Adjustable tower equipment assembling tool and using method

A technology for adjusting towers and equipment groups, which is applied to welding equipment, welding equipment, auxiliary welding equipment, etc., and can solve the problems of large surface damage of towers, difficult control of adjustment force and adjustment accuracy, and high labor intensity of adjustment operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

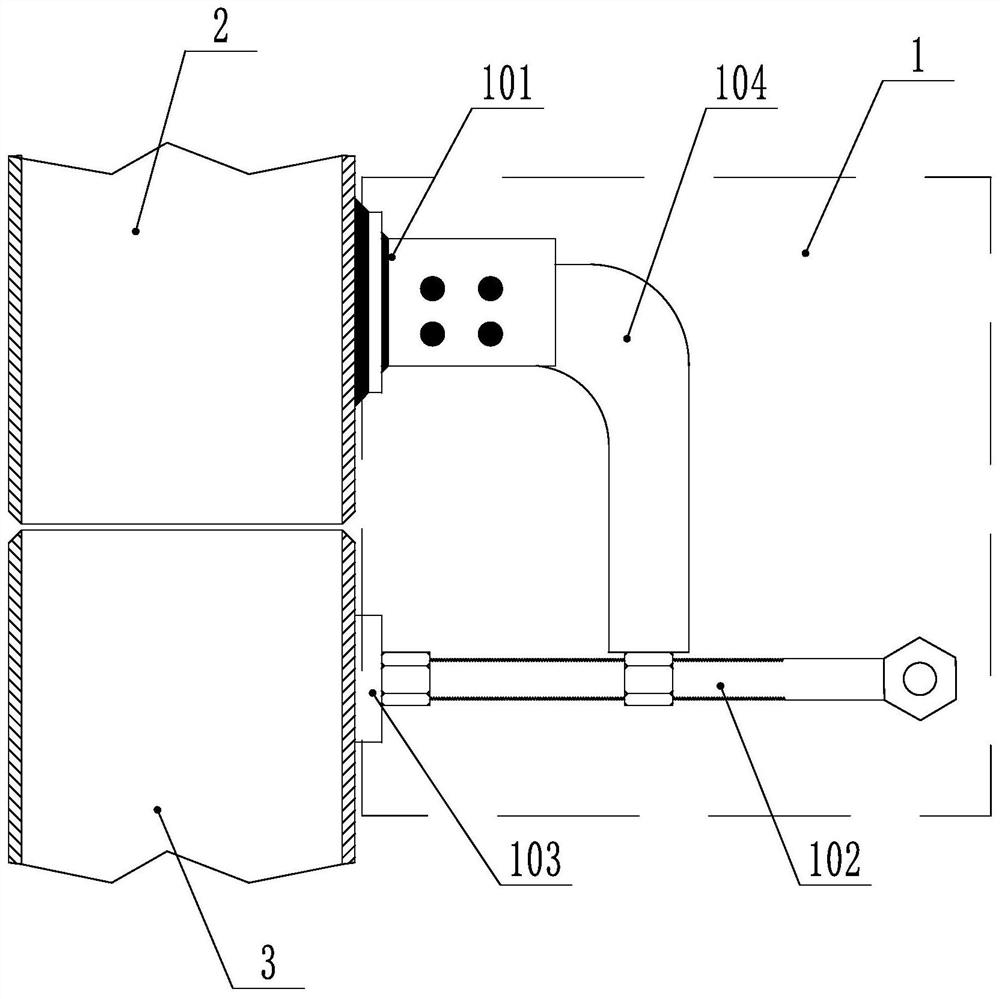

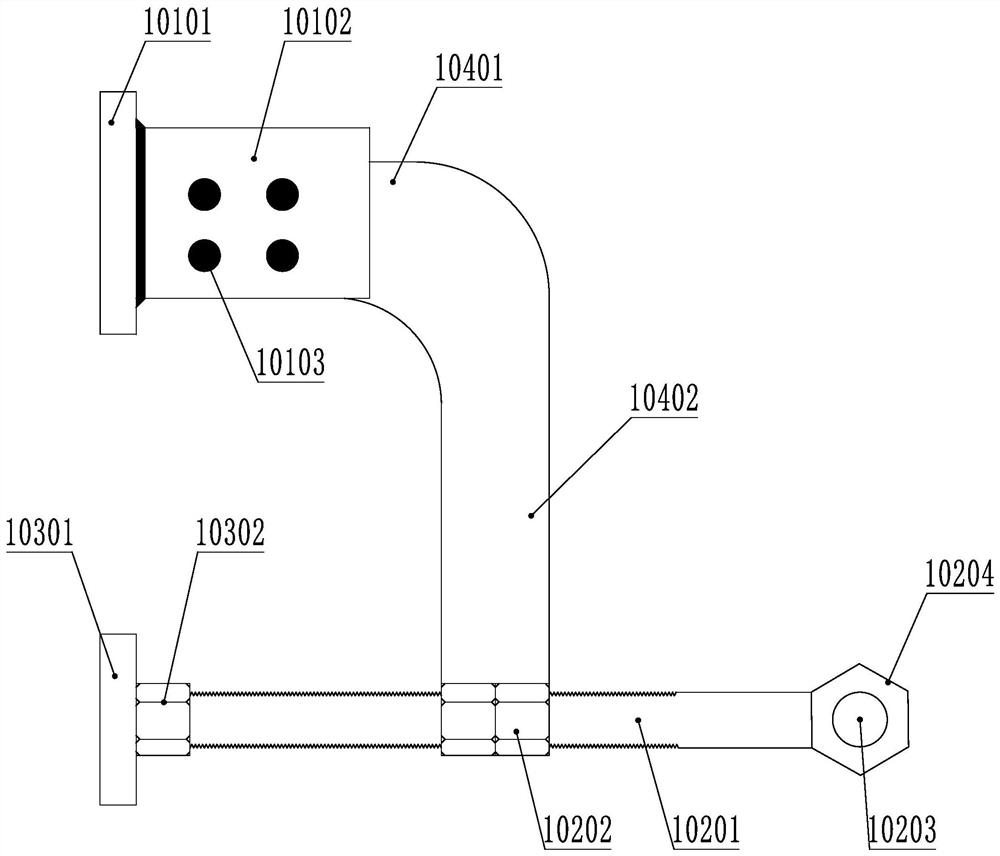

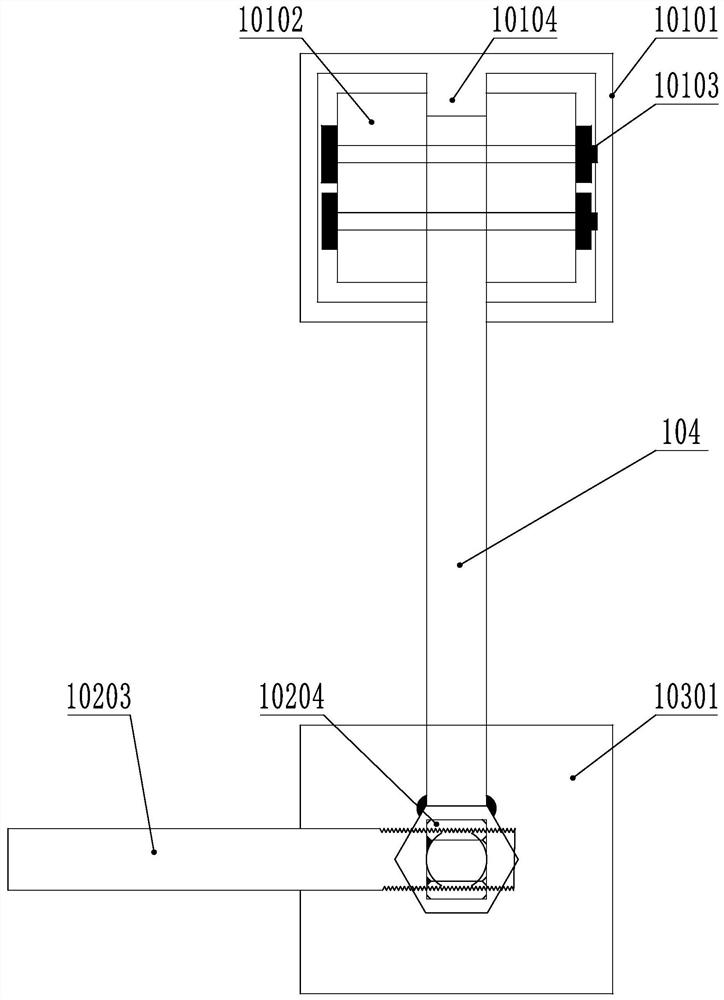

[0033] The technical solutions of the present invention will be further described in detail below with reference to the accompanying drawings.

[0034] like Figure 1-3As shown in the figure, an adjustable tower equipment assembly pair tooling, the tower equipment includes a first tower body 2 and a second tower body 3 that needs to be docked and combined with the first tower body 2, and the assembly pair tooling 1 includes a connecting assembly 101, a support Assembly 103, bracket and adjusting assembly 102. The connecting assembly 101 includes a connecting plate 10101 and a connecting clip 10102. The adjusting assembly 102 includes an adjusting screw 10201, an adjusting nut 10202 and a rotating handle 10203. The support 104 is L-shaped, including a horizontal portion 10401 and a The horizontal part 10401 is integrally connected to the vertical part 10402, the connecting plate 10101 is connected and fixed to the horizontal part 10401 of the connecting clip 10102 of the bracke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com