Blast furnace profile monitoring system

A blast furnace internal shape and monitoring system technology, applied in the direction of inspection devices, etc., can solve problems such as abnormal gas flow distribution, inability to meet the continuous production of large blast furnaces, and fluctuations in furnace conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with specific embodiment, the blast furnace internal type monitoring system of the present invention is further described:

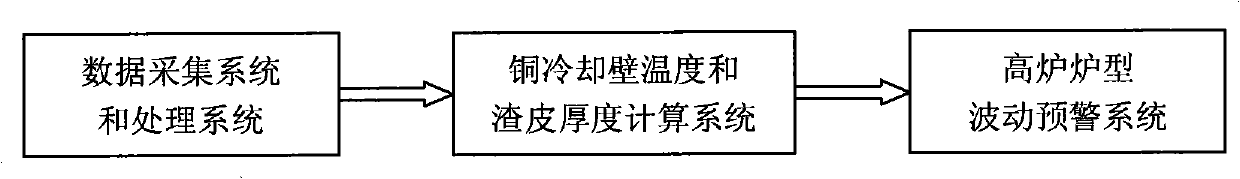

[0032] In this embodiment, the 3200m 3 The blast furnace is the object of implementation. Such as figure 1 As shown, the present invention mainly includes the following three parts: data acquisition system and processing system, copper stave temperature and slag skin thickness calculation system, blast furnace type fluctuation early warning system.

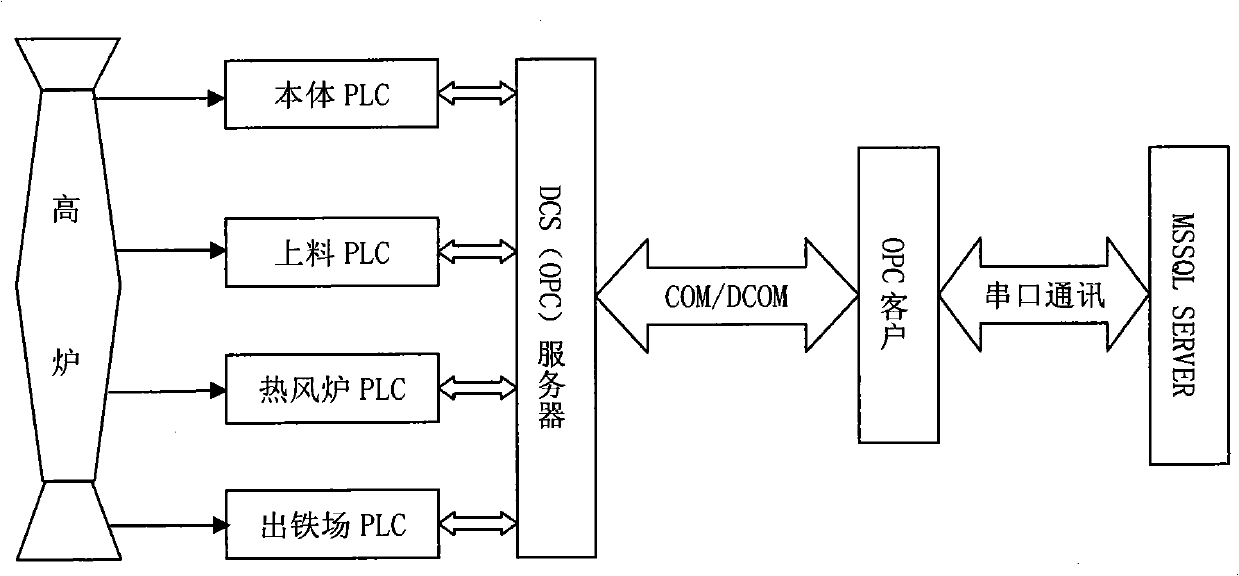

[0033] data acquisition systems and processing systems, such as figure 2 shown. It is used to collect the input parameters required by the temperature calculation model, and it is realized in the following way: the blast furnace includes subsystems such as the blast furnace body, charging, hot blast stove, and casthouse. Its automatic control system is divided into basic automation (level 1) and process automation (level 2), and a management automation (level 3) interface is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com