Patents

Literature

85results about How to "Guaranteed longevity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

OBE (Outcomes-based Education) course development teaching system for higher vocational school

PendingCN108596807ARealize integrationPerfect communicationData processing applicationsSoftware designThe InternetCloud computing

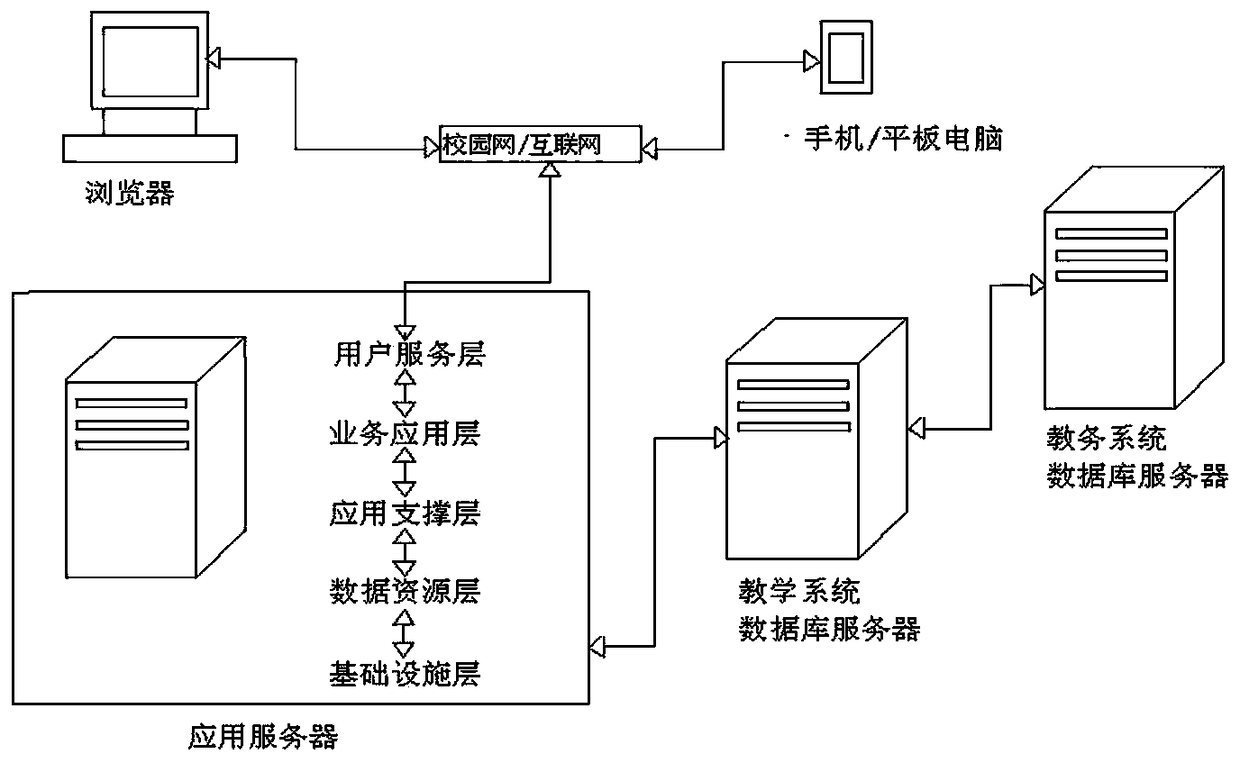

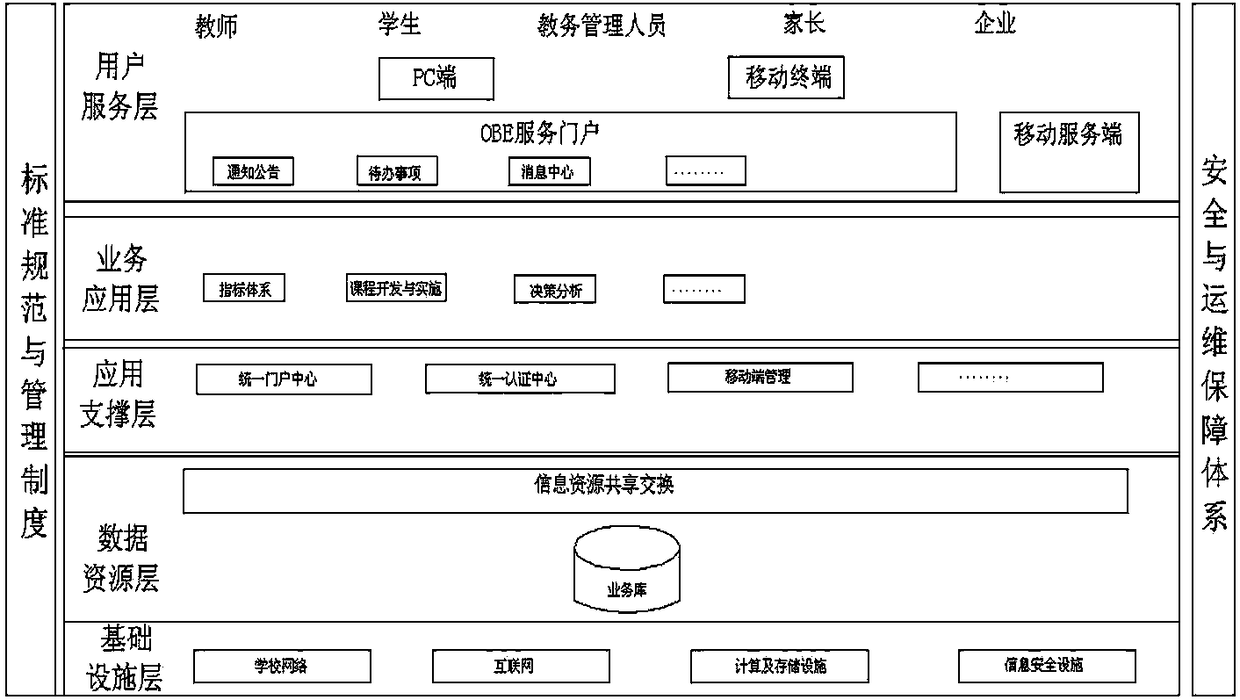

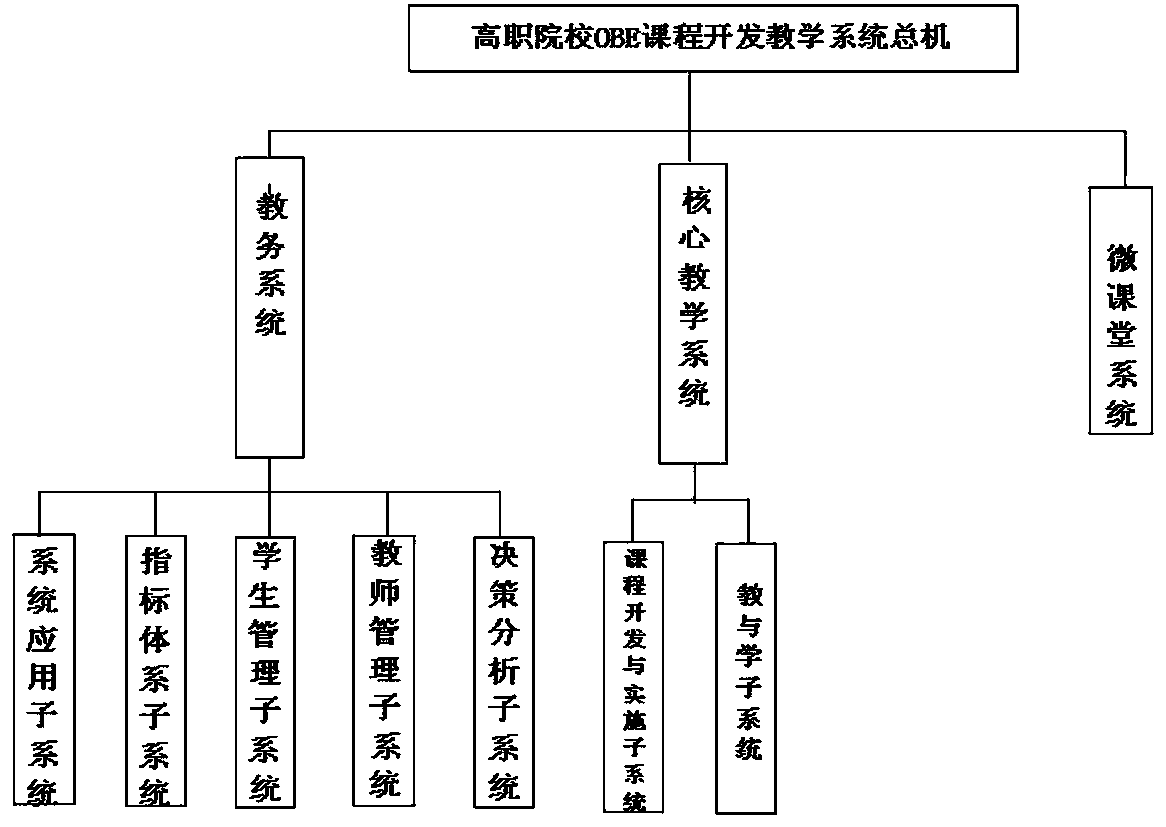

The invention discloses an OBE (Outcomes-based Education) course development teaching system for a higher vocational school. Based on an internet and a cloud computing technology, by gathering educational resources, carrying out a concept of an OBE, designing a course according to a principle of inverse design, constructing a course system with a final learning outcome as a start point and an endpoint, changing a teacher-centered mode into a student-centered mode and changing quality monitoring into continuous improvement, under a new teaching mode, the formulation of a professional talent cultivation scheme, the preparation of a course outline and an interactive manner between a teacher and a student in a class are overturned, and the management and analysis can be scientific and normative; with massive data output under an OBE teaching mode, the teacher is helped to teach and the student is helped to learn; an accurate representation on a learning condition state is brought to a school by using big data analysis, so a basis is provided for administrative decision-making; and as a student development archive and a teacher development archive are kept, the system has direct assistant and supporting effects for the teacher to perform course development and can highlight a scientific system flow of the course development.

Owner:HEILONGJIANG PROVINCE ECONOMIC MANAGEMENT CADRE COLLEGE

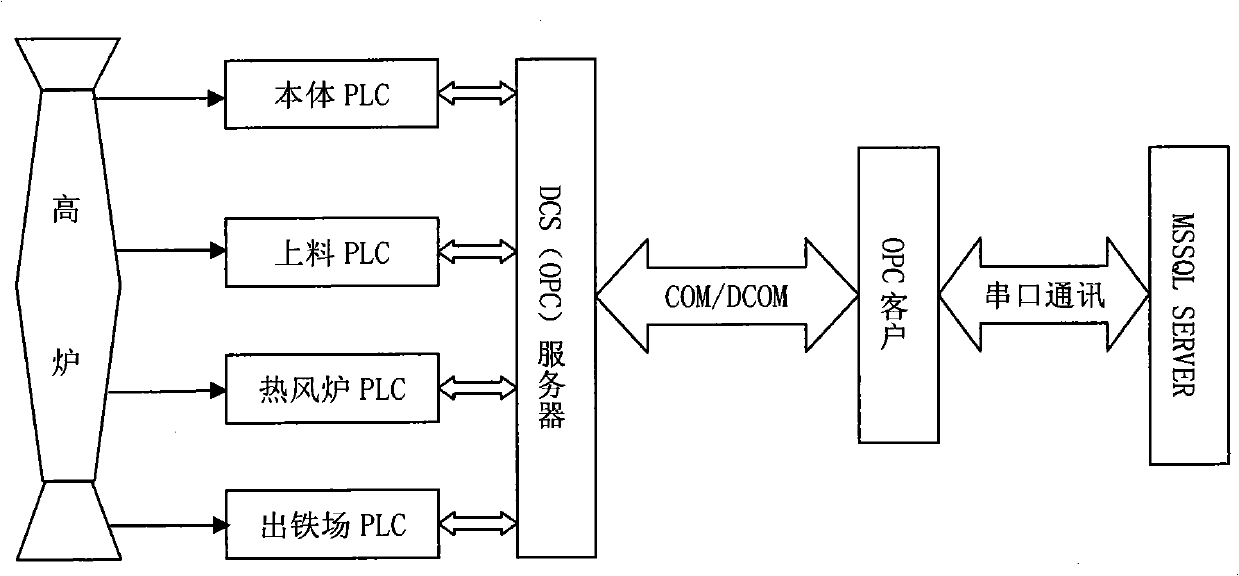

Blast furnace profile monitoring system

InactiveCN102021260AGuaranteed furnace conditionEffective temperature monitoringChecking devicesChemistrySQL

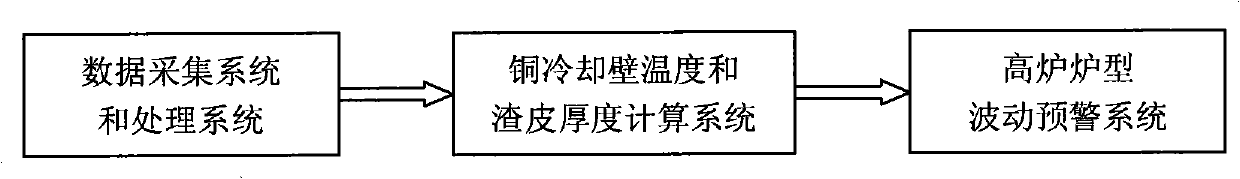

The invention discloses a blast furnace profile monitoring system which mainly comprises a PLC (Programmable Logic Control) system, a DSC (Dynamic Stability Control) system, an OPC (OLE for Process and Control) server, an SQL (Structured Query Language) database technology, a serial port isolation technology, an asynchronous communication technology and a WEB display technology. The blast furnace profile monitoring system is characterized in that a blast furnace data collection system and treatment system, a blast furnace copper cooling wall temperature slag and skin thickness calculation system and a blast furnace type fluctuation prewarning system are respectively established on such a basis, and all subsystems are organically combined through OPC serial port communication, an SQL database and a high-speed Ethernet. The invention can efficiently monitor the slag skin thickness of a heat surface of the copper cooling wall in a blast furnace high heat loading region i.e. a blast furnace profile, form a high-speed blast furnace type and condition information channel with strong calculation capability between the blast furnace and a main control chamber, guide blast furnace operation under the abnormal furnace conditions of slag skin thickening or thinning in the blast furnace high heat loading region and the like and ensure stable and smooth blast furnace condition as well as long service life of the blast furnace.

Owner:ANGANG STEEL CO LTD

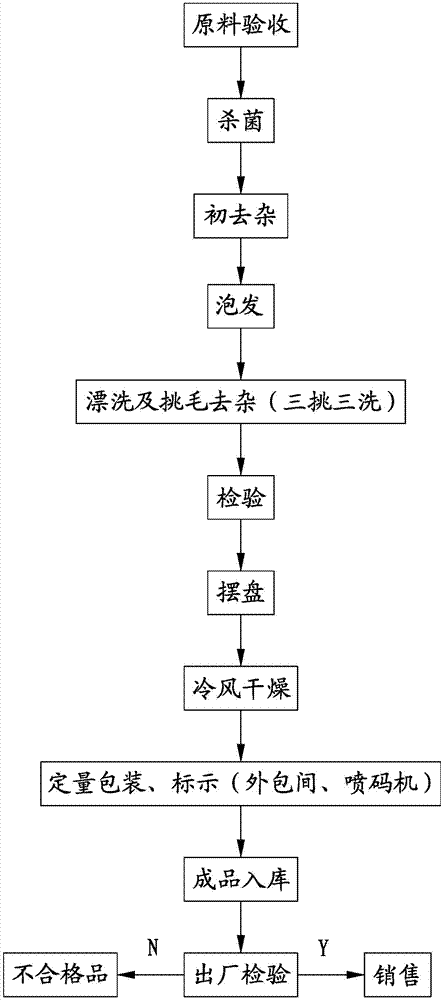

Production method of pure cubilose

The invention discloses a production method of pure cubilose. The production method comprises the following steps of: firstly, checking and accepting raw materials, namely, selecting light hair or medium hair crude cubilose raw materials; secondly, sterilizing, namely, disinfecting and sterilizing the raw materials by using ultraviolet rays; thirdly, primarily removing impurities, namely scrubbing black dots on the raw materials, removing the impurities on the raw materials; fourthly, soaking for swelling; fifthly, rinsing and picking hairs and removing the impurities, wherein the picking and washing are carried out for three times; sixthly, checking. According to the production method, the raw materials are finely checked and accepted, the sterilization and primary impurity-removing procedures are added, the soaking for swelling and the three-time picking and washing are carried out so that the cubilose is high in purity, the effect of the cubilose is ensured, and the cubilose is pure without foreign tastes, and is relatively good in mouth feel.

Owner:XIAMEN YANANJU FOOD

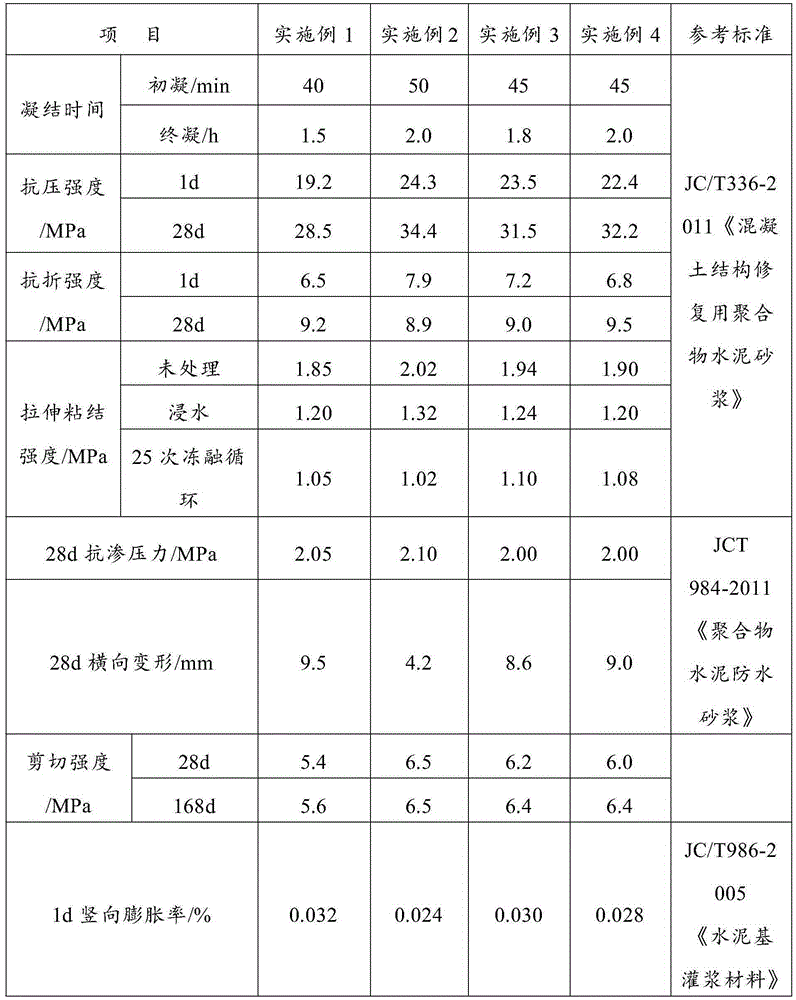

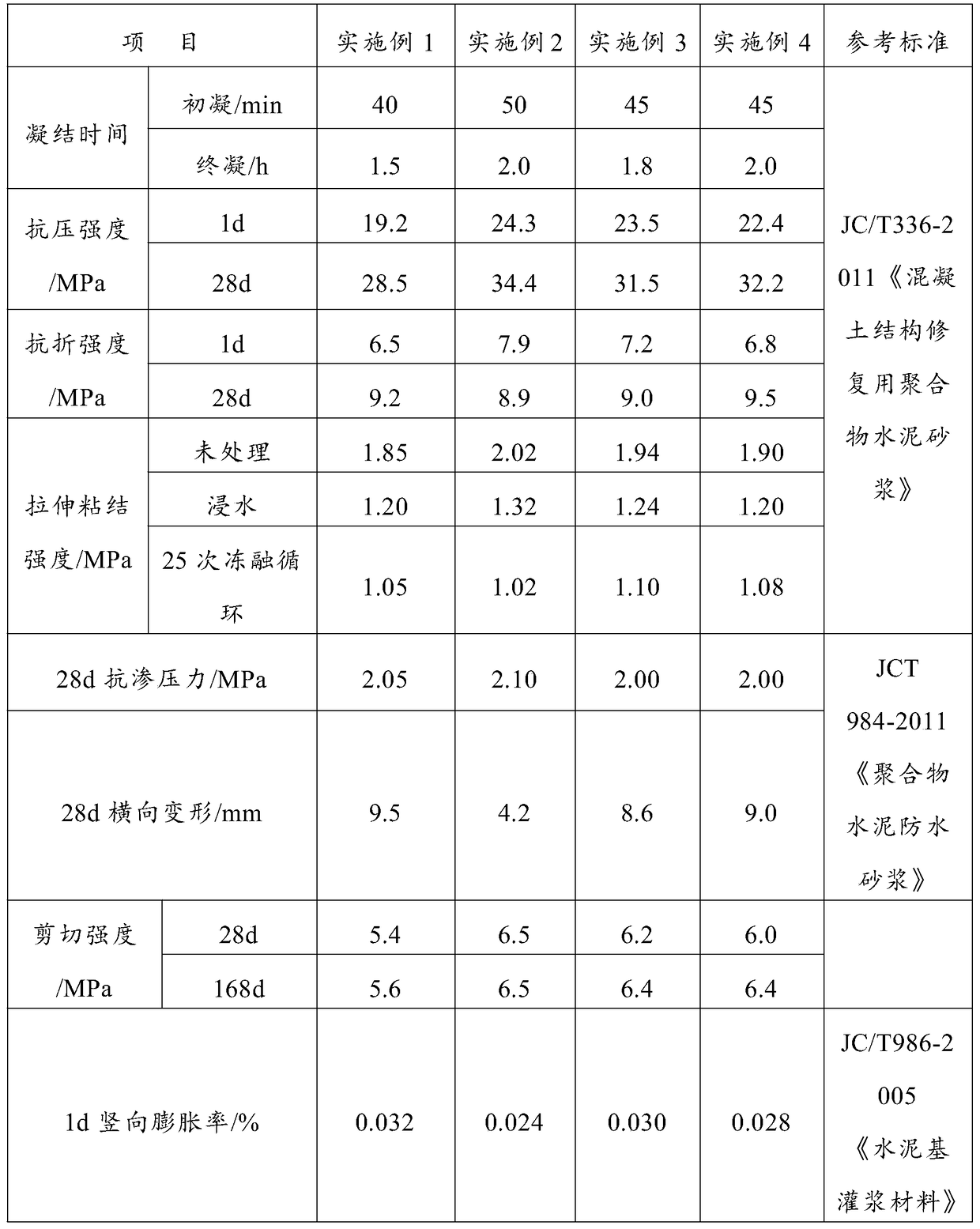

Flexible concrete for seam sealing

The present invention discloses flexible concrete for seam sealing, wherein the flexible concrete comprises, by mass, 15-25% of an inorganic cementing material, 1.0-2.0% of an expansion material, 4-8% of a filler, 40-60% of stone, 15-30% of sand, 0.3-1.0% of high strength special fibers, 3-6% of a macromolecule additive, and the balance of water. According to the present invention, the price of the selected raw materials is low, the bonding requirements with the old base surface can be met, and the good water resistance can be provided; and the flexibility and the expansion property of the concrete are improved so as to effectively reduce the pavement load and the harm caused by vibration.

