Patents

Literature

52results about How to "Effective temperature monitoring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

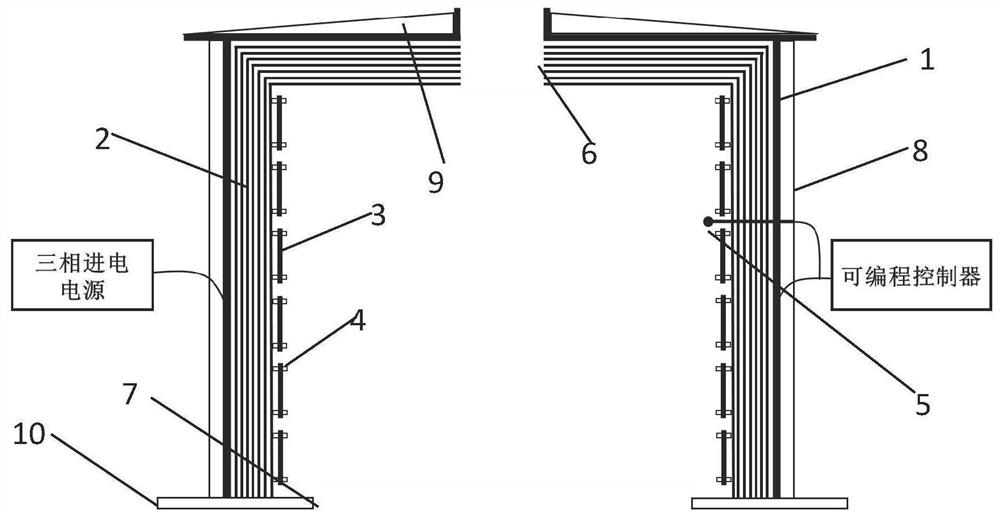

Blast furnace profile monitoring system

InactiveCN102021260AGuaranteed furnace conditionEffective temperature monitoringChecking devicesChemistrySQL

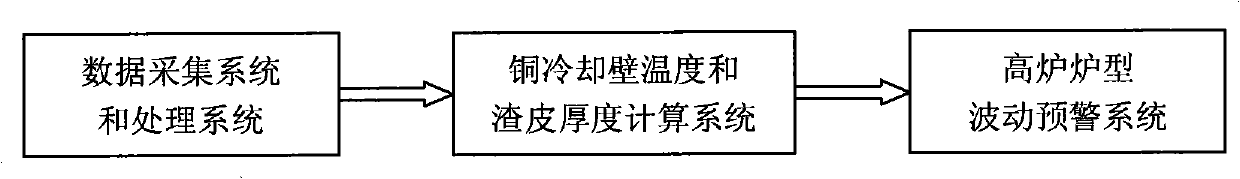

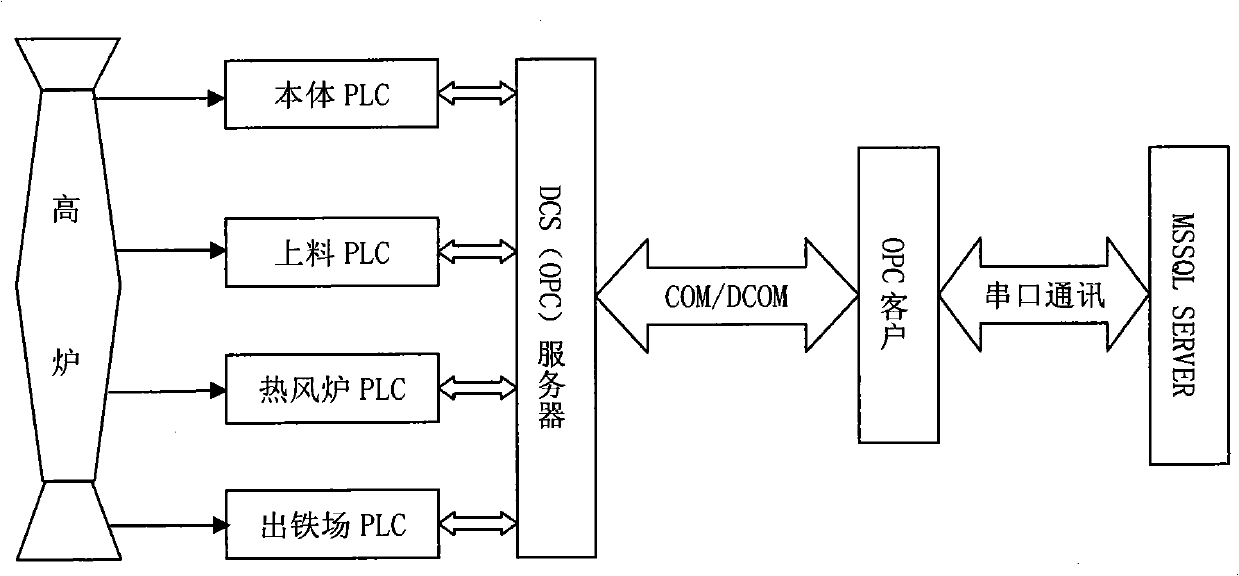

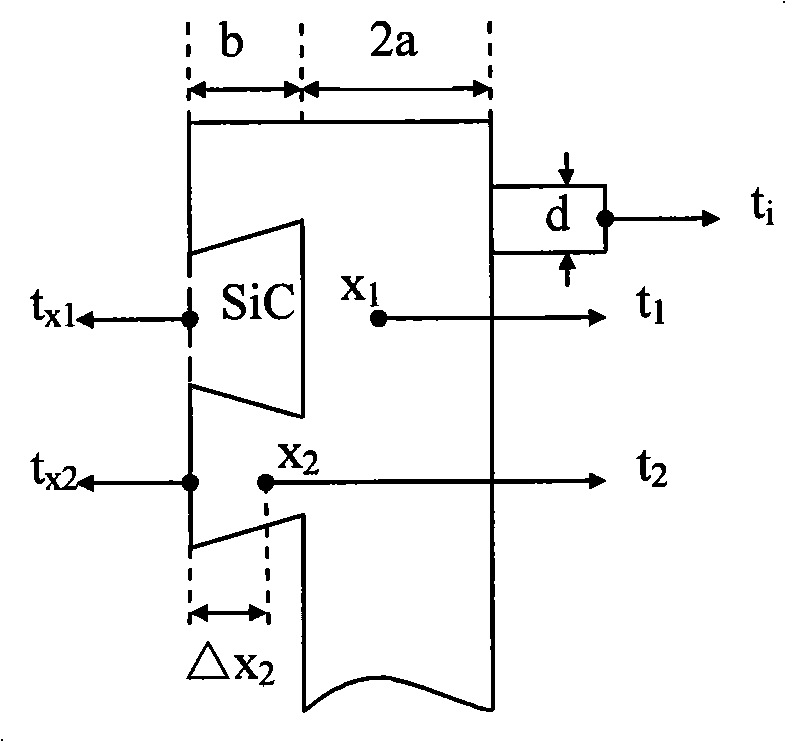

The invention discloses a blast furnace profile monitoring system which mainly comprises a PLC (Programmable Logic Control) system, a DSC (Dynamic Stability Control) system, an OPC (OLE for Process and Control) server, an SQL (Structured Query Language) database technology, a serial port isolation technology, an asynchronous communication technology and a WEB display technology. The blast furnace profile monitoring system is characterized in that a blast furnace data collection system and treatment system, a blast furnace copper cooling wall temperature slag and skin thickness calculation system and a blast furnace type fluctuation prewarning system are respectively established on such a basis, and all subsystems are organically combined through OPC serial port communication, an SQL database and a high-speed Ethernet. The invention can efficiently monitor the slag skin thickness of a heat surface of the copper cooling wall in a blast furnace high heat loading region i.e. a blast furnace profile, form a high-speed blast furnace type and condition information channel with strong calculation capability between the blast furnace and a main control chamber, guide blast furnace operation under the abnormal furnace conditions of slag skin thickening or thinning in the blast furnace high heat loading region and the like and ensure stable and smooth blast furnace condition as well as long service life of the blast furnace.

