Patents

Literature

373results about How to "Solve the problem of air leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

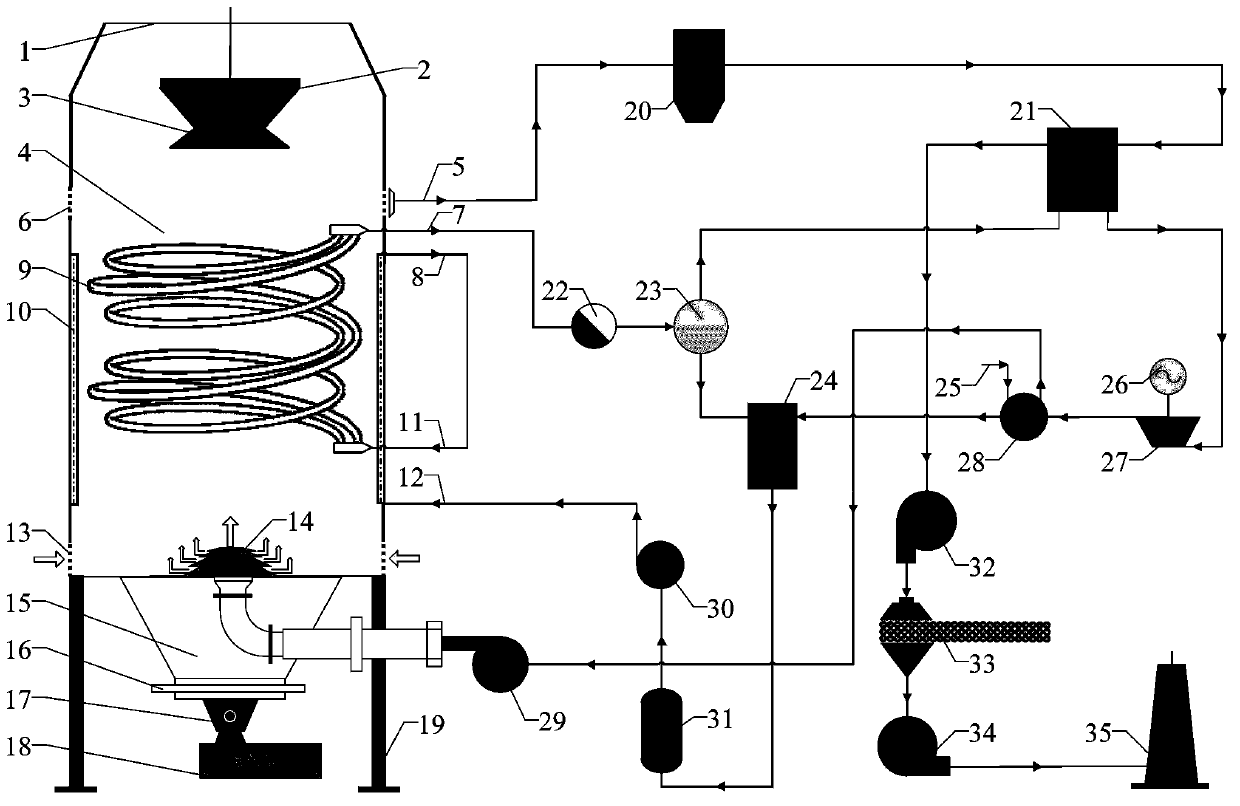

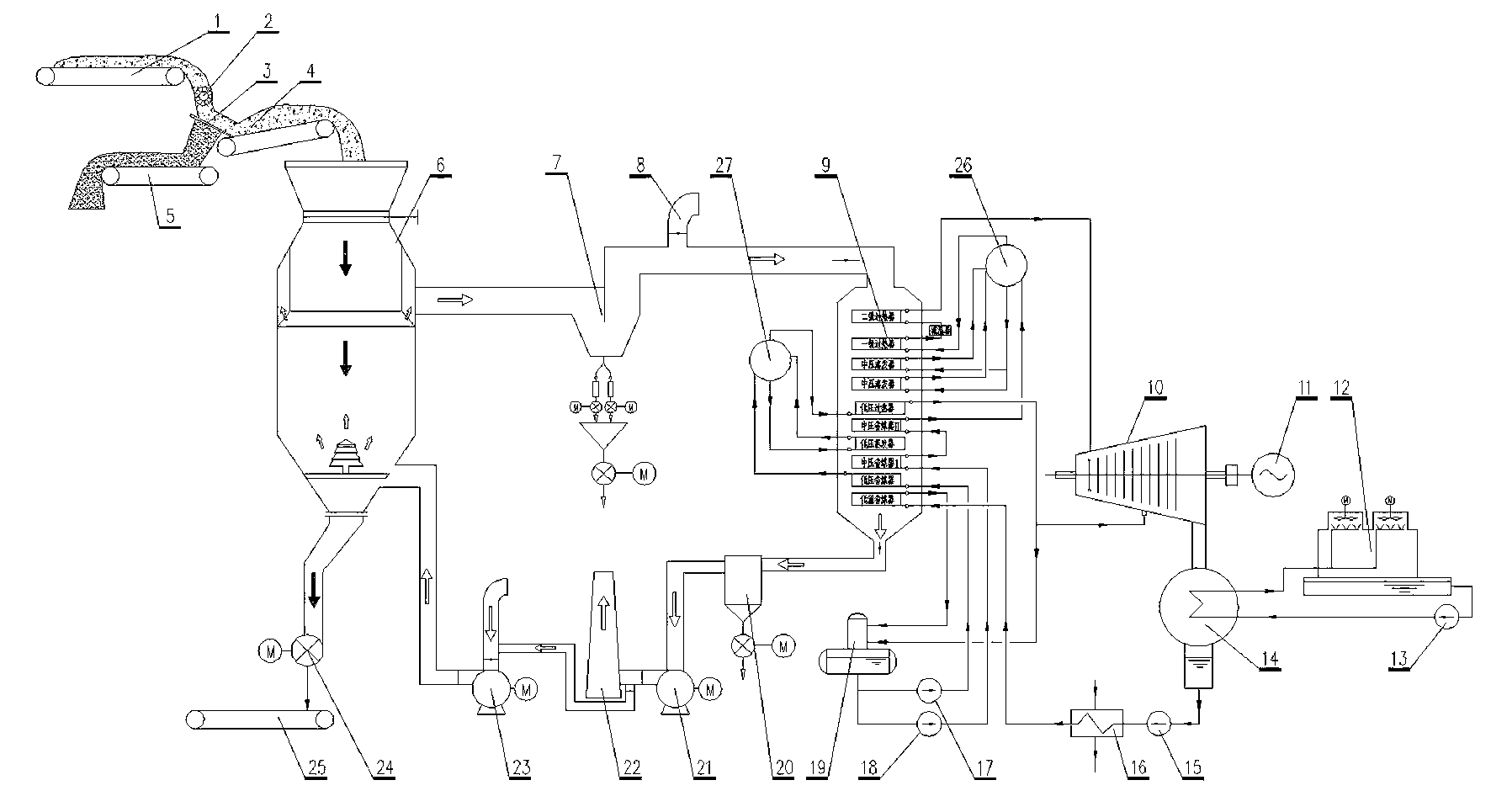

Grading recycling and cascade utilization method of residual heat resources in sintering process and device thereof

ActiveCN101655320AOvercome congenital deficienciesSolve the problem of air leakageLiquid degasificationIncreasing energy efficiencyThermodynamicsEngineering

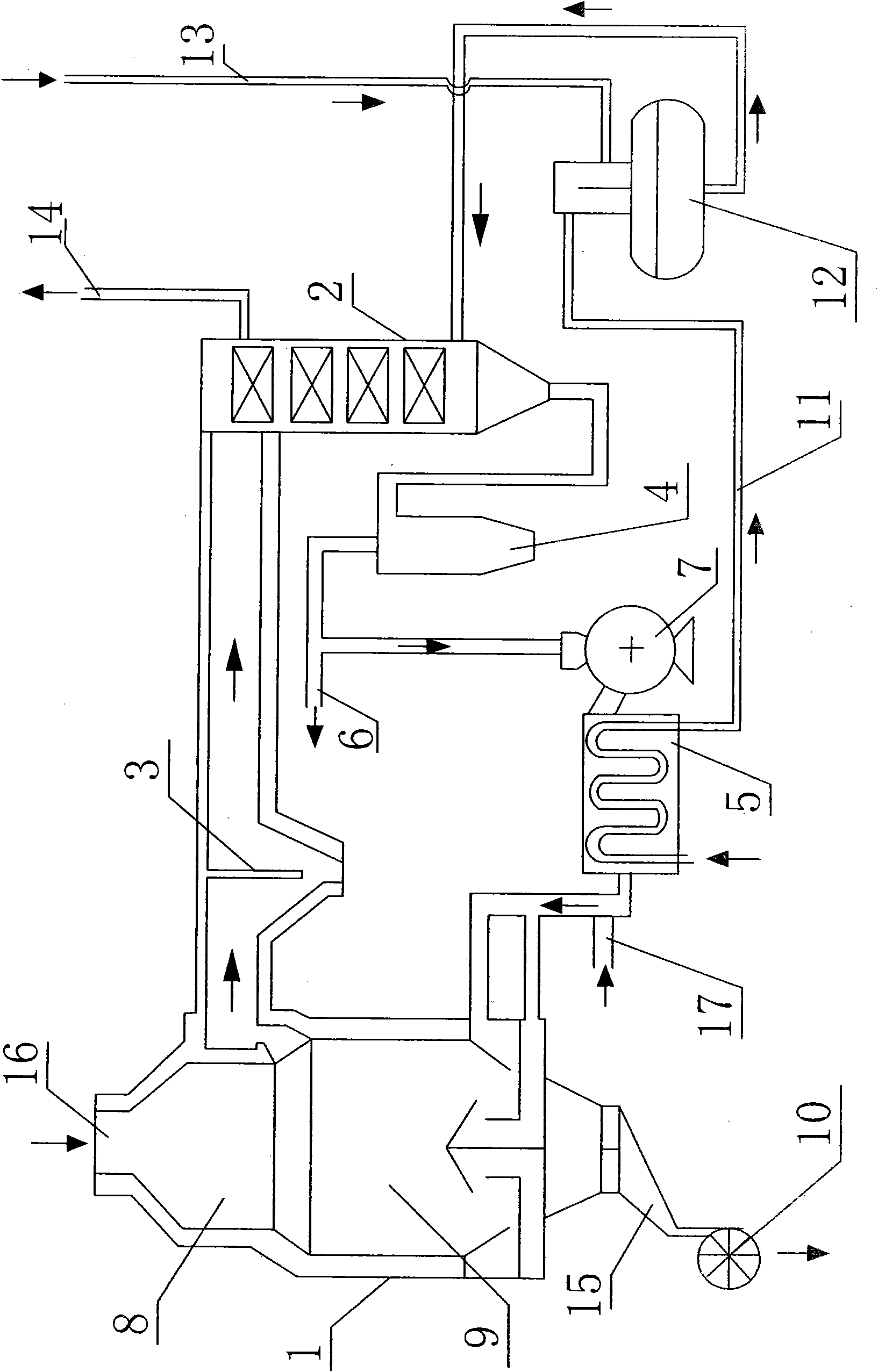

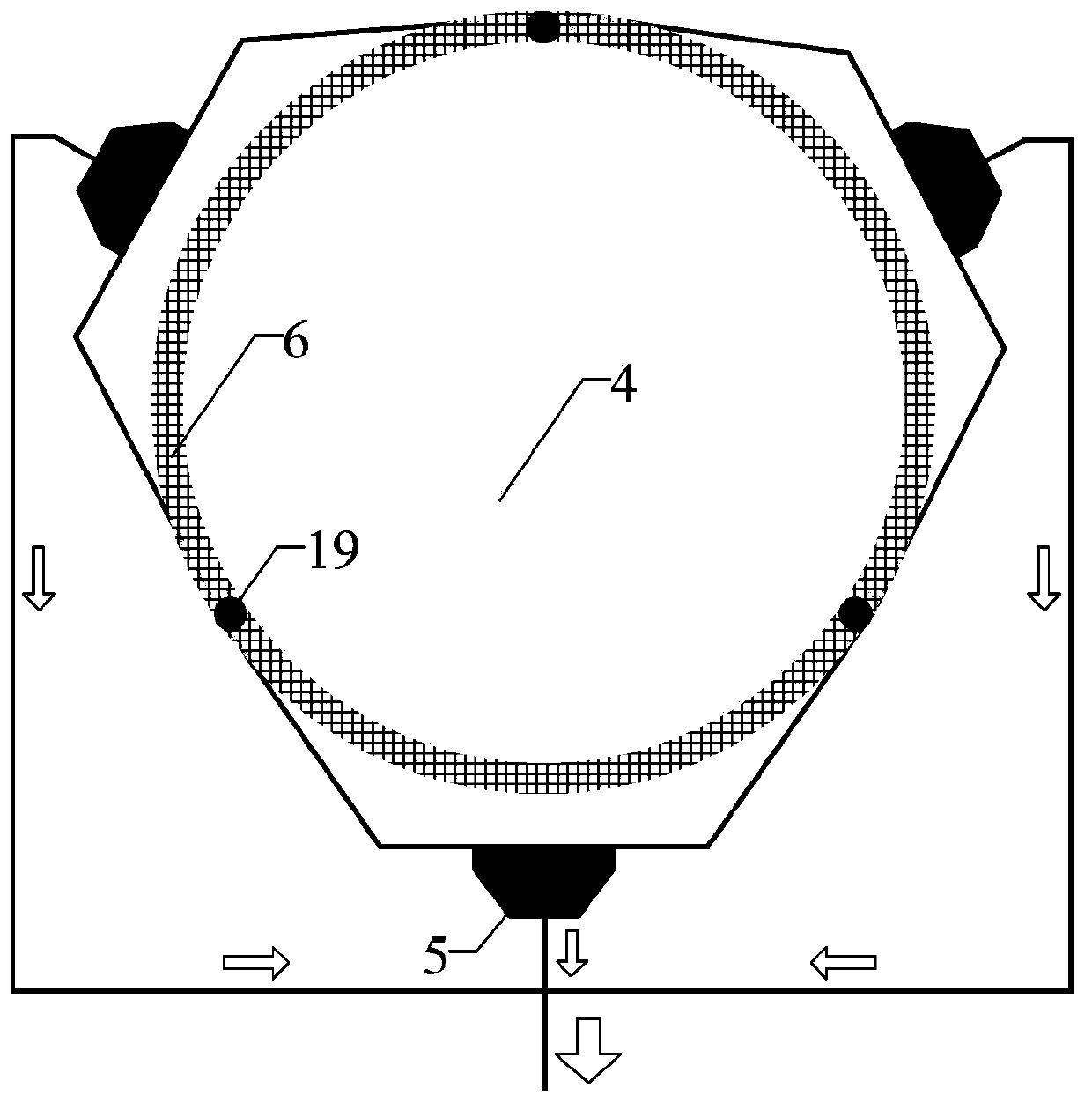

The invention relates to a method for effectively recycling and utilizing residual heat resources in a sintering process and a device thereof. The invention has the main contents that a fiery sinter ore is filled in a vertical and sealed tank body, air is led from the tank body so as to cool the sinter ore, sensible heat of the sinter ore is almost totally carried by the air and is exhausted fromthe top of the tank body at the same time; and hot air is led into a residual heat boiler to generate steam to synchronously generate power. Compared with the prior sintering residual heat recycling and utilization technology, the invention has higher residual heat recycling utilization ratio, effectively reduces the energy consumption of the sintering procedure with reasonable and effective method, simple apparatus and easy operation, and is relatively favorable for popularization and application in the technical field of residual heat resource recycling and utilization in a metallurgy process.

