Formaldehyde-free flame-retardant plywood produced by using large albumen glue and preparation method

A soybean protein glue, plywood technology, applied in the preparation of animal glue or gelatin, protein adhesive, bonding of wooden veneers and other directions, can solve problems such as human injury, achieve high bonding strength, cost-effective, water resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: A formaldehyde-free flame-retardant plywood produced by using large protein glue, the plywood includes flame retardant soaked veneer, flame retardant mixed with soybean protein glue, glue coating, pre-pressing, hot pressing, sanding, veneering, polishing And other processes, in which in order to ensure the flame retardancy of the wood board, both the veneer and the adhesive are combined with the flame retardant, the water-soluble non-halogen flame retardant is used to soak the veneer, and the insoluble powder flame retardant is used for the adhesive mixture, so that the combination method can be more effective Guarantee the flame retardancy and water resistance of plywood.

[0026] The flame retardants used for soaking veneer are water-based non-halogen flame retardants, including monoguanidine phosphate, diguanidine phosphate, ammonium polyphosphate with a degree of polymerization lower than 20, silane coupling agent, soluble borate, potassium molybdate, wate...

Embodiment 2

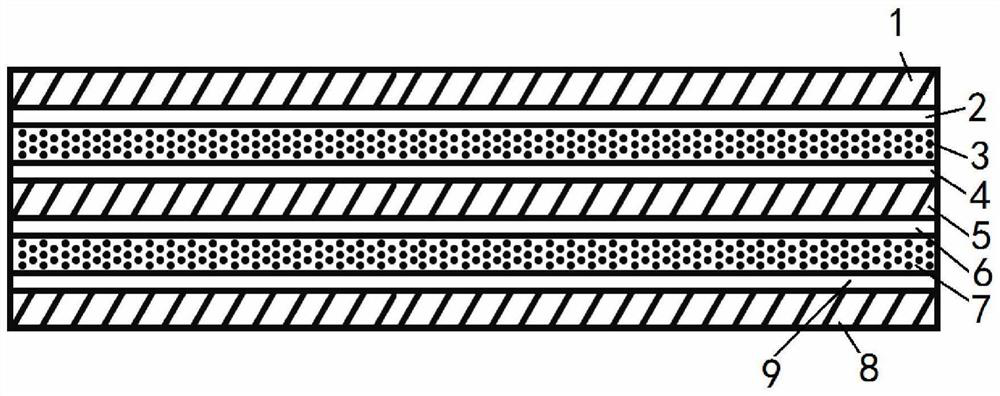

[0033] Embodiment 2: as figure 1 As shown, a formaldehyde-free flame-retardant plywood produced by using large protein glue, the first layer of transverse bark 1 is connected to one side of the first layer of longitudinal bark 2, and the other side of the first layer of longitudinal bark 2 is connected to the second layer A glue layer 3, the other side of the first glue layer 3 connects the second layer of longitudinal bark 4, the other side of the second layer of longitudinal bark 4 connects the second layer of transverse bark 5, the second layer of transverse bark 5 The other side of the third layer of longitudinal bark 6 is connected, the other side of the third layer of longitudinal bark 6 is connected to the second glue layer 7, and the other side of the second glue layer 7 is connected to the third layer of longitudinal bark 9, the second The other side of the three layers of longitudinal bark 9 is connected to the third layer of transverse bark 8 .

[0034] The transve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com