Low-grade heat energy auxiliary-drive composite low-temperature refrigerating system

A low-temperature refrigeration system and auxiliary drive technology, used in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc. problem, to achieve the effect of significant energy saving, power consumption reduction and power saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

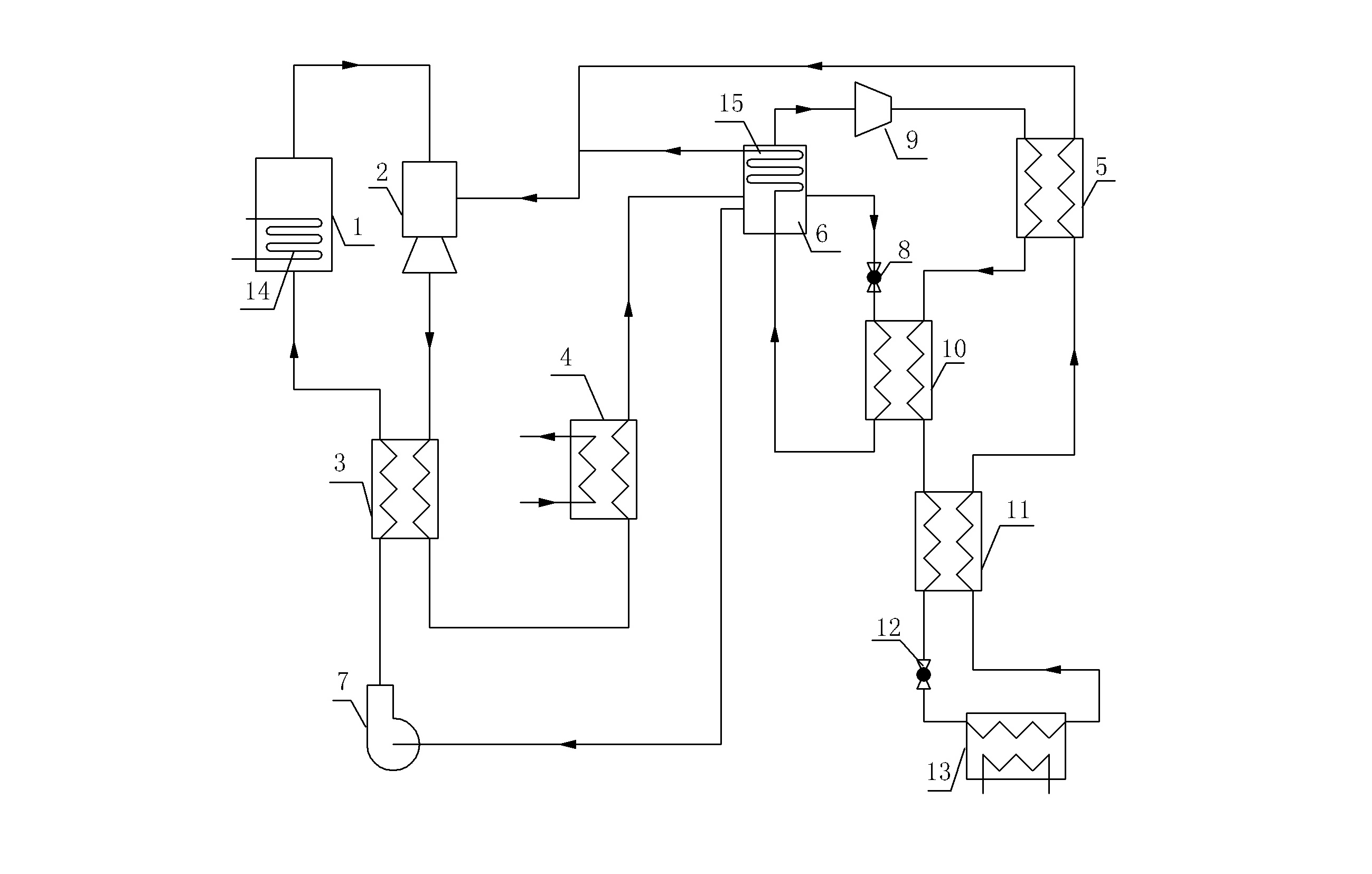

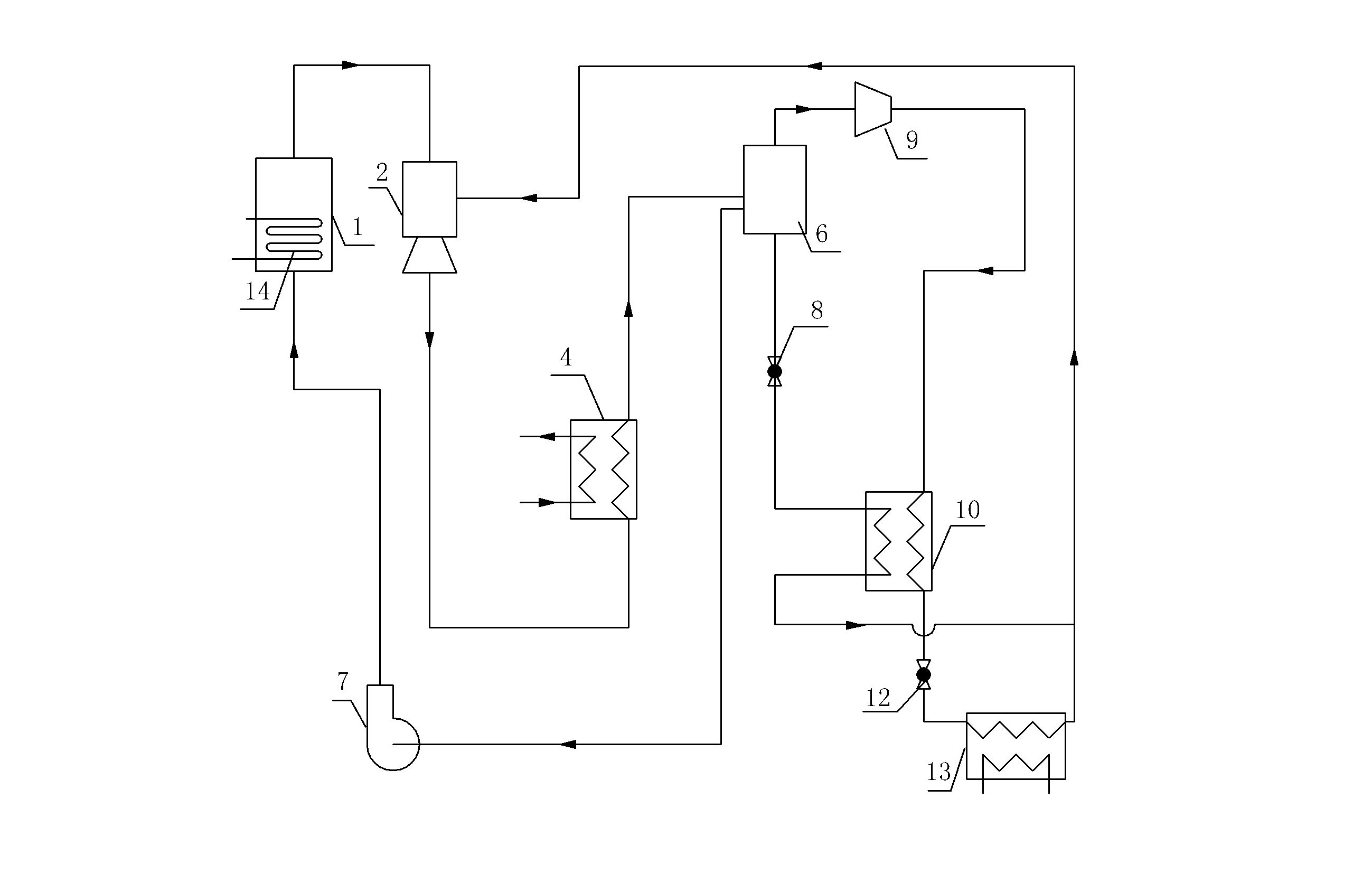

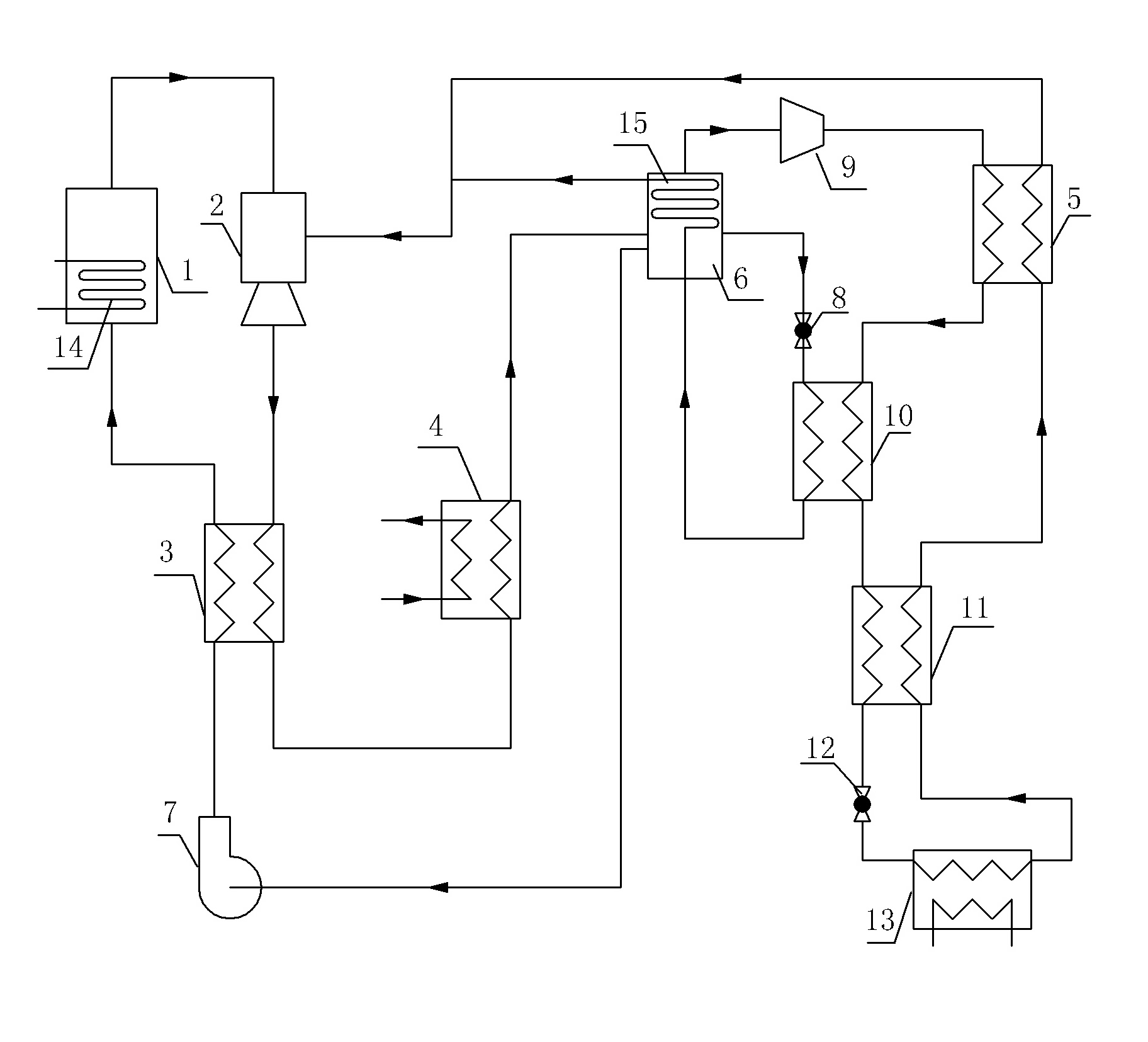

[0013] Such as figure 1 Shown, the embodiment 1 of the composite low-temperature refrigeration system driven by low-grade thermal energy auxiliary drive of the present invention, figure 1 The arrows in indicate the direction of fluid flow in the piping connecting the various parts of the system. The system includes a compression refrigeration part and a low-grade thermal energy auxiliary part. In an embodiment of the system, a binary non-azeotropic mixed refrigerant refrigerant composed of a mixture of a high-boiling point refrigerant and a low-boiling point refrigerant is used. The high-boiling point refrigerant It is one of R600a, R152a, R134a or R22, and the low boiling point working substance is one of R23, R170, R290 or R32.

[0014] The compression refrigeration part is similar to the prior art, including a compressor 9, a second regenerator 5, a high-temperature side channel of a condensation evaporator 10, a third regenerator 11, a second throttling component 12, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com