Vacuum heat insulation plate and preparation method thereof

A technology of vacuum insulation panels and vacuum units, which is applied to heat exchange equipment, mechanical equipment, and pipelines protected by heat insulation, and can solve problems such as complex preparation methods, poor heat preservation and fire prevention, and air leakage, and achieve simple and easy-to-operate preparation methods , good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

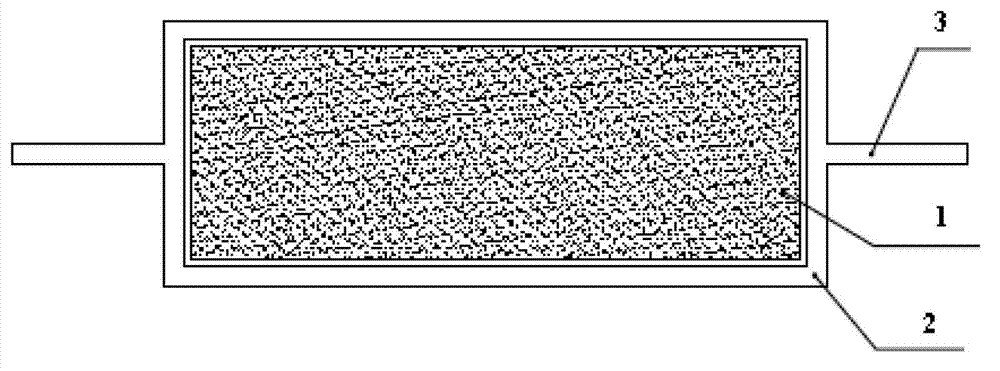

[0026] A vacuum insulation panel, comprising a high-barrier film bag and an insulating core material 1 wrapped therein, the insulating core material 1 comprising basalt fiber, the fiber diameter of the basalt fiber is 8-9 μm, the length is 90-100 mm, and the water content is 1%, the content of sizing agent is 0.2%, and the use temperature is between -260~650℃. The high barrier film bag is an aluminum foil fiber composite vacuum heat insulation bag 2 with a thickness of 3 μm.

[0027] The preparation method of the vacuum insulation panel includes the following steps:

[0028] (1) Select the basalt fiber of the above specification;

[0029] (2) Compress the basalt fiber on a press machine, the compressive strength is 200kPa, the thickness of the thermal insulation core material 1 after pressing is 10mm, and the bulk density is 50kg / m 2 ;

[0030] (3) Use a vacuum dryer to dry, the drying temperature is 220 ° C, the vacuum degree is 1000 Pa, and lasts for 10 minutes;

[0031]...

Embodiment 2

[0034] A vacuum insulation panel, comprising a high-barrier film bag and an insulating core material 1 wrapped therein, the insulating core material 1 comprising basalt fibers, the fiber diameter of the basalt fibers is 7-8 μm, the length is 70-80 mm, and the water content is 0.9%, the sizing content is 0.1%, and the use temperature is between -260~650℃. The thermal insulation core material 1 is a basalt fiber felt made of the basalt fiber, with a thickness of 30mm and a bulk density of 20kg / m 2 . The high barrier film bag is an aluminum foil fiber composite vacuum heat insulation bag 2 with a thickness of 12 μm.

[0035] The preparation method of the vacuum insulation panel includes the following steps:

[0036] (1) Select the basalt fiber felt of the above size and specification, and cut it appropriately if necessary;

[0037] (2) Compress the cut basalt fiber felt on a press machine, the compressive strength is 250kPa, the thickness of the thermal insulation core materia...

Embodiment 3

[0042] A vacuum insulation panel, comprising a high-barrier film bag and an insulating core material 1 wrapped therein, the insulating core material 1 comprising basalt fibers, the fiber diameter of the basalt fibers is 5-6 μm, the length is 55-75 mm, and the water content is 0.5%, the sizing content is 0.15%, and the use temperature is between -260~650℃. The thermal insulation core material 1 is a basalt fiber board made of the basalt fiber, with a thickness of 20 mm and a bulk density of 15 kg / m 2 . The high barrier film bag is an aluminum foil fiber composite vacuum heat insulation bag 2 with a thickness of 10 μm.

[0043] The preparation method of the vacuum insulation panel includes the following steps:

[0044] (1) Select the basalt fiberboard of the above size and specification, and cut it appropriately if necessary;

[0045] (2) Press the cut basalt fiber board on a press machine, the compressive strength is 220kPa, the thickness of the thermal insulation core mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com