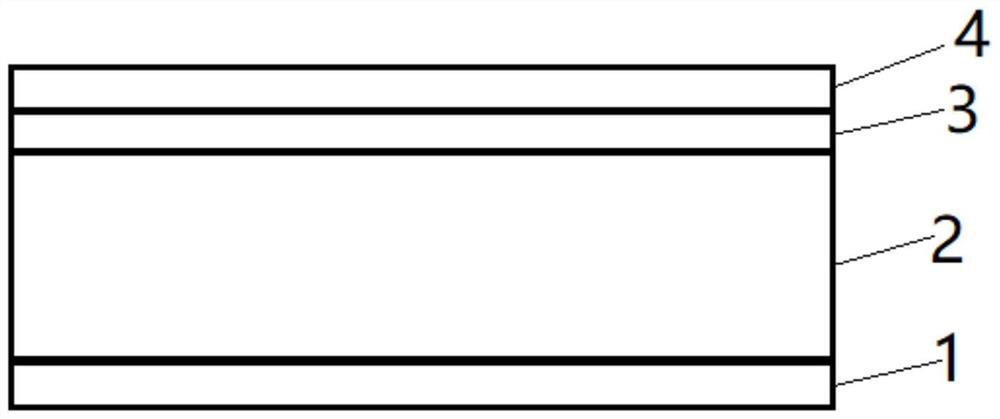

Stainless steel composite plate for petroleum and natural gas conveying pipeline and preparing method of stainless steel composite plate

InactiveCN109624435AImprove toughnessImprove corrosion resistanceWelding apparatusTubular articlesChemical compositionComposite plate

The invention discloses a stainless steel composite plate for a petroleum and natural gas conveying pipeline. The stainless steel composite plate comprises a base material and a covering material, andthe covering material is metallurgically bonded to the base material and made of austenitic stainless steel; the base material is prepared from, by weight, 0.03-0.09% of C, 0.2-0.4% of Si, 1.00-1.70%of Mn, 0-0.02% of P, 0-0.01% of S, 0.015-0.050% of Alt, 0.020-0.090% of Nb, 0-0.05% of V, 0.006-0.030% of Ti, 0.10-0.30% of Cr, 0-0.30% of Ni, 0-0.10% of Mo, 0-0.30% of Cu, 0-0.001% of B and the balance Fe and a few unavoidable impurities. The invention further provides a preparing method of the stainless steel composite plate for the petroleum and natural gas conveying pipeline. The preparing method is simple, feasible and low in cost; the prepared composite plate has good corrosion resistance and strong toughness, a compound interface is straighter, the thickness of the covering material ismore uniform, the surface quality is better, and the stainless steel composite plate can be directly used without annealing heat treatment.

Owner:NANJING IRON & STEEL CO LTD

New energy power battery shell, aluminum alloy and manufacturing method thereof

PendingCN111647775AImprove plastic deformation abilityFulfil requirementsCell component detailsPower batteryMetallurgy

The invention provides a new energy power battery shell, an aluminum alloy and a manufacturing method thereof. The aluminum alloy is prepared from the following components in percentage by weight: 0.17 to 0.30 percent of Si, 0.50 to 0.60 percent of Fe, 0.02 to 0.08 percent of Cu, 0.90 to 1.05 percent of Mn, 0.02 to 0.06 percent of Mg, less than or equal to 0.05 percent, 0.015 to 0.04 percent of Ti, and the balance of Al and the unavoidable impurities with the single element of less than or equal to 0.05 percent and the total amount of less than 0.15 percent. The aluminum alloy provided by theinvention has good plastic deformation capacity, and can meet the requirement on deep drawability and the requirement on surface quality of the battery shell.

Owner:YINBANG CLAD MATERIAL

Preparation method and brazing method of aluminum alloy brazing composite board capable of being subjected to aging strengthening

ActiveCN111926270AGuaranteed uniformityUniform temperature controlMetal rolling arrangementsComposite plateMaterials processing

