Patents

Literature

53results about How to "Increase cooling temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Structure of Hybrid Vehicle

InactiveUS20080164081A1Suppresses reduction efficiencyReduction efficiency can be preventedBatteries circuit arrangementsExhaust apparatusElectrical batteryHybrid vehicle

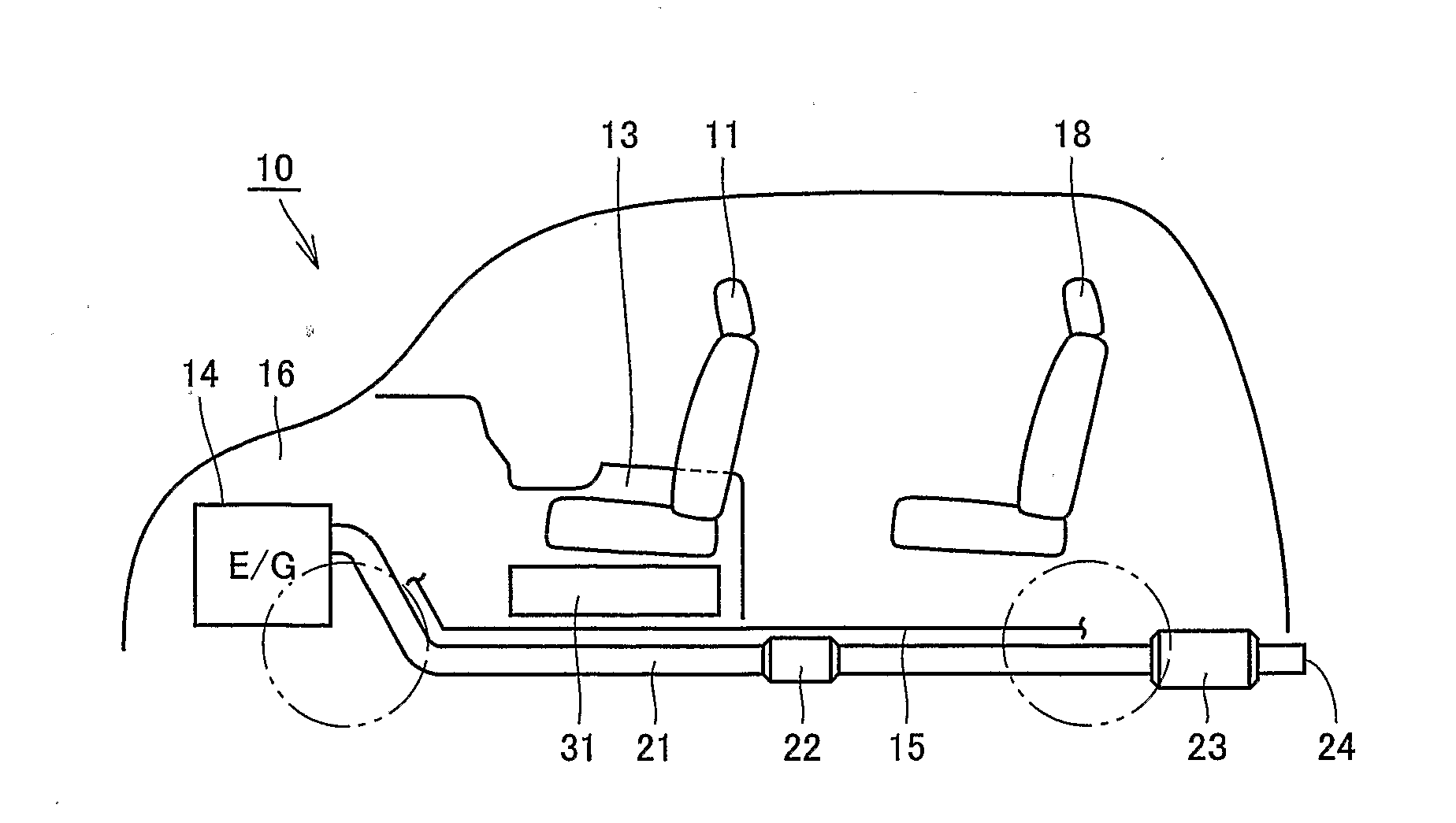

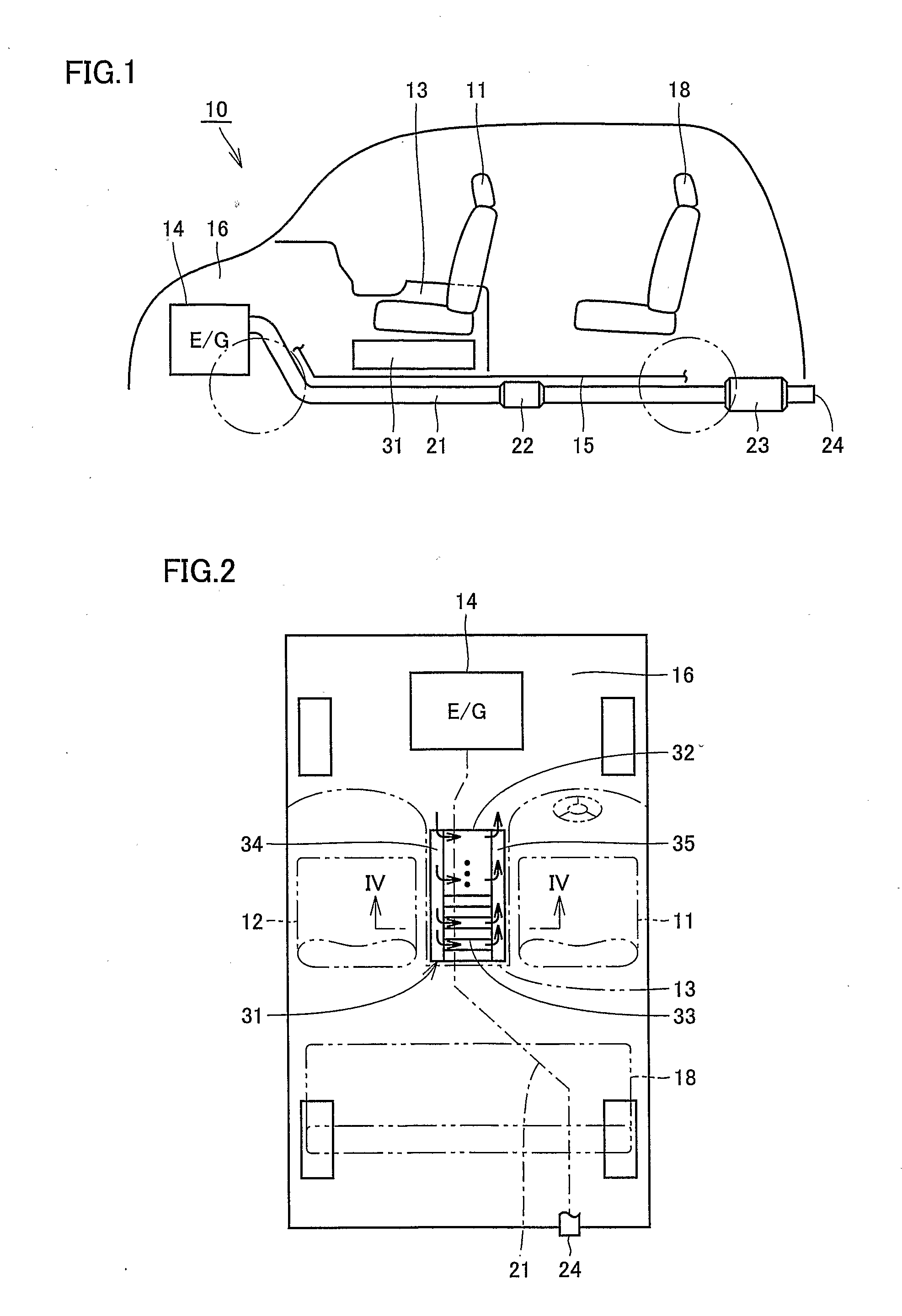

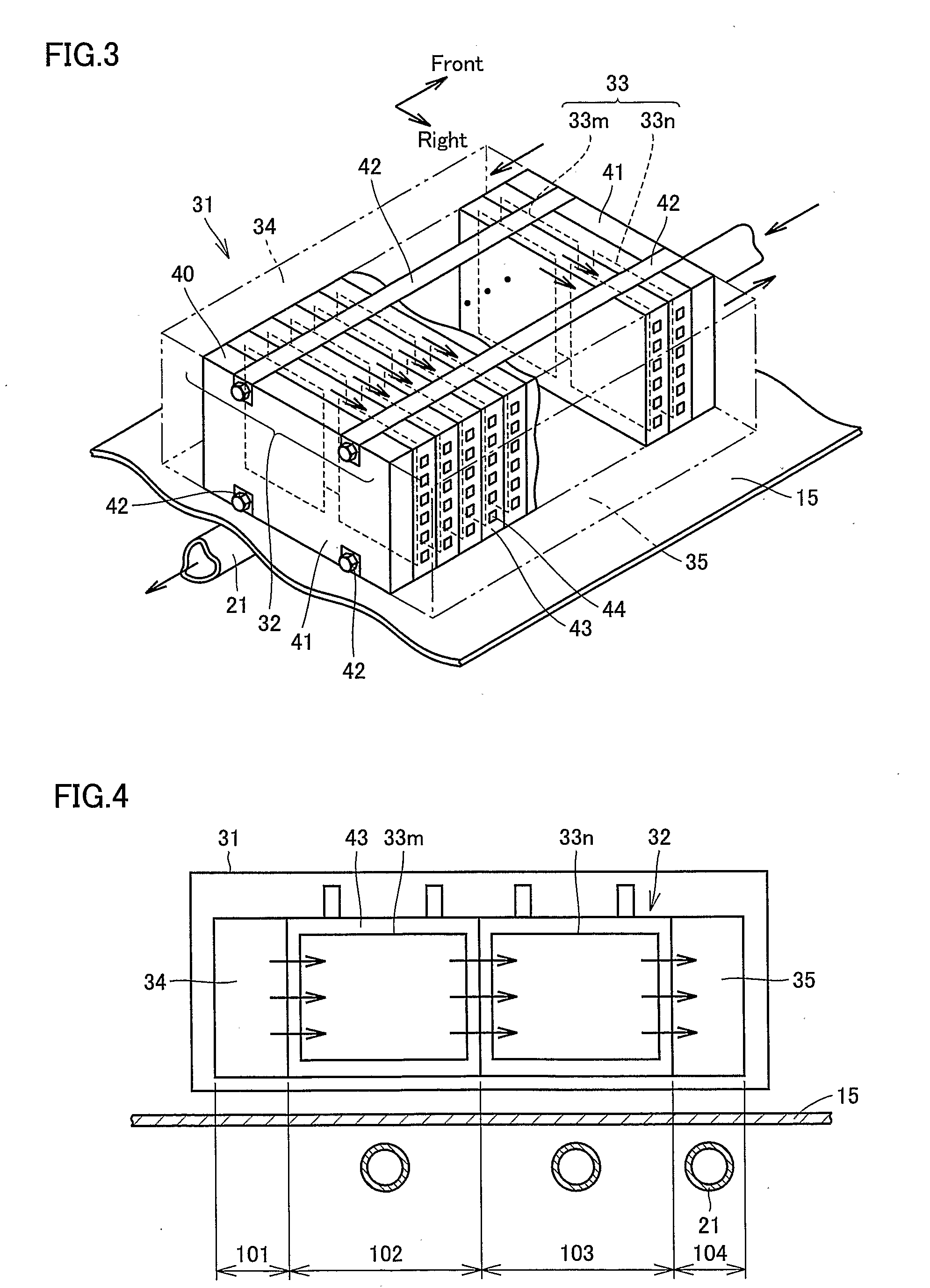

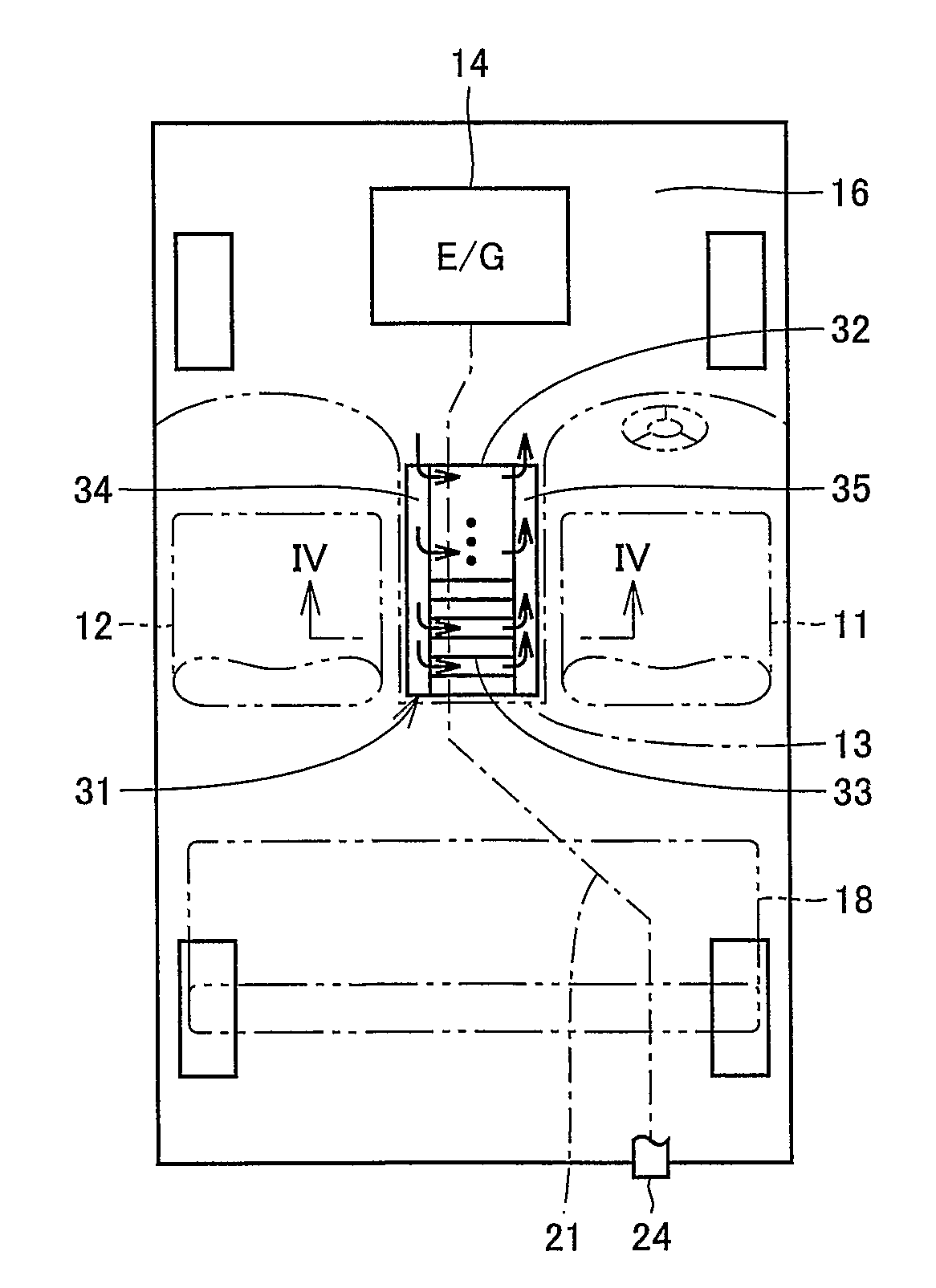

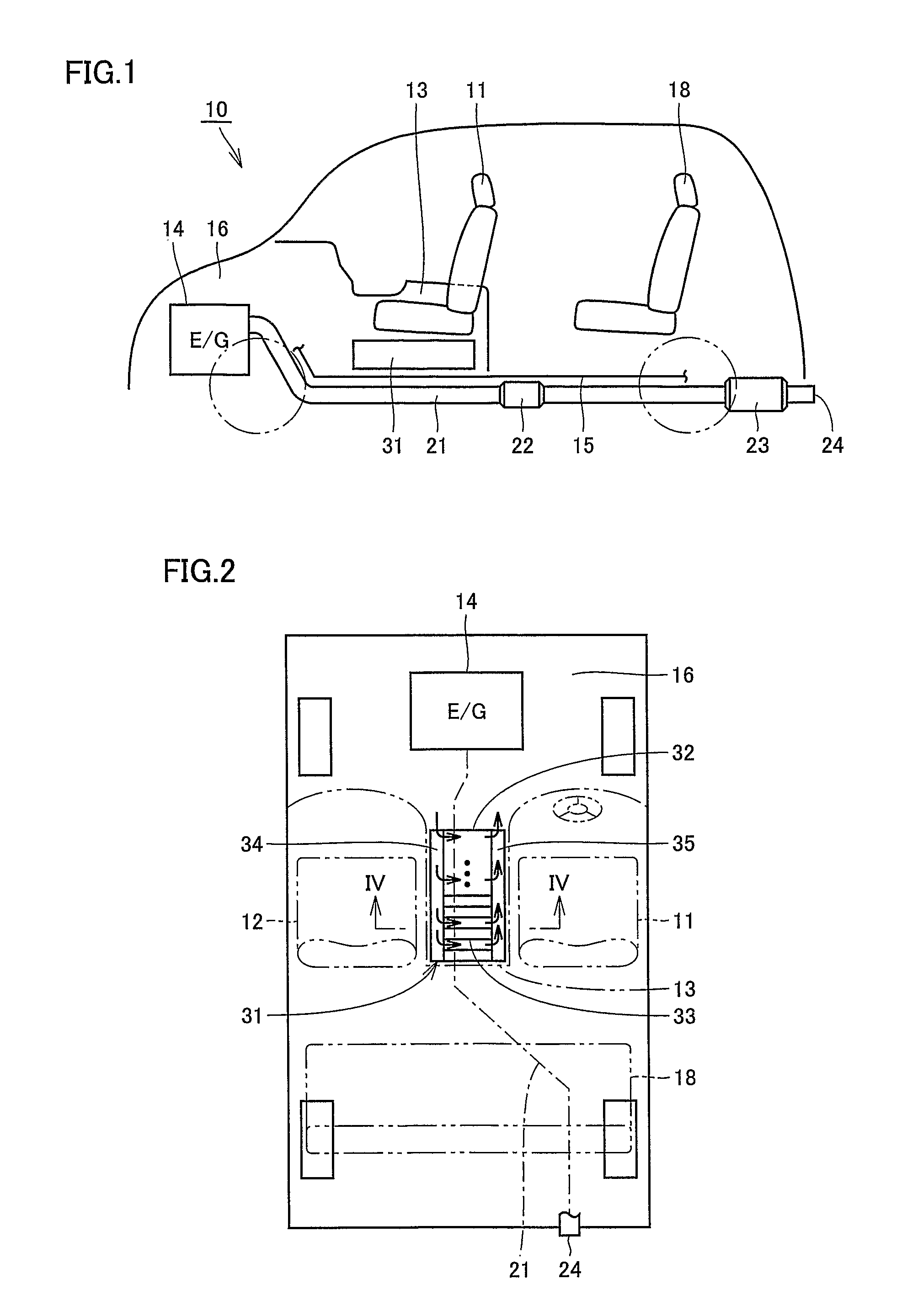

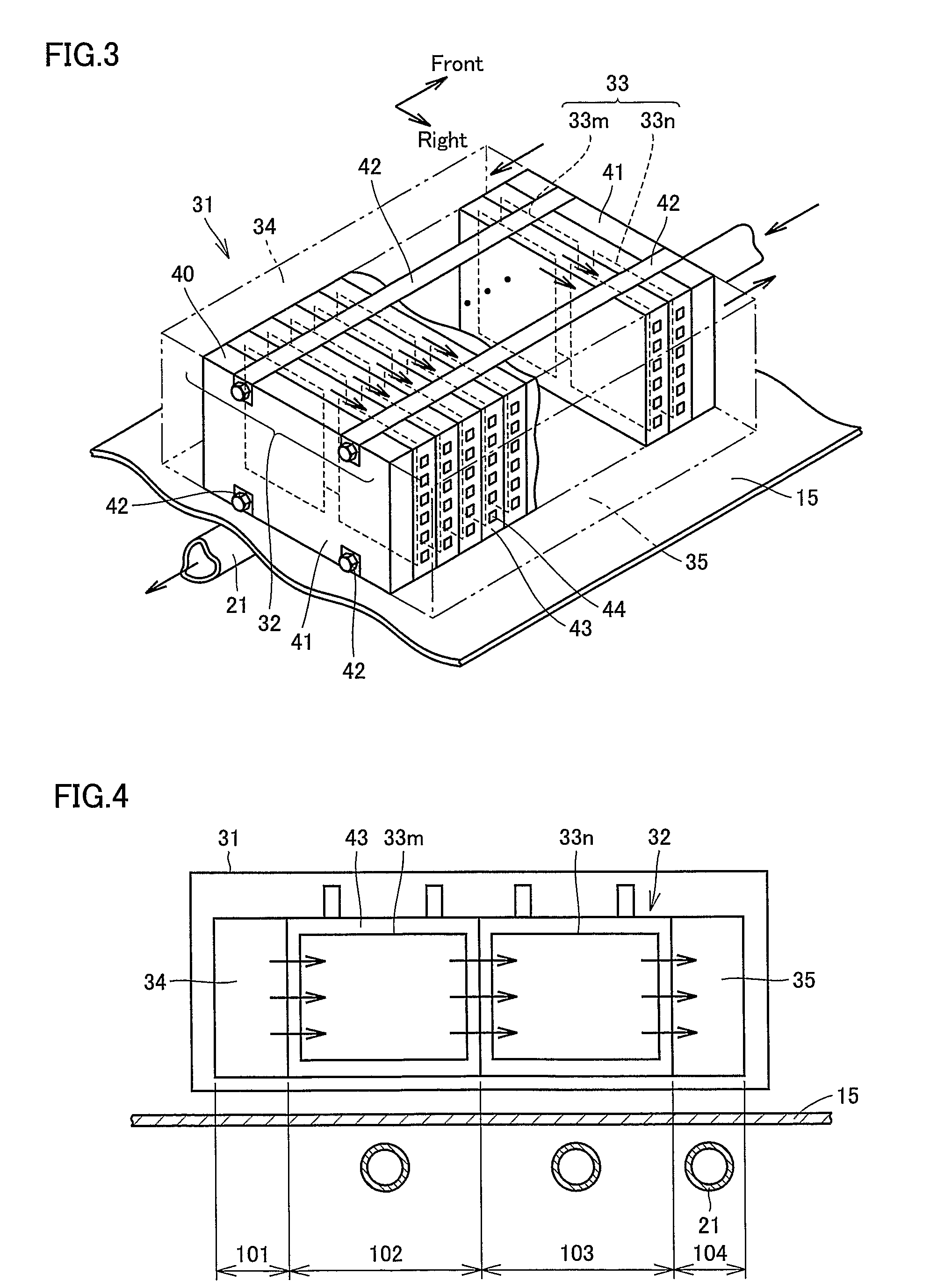

A structure of a hybrid vehicle includes a battery pack arranged on a floor panel and an exhaust pipe extending from an engine, passing below the floor panel, to an exhaust port. The battery pack has a secondary battery constituted by a plurality of battery cells stacked in a vehicle traveling direction for supplying electric power to a motor, and an intake chamber provided adjacent to the secondary battery in a substantially horizontal direction perpendicular to the direction along which the plurality of battery cells are stacked for supplying cooling air between each of the plurality of battery cells. The exhaust pipe is provided so that it passes immediately below the battery pack and passes a position displaced from a position immediately below the intake chamber. With such a configuration, a structure of a hybrid vehicle that suppresses reduction in the efficiency of cooling a secondary battery without placing a great limit on routing of an exhaust pipe is provided.

