Combined-driven metal hydride heat pump system and method

A heat pump system and hydride technology, applied in heat pumps, refrigeration and liquefaction, lighting and heating equipment, etc., can solve problems such as inability to realize heat pump cycles, increase irreversible losses in the heat transfer process, and reduce the flexibility of multi-temperature heat source matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

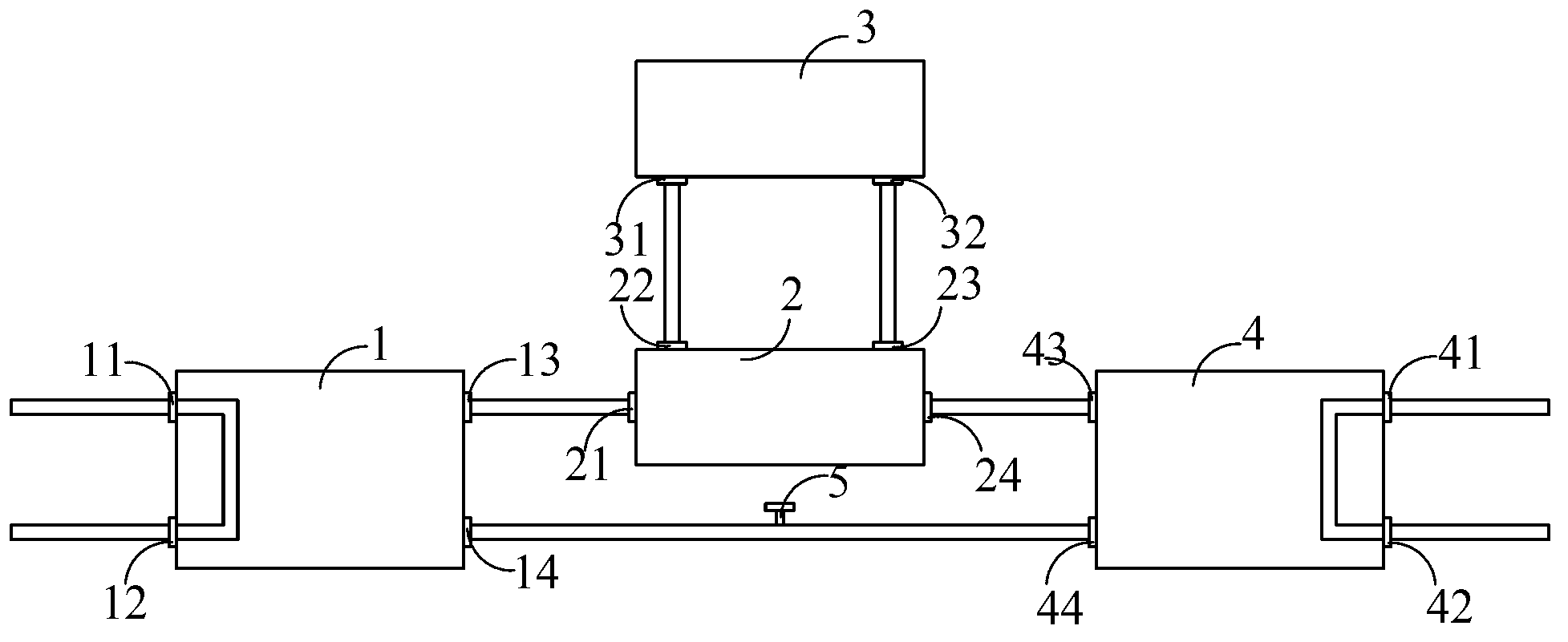

[0038] Implementation example 1, figure 1 A combined drive metal hydride heat pump system is given, including a low temperature reactor 1, a four-way control valve 2, a compressor 3, a high temperature reactor 4 and a valve 5.

[0039] Low temperature reactor 1 is provided with low temperature reactor fluid inlet 11, low temperature reactor fluid outlet 12, low temperature reactor hydrogen port III13 and low temperature reactor hydrogen port IV14; four-way control valve 2 is provided with four-way control valve hydrogen port I21 , four-way control valve hydrogen port II22, four-way control valve hydrogen port III23 and four-way control valve hydrogen port IV24; compressor 3 is provided with compressor hydrogen inlet 31 and compressor hydrogen outlet 32; high temperature reactor 4 is provided with High temperature reactor fluid inlet 41, high temperature reactor fluid outlet 42, high temperature reactor hydrogen interface III43 and high temperature reactor hydrogen interface IV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com