Owner:ANGANG STEEL CO LTD

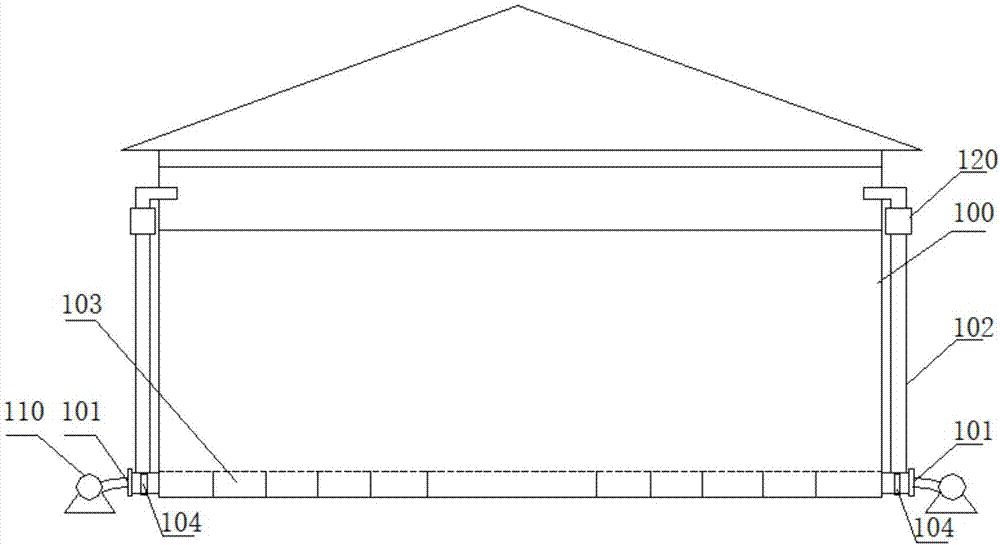

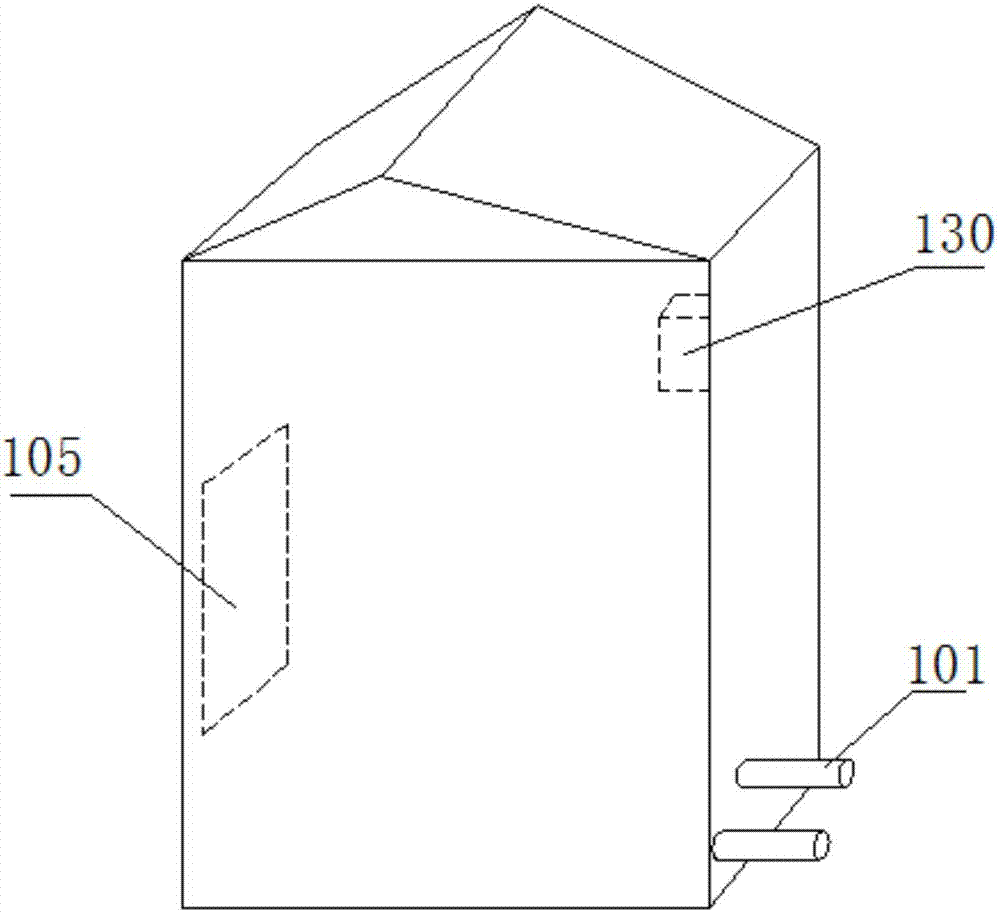

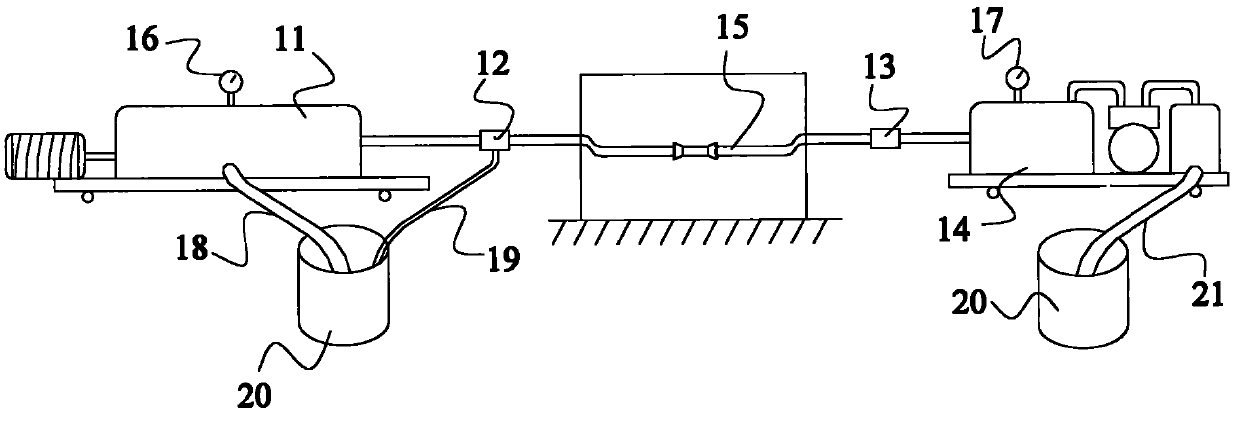

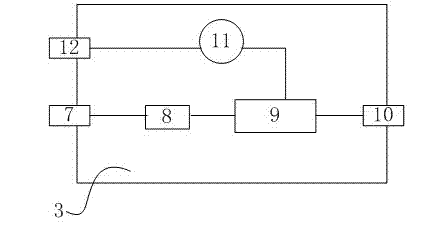

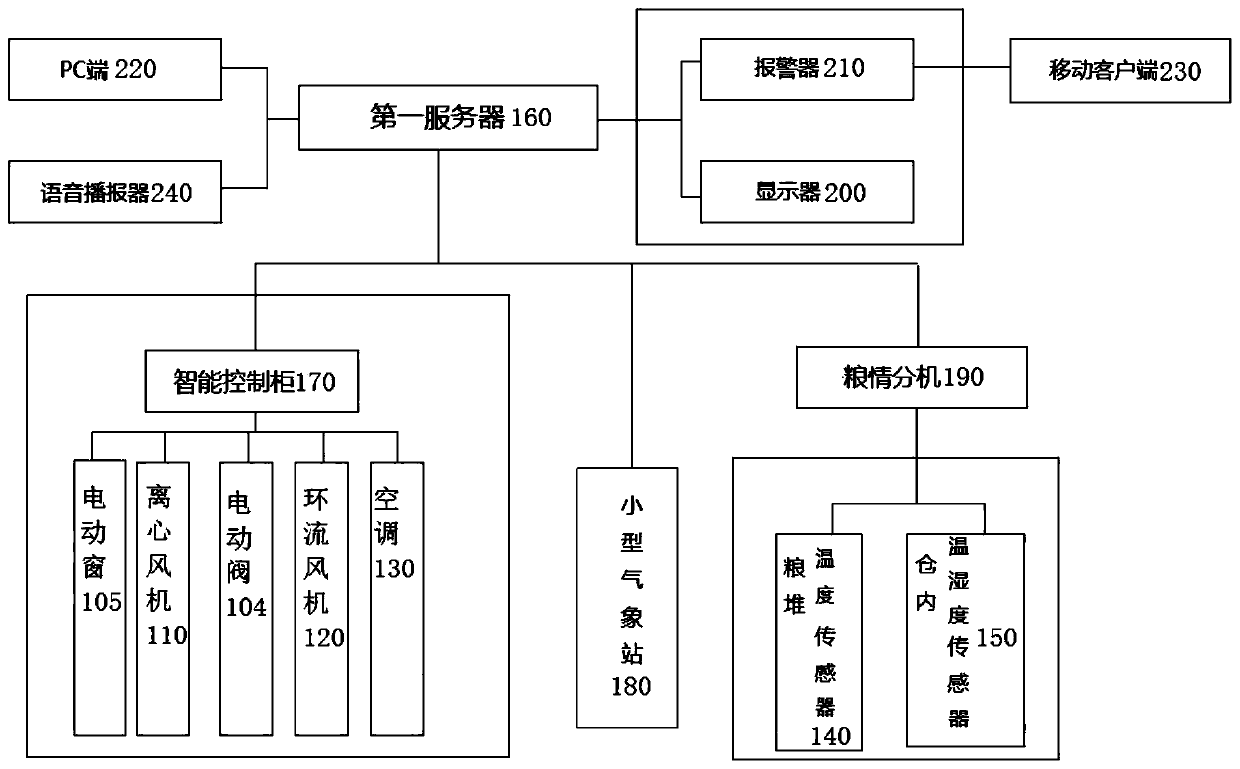

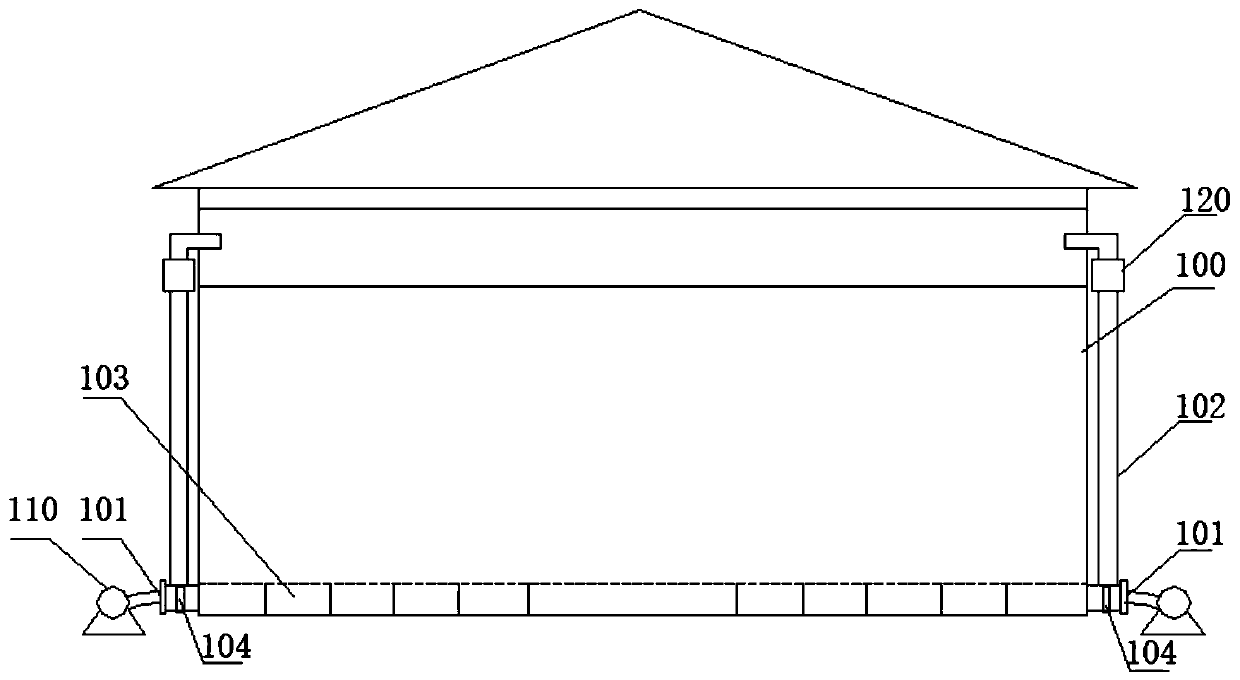

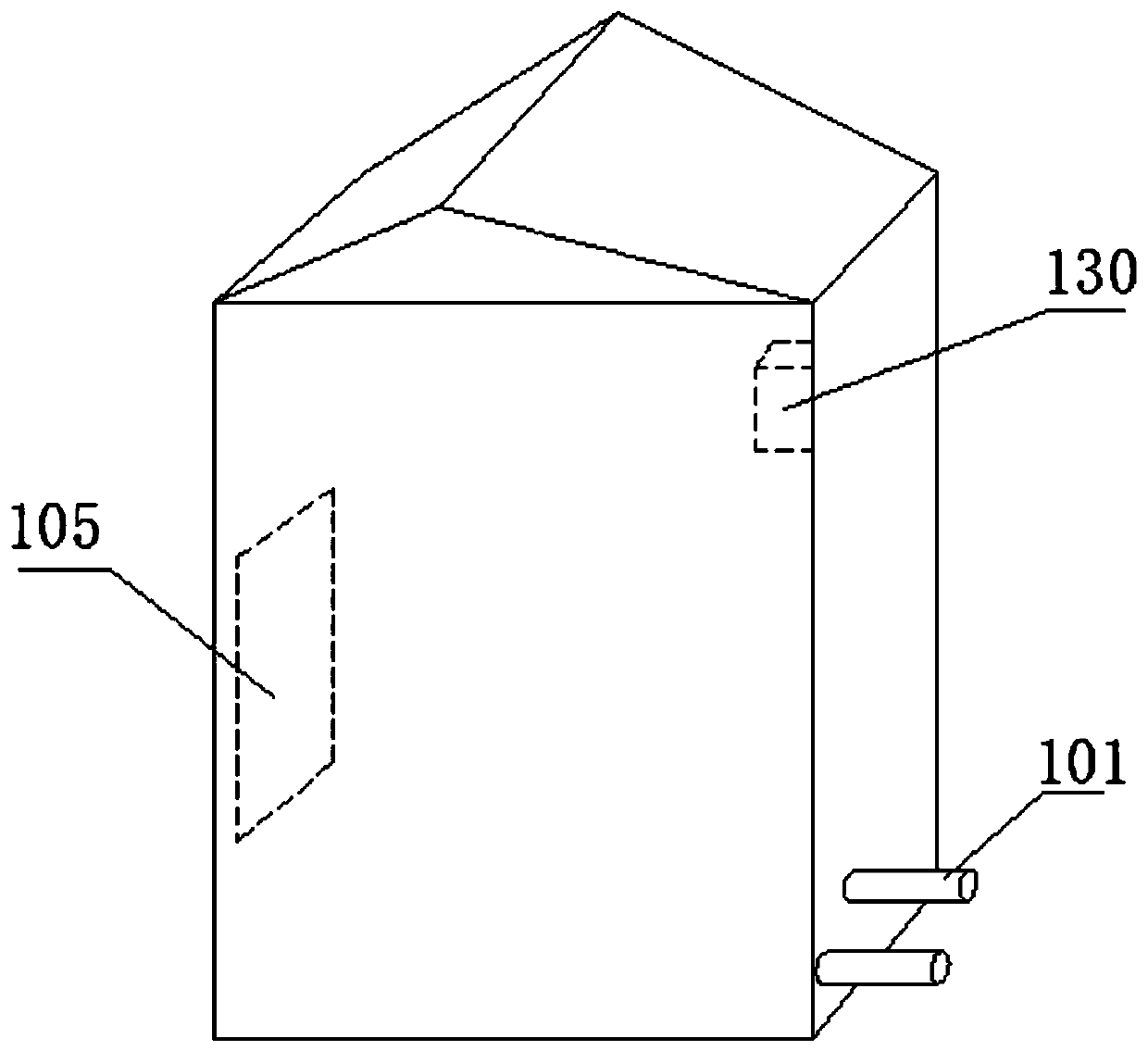

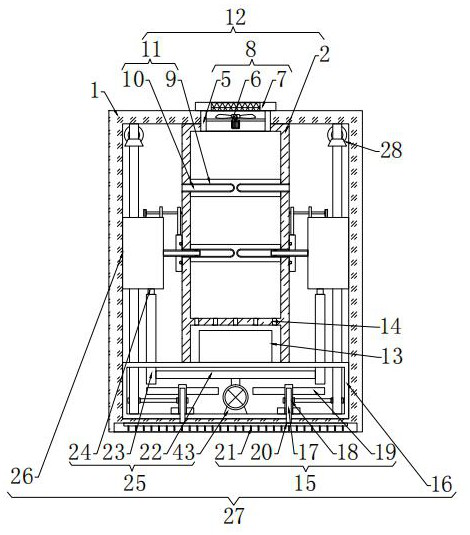

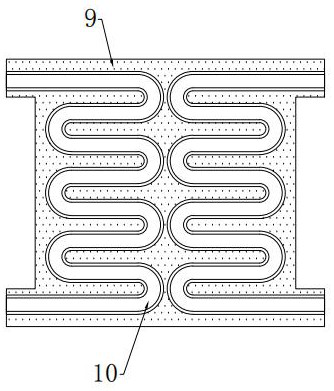

Internal-circulation low temperature grain storage system and method

ActiveCN107246715AEffective temperature monitoringAvoid inaccurate temperature monitoringAgriculture tools and machinesSpace heating and ventilation safety systemsAutomatic controlThermal insulation

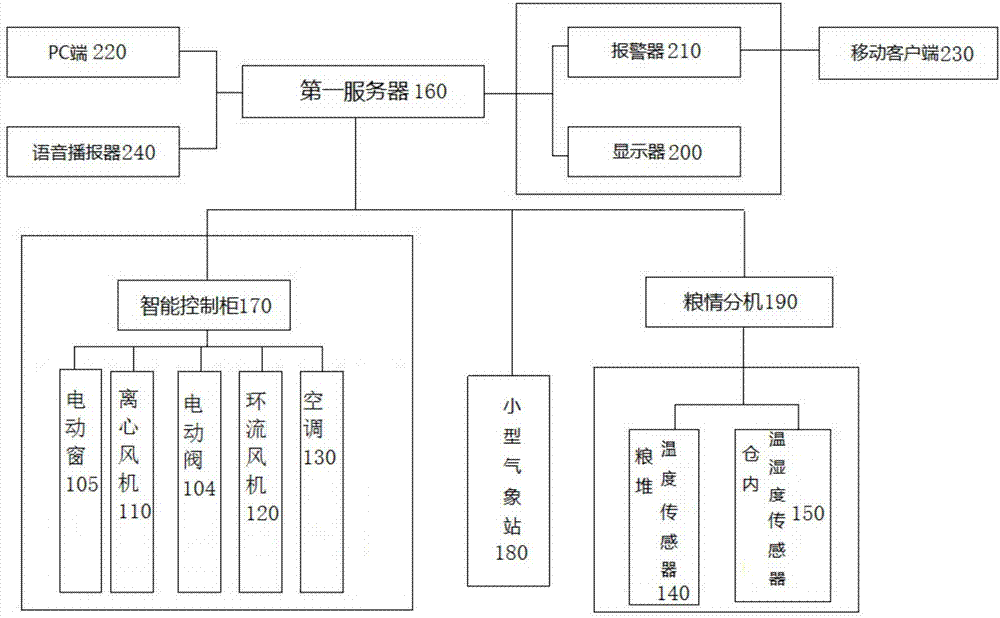

The invention discloses an internal-circulation low temperature grain storage system and method. The internal-circulation low temperature grain storage system comprises a grain bin, ventilation equipment, a grain condition detection unit and an intelligent ventilation unit, wherein at least one ventilation opening is formed in the bottom of the grain bin; an electric window is arranged on one wall surface; an electrically operated valve is arranged at each of the ventilation openings; each of the ventilation openings communicates with one end of a thermal insulation pipe; the other end of each of the thermal insulation pipes is connected with a circulating fan; a ground ventilation cage is arranged on the ground surface in the grain bin; the ventilation equipment comprises at least one centrifugal fan, the at least one circulating fan and at least one air conditioner; the grain condition detection unit comprises a plurality of grain pile temperature sensors and a bin inner temperature and humidity sensor; the intelligent ventilation unit comprises a first server and an intelligent control cabinet; the first server is in communication connection with a small-sized meteorological station outside the bin; and the operation of the ventilation equipment and the opening and closing of the electrically operated valves are automatically controlled by the intelligent control cabinet. According to the internal-circulation low temperature grain storage system and method, the intelligent regulation and control can be carried out timely when the grain pile temperature and the bin inner temperature and humidity deviate from the safe grain storage range, the labor intensity of grain bin keepers is reduced, and the grain bin management cost is greatly reduced.

Owner:HUBEI YE WEI INTELLIGENT TECH +1

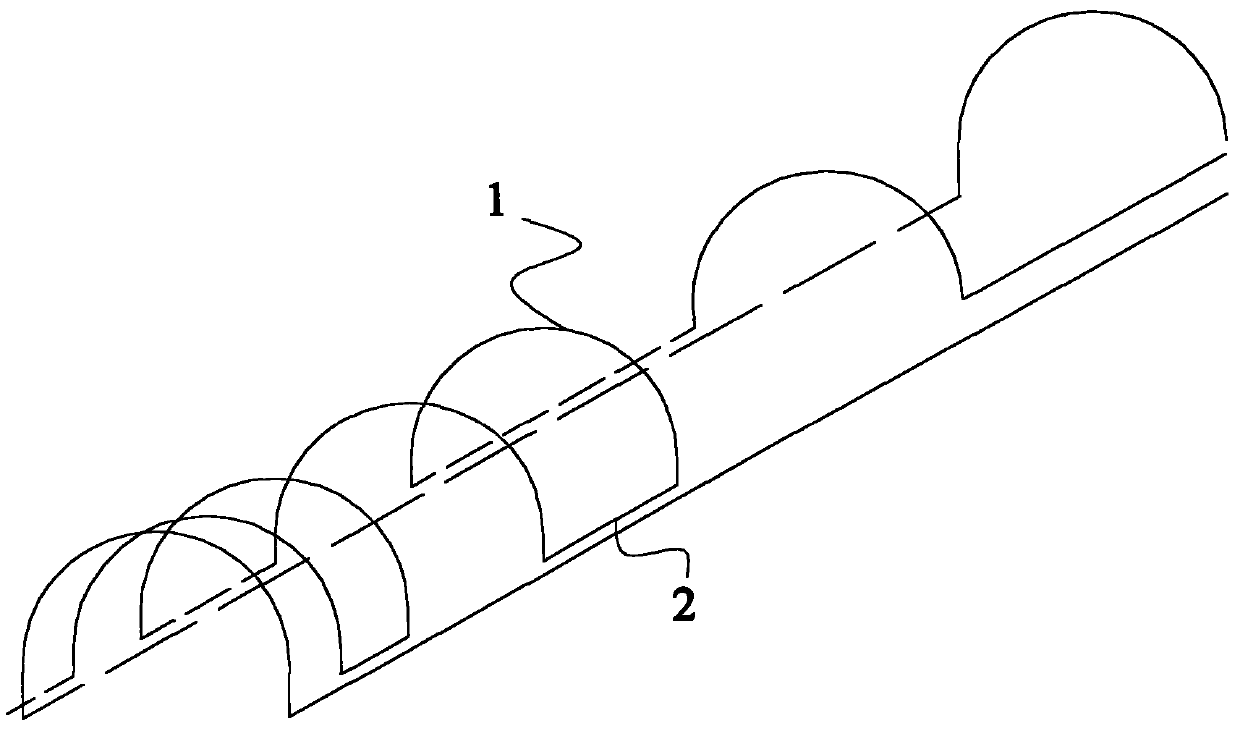

Method for paving internal concrete distributed sensing fibers

InactiveCN101738693AFast layingSolving the Difficulties of Embedding Inside ConcreteOptical fibre/cable installationThermometers using physical/chemical changesFiberStructural monitoring

The invention discloses a method for paving internal concrete distributed sensing fibers, which comprises the following steps: A) checking and cleaning a fiber conduit embedded in the concrete; B) blowing the sensing fibers into the fiber conduit through a fiber gas blowing port; C) selecting a grouting section, injecting slurry into a grouting port of the grouting section, closing a slurry outlet of the grouting section after the slurry is full of the grouting section, and keeping the slurry in the grouting section for 3 to 5 minutes under the pressure of between 1.0 and 1.5MPa so as to fix the sensing fibers in the fiber conduit; and D) circularly operating the step C) till the grouting of all the grouting sections is finished. The method achieves quick and lossless pavement for the long-distance distributed sensing fibers, solves the difficult problem that the structure monitoring field cannot embed the distributed sensing fibers into the concrete, ensures the distributed fiber sensing technology to monitor the structural strain and temperature more effectively, and realizes structural long-term and stable healthy survey.