Owner:TOYOTA JIDOSHA KK

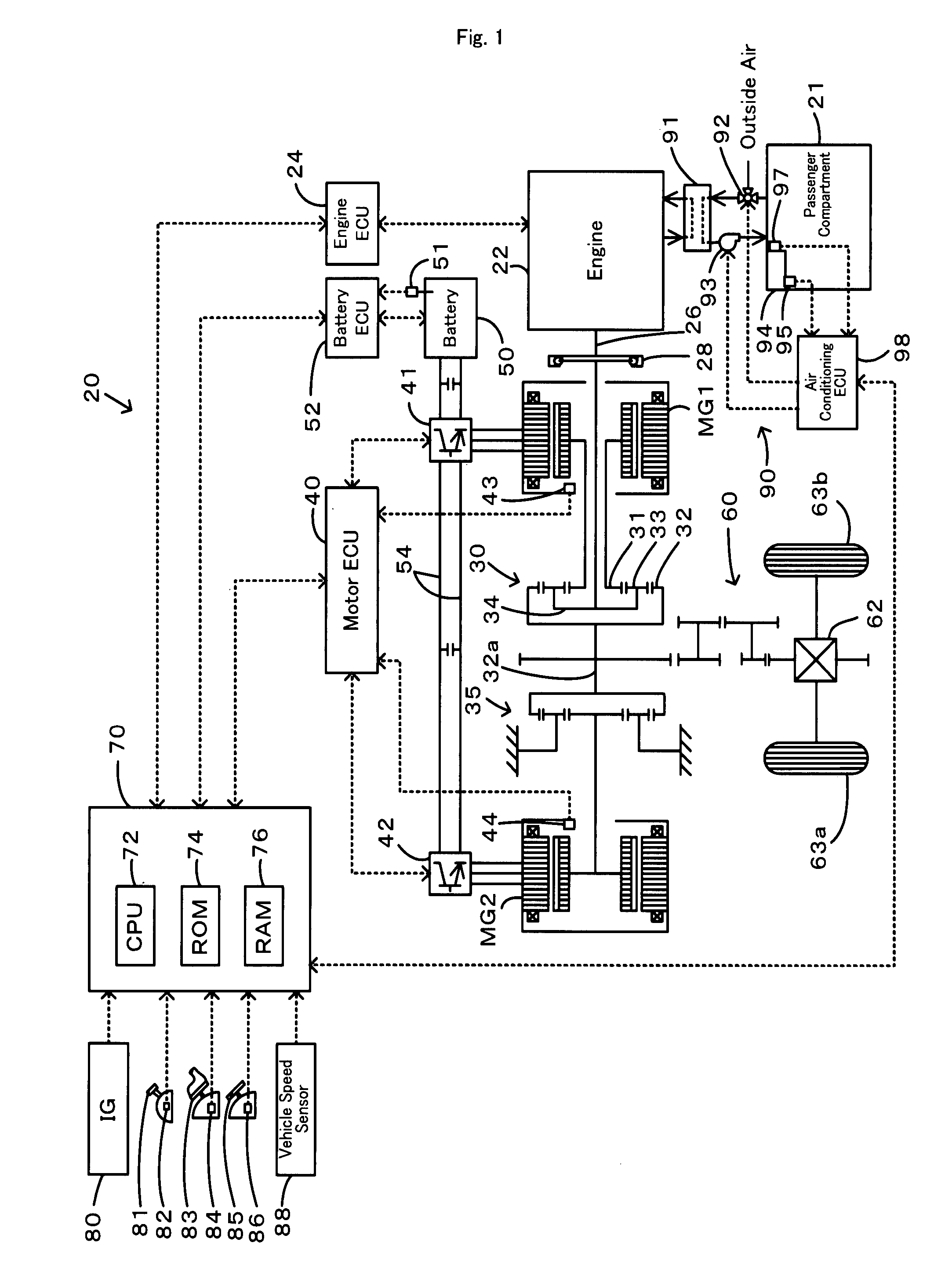

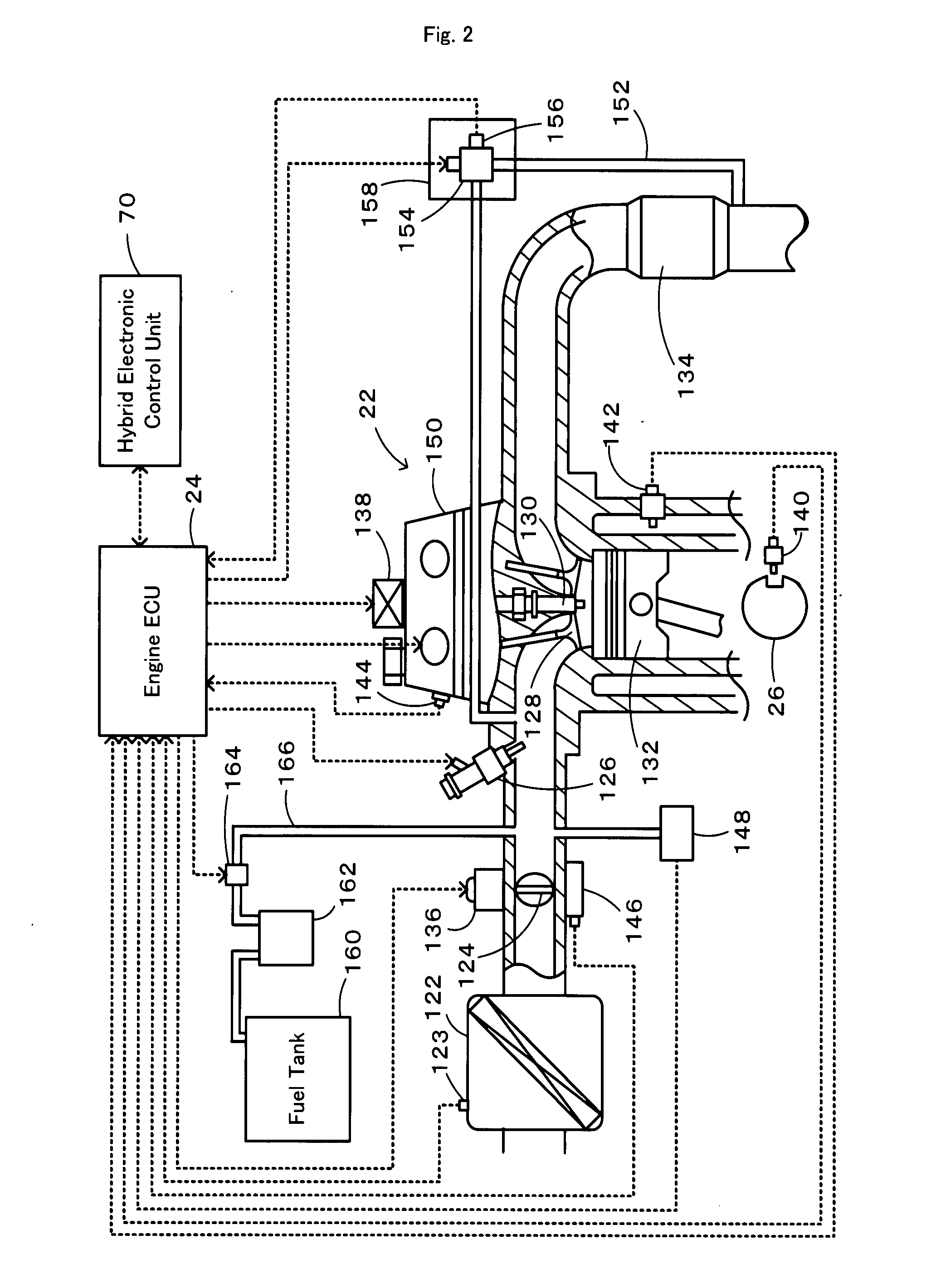

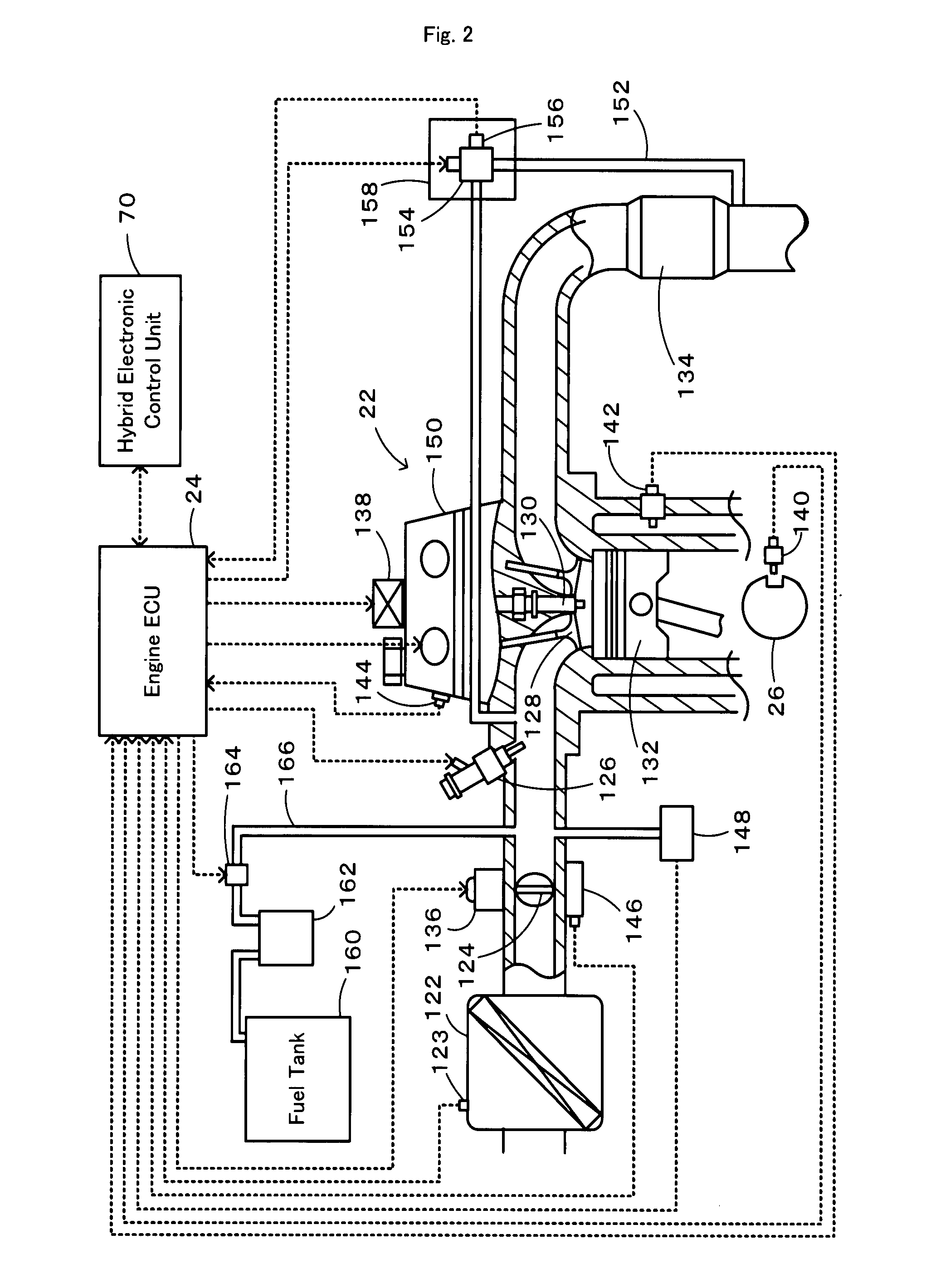

Motor Vehicle and Control Method of Internal Combustion Engine

InactiveUS20070255485A1Improve fuel economyIncrease cooling temperatureHybrid vehiclesAnalogue computers for vehiclesOperation modePressure reduction

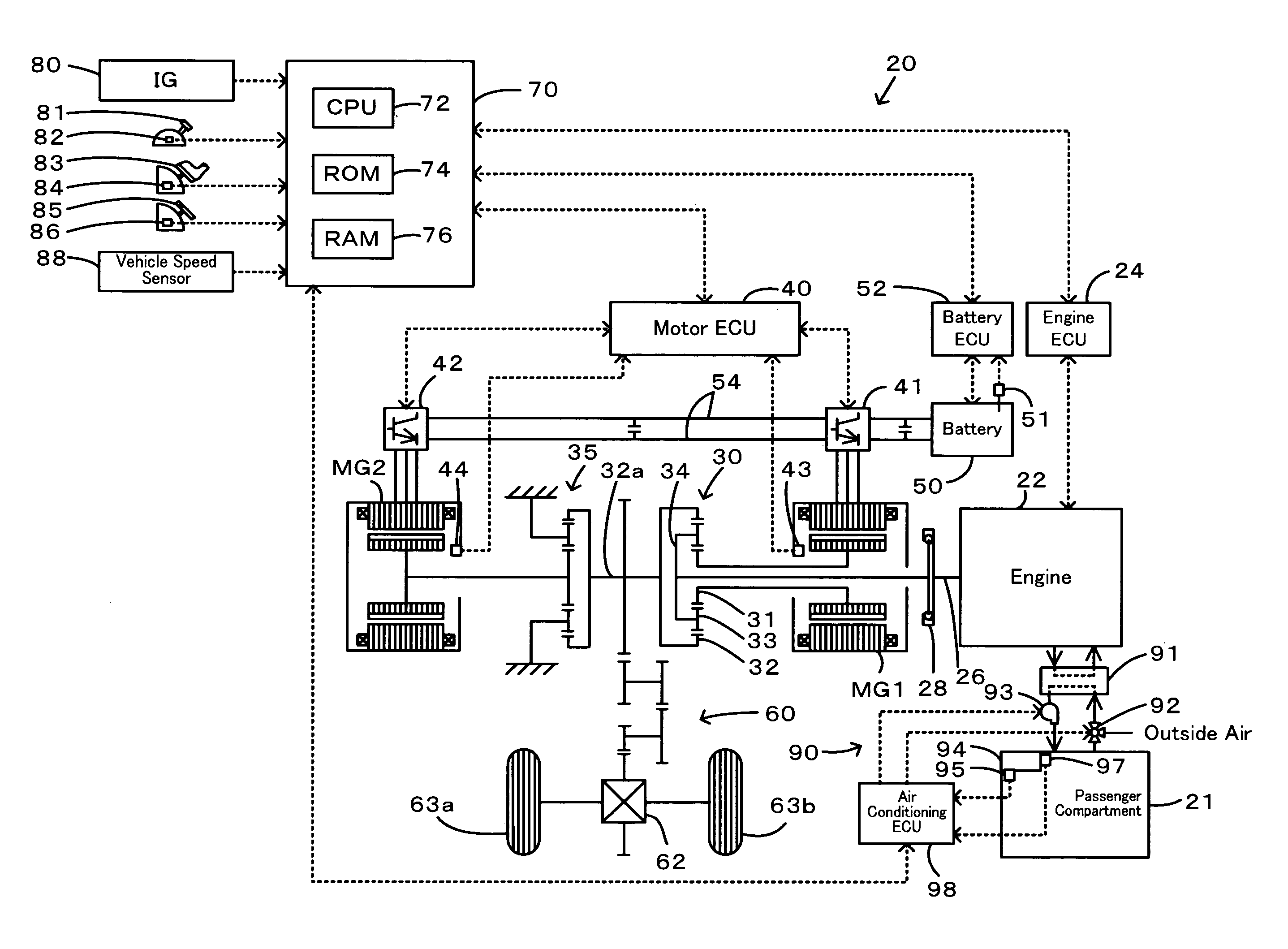

In a motor vehicle of the invention, when an intake air temperature Ta is not lower than a preset reference temperature Tref, warm-up drive control selectively uses an evaporated fuel processing acceleration operation curve, which gives a high level of a negative pressure in an intake manifold, to set a target drive point of an engine and controls the operation of the engine. This ensures good emission of the engine. When the intake air temperature Ta is lower than the preset reference temperature Tref and when the setting of a heating demand Hq requires heating, on the other hand, the warm-up drive control increases an EGR quantity from an ordinary level and switches over an operation mode of a cooling system for the engine to a warm-up circulation mode for making the flow of a cooling medium bypass a radiator. This introduces a greater amount of heat of exhaust into a heat exchanger to enable quick supply of the warm air to a passenger compartment. The warm-up drive control selectively uses a negative pressure reduction operation curve, which gives a lower level of the negative pressure in the intake manifold than the level of the negative pressure set on the evaporated fuel processing acceleration operation curve, to set the target drive point of the engine and controls the operation of the engine. This enhances the operation efficiency of the engine and improves the fuel economy during the warm-up time of the engine.

Owner:TOYOTA JIDOSHA KK

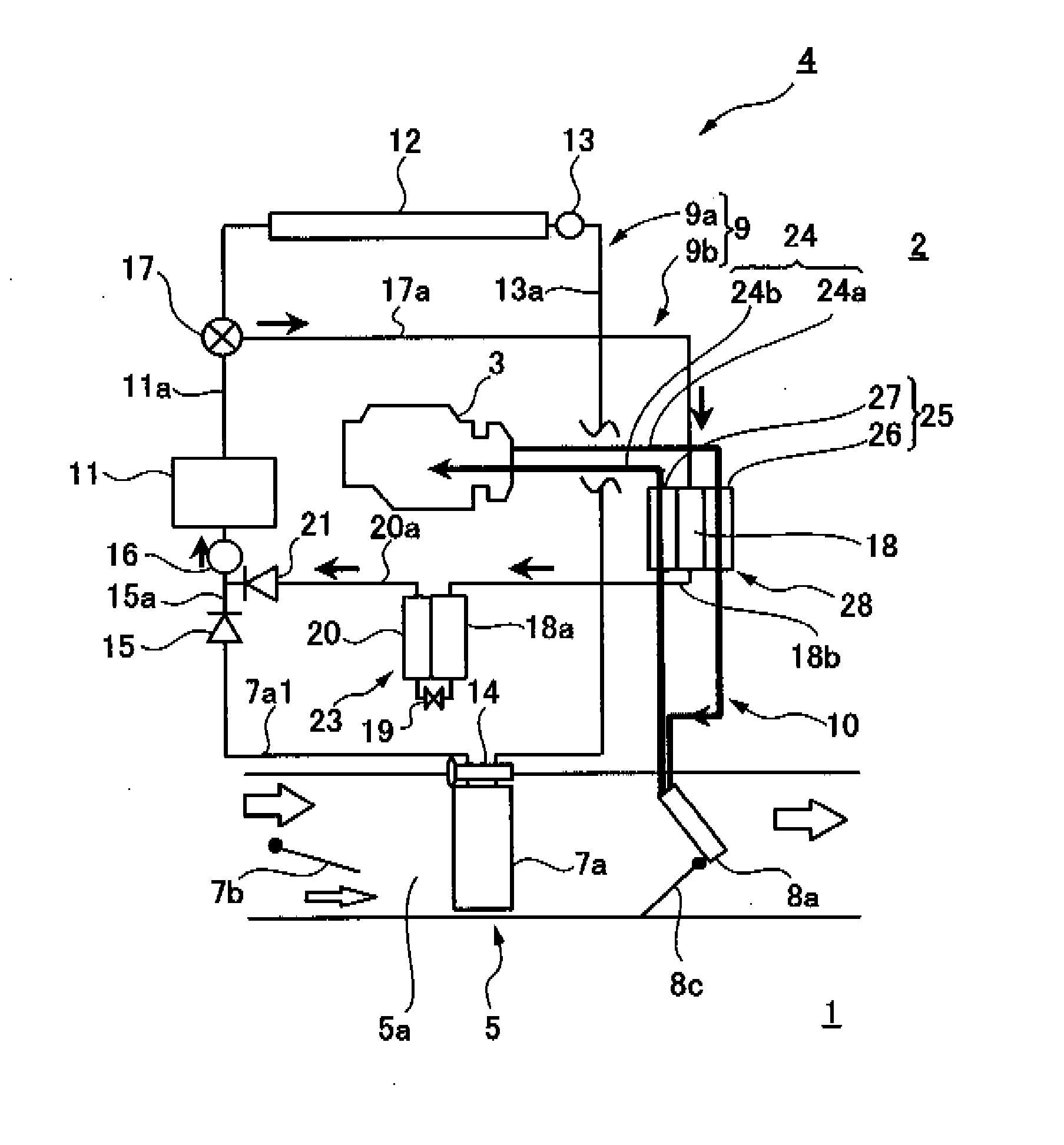

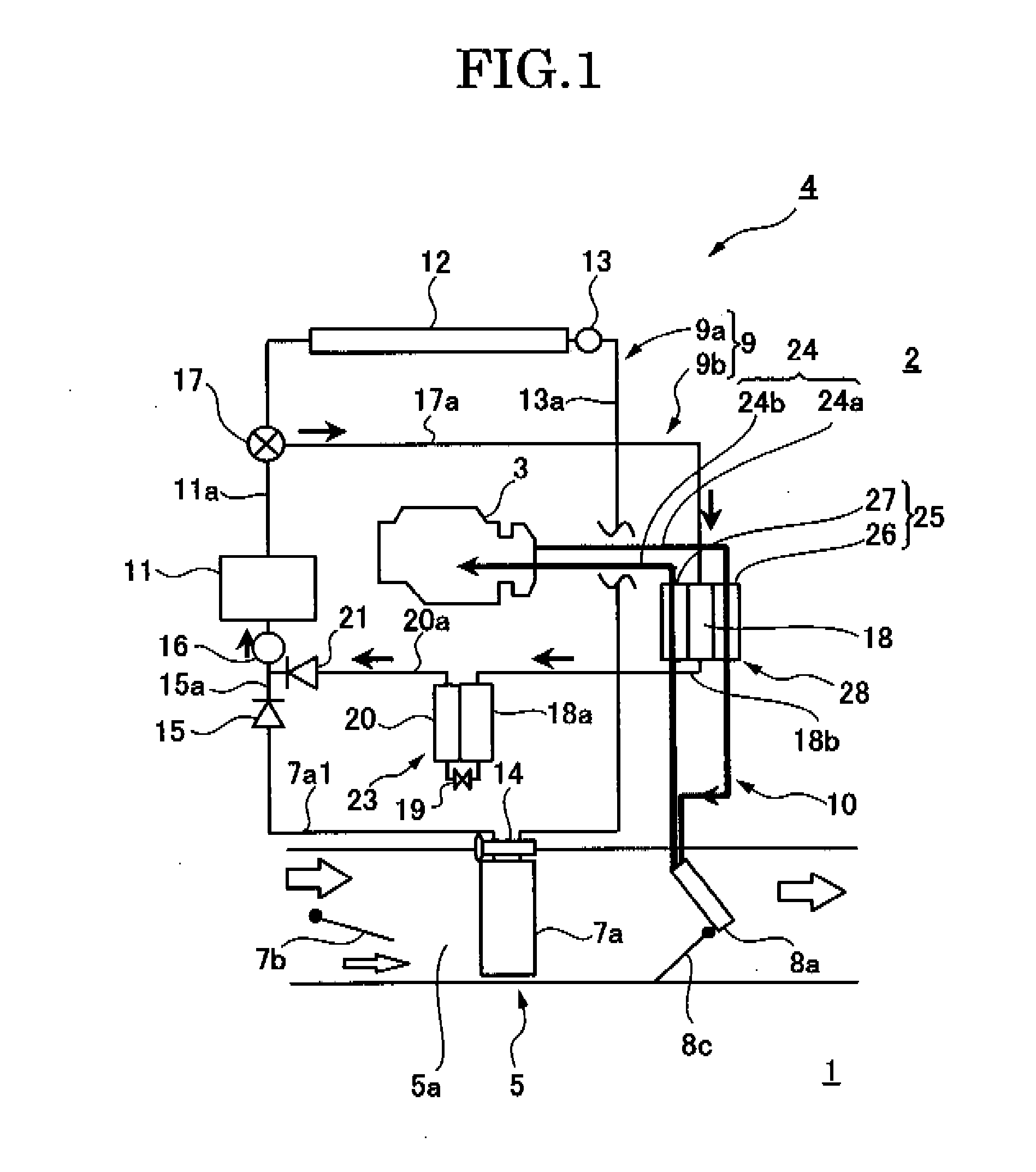

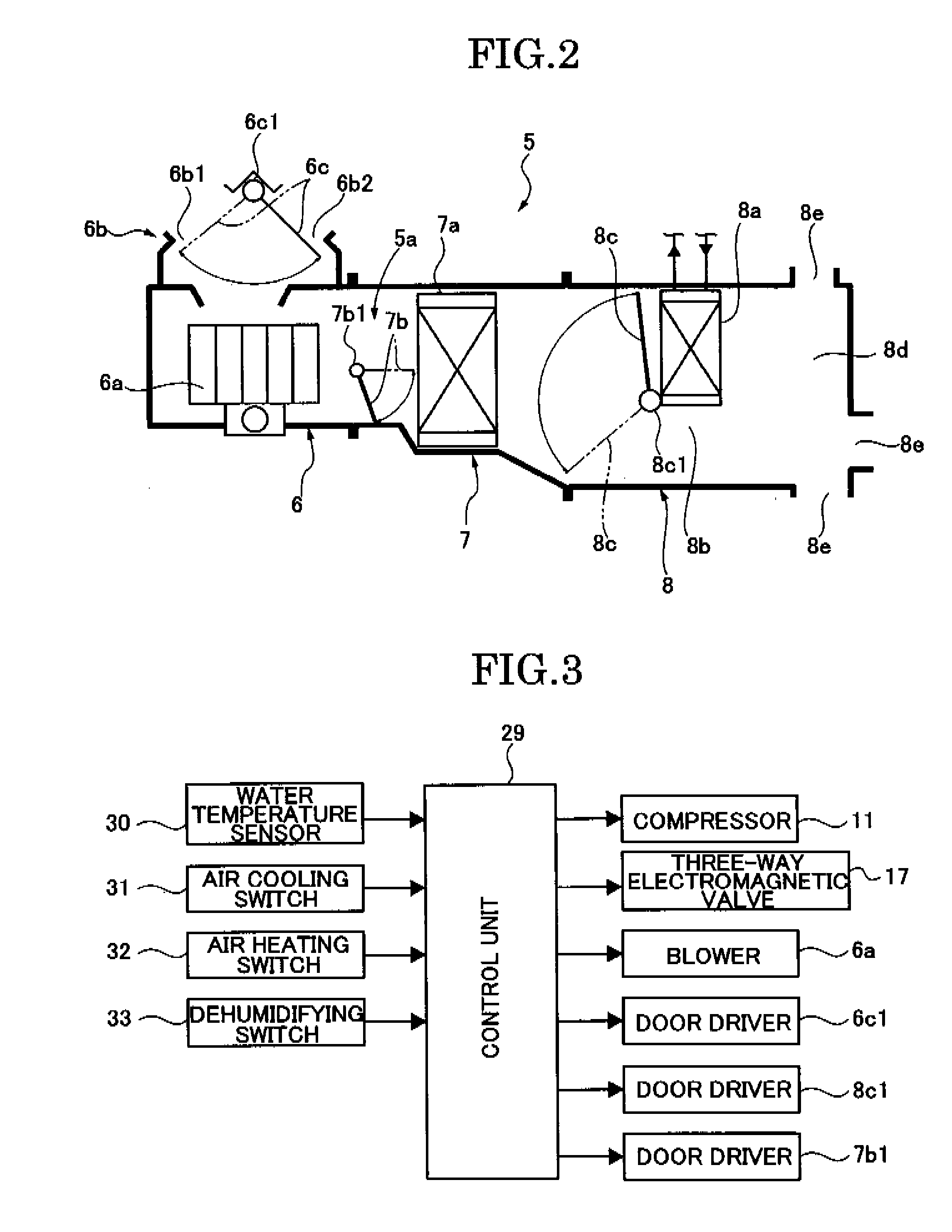

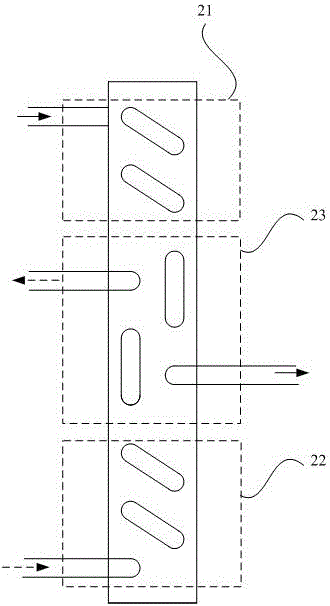

Air conditioning device for vehicle

InactiveUS20120017637A1Increase temperatureSimple structureAir-treating devicesEvaporators/condensersWater useWater flow

Provided is a vehicle air conditioning device with a simple structure which can quickly raise the temperature of engine cooling water used for heating the air in a vehicle cabin in an engine start period in a low ambient temperature. The vehicle air conditioning device comprises the following elements integrally connected with each other: a first water heat exchanger (26) provided in the middle of a passage through which an engine cooling water flows from the water jacket of an engine (3) to a heater core (8a), a second water heat exchanger (27) provided in the middle of a passage through which the engine cooling water flows from the heater core (8a) to the water jacket of the engine (3), and a first external heat exchanger (18) for refrigerant condensation provided between the first and second water heat exchangers (26, 27). In the engine start period in a low ambient temperature, the engine cooling water flowing from the water jacket to the heater core (8a) is heated by heat released from the first external heat exchanger (18) to rise in temperature.