The invention relates to a preparation method and brazing method of an aluminum alloy brazing composite board capable of being subjected to aging strengthening. The preparation method comprises the following steps of sequentially overlapping and pre-preparing a first aluminum alloy plate, a second aluminum alloy plate, a third aluminum alloy plate and a fourth aluminum alloy plate, heating a pre-prepared composite board blank to 490-520 DEG C; keeping the temperature for 2 to 4 hours to obtain a rough blank with the thickness of 30 to 35mm; continuously rolling the hot rough blank on a (1 + 4)hot continuous rolling mill at a time to obtain a hot-rolled coil with the thickness of 3-5mm; carrying out cold rolling on the hot-rolled coil to obtain a cold-rolled coil with the thickness of 1-2mm; and completely annealing the cold-rolled coil in an O state to obtain an aluminum alloy brazing composite plate finished product, and after brazing, carrying out quenching and low-temperature agingstrengthening so that the overall post-welding strength of the material can be obviously improved. According to the preparation method, the strength of the aluminum alloy brazing composite plate obtained through the method after brazing is greatly improved, even compounding is achieved, the material performance after compounding is even and consistent, meanwhile, the material machining process issimplified by reducing the thickness of a hot-rolled blank, and the batch production efficiency is improved.

Owner:湖南中创空天新材料股份有限公司

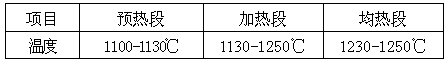

Super duplex stainless steel S32750 medium plate rolling process

ActiveCN103286128BGuaranteed heating timeGuaranteed surface qualityTemperature control deviceMetal rolling arrangementsSheet steelHigh pressure water

The invention discloses a super duplex stainless steel S32750 medium plate rolling process which includes blank selection, heating, high-pressure water descaling, two-roll rough rolling, and four-roll finish rolling. By increasing heating temperature, reducing rolling pass, and increasing finish rolling temperature of steel plates, edge cracks and partial cracks on the surface of the steel plates are reduced, medium plate rejection rate is lowered, rolling yield is increased, and contract fulfillment rate is increased.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

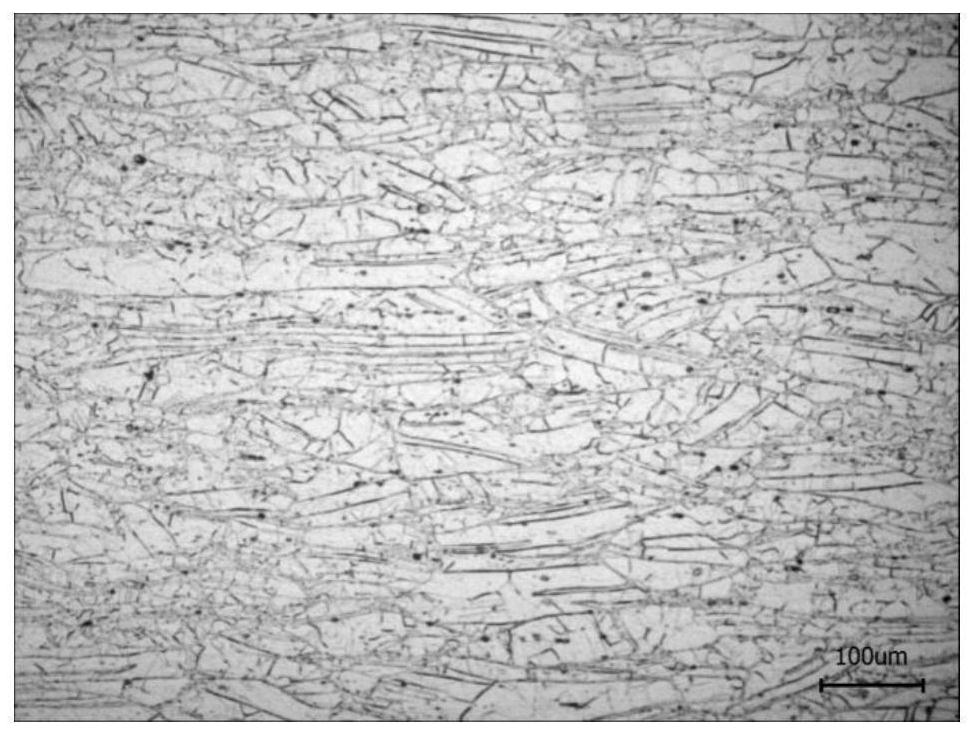

Hot rolling method for non-oriented electrical steel thin strip

InactiveCN105779728AReduce iron loss of finished productGood electromagnetic performanceSteel platesElectrical steel