Owner:ZHEJIANG UNIV

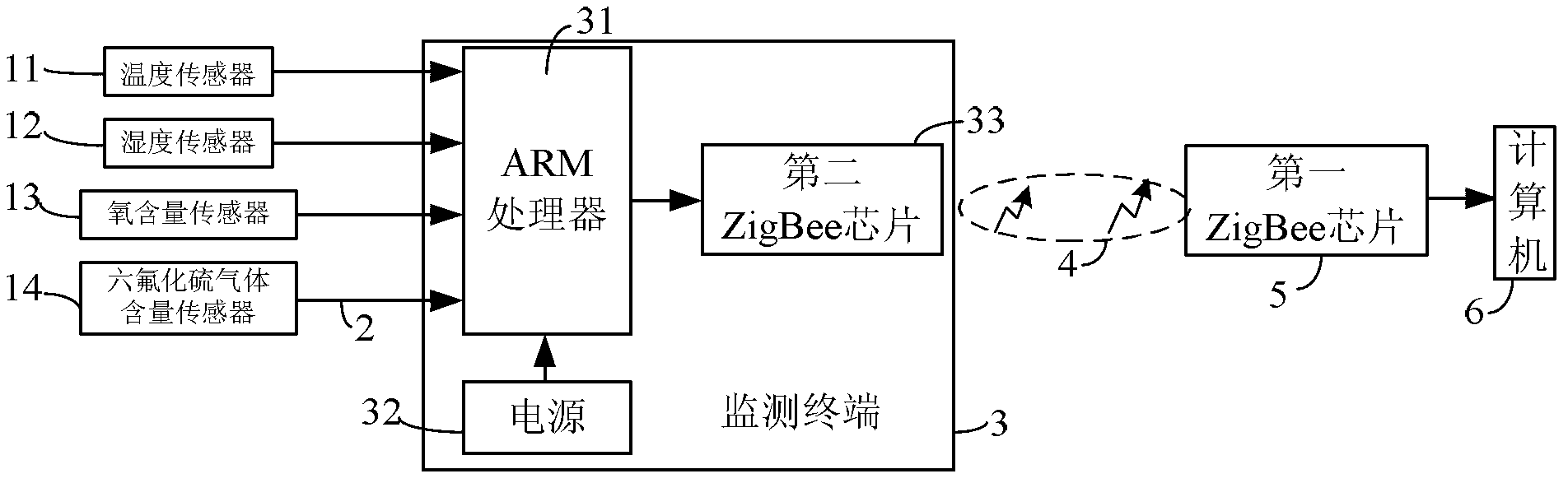

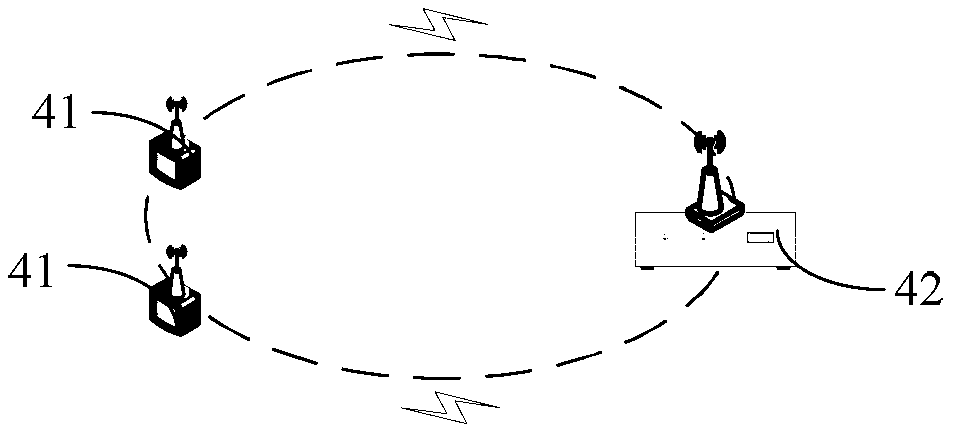

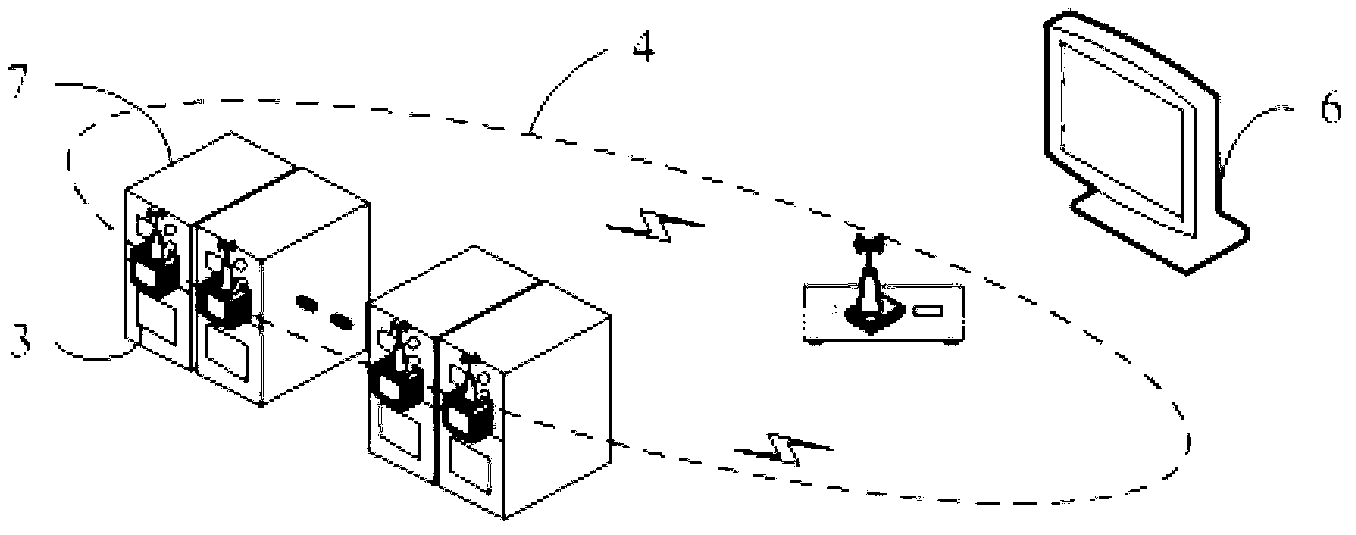

Switchgear environment status parameter monitoring device based on ZigBee network

InactiveCN103234578AEnvironmental state parameter monitoringEffective monitoring of environmental state parametersMeasurement devicesState parameterSwitchgear

The invention discloses a switchgear environment status parameter monitoring device based on a ZigBee network. The switchgear environment status parameter monitoring device comprises a plurality of sensors, multi-core cables, a monitoring terminal, a ZigBee wireless network, a first ZigBee chip and a computer. The sensors are connected with the monitoring terminal through the multi-core cables. The monitoring terminal comprises an ARM (advanced RISC machines) processor, a power source and a second ZigBee chip. The power source and the second ZigBee chip are both connected with the ARM processor. The first ZigBee chip is connected with the computer. The first ZigBee chip and the second ZigBee chip are connected through the ZigBee wireless network. The monitoring terminal is used for performing data transmission with the computer through the ZigBee wireless network. The switchgear environment status parameter monitoring device is compact in structure, the monitoring terminal is of a fixing mount type, the mount structure has no affection on existing design of the switchgear, and the environment status parameter of the switchgear can be effectively monitored on site.

Owner:STATE GRID CORP OF CHINA +2

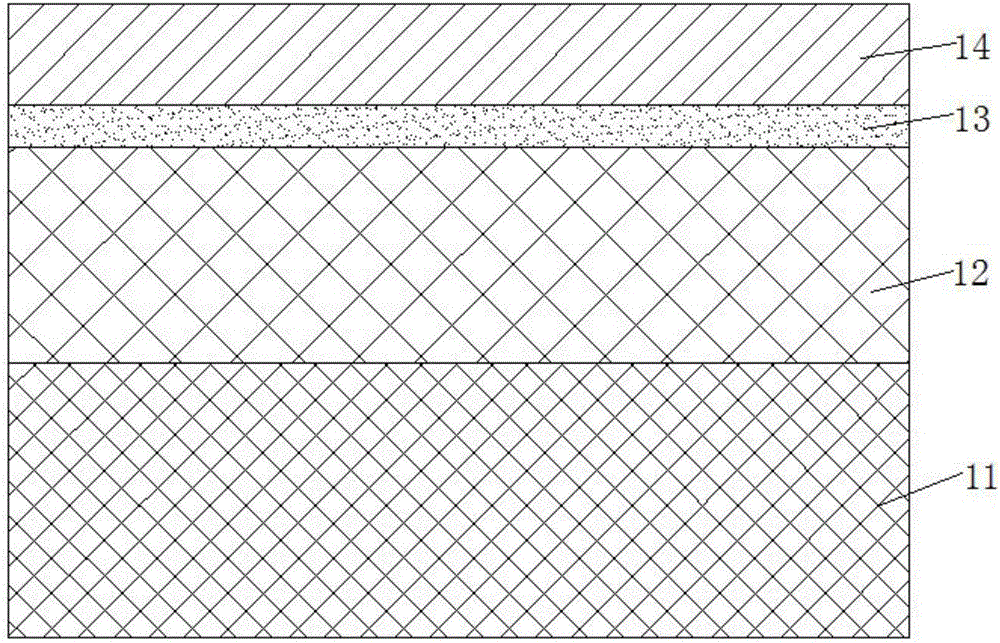

Steel ladle structure and manufacturing method thereof

PendingCN110935871AIncrease package ageEffective temperature monitoringMelt-holding vesselsInsulation layerSlag

The invention discloses a steel ladle structure and a manufacturing method thereof. A protective layer is arranged between a ladle body permanent layer and a working layer. The manufacturing method comprises the building steps of (1) building a ladle bottom, specifically, firstly, bottoming in a steel ladle shell by using a semi-light refractory castable, building refractory bricks on the semi-light refractory castable, and building a ladle bottom platform; (2) attaching a heat preservation layer, specifically, tightly attaching two layers of nanometer heat insulation plates to the inner wallof the steel ladle shell; (3) building a protective layer and a working layer, specifically, building protective layer refractory bricks on the ladle bottom platform, then building working layer refractory bricks, and forming a double-ring brick structure; (4) pouring a ladle body permanent layer, specifically, injecting a semi-light castable between the nanometer heat insulation plate and the protective layer bricks every 2-3 layers of double-ring bricks are built, constructing the ladle body permanent layer, and repeating the step until the edge of a steel ladle opening is reached; and (5) punching a hole in the peripheral steel ladle shell of the steel ladle slag line area to install a thermocouple, and connecting a temperature display. According to the invention, the safety of the steel ladle is effectively improved, the heat loss of molten steel is reduced, and the maintenance workload and material consumption of the steel ladle are greatly reduced.

Owner:新余钢铁股份有限公司

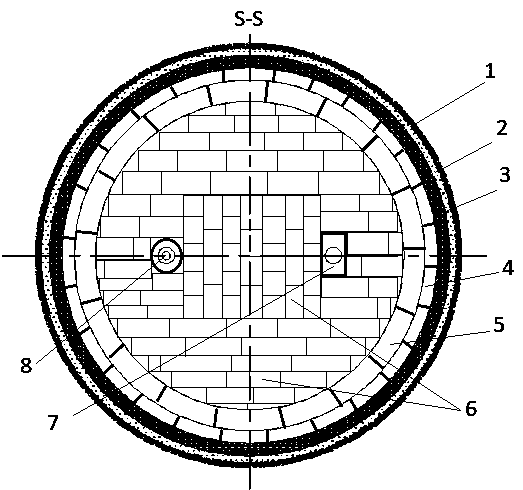

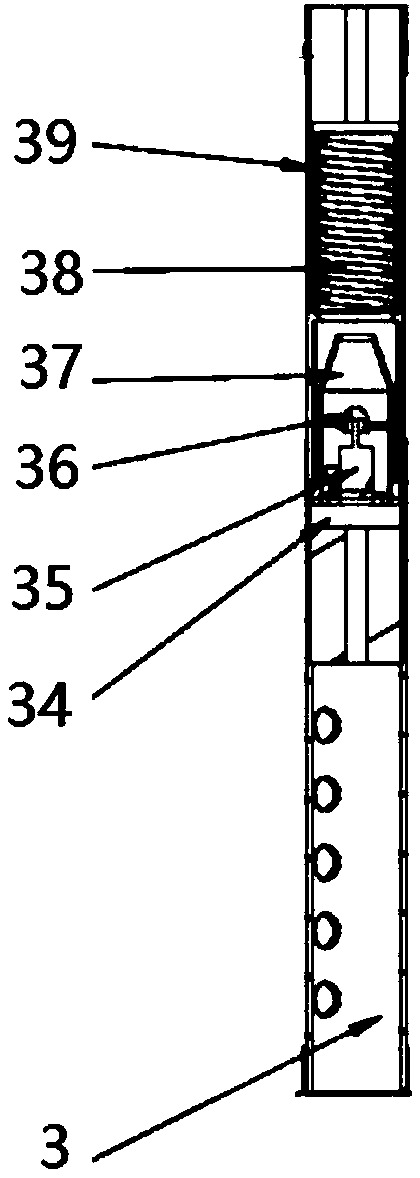

Pouring box stopper for continuous casting

InactiveCN101337273AReduce manufacturing costReduce labor intensityMelt-holding vesselsCasting parameters measurement/indication devicesAutomatic controlEngineering

A pouring box stopper used for continuous casting relates to an auxiliary fitting part comprising a stopper body, in which a corundum tube is mounted; and the upper end of the corundum tube is connected with a temperature measuring device, which comprises a water-cooling device or a wind-cooling device, a temperature measuring probe and a temperature measuring meter, wherein the temperature measuring probe is connected with the temperature measuring meter through a conducting wire. By adopting the above structure, the corundum tube is mounted in the stopper body, and the improved stopper has the temperature measuring function, thereby eliminating the need of installing an additional temperature measuring tube in the pouring box, reducing the manufacture cost of cast steel, reducing the labor intensity, and simplifying the operation flow; furthermore, since the stopper body directly faces to the corresponding molten steel outlet, the temperature of the molten steel inside a crystallizer can be effectively monitored, thereby providing more precise temperature parameters for the automatic control of the pulling rate.