Owner:CALSONIC KANSEI CORP

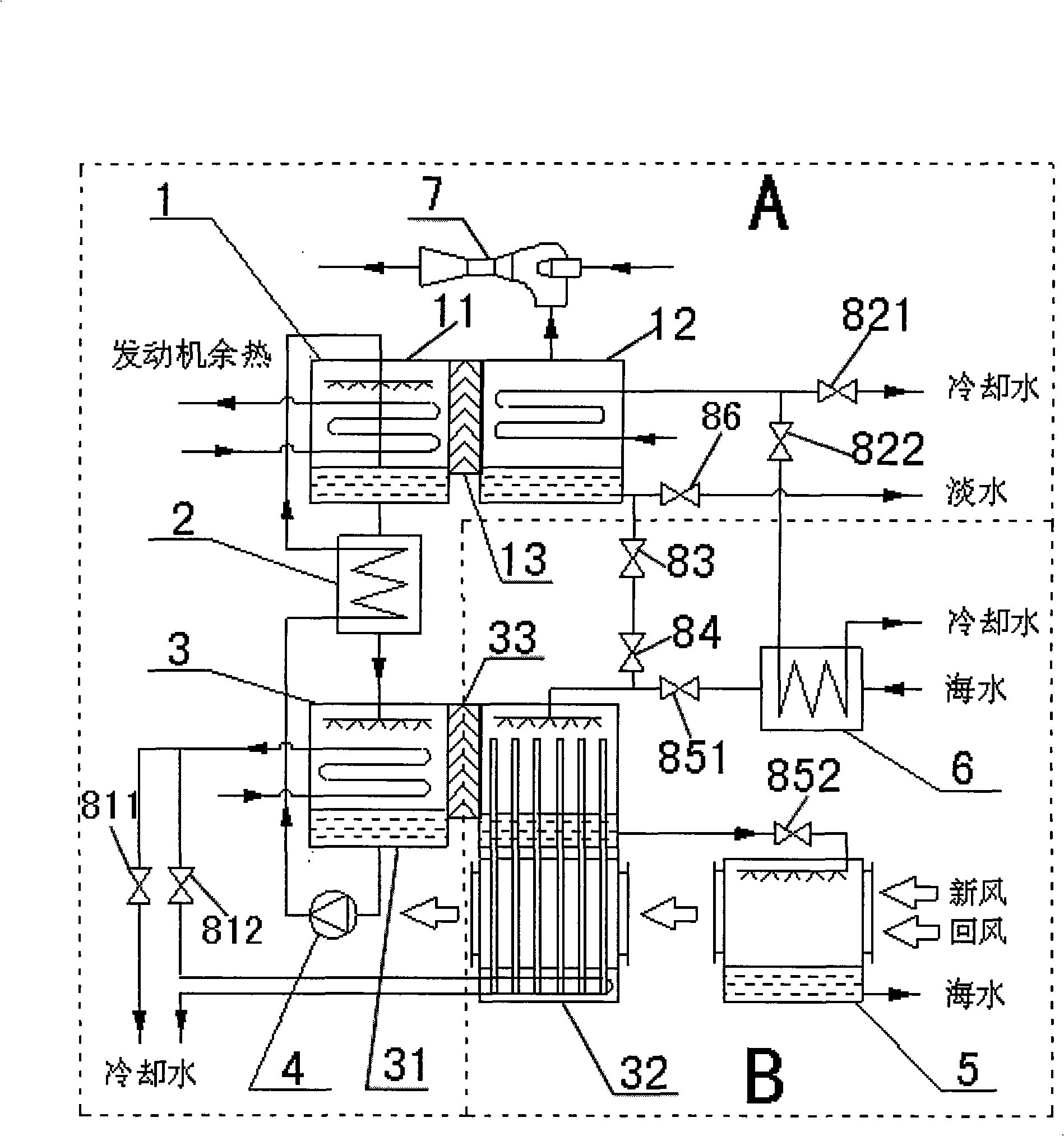

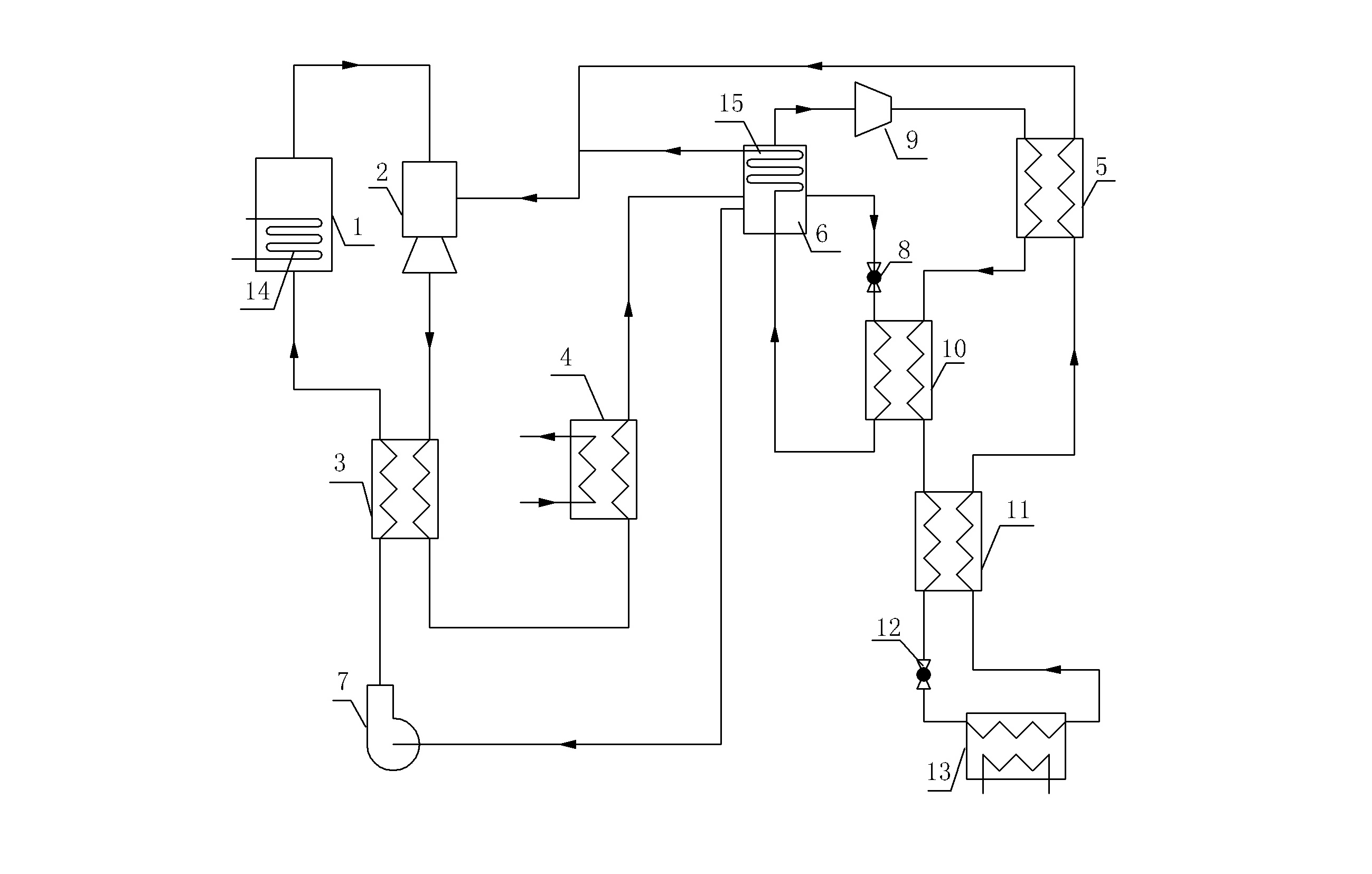

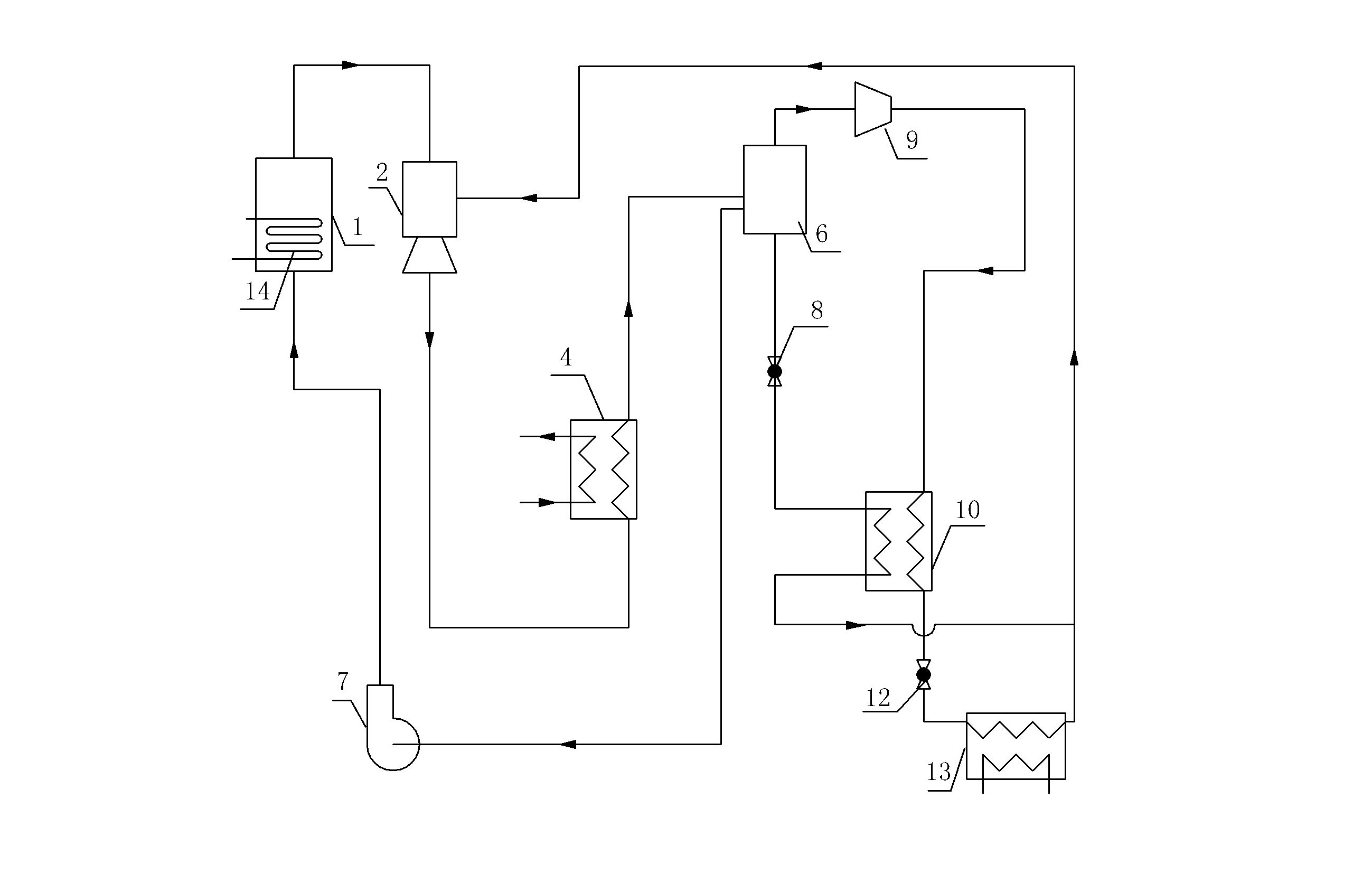

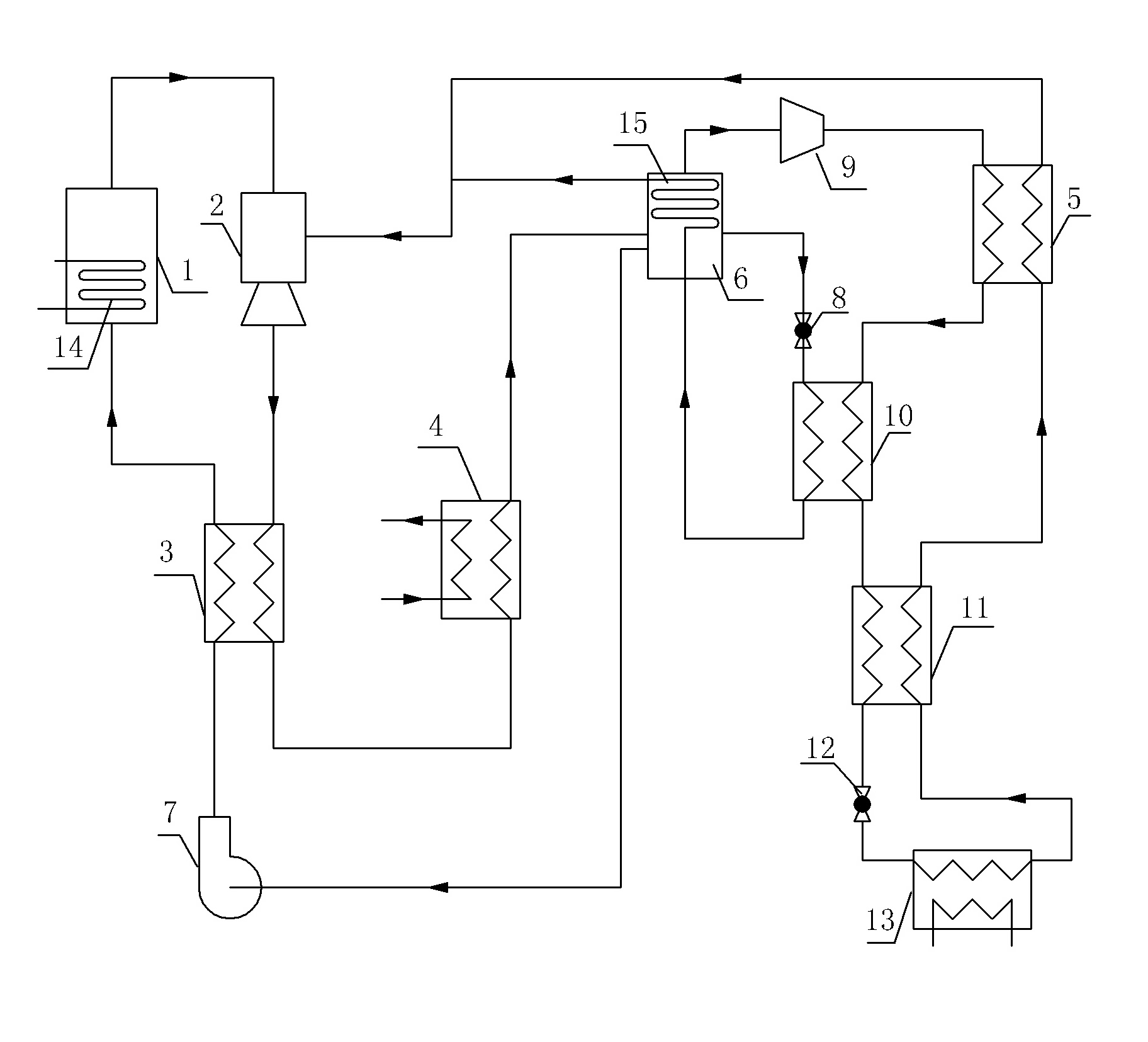

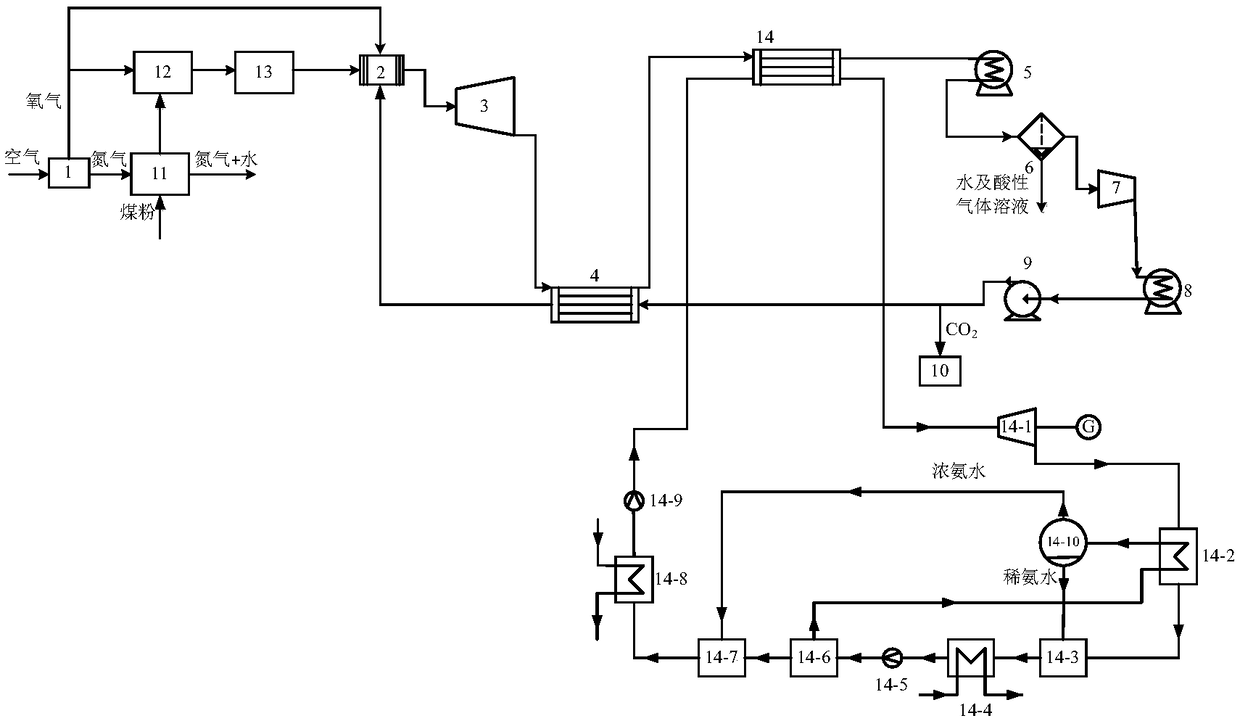

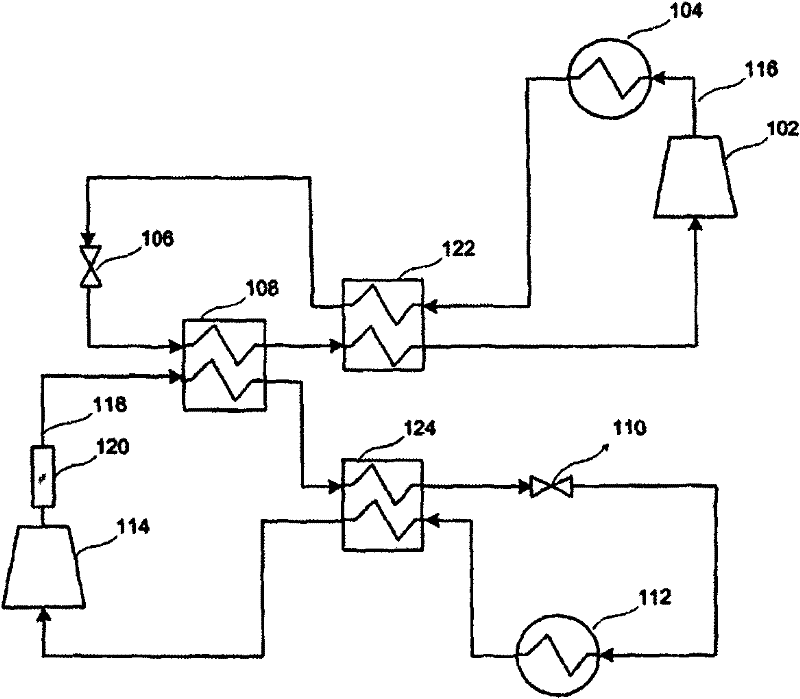

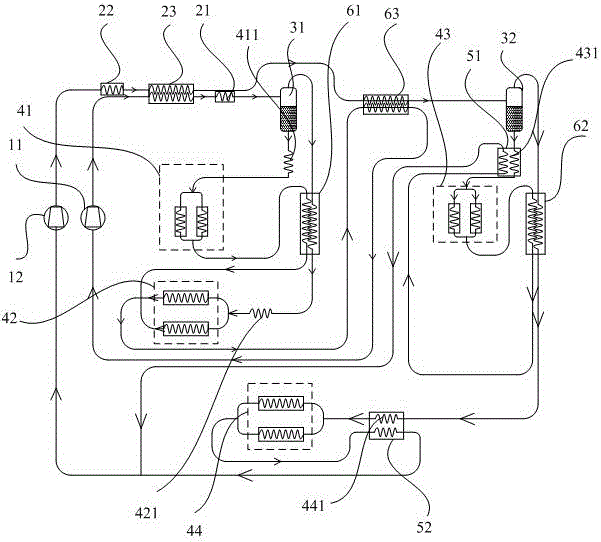

Air conditioner and sea water desalination combined operation system

InactiveCN101344298AImprove efficiencySimple pretreatment processGeneral water supply conservationSeawater treatmentLithium bromideSeawater

The invention relates to an air-conditioning and seawater desalination joint operation system which comprises a lithium bromide solution circulating water yielding system and a sea water evaporation and air processing system. The lithium bromide solution circulating water yielding system comprises: a generation condenser, a heat exchanger, an absorption evaporator, a circulating pump and a regulating valve group; wherein, the generation condenser comprises a generator and a condenser, and a water retaining device is connected between the generator and the condenser. The sea water evaporation and air processing system comprises: the absorption evaporator, a sea water spray chamber, a pre-heater, a regulating valve, a throttle valve and a valve group; wherein, the absorption evaporator comprises an absorber and an evaporator, and the water retaining device is connected between the absorber and the evaporator. The air-conditioning and seawater desalination joint operation system of the invention has the functions of air-conditioning and sea water desalination, simplifies the two separate separation systems of the prior air-conditioning system and the sea water desalination circulating system and effectively saves the energy.