Owner:NORTHEASTERN UNIV

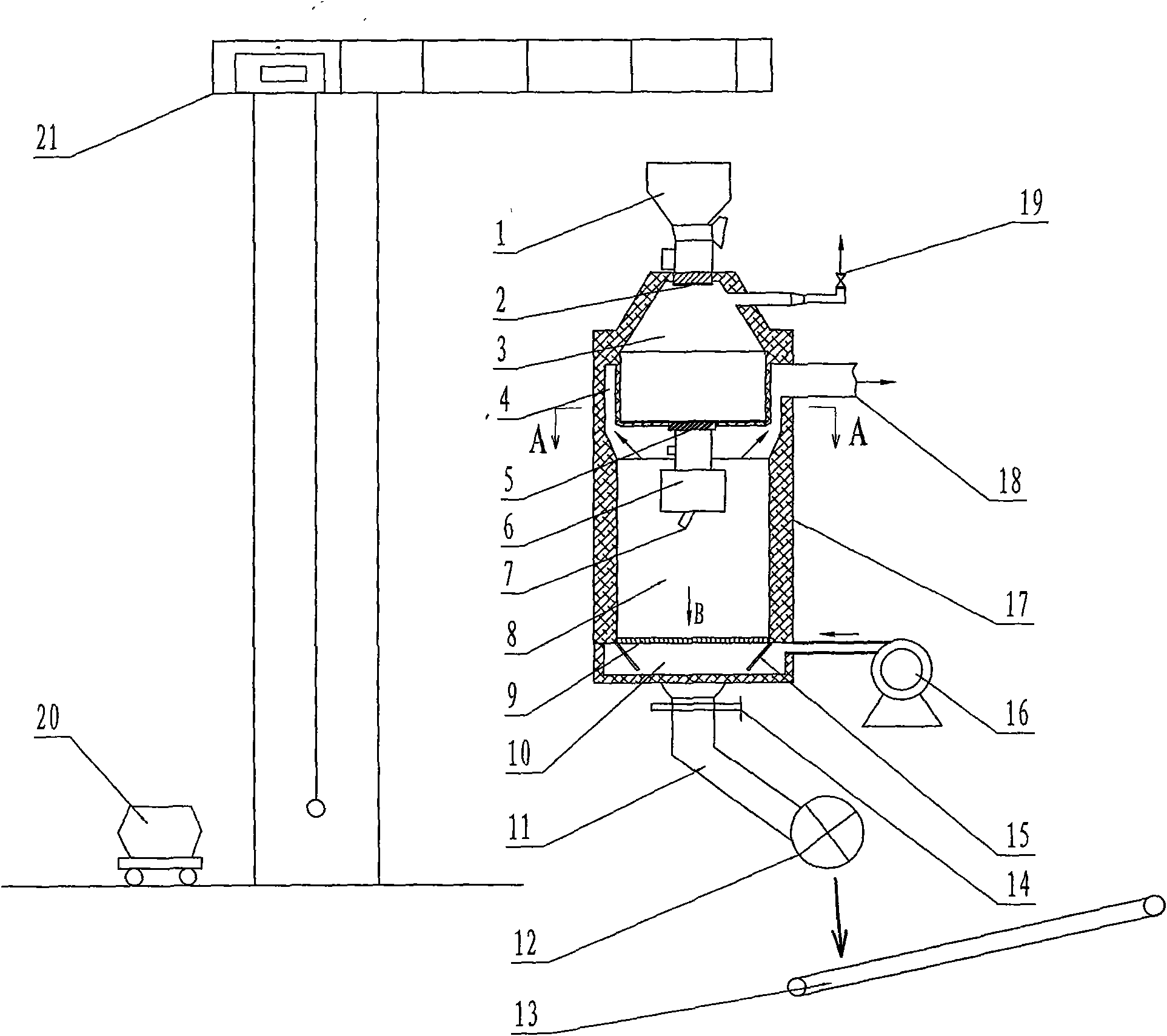

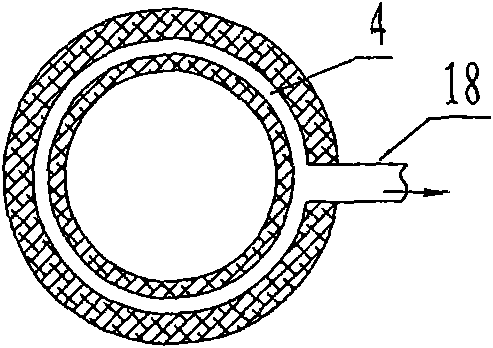

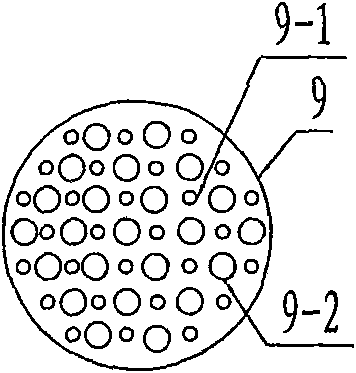

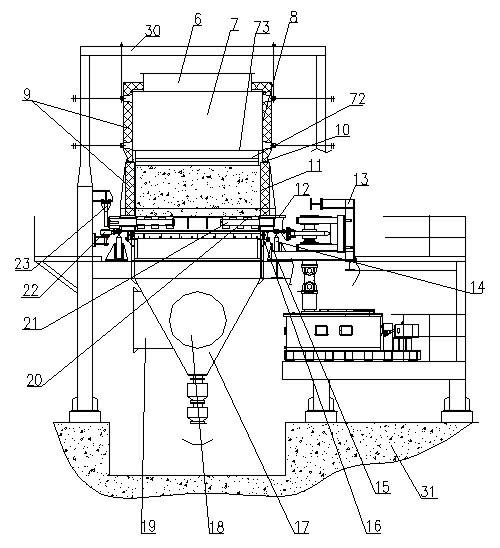

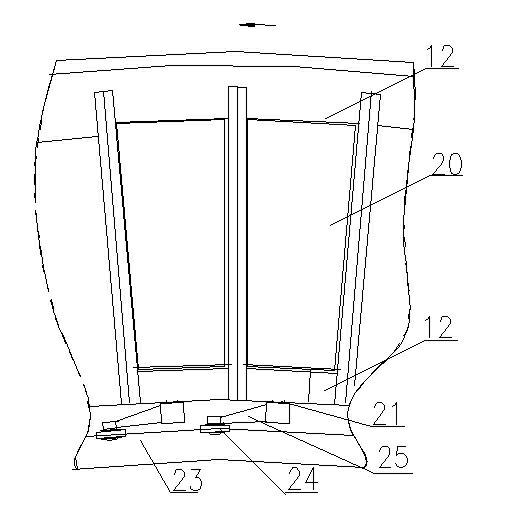

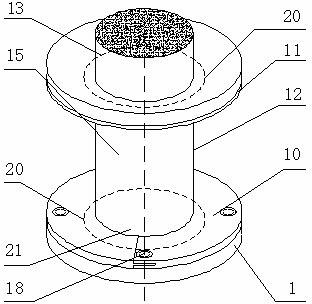

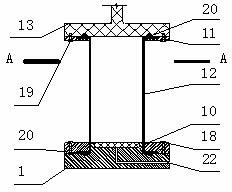

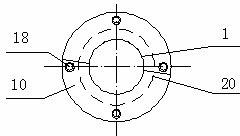

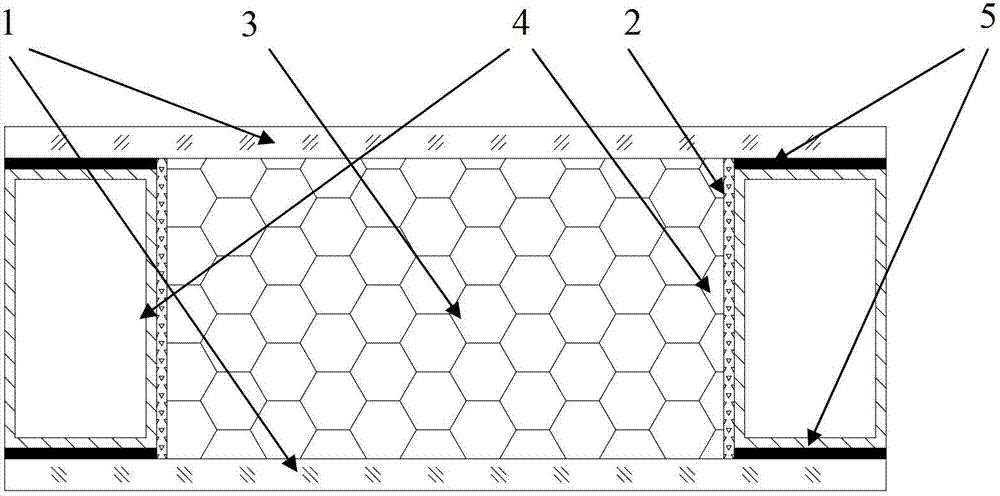

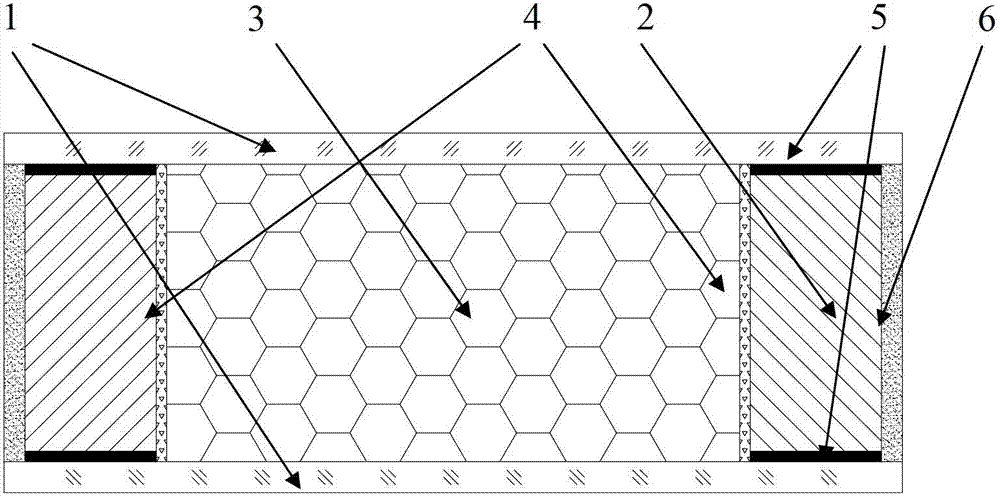

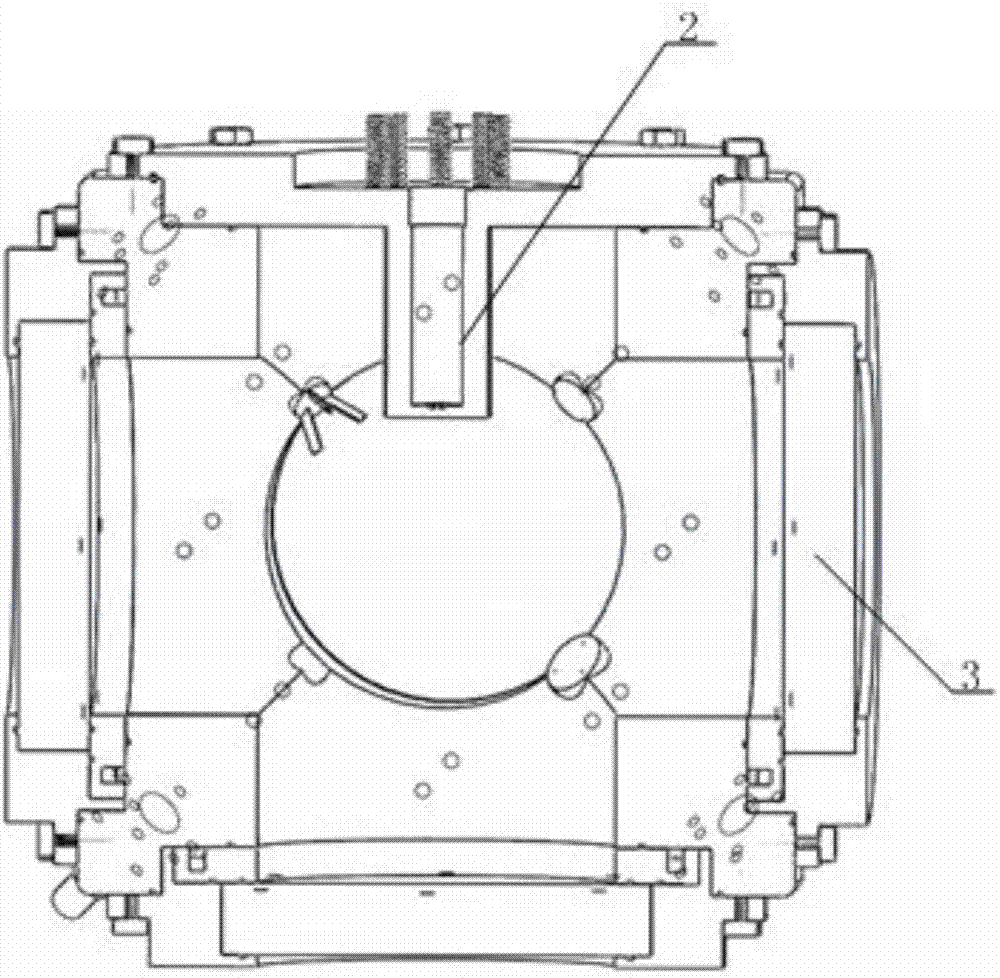

Vertical sinter ore cooling machine capable of efficiently recycling sensible heat of sinter ores

InactiveCN101576351AReduce heat transfer temperature differenceRaise the gradeIncreasing energy efficiencyHandling discharged materialGas solidMaterials science

The invention discloses a vertical sinter ore cooling machine capable of efficiently recycling the sensible heat of sinter ores, which pertains to the technical field of sintering equipment and is used for preventing air leak in the cooling course of sinter ores and effectively recycling the sensible heat of the sinter ores. The technical proposal of the invention is that: the cooling machine consists of a feeding part, a cooling part and a conveying part; the cooling part comprises a vertical closed body, a hot wind pipeline, a blower, as well as a hopper, an upper sealing valve, a pre-storing chamber, a lower sealing valve, a heat exchanging chamber, a wind distributing board, an isopiestic wind chamber and a discharging channel which are in sequence arranged on the body from top to bottom; an annular wind chamber is arranged between the pre-storing chamber and the heat exchanging chamber; the annular wind chamber is communicated with the hot wind pipeline; the isopiestic wind chamber is communicated with the blower; and wind shields and ore falling openings are distributed evenly on the wind distributing board . The vertical sinter ore cooling machine has the following advantages of: 1. an air leak rate near to 0; 2. improved gas-solid heat exchange efficiency of the cooling machine; 3. raised quality of the recycled hot air; and 4. being beneficial to increasing the utilization rate of exhaust-heat boilers. Based on the advantages, the vertical sinter ore cooling machine is expected to be used commonly as an upgraded replacement of the existing sinter cooling machine.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

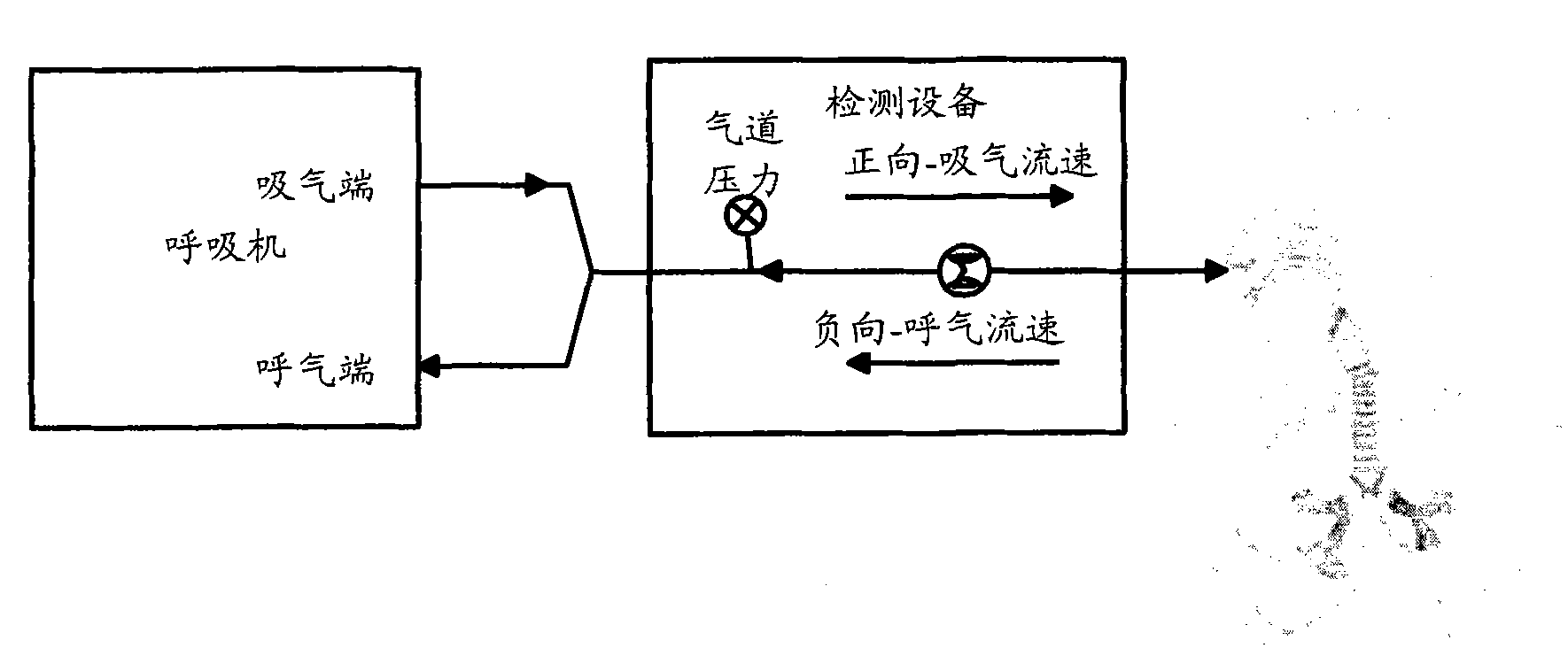

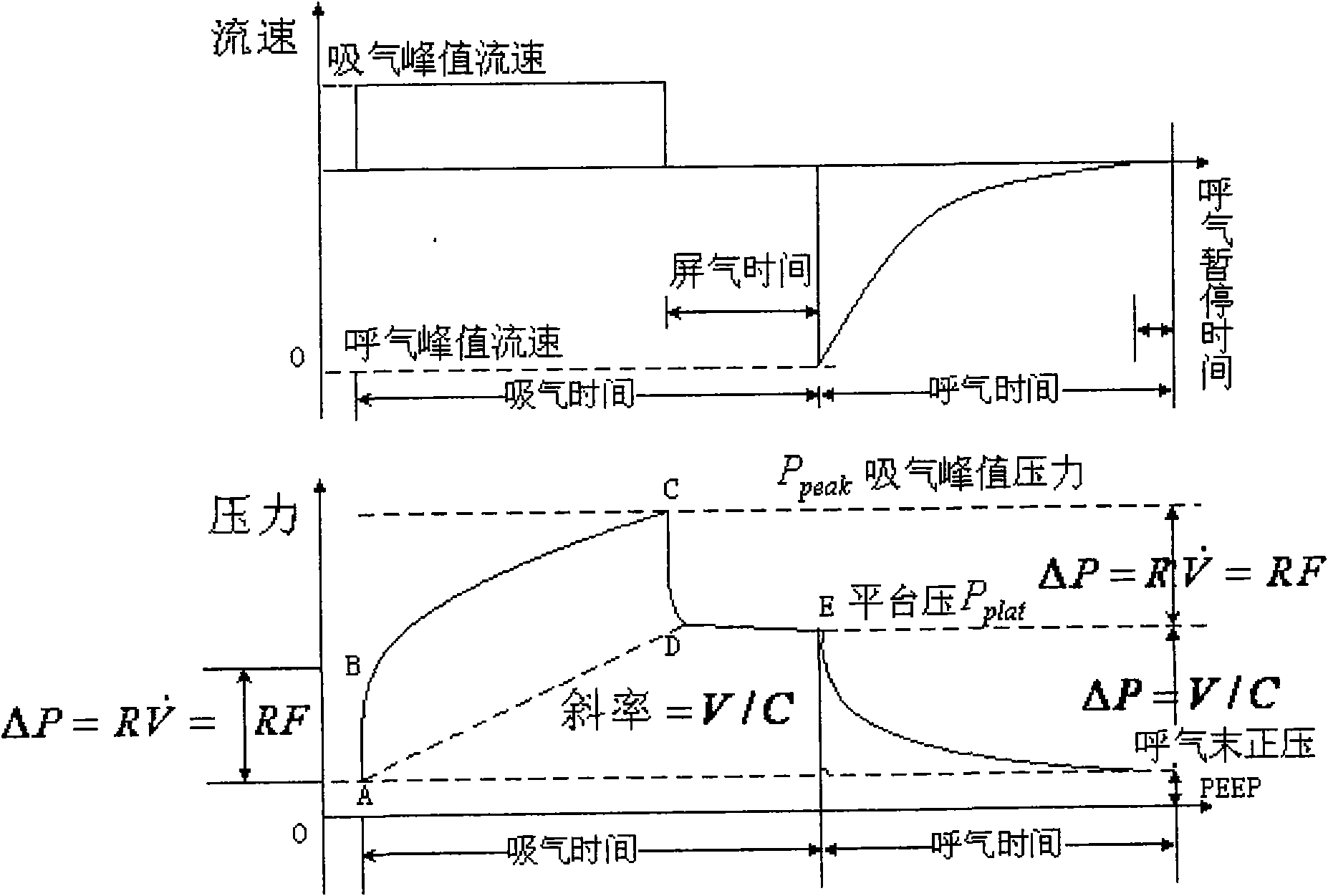

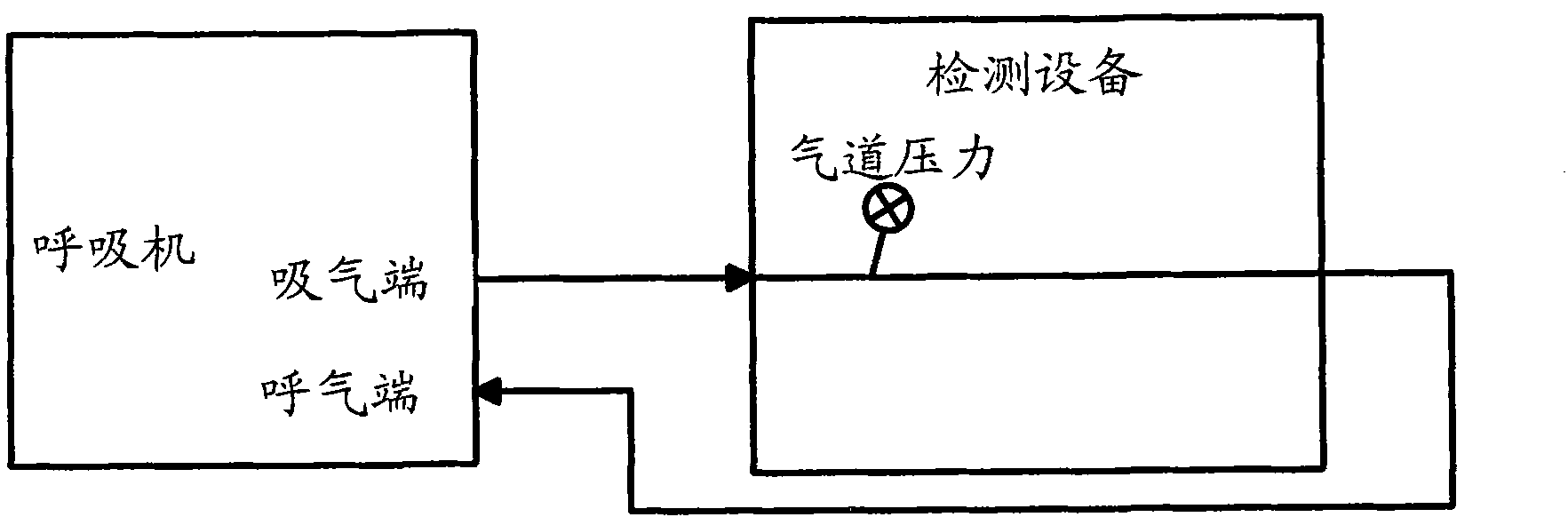

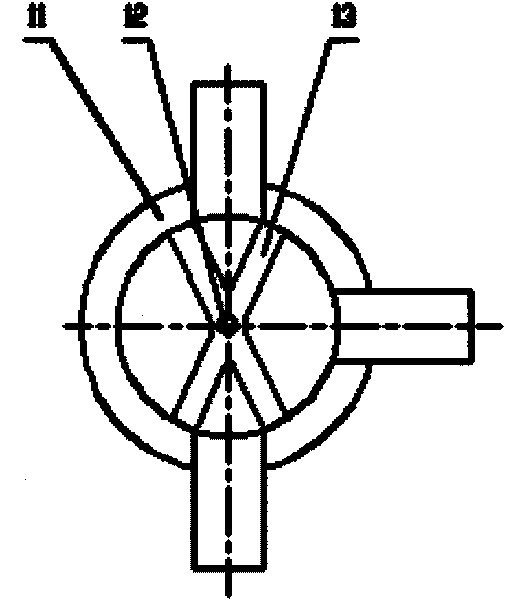

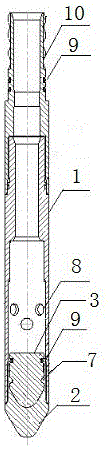

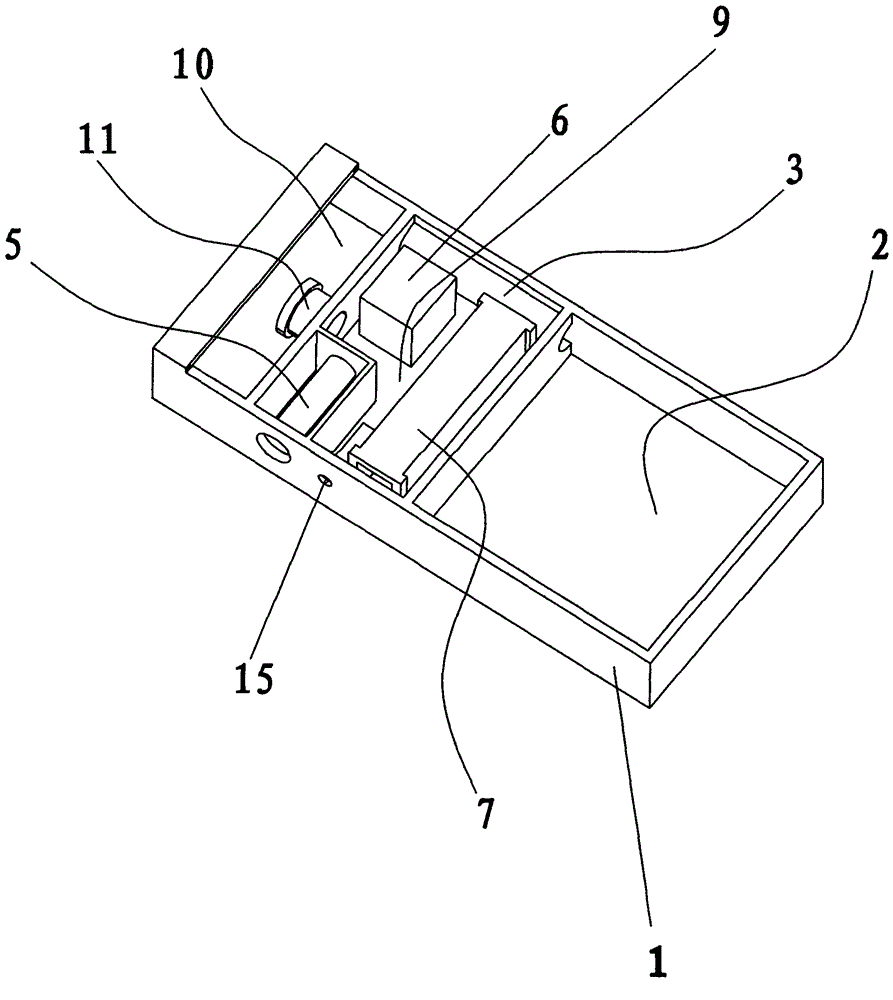

Method, device and system for detecting breathing machine

ActiveCN102114290ASolve the problem of air leakageSolve real-timeRespiratorsIron-lungsMedicineBreathing process

The invention discloses a method, device and system for detecting a breathing machine. The device comprises a simulated lung 10, a gas pressure sensor 8, a first gas passage 11 and a second gas passage 12, wherein the gas pressure sensor 8 is arranged in a third gas passage 13 which is connected with the simulated lung 10, and is used for detecting the gas pressure in the third gas passage 13; one end of the first gas passage 11 is connected to the third gas passage 13, and the other end of the first gas passage 11 is connected to an inspiration end 1 of the breathing machine; one end of the second gas passage 12 is connected to the third gas passage 13, and the other end of the second gas passage 12 is connected to an expiration end 2 of the breathing machine; and a first gas flow rate sensor 5 and a second gas flow rate sensor 6 are respectively arranged in the first gas passage 11 and the second gas passage 12. By using the invention, various parameters of the breathing machine can be better detected.