Owner:赫勇

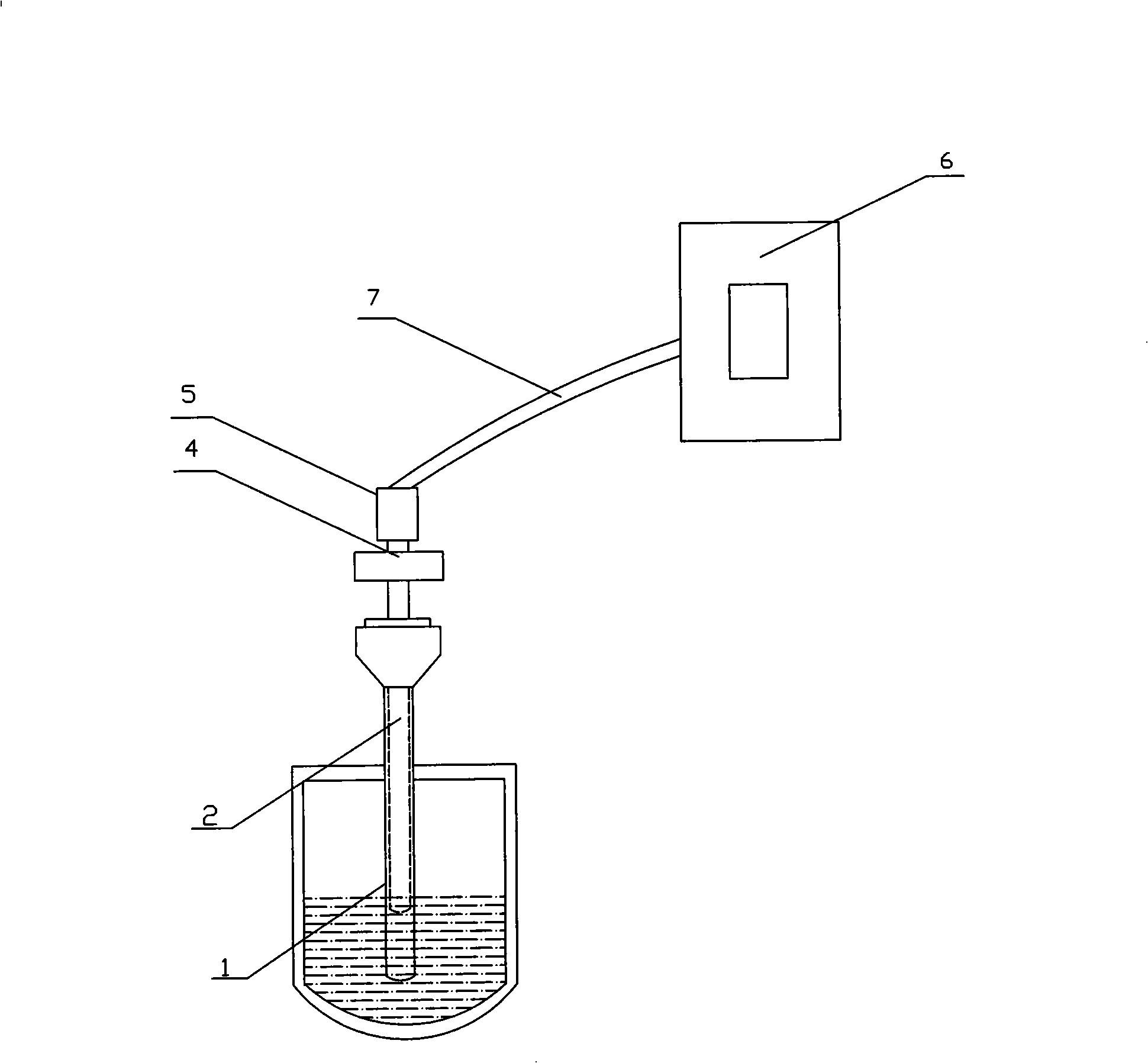

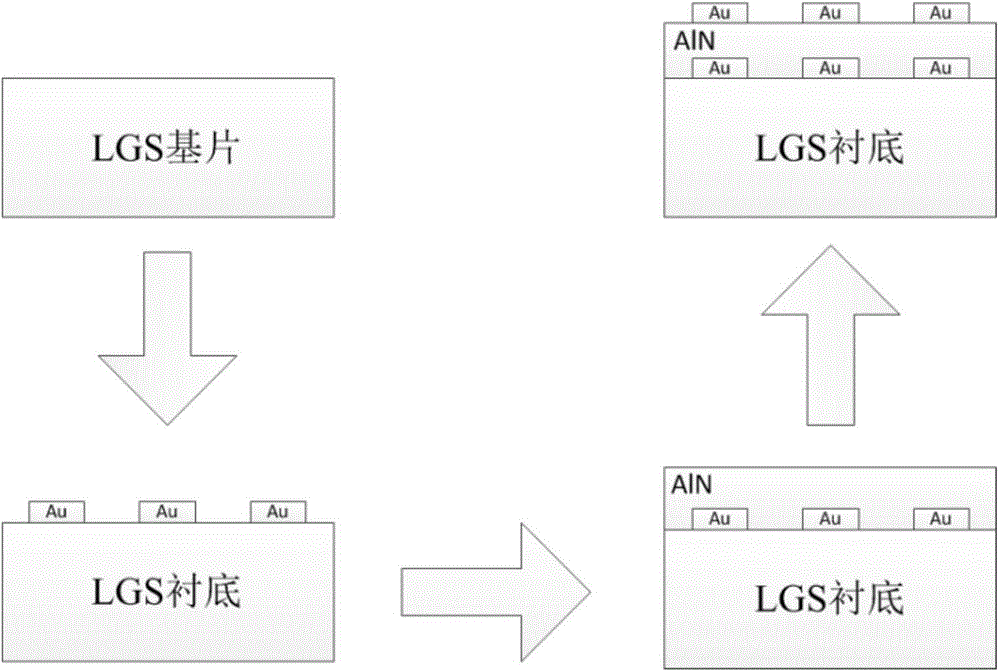

Acoustic surface wave sensor with double sensitive sources

InactiveCN104101451ASimple structureEffective temperature monitoringForce measurementThermometers using physical/chemical changesVertical projectionSurface acoustic wave sensor

An acoustic surface wave sensor with double sensitive sources belongs to the technical field of electronic functional materials and devices. The sensor comprises a substrate, wherein the substrate is an LGS substrate; the substrate is provided with an interface harmonic oscillator and an AlN film layer; the AlN film layer completely covers the interface harmonic oscillator; the AlN film layer is provided with a surface harmonic oscillator; the vertical projection of the surface harmonic oscillator is overlapped with the vertical projection of the interface harmonic oscillator; the interface harmonic oscillator and the surface harmonic oscillator are acoustic surface wave harmonic oscillators; metal film electrodes in the acoustic surface wave harmonic oscillators are made of high-temperature resistant metal. The acoustic surface wave sensor with double sensitive sources is simple in structure, can monitor the stress and temperature efficiently and at the same time, can be applicable for a high-temperature complex environment as LGS, AlN and the high-temperature resistant metal are adopted, has no power source and no wire, and is strong in stability. The acoustic surface wave sensor with double sensitive sources is suitable for monitoring the stress and the temperature at the same time.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

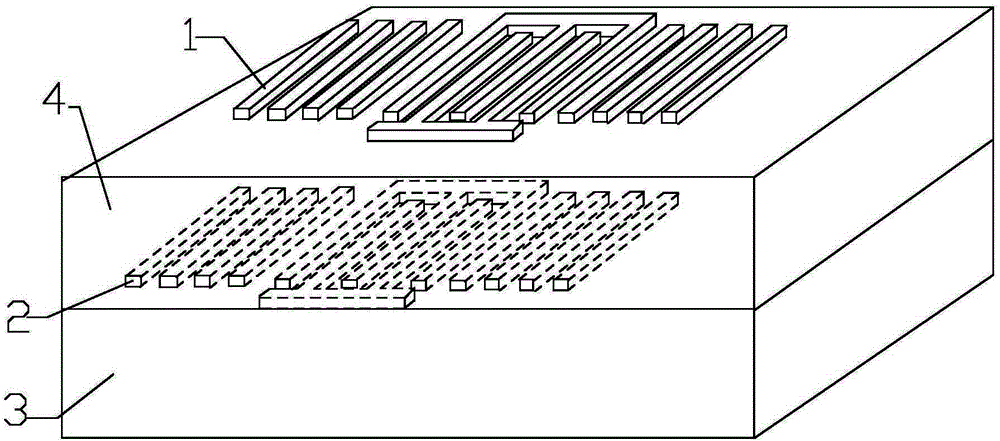

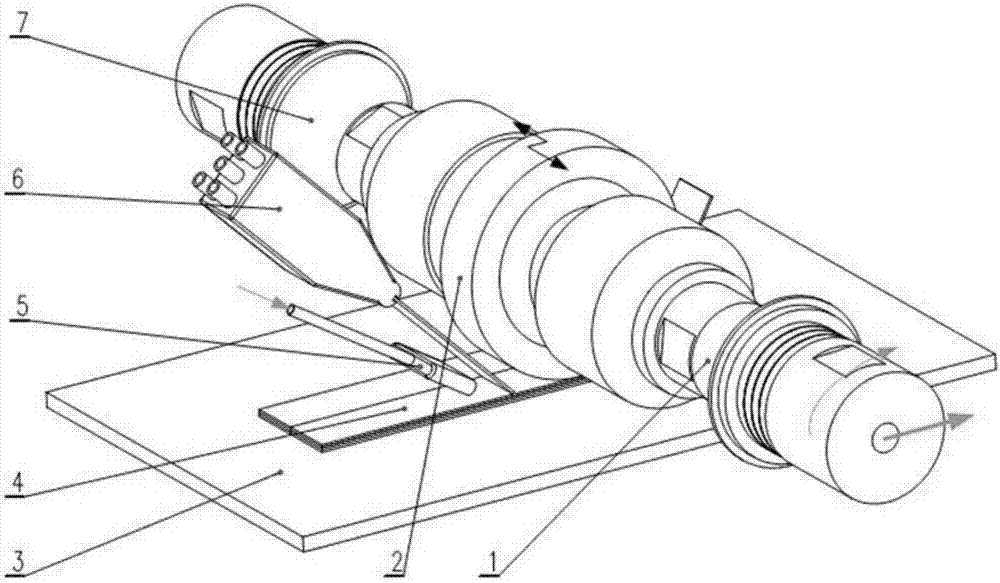

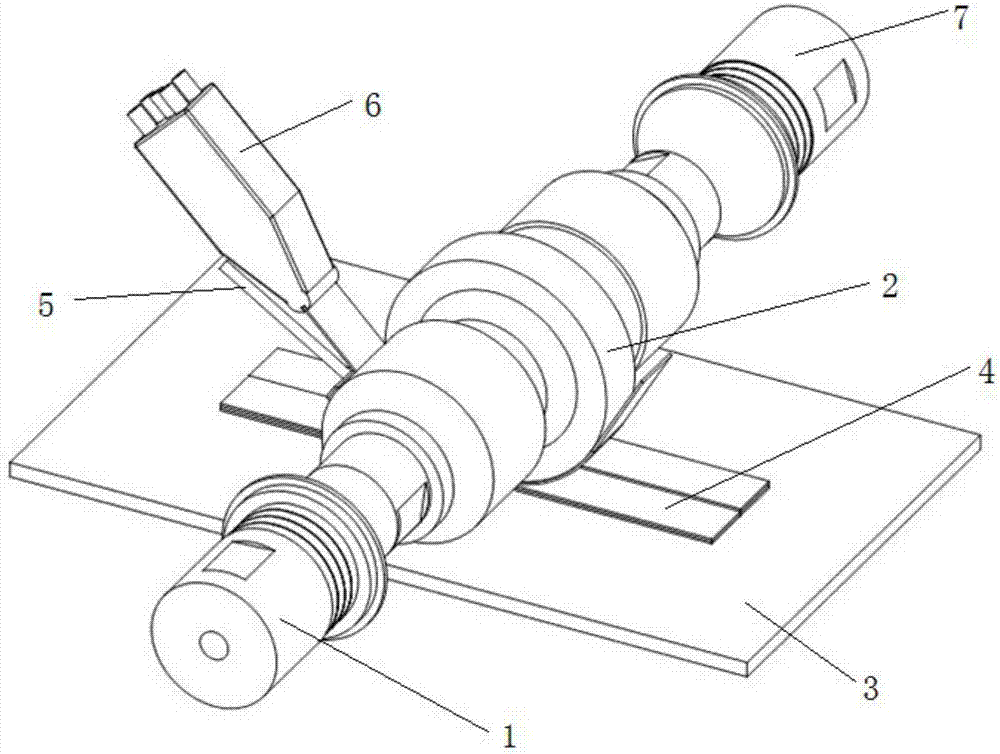

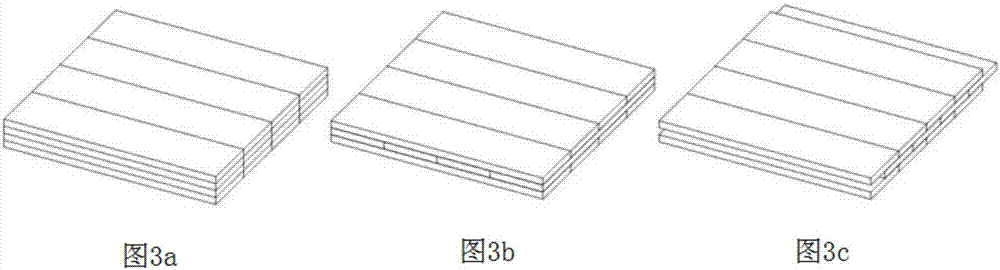

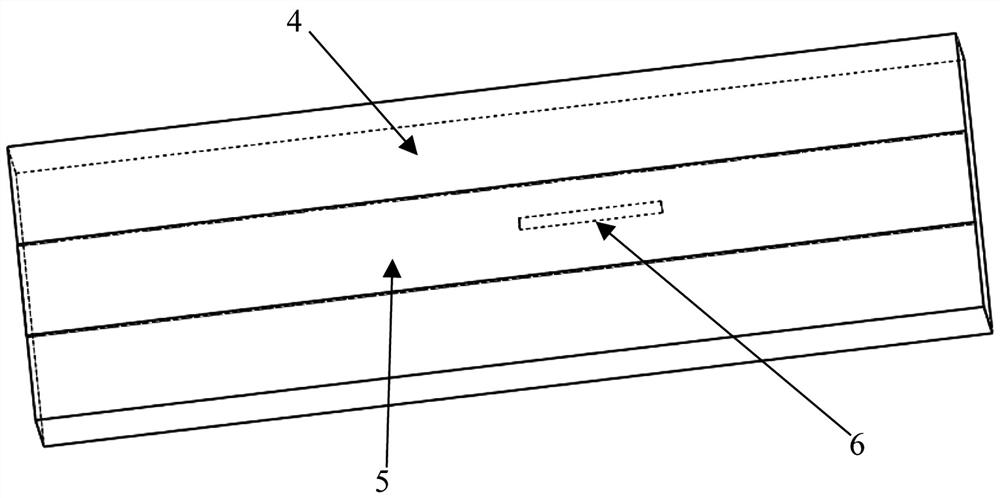

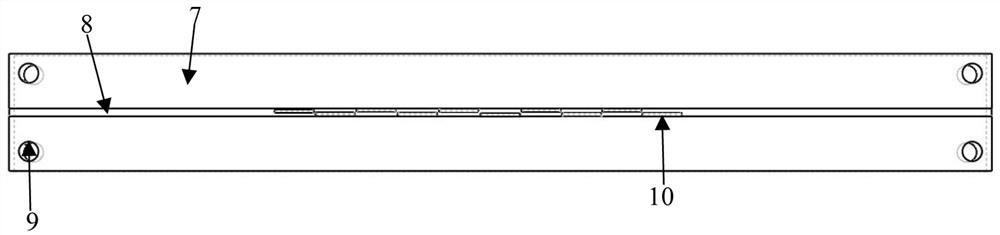

Laser-assisting type ultrasonic additive manufacturing device for metallic foil tape and manufacturing method

PendingCN107498173AIncreasing the thicknessQuality improvementAdditive manufacturing apparatusNon-electric welding apparatusMetallic foilUltrasonic sensor

The invention discloses a laser-assisting type ultrasonic additive manufacturing device for a metallic foil tape and a manufacturing method. The device comprises a working platform, an ultrasonic roll welding pressing head which is positioned on the working platform, a first ultrasonic transducer and a second ultrasonic transducer, wherein the first ultrasonic transducer and the second ultrasonic transducer are correspondingly mounted at two ends of the ultrasonic roll welding pressing head; a scanning laser head and a protecting gas device, which have the same horizontal feeding speed as the first ultrasonic transducer and the second ultrasonic transducer, are arranged at the back of the ultrasonic roll welding pressing head; the metallic foil tape is positioned below the ultrasonic roll welding pressing head on the working platform; an infrared temperature measuring instrument which is in signal connection with the scanning laser head through a control system is arranged above the side surface of the metallic foil tape. According to the device, a welding part is subjected to twice consolidation through laser beams along the ultrasonic roll welding pressing head; the laser consolidation technology is adopted for assisting quick ultrasonic formation, thus the atoms, at the combination interface, of the metallic foil tape, are accelerated to disperse, and as a result, the efficient, high-quality, energy-saving and environmentally friendly ultrasonic additive manufacturing process is achieved.

