Separated scenting device for scented tea

A scenting device and a separate technology, which is applied in the field of separate scented tea scenting devices, can solve the problems of affecting the taste and efficacy of scented tea, not being fully utilized, and having a lot of dust in the tea sifting operation, so as to achieve better taste and increase utilization Value, the effect of avoiding mildew and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

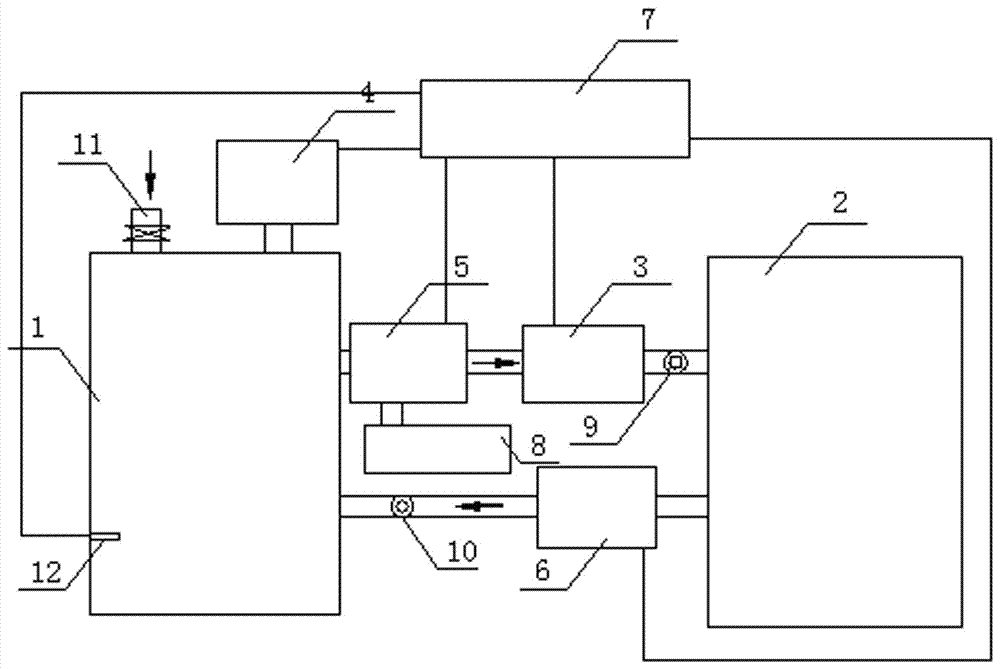

[0036] The separated scented tea scenting device includes a flower bin 1, a tea bin 2 and an automatic controller 7. The upper parts of the flower bin 1 and the tea bin 2 are connected through an upper pipe; the upper pipe is installed sequentially from the side of the flower bin 1 There are condenser 5, fan A3 and temperature sensor A9; the lower part of condenser 5 is connected with water tank 8; the lower part of flower warehouse 1 and tea warehouse 2 are connected through the lower pipeline; Temperature sensor B10 and heater 6; Carbon dioxide detector 12 is installed in described fresh flower warehouse 1; The fan B4 of air inlet 11 and exhaust is arranged on described fresh flower warehouse 1; Automatic controller 7 passes wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com