Leakproof tire and preparation method thereof

A technology for preventing air leakage and tires, which is applied to tire parts, rolling resistance optimization, transportation and packaging, etc. It can solve the problems of poor recovery ability, impact on sealing effect, and deterioration of self-sealing effect, etc., so as to solve the problem of air leakage and nailing air leakage, significant social and economic benefits, and the effect of improving driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

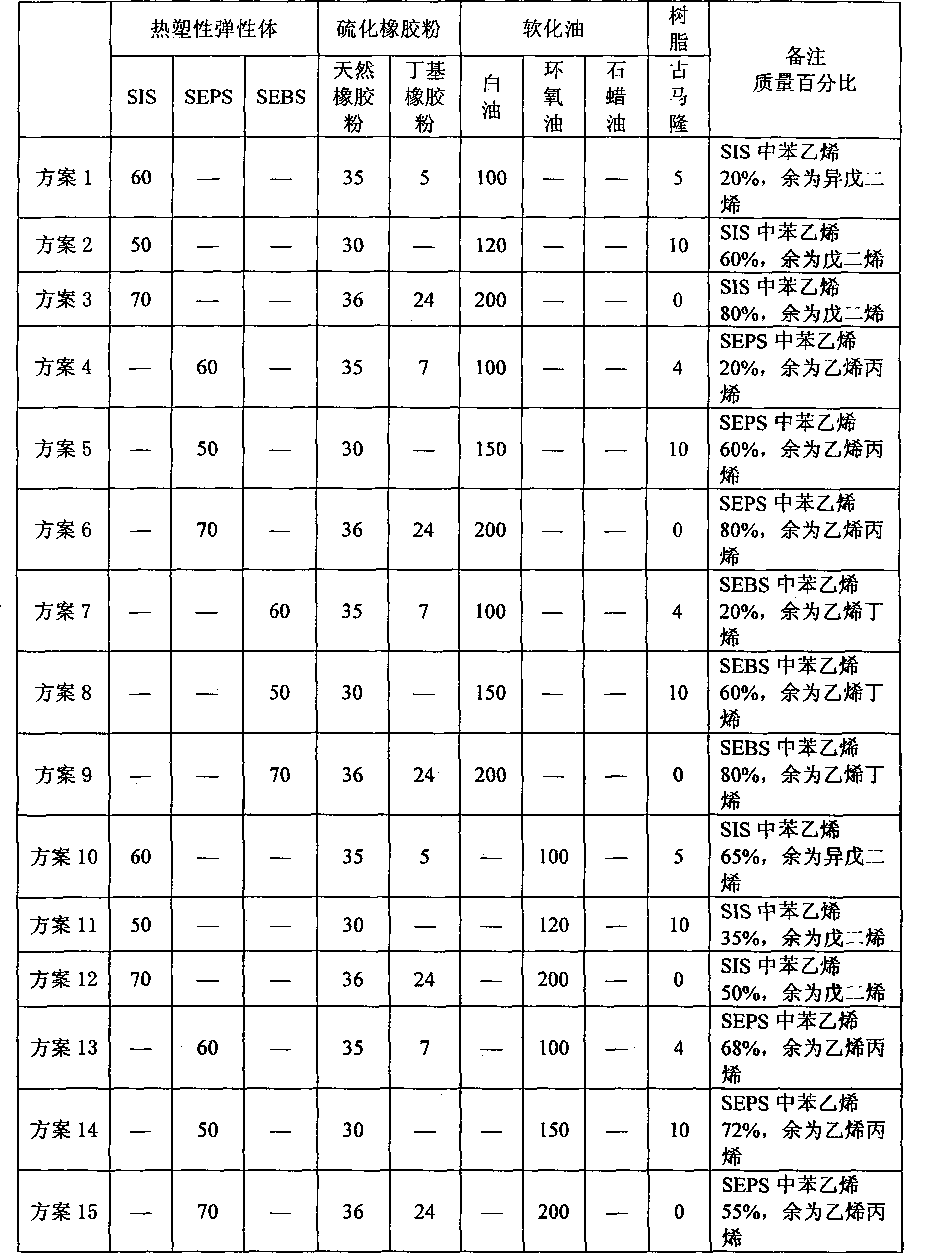

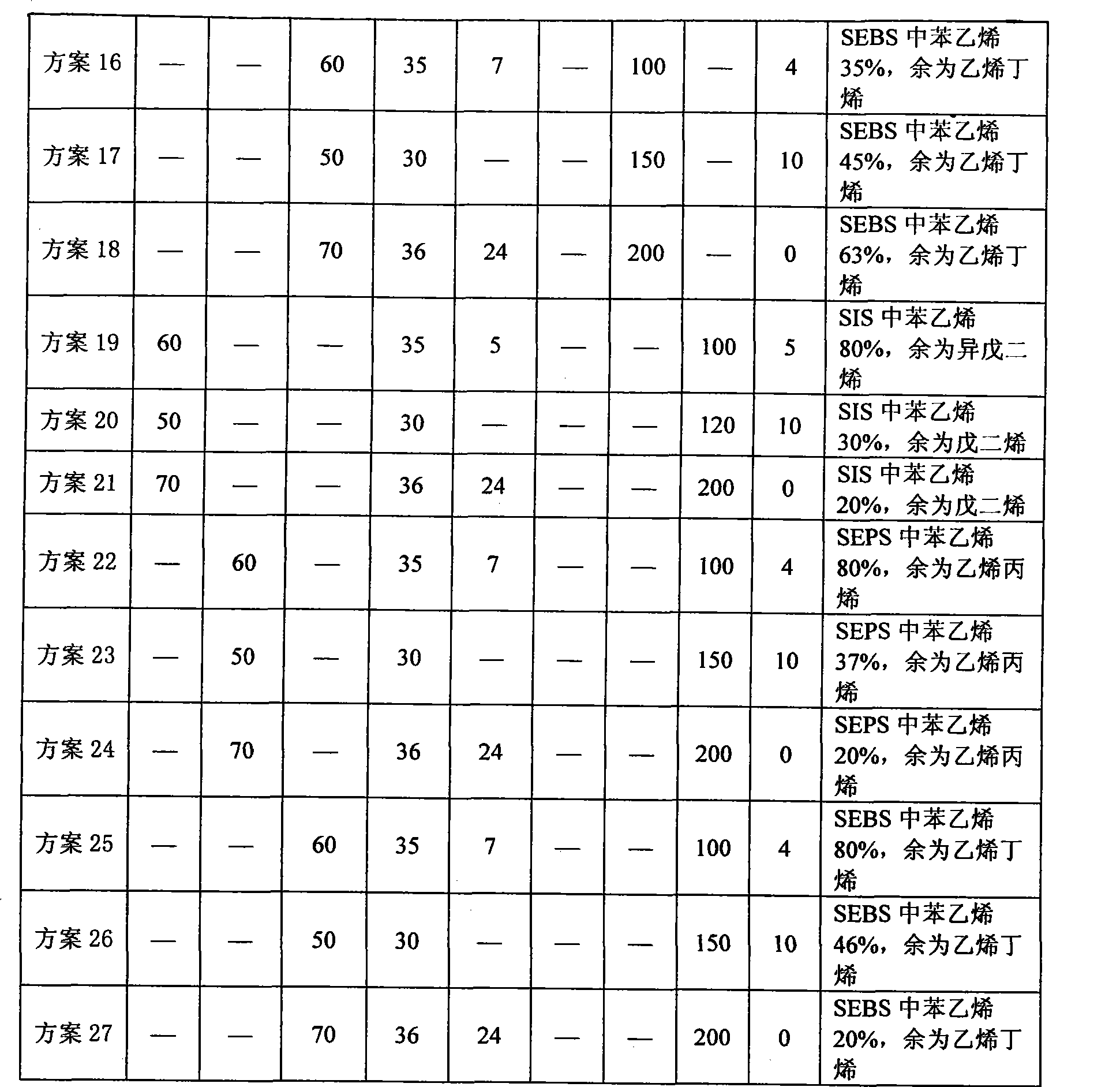

[0034] The main component scheme of the gel state elastomer material is shown in Table 1:

[0035] Table 1

[0036] Unit:kg

[0037]

[0038]

[0039] Mix the components in the above scheme in a reaction kettle, raise the temperature to 200-300°C while stirring, until dispersed into a uniform flowable blend, that is, a molten gel-like elastomer blend is obtained.

[0040] The preparation method of air-run-proof tire of the present invention:

[0041] The tire device is rotated at a certain speed on the fixture, and the molten gel-like elastomer blend obtained in the above scheme is sprayed to the bottom of the inner wall of the rotating tire by a delivery pump at a flow rate of 50-200g / second. Under the action of the tire, a layer of uniform elastomer coating layer 3 with self-sealing function is formed on the inner wall of the tire, with a thickness of 3-5mm.

[0042] As a preferred solution, when spraying, first spray one l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com