Owner:WEIHAI WANFENG MAGNESIUM IND DEV +1

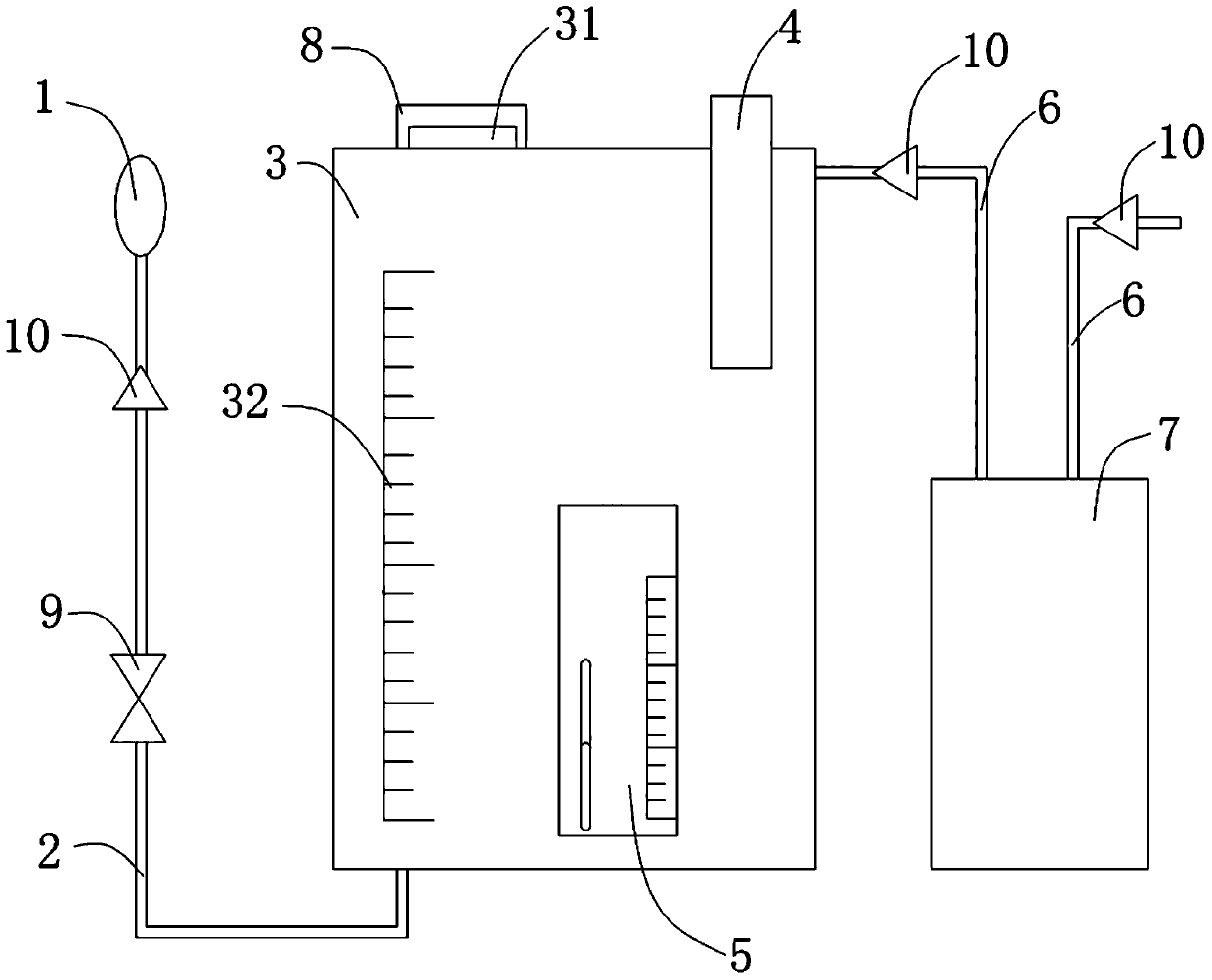

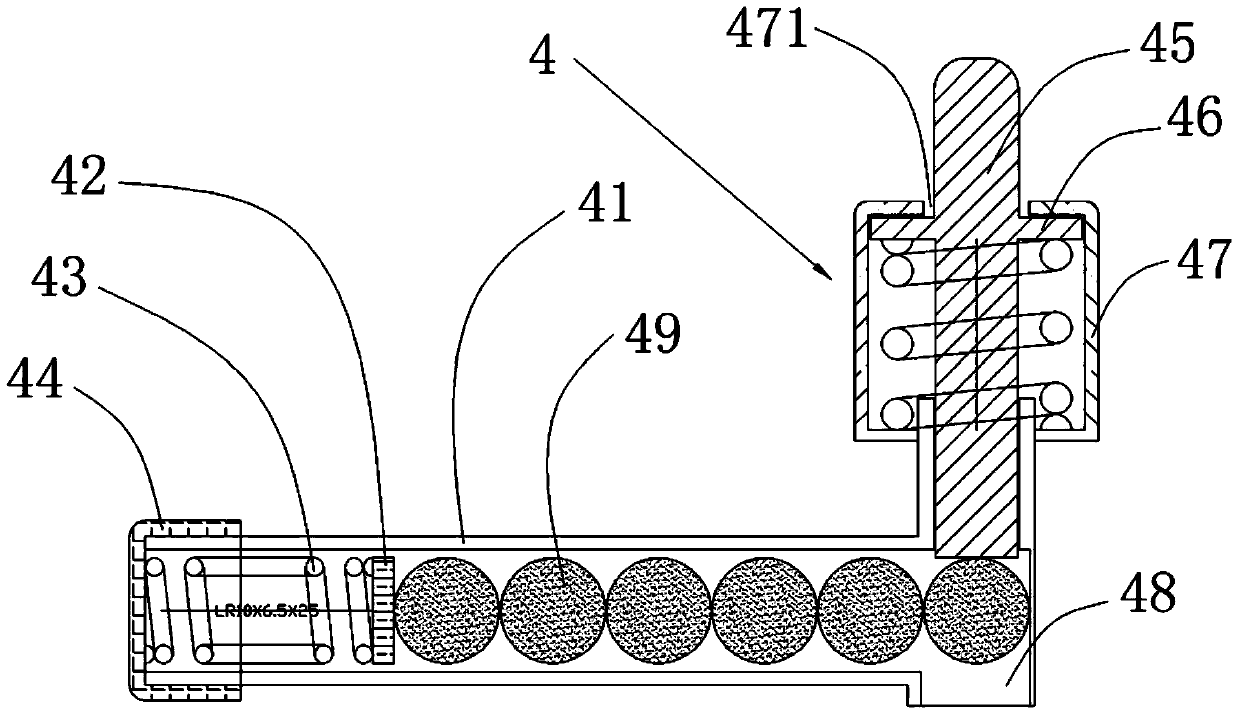

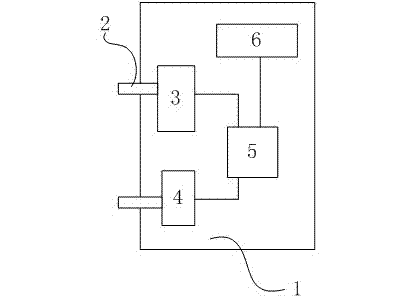

Pressure-adjustable nasal irrigator

The invention discloses a pressure-adjustable nasal irrigator which is convenient for a user to operate and capable of effectively controlling water pressure of a spray nozzle spraying salt water and greatly improving irrigating comfortableness. The pressure-adjustable nasal irrigator comprises the spray nozzle, a diversion pipe, a liquid storage device, a salt adding device, a temperature detection component, air ducts, an inflating device, a pressure valve, a control valve and a plurality of check valves. The diversion pile is communicated between the spray nozzle and the liquid storage device; the check valves and the control valve are arranged on the diversion pipe; the control valve can regulate to increase the water pressure of the cleaning fluid sprayed from the spray nozzle gradually; the air ducts are communicated between the liquid storage device and the inflating device; the liquid storage device is used for storing the cleaning liquid; the inflating device is used for increasing air pressure inside the liquid storage device; another check valve is arranged on the air ducts; the salt adding device is mounted on the liquid storage device so as to add salt into the liquid storage device quantitatively; the temperature detection component is arranged in the liquid storage device, so that water temperature of the cleaning liquid can be monitored in real time; the pressure valve is mounted on a water filling nozzle of the liquid storage device; scale marks are further arranged on the liquid storage device, so that concentration of the cleaning liquid can be effectively controlled.

Owner:卢育华

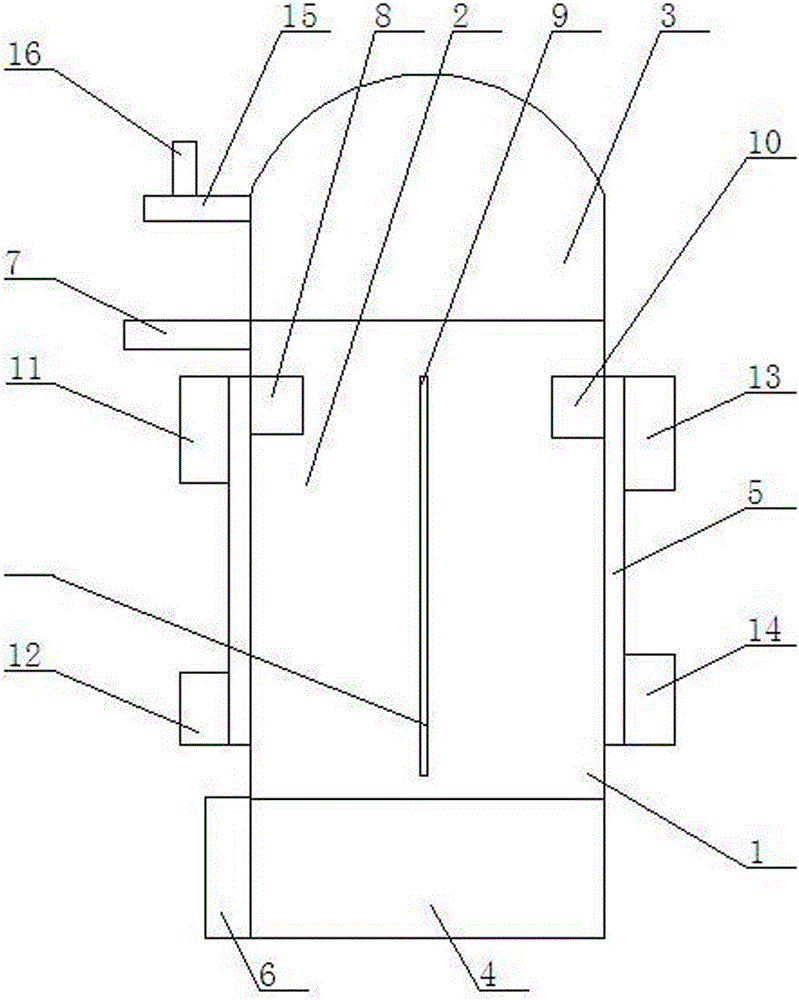

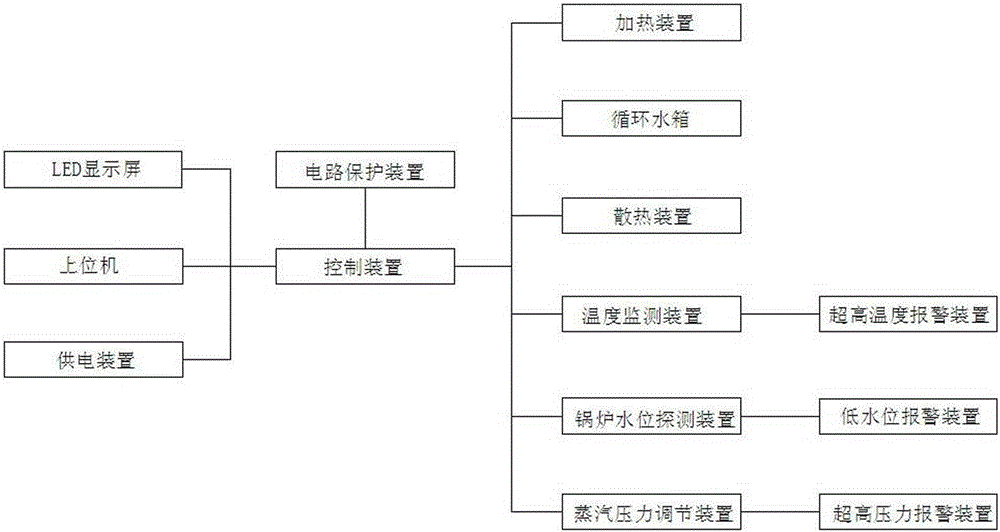

Intelligent electric boiler

InactiveCN105180130AHeating fastImprove thermal efficiencySteam generation heating methodsBoiler controlSteam pressureLED display

Disclosed is an intelligent electric boiler. The intelligent electric boiler comprises a boiler body, a boiler cavity, a circulation water tank, a heating device, radiating devices and a control device. The control device is arranged at the lower left end of the boiler body. Radiating devices are arranged on the outer wall of the middle of the boiler body. The circulation water tank is arranged at the upper end of the boiler body. A steam exhaust pipe is arranged at the upper left end of the boiler body. The heating device is arranged at the lower inner end of the boiler cavity. A temperature monitoring device, a boiler water level detection device and a steam pressure adjusting device are arranged in the boiler cavity. An ultrahigh temperature warning device and a low water level warning device are arranged on the outer side of the radiating device which is arranged at the left end of the boiler body. An ultrahigh pressure warning device and an LED display screen are arranged on the outer side of the radiating device which is arranged at the right end of the boiler body. The control device is connected with the control display screen, the heating device, the circulation water device, the radiating devices, the temperature monitoring device, the boiler water level detection device and the steam pressure adjusting device. The intelligent electric boiler is capable of effectively monitoring the water level, the temperature in the boiler and the pressure in the boiler, and has the advantages of being rapid in heating, high in heat efficiency, convenient to install and use and the like.

Owner:HARBIN JINJING BOILER

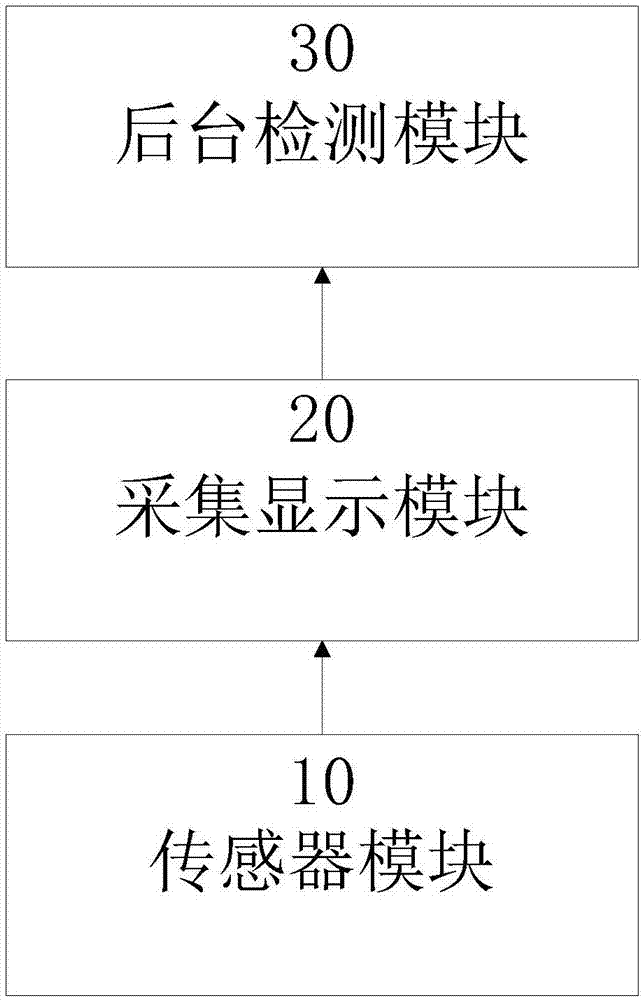

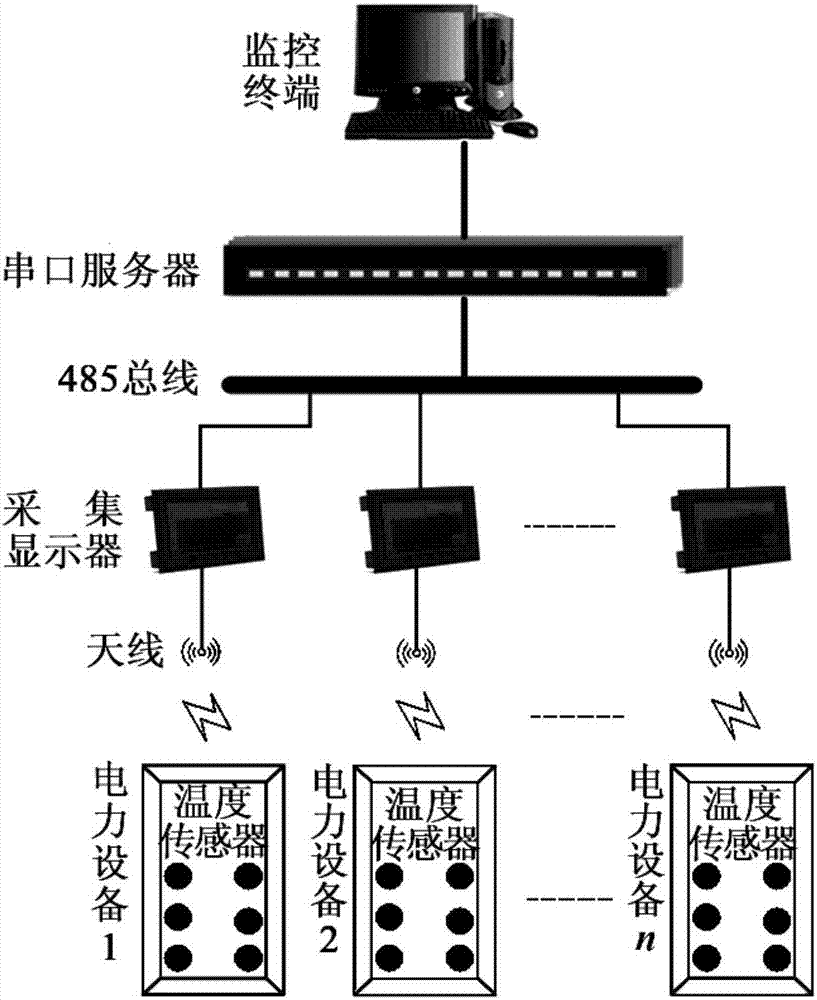

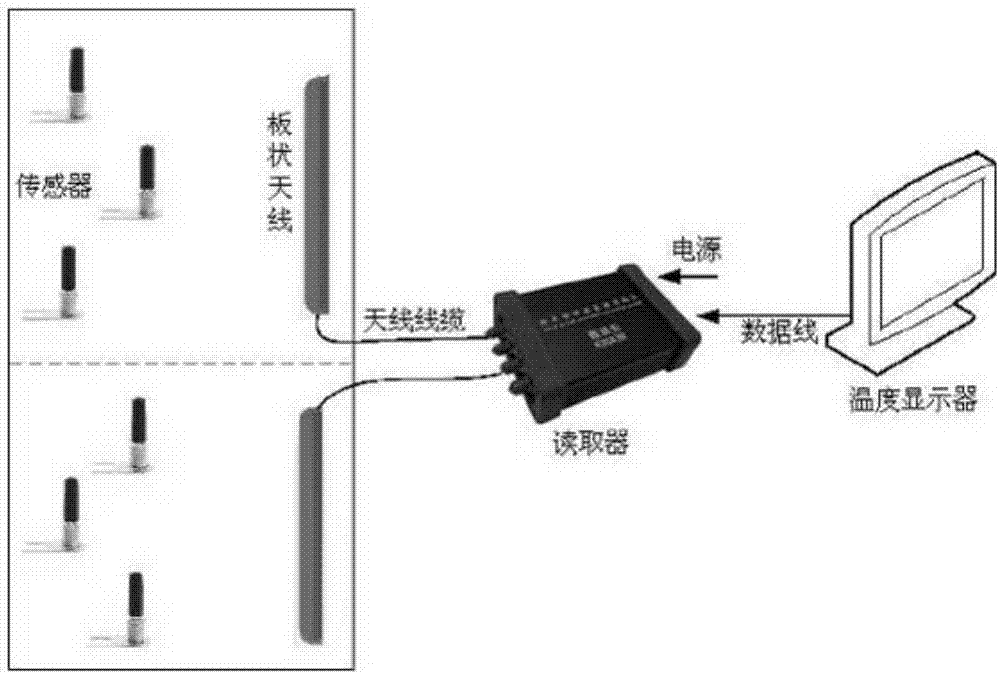

Temperature monitoring device for wireless and passive surface acoustic wave switch cabinet