Owner:北京宝辰联合科技股份有限公司

Preparation and use of sludge-stalk fibrous composite

ActiveCN101475332AImprove adhesionGuaranteed longevitySolid waste managementClimate change adaptationPlant rootsSludge

The invention relates to a method for preparing a sludge-straw fibre composite material and application. Municipal sludge, straw fibre and industrial waste slag (desulfurized clinker and steel slag) are used as raw materials to prepare a sludge-fibre micelle copolymer by sludge modification technology and copolymer even stirring technology; the sludge-fibre micelle copolymer is used for ecological protection and restoration of a rock slope, a clay slope and a landfill field slope. The sludge-fibre micelle copolymer prepared by the technology recycles and utilizes sludge and straw fibre which are difficult to process; and compared with various green substrates, the sludge-fibre micelle copolymer does not need to add nitrogen, phosphorus, potassium and organic fertilizer to soil, reutilizes waste and greatly reduces cost. The straw fibre improves the tensile and flexural mechanical performance of the sludge-fibre micelle copolymer and further achieves the mechanical strength index of the slope protection. Grass seeds are mixed to the copolymer; and the hydrological effect of plant and mechanical reinforcement effect of a plant root system are utilized to effectively circulate moisture and achieve the functions of reinforcing the slope and greening environment.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Vacuum heat insulation plate and preparation method thereof

ActiveCN103090157ASolve bag swellingSolve the problem of air leakageThermal insulationPipe protection by thermal insulationMaterial DegradationHigh resistance

The invention discloses a vacuum heat insulation plate for building outer walls, the vacuum heat insulation plate comprises a high resistance thin film bag and heat preservation core materials wrapped in the high resistance thin film bag, and the heat preservation core materials comprise basalt fibers. The vacuum heat insulation plate has the advantages of being simple in structure, low in cost, energy-saving and environmental, secure, fireproof, and good in heat preservation property. The invention further discloses a preparation method of the vacuum heat insulation plate. The preparation method of the vacuum heat insulation plate comprises: (1) preparing materials, (2) compression molding, (3) drying, and (4) packaging. The problems of bag swelling, air leakage, core material degradation, and durability of vacuum degree of a traditional vacuum heat insulation plate are solved, meanwhile the defects of using silicon dioxide and other powdery materials and difficult composite filling plating of the silicon dioxide and other powdery materials and fibers are overcome. The preparation method is simple and easy to operate, and saves both time and labor.

Owner:山东华德隆建材科技有限公司 +1

Free radical emulsion polymerization manufacturing method and application of functional nanocapsule slurry

InactiveCN102174142ASimple production processHigh cyst rateMicroballoon preparationArtifical filament manufactureSolventChemistry

The invention discloses a free radical emulsion polymerization manufacturing method and application of functional nanocapsule slurry. The manufacturing method comprises the following steps of: mixing 1 to 100 weight parts of functional material, 5 to 30 weight parts of oil-soluble monomer, 0.5 to 5 weight parts of cross-linking agent and 0.01 to 0.5 weight part of initiator to obtain mixed liquor, and heating the mixed liquor to a temperature higher than the melting point of the functional material; and mixing and emulsifying the mixed liquor and 150 to 400 weight parts of emulsifier aqueous solution which contains 0.1 to 20 weight parts of amphiphilic block copolymer, adding 0.01 to 5 weight parts of co-emulsifier in the emulsifying process, introducing nitrogen to remove oxygen, regulating the temperature of polymerization reaction to be between 60 and 90 DEG C under low-speed stirring, and reacting for 3 to 5 hours to obtain the functional nanocapsule slurry. In the application, the functional nanocapsule slurry is directly used as a solvent for wet spinning to prepare spinning solution for preparing functional fibers.

Owner:TIANJIN POLYTECHNIC UNIV

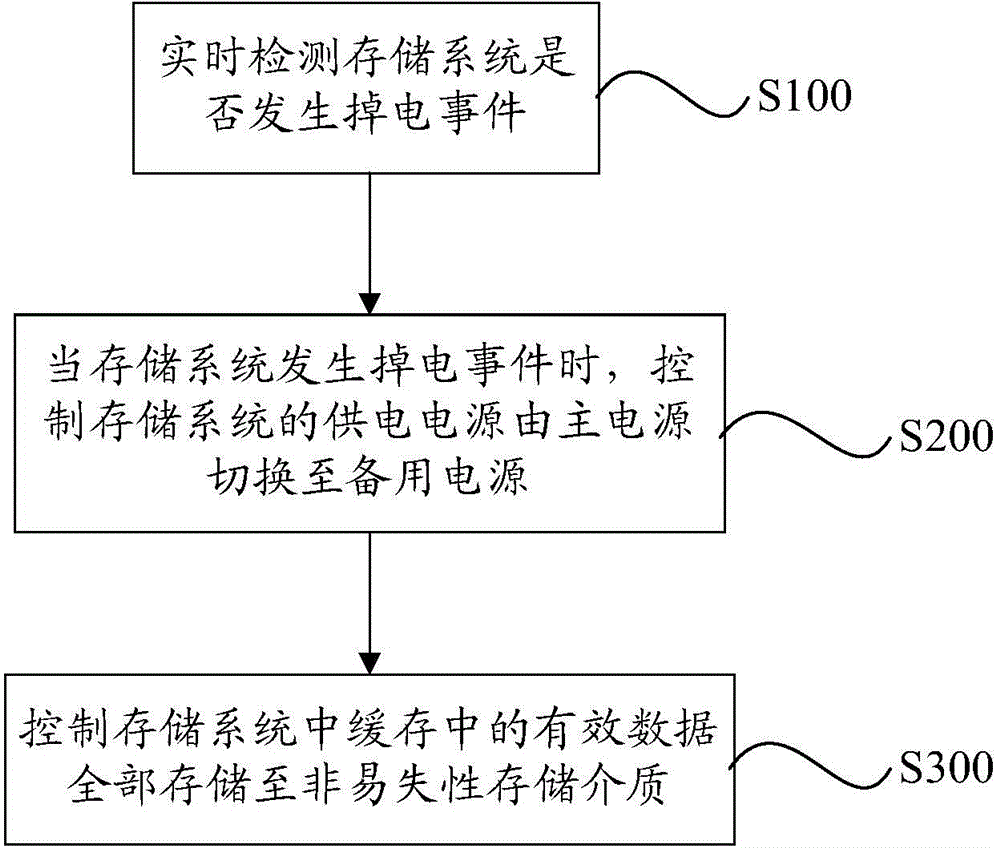

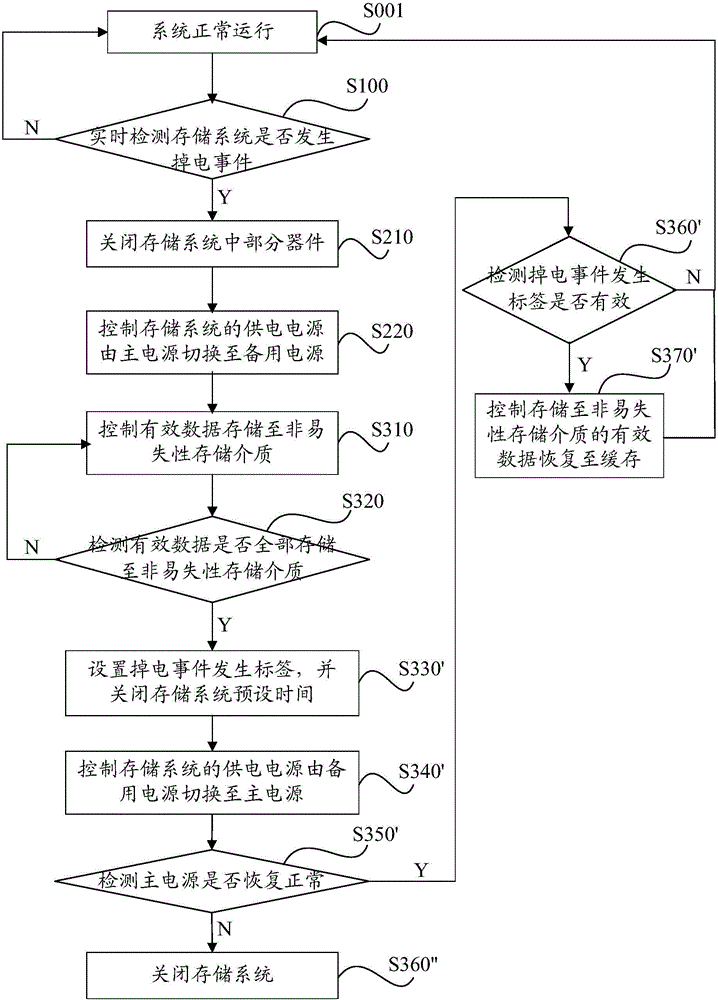

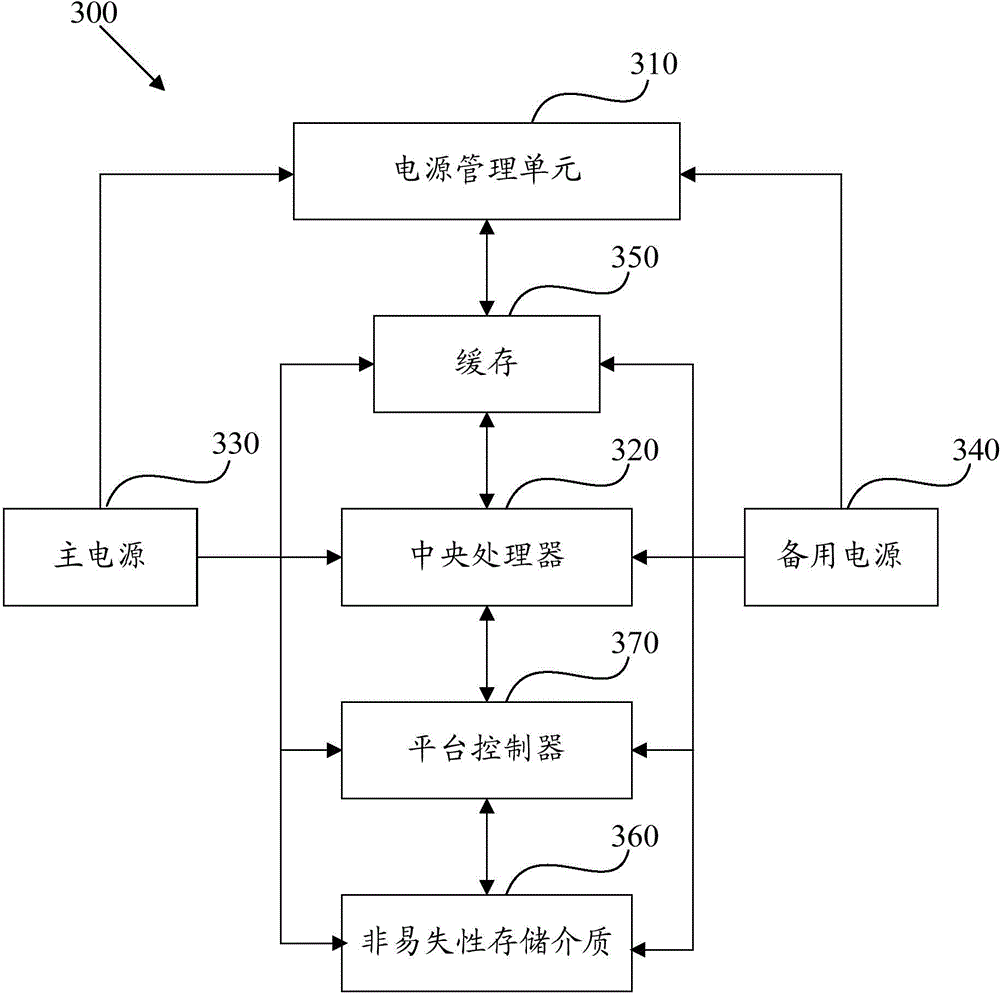

Power-down data protection method and device of storage system

ActiveCN104881375AEnsure safetyGuaranteed longevityMemory loss protectionPower supply for data processingElectricityStandby power

The invention discloses a power-down data protection method and device of a storage system. The method includes the steps of detecting whether power-down occurs in the storage system occurs in real time; if yes, controlling a power supply of the storage system to switch from a main supply to a standby supply; controlling effective data, located in a cache of the storage system, to be all stored to a nonvolatile memory medium. After the power-down of the storage system is detected, the standby supply is used to power the storage system, and the effective data in the cache of the storage system is controlled and all stored to the nonvolatile memory medium; thus, security and persistence of the effective data in the cache is guaranteed. The standby supply is a power type battery low in cost; the problem that the existing storage system power-down data protection mode has high software and hardware costs is effectively solved.

Owner:BEIJING FORTUNET INFORMATION & TECH

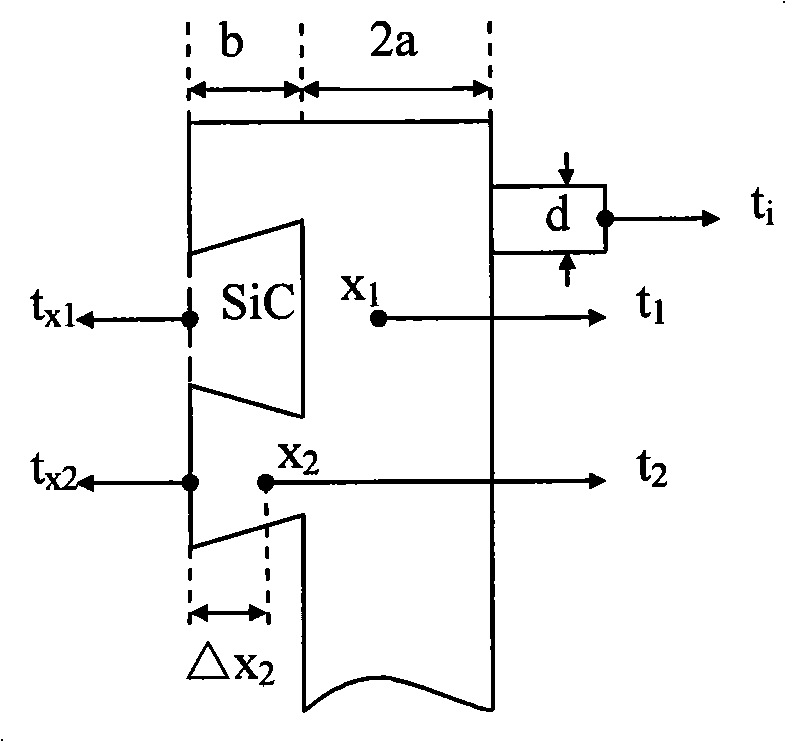

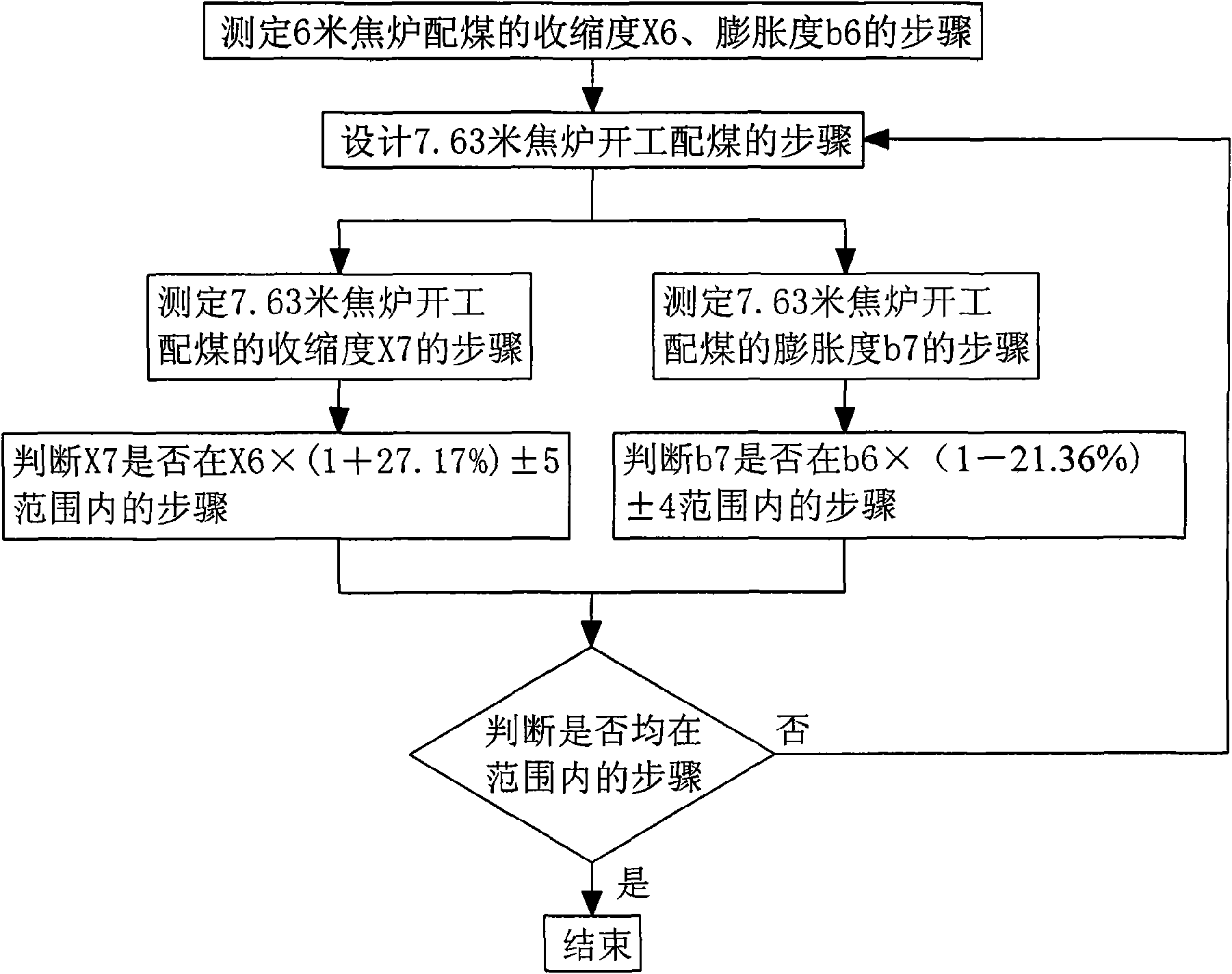

Coal blending method of 7.63m coke oven during starting work

The invention relates to a coal blending method of a 7.63m coke oven during starting work, which comprises of the following steps: measuring X6 and b6; designing the coal blending of the 7.63m coke oven during starting work; measuring and judging; judging whether X7 and b6 are both in a range and carrying out following options; completing. The X6 is the shrinking measure of the coal blending of a 6m coke oven and the b6 is the swelling capacity of the coal blending of the 6m coke oven; if the X7 and the b7 are both in the range, the next step is carried, or the X7 and the b7 are not both in the range, the step (2) is carried out again. The method of the invention ensures that the coke oven has enough shrinkage and proper internal swelling power in a coking process to make for the movable contact of coal particles and coking, has small integral external swelling, ensures the smooth coke pushing of a new coke oven during starting work, prevents oven walls from damage, and obtains coke with relatively good quality.

