Flexible concrete for seam sealing

A flexible concrete and special fiber technology, applied in the field of inorganic non-metallic materials and pavement concrete repair, can solve the problems of inability to effectively adapt to the impact of external forces, poor deformation ability, insufficient cohesion, etc., and achieve excellent waterproof performance and weather resistance. High flexibility and deformability, the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

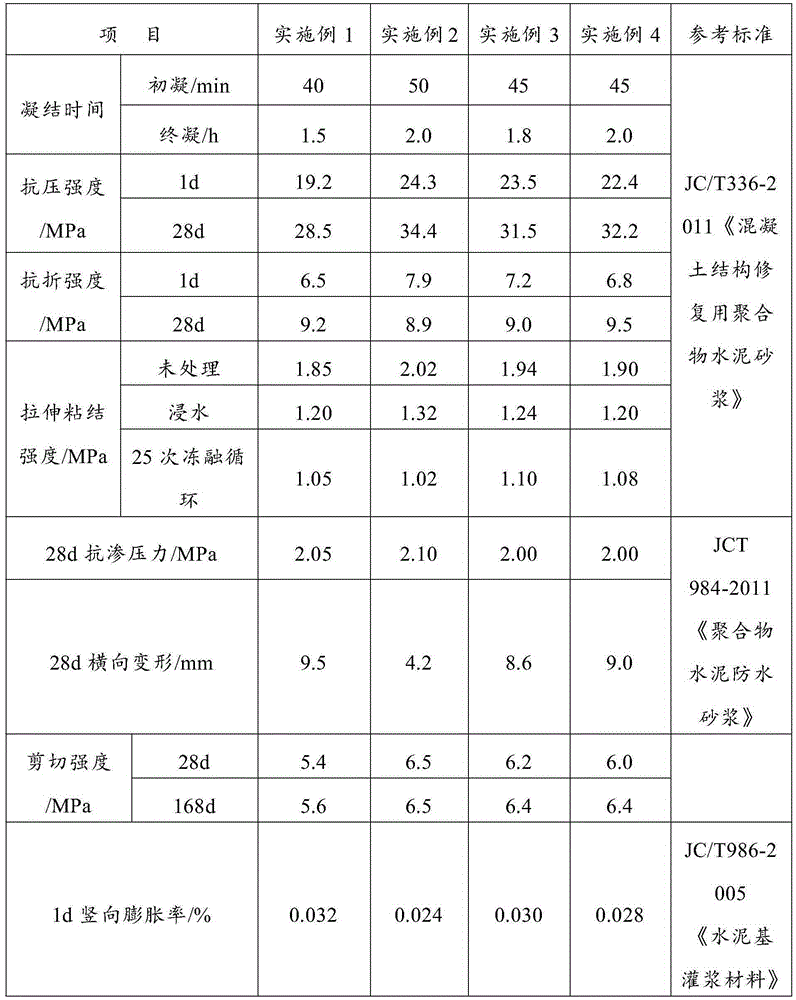

Examples

Embodiment 1

[0048] A kind of flexible concrete for caulking according to the present invention, the flexible concrete comprises the following components in mass fraction ratio: 15% of inorganic cementitious material, 2.0% of expansion material, 8% of filler, 41.5% of stone, 30% of sand, high strength 0.5% of special fiber, 6.0% of polymer additive, and the rest is water.

[0049] The inorganic cementitious material is a mixture of 10% of PⅡ52.5 portland cement and 5.0% of low-alkali 42.5 sulphoaluminate cement.

[0050] The expansion material is UEA expansion agent.

[0051] The filler is 200 mesh heavy calcium.

[0052] The stones are pebbles with a particle size of 5-16mm.

[0053] The sand is washed sand, and the particle size of the sand is 0-4.75mm.

[0054] The high-strength specialty fiber is aramid fiber. Aramid fibers are fibers that have been surface-treated with silane coupling agents.

[0055] The polymer additive includes the following components in mass fraction ratio: ...

Embodiment 2

[0067] A flexible concrete for caulking according to the present invention, the flexible concrete comprises the following components in proportion by mass fraction: 25% of inorganic gelling material, 1.0% of expansion material, 4% of filler, 40% of stone, 26% of sand, high-strength Special fiber 1.0%, polymer additive 3.0%, and the rest is water.

[0068] The inorganic cementitious material is P.O42.5 portland cement 20% and 42.5 aluminate cement 5.0%.

[0069] The expansion material is UEA expansion agent.

[0070] The filler is 200 mesh grade II fly ash.

[0071] The stones are crushed stones with a particle size of 5-16mm.

[0072] The sand is quartz sand, and the grain size of the sand is 0-4.75mm.

[0073] The high-strength special fiber is a mixture of polyvinyl alcohol fiber and aramid fiber. Polyvinyl alcohol and aramid fibers are fibers that have been surface-treated with silane coupling agents.

[0074] The polymer additive includes the following components in m...

Embodiment 3

[0086] A kind of flexible concrete for caulking according to the present invention, the flexible concrete comprises the following components in proportion by mass fraction: 20% of inorganic gelling material, 1.5% of expansion material, 6% of filler, 48% of stone, 19.2% of sand, high-strength Special fiber 0.8%, polymer additive 4.5%, the rest is water.

[0087] The inorganic cementitious material is P.O42.5 portland cement 10% and 42.5 aluminate cement 10%.

[0088] The expansion material is anhydrite.

[0089] The filler is 200 mesh quartz powder.

[0090] The stones are crushed stones with a particle size of 5-16mm.

[0091] The sand is quartz sand, and the grain size of the sand is 0-4.75mm.

[0092] The high-strength special fiber is a mixture of polyvinyl alcohol fiber and polyamide fiber. Polyvinyl alcohol and polyamide fibers are fibers treated with silane coupling agents.

[0093] The polymer additive includes the following components in mass fraction ratio: 3.0% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com