Owner:SHANGHAI MARITIME UNIVERSITY

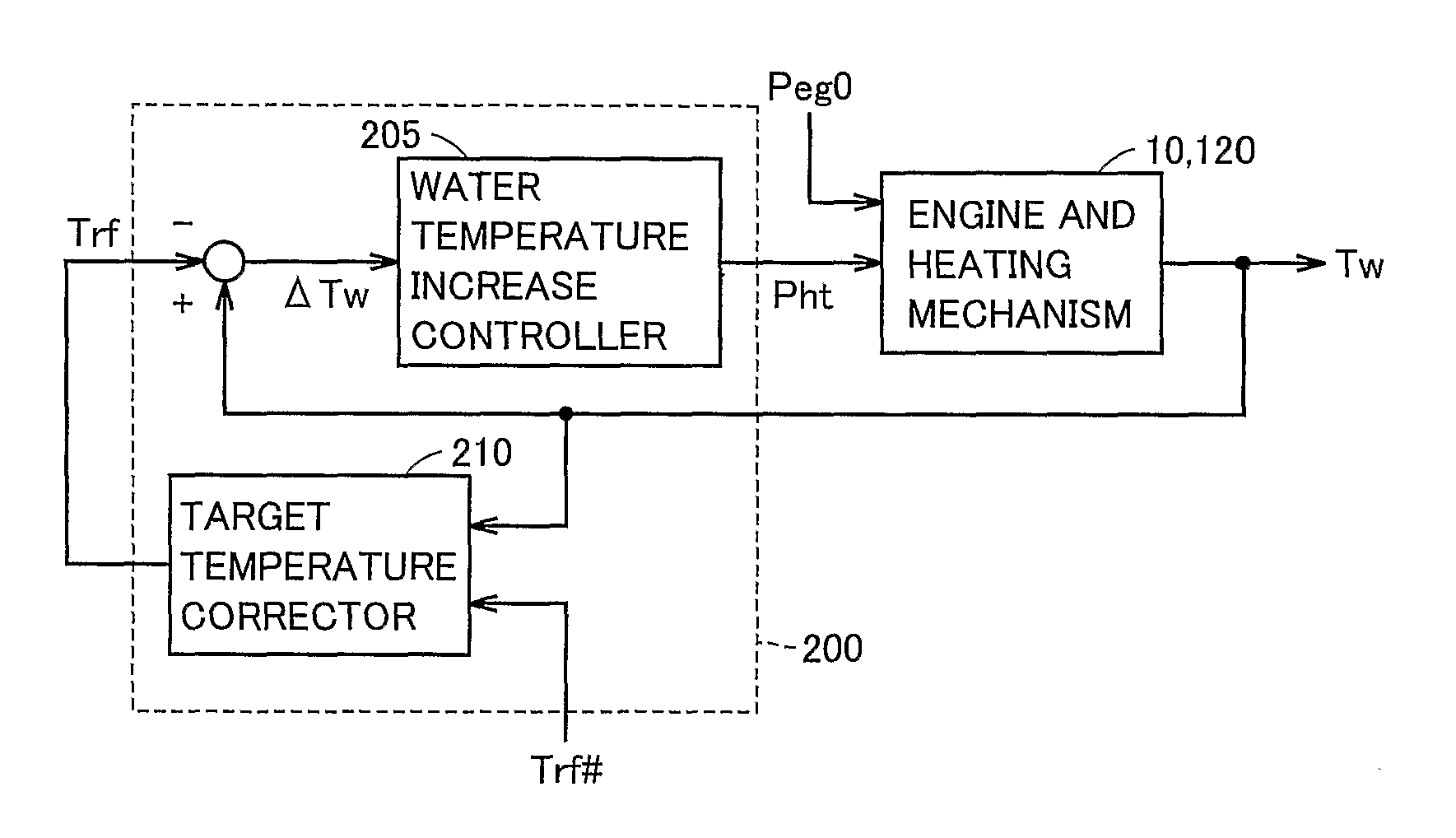

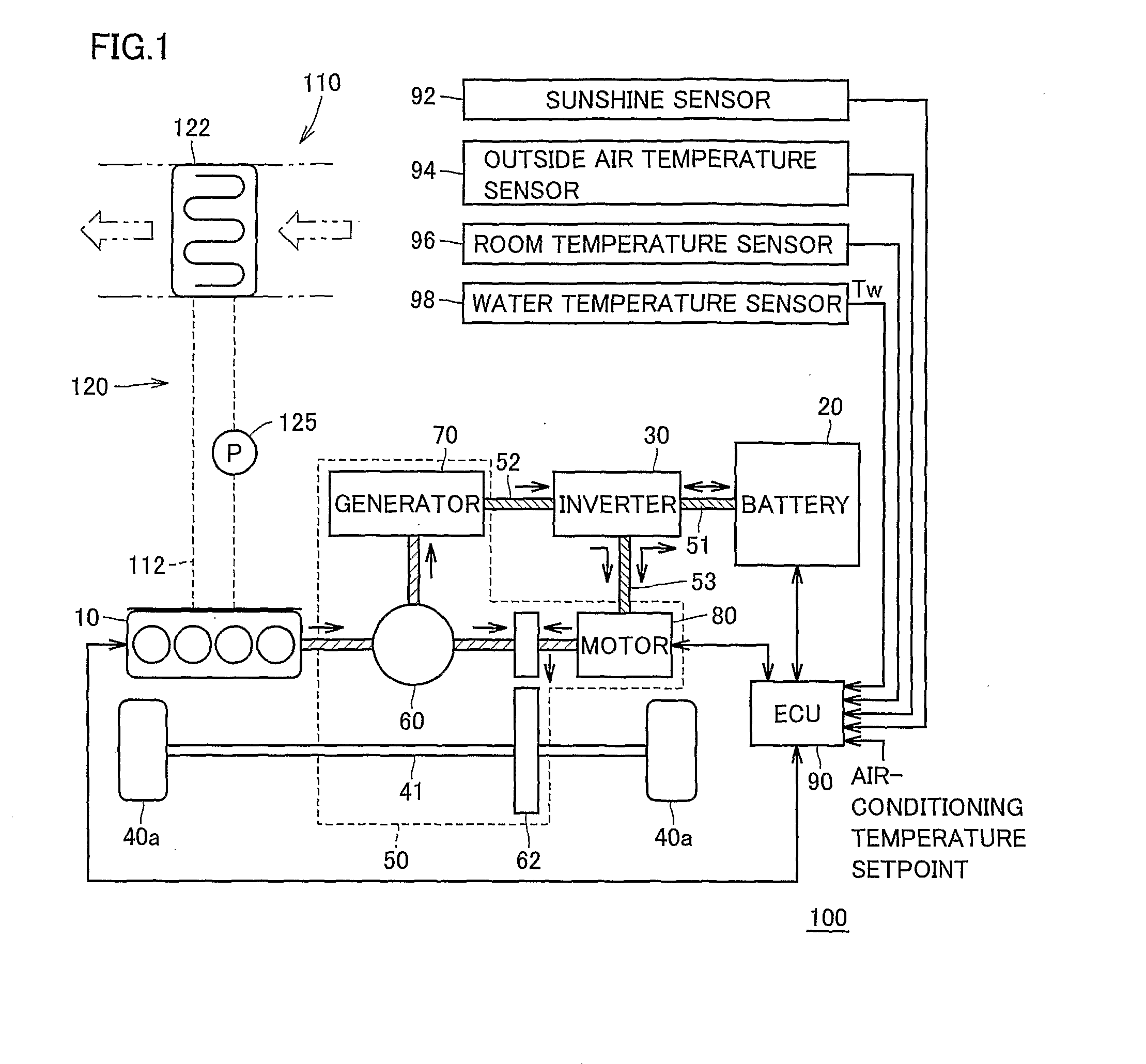

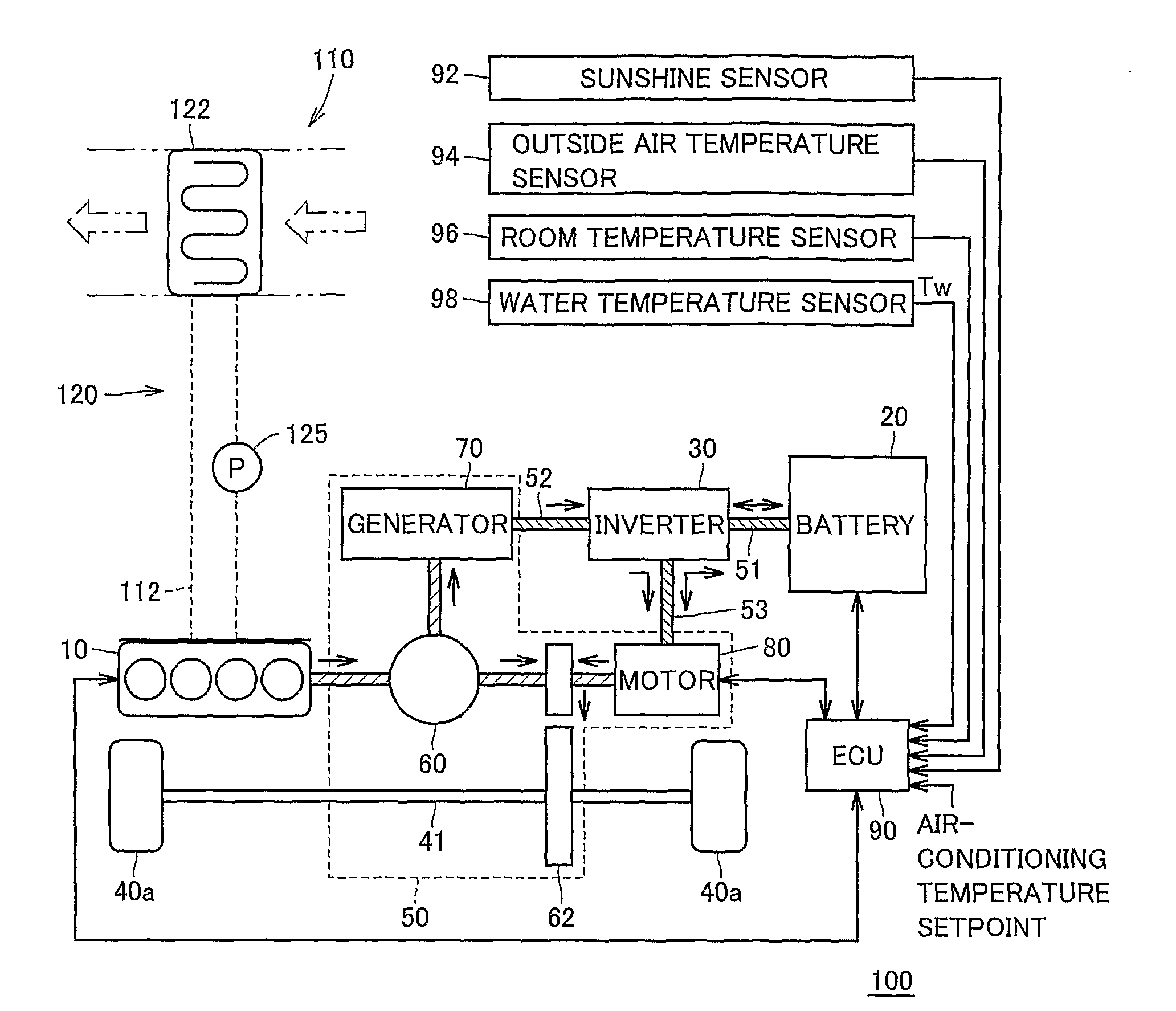

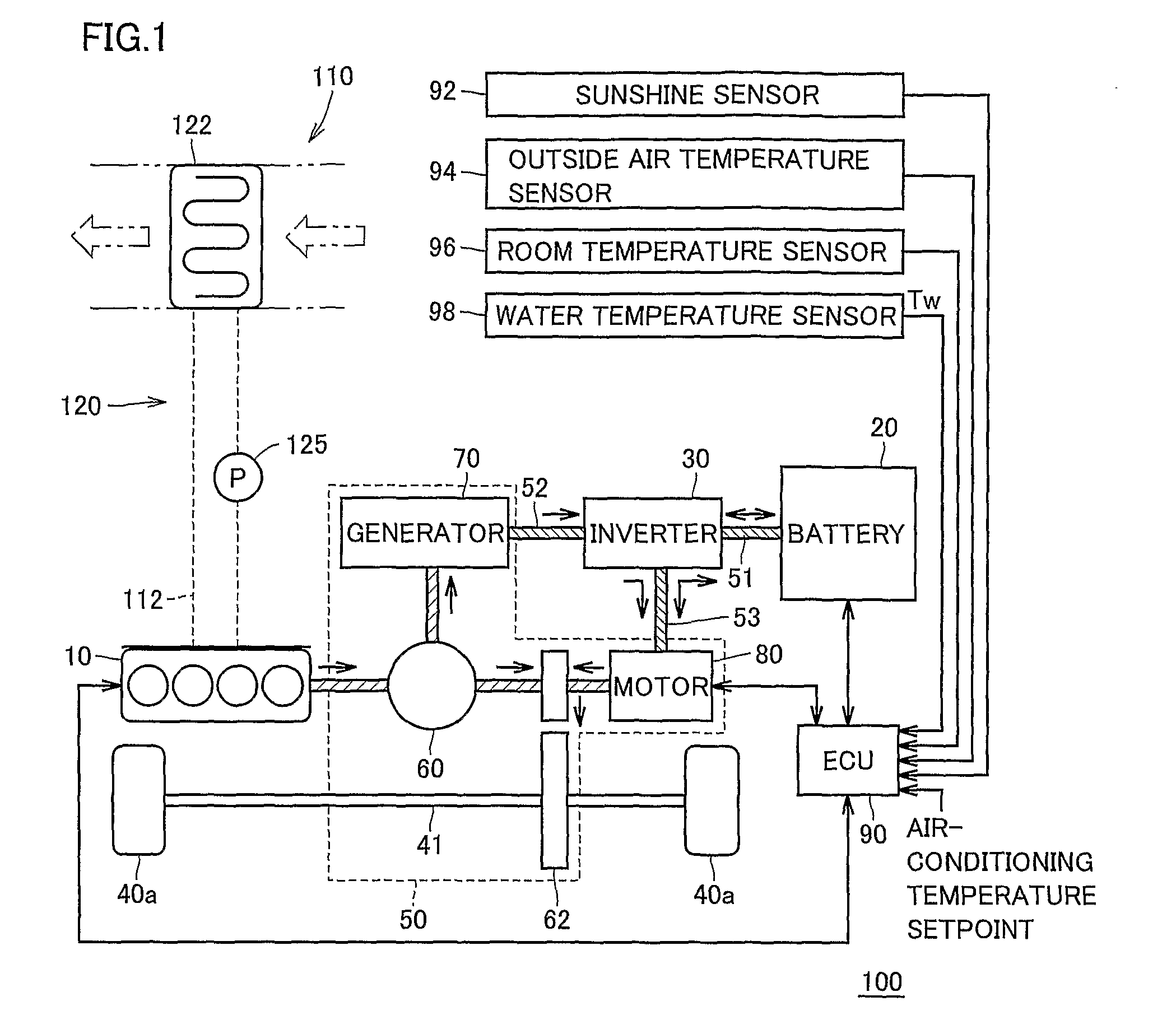

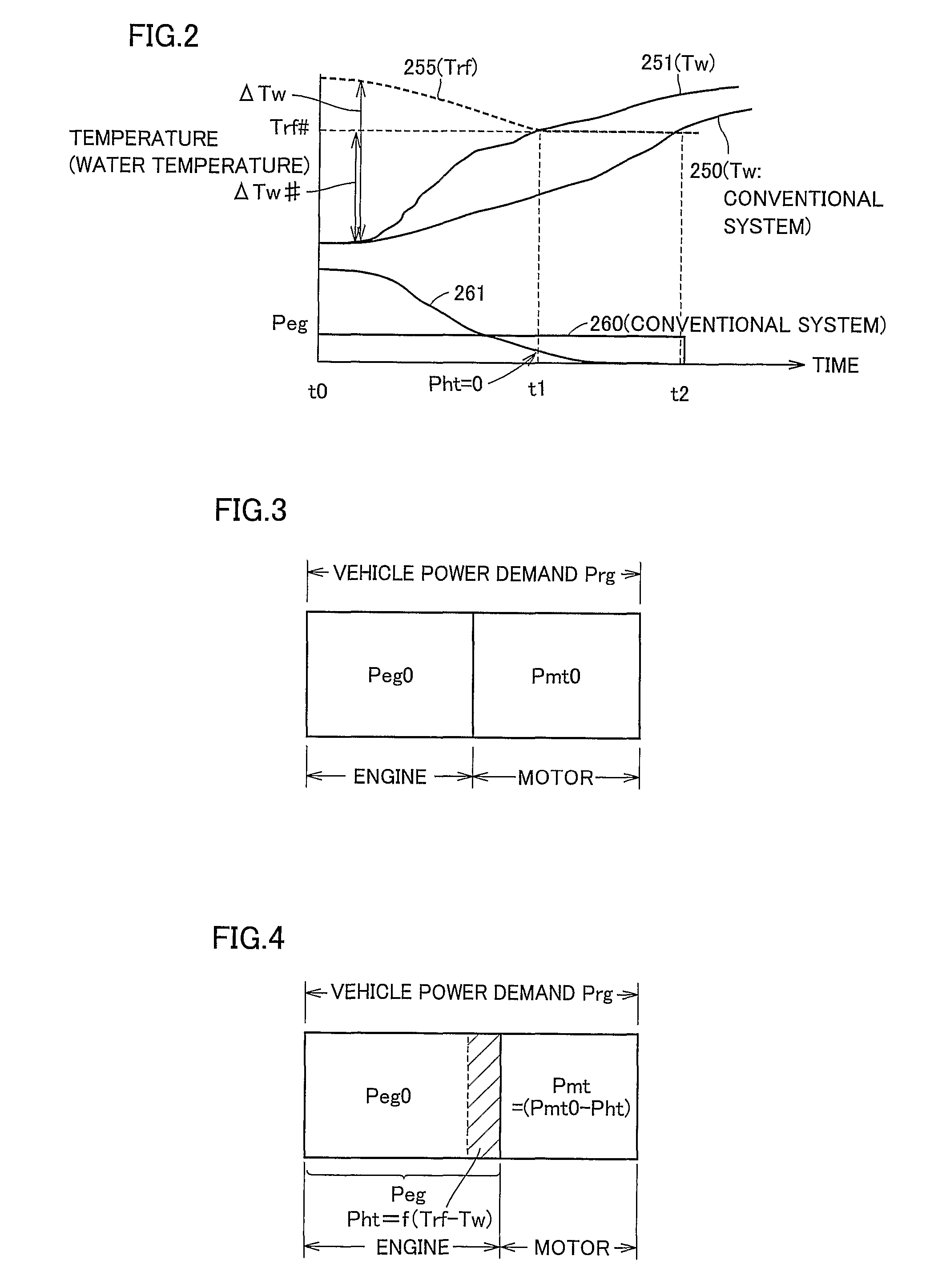

Heating Control System for Vehicle

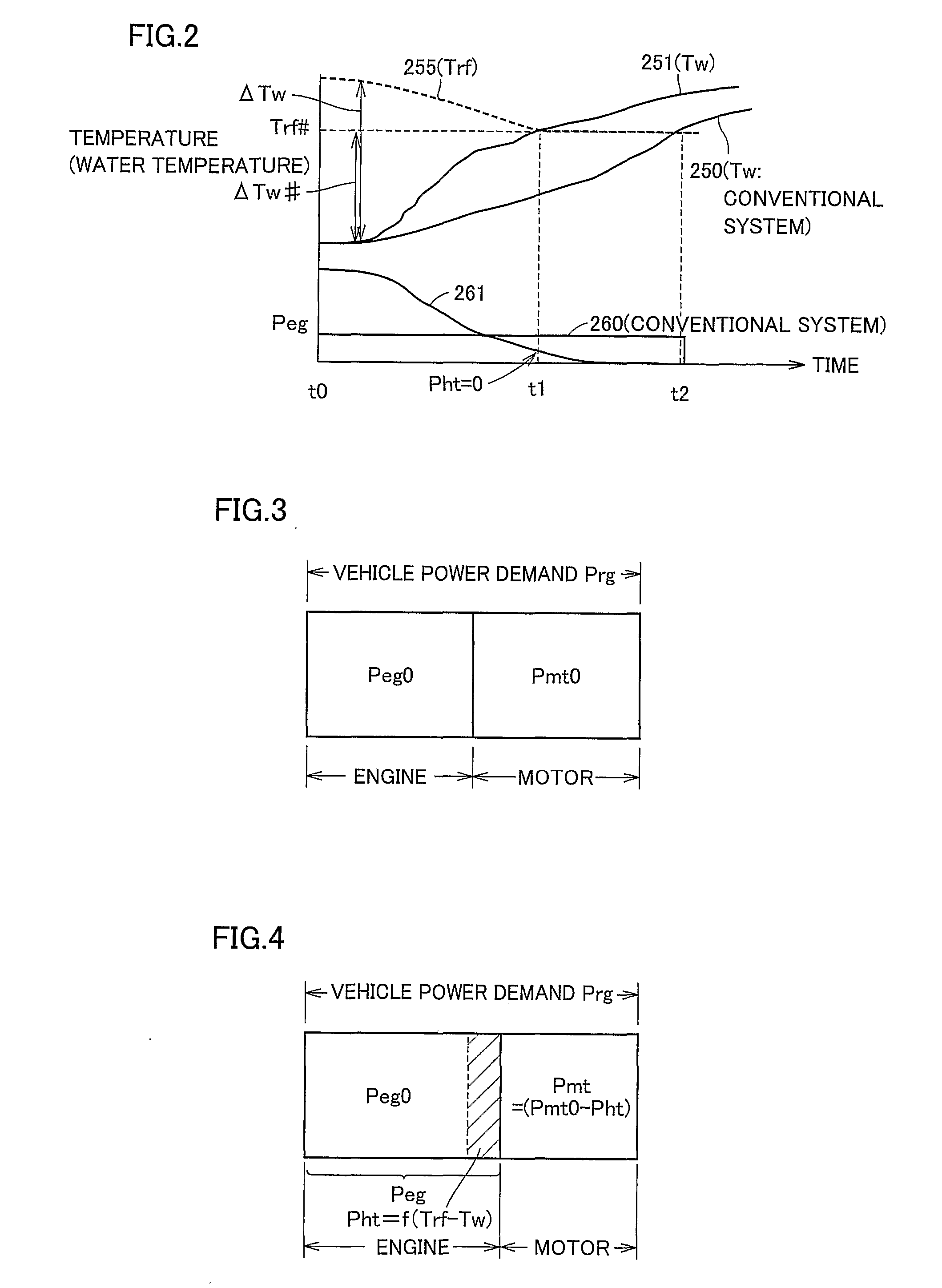

InactiveUS20070246554A1Enhance fuel economyIncrease cooling temperatureHybrid vehiclesPlural diverse prime-mover propulsion mountingAutomotive engineeringCooling water temperature

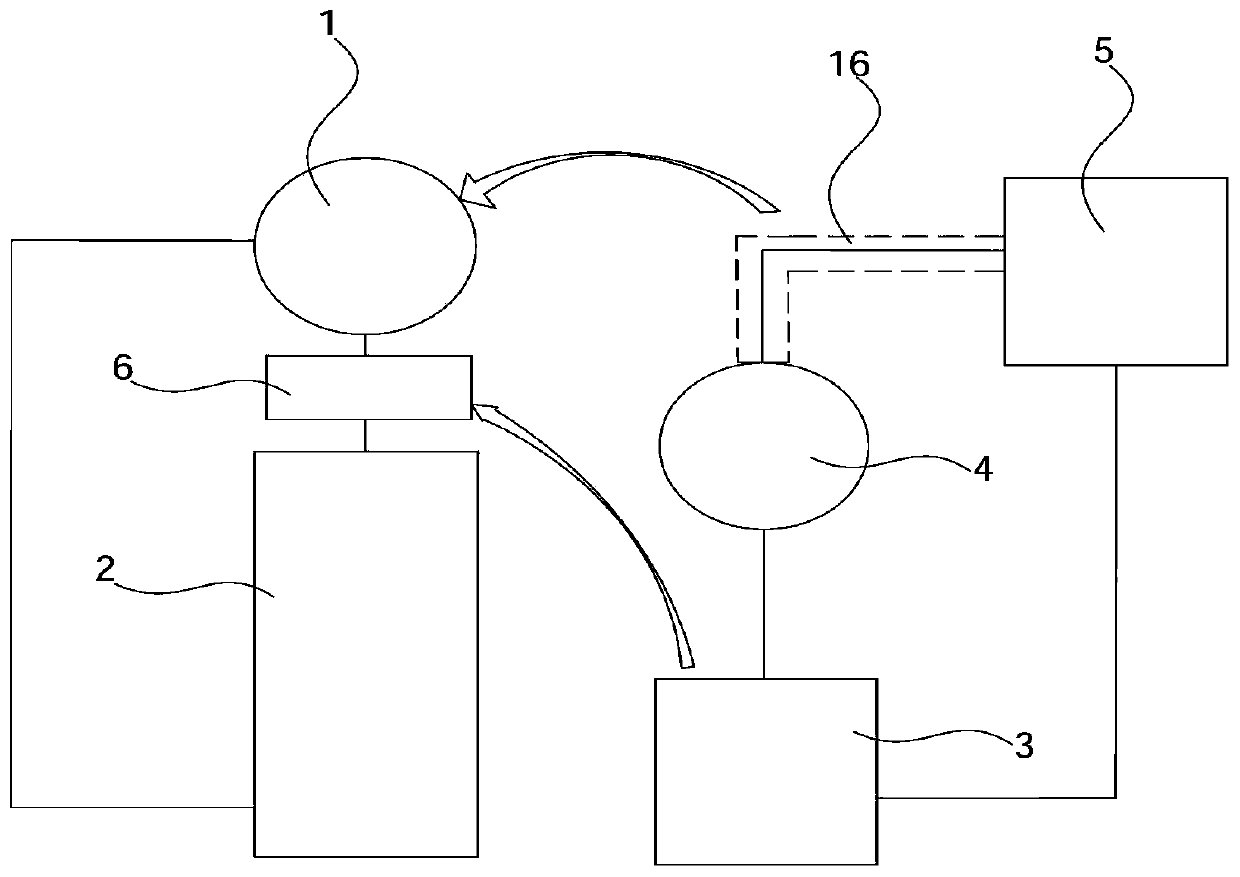

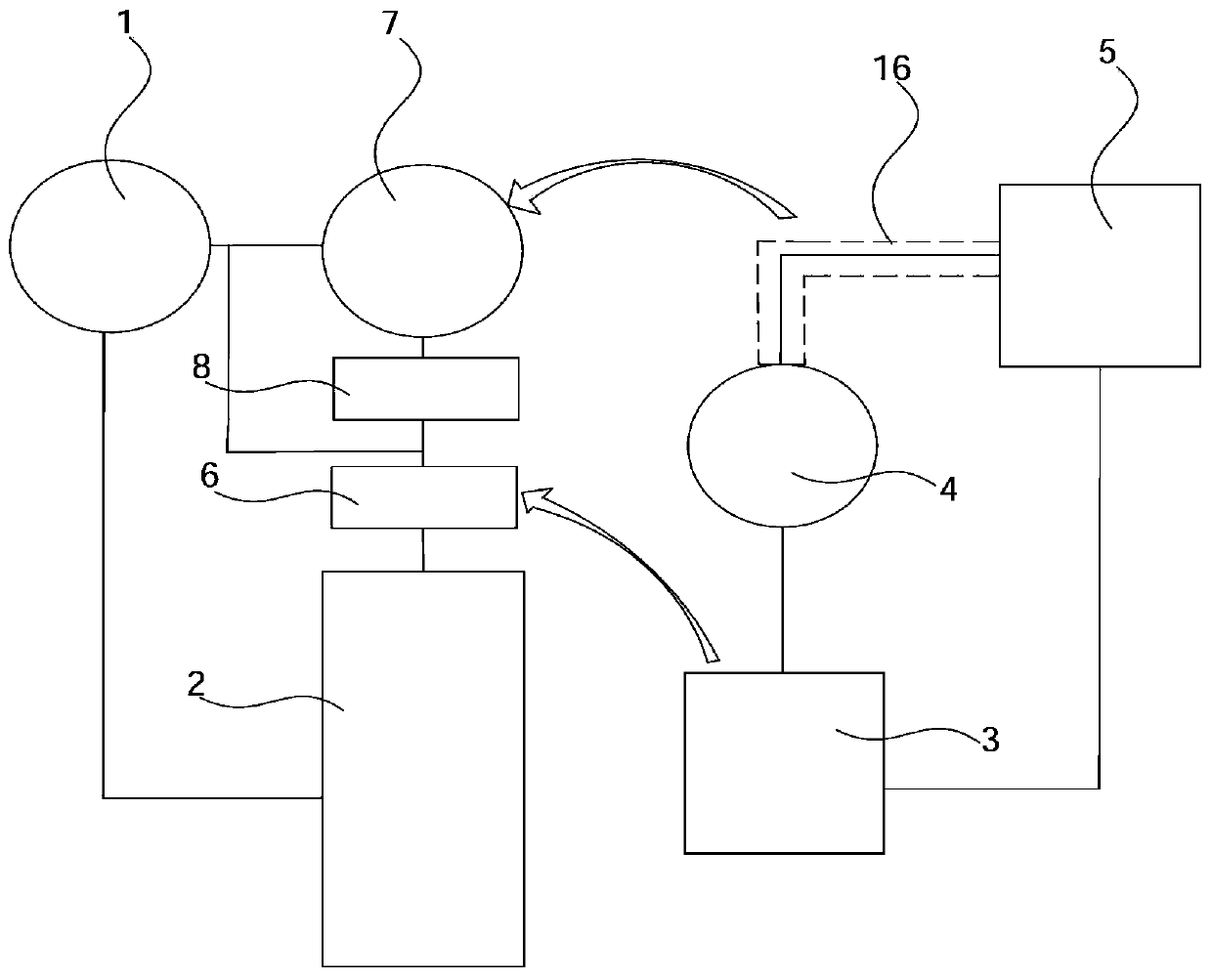

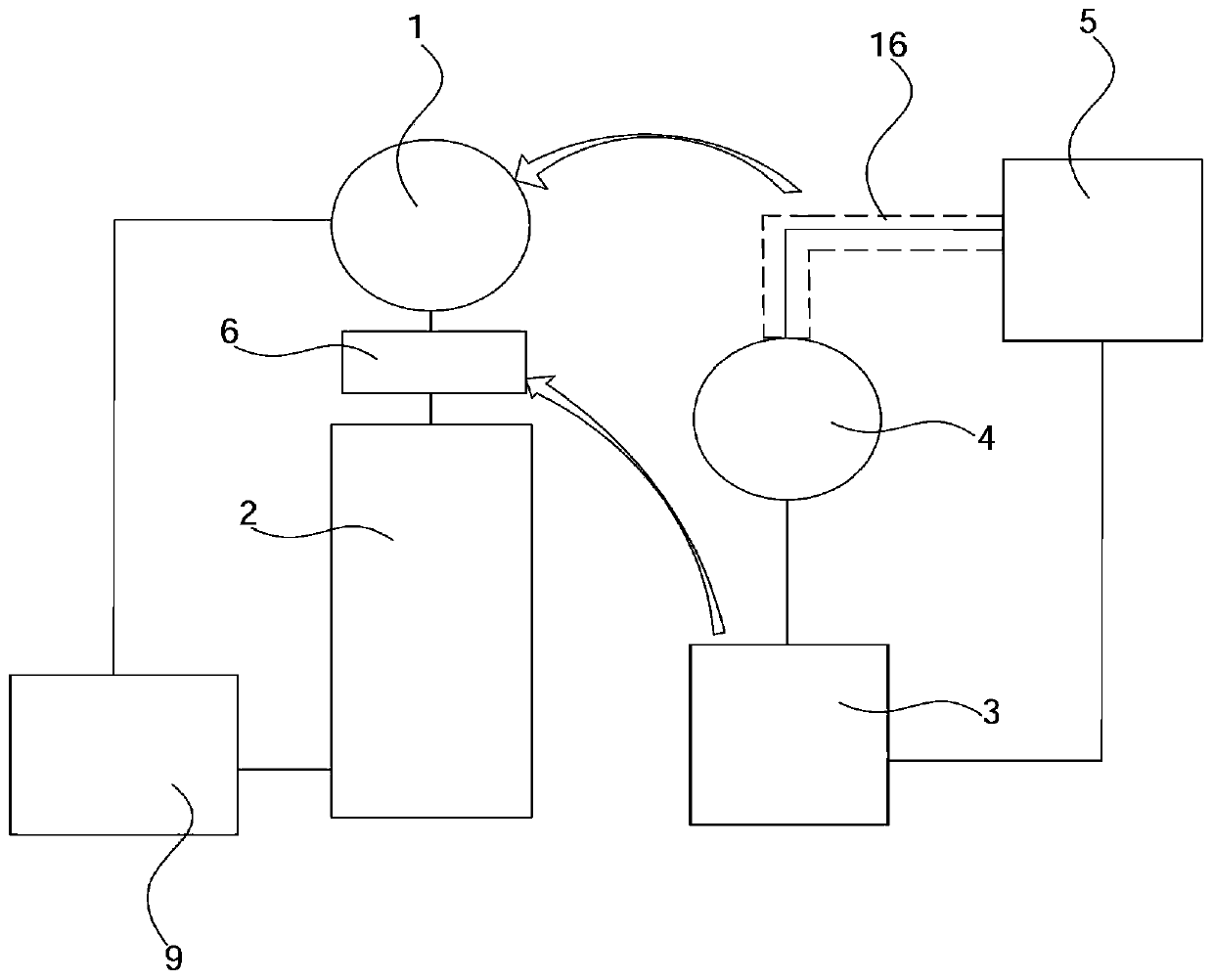

A hybrid vehicle (100) can be driven using both of respective driving forces from an engine (10) and a motor (80). A heating mechanism (120) of an air conditioning apparatus (110) uses thermal energy from cooling water of the engine (10) to heat the interior of a passenger compartment. An ECU (90) takes into consideration engine efficiency from the standpoint of fuel economy enhancement to primarily determine the driving force share ratio between the engine (10) and the motor (80). Further, the ECU (90) calculates a preset temperature corresponding to a cooling water temperature necessary for desired heating as well as a control target temperature in which the preset temperature is reflected, and corrects the primarily determined driving force share ratio to increase the share of the driving force of the engine by an amount according to a deviation between the cooling water temperature (Tw) measured by a water temperature sensor (98) and the control target temperature. Heating performance can thus be ensured promptly without deterioration of fuel economy.

Owner:TOYOTA JIDOSHA KK

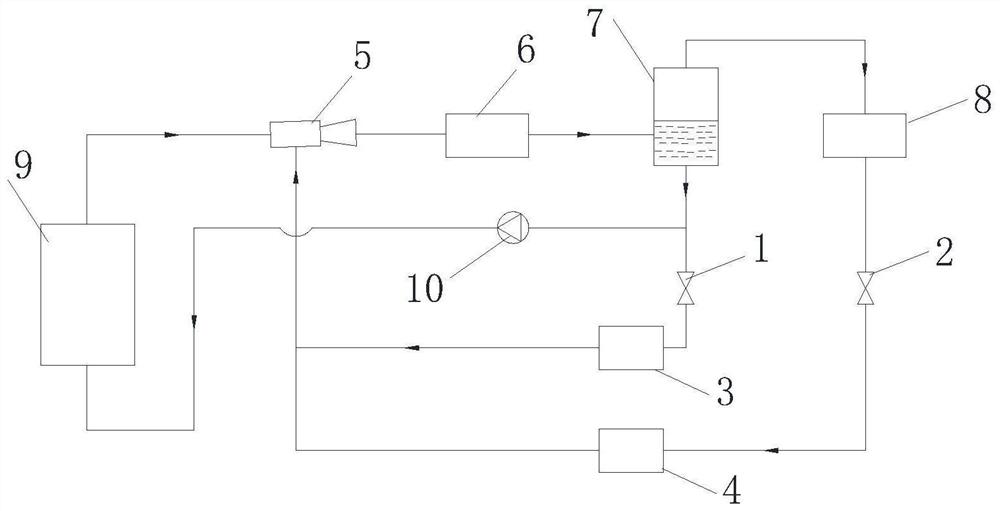

Low-grade heat energy auxiliary-drive composite low-temperature refrigerating system

InactiveCN101949611AImprove energy savingIncrease inspiratory pressureRefrigeration machinesThermal energyVapor–liquid separator

The invention discloses a low-grade heat energy auxiliary-drive composite low-temperature refrigerating system. The system comprises a generator, an ejector, a working medium pump, a condenser, a gas-liquid separator, a compressor, a first throttling component, a condensation evaporator, a second throttling component, an evaporator and a heater. A high-boiling-point component is condensed into liquid to serve as a low-boiling-point component cooling medium through the ejector driven by the low-grade heat energy; and the ejector has another function of increasing suction pressure of the low-boiling-point component at a suction port of the compressor to reduce the compression ratio of the compressor so as to realize lower refrigerating temperature. Because the compression process of the high-boiling-point component during circulation is finished by the ejector, the power consumption of the compressor is reduced; and the ejector also improves the suction pressure of the low-boiling-point component at the suction port of the compressor and is also favorable for further reducing the power consumption of the compressor. The system has the advantages of realizing high-efficiency utilization of a low-grade energy source, along with stable running, obvious energy saving effect and broad application prospect.

