Inter-section scale inhibition method for centrifugal natural gas compressor set

A natural gas and centrifugal technology, which is applied in the direction of machines/engines, mechanical equipment, non-variable pumps, etc., can solve the problems affecting the production of light hydrocarbons affecting natural gas sales, reduced work efficiency, automatic protection shutdown, etc., to overcome congenital deficiencies , increase productivity, increase the effect of export pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

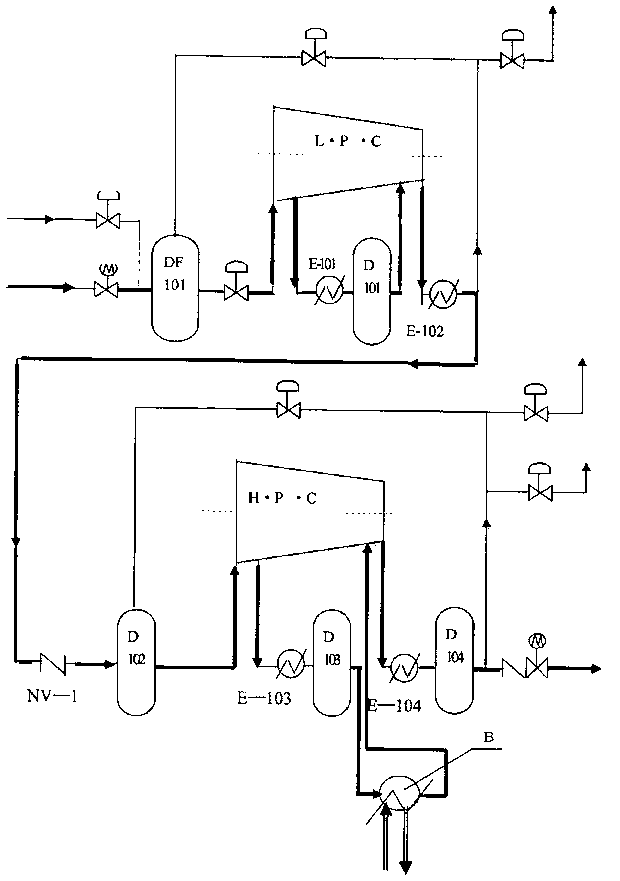

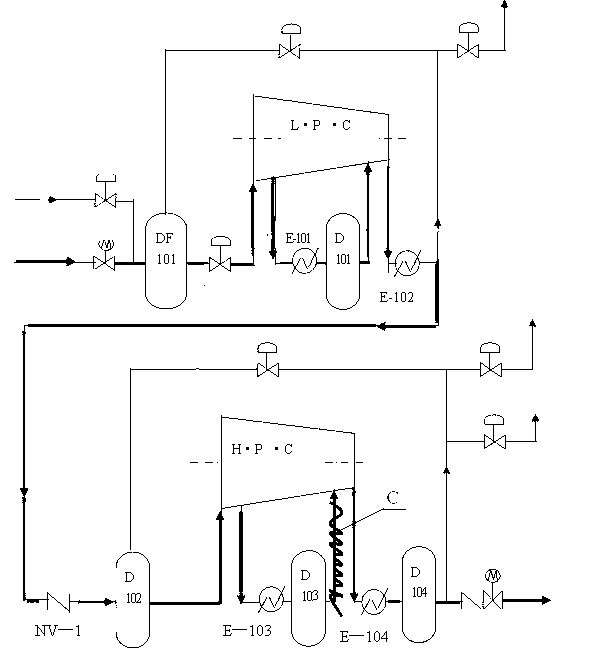

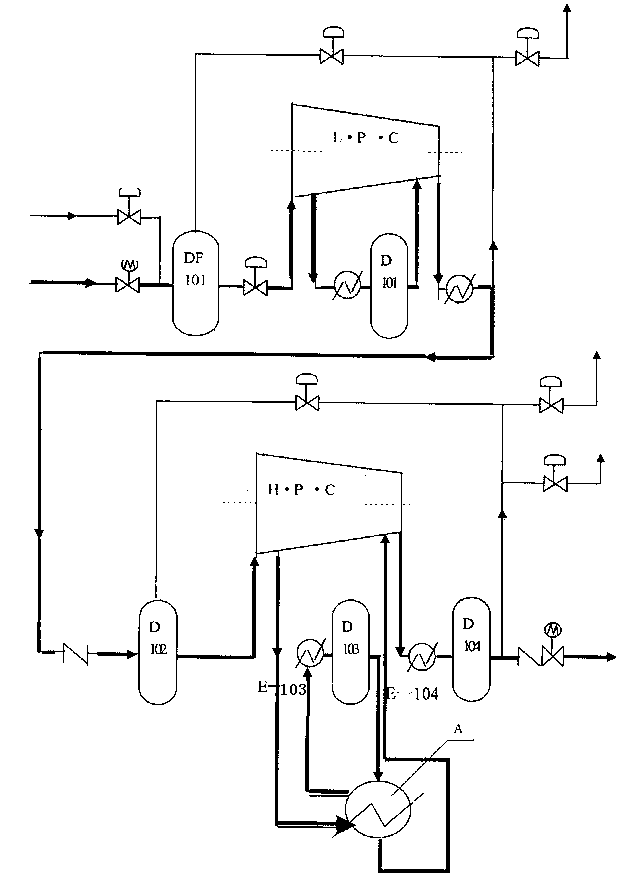

[0026] In order to further disclose the technical solutions of the present invention, the following detailed descriptions are given through embodiments in conjunction with the accompanying drawings in the description.

[0027] illustrate:

[0028] Taking the prevention of fouling in the fourth stage of centrifugal natural gas compressors as an example, through the above statistics, anatomy, analysis and research, the core problem of preventing the increase of fouling in the fourth stage of centrifugal natural gas compressor units is to increase the outlet of the separator at the outlet of the third stage. To the inlet temperature of the first-stage impeller in the fourth stage, the temperature is higher than the outlet temperature of the separator, and the critical temperature of water dew point and hydrocarbon dew point is not generated, so that water and hydrogen hydrocarbons in natural gas do not produce second condensate.

[0029] a. Add a heat exchanger A. The natural gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com