Owner:BEIJING AEONMED

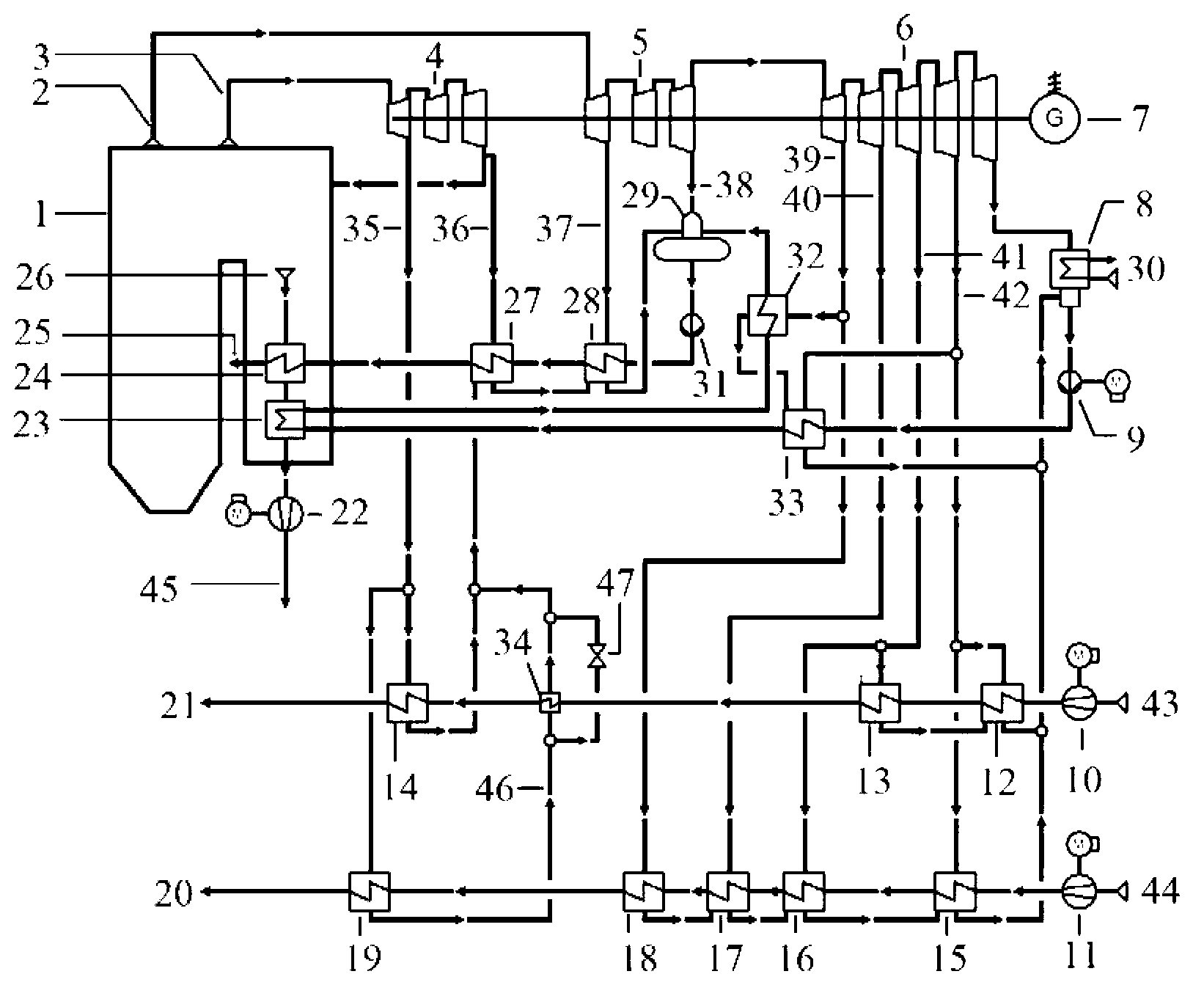

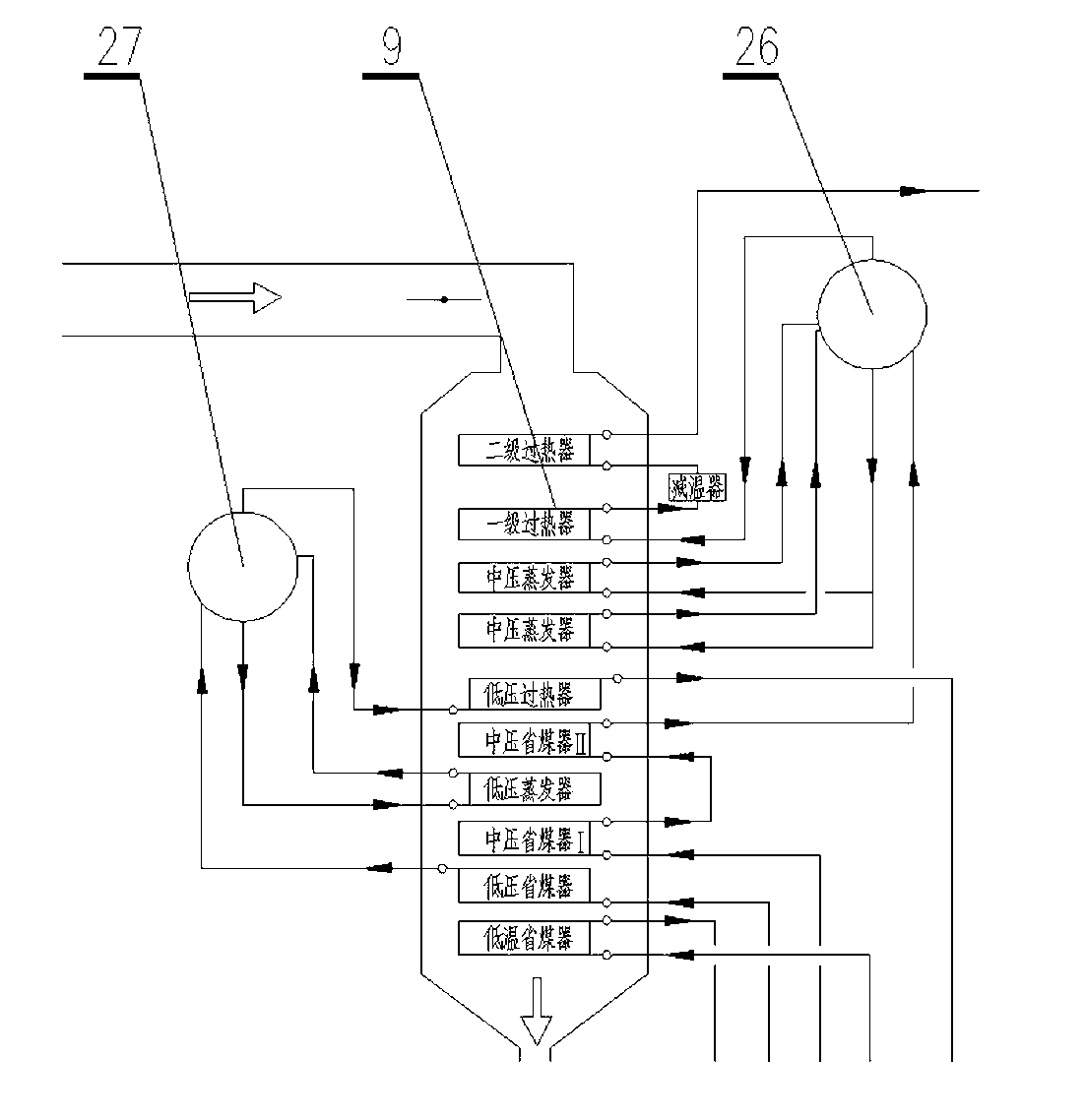

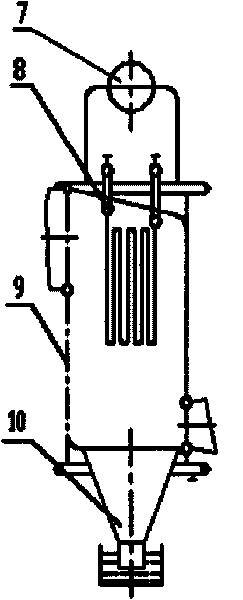

High-temperature material vertical cooler and waste heat using system

ActiveCN103424001AReduce breakageImprove yieldIncreasing energy efficiencyHandling discharged materialSuperheaterEngineering

The invention relates to a high-temperature material vertical cooler and a waste heat using system. The high-temperature material vertical cooler comprises a cylindrical machine body supported by a support, the lower portion of the machine body is a cold air input section, the middle portion of the machine body is a cooling section, and the upper portion of the machine body is a material input section. In the cooling section, materials are cooled by means of combination of air draft and air blowing, heat of the high-temperature materials is obtained by cooling air and a cooling pipe by means of heat conduction and conversion, and preheating is conducted on circulating water through a water cooling wall; the high-temperature cooling air is used for overheating steam generated by the vertical cooler and after the temperature of the cooling air is decreased, the cooling air is led to preheat sintering raw materials in a sintering machine; after air heated by a condenser is mixed with the cold air and the air is led to a central funnel cap; steam generated by the vertical cooler is led to a turbine to drive an electric generator to generate power after passing through a steam super-heater; water output by the condenser and a steam pocket is led to a deoxidizing machine for deoxidization and then is led to a water cooling wall so that circulation can be achieved. The high-temperature material vertical cooler is compact in structure, capable of greatly reducing air leakage of a system, guaranteeing the quality of the materials and effectively recycling the waste heat of the high-temperature materials in a stepped mode.