Owner:HENAN UNIV OF SCI & TECH

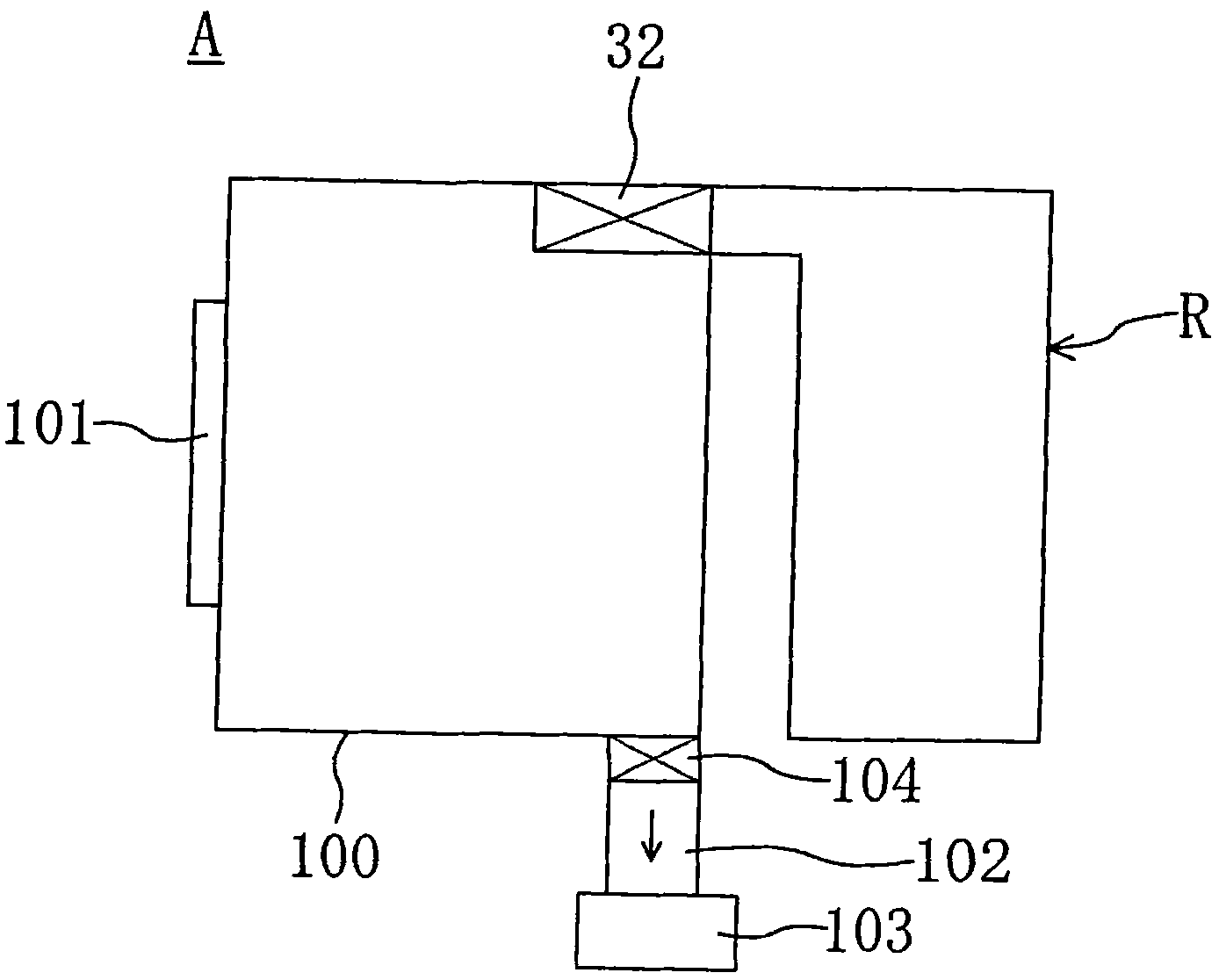

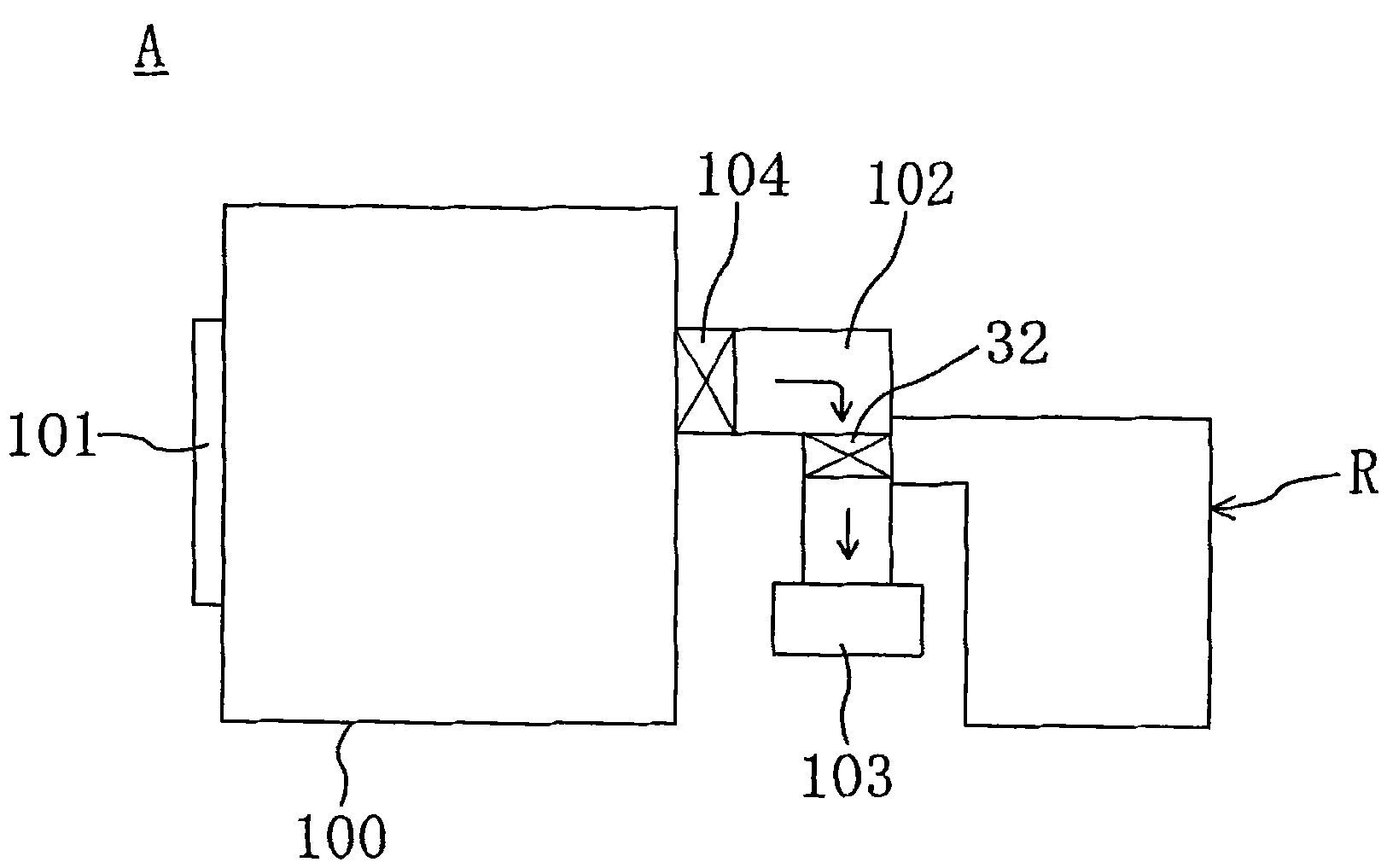

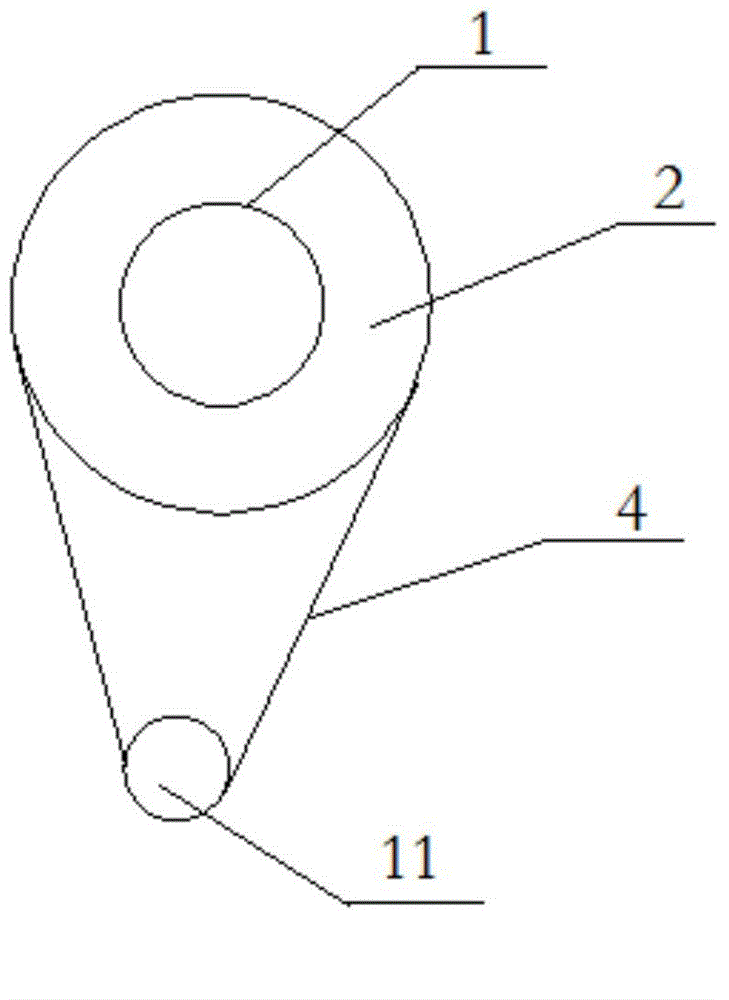

Structure of hybrid vehicle

InactiveUS7823672B2Suppresses reduction efficiencyReduction efficiency can be preventedExhaust apparatusMachines/enginesElectrical batteryHybrid vehicle

A structure of a hybrid vehicle includes a battery pack arranged on a floor panel and an exhaust pipe extending from an engine, passing below the floor panel, to an exhaust port. The battery pack has a secondary battery constituted by a plurality of battery cells stacked in a vehicle traveling direction for supplying electric power to a motor, and an intake chamber provided adjacent to the secondary battery in a substantially horizontal direction perpendicular to the direction along which the plurality of battery cells are stacked for supplying cooling air between each of the plurality of battery cells. The exhaust pipe is provided so that it passes immediately below the battery pack and passes a position displaced from a position immediately below the intake chamber. With such a configuration, a structure of a hybrid vehicle that suppresses reduction in the efficiency of cooling a secondary battery without placing a great limit on routing of an exhaust pipe is provided.

Owner:TOYOTA JIDOSHA KK

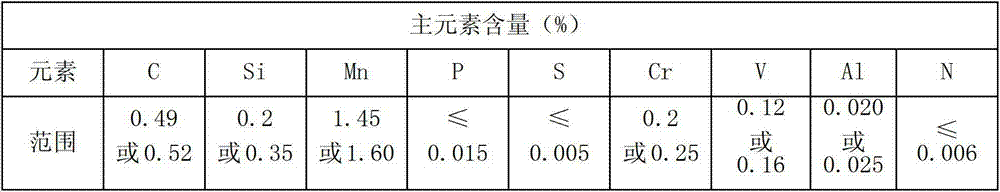

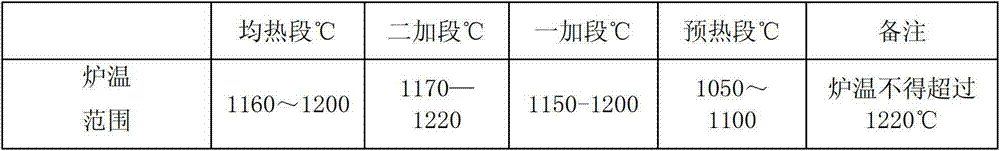

Production method of high-strength saw bit steel coil

ActiveCN103173685AGuaranteed stabilityImproved shape controlTemperature control deviceHeat treatment process controlHardnessSlow cooling

The invention provides a production method of a high-strength saw bit steel coil. The production method is suitable for a rolled steel coil of saw bit or saw blade steel with the thickness of 3.0-14.0mm. The component design comprises 0.49-0.52 of C, 0.2-0.35 of Si, 1.45-1.60 of Mn, less than or equal to 0.015 of P, less than or equal to 0.005 of S, 0.2-0.25 of Cr, 0.12-0.16 of V, 0.020-0.025 of Al and less than or equal to 0.006 of N by weight percent. The production process adopts a converter smelting-LF (ladle furnace) refining-hot continuous rolling process and comprises slab continuous casting and segregation control in saw bit steel production, control of the slab continuous offline slow cooling temperature of the saw bit steel and the control of the roll rolling start temperature, the rolling finished temperature and the coiling temperature. The horizontal yield of the saw bit steel coil is MPa600-750, the horizontal tensile strength is MPa930-1040, the elongation is 19.5-26%, and the hardness of HRC is 20-28.

Owner:XINJIANG BAYI IRON & STEEL

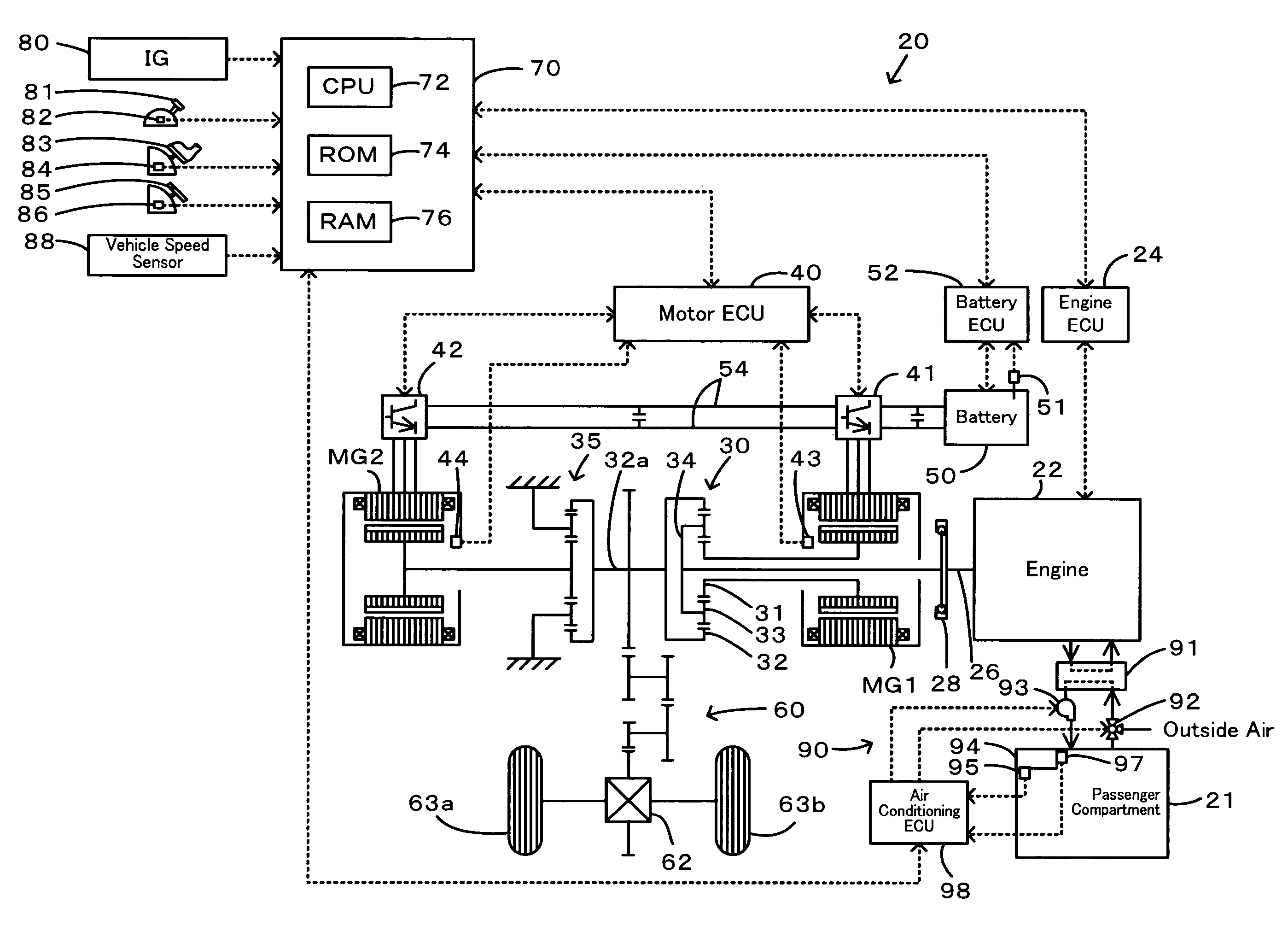

Motor vehicle and control method of internal combustion engine

InactiveUS7430469B2Increase cooling temperatureDeterioration in fuel economyHybrid vehiclesAnalogue computers for vehiclesExternal combustion engineOperation mode

In a motor vehicle, when an intake air temperature Ta is not lower than a preset reference temperature Tref, warm-up drive control selectively uses an evaporated fuel processing acceleration operation curve, which gives a high level of a negative pressure in an intake manifold, to set a target drive point of an engine and controls the operation of the engine. This ensures good emission of the engine. When the intake air temperature Ta is lower than the preset reference temperature Tref and when the setting of a heating demand Hq requires heating, on the other hand, the warm-up drive control increases an EGR quantity from an ordinary level and switches over an operation mode of a cooling system for the engine to a warm-up circulation mode for making the flow of a cooling medium bypass a radiator.

Owner:TOYOTA JIDOSHA KK

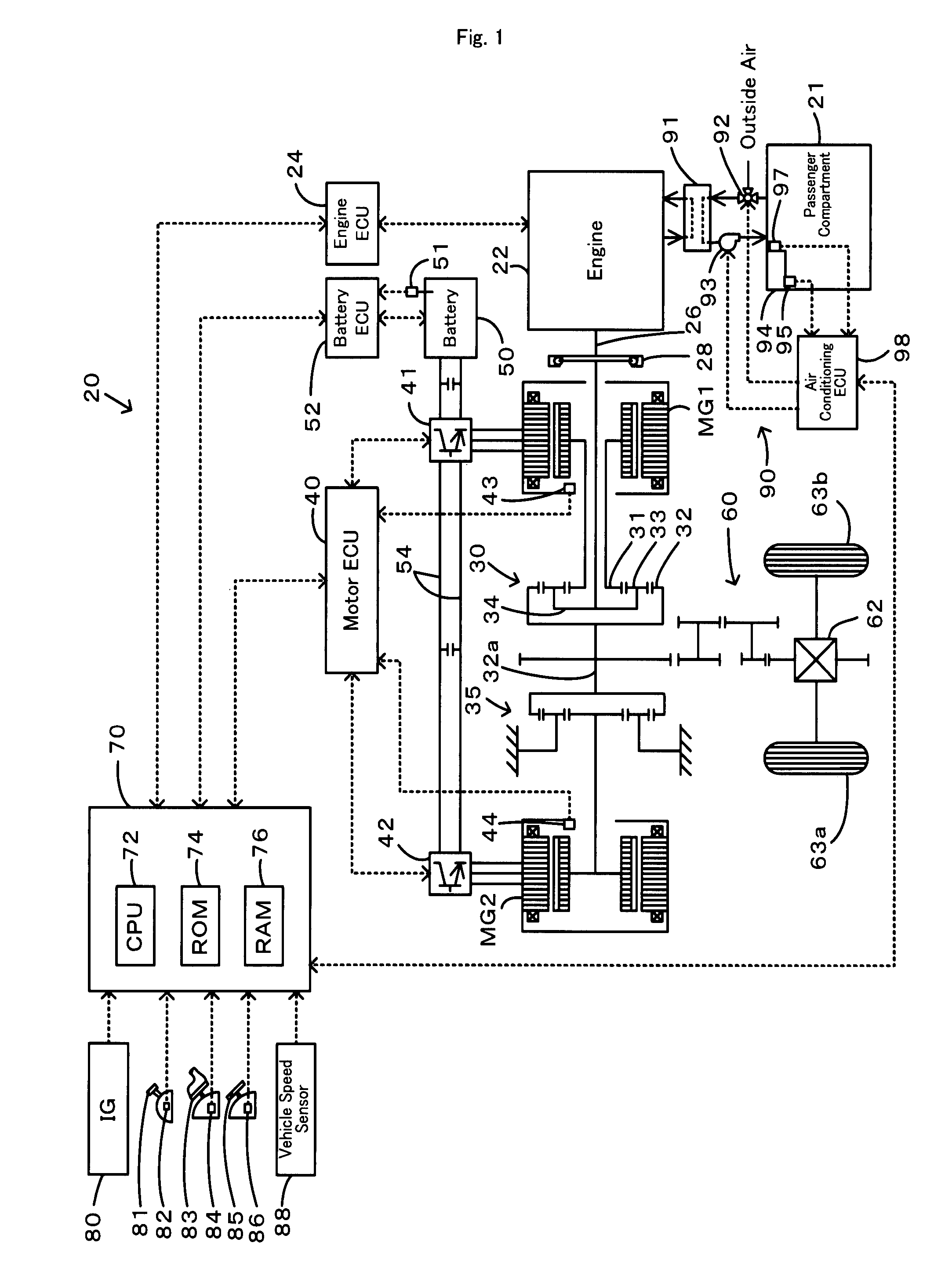

Heating control system for vehicle

InactiveUS8052066B2Increase cooling temperatureImprove fuel economyHybrid vehiclesOther heat production devicesThermal energyEngine efficiency

A hybrid vehicle can be driven using both of respective driving forces from an engine and a motor. A heating mechanism of an air conditioning apparatus uses thermal energy from cooling water of the engine to heat the interior of a passenger compartment. An ECU takes into consideration engine efficiency from the standpoint of fuel economy enhancement to primarily determine the driving force share ratio between the engine and the motor. Further, the ECU calculates a preset temperature corresponding to a cooling water temperature necessary for desired heating as well as a control target temperature in which the preset temperature is reflected, and corrects the primarily determined driving force share ratio to increase the share of the driving force of the engine by an amount according to a deviation between the cooling water temperature measured by a water temperature sensor and the control target temperature. Heating performance can thus be ensured promptly without deterioration of fuel economy.

Owner:TOYOTA JIDOSHA KK

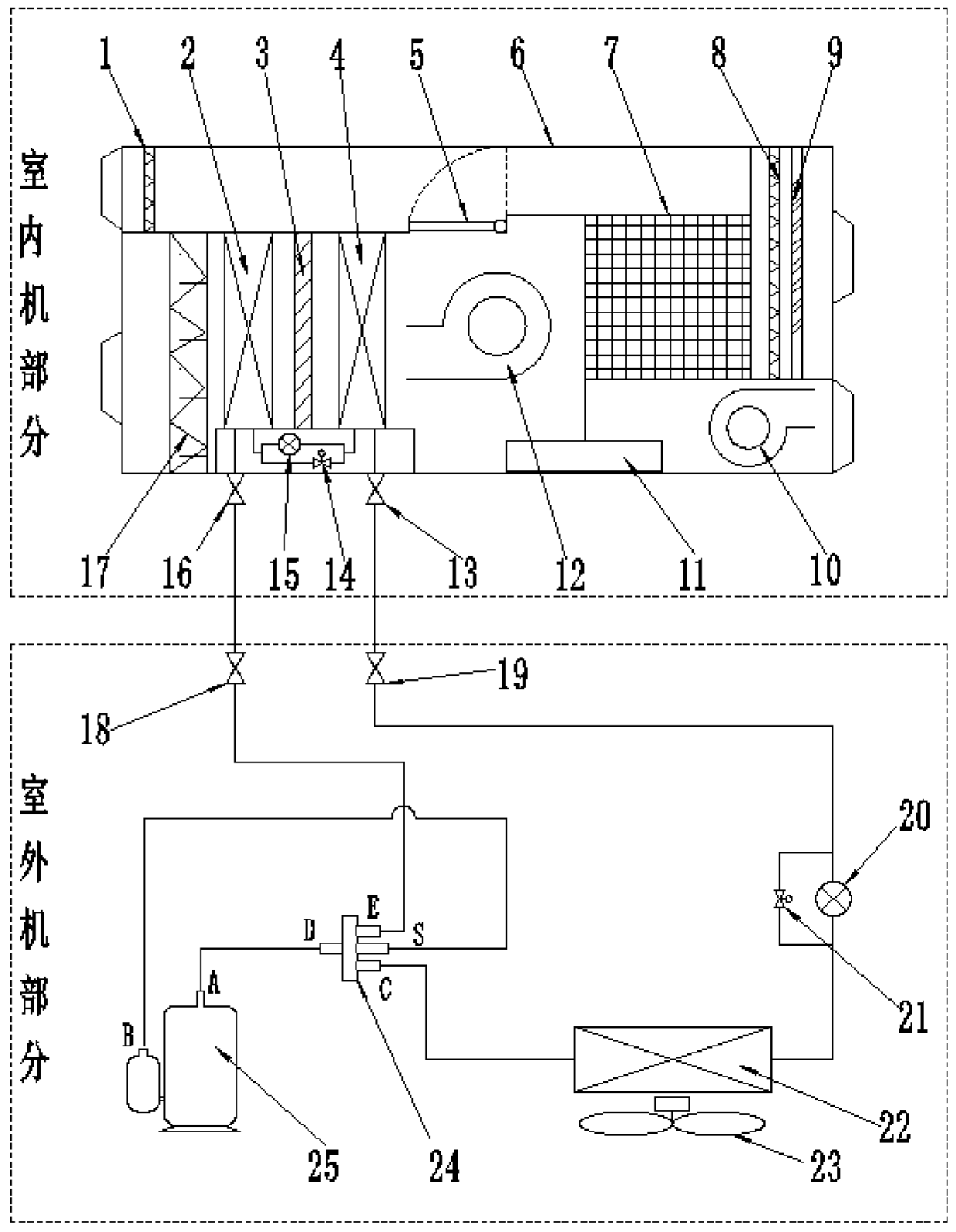

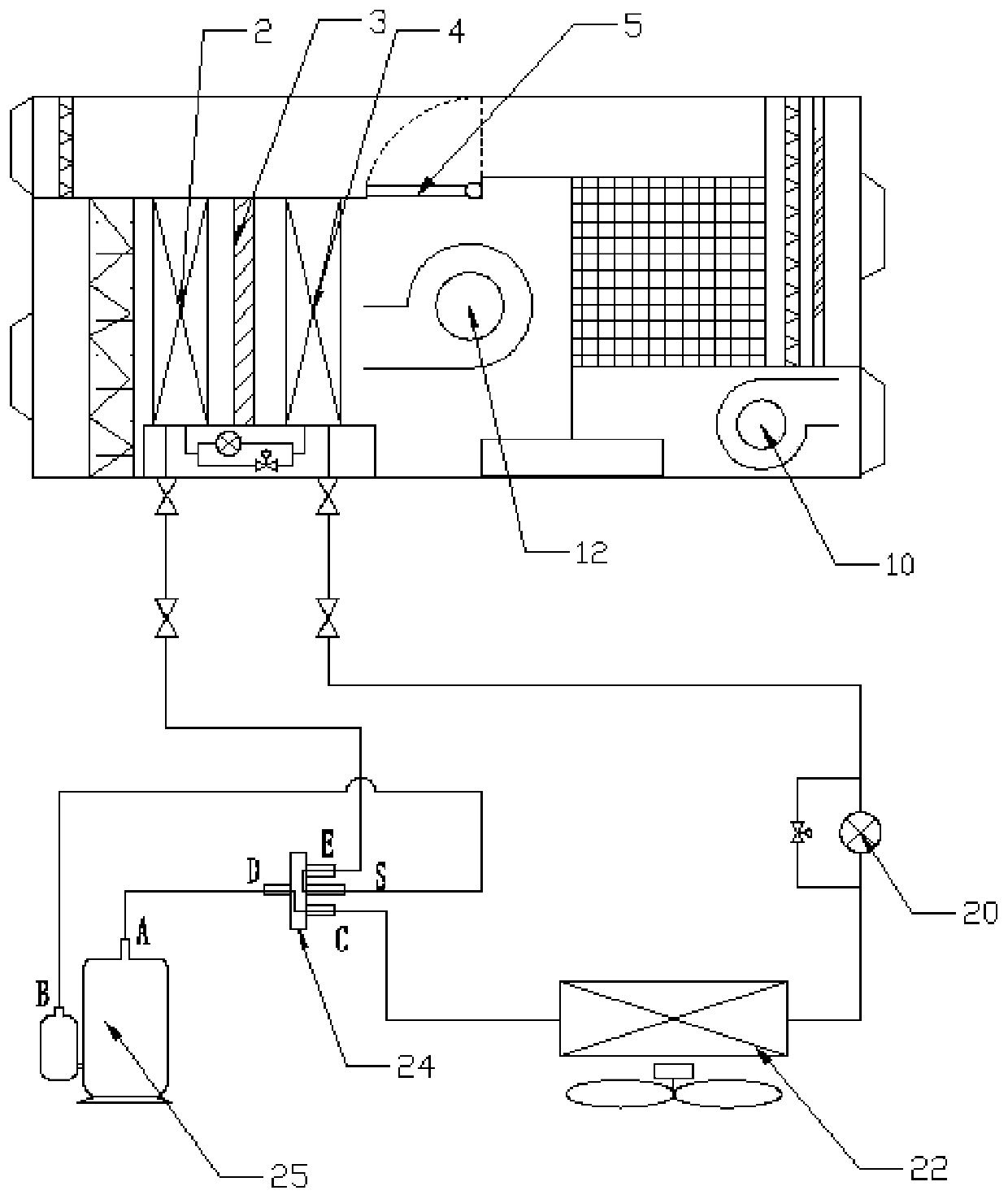

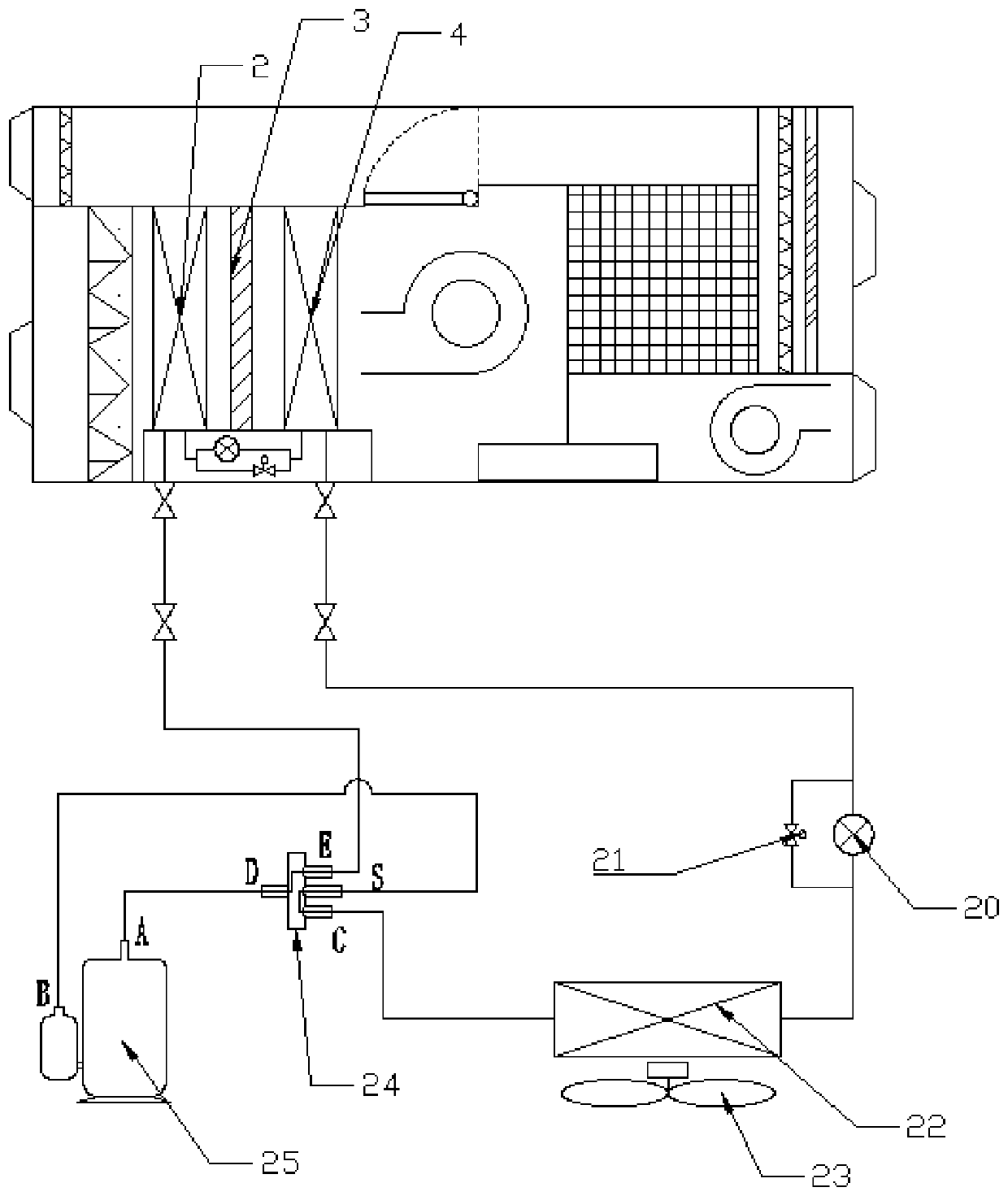

Air conditioner and control method thereof

ActiveCN110260432AImprove use comfort performanceIncrease temperatureMechanical apparatusLighting and heating apparatusFour-way valveEngineering

The invention discloses an air conditioner and a control method thereof, and relates to the technical field of air conditioners. The air conditioner comprises a first heat exchanger, a humidifying film part, a second heat exchanger, a compressor, a four-way valve, a third heat exchanger and a first throttling part, wherein the compressor, the four-way valve, the third heat exchanger, the first throttling part, the first heat exchanger and the second heat exchanger are connected in sequence to form a heat exchange loop; and the humidifying film part is arranged between the first heat exchanger and the second heat exchanger. By arranging modes of the two heat exchangers at an indoor unit side simultaneously, heating or refrigerating can be realized at the same time, so that the heating temperature or the refrigerating temperature of the air conditioner can be conveniently improved, and the comfort of the air conditioner in the heating or refrigerating process can be improved; and in addition, the humidifying film part is arranged between the first heat exchanger and the second heat exchanger, so that preheating, humidifying and heating are realized, the air outlet temperature is controlled while the humidifying amount is effectively improved, so that the using comfort of the air conditioner is improved.