PendingCN107884091ATo achieve the purpose of temperature monitoringTemperature monitoringThermometer detailsTransmission systemsDisplay deviceEngineering

The invention discloses a temperature monitoring device for a wireless and passive surface acoustic wave switch cabinet. The device comprises a sensor module, an acquisition and display module, and abackground detection module. The sensor module is composed of a plurality of SAW temperature sensors. The plurality of SAW temperature sensors are arranged at the to-be-measured temperature positionsof electric equipment in the switch cabinet. The acquisition and display module comprises an acquisition display and an antenna. The antenna is used for receiving electromagnetic wave signals transmitted from the SAW temperature sensors and transmitting the signals to the acquisition display. The acquisition display is used for converting electromagnetic wave signals into a temperature value, displaying the temperature value on a display screen, and sending the temperature value to the background detection module. The background detection module comprises a plurality of computers. The plurality of computers are used for displaying and storing temperature value data in real time. The acquisition display is connected with a serial port server through a 485 bus and then is connected with theplurality of computers respectively. According to the invention, the technical problems of a temperature measuring sensor, such as short service life and single function, are solved.

Owner:STATE GRID CORP OF CHINA +3

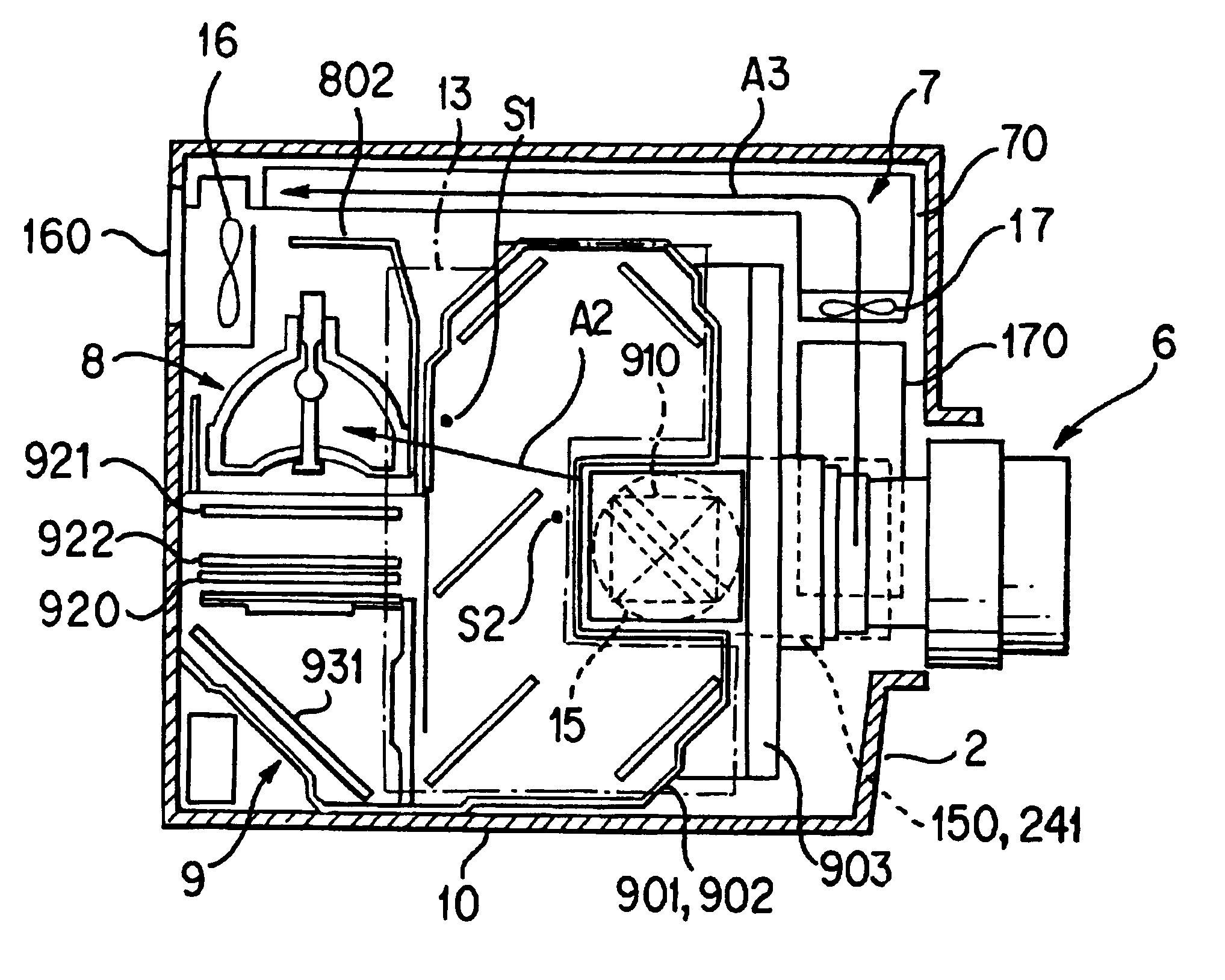

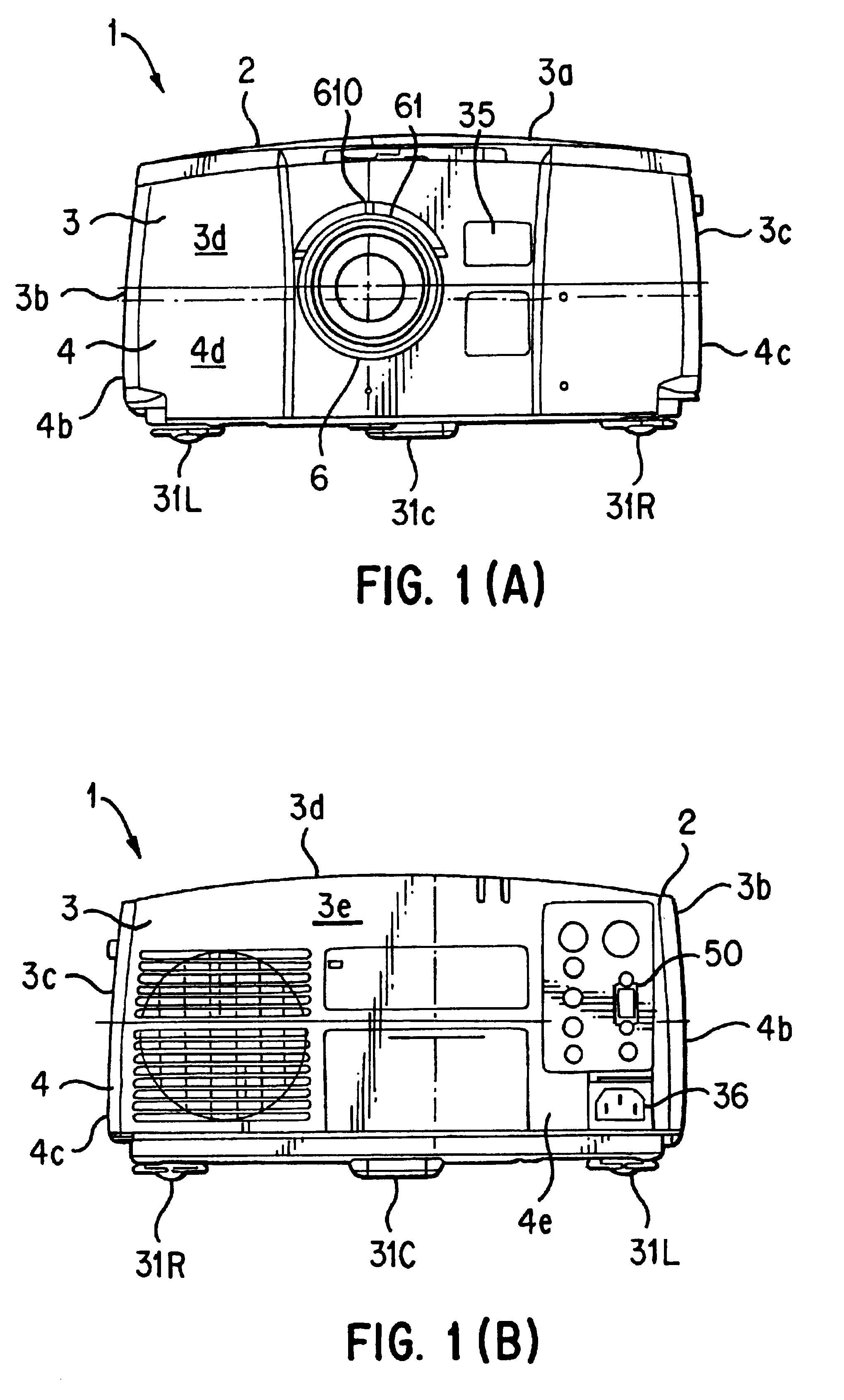

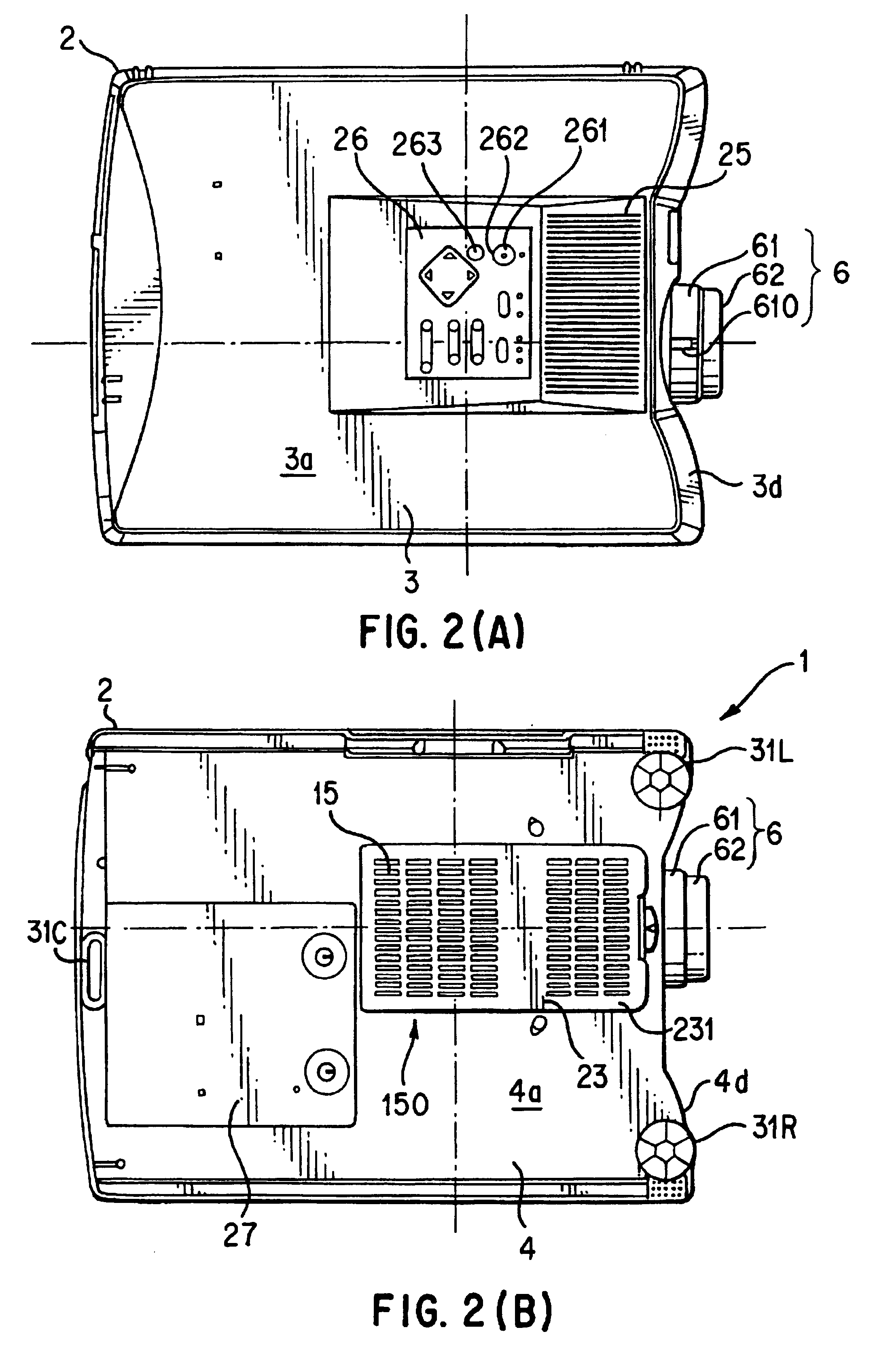

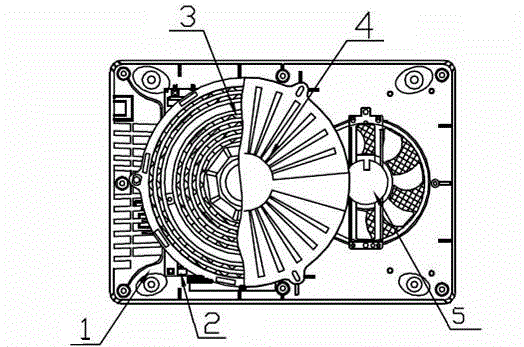

Projector

InactiveUSRE38006E1Effective temperature monitoringImprove cooling effectTelevision system detailsStatic indicating devicesFresh airEngineering

A <DEL-S DATE="20030225" ID="DEL-S-00001" / >projection display device<DEL-E ID="DEL-S-00001" / > <INS-S DATE="20030225" ID="INS-S-00001" / >projector <INS-E ID="INS-S-00001" / >capable of improving cooling efficiency of the power unit includes a light source lamp unit, a projection lens unit, an exhaust fan provided near the light source lamp unit for ventilating an outer case, and a ventilating path provided inside the power unit. A suction fan is provided at the inlet of the ventilating path which is connected to the cooling air intake port through a duct cover to directly conduct fresh air into the ventilating path. Because the interior of the power unit is cooled by fresh air which is cooler than the air inside the outer case, cooling efficiency is enhanced.