Owner:XI AN JIAOTONG UNIV

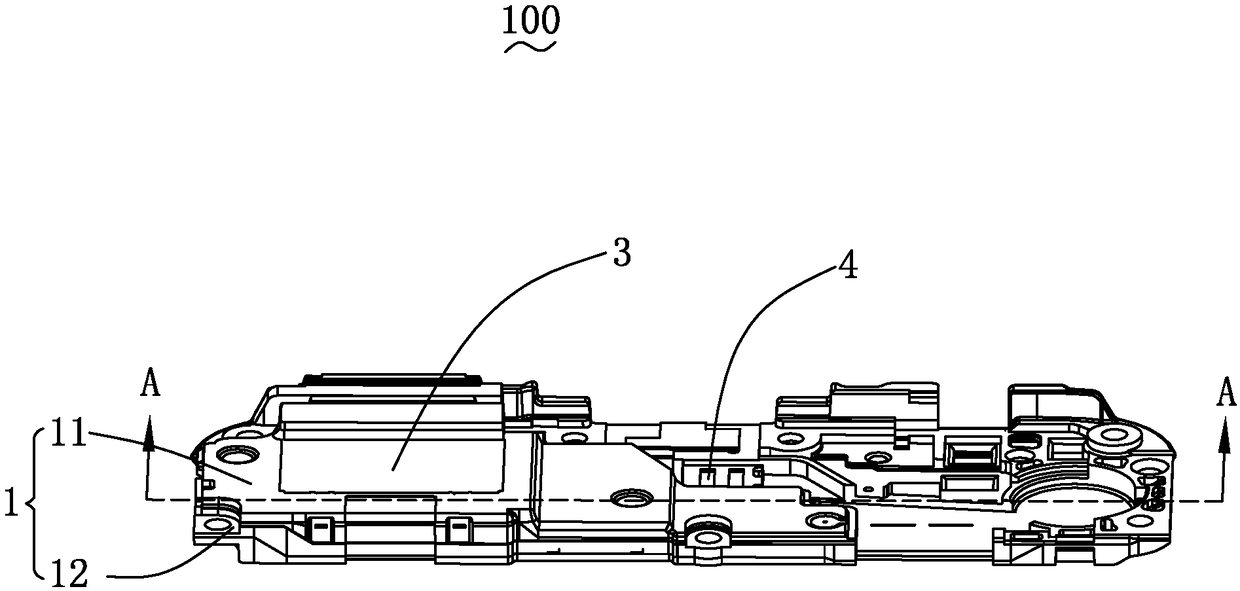

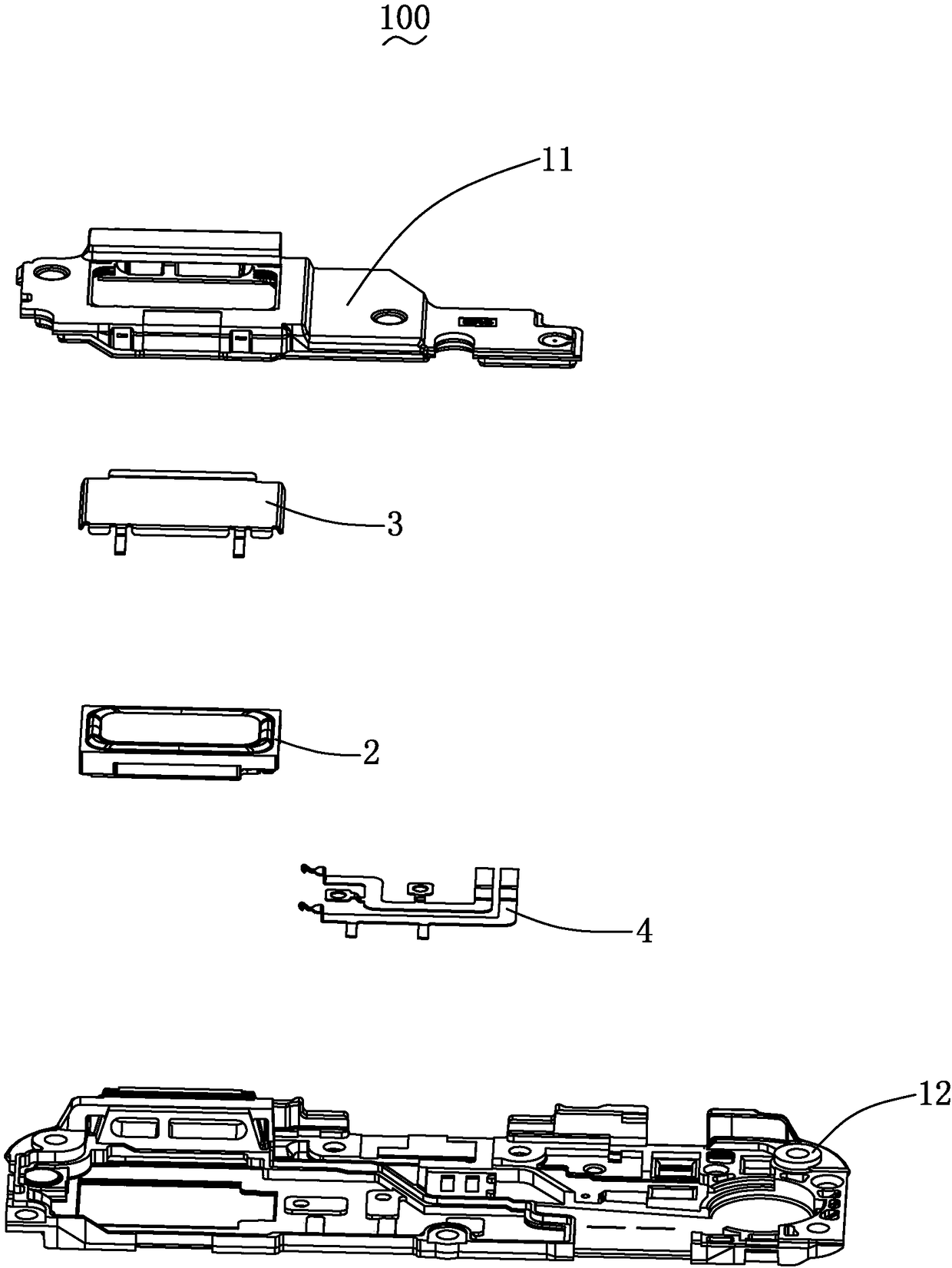

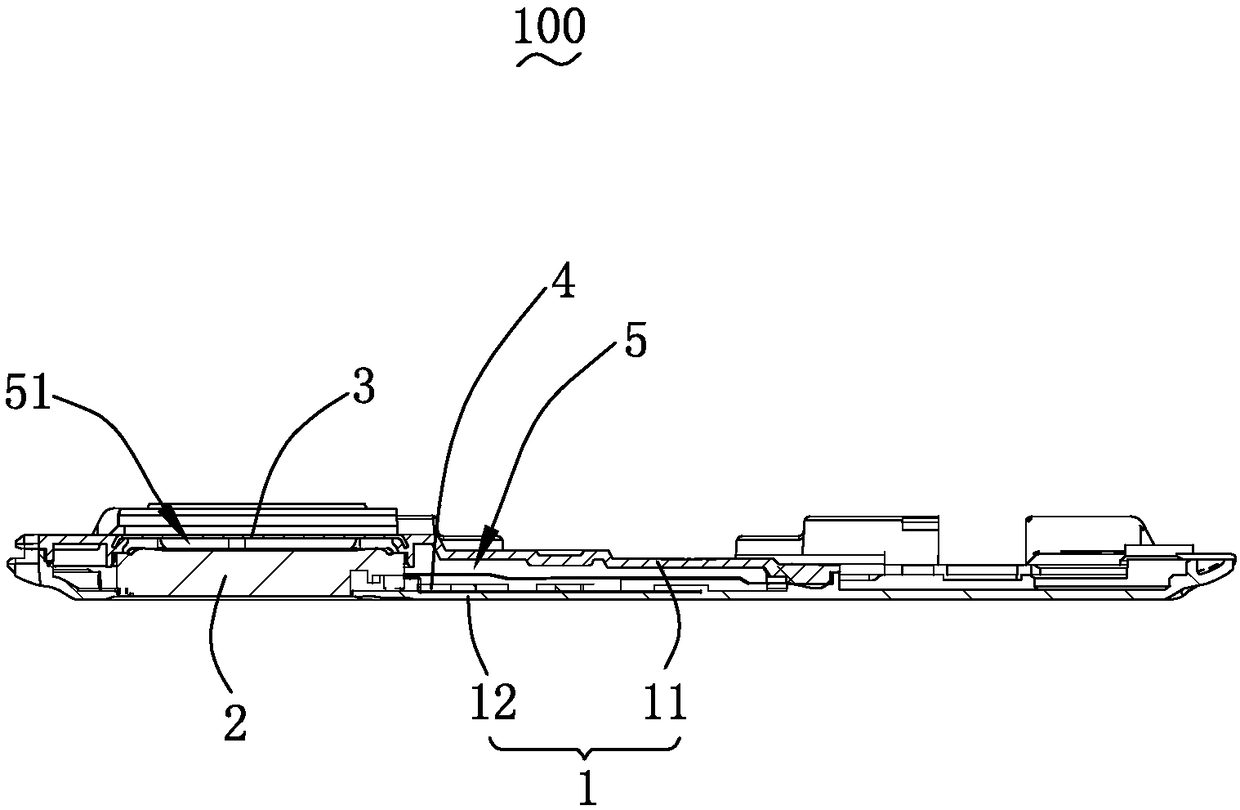

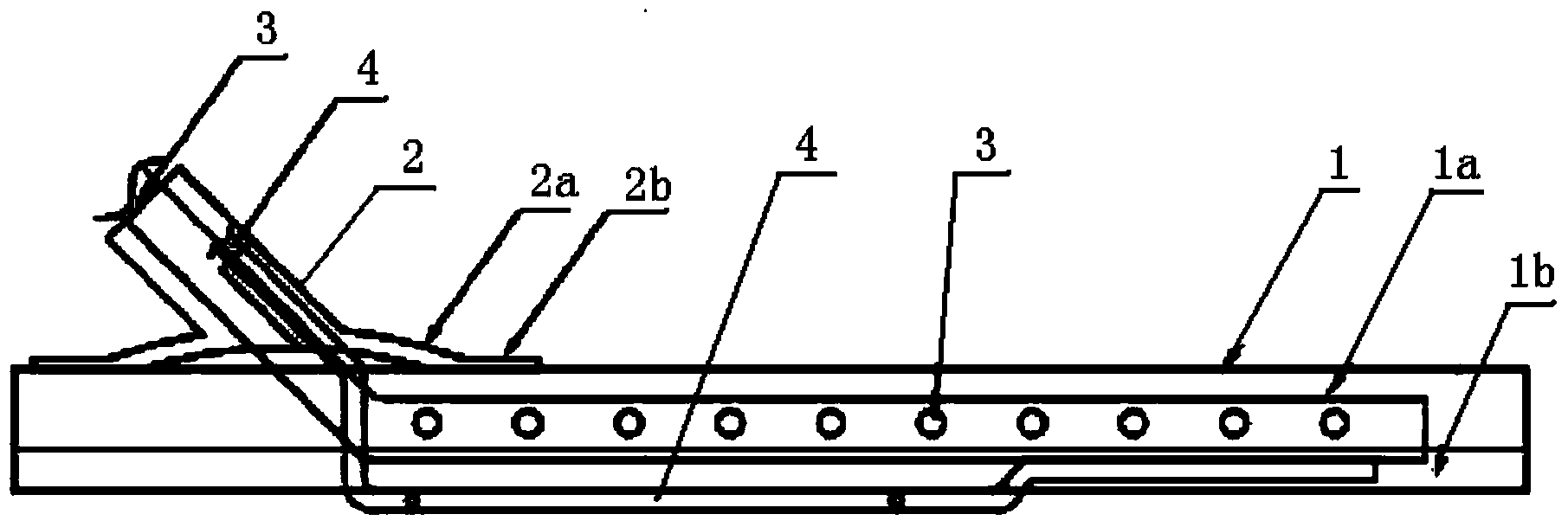

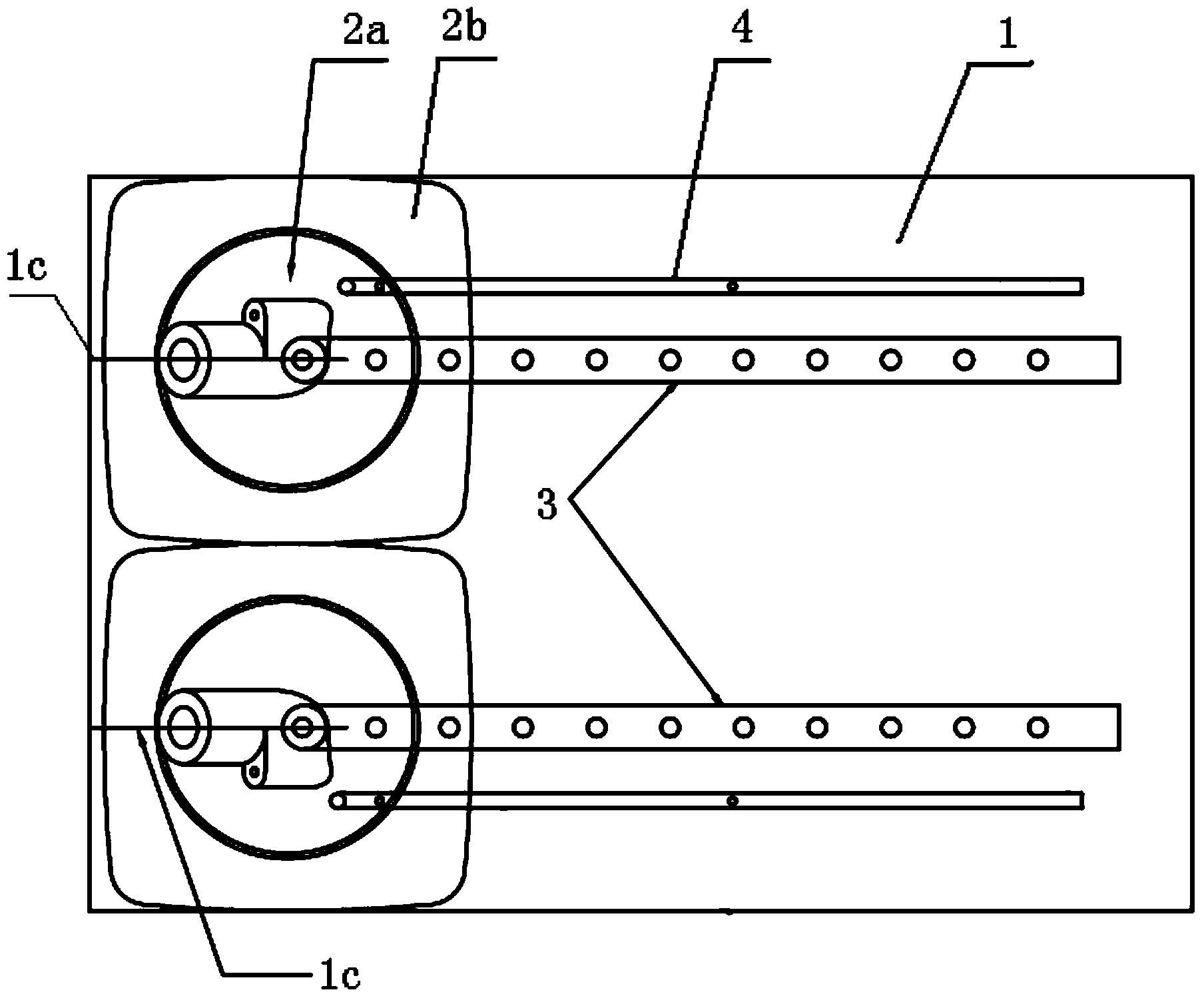

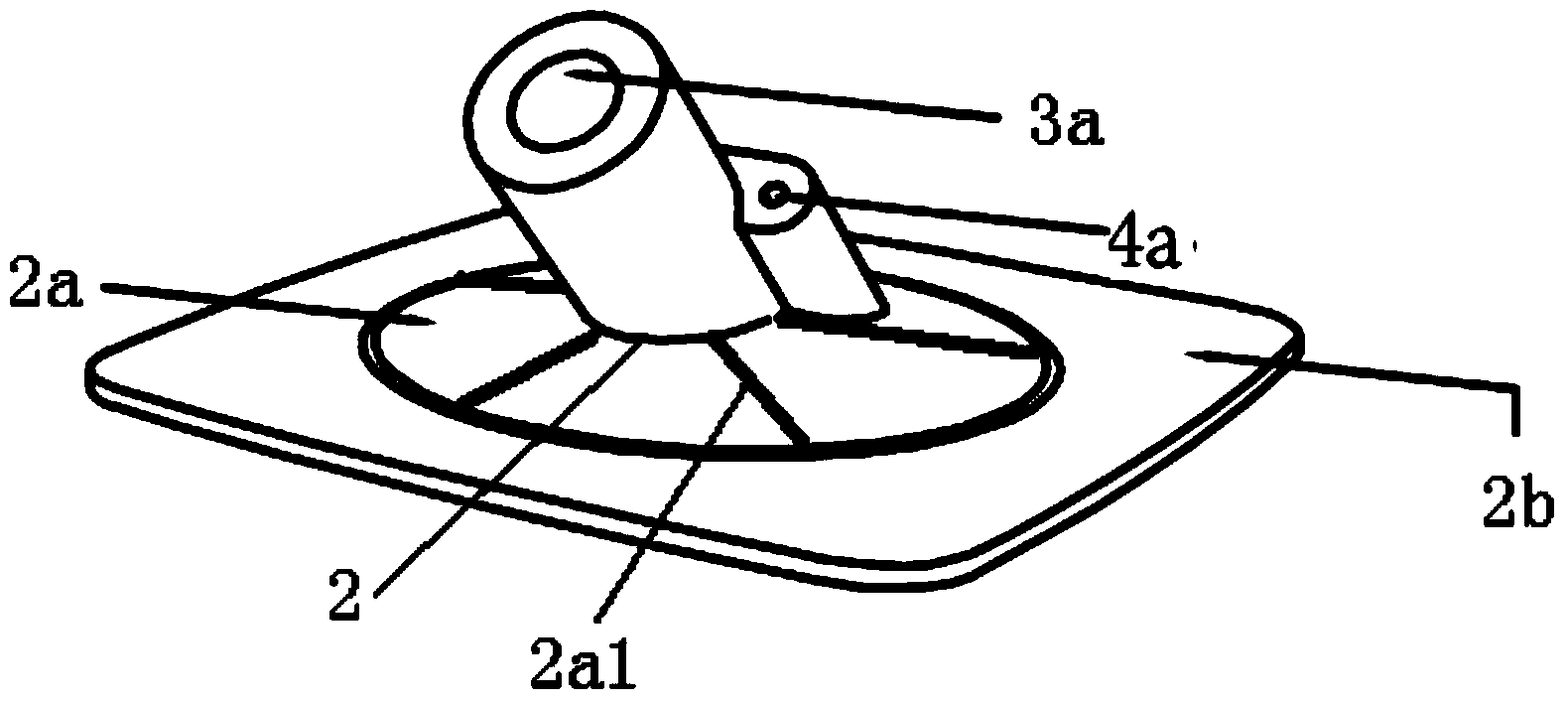

Loudspeaker box

InactiveCN108307277AHigh precisionImprove pass rateElectrical transducersLoudspeakersLoudspeakerSoldering

The invention provides a loudspeaker box. The loudspeaker box comprises a shell and a sound production monomer; the shell is provided with a containing space; the sound production monomer is containedin the containing space; the sound production monomer is provided with a bonding pad; the loudspeaker box further comprises a soldering lug; the soldering lug comprises a main body part, an elastic pin and a conductive terminal; the main body part is fixed on the shell by injection moulding; the elastic pin extends from the main body part; the conductive terminal is connected with the main body part; the elastic pin elastically abuts against the bonding pad; and the conductive terminal is electrically connected with an external circuit. Compared with the prior art, the loudspeaker box provided by the invention is as follows: the soldering lug fixed on the shell by injection moulding is connected to the sound production monomer and the external circuit; the steps of soldering, maintainingpressure, painting notch glue and the like can be avoided; compared with assembly, injection moulding is relatively high in fixation precision; the yield of the loudspeaker box is relatively high; a flexible circuit board is replaced by the soldering lug; the cost is reduced; the wire outlet groove of the flexible circuit board is cancelled; the gas leakage problem of the wire outlet groove is completely evaded; the elastic pin of the soldering lug is connected to the sound production monomer; and thus, the sound production monomer also can be contacted with the elastic pin of the external circuit without arrangement of the elastic pin.

Owner:AAC TECH PTE LTD

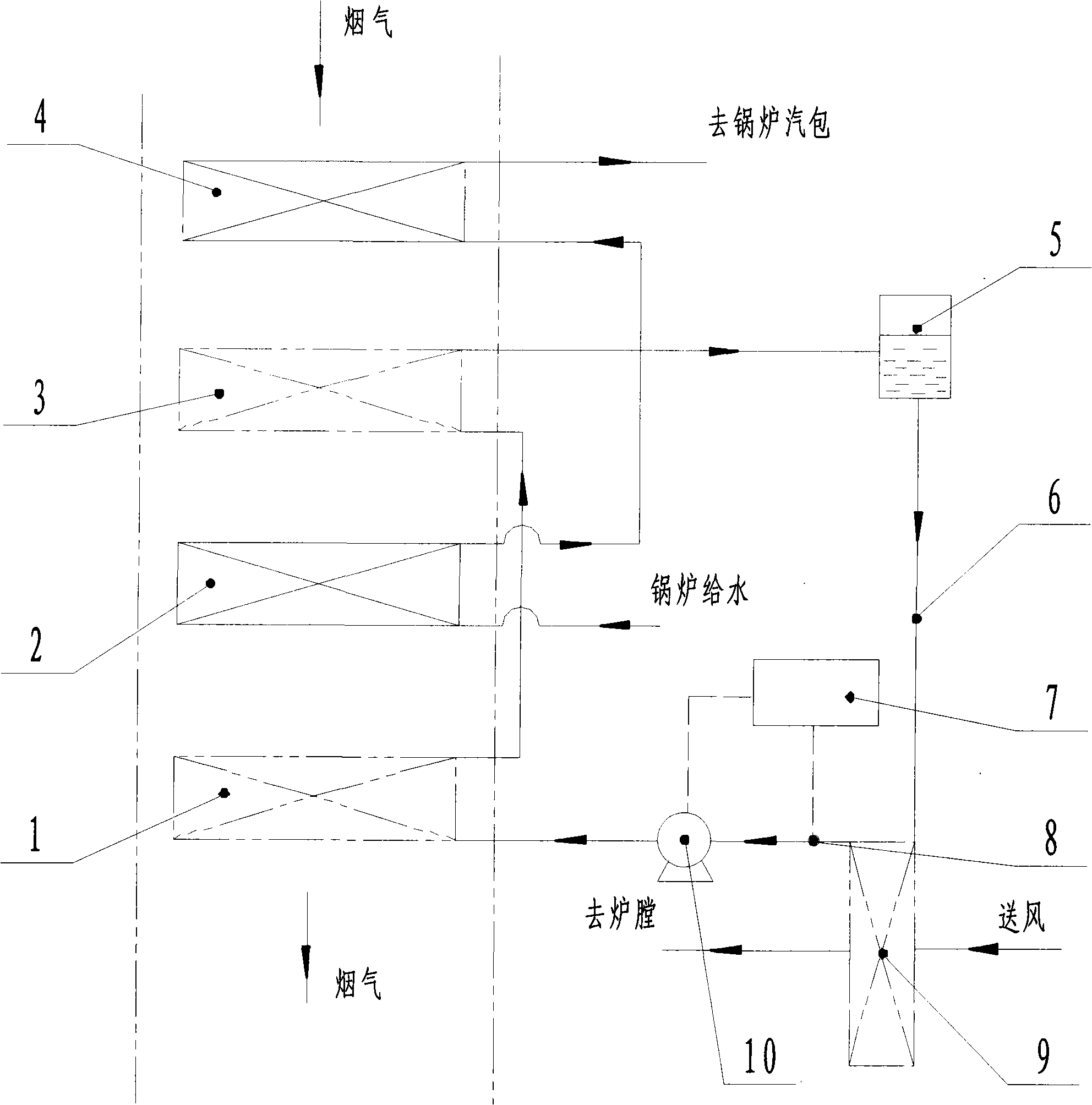

Air preheating system and method performing steam extraction by utilizing steam turbine

InactiveCN103244944AReduce running power consumptionReduce power consumptionFeed-water heatersEngineeringAir temperature

The invention relates to an air preheating system of a thermal power generator set, in particular to an air pre-heating system and method performing steam extraction by utilizing a steam turbine. In the system, a primary air preheating subsystem and a secondary air preheating subsystem are coupled with a boiler system and a steam turbine system of the thermal power generator set to form a novel boil feed water preheating system. Primary air is heated by a four-stage air heater and a first-stage drain water cooler to reach primary air rated temperature. Secondary air is heated by a five-stage air heater to reach a secondary air rated temperature. The air preheating system effectively solves the air leakage problem, reduces operation power consumption of a primary fan, a forced draught blower and an induced draft fan and improves the generating efficiency of a coal-fired power plant. In addition, the primary air temperature and the secondary air temperature can be flexibly adjusted by adjusting steam extraction volume of the air heaters and opening degree of a drain water by-pass valve.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Low-temperature-hot-stamped gold-stamped type tipping paper for cigarettes and preparation method of tipping paper

ActiveCN105200863AImprove efficiencyImproving hot stamping inaccuracySpecial paperInksAdhesive glueProcess engineering

The invention provides low-temperature-hot-stamped gold-stamped type tipping paper for cigarettes and a preparation method of the tipping paper. The low-temperature-hot-stamped gold-stamped type tipping paper for the cigarettes and the preparation method of the tipping paper are used for overcoming the disadvantages in existing high-temperature hot-stamping that the energy consumption is high, and that the rate of finished products is low and the cold hot-stamping effect is poor. The gold-stamped type tipping paper for the cigarettes, provided by the invention, is prepared through firstly printing environment-friendly alcohol-soluble white ink and printing ink on a base paper layer, then, additionally printing a layer of an adhesion-assisting glue material on the environment-friendly alcohol-soluble ink layer, then, carrying out low-temperature hot-stamping at the temperature of 85-100 DEG C, and carrying out laser boring, slitting and rewinding. According to the low-temperature-hot-stamped gold-stamped type tipping paper for the cigarettes, provided by the invention, an adhesion-assisting layer is additionally printed on the ink layer and has the functions of protecting the ink layer, enhancing the hydrophobicity of the ink layer and improving the adherence with a gold-stamped layer and the fastness of adhering of winding-adhesive glue, and special electrochemical aluminum hot-stamping foil for low-temperature hot-stamping is used in a matched manner, so that a low-temperature hot-stamping procedure can be completed at the temperature of 85-100 DEG C, and the energy consumption of a gold-stamping process is greatly lowered, and the service efficiency of a gold-stamping plate is increased, and thus the cost of gold-stamping is reduced.

Owner:玉溪接装纸制造有限公司

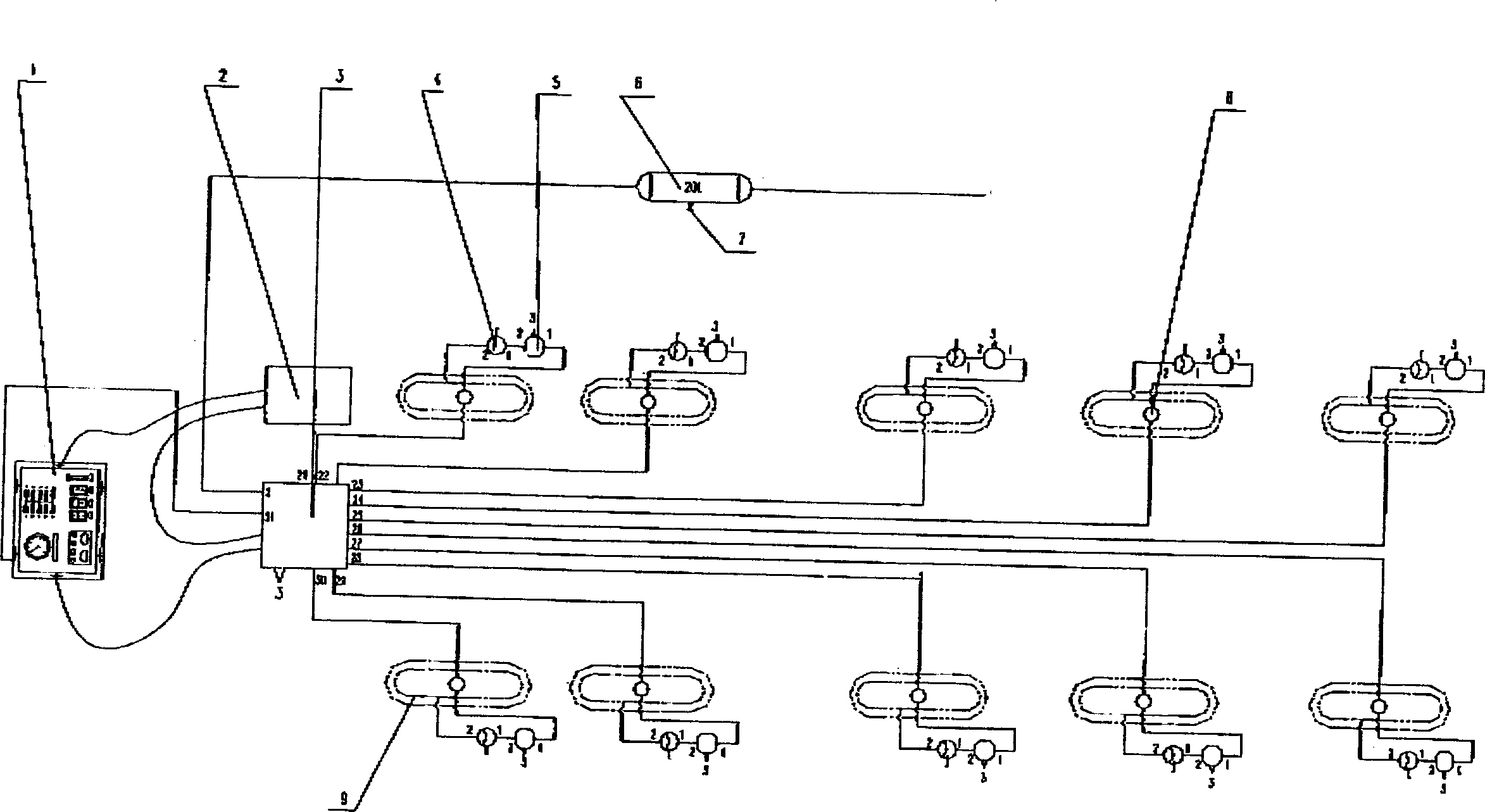

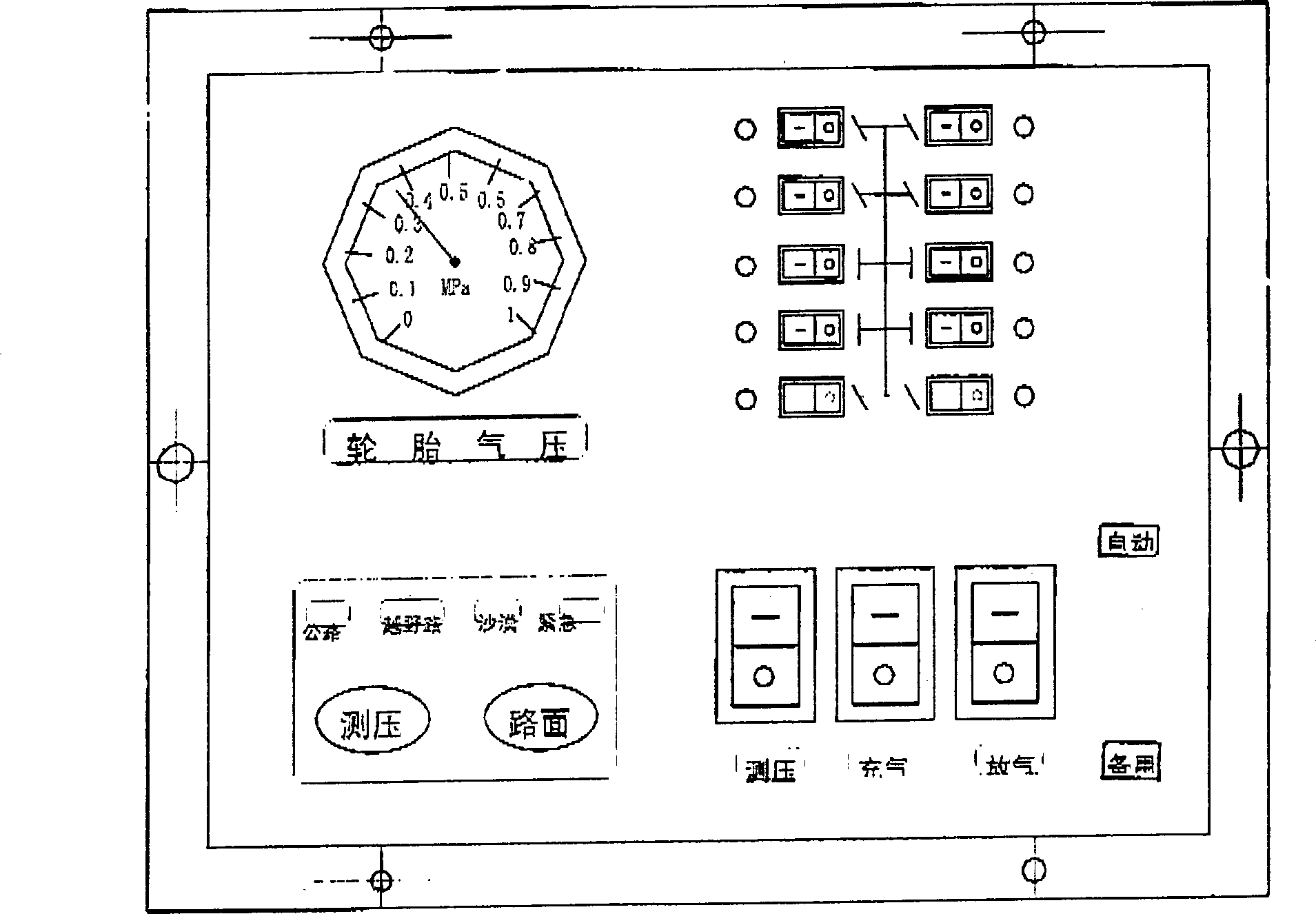

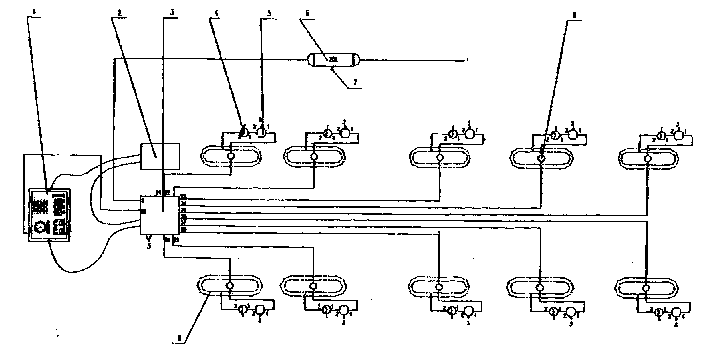

Central air-charging and air-discharging system of tyre of heavy cross-country vehicle