Owner:武汉钢铁有限公司

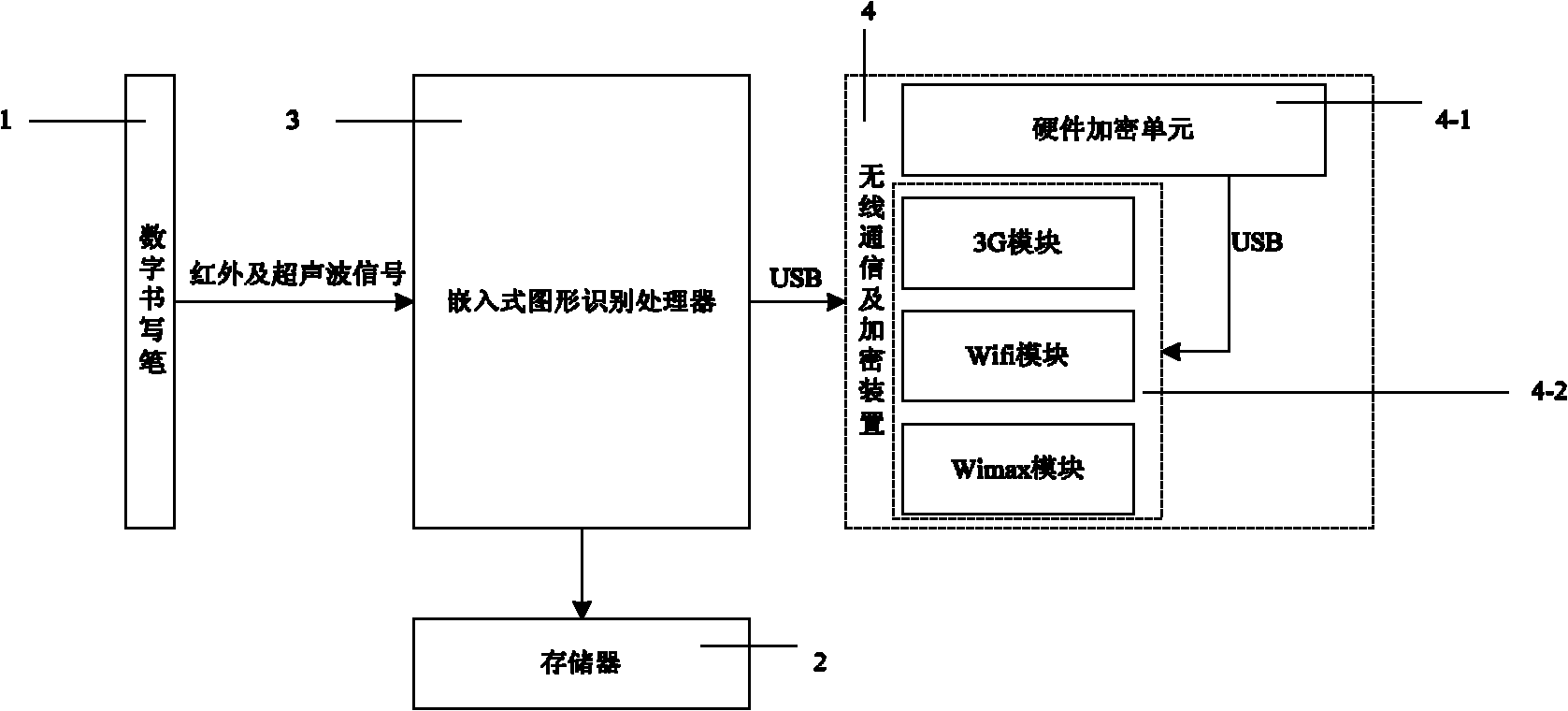

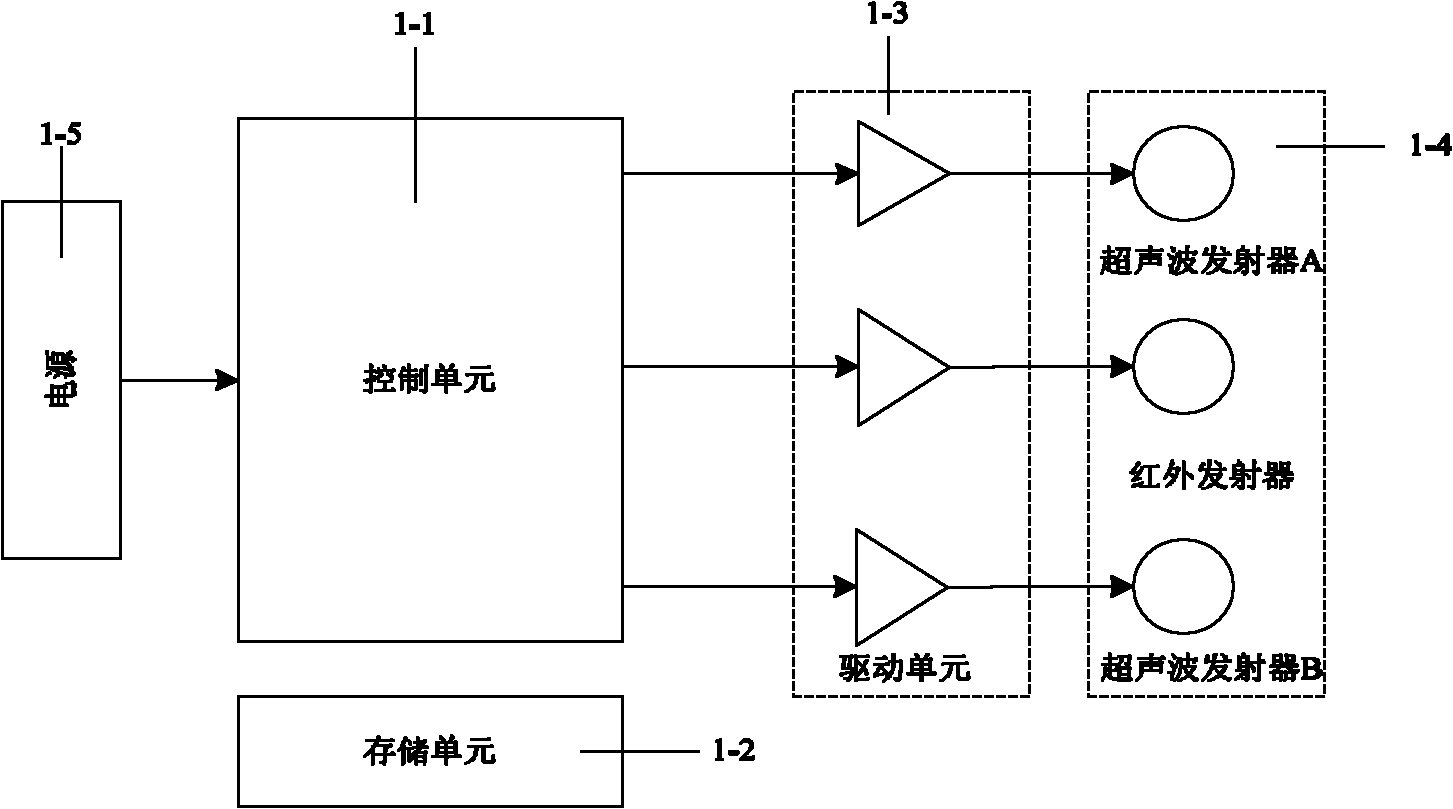

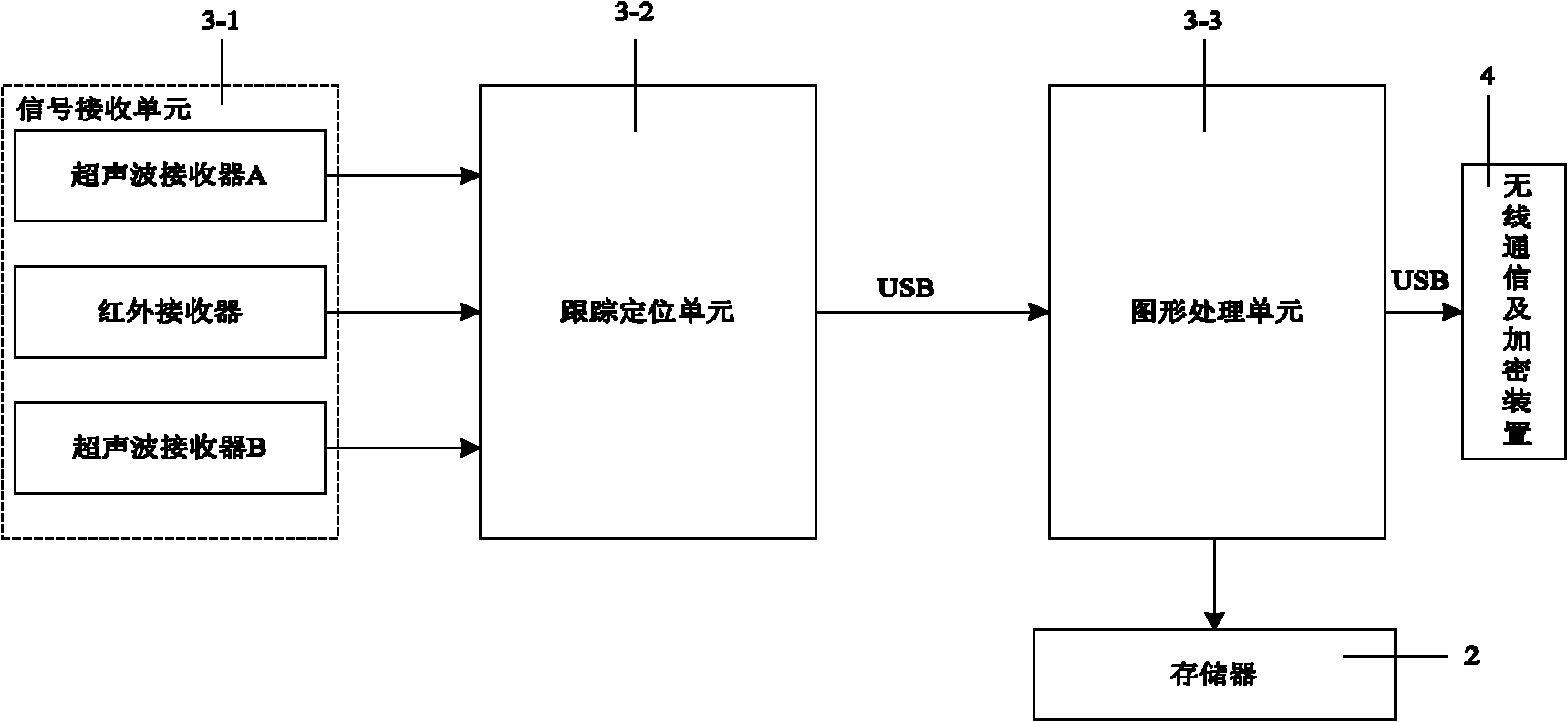

Digital processing system for examinations based on Internet of Things architecture and handwriting recognition method thereof

InactiveCN102324063AGuaranteed accuracyImprove accuracyCharacter and pattern recognitionInput/output processes for data processingDigital writingHandwriting

The invention relates to a digital processing system for examinations based on Internet of Things architecture and a handwriting recognition method thereof. The invention aims at providing the digital processing system for the examinations based on the Internet of Things architecture and the handwriting recognition method thereof, realizing real-time answer marking and question answering, improving the answer marking processing speed and accuracy of an examination system, decreasing the input of manpower and material resources as much as possible, reducing the cost, improving the efficiency and ensuring long-term information saving at the same time. The technical scheme is that the digital processing system for the examinations based on the Internet of Things architecture is characterized in that the system comprises an embedded graphic recognition processor, a digital writing pen which is in wireless connection with the embedded graphic recognition processor, and a memory and a wireless communication and encryption device which are in wired connection with the embedded graphic recognition processor. The system and the method provided by the invention are suitable for automated processing on all kinds of examination occasions.

Owner:张京伦 +3

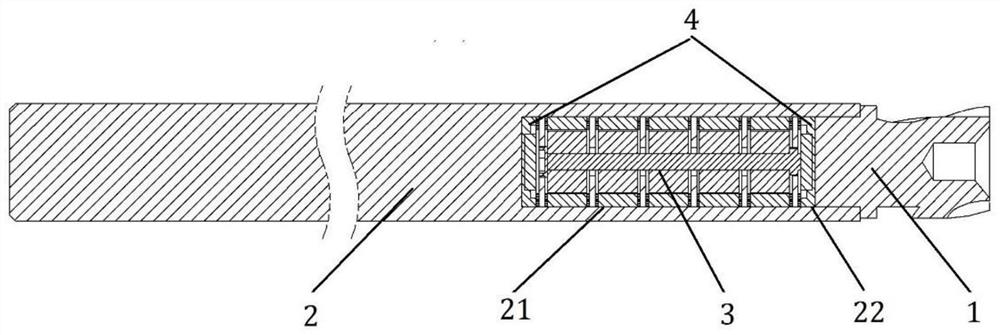

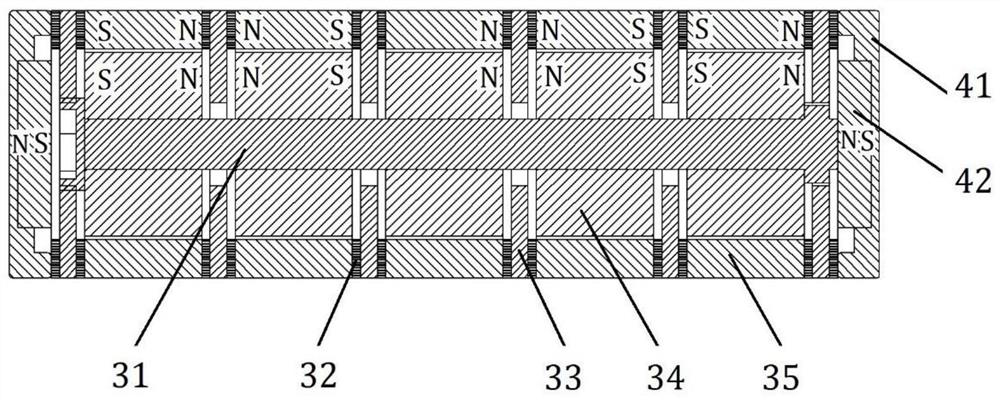

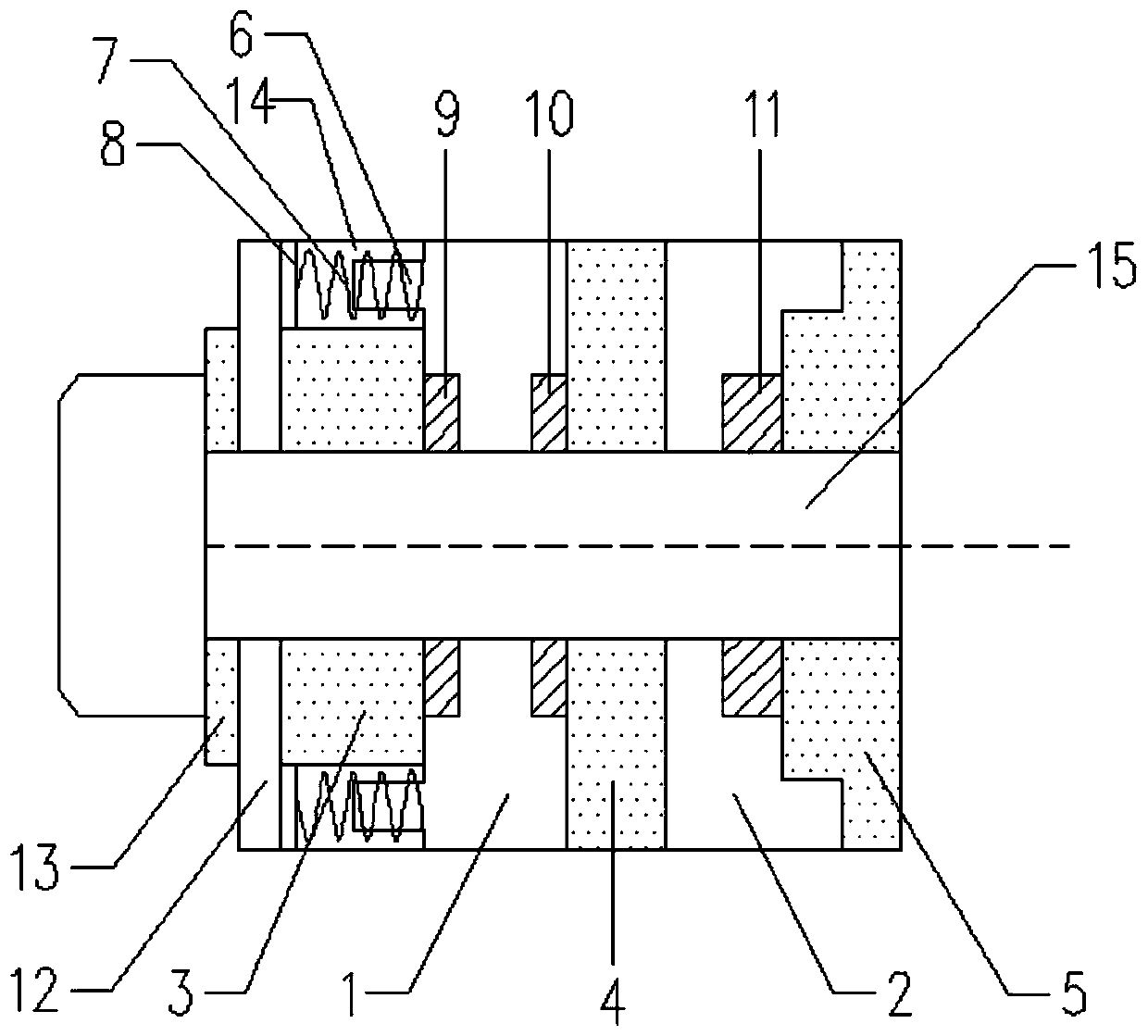

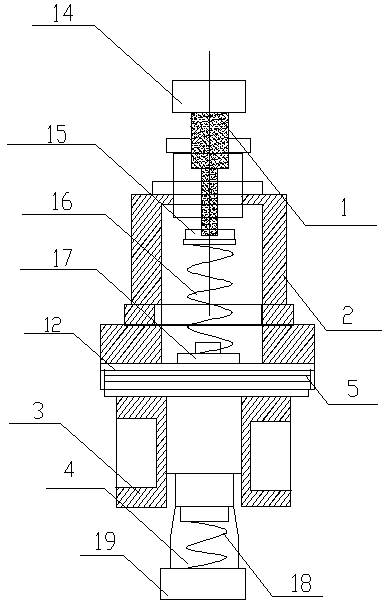

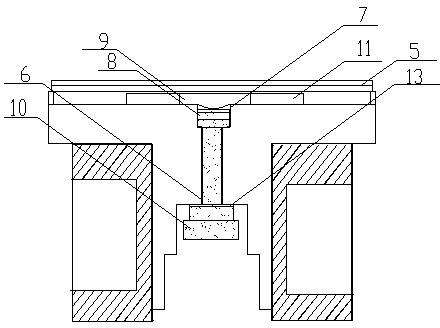

Vibration reduction milling cutter based on layered superposition type permanent magnet dynamic vibration absorber

The invention discloses a vibration reduction milling cutter based on a layered superposition type permanent magnet dynamic vibration absorber. The dynamic vibration reduction milling cutter comprisesa cutter head, a cutter bar, a permanent magnet type dynamic vibration absorber and an axial thrust end cover, and the permanent magnet type dynamic vibration absorber and the axial thrust end coverare installed in a cylindrical cavity of the cutter bar; and the permanent magnet type dynamic vibration absorber is composed of a connecting rod, a rubber gasket, a metal sheet, an inner magnetic ring and an outer magnetic ring. The permanent magnet type dynamic vibration absorber in the dynamic vibration reduction milling cutter is integrally of a layered superposition type structure, it can beguaranteed that the dynamic vibration absorber provides large magnetic rigidity and eddy current damping under the condition of the small size, and therefore rubber and damping materials in a traditional dynamic vibration reduction cutter bar are replaced with the magnetic rigidity and the eddy current damping; the problems of damping liquid leakage, rubber fatigue aging and the like in a traditional dynamic vibration reduction cutter bar are solved, the rigidity and damping of the dynamic vibration absorber are independently designed, the service life of a cutter can be effectively prolonged,and the vibration reduction effect can be effectively improved.

