Method for evaluating overall performance of containment vessel of nuclear power plant based on distributed sensing technology

A technology of sensing technology and evaluation method, which is applied in the field of overall performance evaluation of nuclear power plant containment based on distributed sensing technology. Severity, non-compliance with nuclear safety regulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0114] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

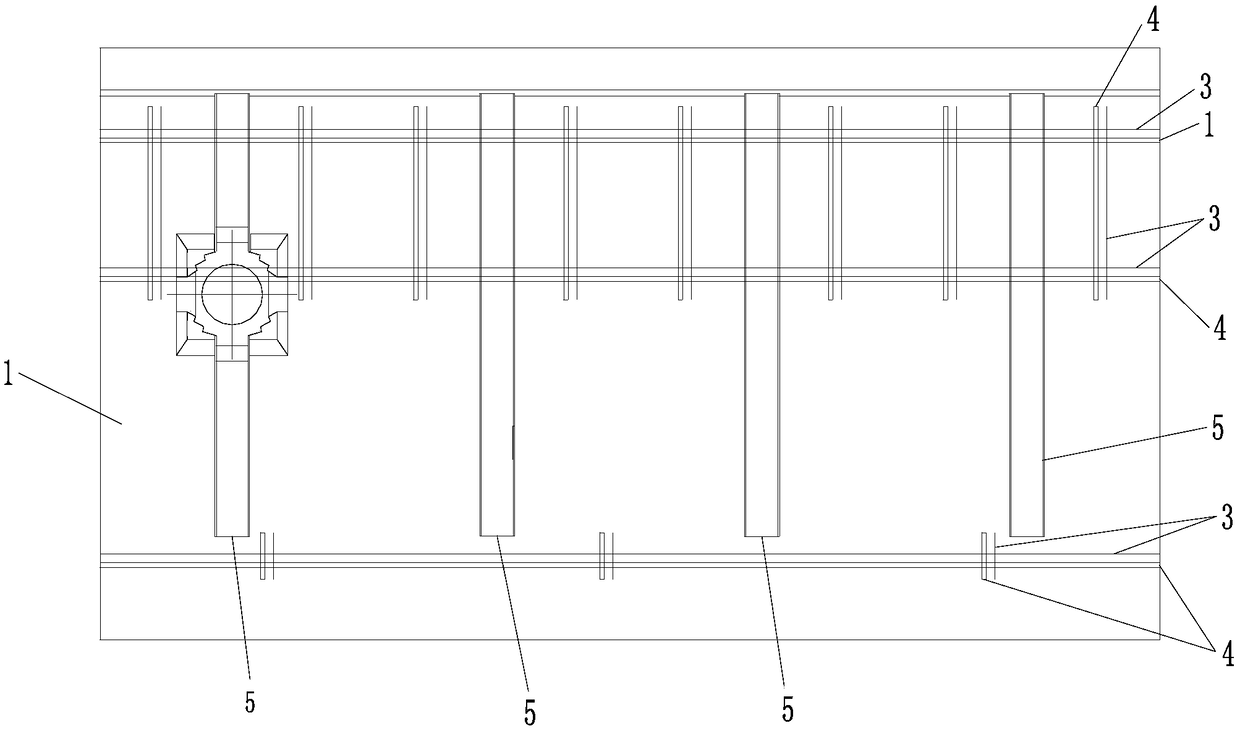

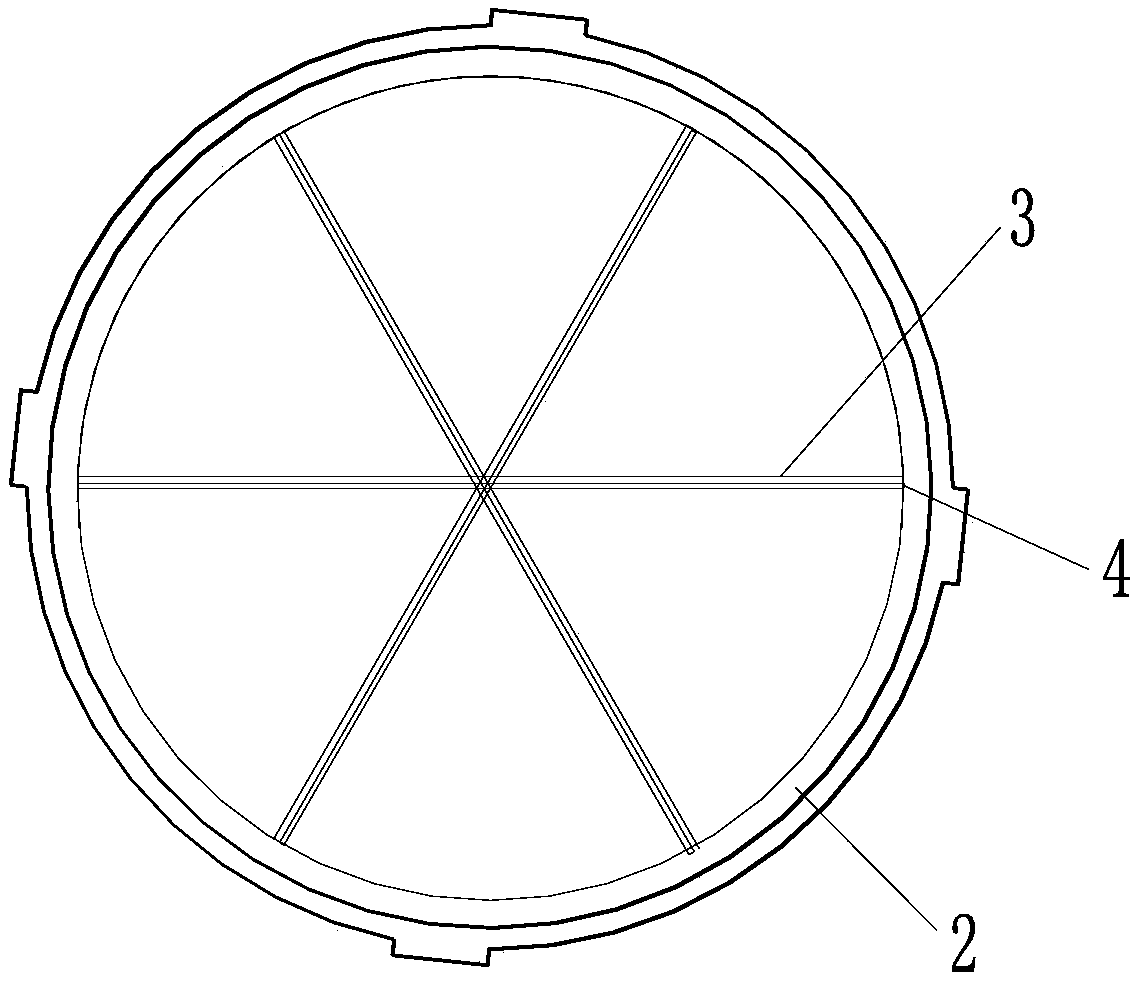

[0115] See attached figure 1 to attach figure 2 The containment vessel includes a prestressed concrete cylindrical shell 1, an arc-shaped dome 2 located above the shell 1, and a thick reinforced concrete foundation plate at the bottom of the shell 1, and the inner surface of the shell 1 is provided with a steel lining. The vertical prestressed steel beams of cylinder 1 start from the top of the prestressed corridor to the junction of the vertical wall and dome 2; the horizontal prestressed steel beams of cylinder 1 run from the bottom to the top of cylinder 1, and two layers of prestressed Stressed steel tendons; the dome 2 prestressed steel tendons are divided into 3 layers, adopting the form of 120° intersecting each other and the angle between the axes of each layer is 60°, and the steel bundles are covered with steel bundle sleeves.

[0116] A me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com