InactiveCN1394765AImplement inflationCarry out pressure testingTyre measurementsRubber ringControl system

The central air-charging and air-discharging system of tyre of heavy-duty cross-country car is formed from power supply, air source, operation control system, rotating sealing device, wheel valve and pipeline. The operation control system is formed from operation panel, electronic control device and electric control air valve group. The rotating sealing device is positioned between wheel hub and semixale tube and is formed from hermetic seal rubber ring, oil seal and isolation cover.

Owner:CHINA NATIONAL HEAVY DUTY TRUCK GROUP

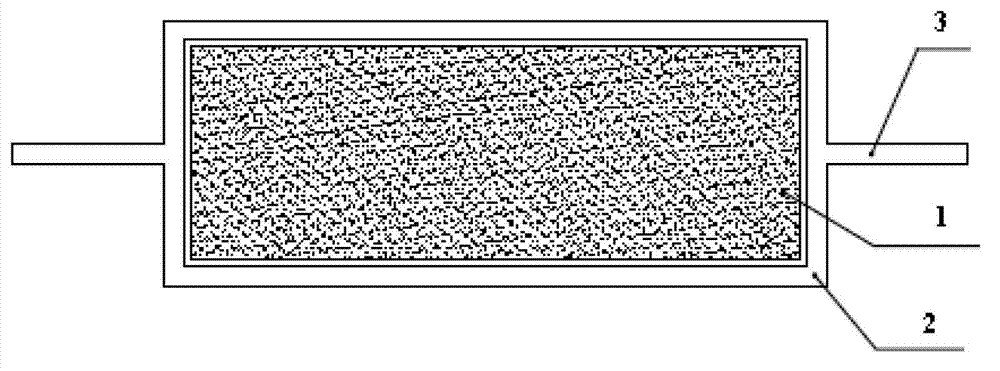

Vacuum heat insulation plate and preparation method thereof

ActiveCN103090157ASolve bag swellingSolve the problem of air leakageThermal insulationPipe protection by thermal insulationMaterial DegradationHigh resistance

The invention discloses a vacuum heat insulation plate for building outer walls, the vacuum heat insulation plate comprises a high resistance thin film bag and heat preservation core materials wrapped in the high resistance thin film bag, and the heat preservation core materials comprise basalt fibers. The vacuum heat insulation plate has the advantages of being simple in structure, low in cost, energy-saving and environmental, secure, fireproof, and good in heat preservation property. The invention further discloses a preparation method of the vacuum heat insulation plate. The preparation method of the vacuum heat insulation plate comprises: (1) preparing materials, (2) compression molding, (3) drying, and (4) packaging. The problems of bag swelling, air leakage, core material degradation, and durability of vacuum degree of a traditional vacuum heat insulation plate are solved, meanwhile the defects of using silicon dioxide and other powdery materials and difficult composite filling plating of the silicon dioxide and other powdery materials and fibers are overcome. The preparation method is simple and easy to operate, and saves both time and labor.

Owner:山东华德隆建材科技有限公司 +1

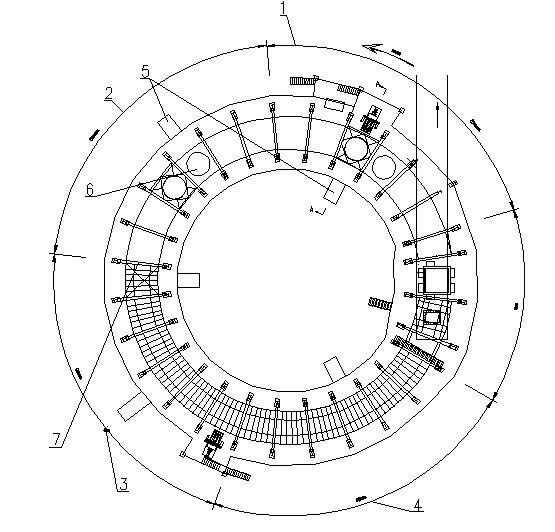

Energy-saving environment-friendly circular cooler

ActiveCN102589303AGuaranteed not to leakImprove cooling efficiencyHandling discharged materialCooling efficiencyElectric energy

The invention relates to cooling equipment in a metallurgy sintering system, in particular to an energy-saving environment-friendly circular cooler, which comprises a framework. Trolleys are arranged in a frame, trolley baffle plates are mounted above the trolleys, the frame is connected with bellows and is a circular rotator structure, the frame and the bellows are provided with sliding sealing rings, sealing covers are connected to upper sides of the trolley baffle plates, heat-insulation bodies are respectively sleeved on outer portions of the sealing covers and the trolley baffle plates, the circular rotator frame is divided into high-temperature waste heat recycling areas and low-temperature cooling areas, a sectioning partition is mounted between sealing rings of each high-temperature waste heat recycling area and the correspondingly adjacent low-temperature cooling area, and an air valve is mounted between the bellows of each high-temperature waste heat recycling area and the correspondingly adjacent low-temperature cooling area. The heat-insulation bodies are respectively sleeved on the outer portions of the trolley baffle plates and the sealing covers, the sliding sealing rings are disposed between the frame and the bellows, and cooling air which is delivered to materials of the trolleys by the bellows cannot leak assuredly; and cooling efficiency can be improved by 40% at least, and a large quantity of electric energy can be saved.

Owner:TANGSHAN HEAVY EQUIP GRP

Device for sealing triaxial test sample of soil body and method for using device

ActiveCN102288480ASimple structureEasy to install and replaceStrength propertiesInternal pressureSoil science

Owner:HOHAI UNIV

Device with griddle and process for generating power by efficiently recycling sinter waste heat

ActiveCN103234364AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialProcess engineeringUtilization rate

A device with a griddle and a process for generating power by efficiently recycling sinter waste heat relate to the technical field of waste heat power generation. The device comprises a sinter cooling system, a waste heat power generation system and a smoke system. The sinter cooling system and the waste heat circulation power generation system are connected through the smoke system to form a loop. The process includes 1) sinter cooling, 2) the smoke system and 3) waste heat power generation. The device and the technological process for waste heat power generation have the advantages of completely utilizing waste heat discharged in the sinter cooling process, obviously increasing power generation quantity, obviously reducing system self power utilization rate and being remarkable in energy-saving effect.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Multilayer negative-pressure closed drainage wound protecting device

ActiveCN104225768AImprove the effectGood material performanceEnemata/irrigatorsWound drainsCushionEngineering

The invention provides a multilayer negative-pressure closed drainage wound protecting device which comprises a porous foam cushion, a drainage tube and an oxygen-containing liquid flushing tube. One end of the drainage tube is positioned in the porous foam cushion, the porous foam cushion is a multilayer composite foam cushion and comprises a negative pressure conducting layer and a drainage protecting layer, the negative pressure conducting layer is a hydrophobic porous foam material layer, the drainage protecting layer is a hydrophilic porous foam material layer, and the drainage tube is disposed in the negative pressure conducting layer; the oxygen-containing flushing tube and the drainage tube enter the porous foam cushion side by side, the drainage tube penetrates the porous foam material layer to be positioned on the lower surface of the drainage protecting layer, the tail end of the drainage tube goes deeply into the drainage protecting layer for positioning, and small holes are distributed in the wall of the drainage tube. The drainage tube and a leading-in end of the oxygen-containing liquid flushing tube are fixed by a shared elastic sealing glue film floppy which comprises a disc and an elastic sealing glue film bonded with the disc and extending outwards, and a drainage leading-in tube orifice of the drainage tube and a flushing leading-in tube orifice of the oxygen-containing liquid flushing tube are arranged in the middle of the disc. A longitudinal breaking joint is formed at a drainage tube incoming end of the porous foam cushion, so that convenience is brought to overturning of the leading-in tube orifice.

Owner:WUHAN VSD MEDICAL SCI & TECH CO LTD

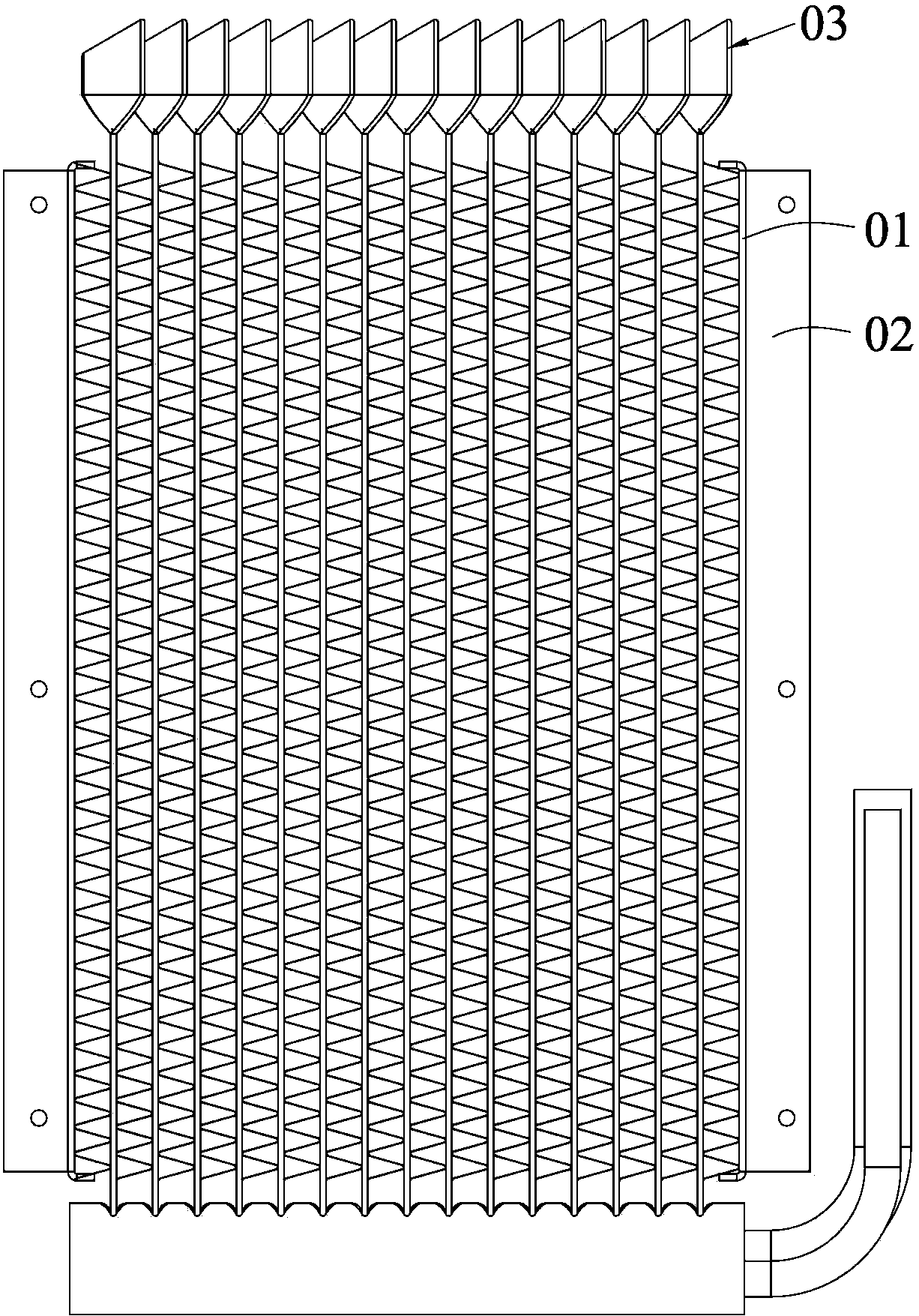

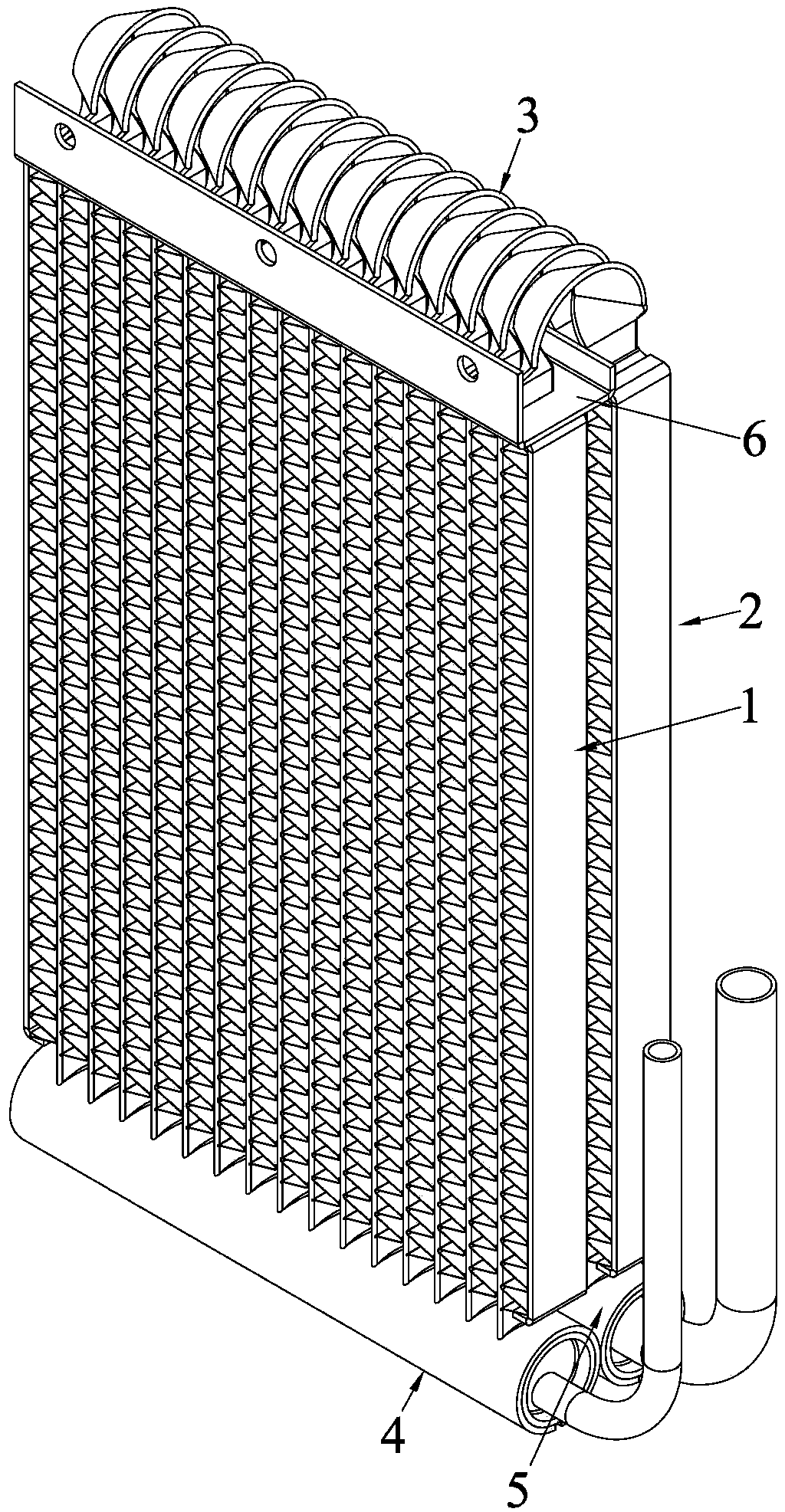

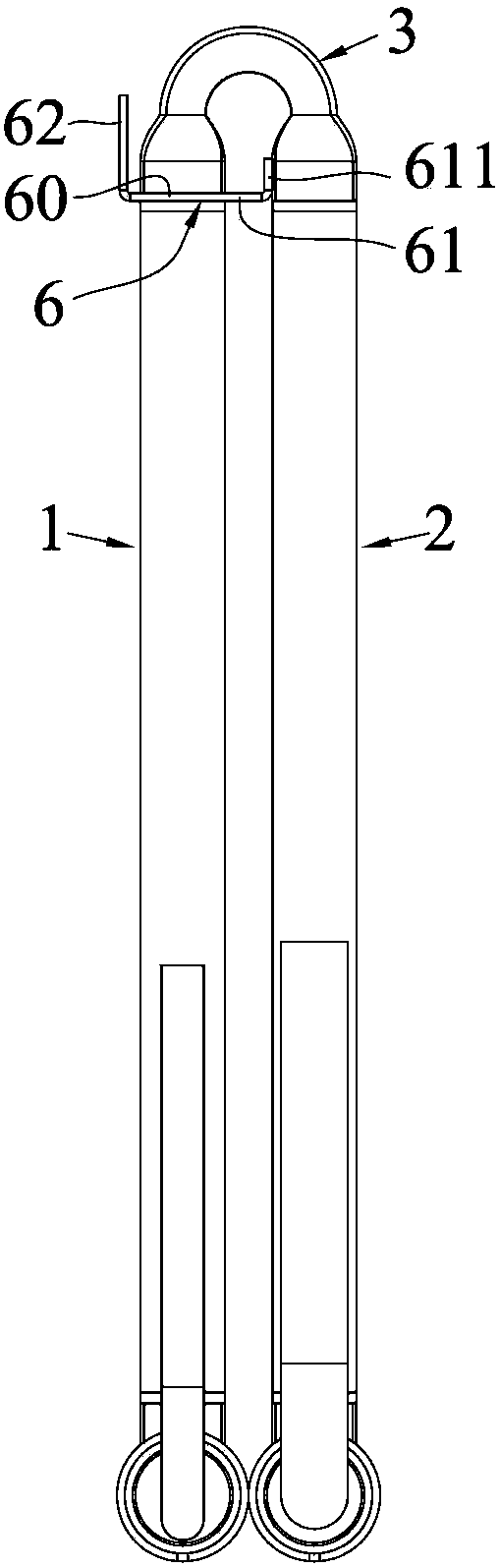

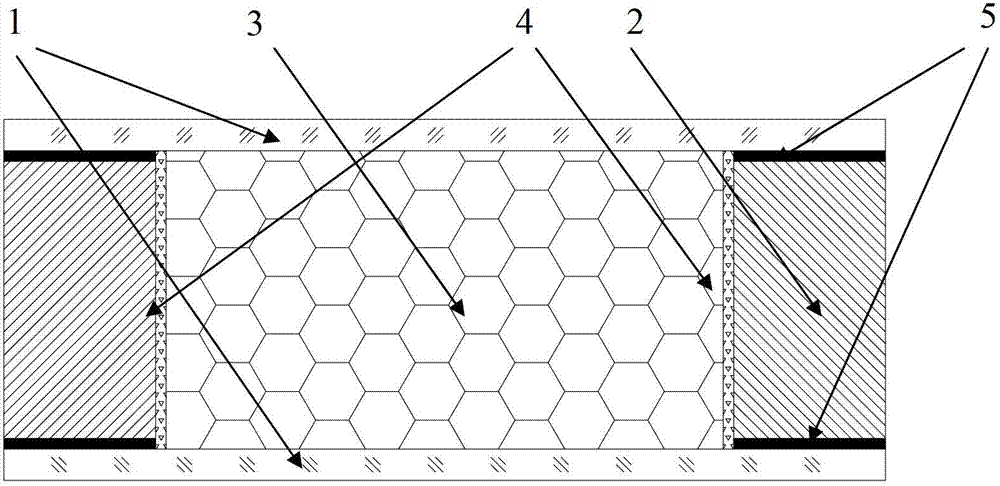

Heat exchanger

ActiveCN104110977AImprove heat transfer performanceImprove heat transfer effectStationary conduit assembliesAirflowEngineering

The invention discloses a heat exchanger, in particular to a microchannel heat exchanger, and belongs to the field of refrigeration equipment. The heat exchanger comprises at least two rows of heat exchange cores, flat-pipe bending portions and flow-baffle components, wherein the flat-pipe bending portions are connected between the two adjacent rows of heat exchange cores, and the flow-baffle components are arranged between the two adjacent rows of heat exchange cores and baffle airflow from entering the flat-pipe bending portions. The problem of air leak of flat-pipe bending portions of existing multi-row microchannel heat exchangers is solved.