Owner:BEIJING UNIV OF TECH

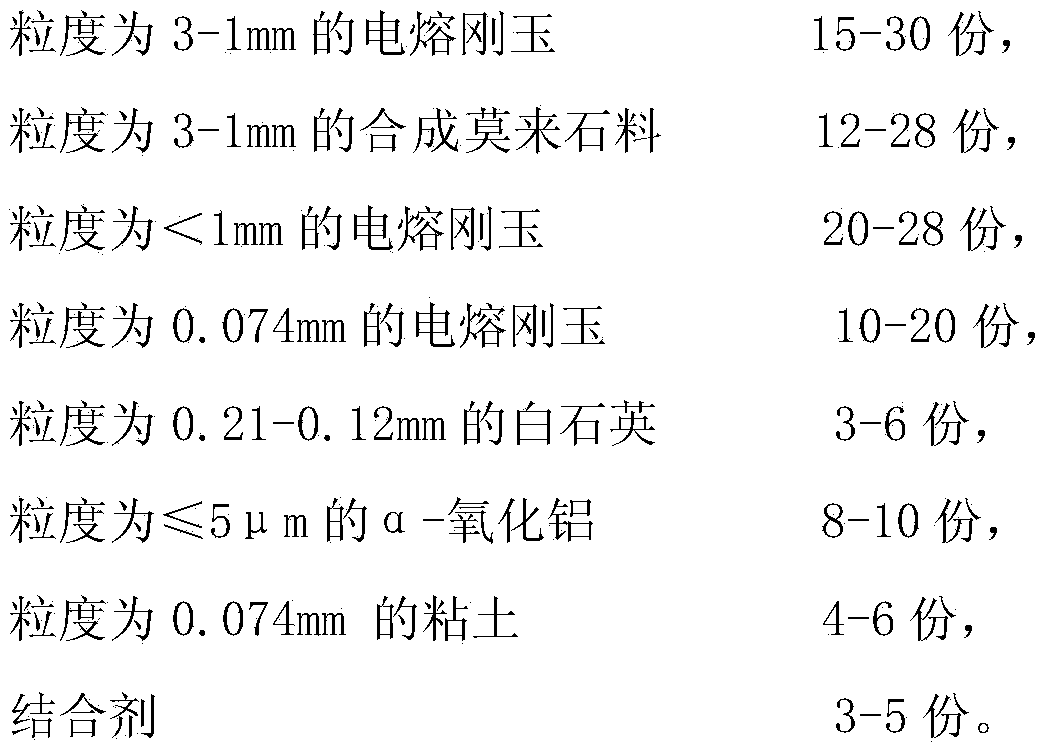

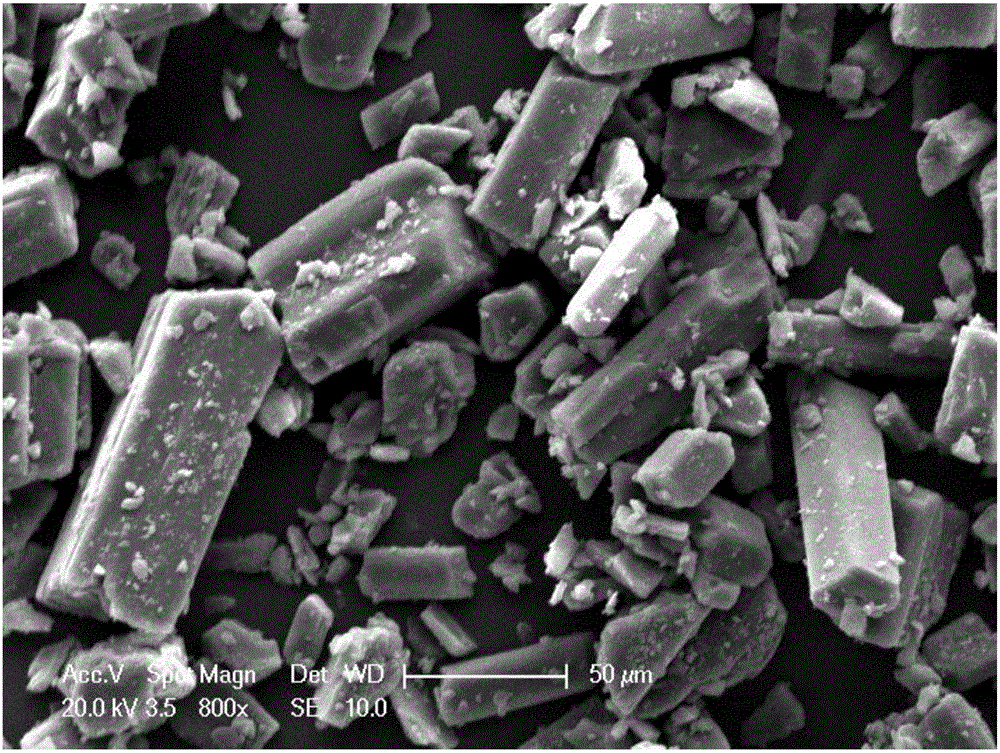

Anti-erosion mullite brick for blast furnace and preparation method thereof

The invention relates to an anti-erosion mullite brick for a blast furnace and a preparation method thereof. The anti-erosion mullite brick is produced from the following raw materials in parts by weight: 15-30 parts of fused corundum having granularity ranging from 3 to 1 mm, 12-28 parts of synthetic mullite having granularity ranging from 3 to 1 mm, 20-28 parts of fused corundum having granularity of less than 1mm, 10-20 parts of fused corundum having granularity of 0.074mm, 3-6 parts of white quartz having granularity ranging from 0.21 to 0.12mm, 8-10 parts of alpha-aluminum oxide having granularity of less than or equal to 5 microns, 4-6 parts of clay having granularity of 0.074mm, and 3-5 parts of binding agent. The anti-erosion mullite brick for the blast furnace provided by the invention has the characteristics of low porosity, low impurity content, high strength, good high-temperature performance, excellent erosion resistance and high penetration resistance; the anti-erosion mullite brick is especially applicable to a vanadium-titanium blast furnace; the anti-erosion mullite brick is capable of maintaining the structure stability under high temperature load for a long time; as a result, the long service life of the vanadium-titanium blast furnace is greatly guaranteed.

Owner:SHANDONG REFRACTORIES GRP LUNAI KILN REFRACTORYCO

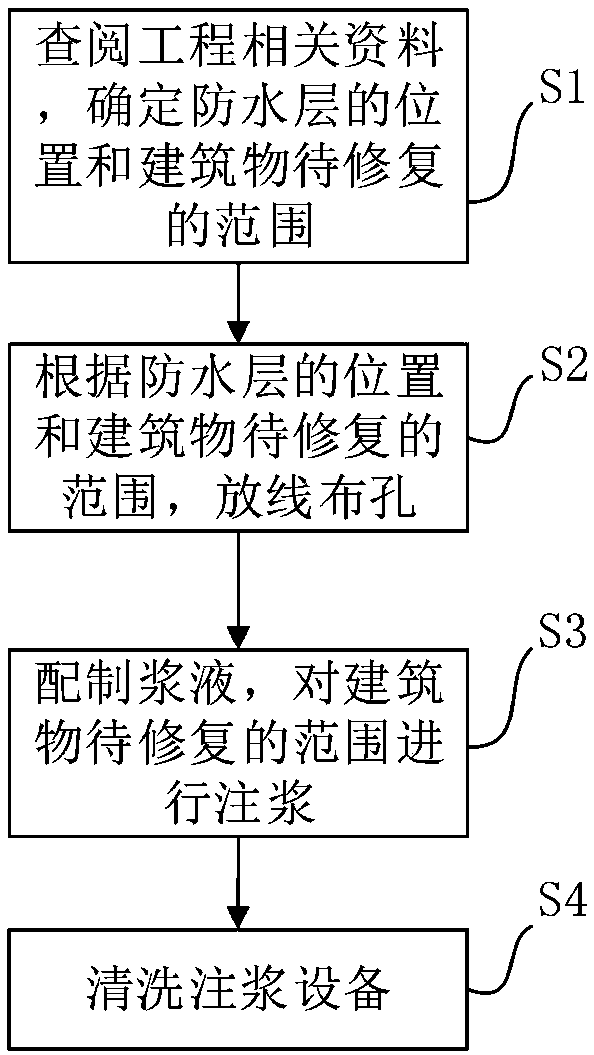

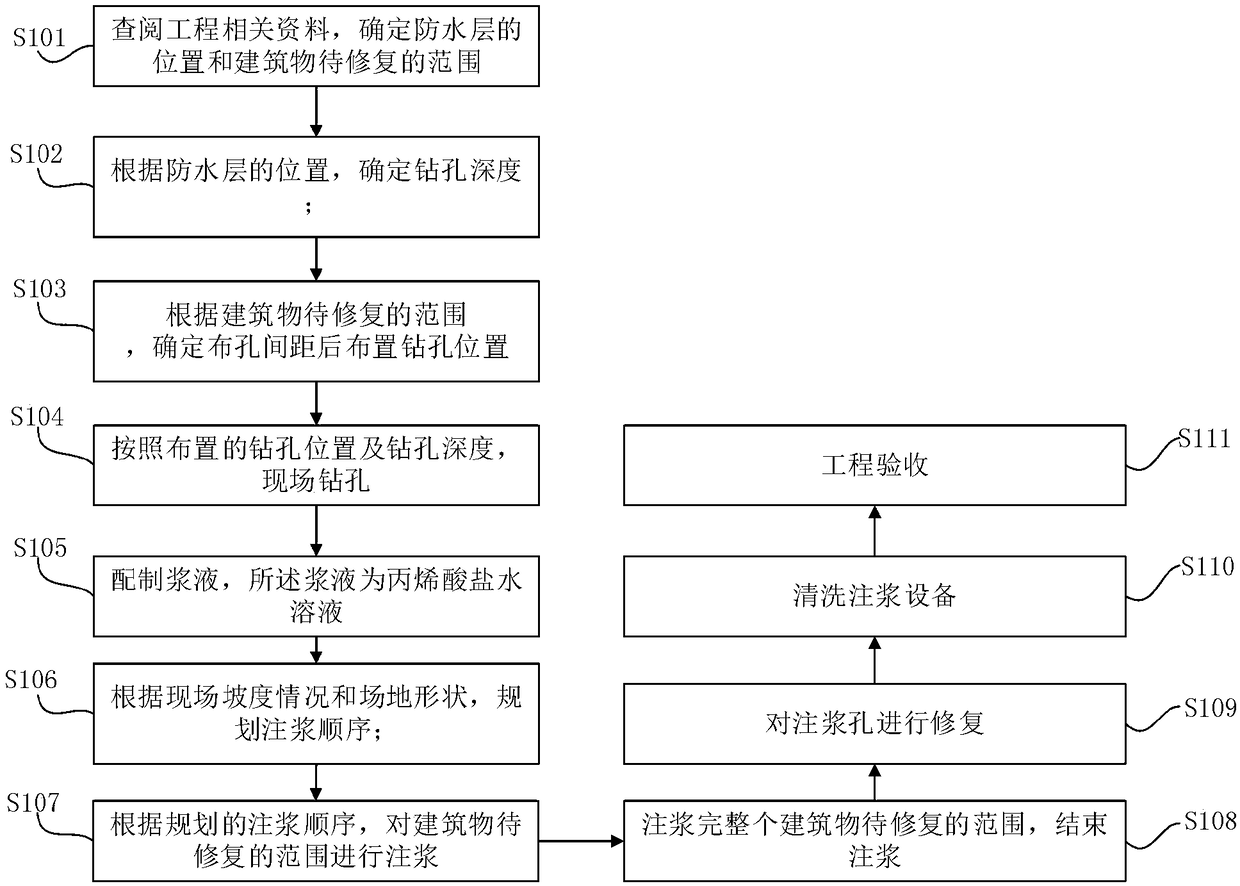

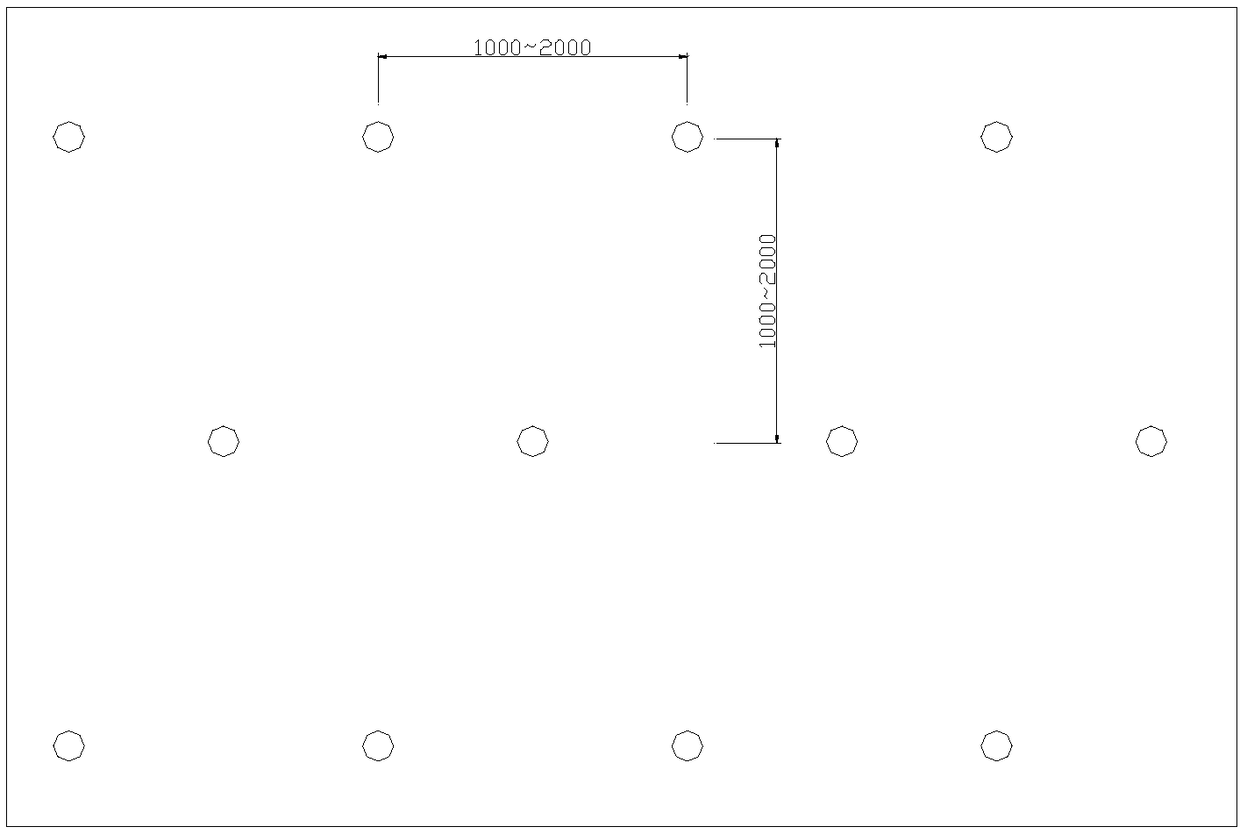

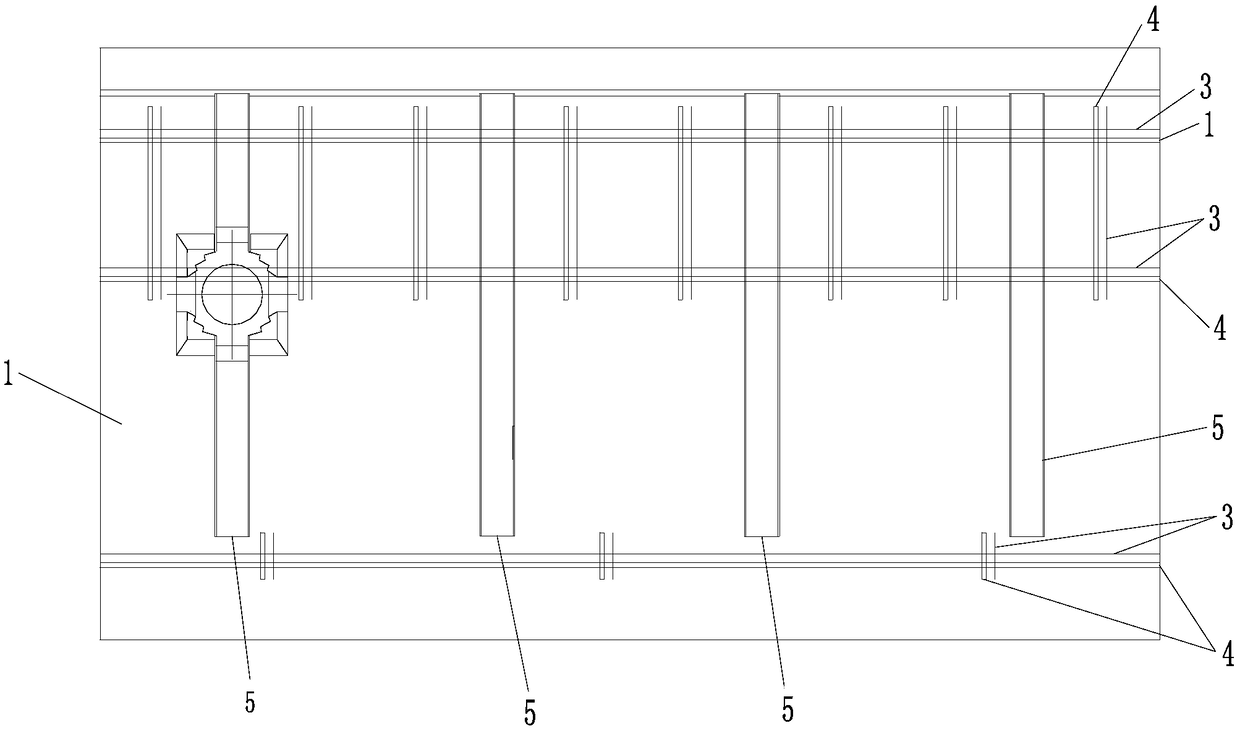

Construction method for grouting reconstruction repairing of existing waterproof layer

PendingCN109281492AReduce processingChange the renovation methodBuilding repairsWater storageLiquid state

The invention discloses a construction method for grouting reconstruction repairing of an existing waterproof layer. By referring to related engineering data, the position of the waterproof layer andthe scope to be repaired of a building are determined, and then setting out, hole arrangement and grouting are performed. A traditional reconstruction method is changed, the construction waste disposal and roofing repairing processes are reduced, grouting holes are arranged in a plum-blossom shape to enable the effective coverage area to be larger, and the cost is saved. Accumulated water betweenthe holes is discharged through the pressure difference between the holes which is formed by row-by-row and hole-by-hole grouting, the discharged water is replaced and supplemented by grout, and a small amount of undischarged water participates in the solidification reaction of the grout, so that the accumulated water of an outer layer of the waterproof layer is completely eliminated, and a new waterproof layer is formed; and the grout replacing the accumulated water solidifies and condenses into a waterproof body in cracks or holes in the waterproof layer, a liquid state of the grout is changes into a solid state, the water storage state above the waterproof layer is completely changed, a permanent overall waterproof layer is formed, and the repair of original leakage points is completed,so that the long-term effect of leakage control is ensured.

Owner:重庆市十八土鑫诚灌浆防水工程有限公司

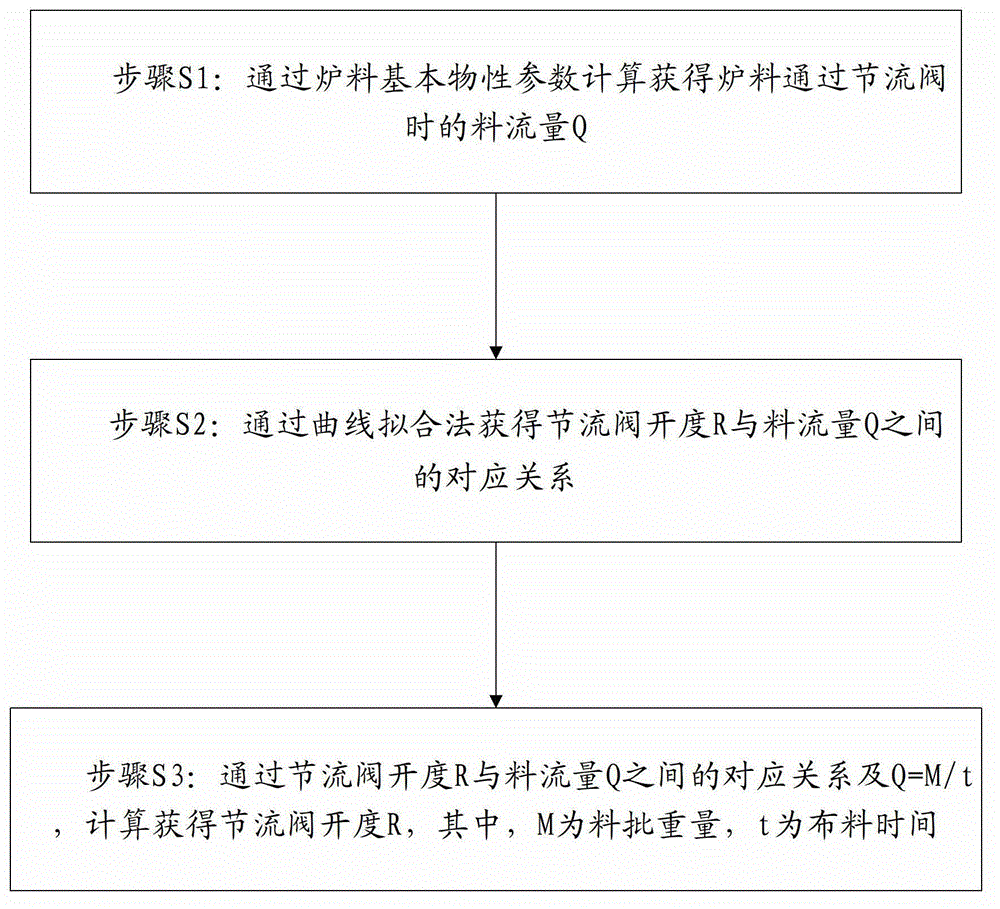

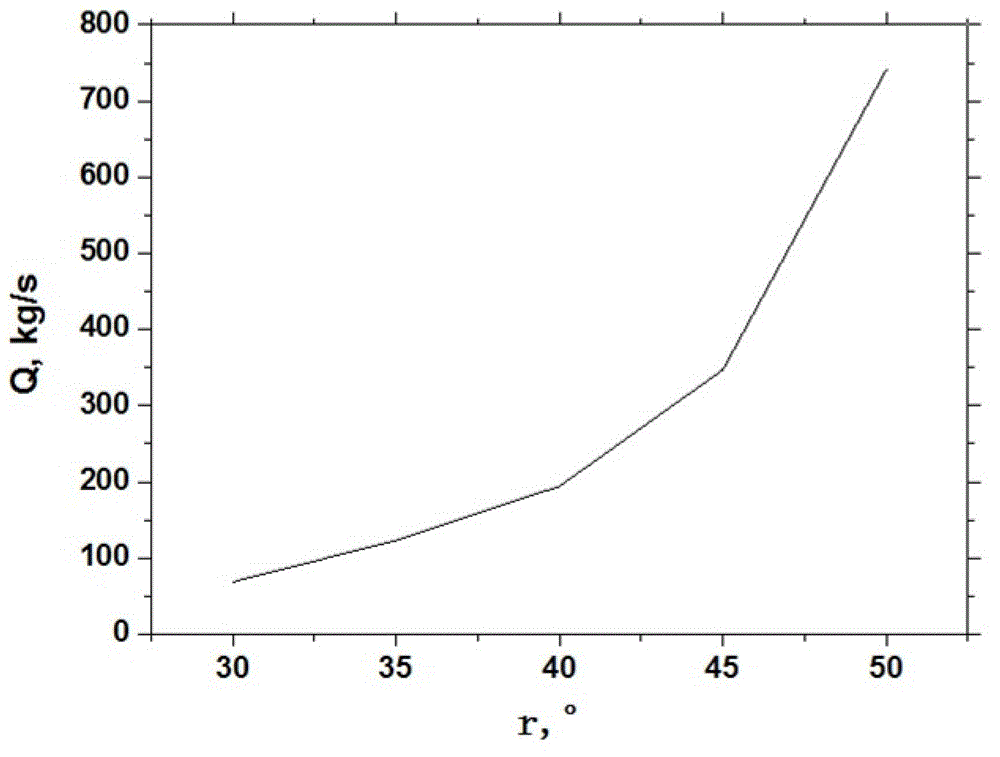

Method for acquiring material flow characteristic at throttling valve on furnace top of blast furnace