Owner:SEIKO EPSON CORP

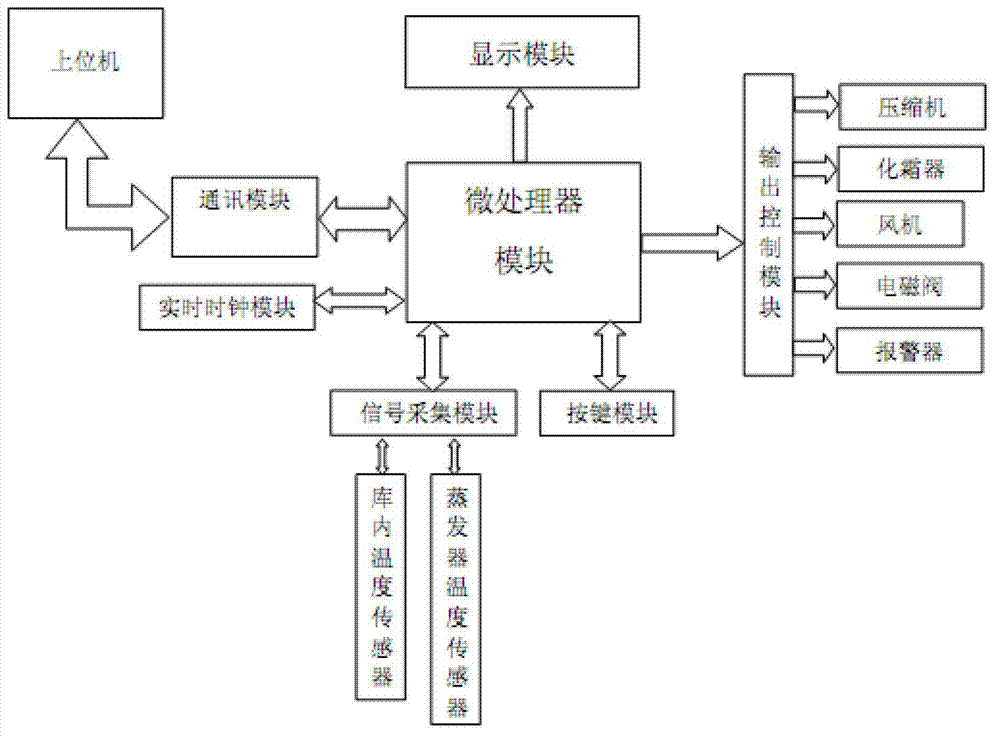

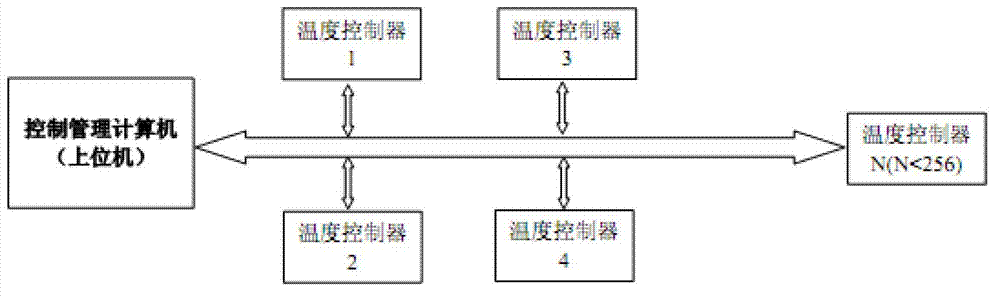

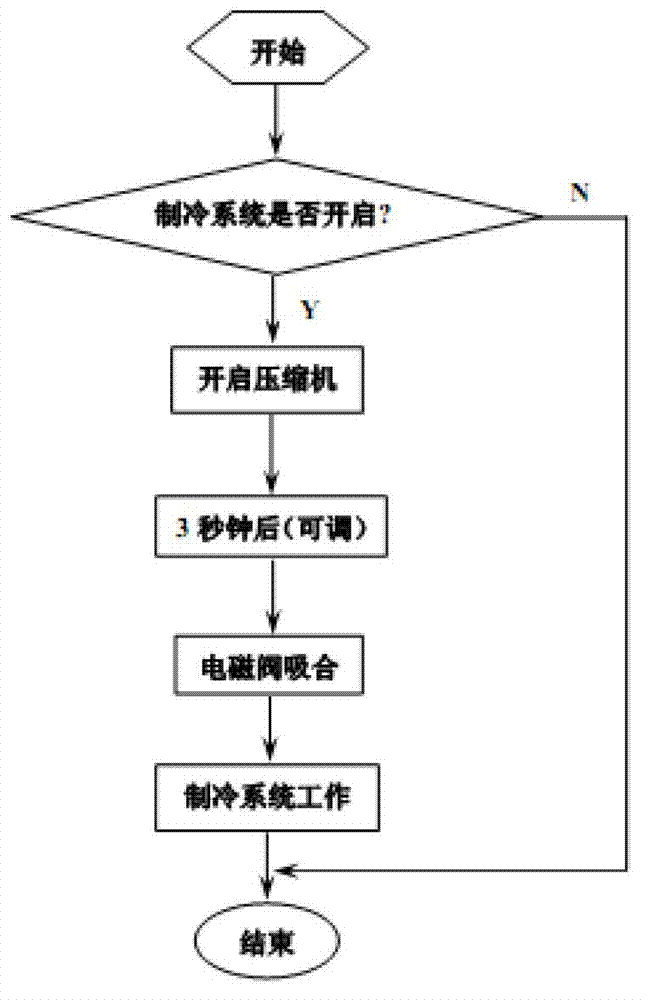

A temperature controller and a control method thereof

ActiveCN103592971AEffective temperature monitoringEffective monitoring statusProgramme controlComputer controlTemperature controlLife time

The invention provides a temperature controller with a communication function and a control method thereof. The temperature controller comprises a microprocessor module, a signal acquisition module connected with the microprocessor module, and a communication module connected with the microprocessor module. The temperature controller provided with a networking communication function has characteristics of reasonably controlling output, effectively protecting a compressor and a refrigeration house, and prolonging a service life.

Owner:JIANGSU JINGCHUANG ELECTRONICS

Allochroic aluminum-plastic packaging film and preparation method thereof

InactiveCN106207022AEffective temperature monitoringEasy to know the temperature changeSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsPlastic packagingEngineering

The invention relates to an allochroic aluminum-plastic packaging film and a preparation method thereof. The allochroic aluminum-plastic packaging film is composed of an inner film layer, and a barrier layer, an allochroic layer and an outer film layer that are arranged on the inner film layer sequentially from bottom to top, and the allochroic layer may vary in color with temperature changes. The preparation method includes the steps of 1, preparing the outer film layer; 2, depositing inorganic thermosensitive particles in a polymer base, and spraying to form a film on the inner side of the outer film layer by the aid of spraying technique; 3, attaching the barrier layer to the inner surface of the allochroic layer of step 1 by dry combining process, and drying; 4, applying modified polypropylene material that is melted to the inner surface of the barrier layer to form the inner film layer. The allochroic aluminum-plastic packaging film and the preparation method thereof have the advantages that the structure is simple, the inner temperature of a battery varies in use so that the allochroic layer varies in color, presenting different colors, it is convenient to know the changes in the inner temperature of the battery, the temperature of the battery is under monitoring, and the preparation method is simple.

Owner:武汉美格科技股份有限公司

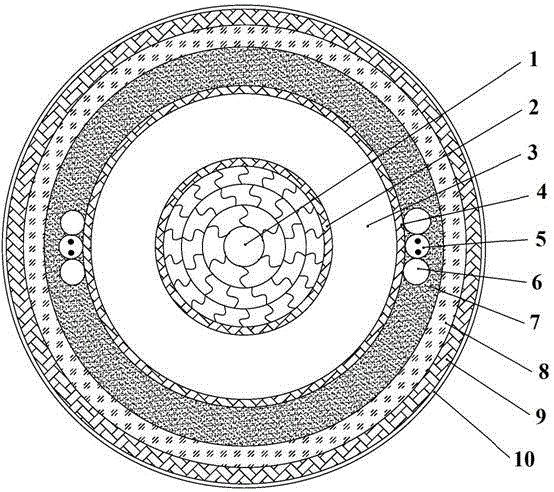

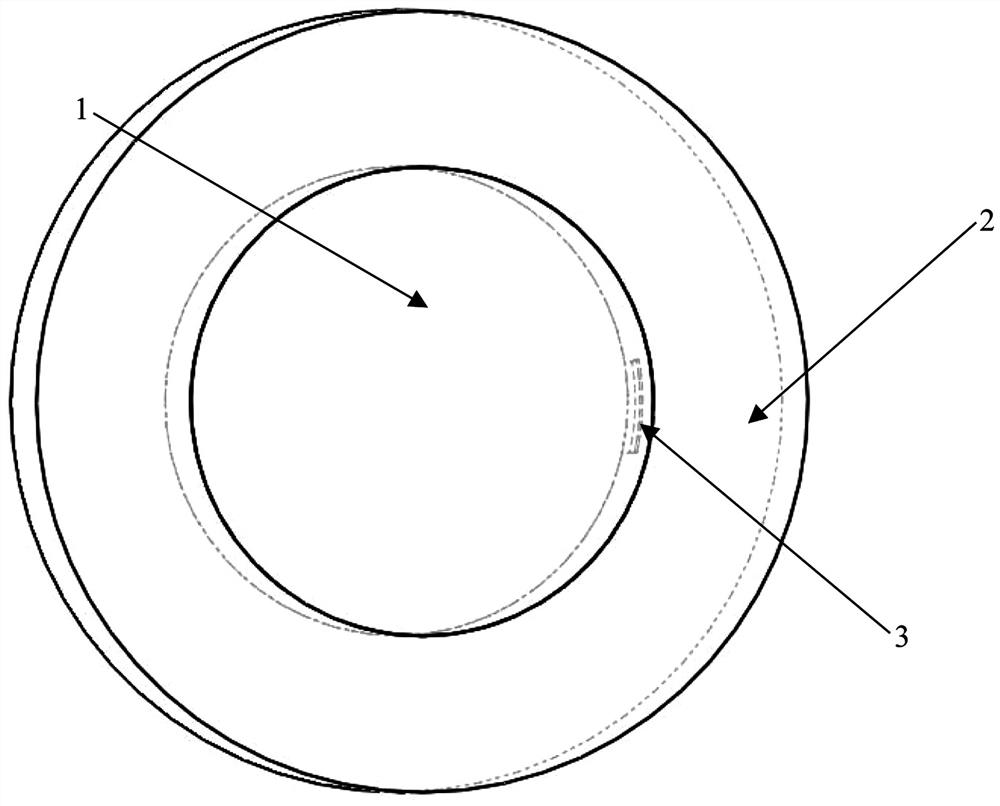

+/-500kV SZ-shaped molded line conductor corrugated aluminum sheath fiber composite DC cable

InactiveCN106128626AStable structureCompact structureSingle bars/rods/wires/strips conductorsPower cables with screens/conductive layersFiberElectrical conductor

The invention discloses a + / -500kV SZ-shaped molded line conductor corrugated aluminum sheath fiber composite DC cable, and the cable comprises a large-section SZ-shaped molded line conductor, a conductor shielding layer, an insulating layer, an insulating shielding layer, a fiber unit, a metal reinforcing core, a semiconductive waterproof buffering layer, a corrugated aluminum sheath, an insulating external protection layer, and a semiconductive layer. The large-section SZ-shaped molded line conductor is formed by the layered intertwisting of a central cable core and an outer SZ-shaped copper filament. The outer SZ-shaped copper filament employs one circular copper wire or an SZ-shaped copper filament which is formed by the compression intertwisting of a plurality of circular filaments, wherein the exterior of the circular cable core is intertwisted with 1-6 layers. The cable employs the large-section SZ-shaped molded line conductor, and is stable and compact in conductor structure. The filling coefficient is not less than 93%. Compared with a compression circular conductor or a segmented conductor under the same current-bearing capability, the cable is smaller in conductor diameter, and greatly saves the overall cost of the cable.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

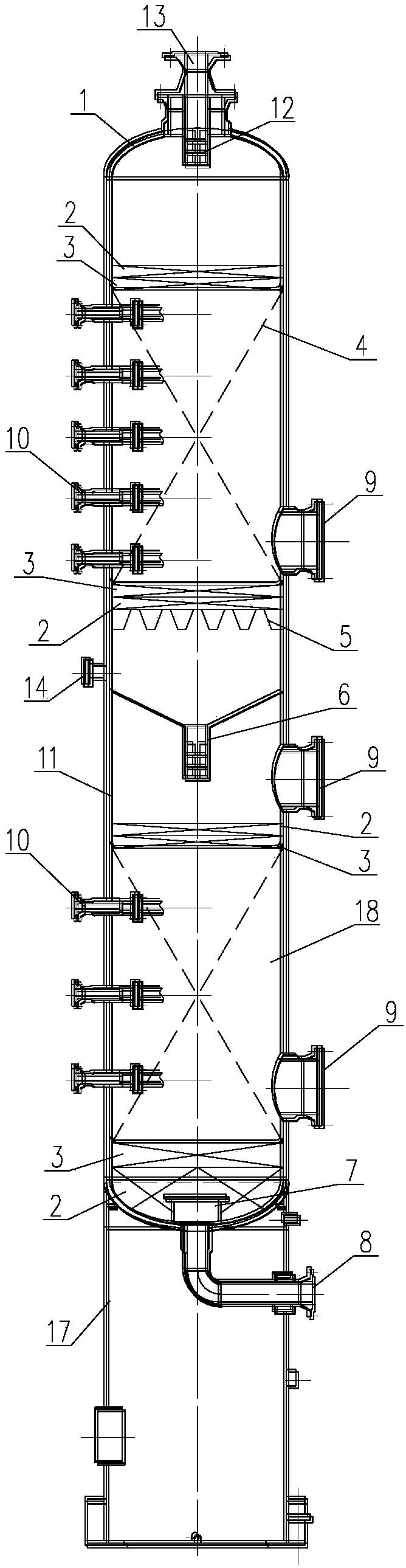

Organic sulfur removal reactor

ActiveCN107815331ASimple structureGood effect in removing organic sulfurGas purification by catalytic conversionGas purification with selectively adsorptive solidsSorbentHydrogenation reaction

The invention relates to an organic sulfur removal reactor. The reactor comprises a skirt seat, a cylinder body arranged on the skirt seat, and upper and lower seal heads. The interior of the cylinderbody is provided with a hydrogenation reaction catalyst bed layer, a redistribution device and an adsorbent bed layer in order from top to bottom. The cylinder body is provided with a plurality of thermometer connecting tubes and manholes; an air inlet and an inlet gas distributor are arranged at the upper seal head, and an air outlet and a gas collection ring are arranged at the lower head. Theadvantages are that the structure is simple, and the removal effect of organic sulfur is good. Since the operating conditions for hydrogenation and desulfurization are basically the same, both operations can be performed in one facility. The reactor of the invention can achieve a goal of completing fine desulfurization in a tower by controlling the amount of a hydrogenation catalyst and the amountof an adsorbent, and also the organic sulfur removal reactors can be used in series to reduce the total sulfur content in final coal gas to 0.1 ppm or below, so only a piece of equipment is needed, equipment materials are saved and space is saved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