Owner:ZHEJIANG DUNAN THERMAL SCI & TECH

Building energy-saving glass

InactiveCN102729545ALow thermal conductivityEffective throughGlass/slag layered productsFlat glassBuilding energy

The invention discloses a building energy-saving glass. The building energy-saving glass comprises two glass sheets and a seal spacer positioned between the two glass sheets, a closed cavity is formed among the seal spacer and the glass sheets, transparent heat insulation SiO2 aerogel plates are filled in the closed cavity, a transparent SiO2 aerogel aqueous rubber is used to seal the transparent heat insulation SiO2 aerogel plates, and a butyl rubber is used to seal the seal spacer and the glass sheets. Convection heat loss and condensation phenomena caused by air transmission are greatly reduced, so compared with a hollow glass and a low-irradiation hollow glass in the prior art, the energy saving glass filled with the transparent heat insulation SiO2 aerogel plates has a high heat insulation performance and simultaneously has a high light transmission rate; and the energy saving glass has a heat insulation performance near to that of a vacuum glass, and has a substantially higher service life than the vacuum glass.

Owner:CHANGSHA XINGNA AEROGEL

Sensible heat recovering system and method of tail gas of converter with afterburning

InactiveCN101705331ANo generationSmall footprintManufacturing convertersIncreasing energy efficiencyElectricityCombustion chamber

The invention relates to a sensible heat recovering system and a method of tail gas of a converter with afterburning. The system comprises a converter, a vaporizing flue, a cooling device and a tail gas dust-removing, recovering and discharging system and also comprises an afterburning chamber and a water-cooling three-way valve, wherein two inlets of the water-cooling three-way valve are respectively connected with the afterburning chamber and the tail gas outlet of the converter, and the outlet is connected with the vaporizing flue. The recovery or discharge of the tail gas and the operation of the afterburning chamber are switched by the water-cooling three-way valve in the oxygen blowing period and the non-oxygen blowing period of the converter. The invention has the advantages that the invention realizes the real dry-method dust removal of the tail gas of the converter to save plenty of water for production and recover ferrum-contained materials in the tail gas, and simultaneously reduces the resistance of the system and the electricity consumption of the recovery of the tail gas; and when consuming a great deal of low-heat value gas with difficult treatment in iron and steel plants, the afterburning chamber reduces the alternating heat stress of the vaporizing flue, prolongs the service life of the vaporizing flue and lowers the gas recovering cost of the converter.

Owner:TSINGHUA UNIV +1

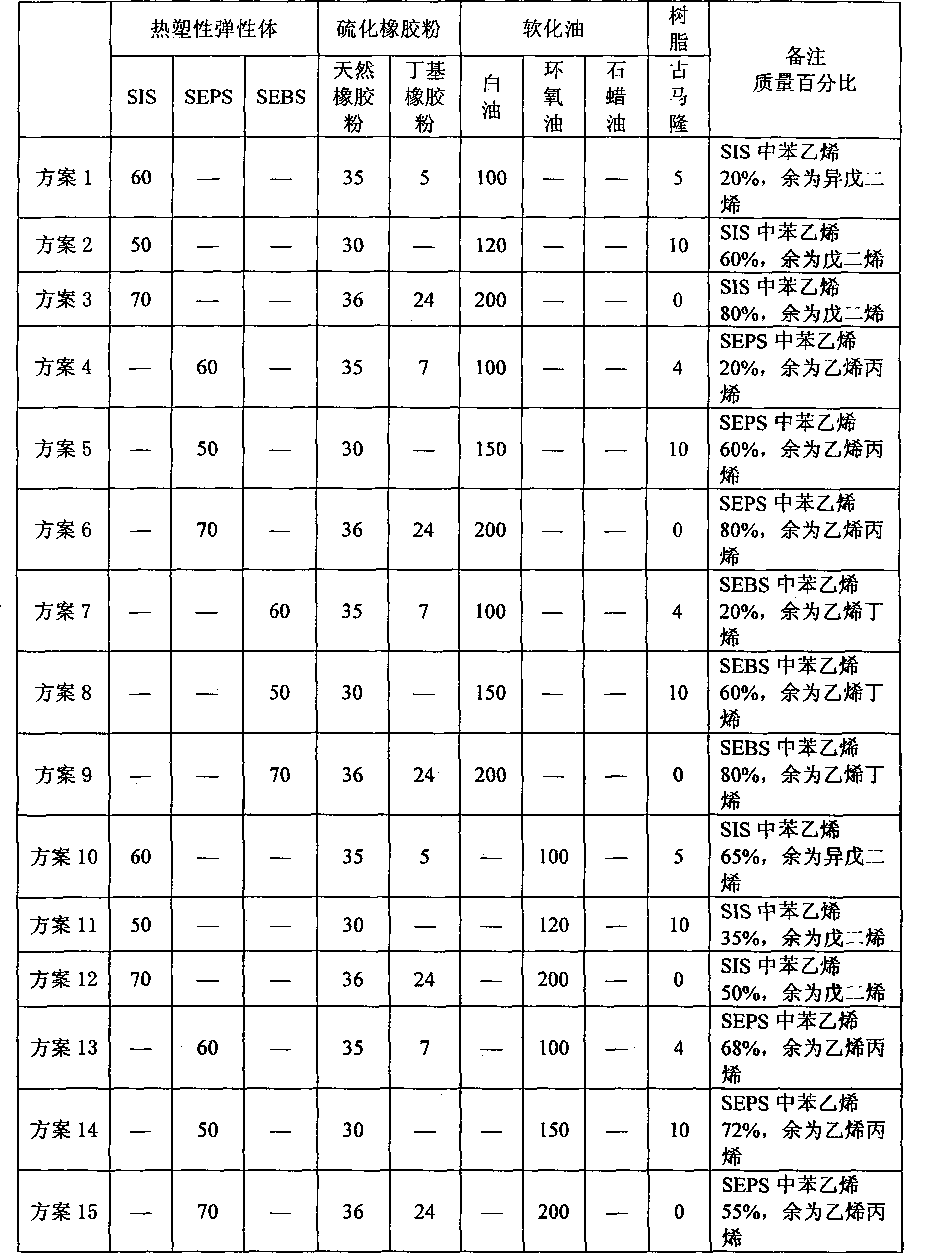

Leakproof tire and preparation method thereof

InactiveCN101480903ANormal tire pressureNo air leakageTyre partsRolling resistance optimizationForeign matterElastomer

The invention relates to an anti-leakage tyre and a production method thereof, belonging to the technical field of vehicle tyres. The anti-leakage tyre comprises a tyre surface, a tyre shoulder and a coating layer in the tyre, and is characterized in that the coating layer in the tyre is formed by solidifying elastomer materials in a gel state, and the elastomer materials in a gel state are mainly formed by mixing following raw materials by weight: 50 to 70 portions of thermoplastic elastomer, 100 to 200 portions of softening oil, 30 to 60 portions of perduren powder and 0 to 10 portions of resin. The coating layer in the anti-leakage tyre cannot be softened to flow into a conglobation at higher ambient temperature or during high-speed driving of the tyre or the increase of heat accumulation temperature. The anti-leakage tyre can keep elasticity at lower temperature and has good self-sealing effect. When the tyre is broken by unctuous foreign matters at normal temperature, the tyre cannot leak and can be continuously used, thereby being safe and convenient.

Owner:刘锦磊

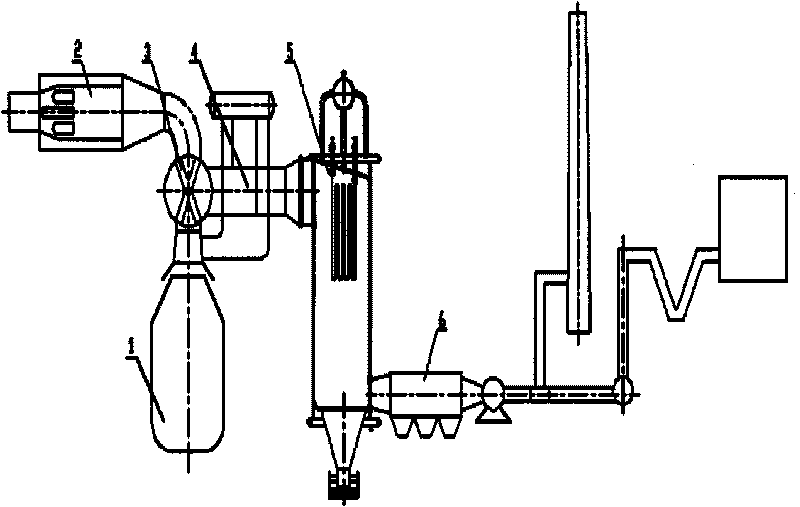

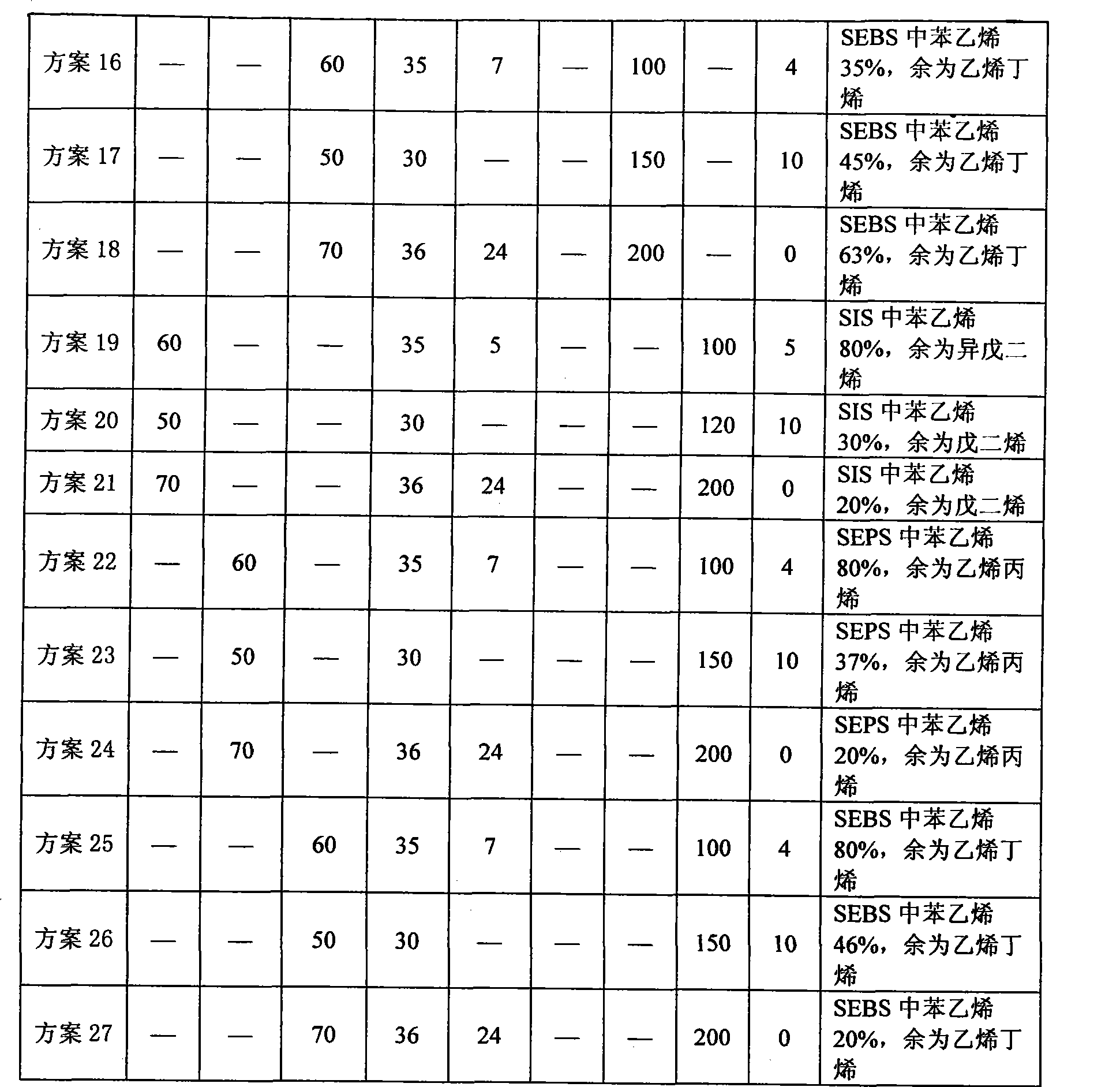

Furnace type efficient recovery system for flue gas waste heat of cooled sinter

InactiveCN103234363AImprove qualityImprove waste heat utilization efficiencyIncreasing energy efficiencyWaste heat treatmentProcess engineeringFlue gas

A furnace type efficient recovery system for flue gas waste heat of cooled sinter comprises an air blower, a cooling furnace, a primary dust remover, an emergency blow-off valve, a waste heat boiler, a secondary dust remover, a draft fan and a chimney. An outlet of the air blower is communicated with a cooling air inlet on the lower portion of the cooling furnace. A flue gas outlet on the upper portion of the cooling furnace is communicated with the primary dust remover, the waste heat boiler, the secondary dust remover, the draft fan and the chimney through pipelines successively. The emergency blow-off valve is arranged on a pipeline between the primary dust remover and the waste heat boiler. A connection pipeline is arranged between the draft fan and the air blower. The furnace type efficient recovery system for flue gas waste heat of cooled sinter has the advantages that the sinter quality is improved, the sinter return rate is reduced, flue gas parameters are stable, the system own power consumption rate is reduced, and the energy-saving effect is apparent.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

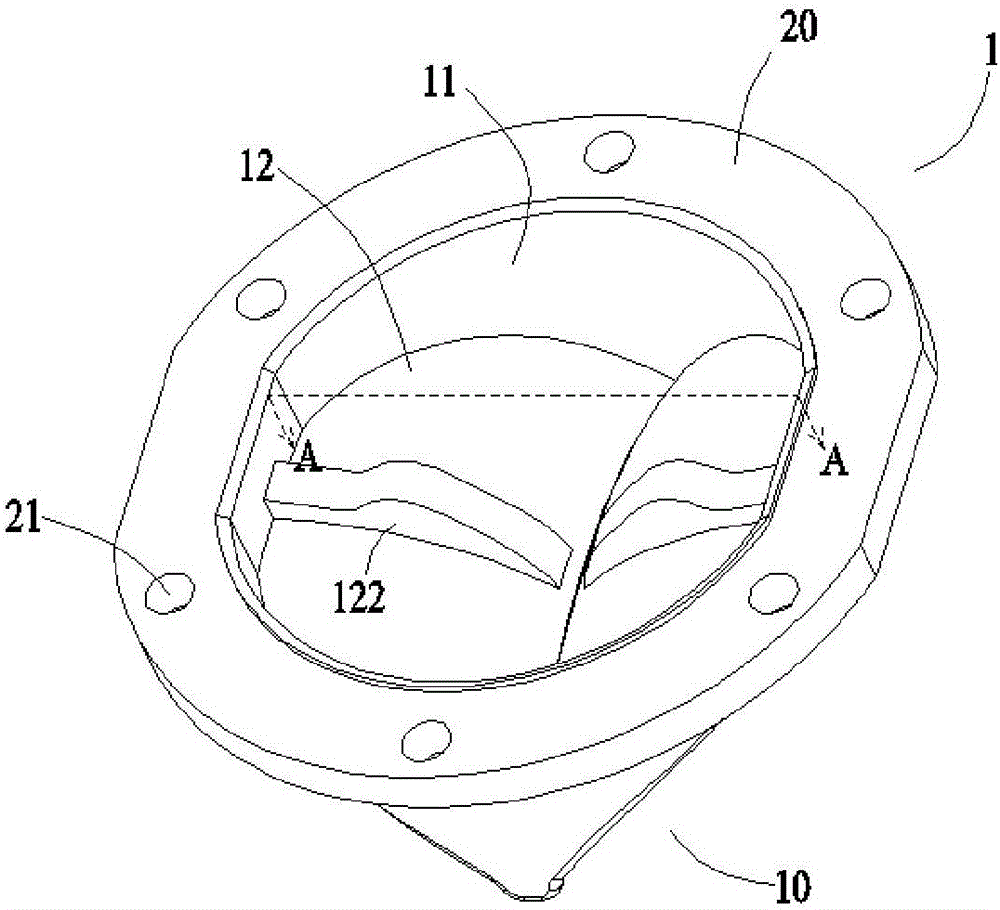

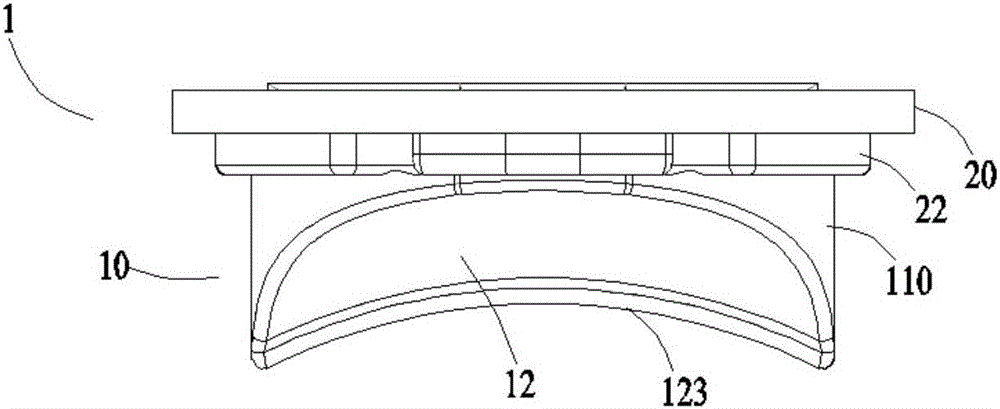

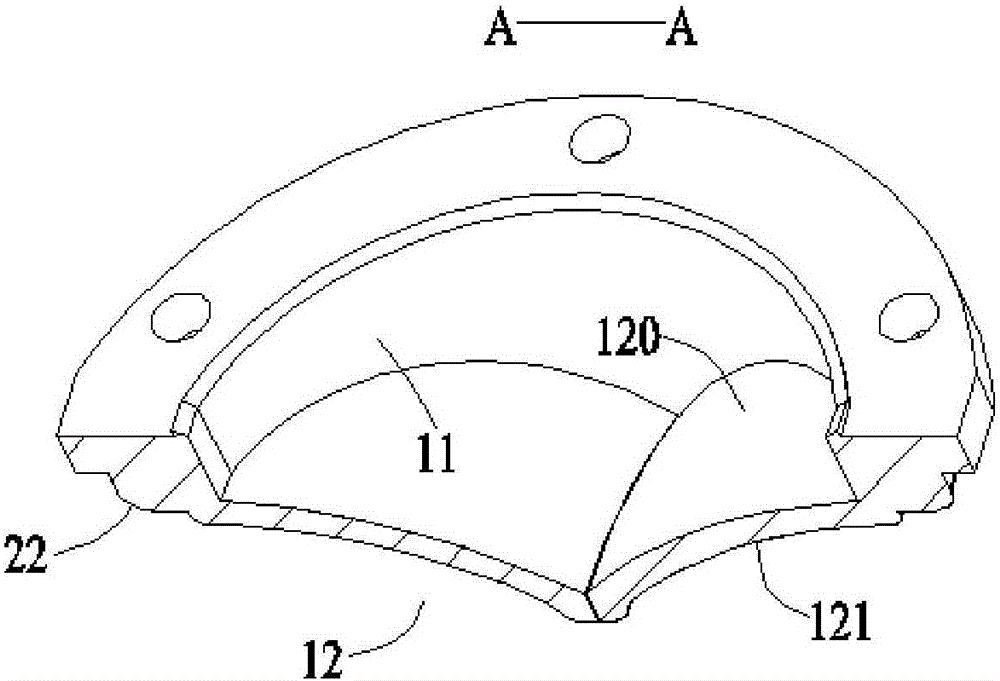

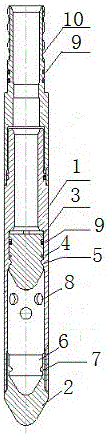

Seal cartridge and puncture outfit with same

The invention discloses a seal cartridge and a puncture outfit with the same. The seal cartridge comprises a seal body and an assembly flange, wherein the seal body comprises a seal cylinder and a plurality of seal valves; the seal cylinder is arranged in penetrating manner, and is provided with an upper opening and a lower opening; the upper end of an arbitrary seal valve is smoothly connected with the edge of the lower opening of the seal cylinder; the lower end edges of the plurality of seal valves are supported against one another; the lower opening of the seal cylinder is optionally opened or closed; each seal valve is provided with a top surface and a bottom surface opposite to the top surface, the top of each seal valve is arranged toward the upper opening of the seal cylinder, and the bottom of each seal valve is a concave curved surface; and the assembly flange is positioned on the outer surface of the seal cylinder. According to the seal cartridge, the seal valves are optimized, so that the seal cartridge can be well closed when a puncture core pin is pulled out, the sealing property of a passage formed by a puncture sleeve can be effectively guaranteed, and occurrence gas leakage can be avoided.