ActiveCN102982218AAffect the anterograde effectHigh quality materialBlast furnace detailsSpecial data processing applicationsCurve fittingStreamflow

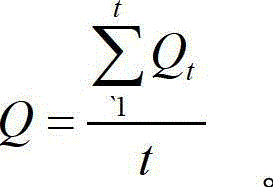

The invention discloses a method for acquiring a material flow characteristic at a throttling valve on the furnace top of a blast furnace, which comprises the following steps: by basis physical property parameters of furnace charges, calculating material flow Q of the furnace charges when the furnace charges pass through the throttling valve; by a curve fitting method, acquiring a corresponding relation between the opening degree R of the throttling valve and the material flow Q; and by the corresponding relation between the opening degree R of the throttling valve and the material flow Q, obtaining the opening degree R of the throttling valve, wherein M represents a charge weight and t represents distribution time. The method for acquiring the material flow characteristic at the throttling valve on the furnace top of the blast furnace, which is provided by the invention, not only is beneficial for avoiding the condition that due to distribution segregation, the edge or the center is excessively heavy so as to influence the forward movement effect of the blast furnace, but also is beneficial for selecting a proper and high-quality throttling valve plate material and ensuring long service life and high efficiency use of distribution equipment.

Owner:SHOUGANG CORPORATION

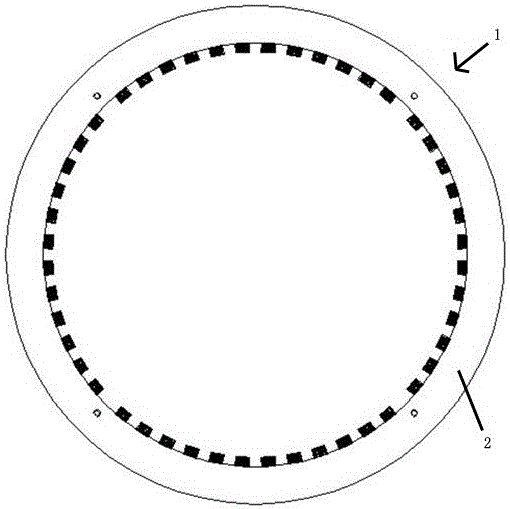

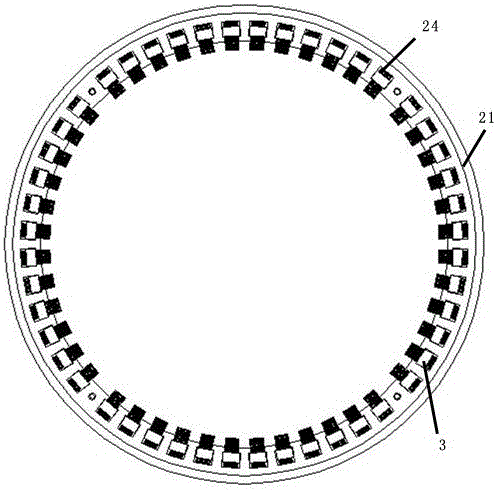

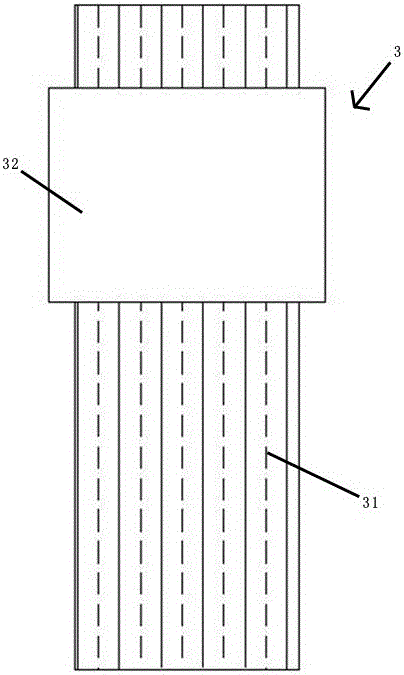

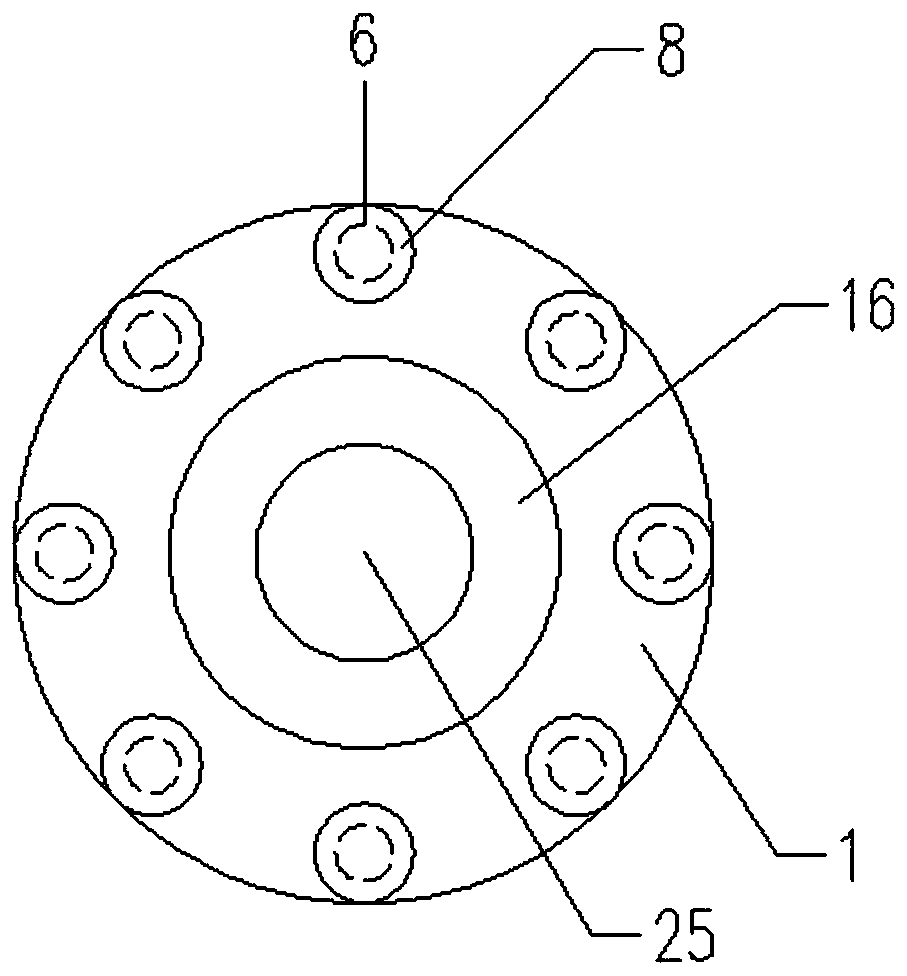

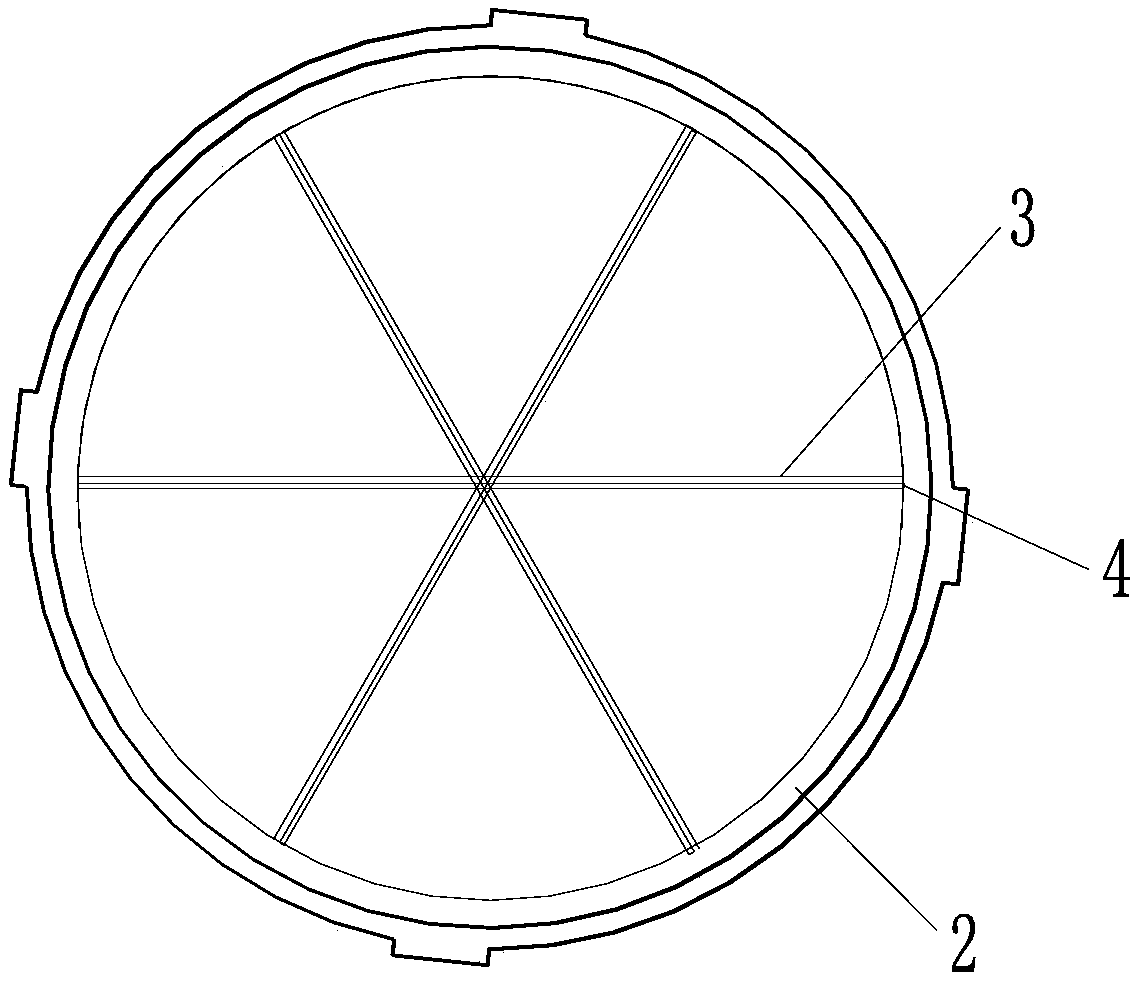

Ultra-thin side circuit conductive ring

PendingCN106787455AGuaranteed longevitySolve the problem of stable fasteningStructural associationElectric machinesMotor shaftFiber bundle

The invention discloses an ultra-thin side circuit conductive ring. The ultra-thin side circuit conductive ring comprises an annular outer cover and conductive elements arranged on the annular outer cover; the conductive elements comprise at least one conductive fiber bundle and a conductive sleeve for fixing the conductive fiber bundles; a fixing part used for fixing the conductive sleeve is arranged on the annular outer cover; and the conductive fiber bundles and a motor shaft are in interference contact. By adopting a novel structure, the problem existing in realization of stability and fastening of the conductive fiber bundles on the annular outer cover under relatively thin thickness requirement is solved; and fixation and durability of conductivity are fully guaranteed.

Owner:吴江天龙电子机械设备有限公司

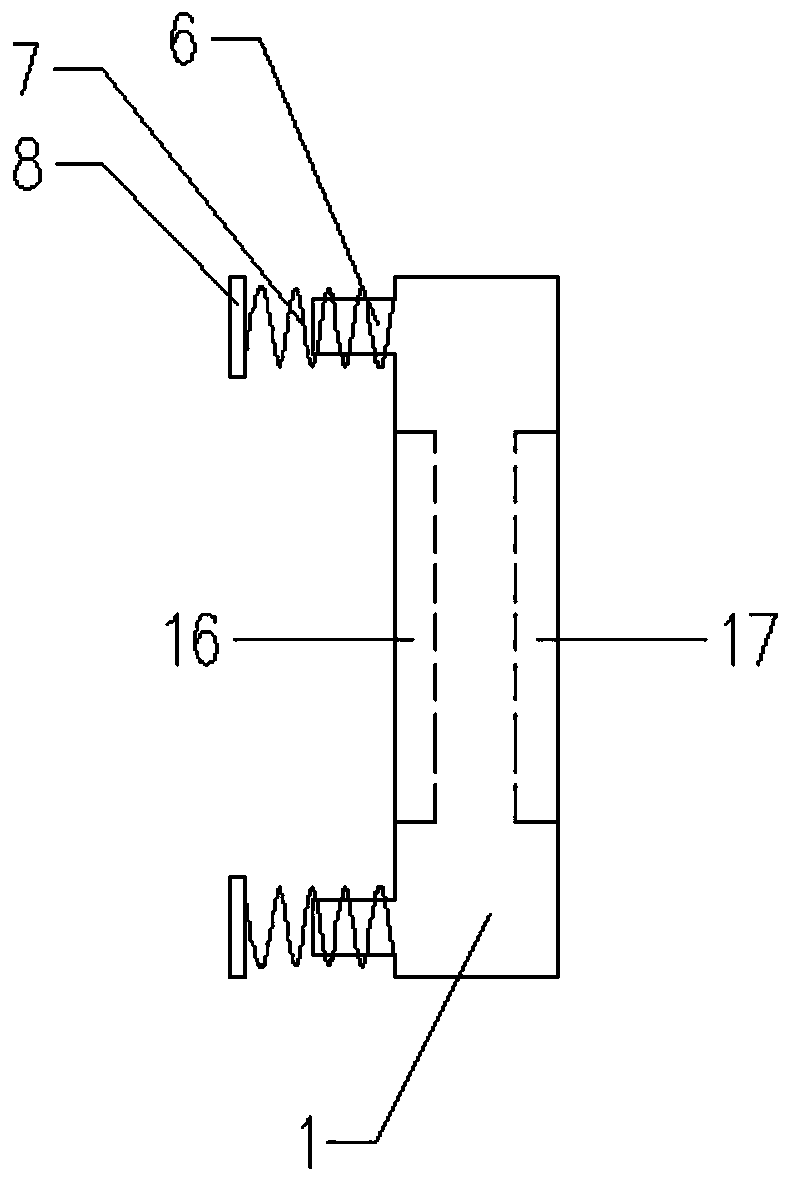

Damping energy dissipation device of shield tunnel bolt joint

ActiveCN110107577AEasy to installStrong shock absorption and energy dissipation effectNon-rotating vibration suppressionNutsUltrasound attenuationPetroleum engineering

The invention discloses a damping energy dissipation device of a shield tunnel bolt joint, and belongs to the technical field of shield tunnel shockproof engineering. The damping energy dissipation device comprises a joint gasket, a first rubber gasket, a first sleeve, a second rubber gasket, a second sleeve and a third rubber gasket which are coaxially arranged in sequence, the first sleeve is provided with a first elastic waterproof sealing ring and a second elastic waterproof sealing ring, a plurality of protrusions are uniformly arranged on the first sleeve in the circumferential direction, each protrusion is sleeved with a damping spring, each damping spring is provided with a round gasket, a plurality of through holes corresponding to the protrusions are formed in the first rubber gasket, the second sleeve is provided with a third step groove, the third rubber gasket is provided with a third step protrusion corresponding to the third step groove, and the third step groove is provided with a third elastic waterproof sealing ring. The damping energy dissipation device has the advantages of being convenient to install, high in damping energy dissipation effect, capable of effectively achieving attenuation vibration and good in waterproof effect.

