Shield machine pipe extension device and connecting method for slurry pipeline in tunnel

A technology for mud pipelines and shield machines, which is applied in tunnels, earthwork drilling, mining equipment, etc. It can solve the problems of high production requirements for three-way valves and blocking balls, time-consuming and labor-intensive manual cleaning, and damage to the seals of three-way valves. Achieve the effect of reducing labor intensity and time cost, simple mechanism and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art.

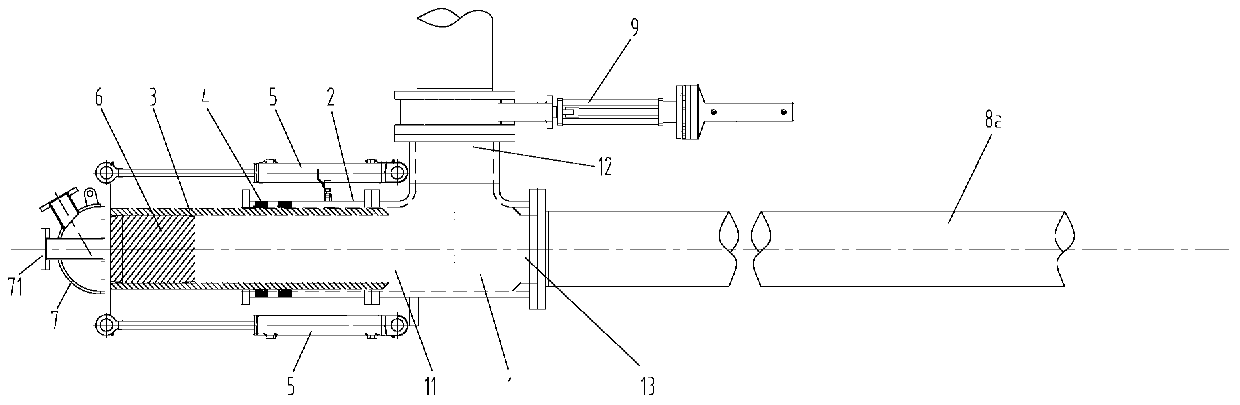

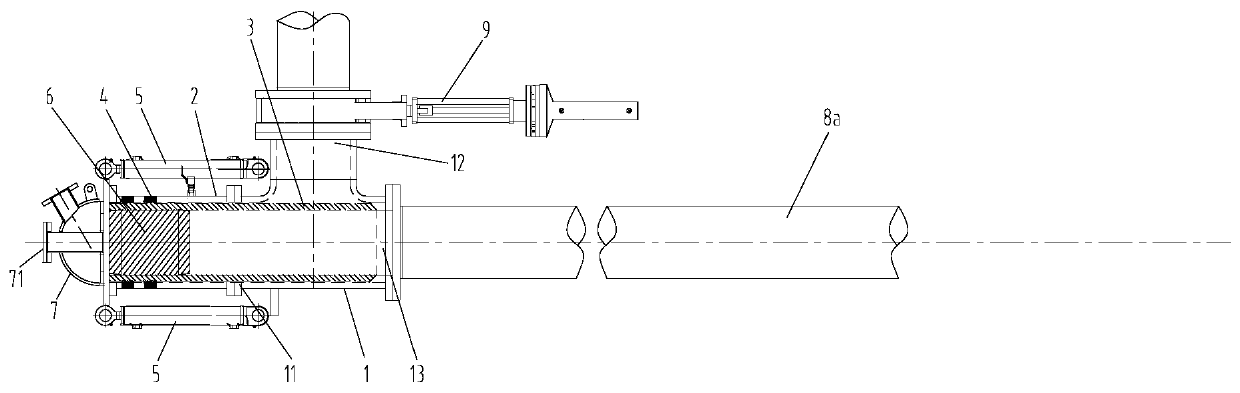

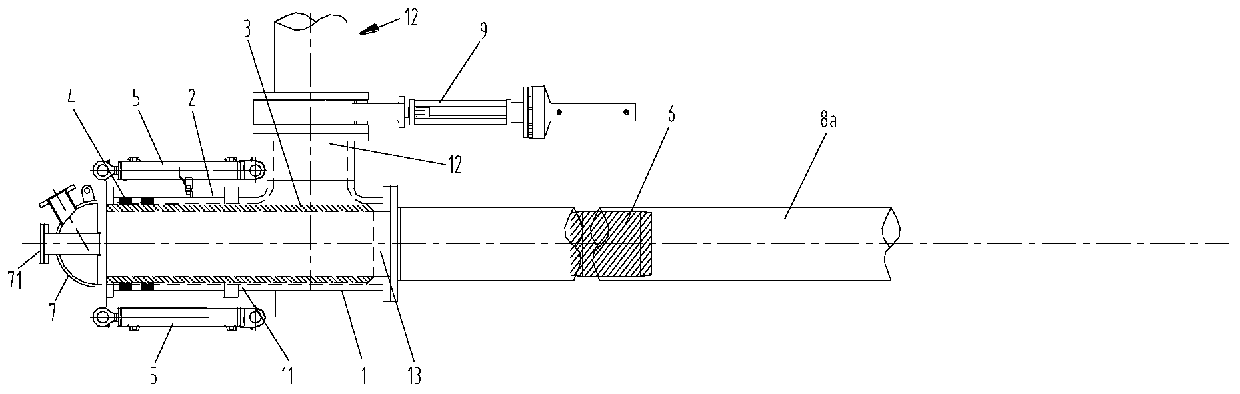

[0033] Reference attached figure 1 to attach Figure 5 , a shield machine tube extension device in this embodiment, including a tee tube 1 with a first port 11, an outer sleeve 2 connected to the first port 11 at one end, and one end can be connected from the other end of the outer sleeve 2 The telescopic tube 3 that is telescopically inserted and can extend into the inside of the tee pipe 1, the seal 4 arranged between the telescopic tube 3 and the outer sleeve 2, the driving device 5 for driving the telescopic tube 3 to move, and the Under the action of entering or breaking away from the blocking ball 6 of the telescopic tube 3, the tee tube 1 also has a second port 12 that can be blocked and connected to the mud pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com