Energy-saving environment-friendly circular cooler

A ring cooler, an energy-saving and environmentally-friendly technology, applied in the field of cooling equipment, can solve problems such as air leakage, achieve the effects of saving electric energy, improving cooling efficiency, and preventing heat radiation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Describe the present invention in detail below in conjunction with embodiment:

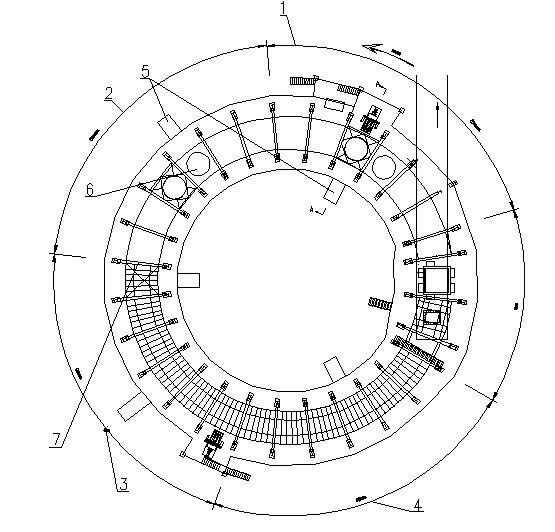

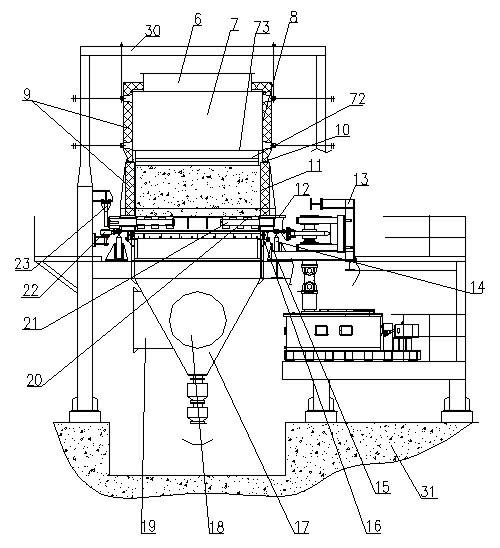

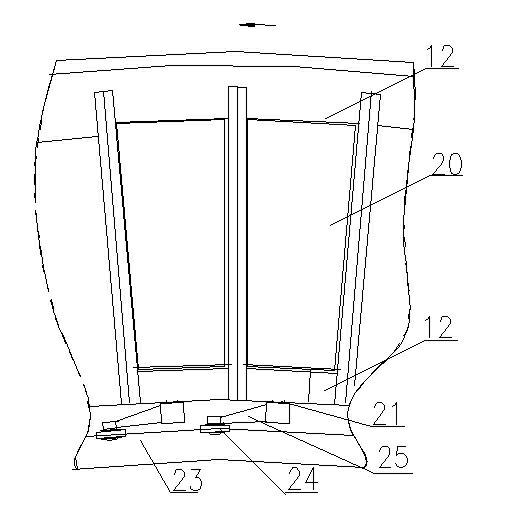

[0025] An energy-saving and environment-friendly annular cooler, see attached figure 1 to attach Image 6

[0026] In the figure: the first high-temperature cooling zone 1, the second high-temperature cooling zone 2, the first low-temperature cooling zone 3, the second low-temperature cooling zone 4; air cooler 5, waste heat recovery interface 6, partition 7, fixed partition 71, movable partition 72 , articulated shaft 73, sealing cover 8, heat insulator 9, sealing body 10, trolley fence 11; revolving body frame 12, frame 13, supporting roller 14, outer layer sliding seal 15, inner layer sliding seal 16, bellows 17, air duct 18; air inlet port 19, fan trolley 20, pin shaft 21; side stop roller 22, track 23, roller 24, turning arm 25, curved pressure rail 26, ejector rod 27, material 28, support beam 29 , beam 30; foundation 31, unloading discharge port 32; air valve 33; pillar 34.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com