Owner:GREE ELECTRIC APPLIANCES INC

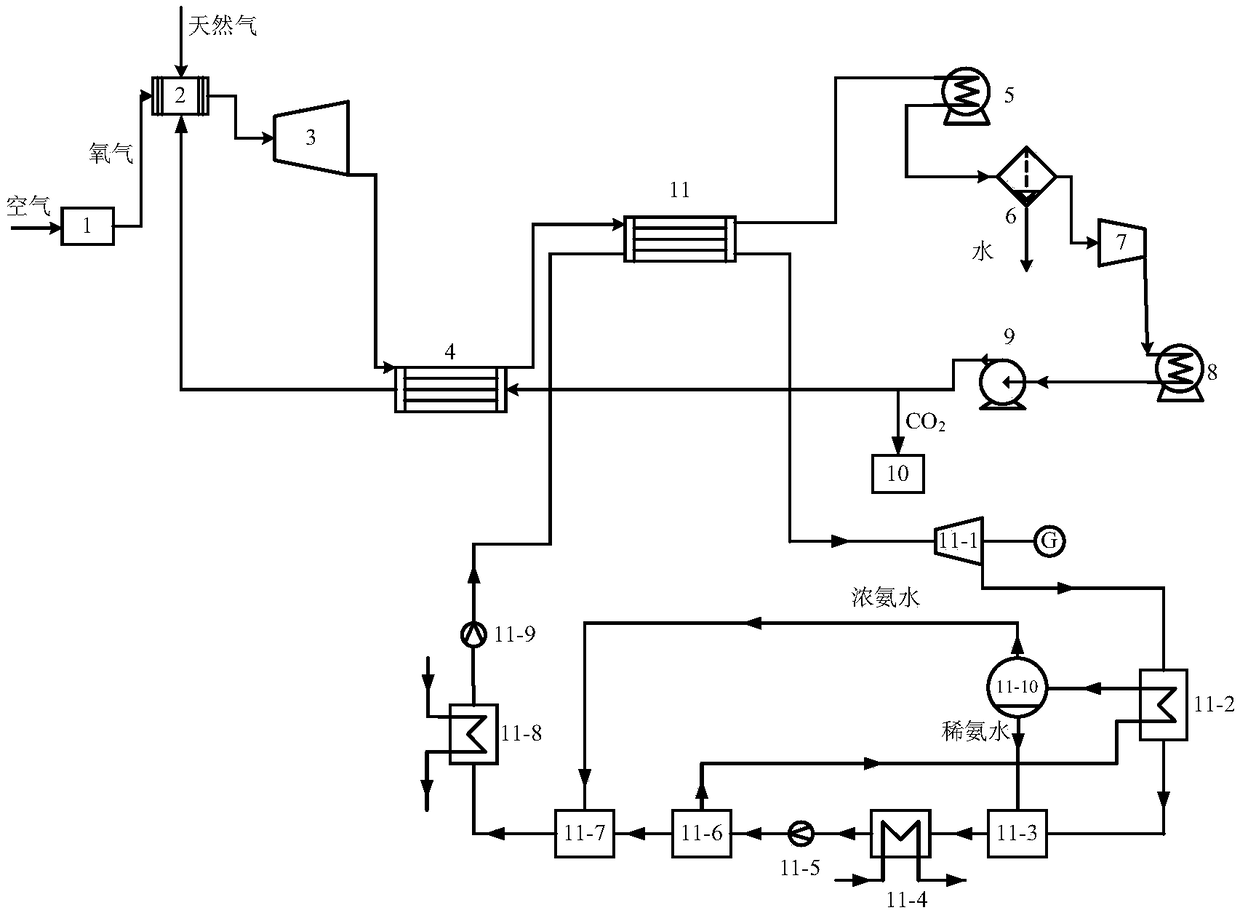

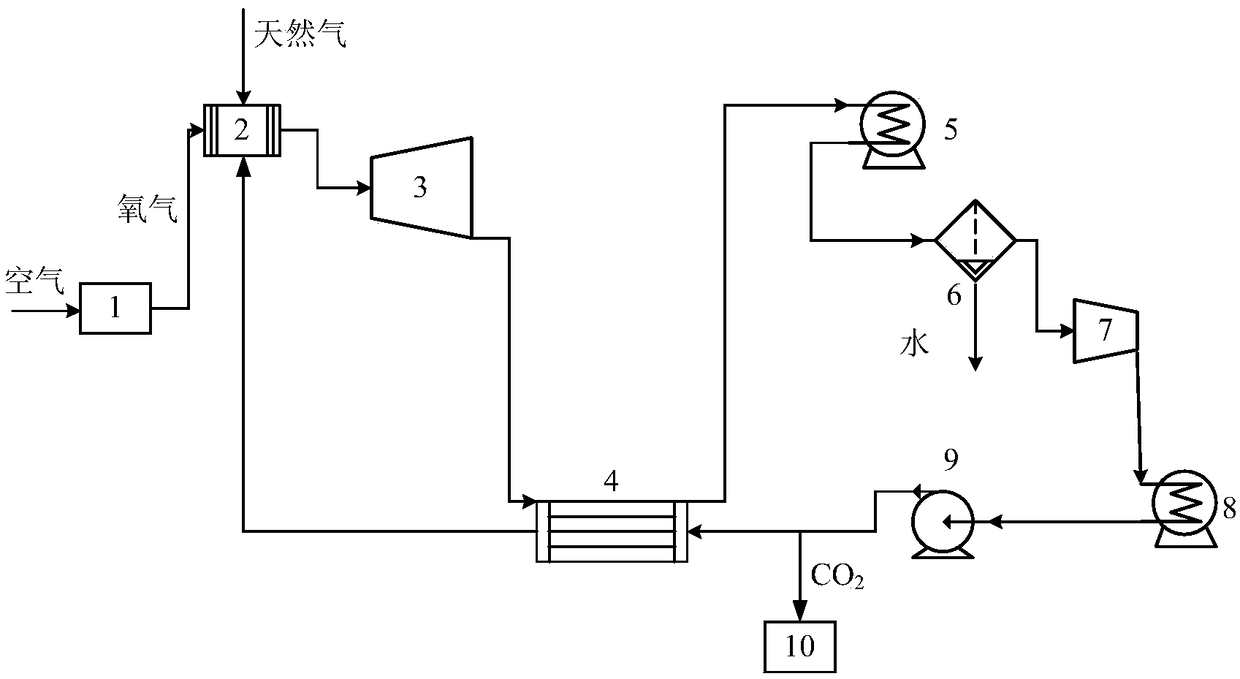

Supercritical carbon dioxide power generation system and method based on natural gas waste heat recovery

PendingCN109322743ARealize full captureThe actual compression work decreasesCarbon compoundsEnergy inputCyclic processExothermic process

The invention provides a supercritical carbon dioxide power generation system and method based on natural gas waste heat recovery. The supercritical carbon dioxide power generation system comprises anair separation device, a combustor, a carbon dioxide turbine, a heat regenerator, a water separator, a first carbon dioxide pressurization device, a carbon dioxide recovery device, a waste-heat-recovery heat exchanger, a Kalina turbine, a Kalina heat regenerator, a first mixer, an ammonia separator, a second mixer, a high-pressure condenser and a gas-liquid separator. According to the supercritical carbon dioxide power generation system, natural gas is taken as fuel, and the full capture of carbon dioxide is achieved by adopting an oxygen-enriched combustion method; in the carbon dioxide turbine, carbon dioxide expands to the subcritical state and achieves a higher expansion ratio than that the supercritical carbon dioxide Brayton cycle, so that the carbon dioxide turbine can do more workand the cycle efficiency can be improved; and during the bottom cycle, waste heat of the supercritical carbon dioxide cycle is recovered by adopting the Kalina cycle, and the concentration of a working medium changes in the working medium phase-change non-isothermal process and cycle process, so that the vaporization process and the heat-source heat release process can be matched well, the irreversible loss in the heat exchange process can be reduced, and the waste heat utilization efficiency can be improved.

Owner:HUANENG CLEAN ENERGY RES INST

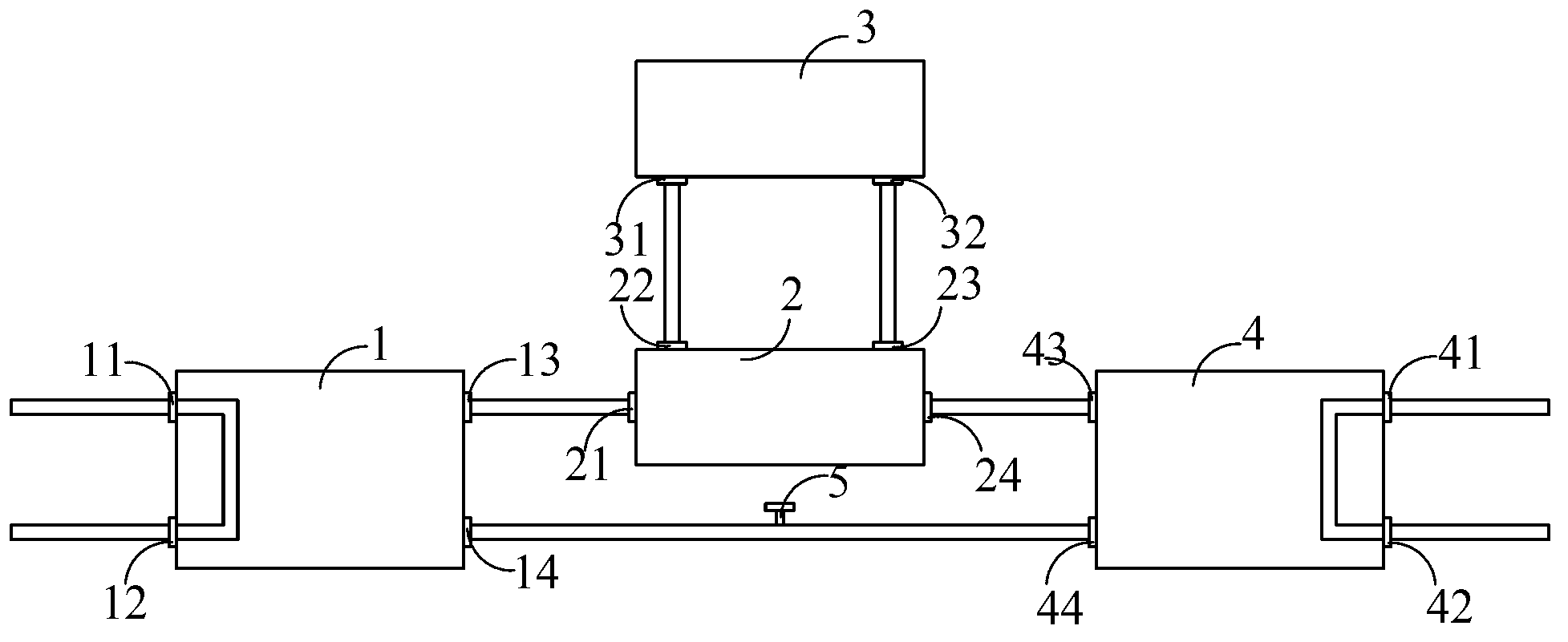

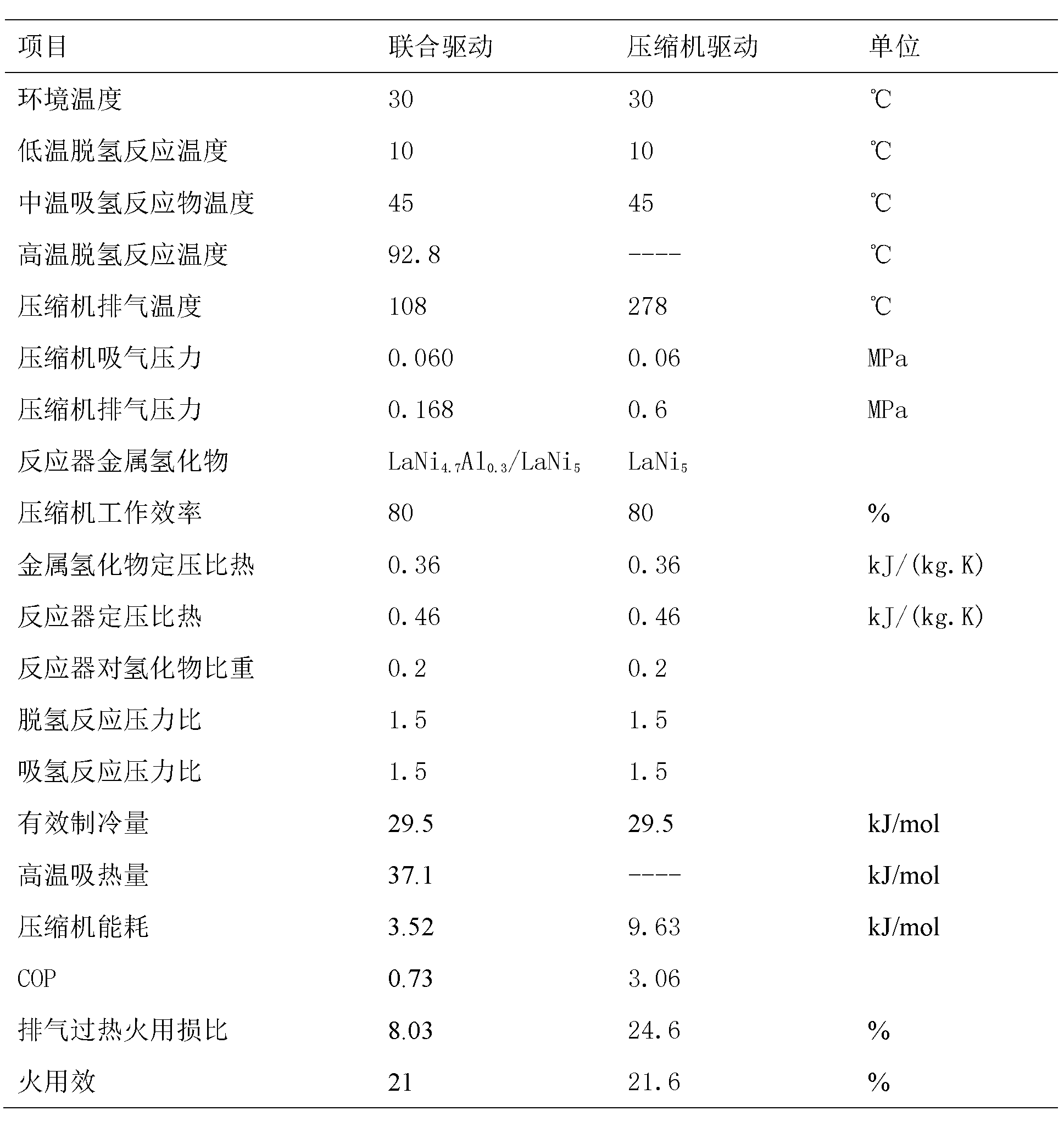

Combined-driven metal hydride heat pump system and method

InactiveCN103277938AReduce the difficulty of pairingReduce irreversible lossHeat pumpsProcess engineeringControl valves

The invention discloses a combined-driven metal hydride heat pump system. The heat pump system comprises a low-temperature reactor, a four-way control valve, a compressor, a high-temperature reactor and a valve, wherein a low-temperature reactor hydrogen interface III of the low-temperature reactor is connected with a four-way control valve hydrogen interface I of the four-way control valve, a four-way control valve hydrogen interface II of the four-way control valve is connected with a compressor hydrogen inlet of the compressor, a compressor hydrogen outlet of the compressor is connected with a four-way control valve hydrogen interface III of the four-way control valve, a four-way control valve hydrogen interface IV of the four-way control valve is connected with a high-temperature reactor hydrogen interface III of the high-temperature reactor, a high-temperature reactor hydrogen interface IV of the high-temperature reactor is connected with a low-temperature reactor hydrogen interface IV of the low-temperature reactor through the valve, and the low-temperature reactor and the high-temperature reactor contain different metal hydride respectively.

Owner:ZHEJIANG SCI-TECH UNIV

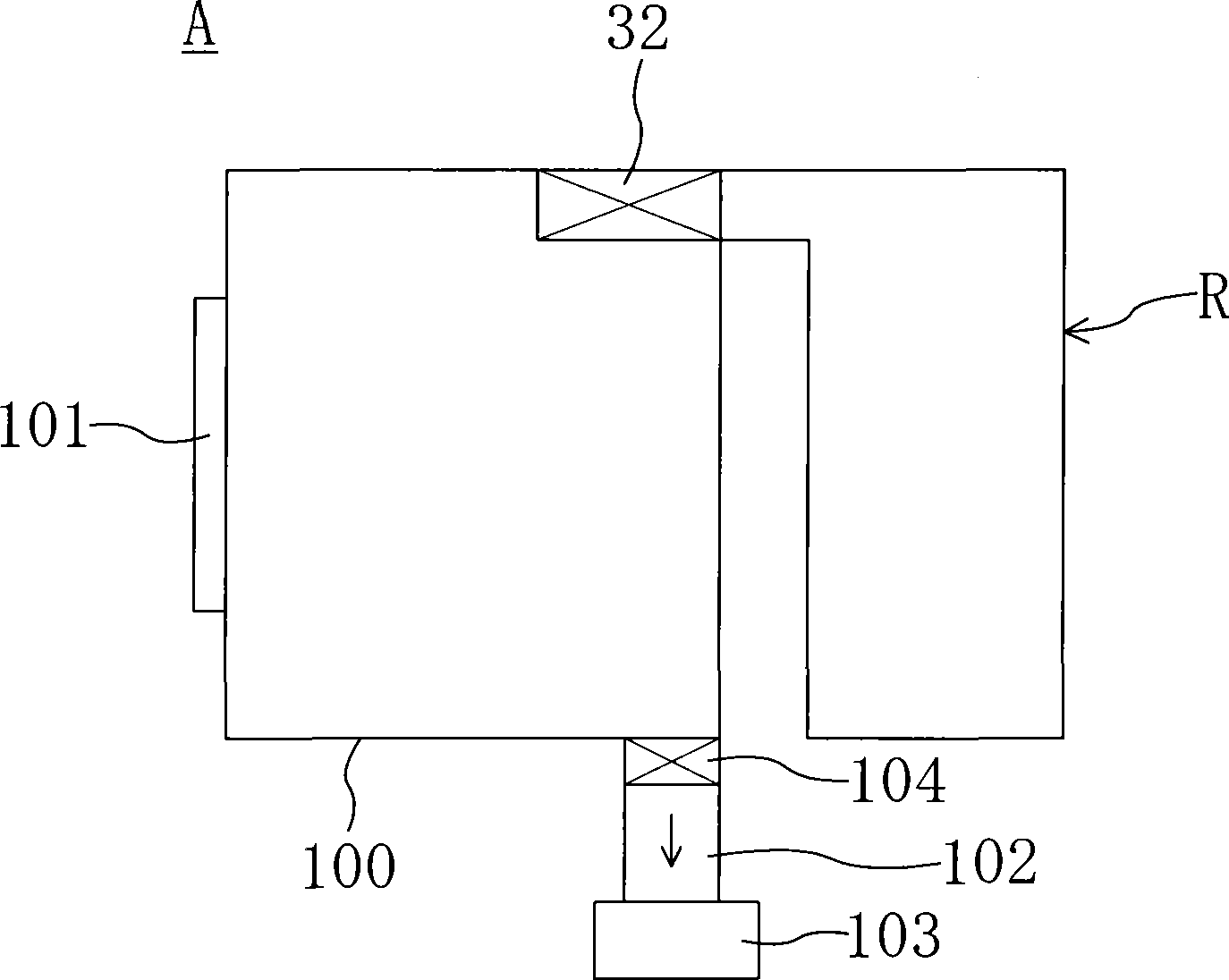

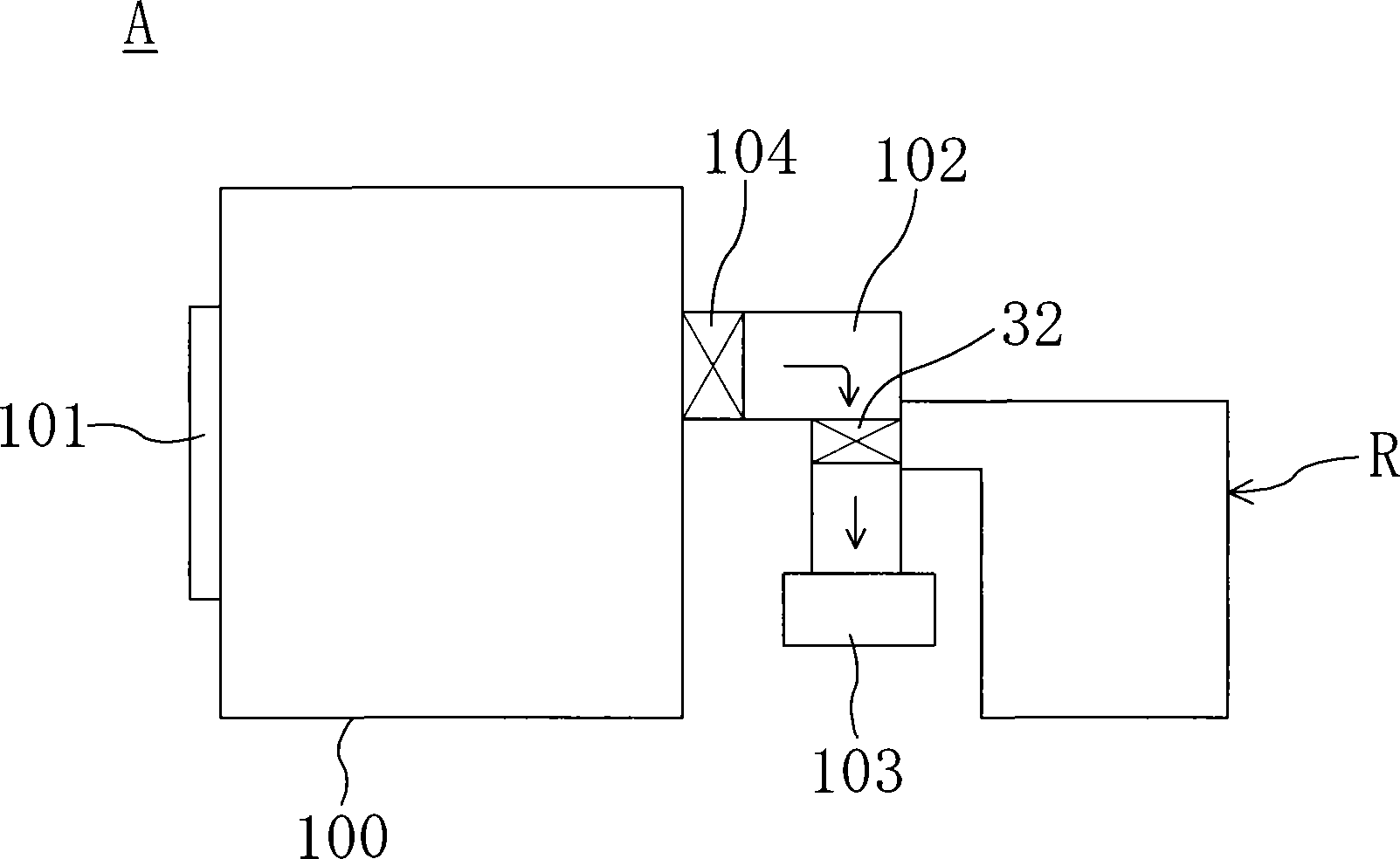

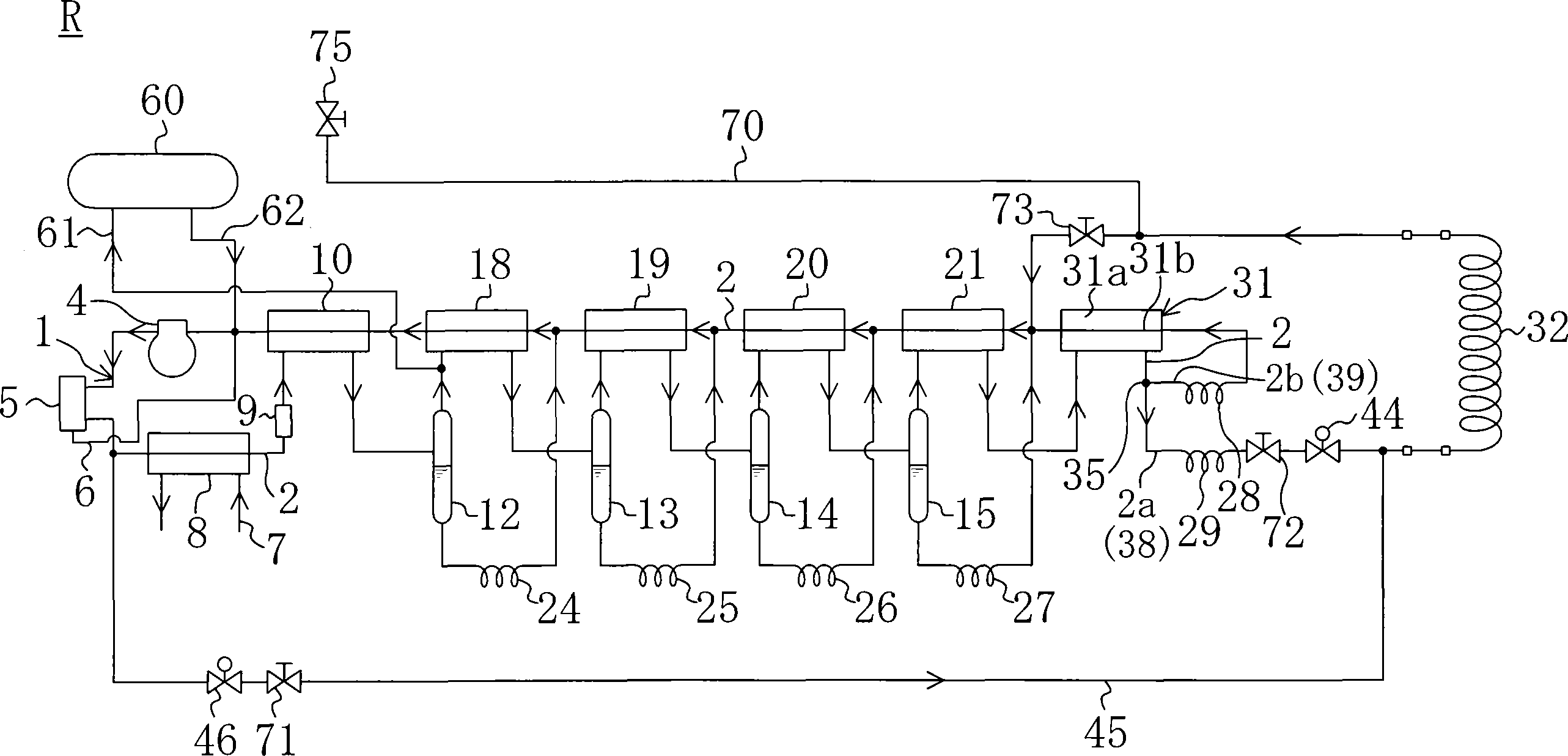

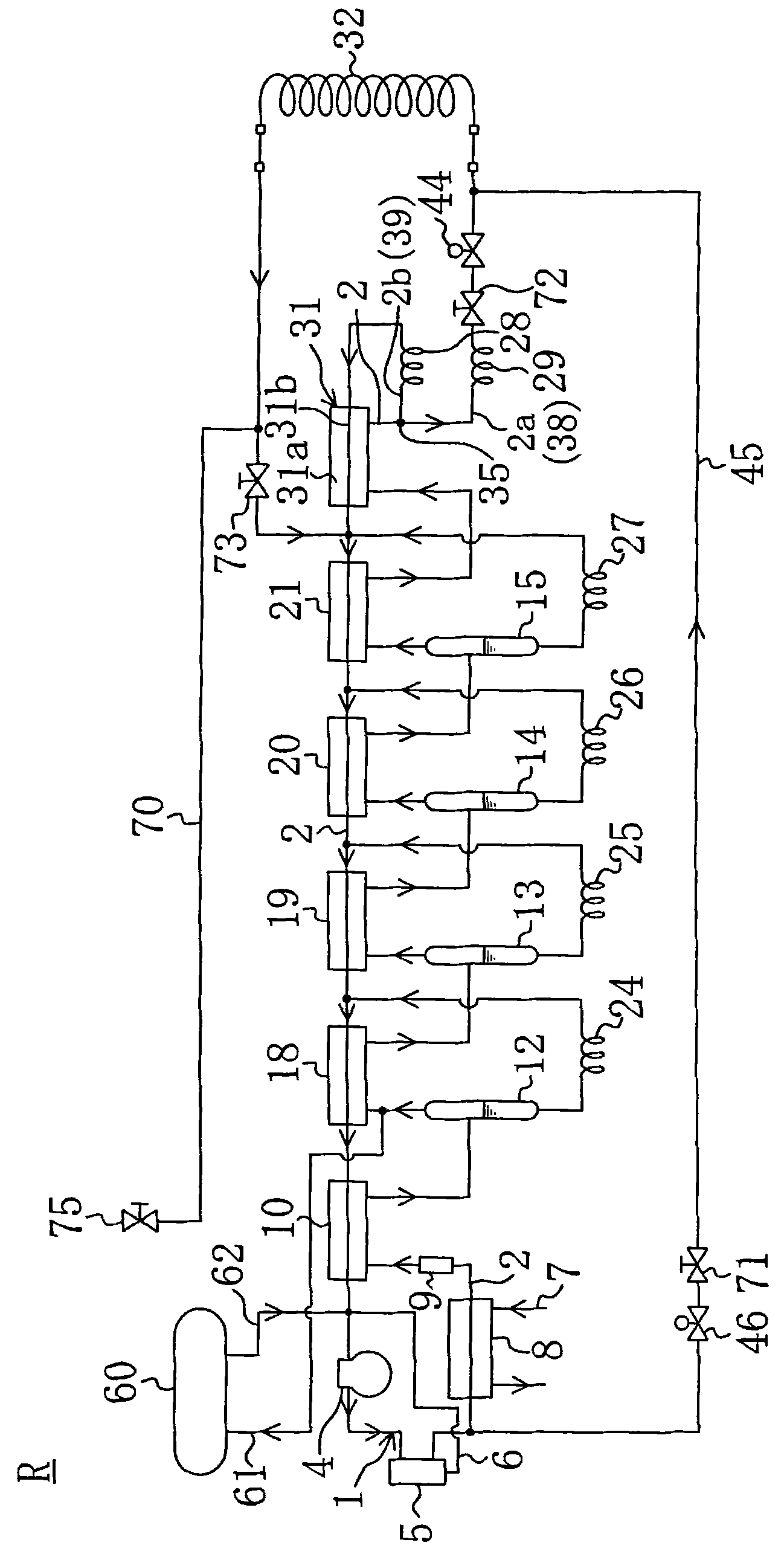

Ultralow temperature refrigerator, refrigerating system, and vacuum apparatus

ActiveCN1910411AImprove cooling efficiencyEfficient cycleCompression machines with cascade operationBoiling pointEngineering

An ultralow temperature refrigerator (R) using a mixed refrigerant containing a plurality of kinds of refrigerants having different boiling points. The refrigerator comprises a main refrigerant circuit (38) provided with a criocoil and a capillary tube (29) and a sub-refrigerant circuit (39) the upstream end of which is branched and connected to the upstream end of the main refrigerant circuit (38) and which is provided with a capillary tube (28). In order to ensure the flow of the liquid refrigerant for a supercooler (31) and to enhance the cooling eficiiency of the criocoil (32), the height of the sub-refrigerant circuit (39) is less than the height of the main refrigerant circuit (38). The flow of the refrigerant in a gas-liquid mixed state discharged from the primary side (31a) of the supercooler (31) and flowing into the sub-refrigerant circuit (39) is greater than the flow into the main refrigerant circuit (38), so that the flow of the liquid refrigerant into the sub-refrigerant circuit (39) is increased more than the flow into the main refrigerant circuit (38).

