High-ductility FH500-grade ship plate steel and preparation method thereof

A ship plate steel, ductility technology, applied in the field of metallurgy, can solve the problems of low steel plate surface elongation, poor steel plate surface quality, complex production process, etc., to achieve the effects of reducing MnS inclusions, low production costs, and improving tissue uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

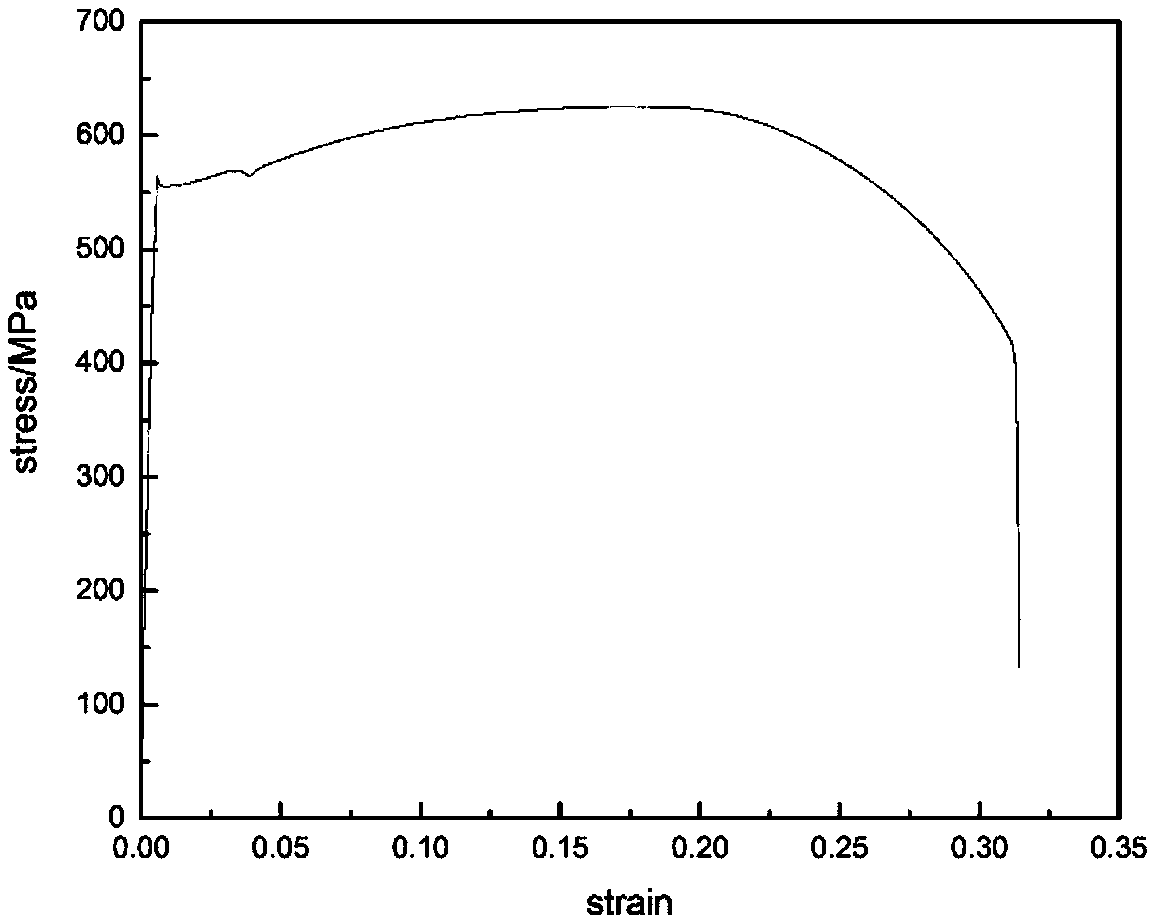

[0030] A preparation method of high ductility FH500 ship plate steel with a thickness of 19mm, specifically comprising the following process steps:

[0031] step 1:

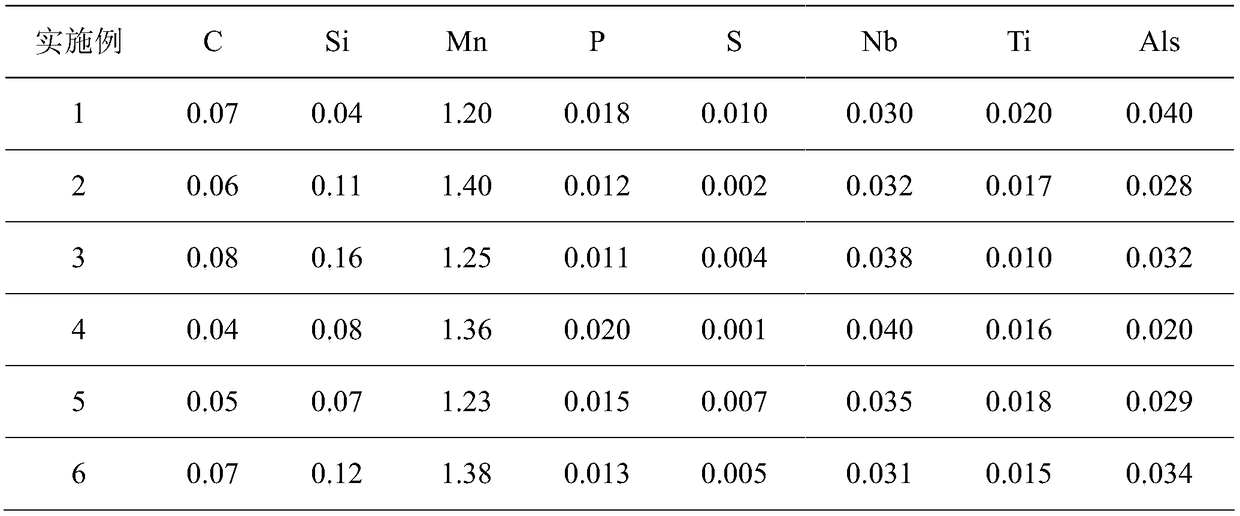

[0032] According to the composition design, the molten steel was smelted and cast into a billet with a thickness of 120 mm. The billet was heated to 1210 °C and kept for 1.5 hours. The chemical composition and weight percentage of the billet are shown in Table 1;

[0033] Step 2:

[0034] (1) Rough rolling is carried out on the heated billet for 3 passes, the starting rolling temperature is 1060°C, the rolling thickness is 120mm → 84mm → 59mm → 42mm, the total cumulative reduction rate is 65%, and the intermediate rolling thickness is 42mm. Blank;

[0035] (2) Perform 3 passes of finish rolling on the intermediate slab, the starting rolling temperature is 960°C, the rolling thickness is 42mm→32mm→24mm→19mm, the total cumulative reduction rate is 54.8%, and the finishing rolling temperature is 900°C. Steel plat...

Embodiment 2

[0040] A kind of preparation method of high ductility FH500 grade ship plate steel with a thickness of 30mm, specifically comprises the following process steps:

[0041] step 1:

[0042] According to the composition design, the molten steel was smelted and cast into a billet with a thickness of 140 mm. The billet was heated to 1236 °C and kept for 1 hour. The chemical composition and weight percentage of the billet are shown in Table 1;

[0043] Step 2:

[0044] (1) Carry out 3 passes of rough rolling on the heated billet, the starting rolling temperature is 1150°C, the rolling thickness is 140mm→102mm→76mm→58mm, the total cumulative reduction rate is 58.6%, and the intermediate billet with a thickness of 58mm is obtained ;

[0045] (2) Perform 3 passes of finish rolling on the intermediate slab, the starting rolling temperature is 950°C, the rolling thickness is 58mm→46mm→37mm→30mm, the total cumulative reduction rate is 48.3%, and the finishing rolling temperature is 890°C...

Embodiment 3

[0050] A kind of preparation method that is the high ductility FH500 ship plate steel of 25mm in thickness, specifically comprises the following process steps:

[0051] step 1:

[0052] According to the composition design, the molten steel was smelted and cast into a billet with a thickness of 130 mm. The billet was heated to 1230 °C and kept for 1 hour. The chemical composition and weight percentage of the billet are shown in Table 1;

[0053] Step 2:

[0054] (1) Rough rolling is carried out on the heated billet for 3 passes, the starting rolling temperature is 1143°C, the rolling thickness is 130mm → 91mm → 67mm → 52mm, the total cumulative reduction rate is 60%, and the intermediate rolling thickness of 52mm is obtained. Blank;

[0055] (2) Perform 3 passes of finish rolling on the intermediate slab, the starting rolling temperature is 940°C, the rolling thickness is 52mm→40mm→31mm→25mm, the total cumulative reduction rate is 51.9%, and the finishing rolling temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com