The invention provides a hot rolling method for a non-oriented electrical steel thin strip. The electrical steel thin strip comprises, by weight, C<=0.003%, 3.5%-7.0% of Si, Al<=3.0%, 0.10%-1.50% of Mn, P<=0.03%, S<=0. 01%, N<=0.05%, and the balance Fe and unavoidable impurities. Before finish rolling, a plurality of slabs are stacked together to be rolled, the slabs are the same in thickness and component, and the thickness of each slab is 30-40 mm. The rolling starting temperature is controlled to be 950 DEG C or below. In the rolling process, cooling water in a rack is stopped. The final rolling temperature is controlled to be 800 DEG C or above. The coiling temperature is controlled to be 700 DEG C or below. Each roll of steel plate is rolled to be 0.2-0.7 mm. Slow cooling is conducted after coiling. After slow cooling, edge cutting and roll division are conducted. According to the hot rolling method, hot stacking continuous rolling is adopted, and the final rolling temperature is raised, so that a hot rolled plate is fully recrystallized, and the finished product iron loss is further reduced. The electromagnetic property is excellent, the production efficiency is improved, the steel plate is even in thickness, and the hot rolling method is suitable for high-speed stamping and automatic lamination.

Owner:ANGANG STEEL CO LTD

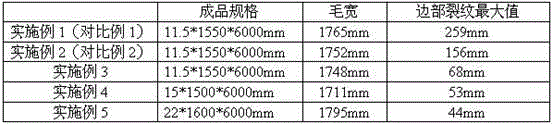

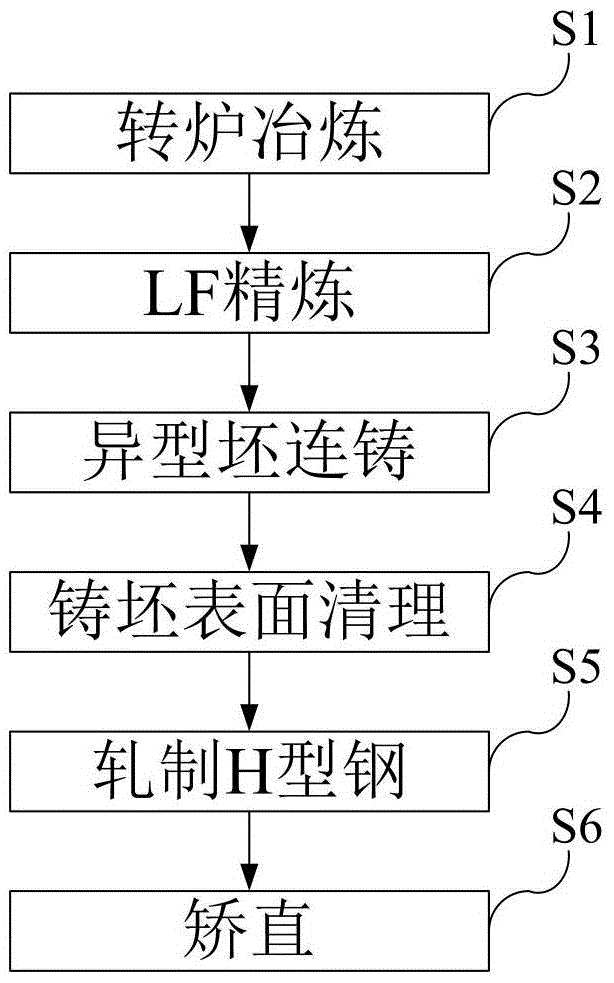

Production method of large section h-beam

ActiveCN103589951BImprove performanceSimple production processMetal rolling arrangementsSurface cleaningMaterials science

The invention discloses a large section H shaped steel, which comprises the following chemical components by mass: 0.16-0.20% of C, 0.25-0.40% of Si, 1.35-1.50% of Mn, less than or equal to 0.03% of P, less than or equal to 0.020% of S, less than or equal to 0.012% of N, 0.10-0.20% of V, greater than or equal to 0.015% and less than or equal to 0.030% of Al, and the balance Fe and impurities. The invention also discloses a production method for the large section H shaped steel. The method consists of: converter smelting, LF refining, beam blank continuous casting, casting blank surface cleaning, H shaped steel rolling and straightening. By means of reasonable component design, and under the circumstance of only adding the microalloy element V, comprehensive properties of the large section H shaped steel can be improved, and the production process is simple and is in favor of popularization.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