Owner:FENGH MEDICAL CO LTD

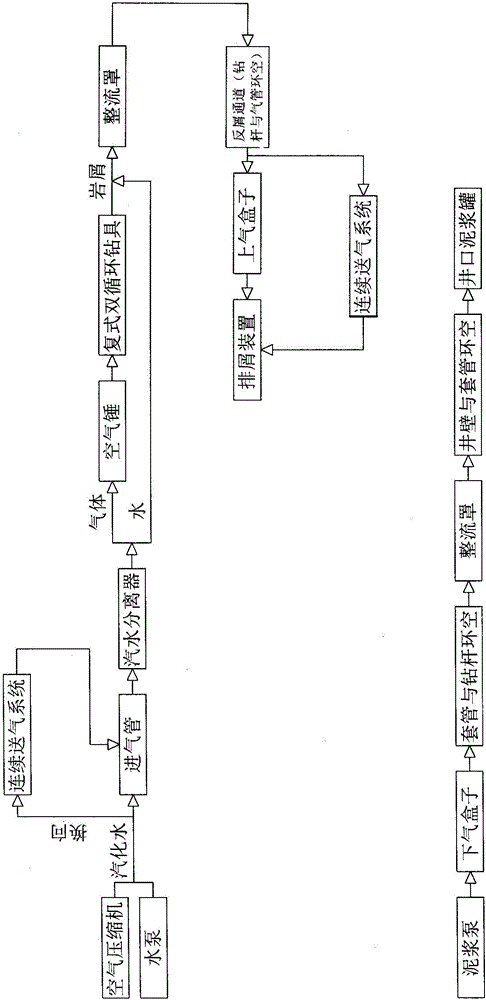

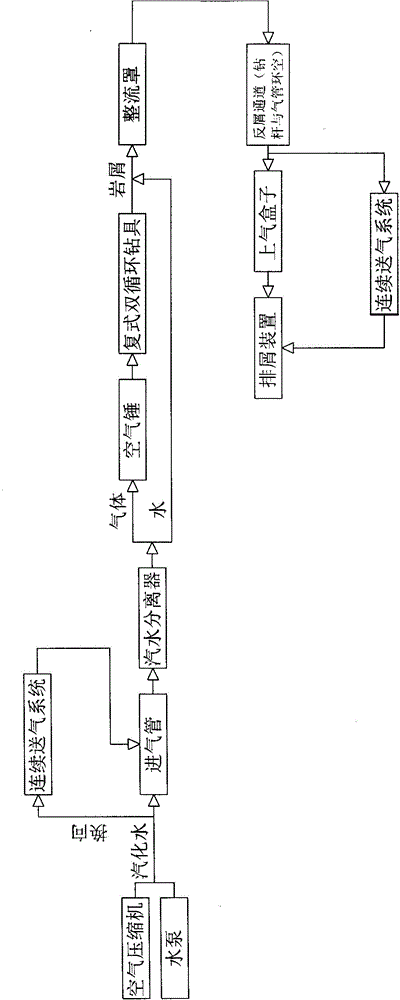

Compound double-circulation under-balanced casing pipe while-drilling drilling technology

ActiveCN104453716APrevent landslidesAvoid problems such as stuck main drill pipeConstructionsFlushingWell drillingAir compressor

The invention relates to a compound double-circulation under-balanced casing pipe while-drilling drilling technology. The compound double-circulation under-balanced casing pipe while-drilling drilling technology is characterized in that a drilling and make-a-connection drilling technology is adopted, an air compressor and a water pump are started, vaporous water in a pipeline pushes an air hammer to work through an air inlet pipe, a compound double-circulation drilling tool is driven to work, finally vaporous water is drained through a chip removal device, a slush pump is started at the same time, slush enters the annular part of a casing pipe and the annular part of a drilling rod through an air exhaust box, flows to the well wall and the annular part of the casing pipe through a fairing, upwards returns to a wellhead slush tank and circulates repeatedly, and it is ensured that pressure of the well wall is balanced; when make-a-connection is performed, a three-way valve is opened, and vaporous water formed by the air compressor and the water pump is reversed by the three-way valve, enters a continuous air supplying system and enters the air inlet pipe through the continuous air supplying system to push the air hammer to work and drive the compound double-circulation drilling tool to work. The difficult problems such as collapse, air leakage, hole shrinkage, chip off-falling, deviation control, straight hitting, water coning, drilling tool jamming and blowout in the under-balanced drilling process are solved, and the drilling speed is greatly increased.

Owner:上海万维亿通装备制造有限公司

Blocking device for drainage gas recovery of horizontal well velocity string

PendingCN106677735AImprove the effect of drainage and gas recoveryAvoid cloggingSealing/packingEngineeringSelf locking

The invention provides a blocking device for drainage gas recovery of a horizontal well velocity string. The blocking device for the drainage gas recovery of the horizontal well velocity string is mainly used for the drainage gas recovery of a horizontal well. The blocking device adopts groove type design, adopts rolling type connection with the velocity string overall, is sealed through two seal rings, and then is sealed and firm in overall structure. A plug adopts embedded type design, and is embedded in the body of the blocking device. The lower portion of the body of the blocking device is provided with sieve holes and a pocket, and a self-locking buckle is arranged on the pocket, can lock the plug which is hit down, and then prevents the plug from moving upwards so as to prevent the plug from blocking a production channel. The blocking device for the drainage gas recovery of the horizontal well velocity string solve the problems of gas leakage and dropping, caused due to the fact that a conventional blocking device at an inclined well segment of the horizontal well scratches the wall of an oil pipe, and above all, the velocity string can be enabled to pass through downhole tools of safety joints, hydraulic anchors and the like in a wellbore by using the blocking device, and therefore the velocity string is dropped to a horizontal segment of the gas well, drainage gas recovery effects of the horizontal well velocity string are improved, and furthermore the blocking device for the drainage gas recovery of the horizontal well velocity string has the advantages of being simple in structure, firm in sealing, quick to install and the like.

Owner:PETROCHINA CO LTD

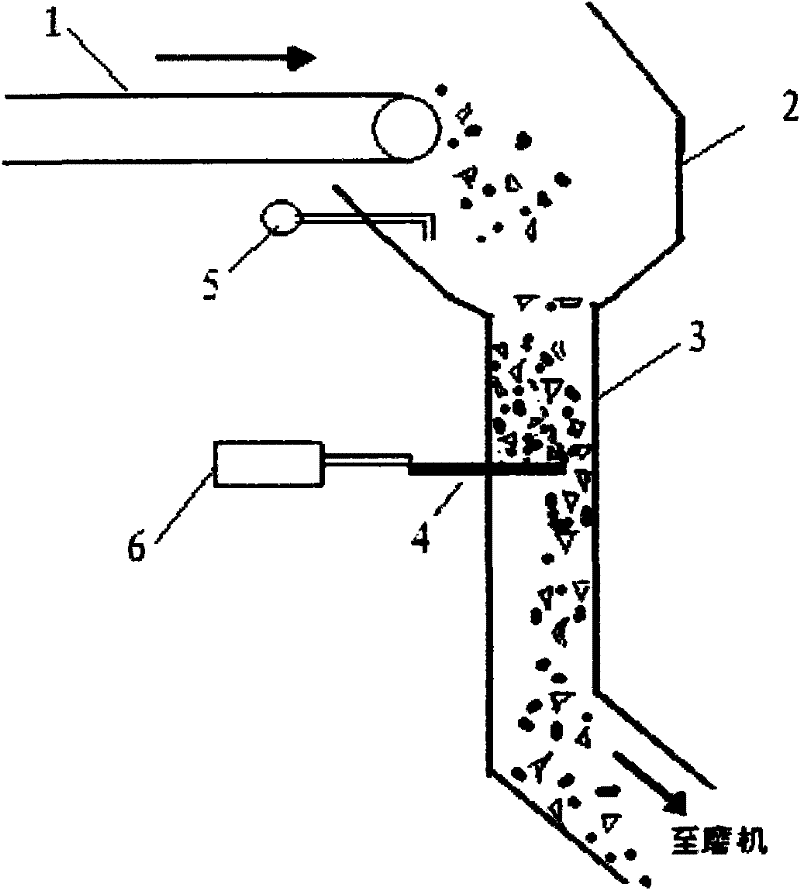

Separated scenting device for scented tea

The invention discloses a separated scenting device for scented tea. The separating scenting device comprises a fresh flower bin, a tea bin and an automatic controller, wherein the upper part of the fresh flower bin is communicated with the upper part of the tea bin through an upper pipeline; a condenser, a fan A and a temperature sensor A are sequentially arranged on the upper pipeline from one side of the fresh flower bin; a water receiving tank is connected to the lower part of the condenser; the lower part of the fresh flower bin is communicated with the lower part of the tea bin through a lower pipeline; a temperature sensor B and a heater are sequentially arranged on the lower pipeline from one side of the fresh flower bin; a carbon dioxide detector is arranged inside the fresh flower bin; an air inlet and a fan B for pumping and exhausting air are formed in the fresh flower bin; the automatic controller is respectively connected with the fan A, the fan B, the condenser, the heater, the temperature sensor A, the temperature sensor B and the carbon dioxide detector through leads. The scented tea scented by the device disclosed by the invention has the advantages of higher cleanness, better mouth feel and higher nutritional value; the energy consumption is reduced, drying procedures are reduced, the cost is reduced and the utilization value of fresh flowers is increased.

Owner:谢锡霞

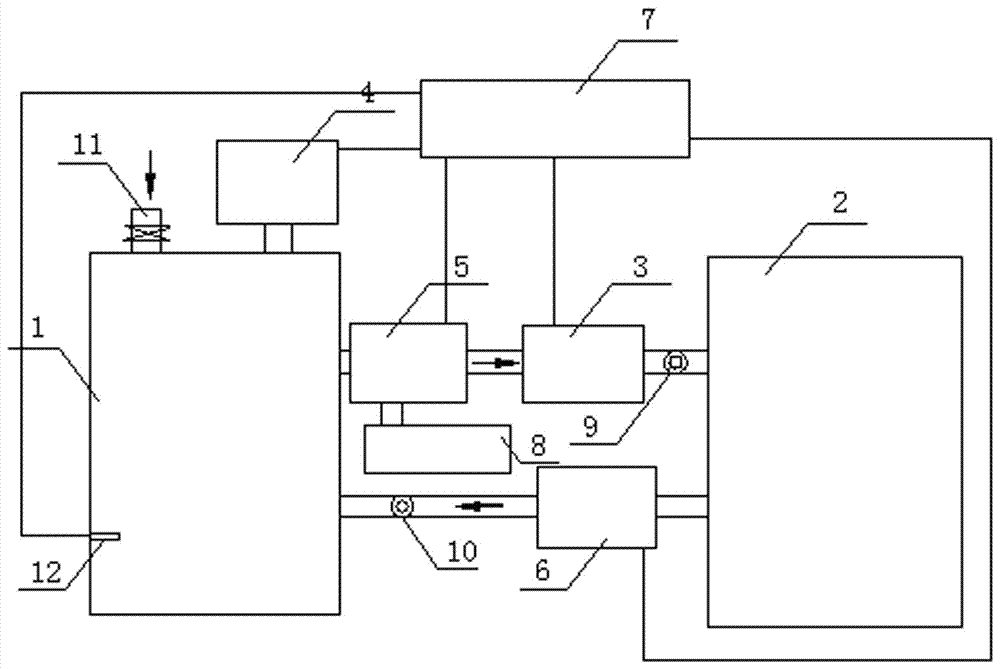

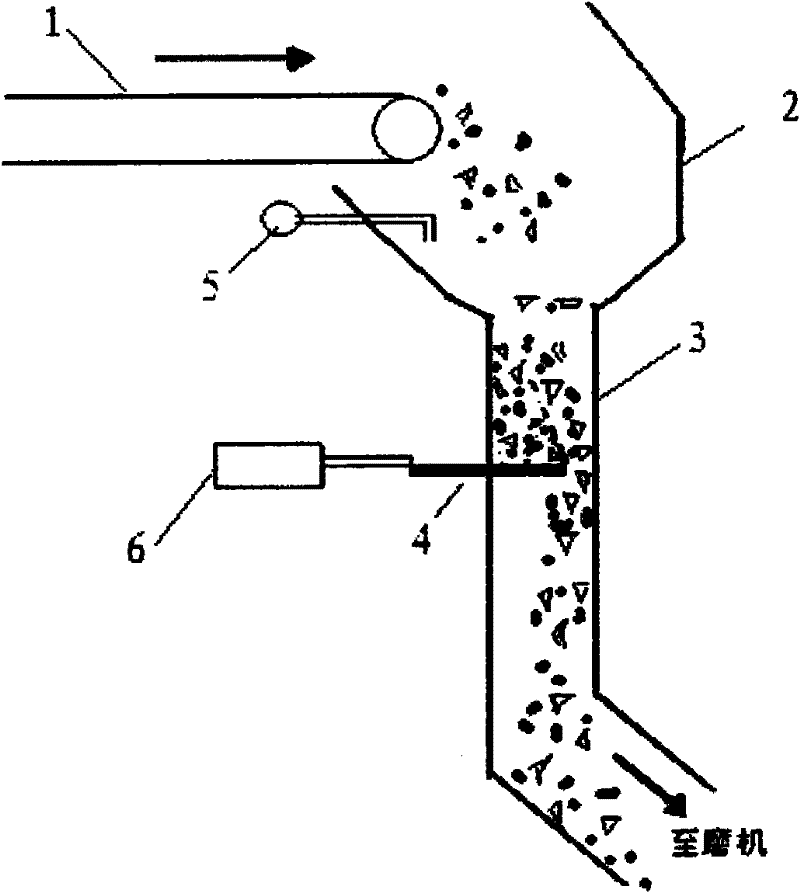

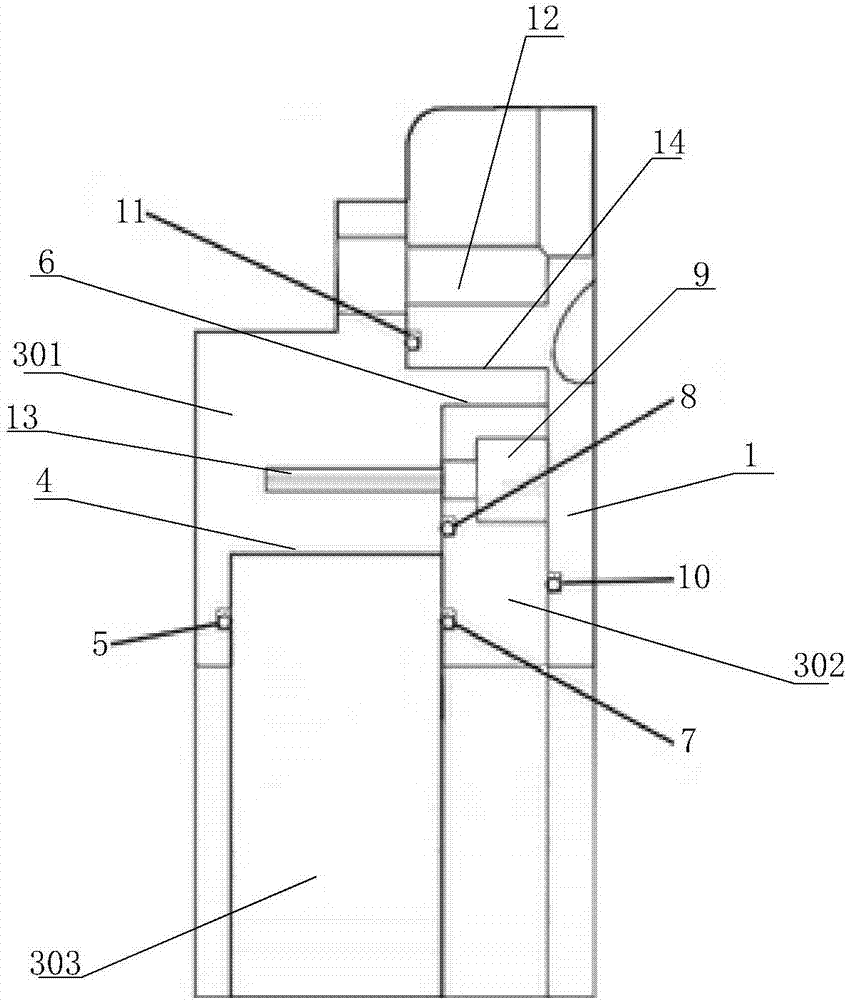

Vertical Mill Sealed Feeder

ActiveCN102259758ASolve the problem of air leakageSolve the vibrationLarge containersConveyor partsLower limitPressure rise

The invention provides a hermetic feeder for a vertical mill. The feeder comprises a mill feed belt, a blanking pipe, a blanking straight pipe, a horizontal insertion plate and a negative pressure meter, wherein the blanking pipe is arranged below the mill feed belt; the blanking straight pipe is connected below the blanking pipe; the horizontal insertion plate is arranged in the middle section of the blanking straight pipe; the length of the horizontal insertion plate stretching into the blanking straight pipe can be adjusted by an actuating mechanism, so that a blanking space is formed by agap between the horizontal insertion plate and the blanking straight pipe and is used for materials to pass through; and the negative pressure meter is arranged above the blanking pipe, is connected with an automatic control system and a central controller, and is provided with an upper limit value and a lower limit value, so that negative pressure starts dropping from a normal value when the blanking straight pipe is blocked, the automatic control system makes the actuating mechanism start acting to open the horizontal insertion plate when the negative pressure reaches the lower limit value,the negative pressure rises due to automatic dredging of material scouring, the automatic control system makes the actuating mechanism close the horizontal insertion plate when the negative pressure reaches the upper limit value, and the negative pressure is restored to the normal value.

Owner:SICHUAN ESHENG CEMENT GROUP

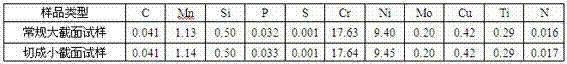

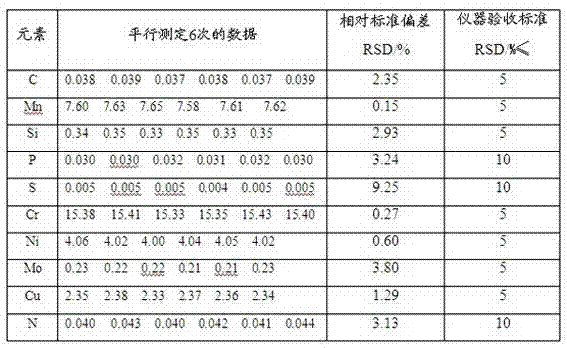

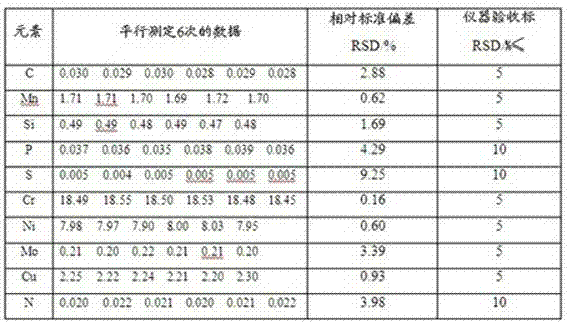

Method for analyzing small-section metal sample through direct reading spectrometry

InactiveCN102359957ASolve the air leakage of the spark tableEasy to operatePreparing sample for investigationAnalysis by electrical excitationDirect readingIron production

The present invention relates to a method for analyzing a small-section metal sample through direct reading spectrometry, and belongs to the technical field of metallurgy analysis and detection. The method comprises the following three steps: inlaying, grinding and analyzing. With adopting inlaying for the small-section metal sample, the section of the inlayed sample is large, the thickness is high, such that the problems of inconvenience during the small-section metal sample grinding, air leakage of the spark table during analyzing, and the like are solved. According to the present invention, the small fixture is not required; the method has advantages of simple operation, rapidness and precision, and is suitable for popularization in iron and steel production and test.