Owner:SHIN MEIWA IND CO LTD

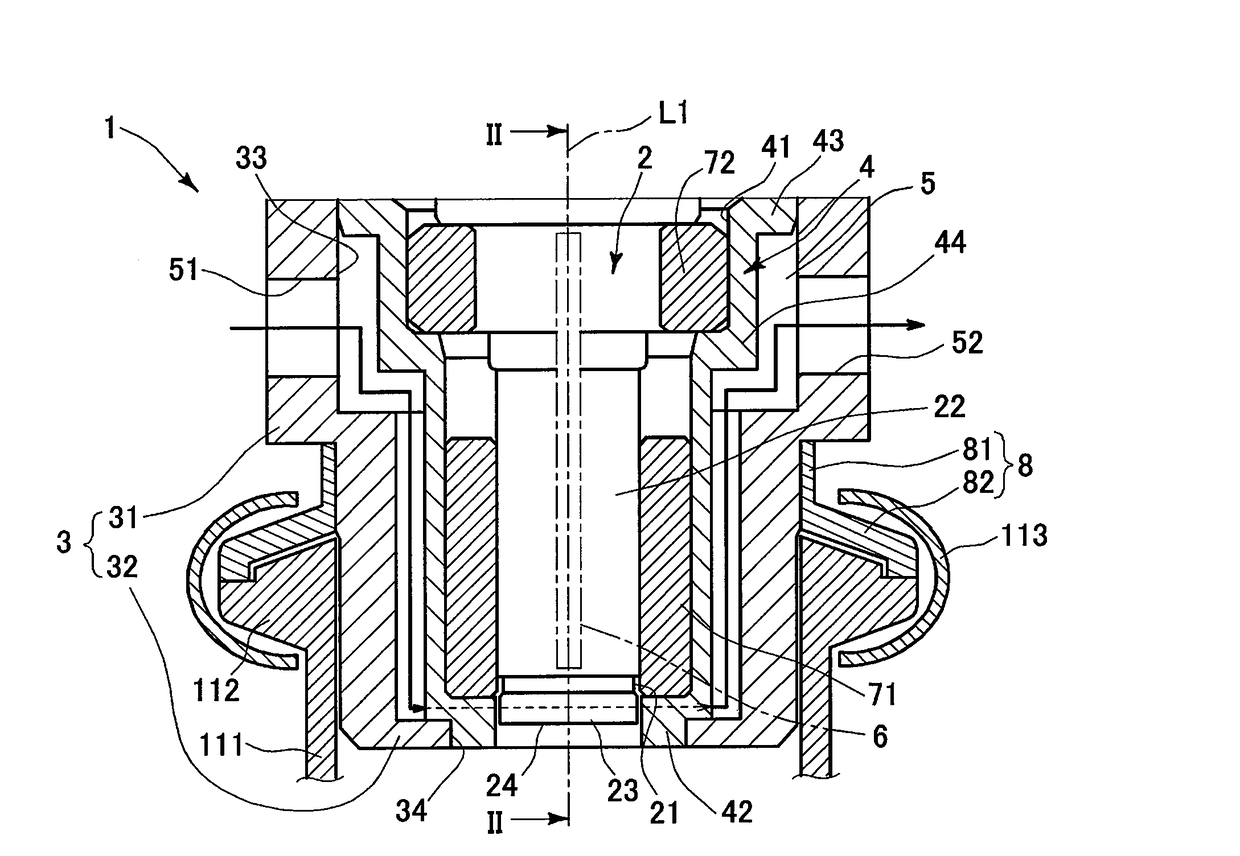

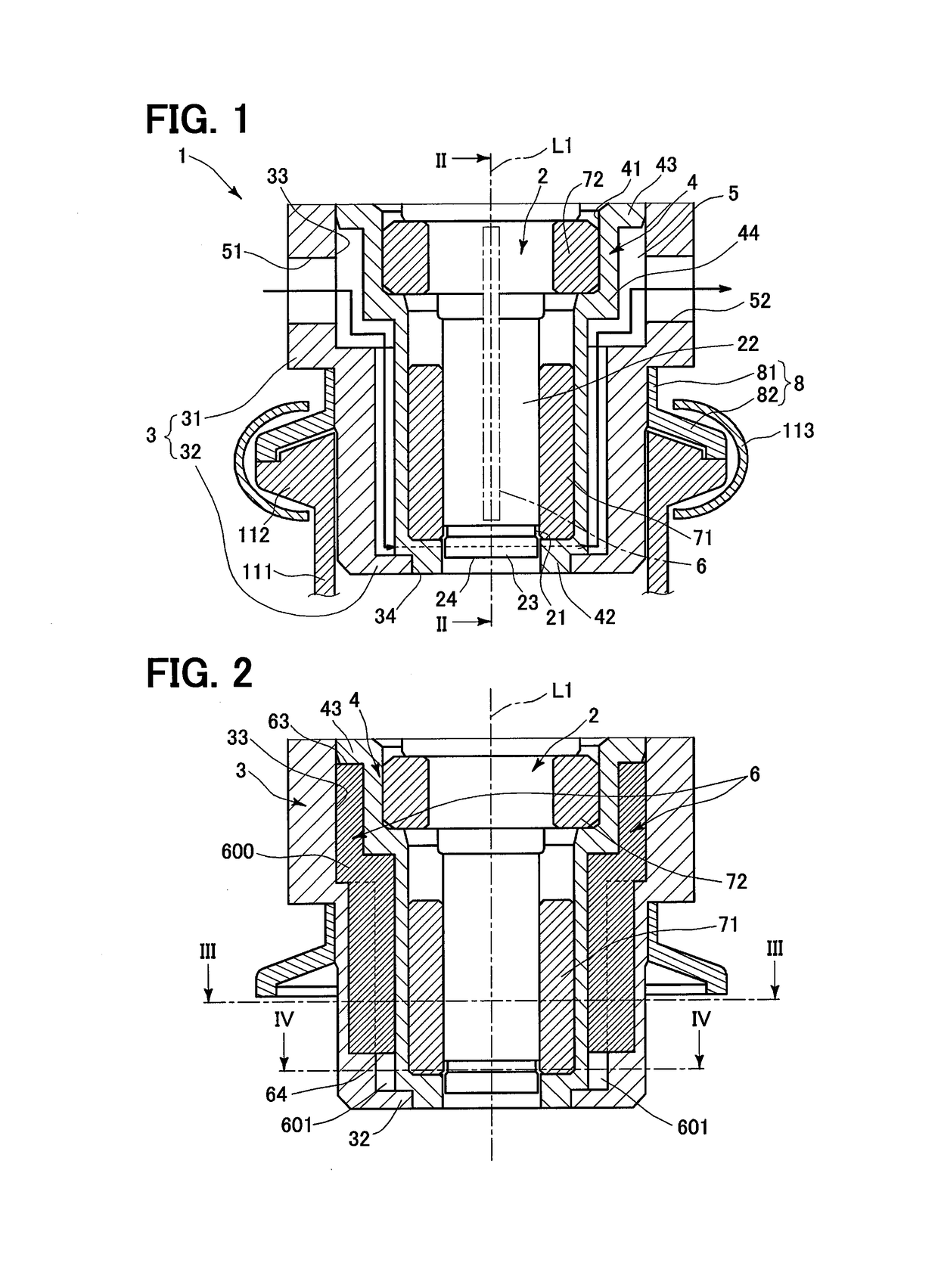

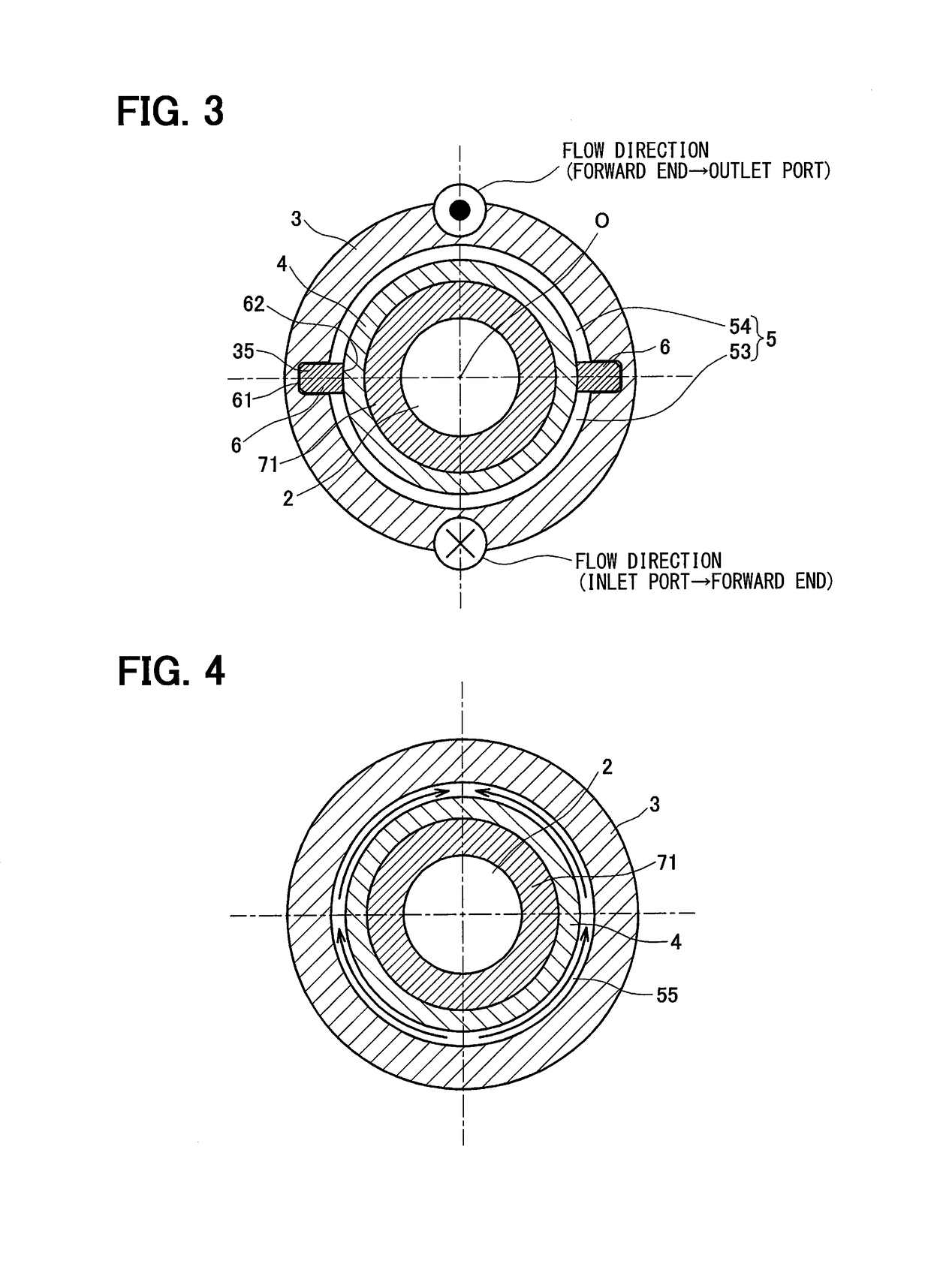

Cooling device for injector

InactiveUS20170363053A1Improve cooling effectIncrease cooling temperatureLiquid coolingGas treatmentWater flowEngineering

A partitioning wall is provided in a fluid space formed between a cover member and a body member, which surrounds a forward end of a fluid injection valve. The partitioning wall divides the fluid space into an inlet-side fluid space and an outlet-side fluid space in a circumferential direction of the fluid injection valve. A forward-end space, which is formed at a bottom of the fluid space, is communicated to the inlet-side and the outlet-side fluid spaces, so that cooling water flows from the inlet-side fluid space to the outlet-side fluid space through the forward-end space. The cooling water circulates in the forward-end space surrounding the forward end of the fluid injection valve to effectively cool down the fluid injection valve.

Owner:DENSO CORP +1

Coal gasification supercritical carbon dioxide power generation system and method capable of realizing waste heat recovery

PendingCN109322744ARealize full captureContribute a lotCarbon compoundsEnergy inputBrayton cycleIrreversible loss

The invention provides a coal gasification supercritical carbon dioxide power generation system and method capable of realizing waste heat recovery. The system comprises an air separating device, a burner, a carbon dioxide turbine, a heat regenerator, a water separator, a first carbon dioxide supercharging device, a carbon dioxide recovery device, a waste heat recovery device, a coal gasificationdevice, a Kalina turbine, a Kalina heat regenerator, a first mixer, an ammonia separator, a second mixer, a high-pressure condenser and a gas-liquid separator. According to the system, coal gas is used as fuel, and total capture of carbon dioxide is realized through oxygen-enriched combustion; the carbon dioxide expands to the subcritical state in the turbine, and the expansion ratio is higher than that of supercritical carbon dioxide Brayton cycle, so that the turbine works more, and the cycle efficiency is improved; supercritical carbon dioxide cycle waste heat is recovered through Kalina cycle during bottom cycle, by the aid of change of the working medium concentration in the non-isothermal process and the cyclic process of the working medium phase change, the gasification process andthe heat release process of a heat source are well matched, the irreversible loss of the heat exchange process is reduced, and the waste heat utilization efficiency is improved.

Owner:HUANENG CLEAN ENERGY RES INST

Ultra-low temperature freezer, refrigeration system and vacuum apparatus

InactiveCN101943498AImprove cooling effectCool down fullyDrying solid materials without heatEvaporators/condensersCapillary TubingEngineering

An ultralow temperature refrigerator (R) using a mixed refrigerant containing a plurality of kinds of refrigerants having different boiling points. The refrigerator (R) comprises a main refrigerant circuit (38) provided with a criocoil (32) and a capillary tube (29) and a sub-refrigerant circuit (39) the upstream end of which is branched and connected to the upstream end of the main refrigerant circuit (38) and which is provided with a capillary tube (28). In order to ensure the flow of the liquid refrigerant for a supercooler (31) and to enhance the cooling eficiiency of the criocoil (32), the height of the sub-refrigerant circuit (39) is less than the height of the main refrigerant circuit (38). The flow of the refrigerant in a gas-liquid mixed state discharged from the primary side (31a) of the supercooler (31) and flowing into the sub-refrigerant circuit (39) is greater than the flow into the main refrigerant circuit (38), so that the flow of the liquid refrigerant into the sub-refrigerant circuit (39) is increased more than the flow into the main refrigerant circuit (38).

Owner:SHIN MEIWA IND CO LTD

Nano water ion cluster generator

ActiveCN113300222AAvoid breakingInhibit sheddingElectrical apparatusDisinfectionEngineeringElectron avalanche

The invention belongs to the field of disinfection, epidemic prevention and healthy air, and particularly relates to a nano water ion group generator. The generator comprises at least one pair of P / N type semiconductor crystal grains, wherein the paired P / N type semiconductor crystal grains are composed of P type semiconductor crystal grains and N type semiconductor crystal grains, one end of each P / N type semiconductor crystal grain is a refrigeration end, and the other end of each P / N type semiconductor crystal grain is a heating end; a heat absorption piece which is used for obtaining the cold energy generated by the refrigeration end and transmitting the cold energy to the blocking piece; a blocking piece which is used for conducting the cooling capacity obtained by the heat absorption piece so as to obtain condensate water or air with high relative humidity; an ionization piece which is arranged on one side of the blocking piece to absorb, gather or accumulate moisture in cold energy, condensate water or high-relative-humidity air, is electrically coupled to the high-voltage power supply and is used for loading a high-voltage electric field so as to ionize air and moisture around the ionization piece under the action of an electron avalanche effect, and obtain at least one nano-particle-size substance of charged particles and oxygen-containing free radicals.

Owner:HANGZHOU DAZHAN ELECTROMECHANICAL TECH CO LTD

Annealing method for improving laser output power of Nd3+:YAG crystal

The invention discloses an annealing method for improving laser output power of Nd3+:YAG crystal. The annealing method comprises the following steps of 1, putting an Nd3+:YAG crystal bar into a vacuum annealing furnace, and vacuumizing the vacuum annealing furnace to 0.08MPa by a vacuum pump; 2, opening an air inflation device, supplying a mixture gas of nitrogen and oxygen into the vacuum annealing furnace by a vacuum pipe, and maintaining the air pressure in the vacuum annealing furnace to 0MPa; 3, after the step 2 is finished, increasing the temperature in the vacuum annealing furnace to 1250-1300 DEG C; 4, maintaining the temperature in the vacuum annealing furnace to 1250-1300 DEG C; 5, after the step 4 is completed, lowering the temperature in the vacuum annealing furnace to 800 DEG C, and naturally cooling to the room temperature along with the furnace. Theannealing method has the advantages that by changing the annealing atmosphere, the constant temperature and the constant-temperature yearly hour are improved, so that the laser output power of the Nd3+:YAG crystal is greatly improved; compared with similar types of existing products, the laser output power is improved by 10-15%.

Owner:成都新源汇博光电科技有限公司

Heating working medium and preparing method thereof

This invention involves the technological field of working medium of heating, the working medium additive of affiliated heating, it is the association thing made of raw materials of the following matching of manner of weight; calcium chloride 5-9, chlorine magnesium 12-15, antiseptic 0.01-0.05; Stated heating working medium that additive prepare is according to weight manner mixture that raw materials make of matching; calcium chloride 5-9, chlorine magnesium 12-15, antiseptic 0.01-0.05, water 14-20. Stated heating working medium preparation method, according to the raw materials of the matching of manner of weight: calcium chloride 5-9, chlorine magnesium 12-15, antiseptic 0.01-0.05, water mixes and makes heating working medium by 14-20, the working medium thermal efficiency of above-mentioned heating is high, economize the energy, lighten pollution, is suitable for the heating in winter.

Owner:郭建民

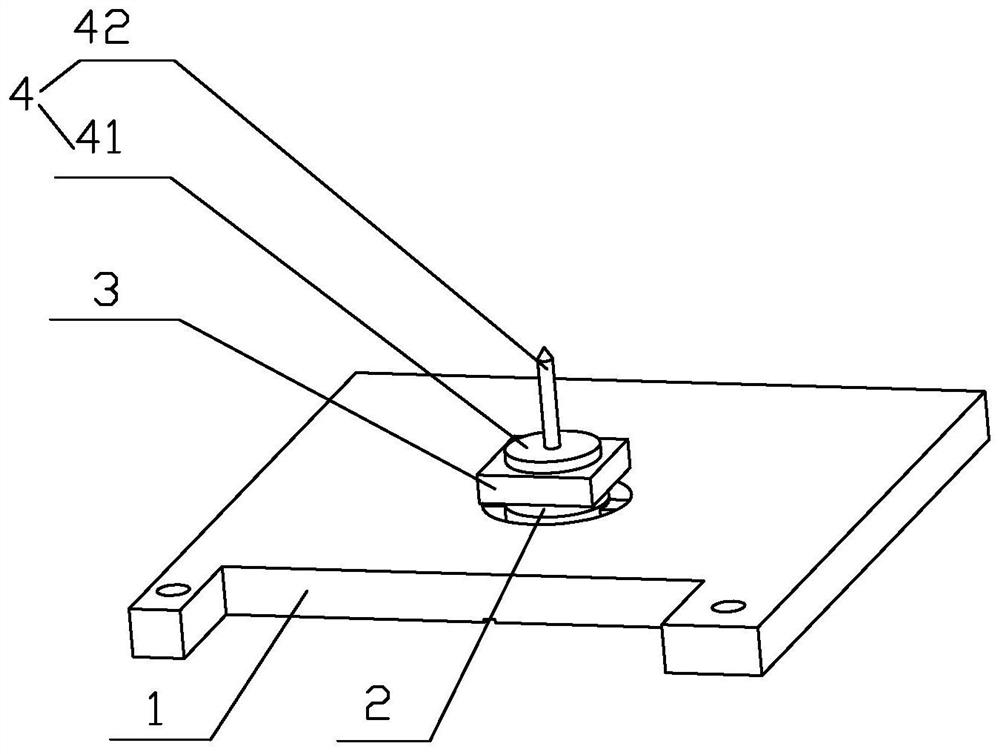

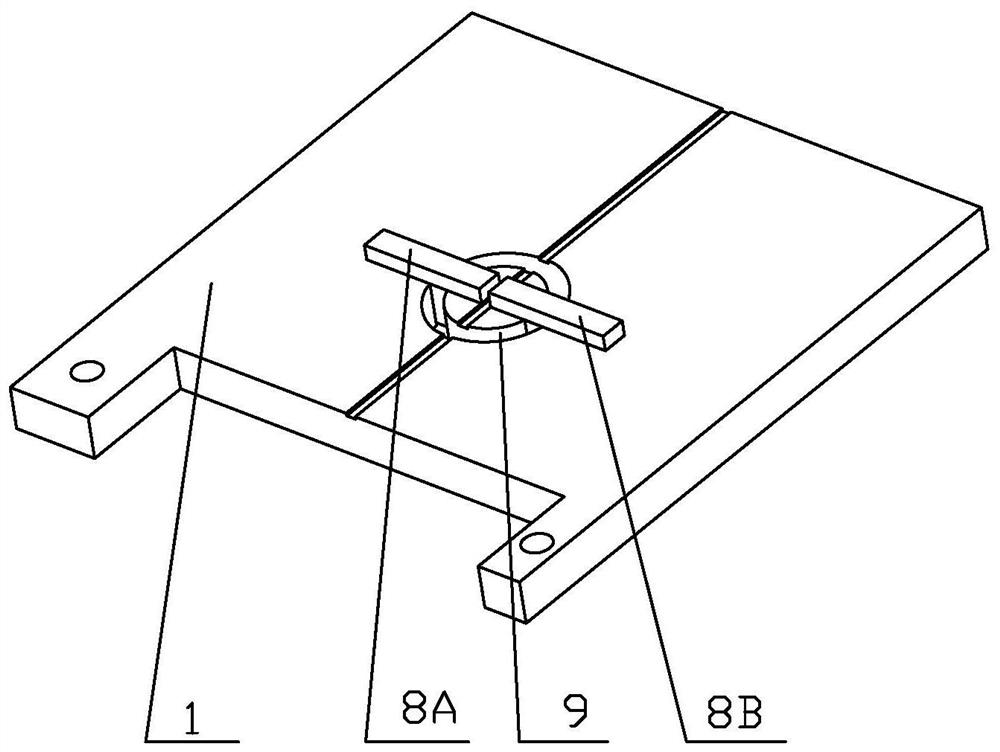

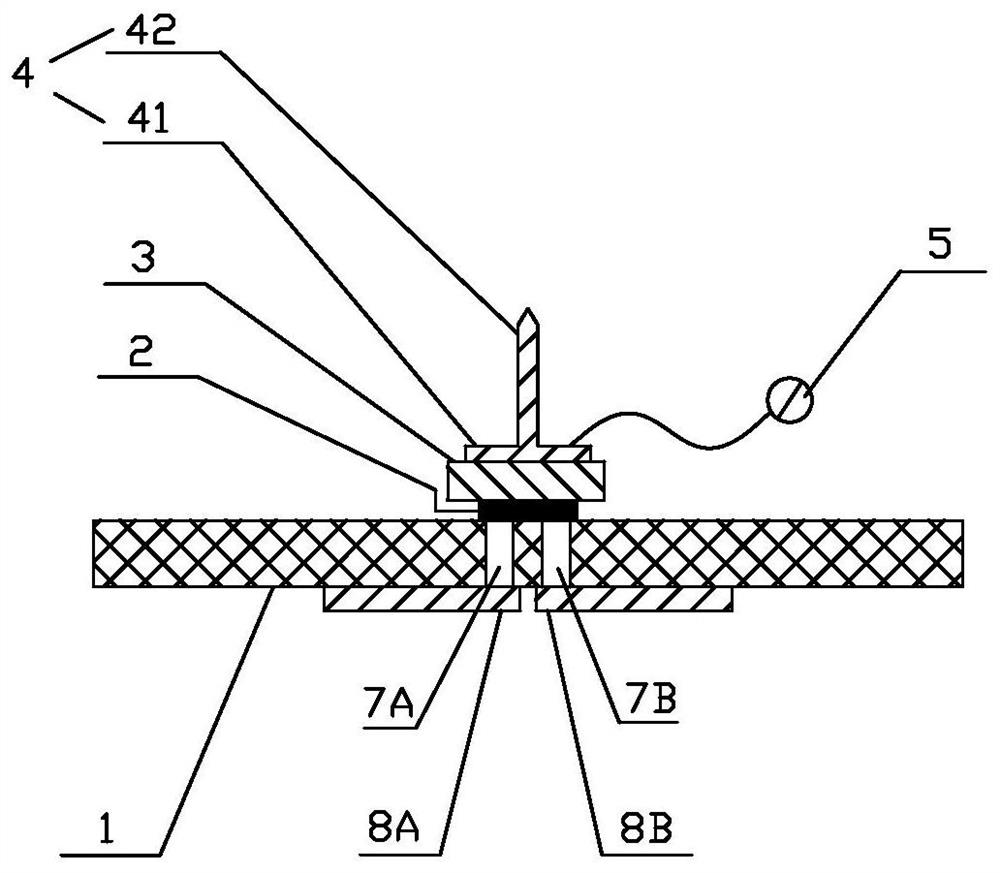

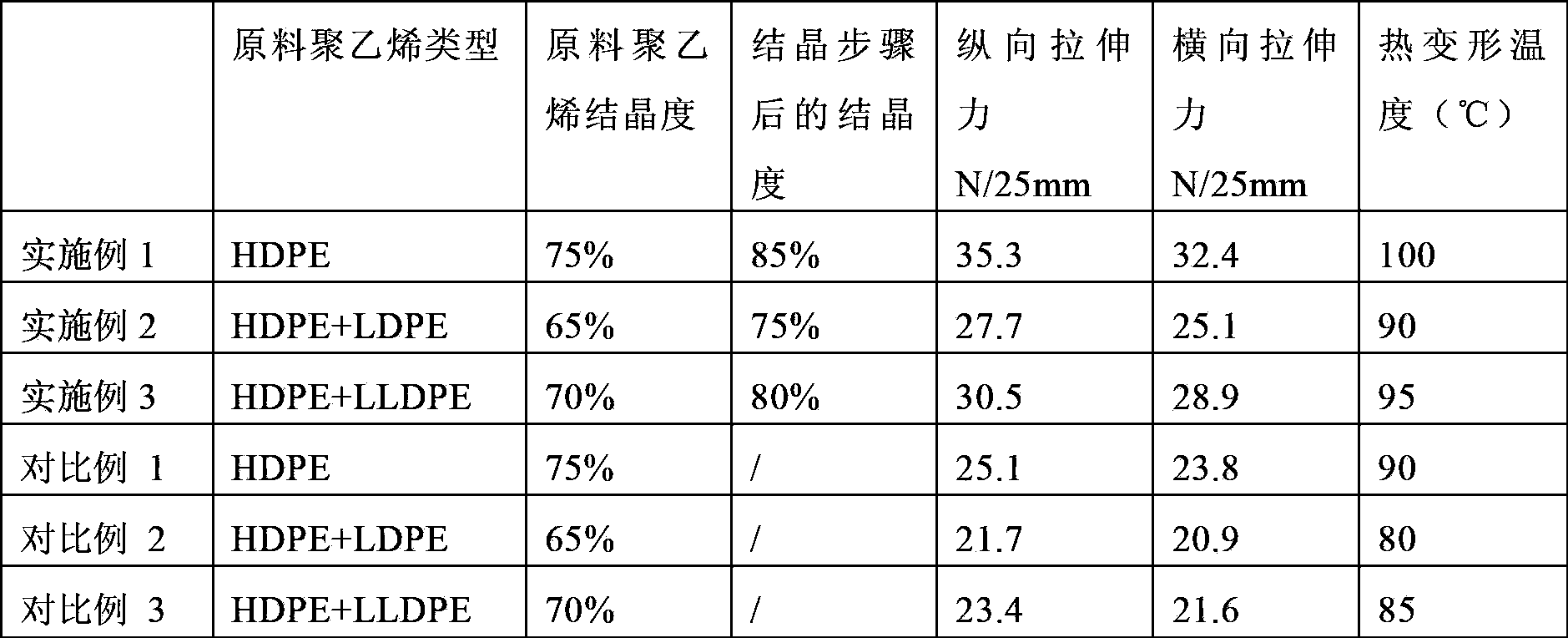

Preparation method of polyethylene casting film

Owner:SHANGHAI ZIHUA FILM TECH CO LTD

Calcium carbonate preparation method for accelerating carbonatation reaction

ActiveCN108046303AIncrease concentrationImprove solubilityCalcium/strontium/barium carbonatesMaterial nanotechnologyPrecipitated calcium carbonateCarbonatation

The invention discloses a calcium carbonate preparation method for accelerating a carbonatation reaction and belongs to the technical field of calcium carbonate powder preparation. The calcium carbonate preparation method for accelerating the carbonatation reaction comprises the steps that the inner wall of a carbonatation reaction kettle is coated with a carbon dioxide gas adsorption material, and after the coating material fixed on the inner wall of the reaction kettle, by using the reaction kettle which is improved through coating, the carbonatation reaction is conducted to prepare precipitated calcium carbonate. According to the calcium carbonate preparation method, the problems are solved that in the prior art, prepared calcium carbonate is long in reaction time and uneven and unstable in product quality.

