Production method of large section h-beam

A production method, the technology of H-shaped steel, applied in the direction of metal rolling, etc., can solve the problems of large market potential, high efficiency, and inability to produce in ordinary steel factories, so as to improve comprehensive performance, simple production process, reduce load and energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

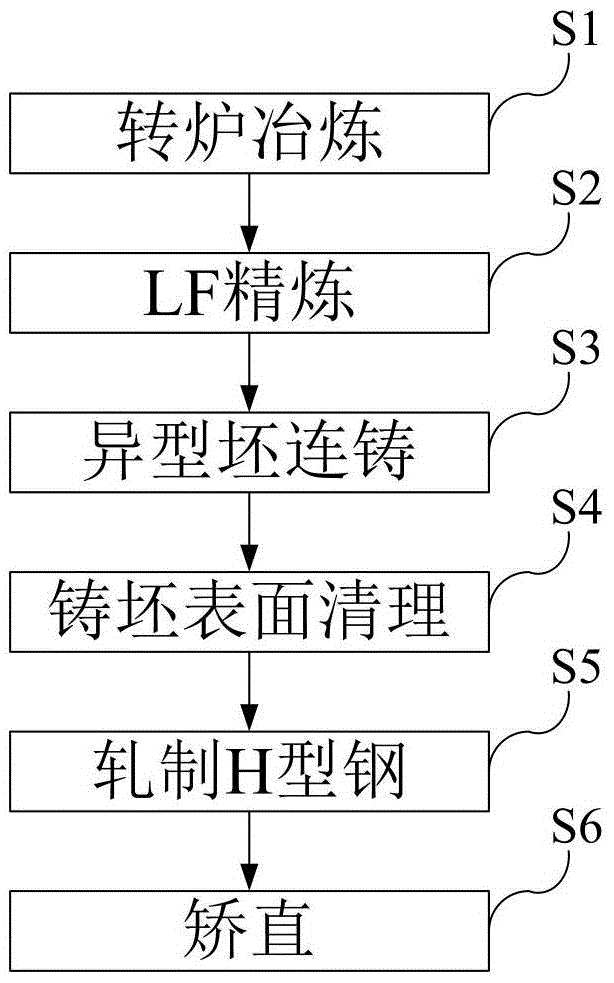

[0038] The production method of this embodiment sequentially includes 150 t converter smelting, LF refining, continuous casting of shaped billets, surface cleaning of cast billets, rolling H-shaped steel and straightening.

[0039] The 150t converter is smelted using deoxidation alloying of silicomanganese and ferromanganese, with final deoxidation of aluminum. The mass percentage of C at the end point of 150t converter smelting is 0.06%, the mass percentage of P is 0.02%, and the mass percentage of S is 0.04%. The tapping temperature of controlled converter smelting is 1650°C.

[0040] White slag is used for LF refining, and ferrovanadium is added at the end of LF refining. The amount of slag and alloy added per 100 tons of LF refined molten steel includes: 401 kg of lime, 201 kg of bauxite, 80 kg of calcium carbide, 60 kg of anthracite, 451 kg of ferromanganese, 201 kg of ferrosilicon, and 130 kg of ferrovanadium. The in-situ temperature for LF refining is 1554°C, the off-...

Embodiment 2

[0048] The production method of this embodiment sequentially includes 150 t converter smelting, LF refining, continuous casting of shaped billets, surface cleaning of cast billets, rolling H-shaped steel and straightening.

[0049] The 150t converter is smelted using deoxidation alloying of silicomanganese and ferromanganese, with final deoxidation of aluminum. The mass percentage content of C at the converter end point of 150t converter smelting is 0.09%, the mass percentage content of P is 0.020%, and the mass percentage content of S is 0.04%. The tapping temperature of controlled converter smelting is 1650°C.

[0050] White slag is used for LF refining, and ferrovanadium is added at the end of LF refining. The amount of slag and alloy added per 100 tons of LF refined molten steel includes: 401 kg of lime, 203 kg of bauxite, 80 kg of calcium carbide, 20 kg of anthracite, 371 kg of ferromanganese, 201 kg of ferrosilicon, and 70 kg of ferrovanadium. The in-situ temperature f...

Embodiment 3

[0058] The production method of this embodiment sequentially includes 150 t converter smelting, LF refining, continuous casting of shaped billets, surface cleaning of cast billets, rolling H-shaped steel and straightening.

[0059] The 150t converter is smelted using deoxidation alloying of silicomanganese and ferromanganese, with final deoxidation of aluminum. The mass percent content of C at the converter end point of 150t converter smelting is 0.05%, the mass percent content of P is 0.01%, and the mass percent content of S is 0.03%. The tapping temperature of controlled converter smelting is 1650°C.

[0060] White slag is used for LF refining, and ferrovanadium is added at the end of LF refining. The amount of slag and alloy added per 100 tons of LF refined molten steel includes: 401 kg of lime, 201 kg of bauxite, 80 kg of calcium carbide, 55 kg of anthracite, 463 kg of ferromanganese, 201 kg of ferrosilicon, and 125 kg of ferrovanadium. The in-situ temperature for LF ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| brittleness temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com