Owner:NORTHEASTERN UNIV

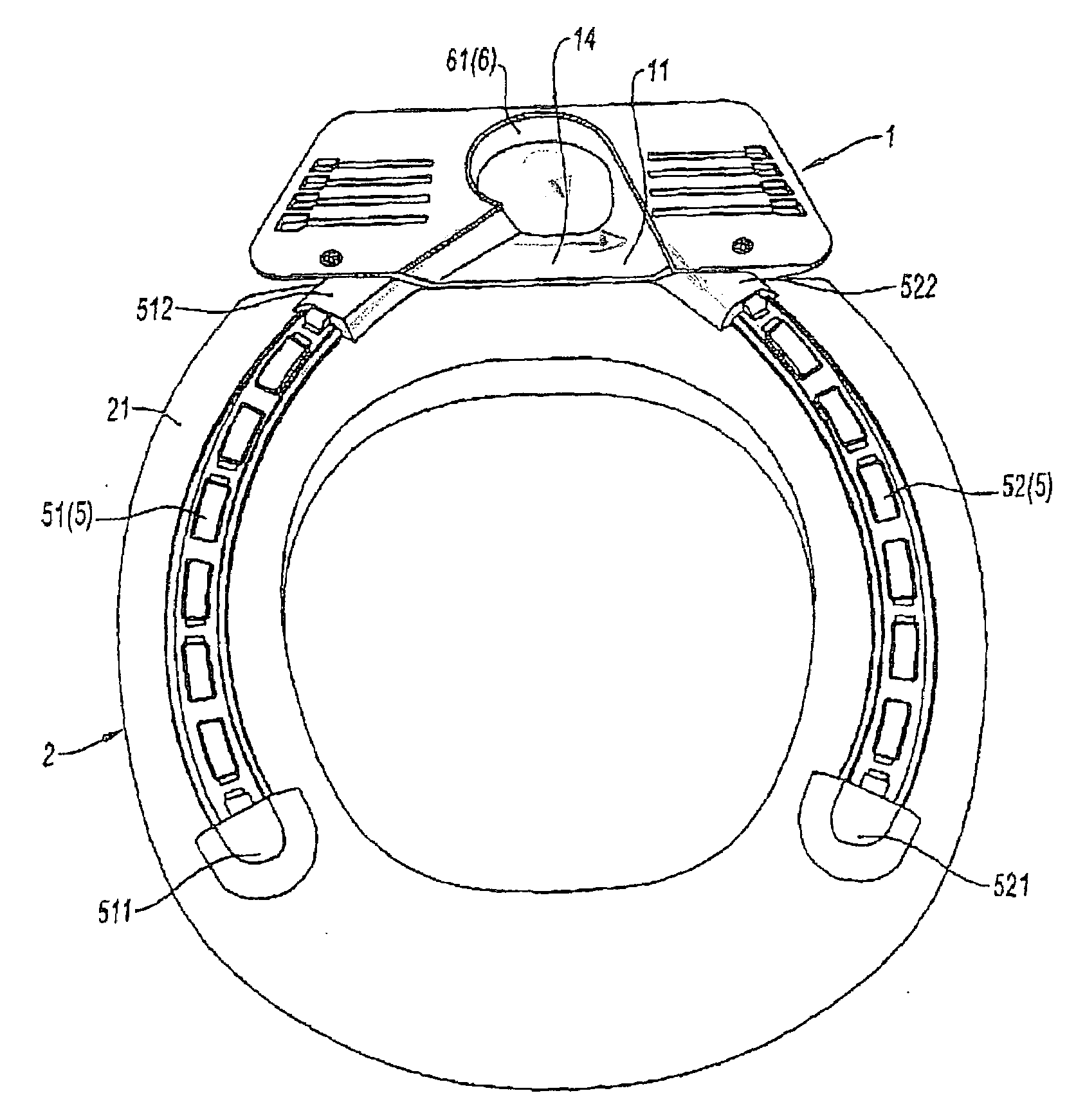

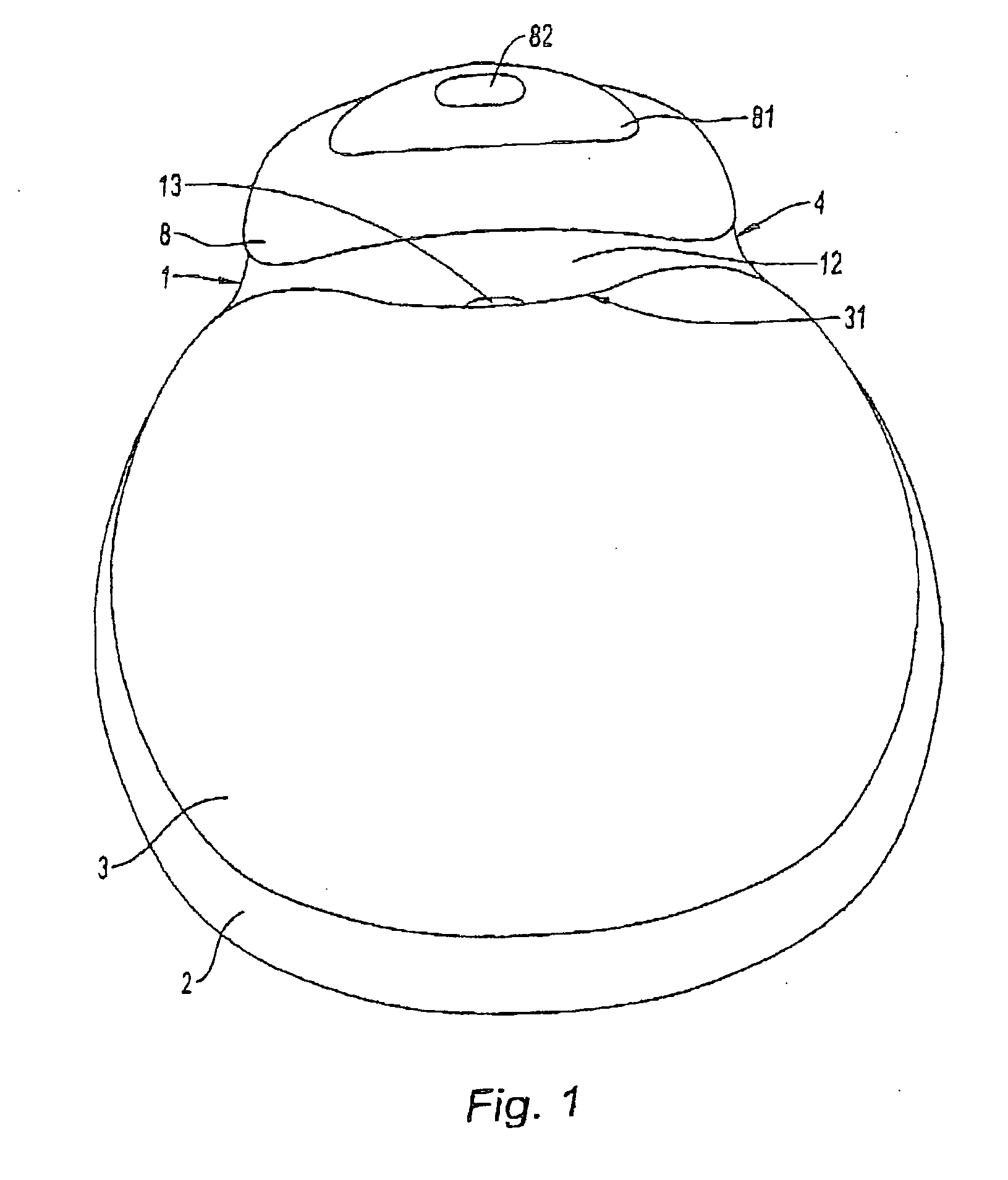

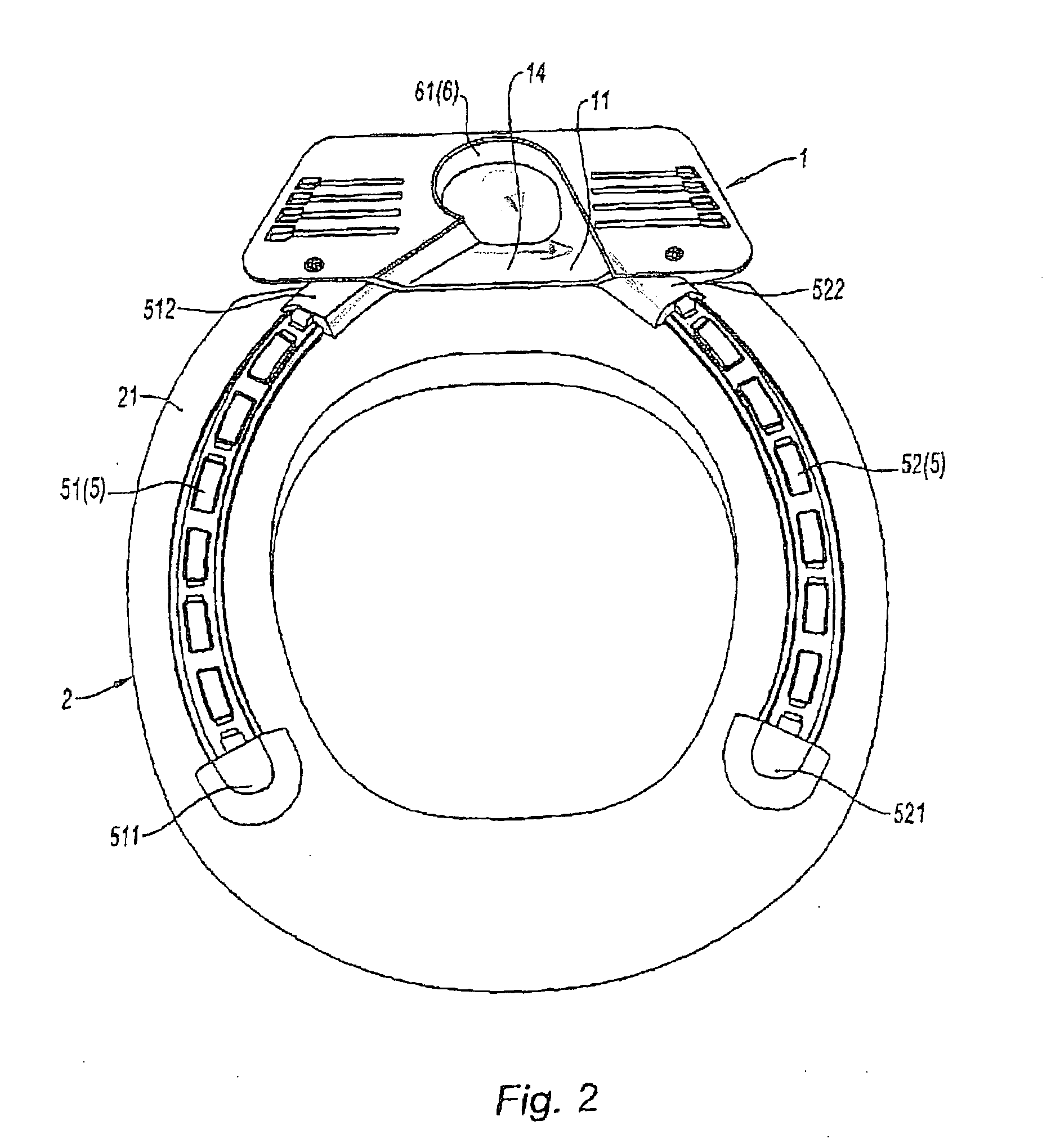

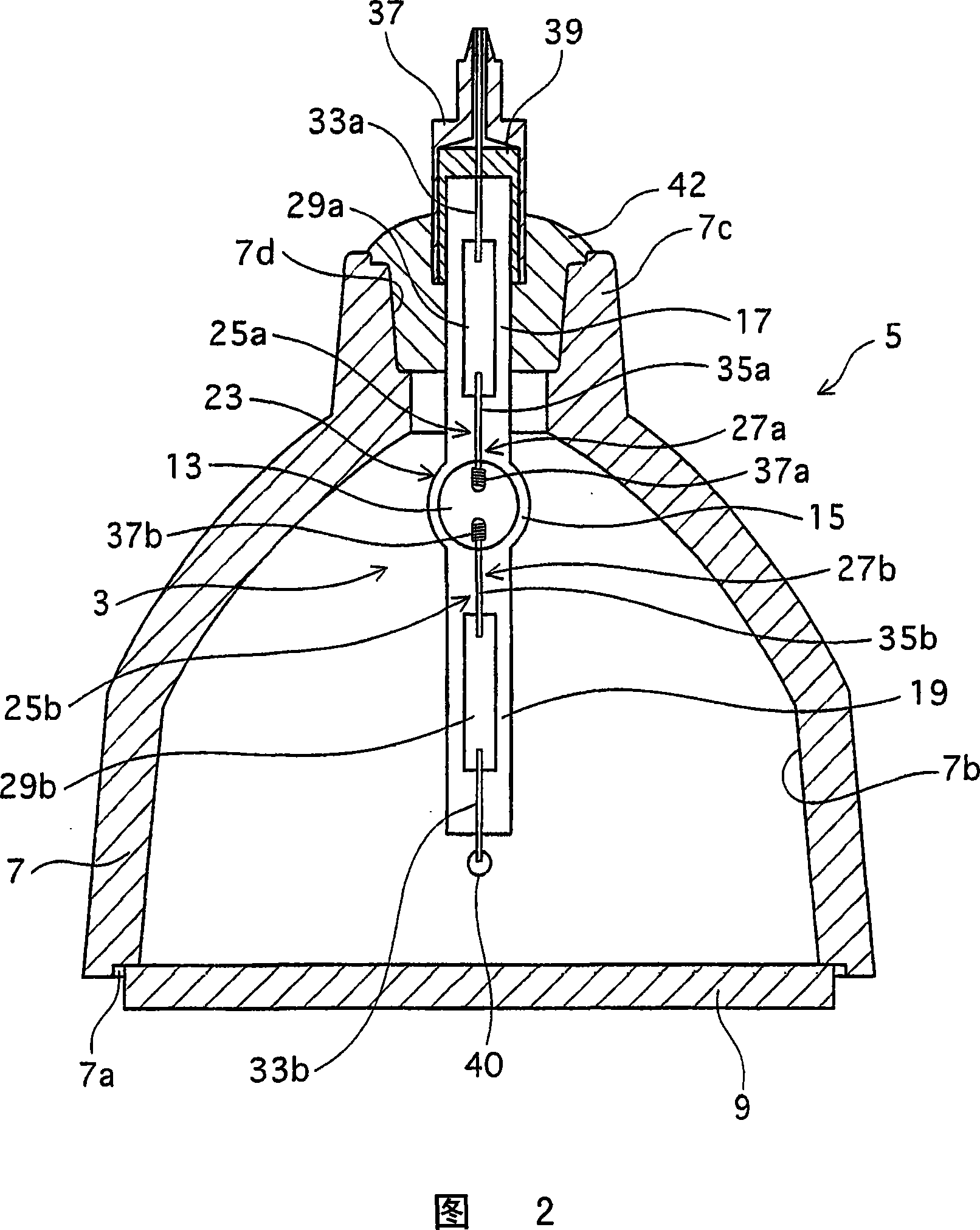

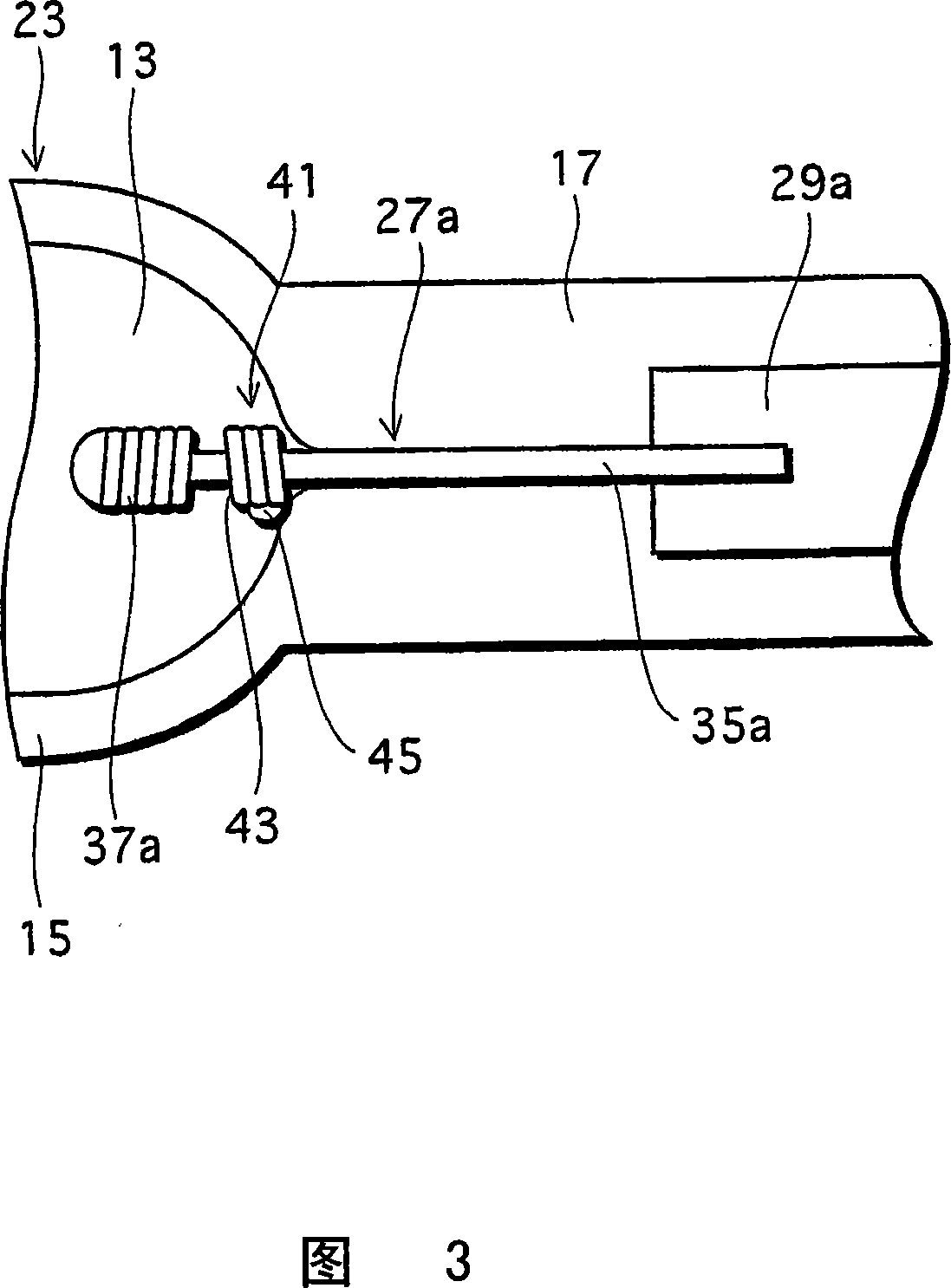

Toilet bowl assembly with air aspiration and filtration

InactiveUS20100071120A1Improve tightnessImprove distributionBathroom coversLavatory sanitoryFiltrationFlush toilet

A toilet bowl assembly comprising a base fixed to a bowl, provided with a toilet seat and a device for aspirating air from the bowl. The base comprises an extension that has its upper part provided with a presence detection window directed to above the seat and forming an aspiration channel opening into the bowl. A circuit for controlling the function of the aspirating device with an infrared detector situated in the detection window to detect a presence on the seat and with an electric power supply for the circuit and the aspirating device.