Owner:GUANGXI UNIV +1

Isoworking medium and same working medium gas compression acting device

PendingCN110398079AReduce wasteEfficient use ofCompression machines with non-reversible cycleSteam engine plantsBoiling pointProcess engineering

The invention discloses an isoworking medium and same working medium gas compression acting device. The isoworking medium and same working medium gas compression acting device comprises a first actingcomponent, a first condenser and a first evaporator, wherein the first condenser is connected with an outlet of the first acting component, and the first evaporator is connected with an outlet of thefirst condenser; a refrigerating system comprises a compressor, a second condenser and a second evaporator, wherein the second condenser is connected with an outlet of the compressor, and the secondevaporator is connected with an outlet of the second condenser; a heating area is formed between the outlet of the compressor and the second condenser; and the heating area exchanges heat with the first evaporator, the second evaporator exchanges heat with the first condenser, the boiling point of a working medium in an acting system is lower than that of the working medium in the refrigerating system, and the working medium of the acting system can be condensed by the working medium of the refrigerating system. The isoworking medium and same working medium gas compression acting device has the technical effect of effectively utilizing the low temperature.

Owner:郑成勋

Carbon dioxide full gathering type supercritical carbon dioxide power generation system and method

PendingCN109184915AContribute a lotImprove conversion efficiencyGas turbine plantsPump installationsCombustorProcess engineering

The invention provides a carbon dioxide full gathering type supercritical carbon dioxide power generation system and method. The system comprises an air separation device, a combustor, a turbine and agas circulation system, wherein air enters the air separation device for gas separation, oxygen separated from the air enters the combustor through an outlet of the air separation device and burns with natural gas in the combustor, and high-temperature supercritical carbon dioxide is generated and enters the turbine through an outlet of the combustor to do work for power generation; and gas exhausted from the turbine enters the combustor through a gas circulation system again. Through the structure, the efficiency of conversion of heat into power can be substantially improved, the equipment size is decreased, and the quite high economical efficiency is achieved.

Owner:HUANENG CLEAN ENERGY RES INST

Inter-section scale inhibition method for centrifugal natural gas compressor set

InactiveCN102996489AOvercome congenital deficienciesSolve fouling and cloggingPump componentsPumpsImpellerHydrocarbon dew point

An inter-section scale inhibition method for a centrifugal natural gas compressor set includes a method a, a method b or a method c. A heat exchanger is additionally arranged at the position between an inter-section separator outlet to a next section first stage impeller inlet, an outlet pipeline at the back of a scaling section of the centrifugal natural gas compressor set is connected with an inlet of the additionally arranged heat exchanger, an outlet of the additionally arranged heat exchanger is connected with an inlet of a cooler through a pipeline, an outlet of the cooler is connected with an inlet of a separator, an outlet of the separator is connected with an inlet of a heat exchange coil pipe arranged in the heat exchanger, and an outlet of the heat exchange coil pipe is connected with an inlet of a scaling section first stage impeller. High-temperature natural gases at an outlet behind the scaling section and low-temperature natural gases emitted from the separator are exchanged, and temperature at the separator outlet after heat exchange compensates external temperature loss and is higher than the critical temperature for generating the water dew point and the hydrocarbon dew point.

Owner:CHINA PETROLEUM & CHEM CORP +1

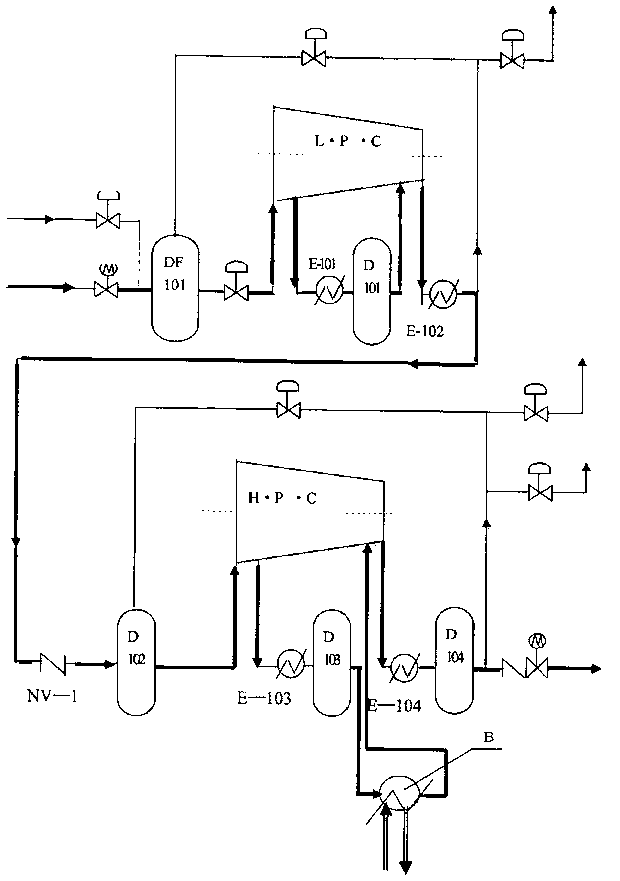

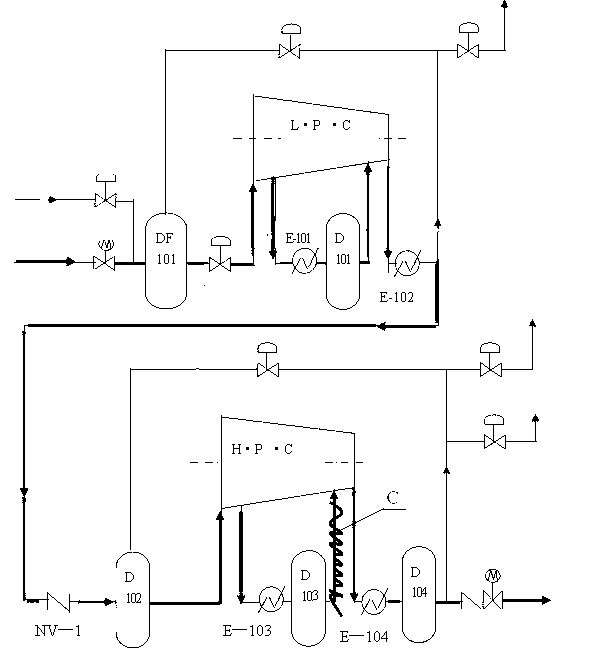

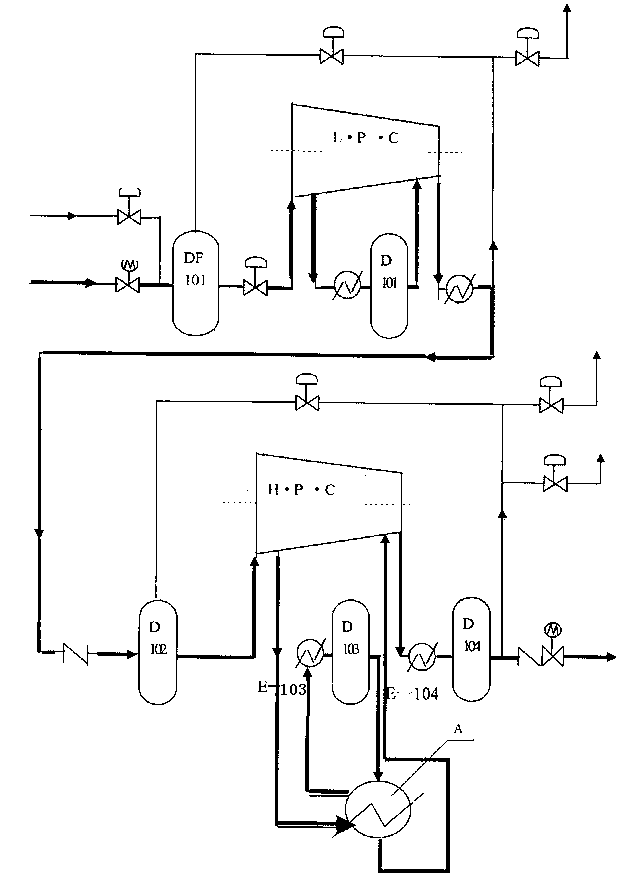

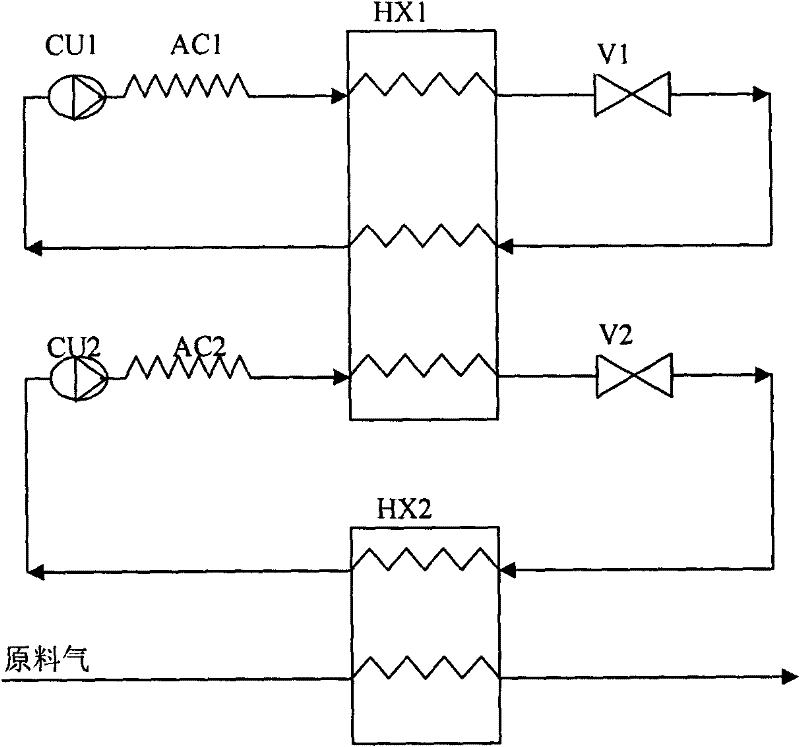

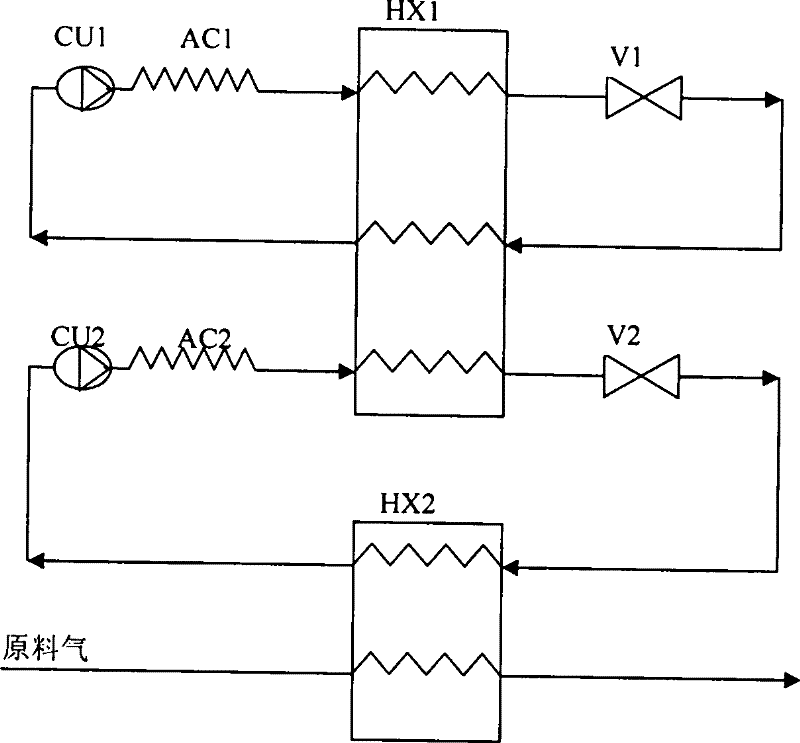

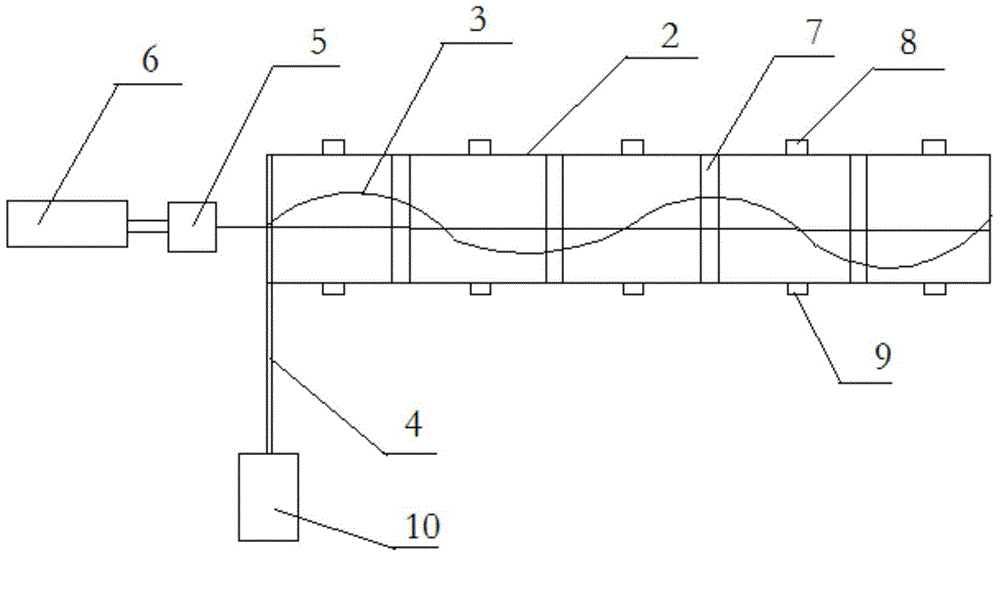

Low-temperature liquefaction system for dual cycle of mixed working medium

ActiveCN101893344BIncrease cooling temperatureAvoid large heat transfer temperature differencesCompression machines with cascade operationSystems designProcess engineering

The invention relates to a low-temperature liquefaction system for dual cycle of a mixed working medium. The system comprises a first refrigeration cycle loop, a second refrigeration cycle loop and a feed gas pipeline, wherein a mixed refrigeration working medium is used in the first refrigeration cycle loop and the first refrigeration cycle loop consists of a first compressor, a first condenser,a main heat exchanger and a first throttling valve which are connected sequentially; a non-combustible pure working medium or a non-combustible mixed working medium is used in the second refrigeration cycle loop and the second refrigeration cycle loop consists of a second compressor, a second condenser, a distributed heat exchanger and a second throttling valve which are connected sequentially; and the feed gas pipeline consists of the distributed heat exchanger and a pipeline, feed gas after dust removal treatment is connected with the inlet of the distributed heat exchanger through the pipeline, and the outlet of the distributed heat exchanger is the outlet of the liquefied feed gas. The system has the advantages of flexible design, simpleness and compactness, low cost, high operationalefficiency, high system safety because the non-combustible working medium is used in the second refrigeration cycle, and remote cold delivering.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Double-loop separated type refrigeration equipment

InactiveCN106556201AImprove energy efficiencyLow cooling temperatureMechanical apparatusCompression machines with non-reversible cycleVapor–liquid separatorRefrigeration temperature

The invention provides double-loop separated type refrigeration equipment. The double-loop separated type refrigeration equipment comprises a dual refrigeration system, a fan, an outdoor unit shell and a plurality of indoor storage cabinets; in the dual refrigeration system, a first condenser is connected with a first air and liquid separator; the first air and liquid separator is connected with a first heat exchanger; the first heat exchanger is connected with a second evaporator; the first air and liquid separator is connected with a first evaporator; the first evaporator is connected with the first heat exchanger; the second evaporator and the first heat exchanger are separately connected with a first compressor through a third heat exchanger; a first heat regenerator is provided with a third capillary tube and a first heat regenerating tube which exchange heat with each other; a second heat regenerator is provided with a fourth capillary tube and a second heat regenerating tube which exchange heat with each other; a heat exchange passage II of the second heat exchanger is connected with an inlet of a second compressor through the first heat regenerating tube; and an outlet of a fourth evaporator is connected with the inlet of the second compressor through the second heat regenerating tube. The double-loop separated type refrigeration equipment can increase the utilization rate of energy, improve the refrigeration performance and widen the refrigeration temperature range so as to improve the universality.

Owner:QINGDAO HAIER SPECIAL ICEBOX

Double-evaporation-temperature jet refrigerating machine and method based on mixed working medium

ActiveCN113280522AReduce ejection compression ratioImprove injection coefficientMechanical apparatusCompression machines with several evaporatorsVapor–liquid separatorPower cycle

The invention discloses a double-evaporation-temperature injection refrigerating machine and method based on a mixed working medium. The refrigerating machine comprises a first throttling valve, a second throttling valve, a high-temperature evaporator, a low-temperature evaporator, an injector, an air-cooled condenser, a gas-liquid separator, a water-cooled condenser, a generator and a circulating pump; the generator, the ejector, the air-cooled condenser, the gas-liquid separator and the circulating pump form a power cycle; the ejector, the air-cooled condenser, the gas-liquid separator, the first throttling valve and the high-temperature evaporator form a first refrigeration cycle, and high refrigeration temperature is achieved; and the ejector, the air-cooled condenser, the gas-liquid separator, the water-cooled condenser, the second throttling valve and the low-temperature evaporator form a second refrigeration cycle, and low refrigeration temperature is achieved. A non-azeotropic mixed working medium is adopted, the ejection compression ratio of the ejector is reduced, the ejection coefficient of the ejector is improved, meanwhile, a low evaporation refrigeration temperature and a high evaporation refrigeration temperature are achieved, and the overall refrigeration coefficient of the device is improved.

Owner:CHINA UNIV OF MINING & TECH

Material transmission device

The invention provides a material transmission device which comprises a conveying cylinder and a cooling tube, wherein a packing auger connected with a motor is arranged inside the conveying cylinder; the conveying cylinder is sleeved by the cooling tube; the cooling tube can rotate along the conveying cylinder; the cavity of the cooling tube is divided into a plurality of cooling spaces; water inlets are formed in the top of the cooling tube; water outlets are formed in the bottom of the cooling tube; the water outlets of the cooling tube are connected with the water inlet of a heat radiator through water tubes; the water outlet of the heat radiator is connected with the water inlets in the cooling tube. A high-temperature material is cooled through the cooling tube in the conveying process, the material can be prevented from fire caused by too high temperature, and the material transmission device has the advantages of being simple in structure, high in working efficiency, long in service life, low in cost and the like.

Owner:TIANJIN YUFENG CHEM

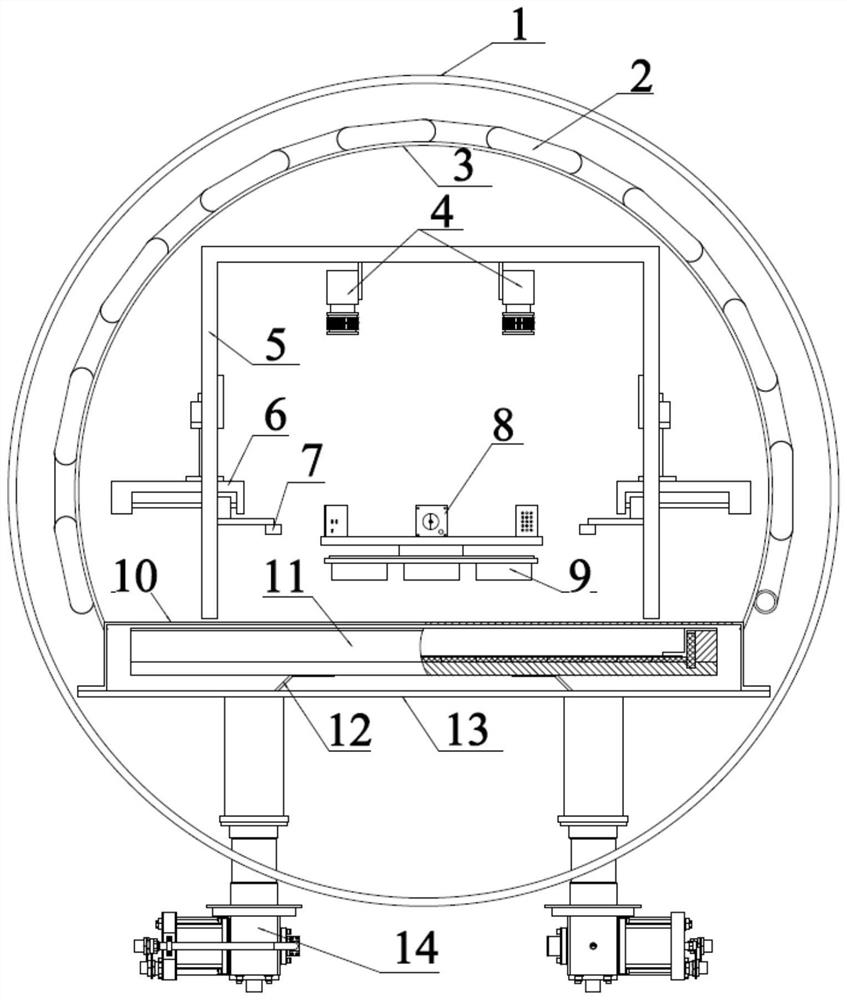

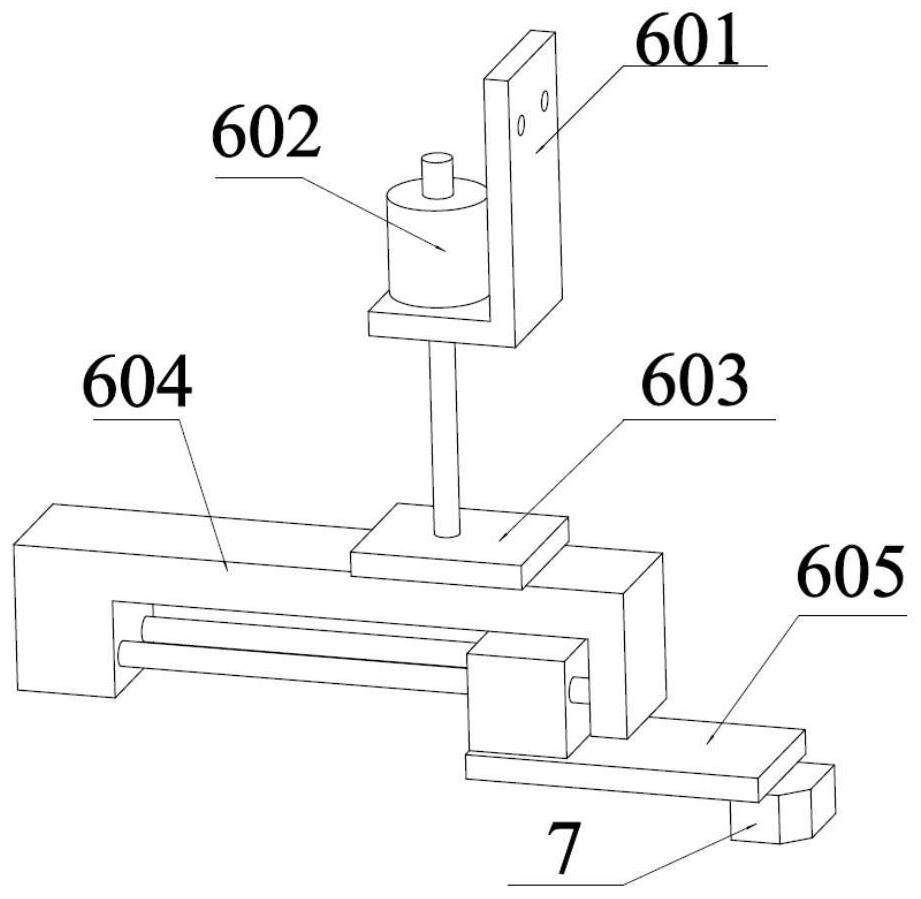

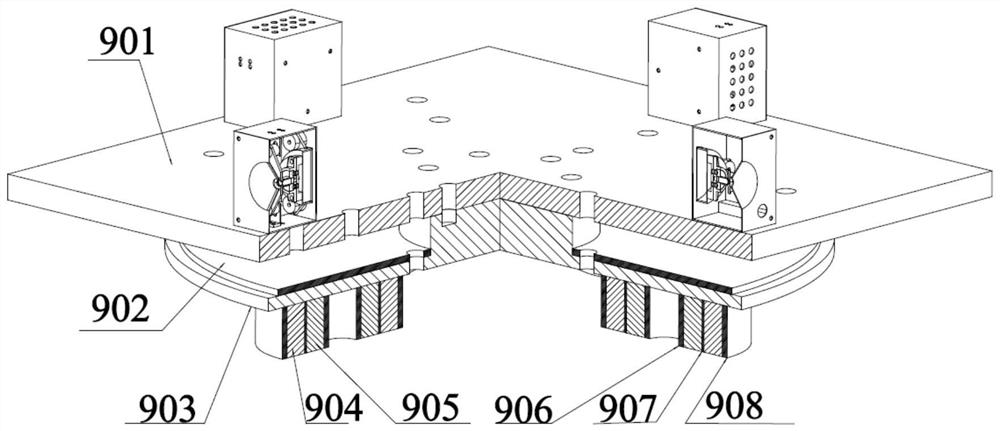

Sub-mN-level superconductive plane suspension type vacuum attitude and orbit control test system

PendingCN114013695ALarge range of motionLow motion dampingCosmonautic condition simulationsEngineeringBinocular vision

The invention discloses a sub-mN superconductive plane suspension type vacuum attitude and orbit control test system, which specifically comprises a superconductive translation magnetic suspension system, a dual-mode motion measurement device and an ultralow-temperature refrigeration system, and realizes a large-area low-damping translation suspension method based on complete diamagnetism of a superconductor under zero-field cooling. A superconductive fence structure is introduced to inhibit the fringe effect of a superconductive plane, and more than 80% of an effective translation area is realized; in order to achieve a high-suspension air gap exceeding 10 mm, the superconductive temperature of the ultralow-temperature refrigerating system is required to be lower than 5 K; in order to realize sub-mN level translation resistance, the low-temperature uniformity of a superconducting plane is required to be superior to 0.5 K, the mounting planeness is required to be superior to 0.5 mm, and the magnetic field uniformity of a circular ring magnetic structure below a permanent magnetic levitation platform is controlled to be 1% or less; in order to measure the [mu]N-level micro force, a combined measurement mode of circumferential distribution of four precision nm-level displacement sensors is adopted; and in order to evaluate the large-range motion control capability of the micro-thruster, binocular vision is adopted to collect motion trails.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com