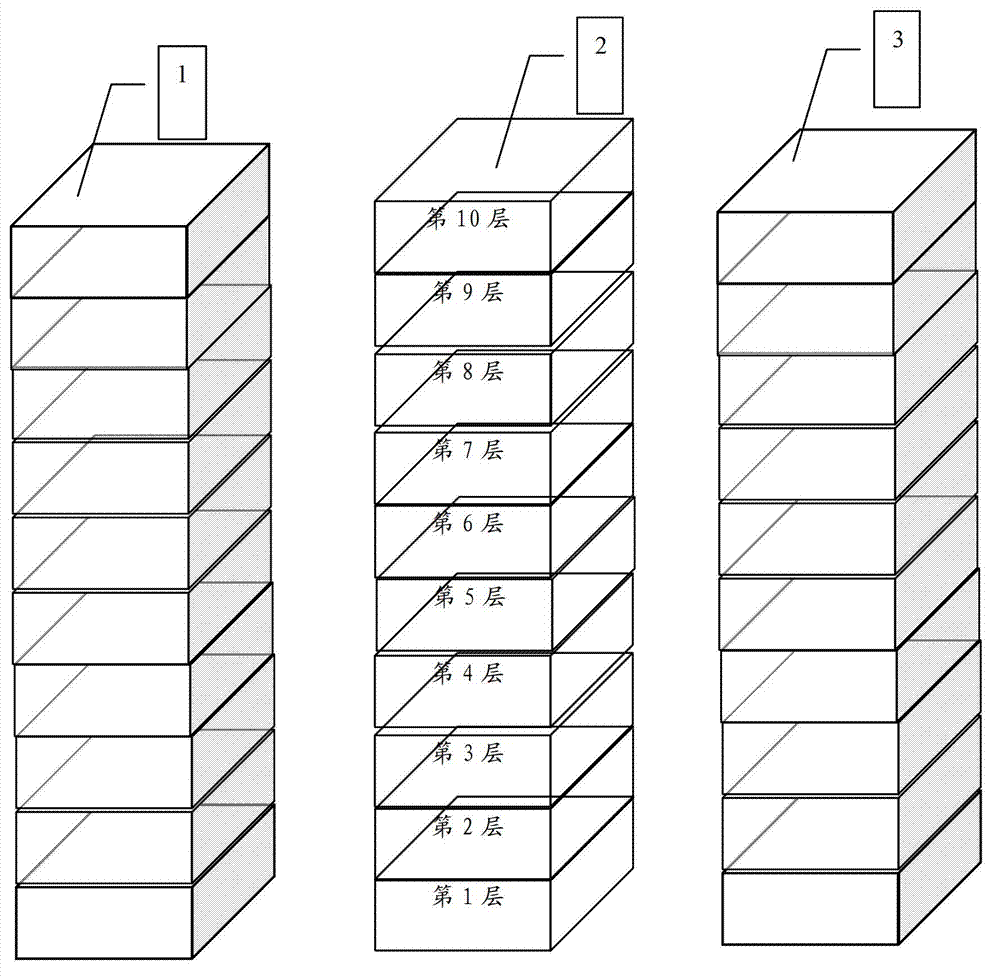

Preparation method of wide alloy plate

ActiveCN113913648AImprove flatnessLarge formatRoll force/gap control deviceMetal rolling arrangementsSuperalloyLarge deformation

A preparation method of a wide alloy plate comprises the following steps that a high-temperature alloy plate blank is subjected to first-fire rolling at the temperature of 1130-1150 DEG C and then subjected to material separation, then subjected to second-fire rolling at the temperature of 1130-1150 DEG C and then subjected to material separation, then subjected to third-fire rolling at the temperature of 1050-1080 DEG C and finally subjected to solid solution leveling treatment; wherein the total deformation of the first-fire rolling is 45%-55%, and the total deformation of the second-fire rolling is 45%-55%; and the total deformation of the third-fire rolling is 60-80%. According to the method, a multi-heating-number and multi-pass forming mode is adopted, firstly, small-deformation cogging is adopted, deformation resistance is reduced, the requirement for equipment is reduced, large-deformation reversing rolling is conducted after cogging is completed, all consistency of the plate structure is improved, and the structure uniformity and performance uniformity of the plate are guaranteed.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com