Owner:GHARDI RAMEZ +1

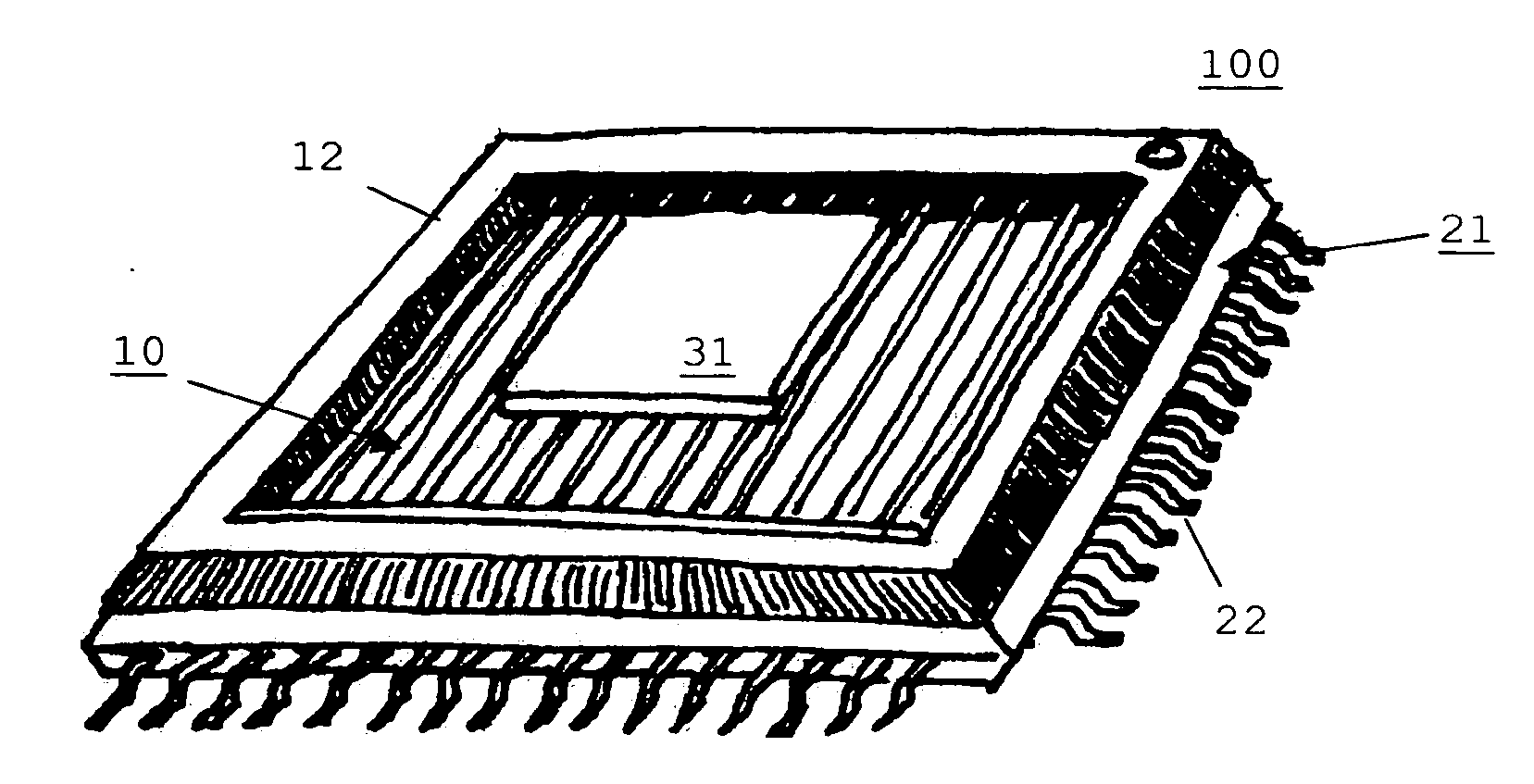

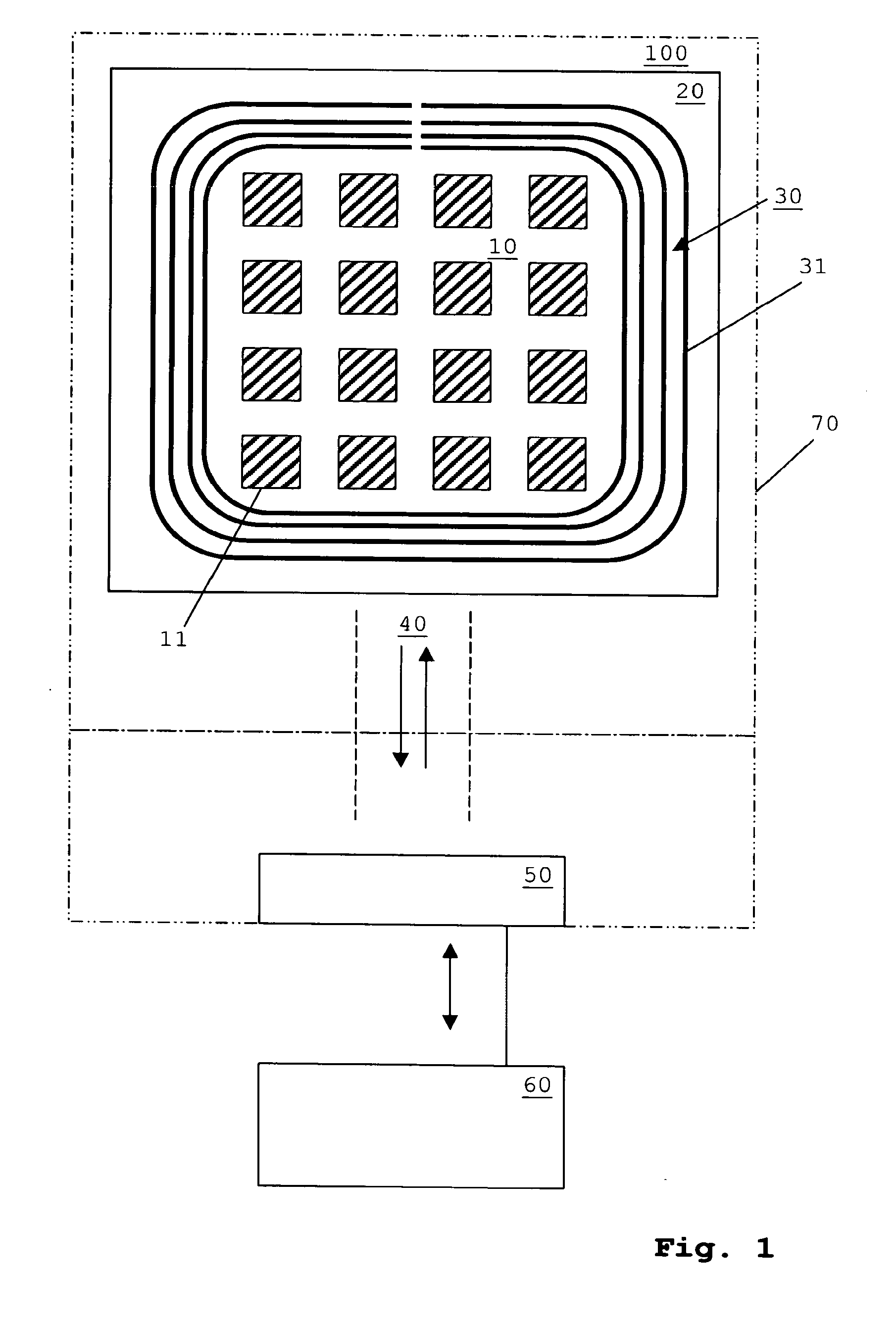

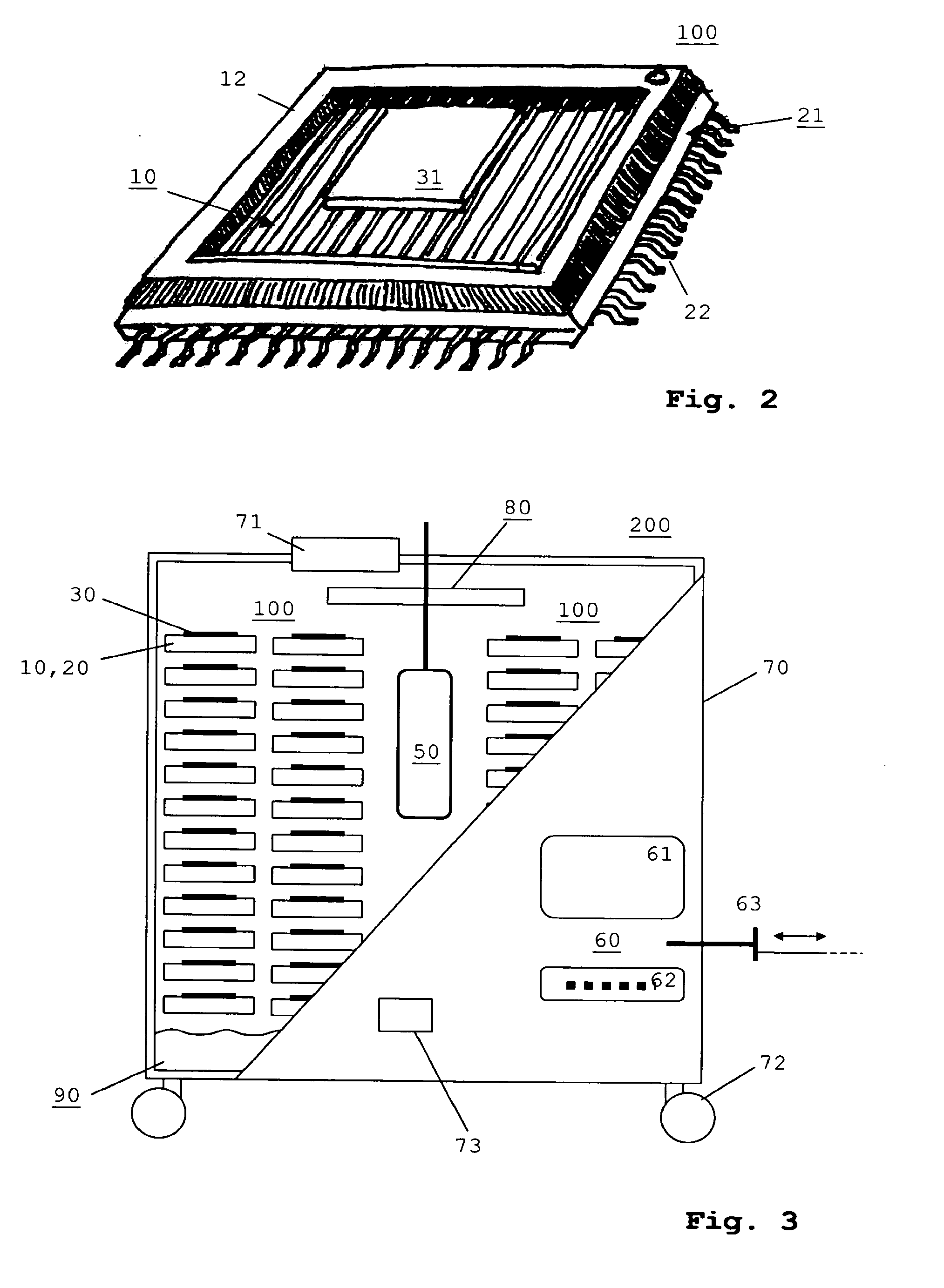

Cryogenic storage device comprising a transponder

InactiveUS20110277486A1Simple structureAdaptableLighting and heating apparatusContainer filling methodsWireless transmissionData memory

A method for operating a cryostorage device (100), especially for biological samples, is described which comprises a sample carrier (10) to receive at least one sample (11) and a data storage (20), wherein data are inductively transmitted from the data storage device (20) into a wireless transmission channel (40) and / or conversely using a resonant circuit (30) connected to the data storage device (20).

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

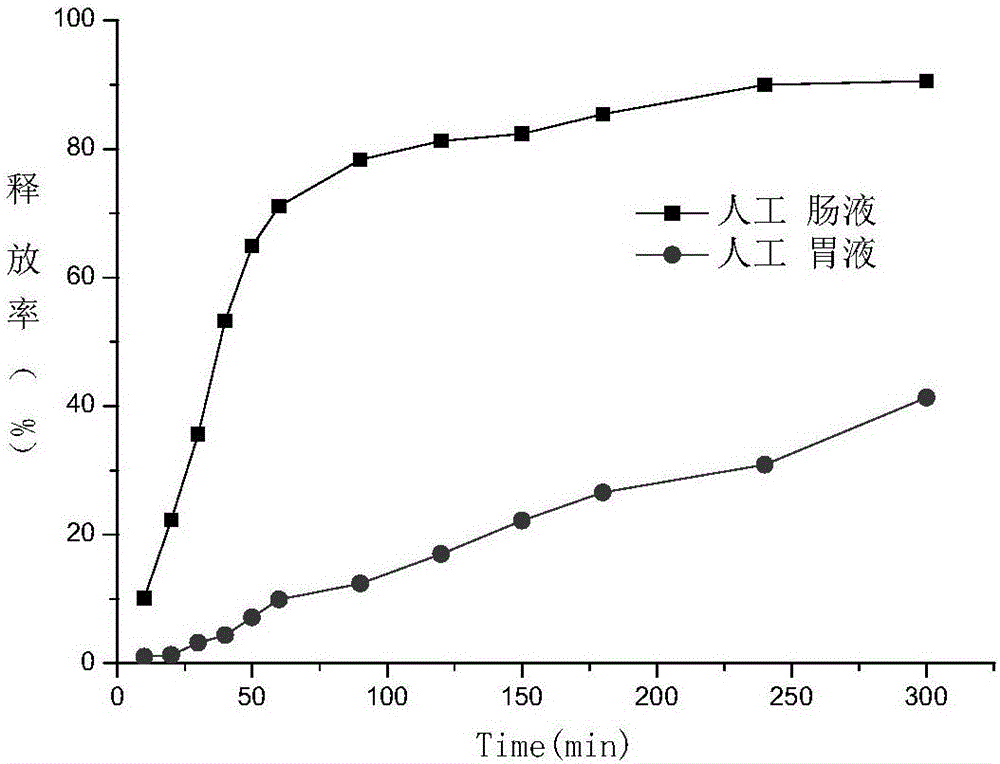

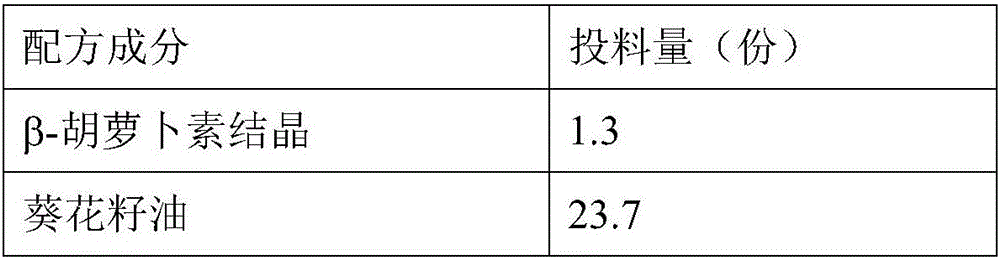

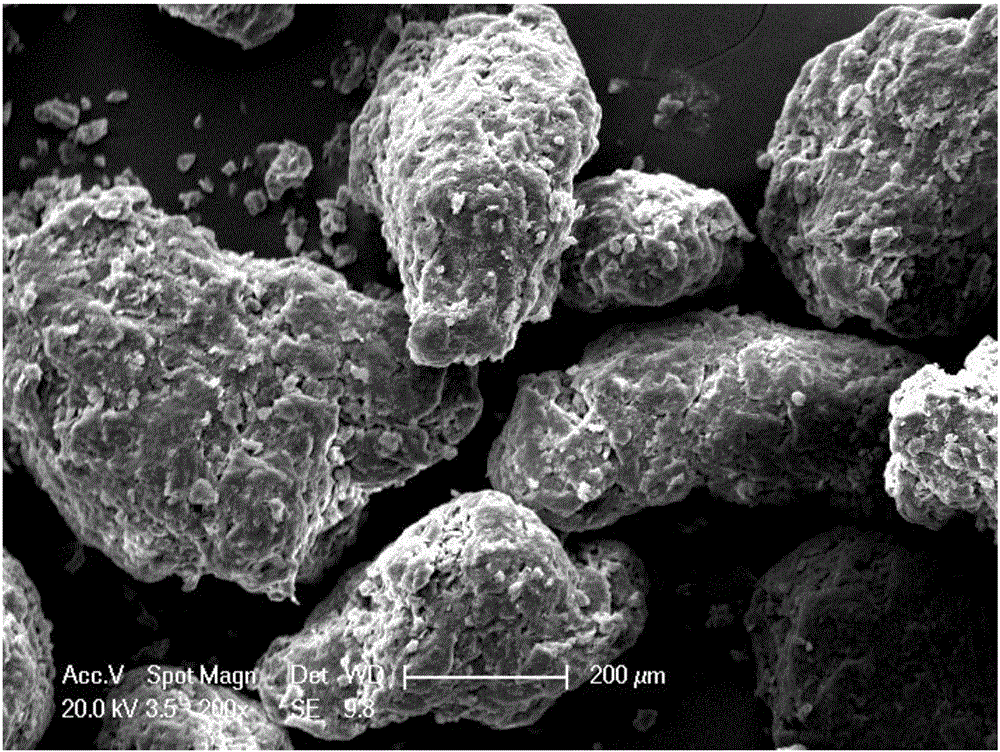

Sugar-free beta-carotene microcapsules and preparation method thereof

The invention discloses sugar-free beta-carotene microcapsules and a preparation method thereof. The microcapsules contain the ingredients in percentage by mass: 1% to 15% of beta-carotene crystals, 10% to 30% of carrier oil, 15% to 50% of maltitol, 5% to 15% of sodium caseinate, 0.5% to 10% of antioxidant, 0.5% to 10% of emulsifier and 5% to 35% of coating material. According to the preparation method of the sugar-free beta-carotene microcapsules, disclosed by the invention, the powder yield rate is high, the coating effect is good, and the microcapsules have good water dispersity, so that the product intake of human bodies can be improved.

Owner:XIAMEN KINGDOMWAY BIOTECH CO LTD +1

Controlling method for shrinkage degree of coal-as-fired with different moisture

The invention discloses a control method for shrinkage degree of coal-as-fired with different moisture, and belongs to the technical field of coal blending and coking in metallurgy. The control method includes 1), selecting standard matched coal; 2) selecting production application matched coal; 3), coking the matched coal 2#; 4), evaluating the shrinkage degree, ending the evaluating process if the matched coal 2# meets production application requirements, and adjusting moisture of the matched coal 2# or increasing proportioning of coking coal with the shrinkage degree, in which X is larger than 35mm and b is smaller than or equal to 0%, if the matched coal 2# does not meet the production application requirements. The control method has the advantages that coking energy consumption can be minimized by controlling the moisture of the coal-as-fired on the basis of successful coke cake pushing, coal blending structure can be optimized, coal cake shrinkage is guaranteed without changing the moisture of the matched coal, and smooth coking production can be achieved.

Owner:武汉钢铁有限公司

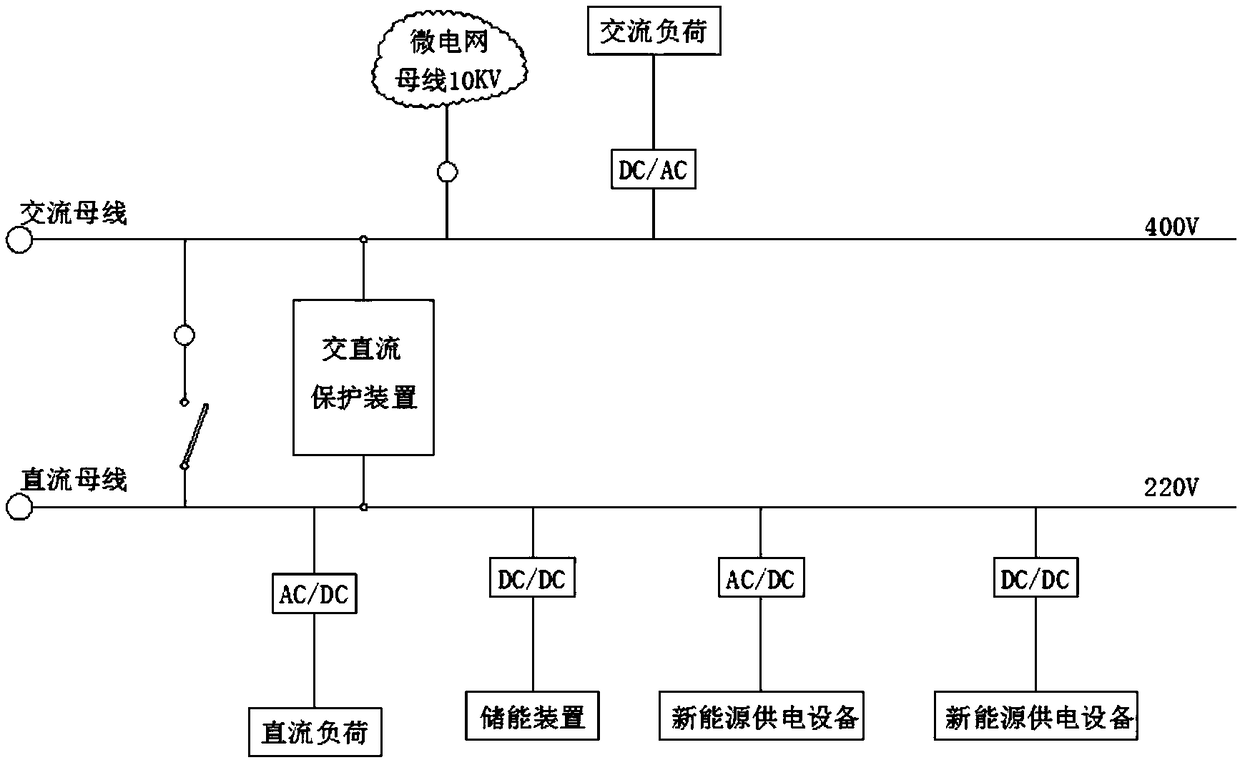

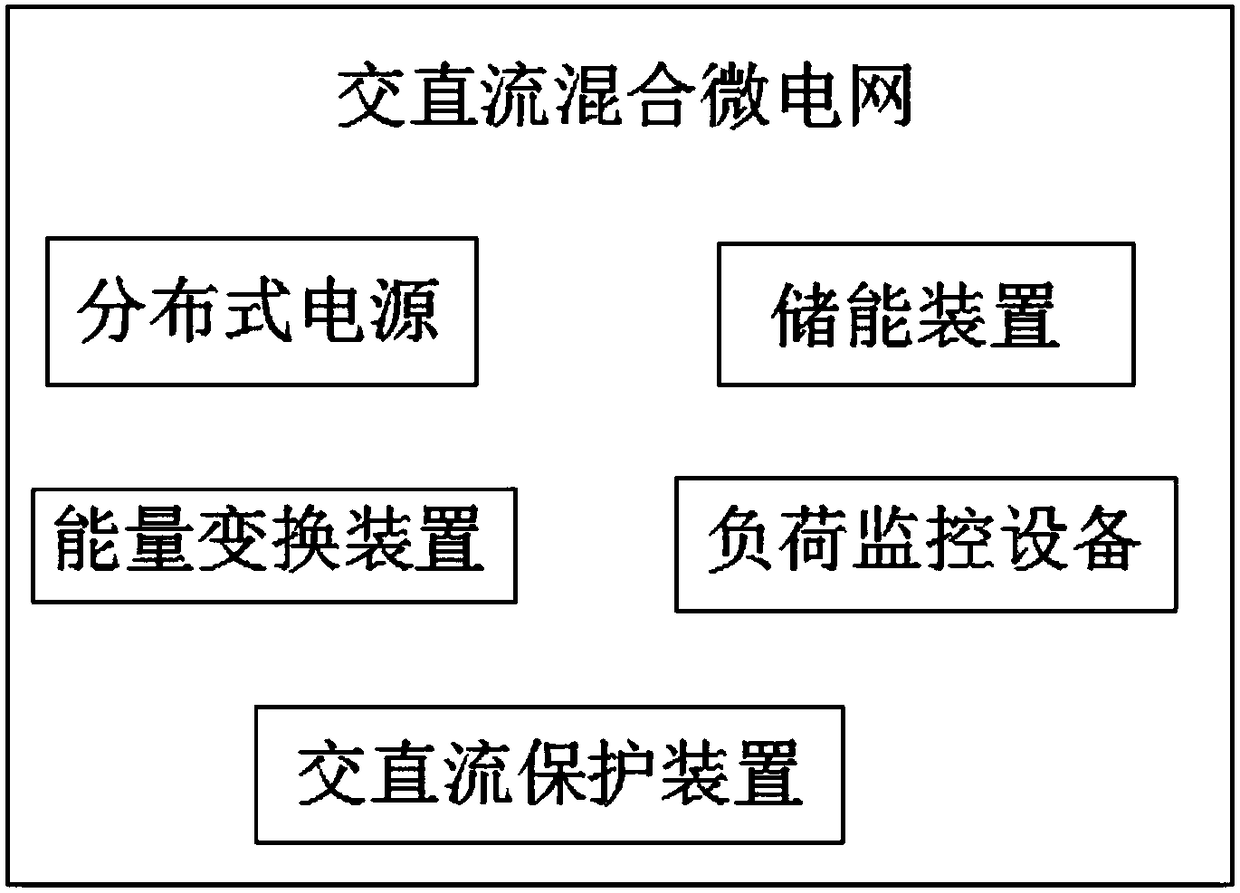

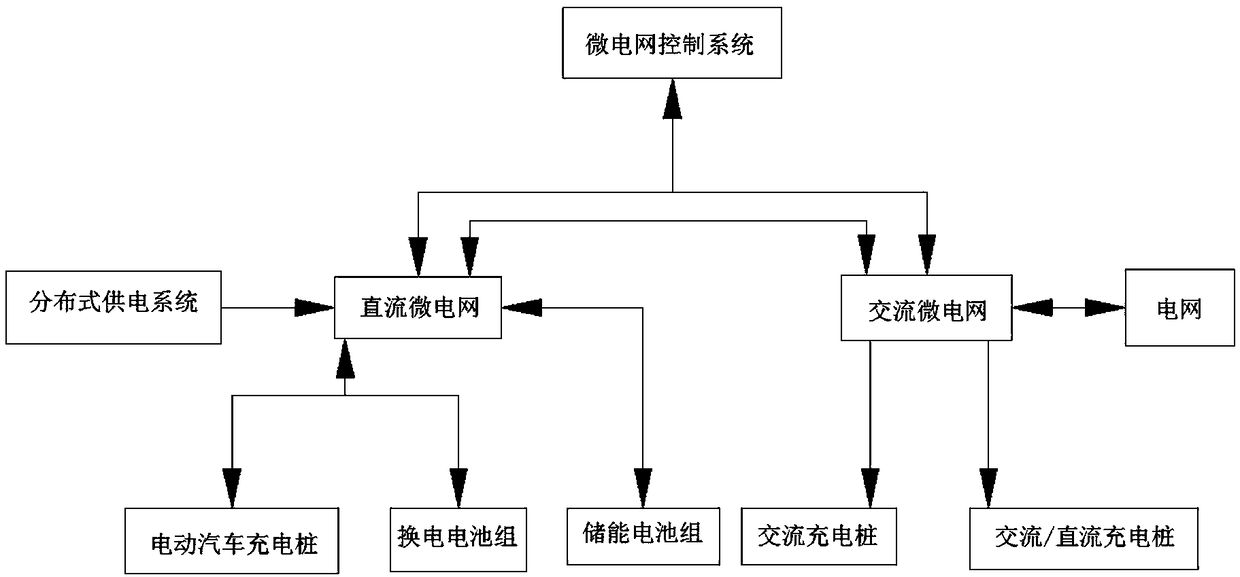

AC/DC hybrid microgrid and operation method thereof

InactiveCN108832635AGuaranteed uptimeEffective controlAc networks with different sources same frequencyElectricityMicrogrid

The invention relates to the technical field of AC / DC hybrid microgrids, and discloses an AC / DC hybrid microgrid. The AC / DC hybrid microgrid comprises a distributed power source, an energy storage device, an energy conversion device, composite monitoring equipment and an AC / DC protection device internally. The AC / DC hybrid microgrid and the operation method thereof can perform coordinated controlon a DC microgrid and an AC microgrid, improve the charging and discharging efficiency of the energy storage device, enable the electric energy in the microgrid to flow flexibly, prolong the service life of the AC / DC hybrid microgrid, ensure the long-term performance of the AC / DC hybrid microgrid, improve the operating speed of the system, improve the coordination rate of the power grid, and solvethe problems that circuit equipment is prone to fail, the electrical load is increased, equipment is worn or damaged, the normal operation of the microgrid system is affected and the effective control over the microgrid is affected because the power supply stability cannot be well satisfied.

