Production method of high-strength saw bit steel coil

A production method and high-strength technology, applied in the direction of temperature control, heat treatment equipment, heat treatment process control, etc., can solve the problems of broken billet, excessive cooling rate of casting billet, difficult processing, etc., to improve plate shape control and mechanical properties. , highlight the effect of technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The key control points of this method, take the saw blade or saw blade steel as an example;

[0031] 1) The production process of this method: converter smelting-LF refining-hot continuous rolling;

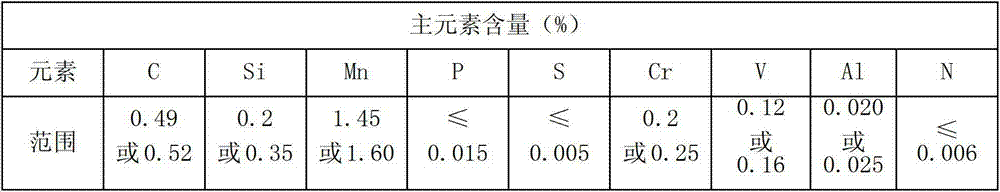

[0032] 2) Composition design: See Table 1 for the composition design of saw blade steel.

[0033] Table 1

[0034]

[0035] Adopt carbon, manganese and added V microalloying elements to strengthen the composition design scheme, the content of carbon in the steel is lower than the traditional 50Mn2V, and the control range of carbon is narrow, which ensures the stability of various properties of the steel and improves the rolling time. The plate shape is controlled, and a certain amount of chromium is added at the same time, which improves the hardenability and hardenability of the material.

[0036] 3) Surface defect and segregation control of slab continuous casting

[0037] Since it is a medium-high carbon alloy steel, the crack sensitivity of the slab is extremely s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com