Method for acquiring material flow characteristic at throttling valve on furnace top of blast furnace

A technology for throttle valves and blast furnaces, applied in blast furnace details, blast furnaces, furnaces, etc., can solve the disadvantages of choosing throttle valve plates, lack of analysis and understanding of throttle plate force conditions, and difficulty in obtaining real-time charge speed and other problems to achieve the effect of avoiding fabric segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

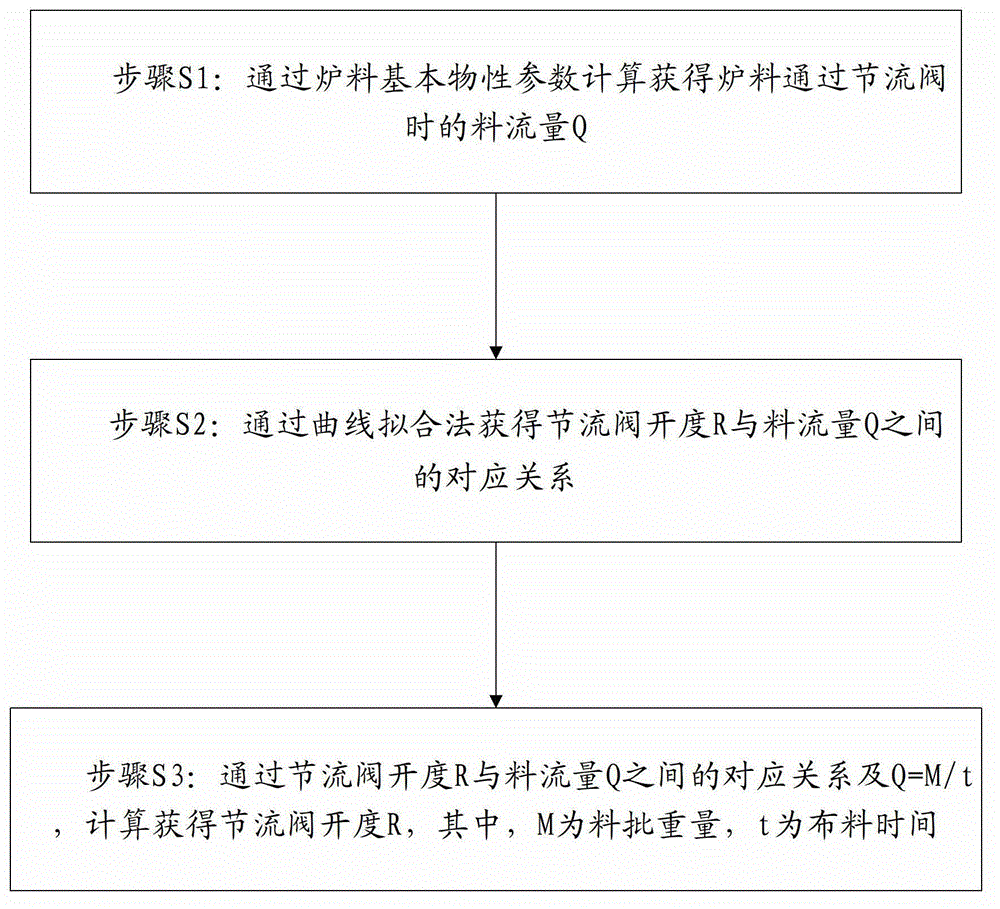

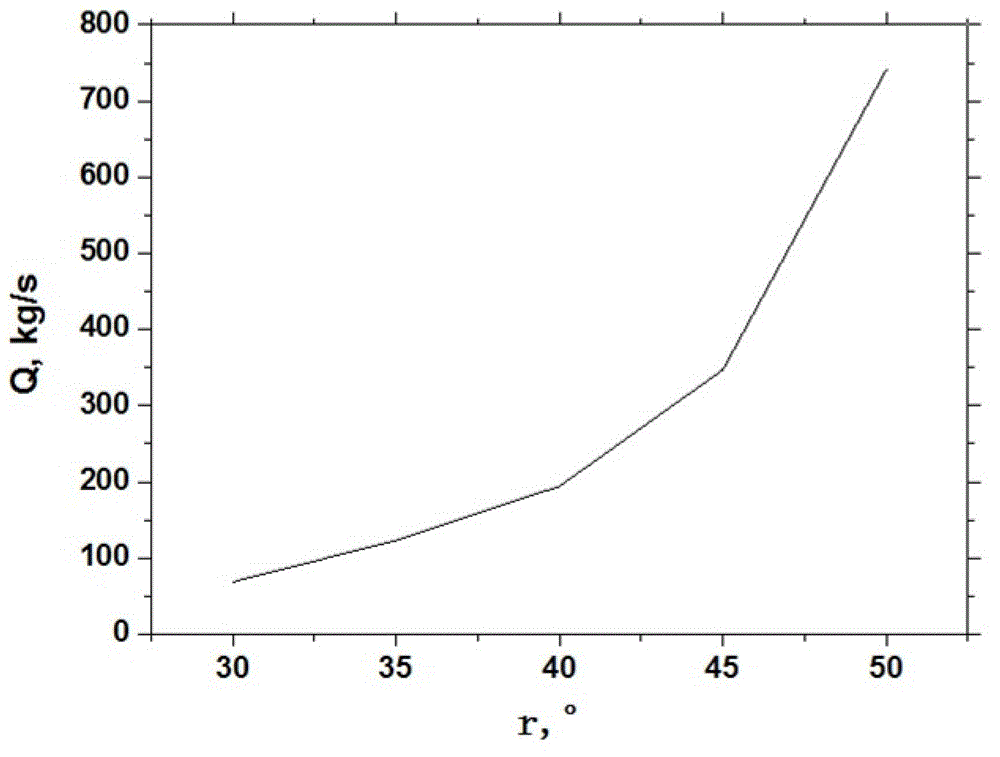

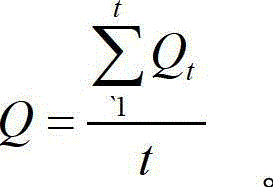

Method used

Image

Examples

Embodiment 1

[0105] Step A11: Obtain the basic physical parameters of the furnace material and the size of the material tank through measurement, and then calculate the force condition F of the particles through the calculation of the basic physical properties of the material.

[0106] Taking coke as an example, the basic physical properties of coke can be measured through physical experiments, as shown in Table 1, density (ρ), coefficient of rolling friction (μ r ), coefficient of sliding friction (μ), Poisson’s ratio (ν), modulus of elasticity (E) and tank size.

[0107] Table 1

[0108]

[0109] First set the center of the tank outlet as the origin of the three-dimensional coordinates (0,0,0), and now a coke particle at (1.69,1.73,2.87), the normal and tangential forces it receives f s,t They are:

[0110] F n , t = 286968 , f s,t =526400

[0111] Step A12: C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com