Owner:YONGXING SPECIAL STAINLESS STEEL

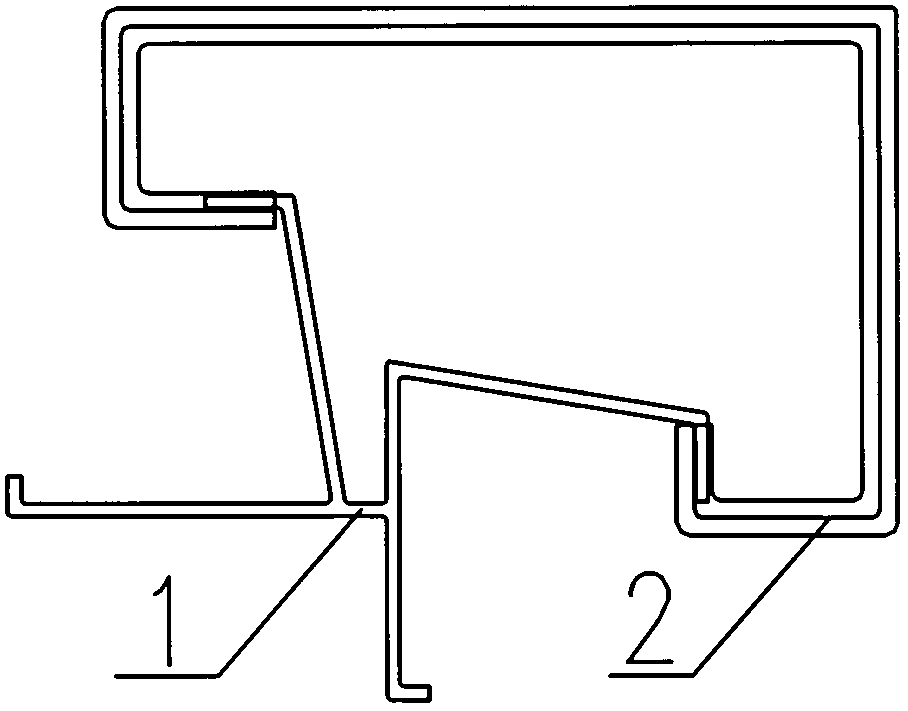

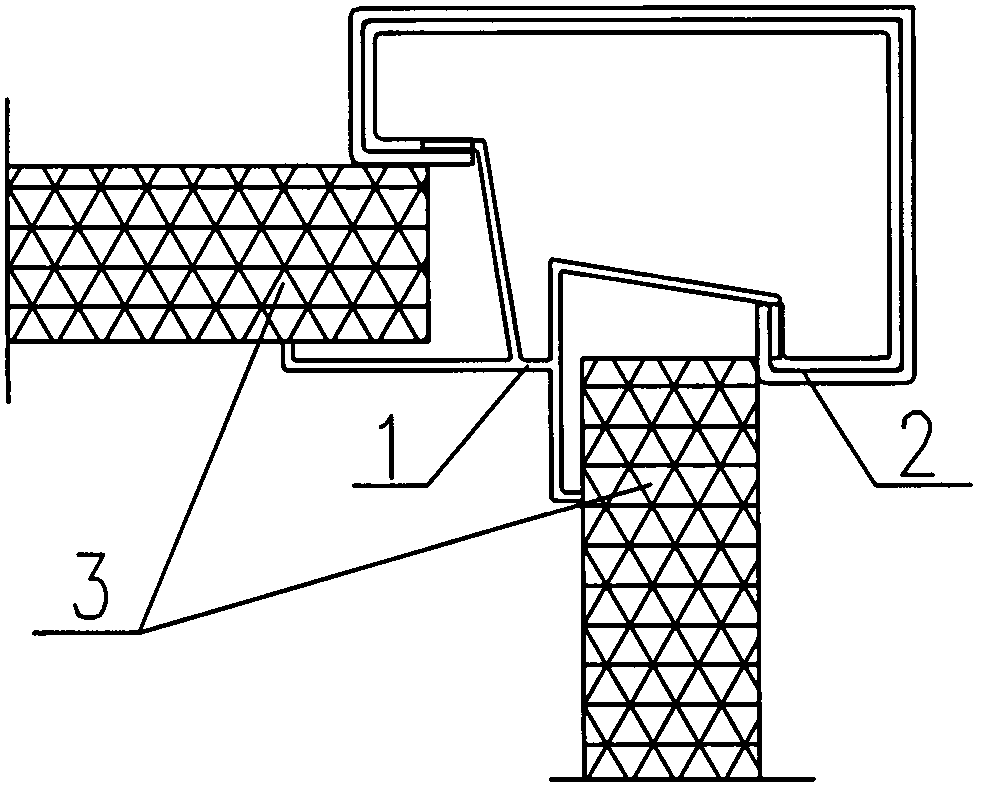

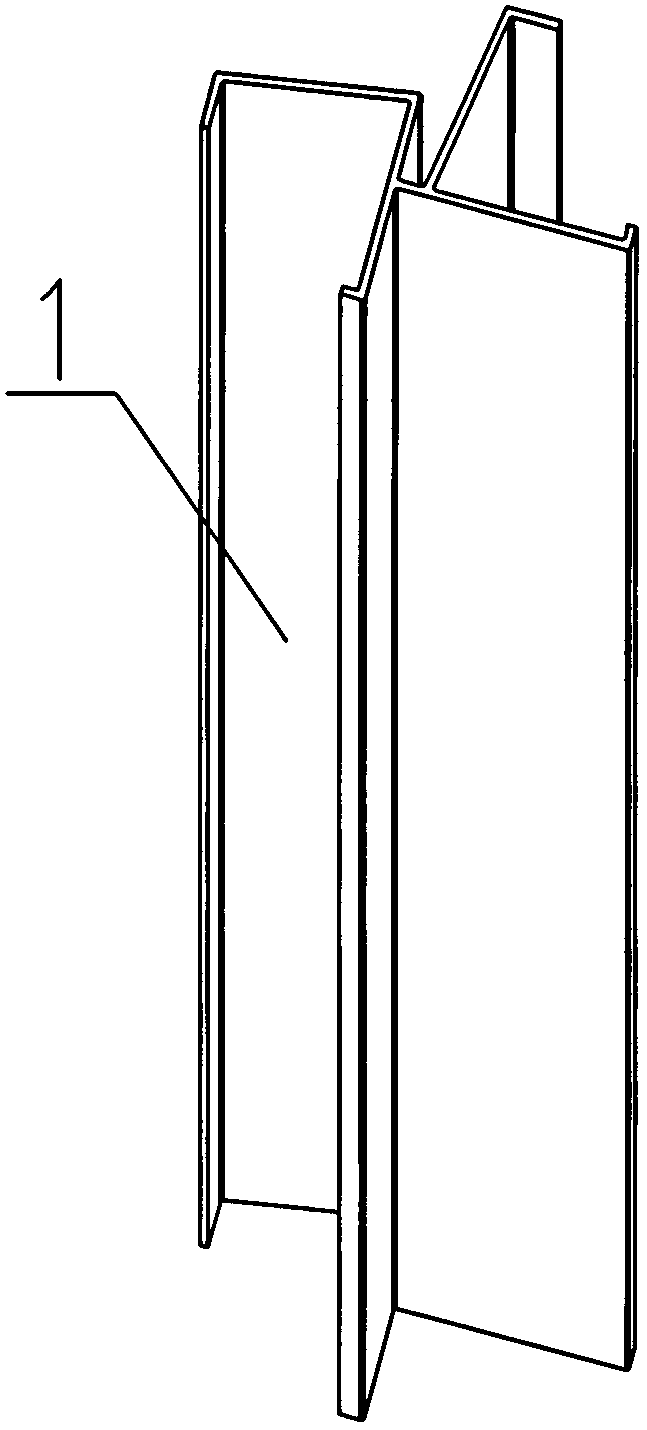

Clamping groove device for fixing wall plates

The invention discloses a clamping groove device for fixing wall plates. The clamping groove device for fixing the wall plates comprises a steel angle and a clamping groove; the clamping groove is provided with four sides, wherein two sides are inserted into the notches in the two sides of the steel angle; the steel angle and the clamping groove are fixed by sleeving mutually; one section of a wall plate is embedded into the clamping groove to achieve the effect of connecting the wall plates in a corner.

Owner:SUZHOU TIANDI COLORBOND MFG

Duplex double-circulating under-balanced drilling technology

ActiveCN104533282APrevent landslidesAvoid problems such as stuck main drill pipeDrilling rodsConstructionsWell drillingProduct gas

The invention relates to a duplex double-circulating under-balanced drilling technology. The duplex double-circulating under-balanced drilling technology is characterized by comprising the steps of drilling and making up a joint for drilling; an air compressor and a water pump are started; vaporous water generated in the pipeline enters a steam-water separator through an air inlet pipe; the separated air is used for propelling an air hammer to drive a duplex double-circulating drill to work; the separated water is mixed with rock debris generated in the work of the duplex double-circulating drill to form slurry which flows through a rectifying cover; the slurry flows through a debris returning channel formed between a drilling rod and the air inlet pipe to be returned to an upper air box and then is discharged through a debris discharging device; the step of making up the joint is that the vaporous water is reversed through a three-way valve and then enters a continuous air supply system; the vaporous water in the continuous air supply system enters a steam-water separator through the air inlet pipe; the separated air propels the air hammer to drive the duplex double-circulating drill to work. According to the technology, the separated water is mixed with the with rock debris generated in the work of the duplex double-circulating drill to form slurry which flows through the rectifying cover; the slurry flows through the debris returning channel formed between the drilling rod and the air inlet pipe to be returned to the upper air box and then the discharged through the debris discharging device.

Owner:上海万维亿通装备制造有限公司

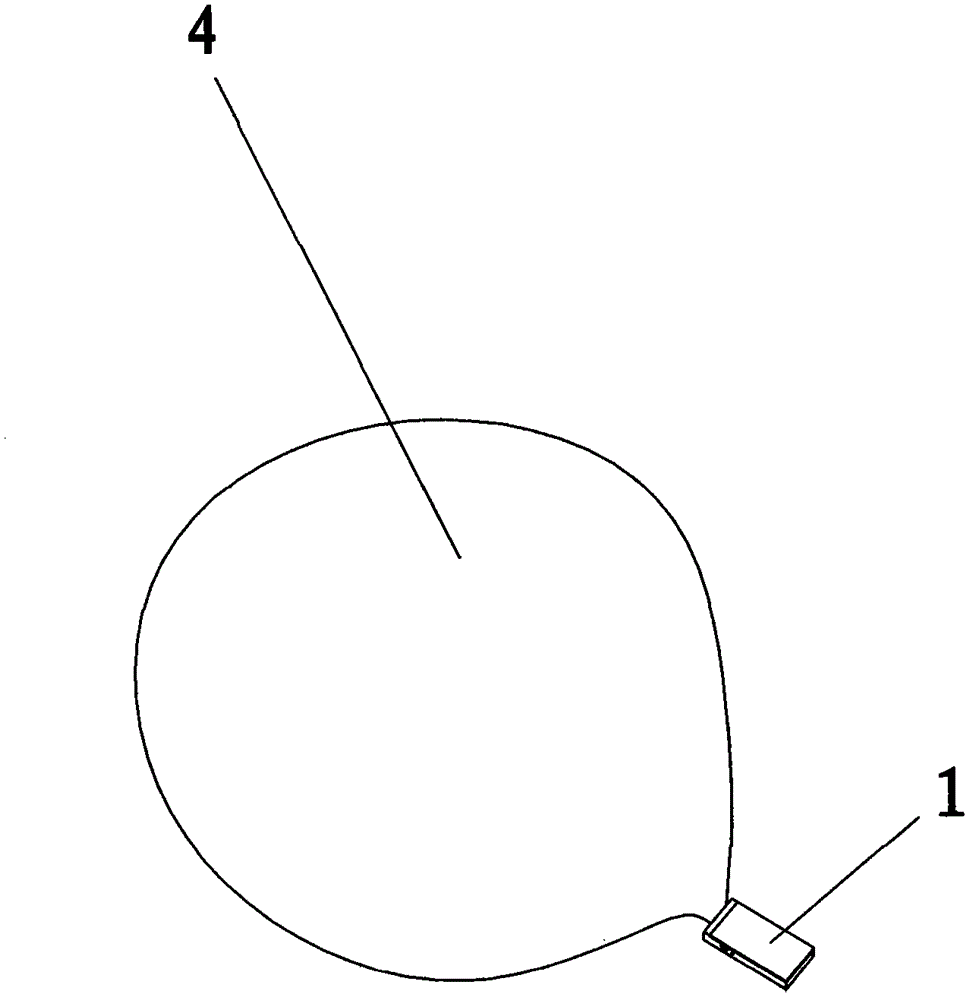

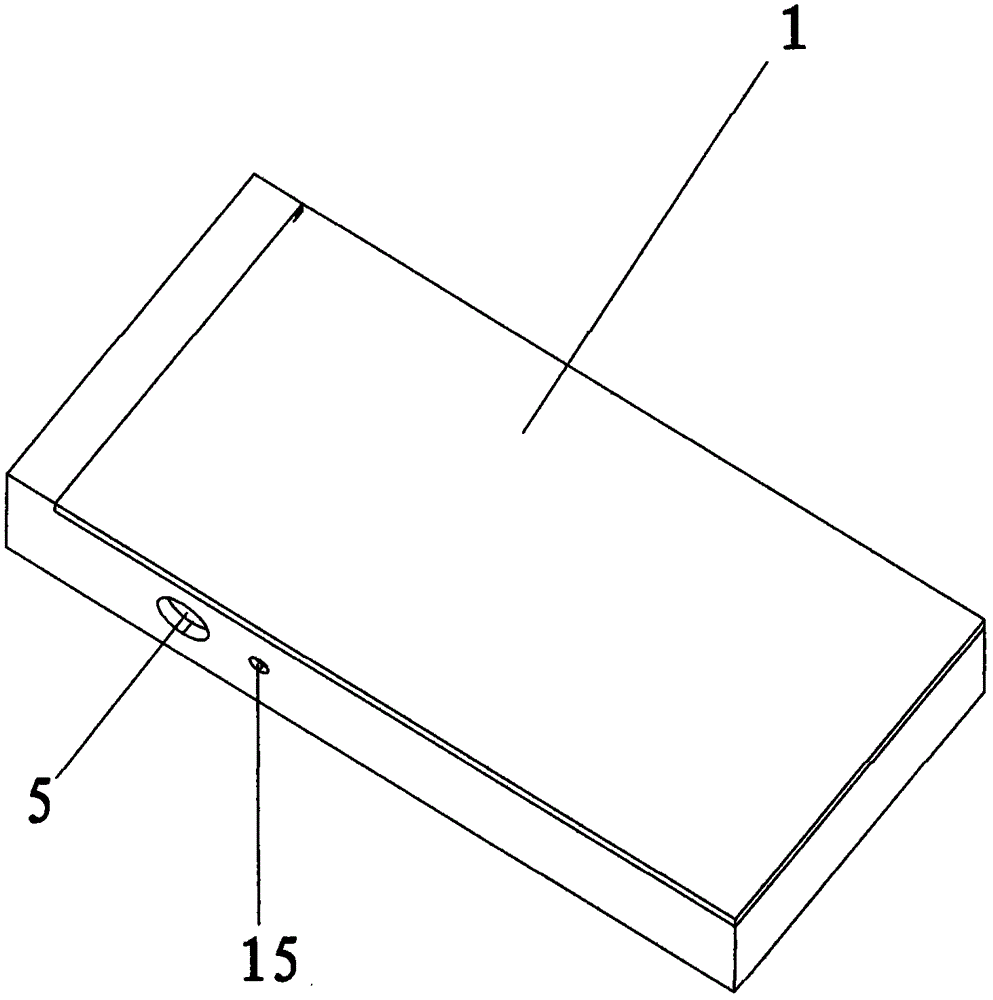

Underwater life-saving device

PendingCN104590509AReduce consumptionSolve the problem of air leakageVessel signalling devicesLife-savingUnderwaterMiniaturization

The invention discloses an underwater life-saving device, which comprises a sealed shell, wherein a high-pressure gas chamber is arranged in the shell, a gas leakage hole is formed in the high-pressure gas chamber and externally connected with an air bag, a ventilation device for opening the gas leakage hole is also arranged beside the gas leakage hole, the air bag is stored in the shell in a deflation state, a water pressure sensor and a power supply are also arranged in the shell, the water pressure sensor is connected with the ventilation device through a control circuit board and controls the action of the ventilation device, and the water pressure sensor, the control circuit board and the ventilation device are all connected with a power supply; and the shell is externally provided with a fixing piece being fixed together with a human body. Firstly, the device is small in size, and can be fixed on the body through the fixing part without generation of the use discomfort, and the long-time swimming of a user underwater is not affected.

Owner:NINGBO YIZHOU PRECISION MACHINERY MFG

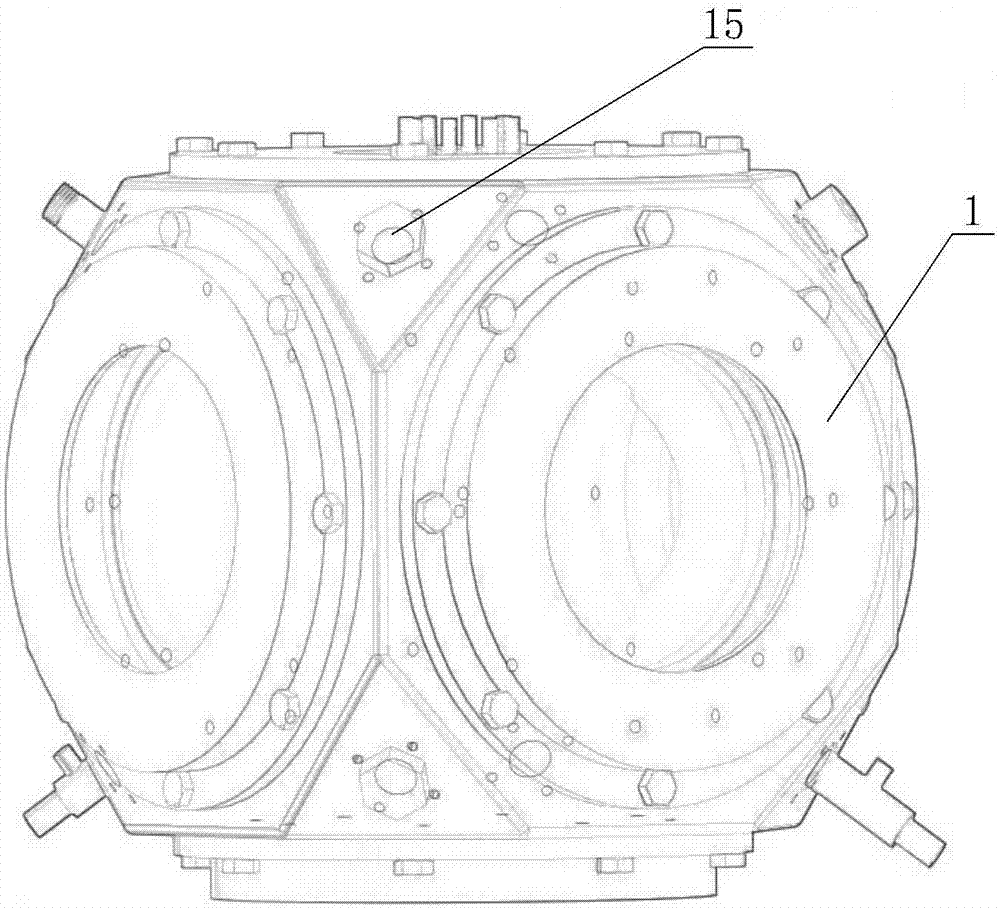

Constant volume chamber and oil atomizer spraying visual test system with same

InactiveCN107420241AImprove sealingEasy to buildEngine testingFuel injection apparatusVisual testIrradiation

The invention discloses a constant volume chamber and an oil atomizer spraying visual test system with the same and belongs to the field of oil atomizer spraying characteristic tests. The constant volume chamber comprises a constant volume chamber body which is of a cube shape; the constant volume chamber body is internally provided with through-holes in three axial directions, and the through-holes are perpendicular and crossed, so that an internal cavity is formed; one mouth portion of one of the through-holes is provided with an oil atomizer module, and the other mouth portion of the corresponding through-hole and the mouth portions of the other through-holes are each provided with a visual window module; each visual window module comprises an outer end cover, an inner side cover plate and quartz glass located between the outer end cover and the inner side cover plate; the visual test system comprises the constant volume chamber, and the two opposite sides of the constant volume chamber body are provided with an ultraviolet lamp and a camera correspondingly; and a fluorescent agent which can shine under the irradiation of the ultraviolet lamp is added to the diesel oil in the constant volume chamber. By means of the constant volume chamber and the oil atomizer spraying visual test system with the constant volume chamber, the leakproofness of the constant volume chamber can be improved, and the problem that the subsequent oil beam outline is disturbed by a background light in a visual test can also be solved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Method for sealing closed gas drainage hole in soft coal bed areas

ActiveCN103244073ASolve the problem of air leakageReasonable designSealing/packingFree wallCement paste

The invention relates to the technical field of mine ventilation and safety-type coal bed gas drainage, particularly to a method for sealing soft coal bed gas drainage hole areas, and solves the problem of severe air leakage of soft coal bed gas drainage hole areas. The method comprises the steps of (1), sealing gas drainage holes on a roadway lane; (2), evenly distributing 2-4 closed short holes which are 6-8m in depth within a range with the circle center of each gas drainage hole serving as the center and the radius of 1-1.5m; (3), filling each closed short hole with low-consistence high-expansion cement which permeates into coal bed fracture areas until cement paste seeps from a coal wall; (4), standing for 20-24h for solidification of cement paste to form a fracture-free wall composed of coal bodies and cement. According to the method, the design is reasonable, the hole sealing technology is improved, the defects of existing hole sealing technologies are overcome, and the problem of air leakage of coal walls is solved thoroughly.

Owner:JINCHENG MINGSHI COAL LAYER USING

Liquid phase intermediate medium heat exchanging type heat exchanger

InactiveCN101261008AReasonable heat transferIncrease flexibilityIncreasing energy efficiencyFeed-water heatersChemical industryAutomatic control

The invention relates to a liquid-phase intermediate medium heat-exchanging type heat exchanger used in boilers, chemical industry and industrial furnaces, comprising a circulating pipeline, a medium recycle pump with a frequency converter which is arranged on the circulating pipeline, a medium heating section which is arranged on the circulating pipeline in a flue gas channel, and a medium heat output section arranged on the circulating pipeline. The temperature rises when a heat transmission medium absorbs waste heat of flue gas on the medium heating section without phase transition, while the temperature reduces when heat is released to a heated medium through the medium heat output section, so that the liquid-phase intermediate medium heat-exchanging type heat exchanger has the characteristics of guaranteeing that the lowest wall temperature of a heating surface is higher than the flue gas acid dew point while greatly reducing the exhaust gas temperature of a boiler so as to avoid the occurrence of low temperature corrosion; an automatic control device can be used to automatically control and adjust the lowest wall temperature through adjusting flow rate of the recycle pump to adapt to the working condition of the boiler and the variance in fuel; moreover, the liquid-phase intermediate medium heat-exchanging type heat exchanger has the characteristics of flexibility, space saving, etc. in the arrangement of equipment; the heat exchanger can replace a rotating air preheater, a tube type air preheater, a heat pipe air preheater and a compound phase-changing heat exchanger.

Owner:王敏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com