Owner:杭州新融方科技有限公司

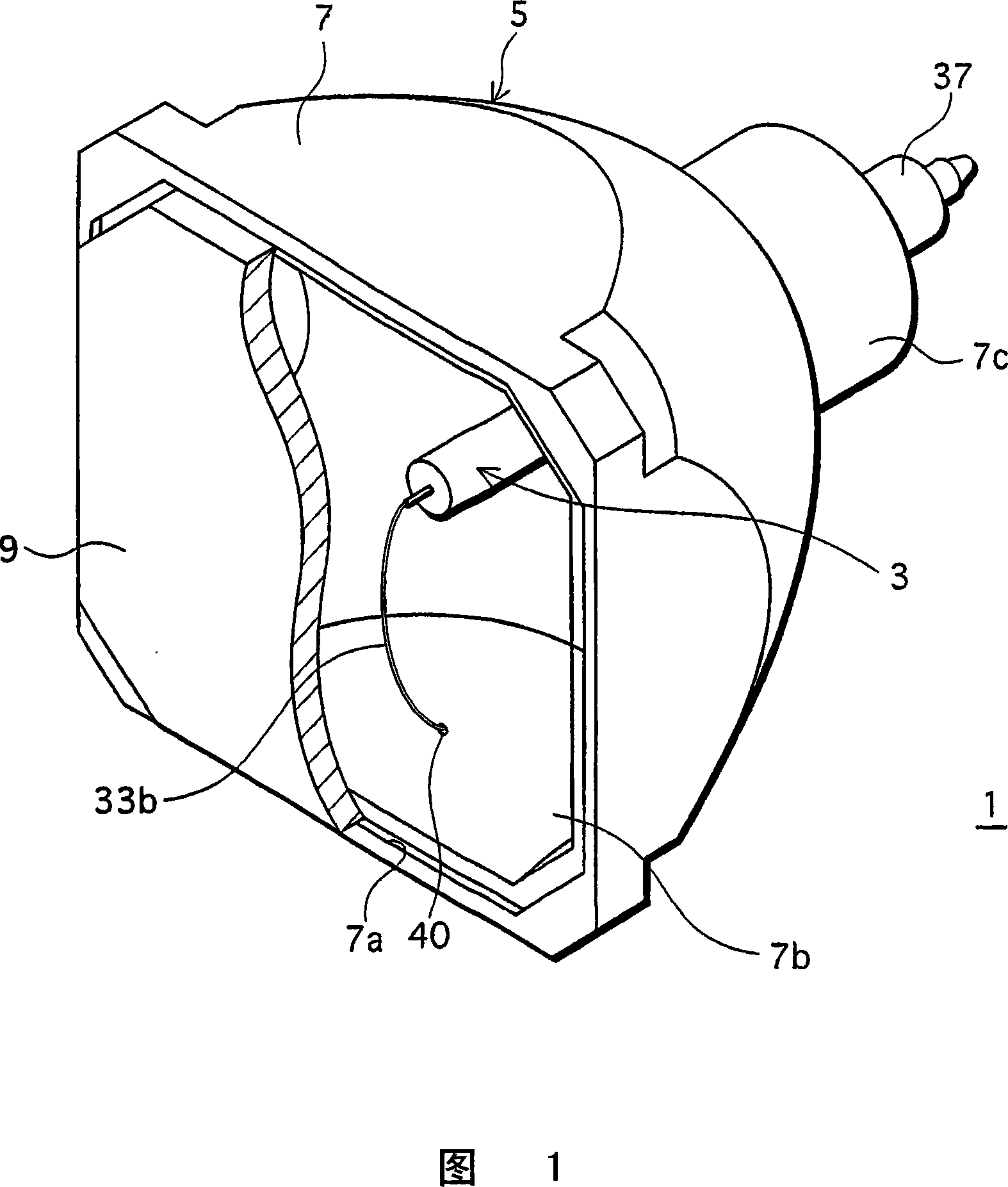

High-pressure mercury lamp, lamp unit, and image display apparatus

Owner:PANASONIC CORP

A kind of flexible concrete for caulking

Owner:北京宝辰联合科技股份有限公司

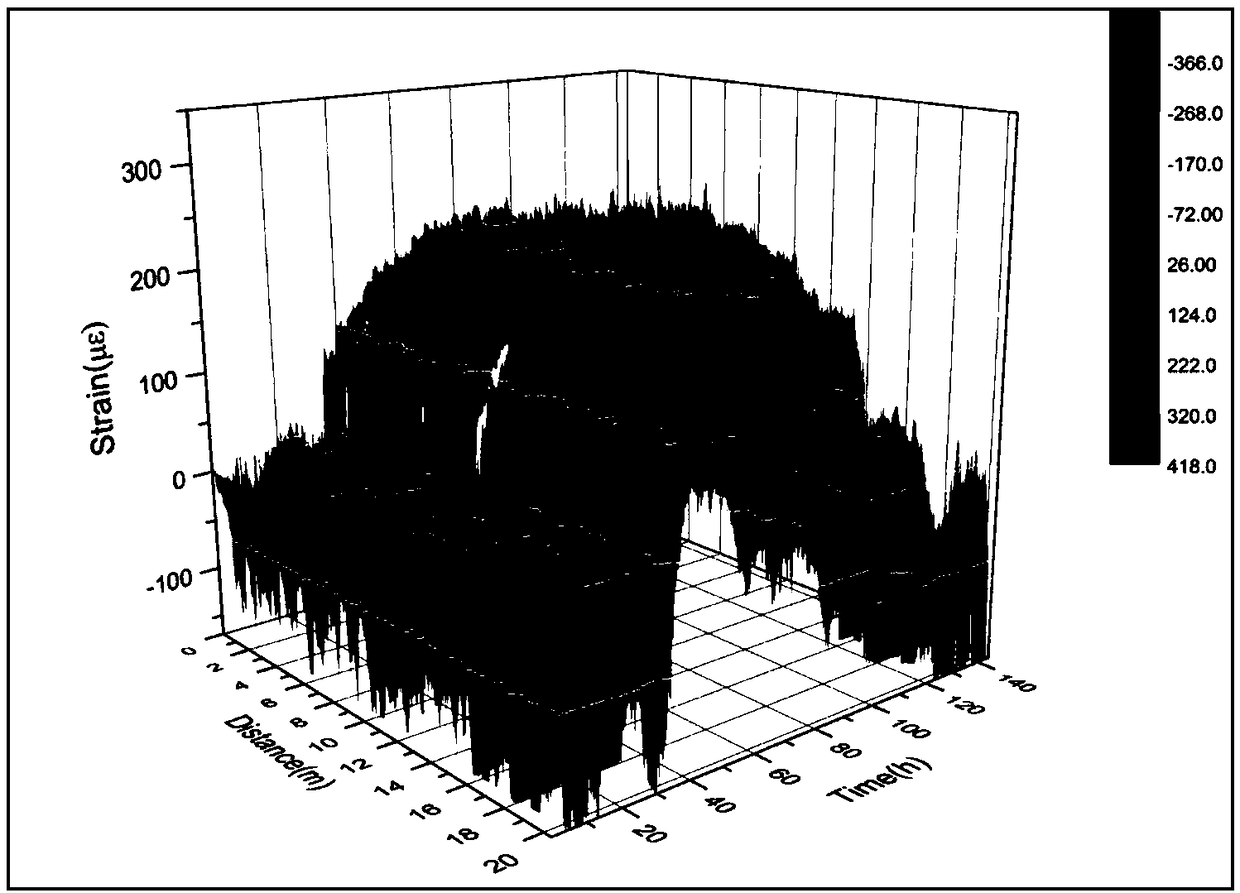

Method for evaluating overall performance of containment vessel of nuclear power plant based on distributed sensing technology

ActiveCN109357785ANo damageGuaranteed longevityNuclear energy generationNuclear monitoringNuclear plantNuclear power

The invention relates to the field of safety monitoring of major civil engineering structures and nuclear safety, specifically relates to a method for evaluating the overall performance of a containment vessel of a nuclear power plant based on a distributed sensing technology. The method comprises the following steps: laying sensing optical fibers on the containment vessel; acquiring a true strainvalue and a radial displacement value of a cylinder; obtaining a theoretical strain value and a radial displacement value of the cylinder; evaluating performance of the containment vessel; and judging whether the containment vessel meets an overall strength requirement. The method for evaluating the overall performance of the containment vessel of the nuclear power plant based on the distributedsensing technology can still perform the overall performance evaluation even in an event of a failure of a vibrating wire sensor pre-buried in the containment vessel structure, has innovative points and advantages of multi-area laying, long distance, rich data, and capable of eliminating an accidental error of the local position., can meet the needs of existing pre-buried strain monitoring sensorssupplementation and the needs of upgrading and transformation before the failure, and ensures the long-life operation of the nuclear power plant.

Owner:SUZHOU NUCLEAR POWER RES INST +2

Gingko root kudzuvine fine dried noodles and preparation method thereof

InactiveCN103621898ACrispy tasteIncrease blood flowFood ingredient functionsFood preparationHigh cholesterolHigh Blood Pressures

The invention relates to gingko root kudzuvine fine dried noodles and a preparation method thereof. Gingko kernel freeze-dried powder prepared through freeze-drying production technology and root kudzuvine powder prepared through traditional technology are fed into high quality wheat flour according to certain ratio, and the gingko root kudzuvine fine dried noodles are obtained through dough kneading, maturing, hanging, drying, cutting, softening and packaging. The advanced freeze-drying technology keeps all nutrition ingredients of gingko kernels, and the traditional milling technology also keeps active ingredients of root kudzuvine. The noodles adopt scientific ratio, and achieves the purposes of rich nutrition required by human body, softness and palatability; ginkgetin and pueraria flavones complement each other, so that consumers with heart and cerebral vusculer diseases, coronary heart disease, high cholesterol, high blood sugar and high blood pressure achieve the effects of prevention and health protection, and the noodles guarantee the health and longevity of people through diet.

Owner:重庆市万州区食品工业研究所

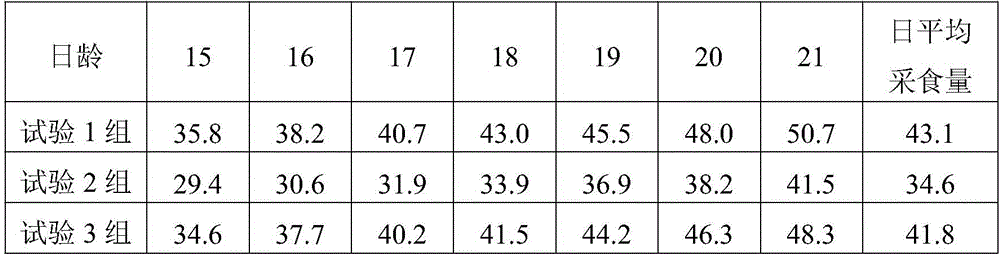

Dimetridazole encapsulated preparation and preparation method thereof

InactiveCN106511314AEasy to prepareLow costAntibacterial agentsOrganic active ingredientsSucroseStearic acid

The invention discloses a dimetridazole encapsulated preparation and a preparation method thereof. The preparation method comprises the steps of firstly adding dimetridazole raw powder into a stearic acid oil agent dissolved with calcium stearate and propylene glycol fatty acidate, adequately and uniformly stirring to obtain a mixture, adding the mixture into a water solution dissolved with chitosan, sodium alginate and sucrose ester, adequately and uniformly stirring, cooling, sieving, and drying, so as to obtain the dimetridazole microcapsule preparation. The preparation method is simple and scientific, the encapsulation rate and recovery rate of raw material drugs are relatively high, and the particle size of the medicament can be controlled. Clinical tests show that the dimetridazole encapsulated preparation is capable of obviously improving the palatability of livestock and has relatively good slow release performance; the efficient dimetridazole encapsulated preparation is provided for the livestock breeding industry.

Owner:HUAIYIN TEACHERS COLLEGE

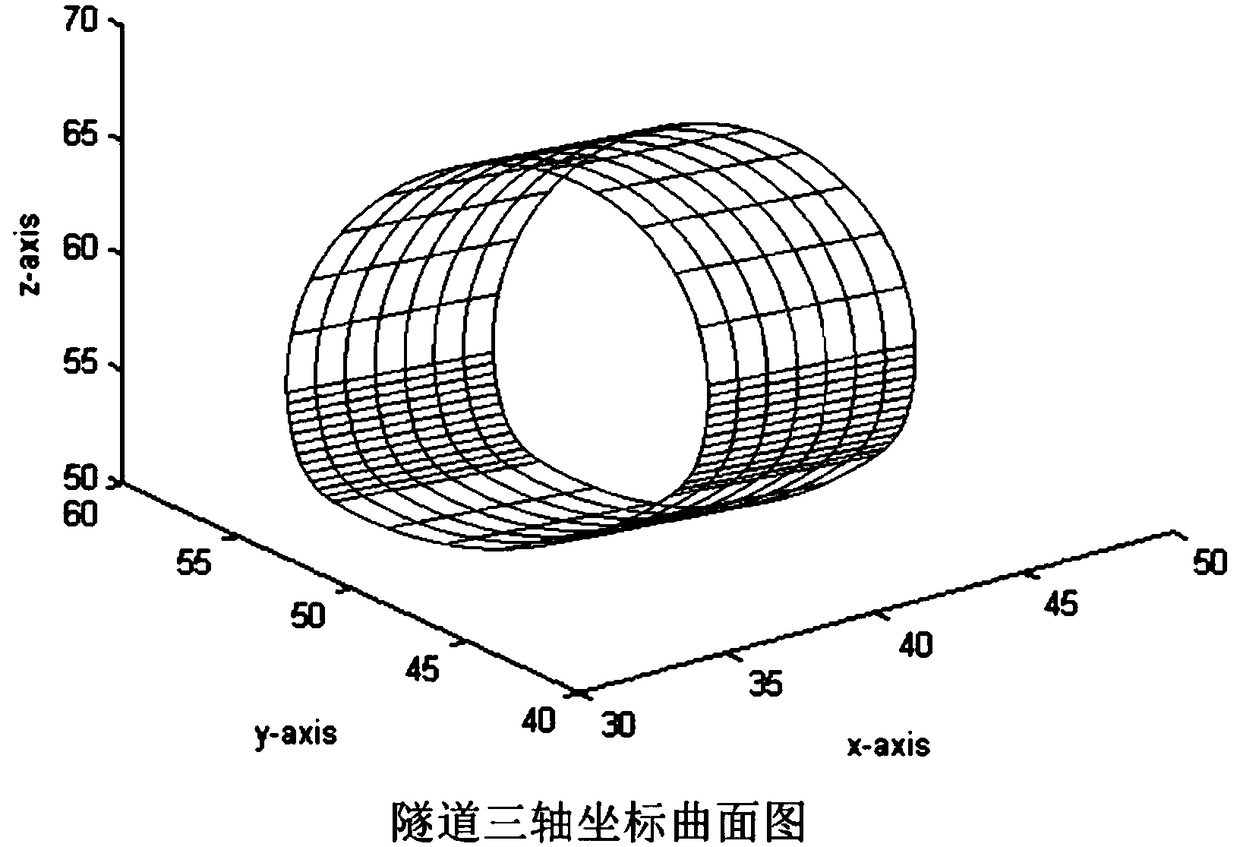

Tunnel secondary lining thickness precise detection method based on function curve fitting

ActiveCN109211167AIncreasing the thicknessHigh precisionMeasurement devicesCurve fittingStandard function

The invention discloses a tunnel secondary lining thickness precise detection method based on function curve fitting. The method comprises the steps of establishing a standard function curve of tunnelsecondary lining, and determining a designed tri-axis standard coordinate value of any point on a secondary lining outer contour curve; collecting a tri-axis coordinate value of a reference point; onthe basis that the tri-axis coordinate value of the reference point is known, measuring the tri-axis coordinate values of tunnel secondary lining detection points; obtaining Y-axis and Z-axis designed coordinate values of the corresponding detection points according to an X-axis coordinate value of each detection point, comparing the Y-axis and Z-axis designed coordinate values with practically measured Z-axis and Y-axis coordinate values, computing offset difference values of the corresponding detection points, and obtaining a tunnel secondary lining thickness difference value and a tunnel secondary lining offset difference value. According to the method, on the basis of the function curve fitting, precision of the tunnel secondary lining thickness difference value and the tunnel secondary lining offset difference value is improved.

Owner:SHANDONG UNIV

Silica gel reflective lettering film decoration forming method

PendingCN112526657AWon't fall offGuaranteed longevityOrnamental structuresLight effect designsPolymer scienceHot melt

The invention provides a silica gel reflective lettering film decoration forming method which comprises the following steps: (1) taking a PET coiled material, coating the surface of the PET coiled material with a release surface and an anilox roller with 200 meshes, and coating and baking for 3-5 minutes at the temperature of 80-120 DEG C; 2) scraping a PP resin layer on the surface of the releasesurface after the step 1) is completed; 3) implanting at least one glass bead into the surface layer of the PP resin layer after the step 2) is completed; (4) flattening the glass beads by using a silica gel roller at the temperature of 140-170 DEG C after the step (3) is finished, and melting the glass beads to 1 / 4-1 / 2 of the thickness of PP resin; (5) blade-coating an environment-friendly silica gel layer on the glass beads; (6) roller-coating an environment-friendly resin layer on the surface of the environment-friendly silica gel layer; and (8) slitting the material according to the specification, trimming and confirming the product quality. According to the invention, at least one glass bead is implanted into the surface layer of the PP resin layer, and the glass bead is melted to 1 / 3 of the thickness of the PP resin layer so that the reflective bead does not fall off, and the durability of the reflective effect is ensured.

Owner:东莞市松烁硅胶科技有限公司

Pueraria peanut soymilk and preparation method thereof

The invention relates to pueraria peanut soymilk and a preparation method of the pueraria peanut soymilk. It is indicated that pueraria peanut soymilk products and preparation method do not exist according to prior market conditions of pueraria beverages. In the method, wild pueraria juice is used, dry wild pueraria pieces are subject to extraction, filtering and grinding, peanuts and soybeans are subject to screening, soaking, grinding, filtering, decocting, mixing, emulsification, sterilization, filling and checking, and finished products are filled into boxes. Natural activity components of pueraria are reserved in the products, the peanuts, and the soybeans, milk powder and white granulated sugar are additionally added into the products to make the nutrition of the products more sufficient and make the products capable of being more easily absorbed and transformed. The pueraria peanut soymilk is a health and green drink for people to supplement energy.

Owner:重庆市万州区食品工业研究所

Special economical pressure regulating valve for welding heat-insulating gas cylinder

ActiveCN103912699AImprove sealingSolve the problem of blocked valve portOperating means/releasing devices for valvesEqualizing valvesGas cylinderVALVE PORT

A special economical pressure regulating valve for a welding heat-insulating gas cylinder comprises a regulator, a valve deck, a valve body and a valve base. The regulator penetrates through the valve deck, the valve deck and the valve body are embedded in each other through their threads, the valve base is screwed into the bottom of the valve body, a diaphragm is arranged on the top face of the valve body, a valve cavity is formed in the middle of the valve body, the valve cavity is communicated with a valve port formed in the top face of the valve body, a sealing ring is arranged in an inner circle of the valve port, the valve port is covered with a patch, and a valve of an I-shaped structure is arranged in the valve cavity. Thus, the problem that the patch blocks the valve port in the re-pressurizing process of the regulator is solved; excessive gas in the steel cylinder is used preferentially, resources are saved, and meanwhile the pressurizing rate is increased. When the valve port is not closed, the opening distance between a valve element and the valve port is controlled between 1.2 mm and 1.5 mm through a limiting platform boundary, the deformation amount of the diaphragm is reduced, and the service life and the sealing persistence of the diaphragm are guaranteed.

Owner:DANYANG SAIBANG FILLING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com