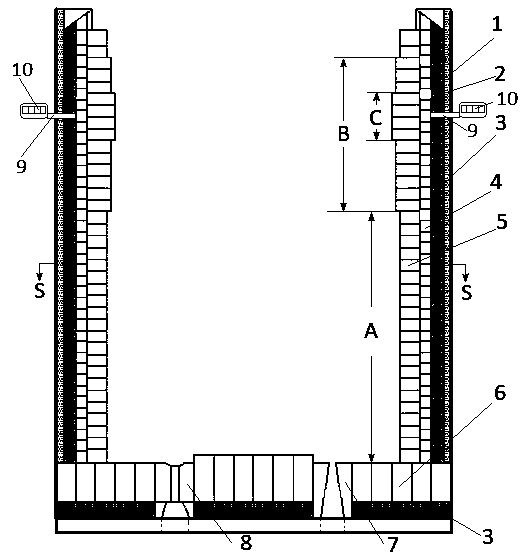

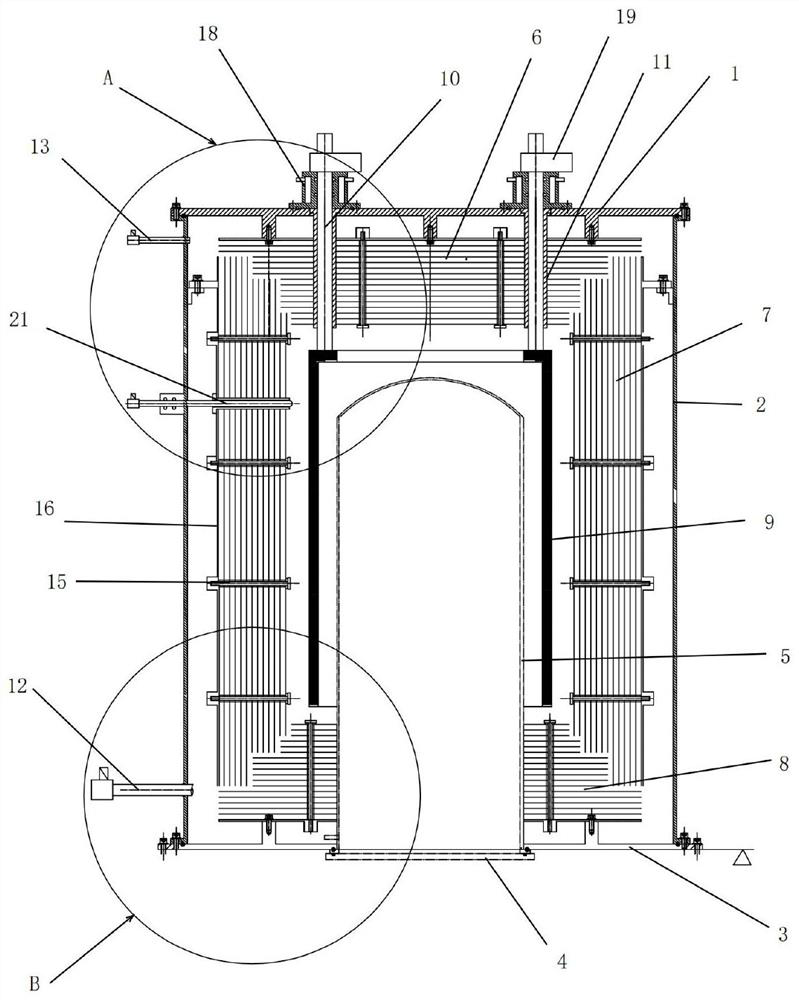

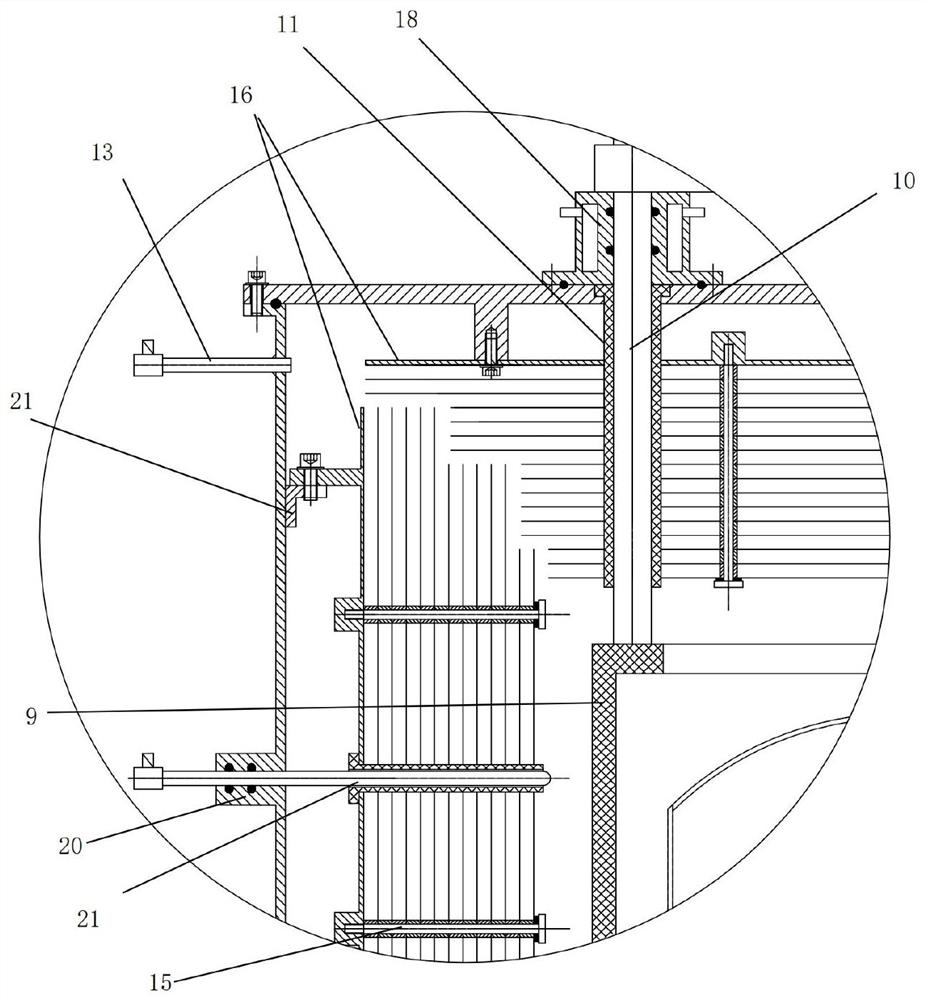

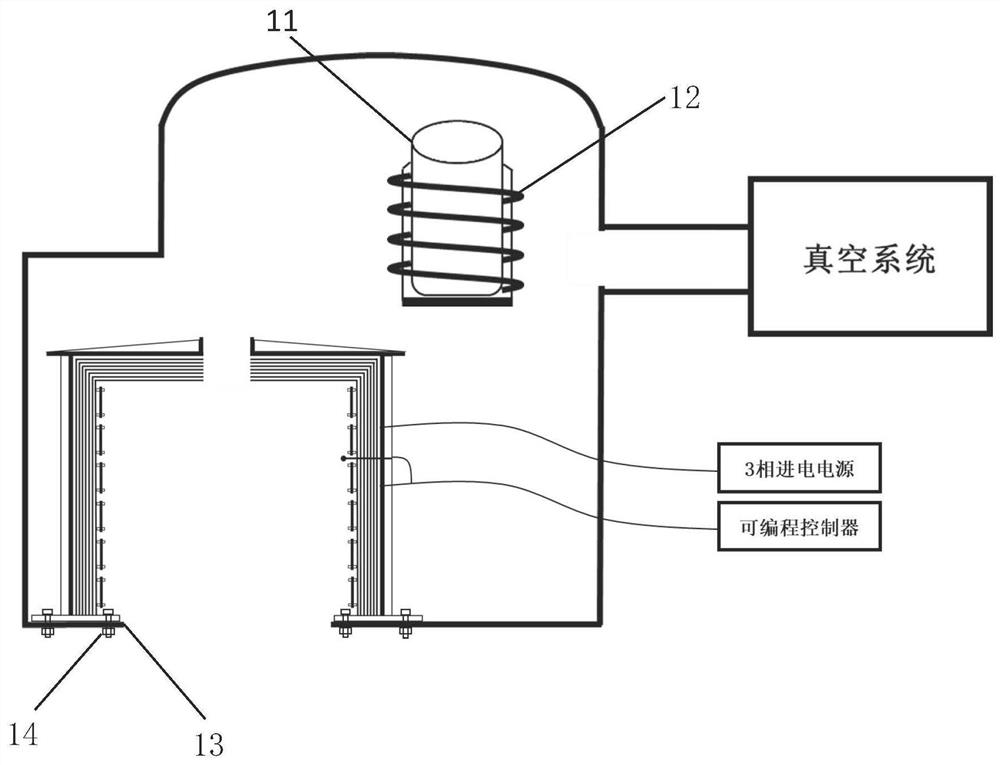

Vacuum sealing reflecting screen hearth structure of vertical high-temperature furnace

PendingCN112857045AAvoid spillingReduce consumptionFurnace coolingElectric heating for furnacesHearthHot Temperature

The invention relates to a vacuum sealing reflecting screen hearth structure of a vertical high-temperature furnace. The vacuum sealing reflecting screen hearth structure is characterized in that a furnace cover, a furnace shell and a furnace bottom flange are fastened through bolts and sealed through sealing rings; a vacuum sealing hearth defined by a sealing flange and a process pipe is hermetically mounted in the furnace bottom flange; a process cavity defined by the process pipe is formed in the vacuum sealing hearth, and is used for carrying out the technological process of a process piece; a furnace cover heat insulation screen, a furnace shell heat insulation screen and a furnace bottom heat insulation screen are arranged in the vacuum sealing hearth; labyrinth-shaped sealing joints are formed among the furnace cover heat insulation screen, the furnace shell heat insulation screen and the furnace bottom heat insulation screen; a heating cavity is formed among the furnace cover heat insulation screen, the furnace shell heat insulation screen, the furnace bottom heat insulation screen and the process pipe; and a heater is arranged in the heating cavity. The furnace cover heat insulation screen, the furnace shell heat insulation screen and the furnace bottom heat insulation screen which are formed by stacking multiple layers of heat insulation screens at intervals are arranged in the vacuum sealing hearth, and the labyrinth-shaped sealing joints in the three sets of heat insulation screens permit heat diffused outwards in the vertical high-temperature oxidation furnace to be reflected, so that the temperature reached by heating can be stably kept, the energy consumption is reduced, and the high-temperature influence on assemblies outside the furnace is also reduced.

Owner:赛瑞达智能电子装备(无锡)有限公司

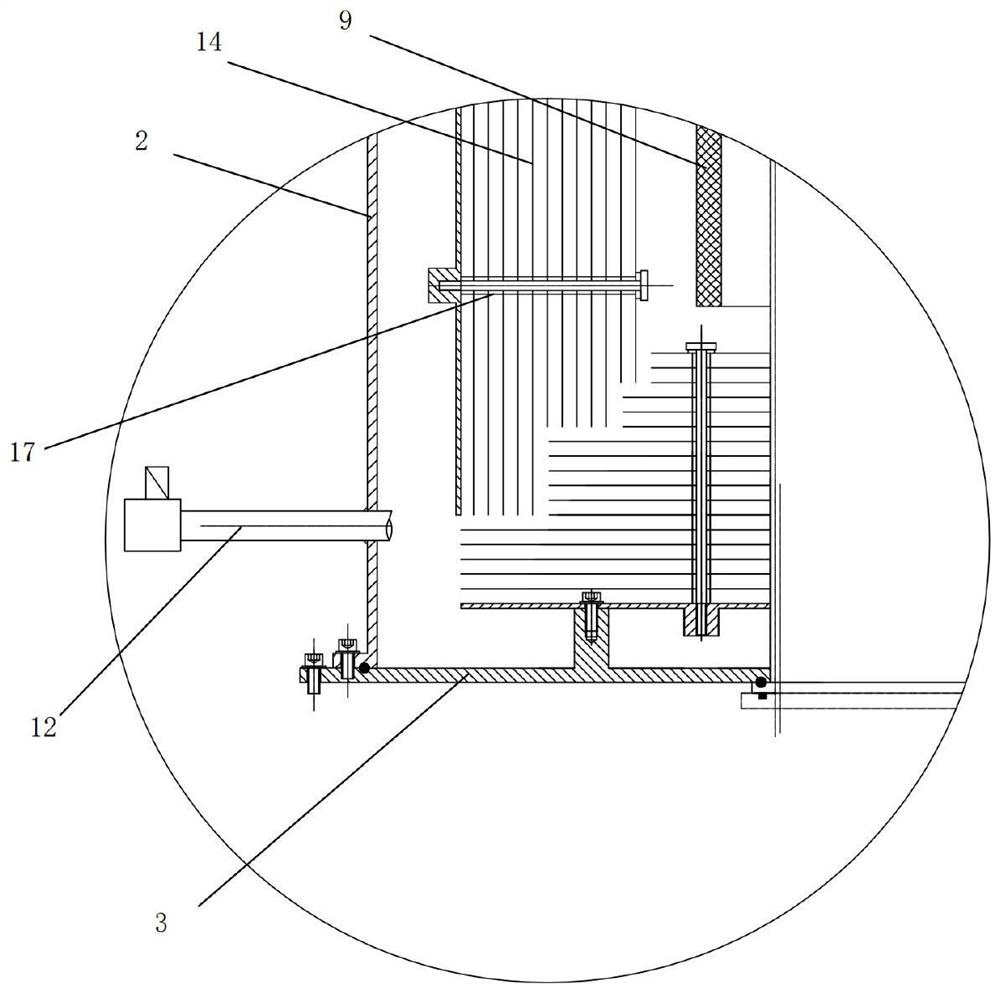

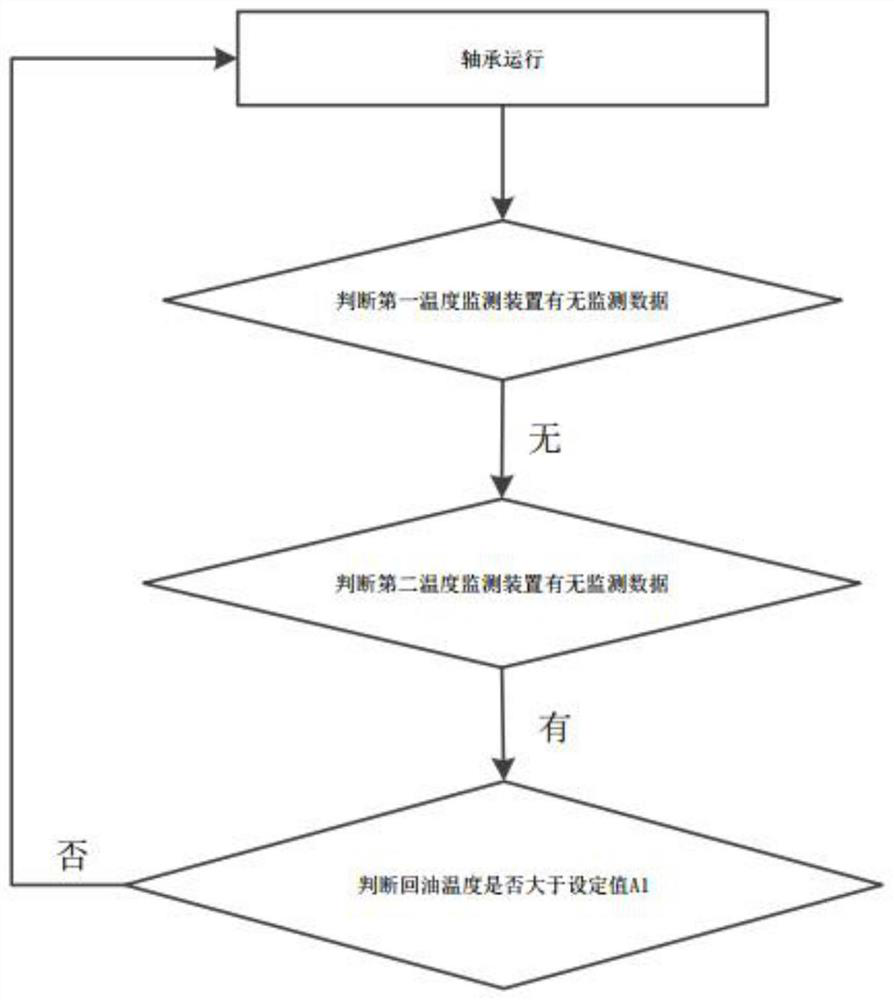

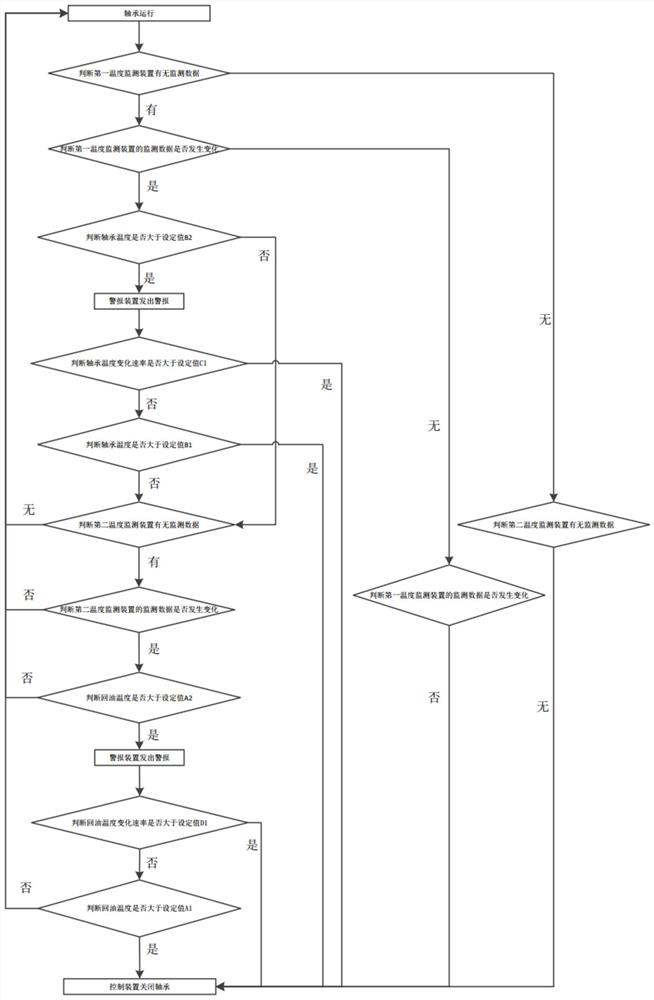

Bearing temperature monitoring method and bearing temperature monitoring system

PendingCN113447162AEffective temperature monitoringEffective monitoring of return oil temperatureThermometer detailsThermometer applicationsTemperature monitoringPetroleum engineering

The invention belongs to the technical field of bearing temperature monitoring, and discloses a bearing temperature monitoring method and a bearing temperature monitoring system. The bearing temperature monitoring method monitors the bearing temperature through a first temperature monitoring device and monitors the bearing oil return temperature through a second temperature monitoring device. Due to the fact that the oil return temperature variation trend of the bearing lubricating oil is the same as the temperature variation trend of the bearing, the temperature variation trend of the bearing can be effectively monitored according to the oil return temperature variation trend of the lubricating oil. When the first temperature monitoring device breaks down and has no monitoring data, the bearing temperature can be indirectly monitored through the oil return temperature measured by the second temperature monitoring device; and if the oil return temperature is not larger than a set value, the bearing can continue to operate. Therefore, shutdown maintenance is not needed when the first temperature monitoring device breaks down and has no monitoring data, and economic loss caused by influence on production operation is avoided.

Owner:CNOOC DEEPWATER DEV

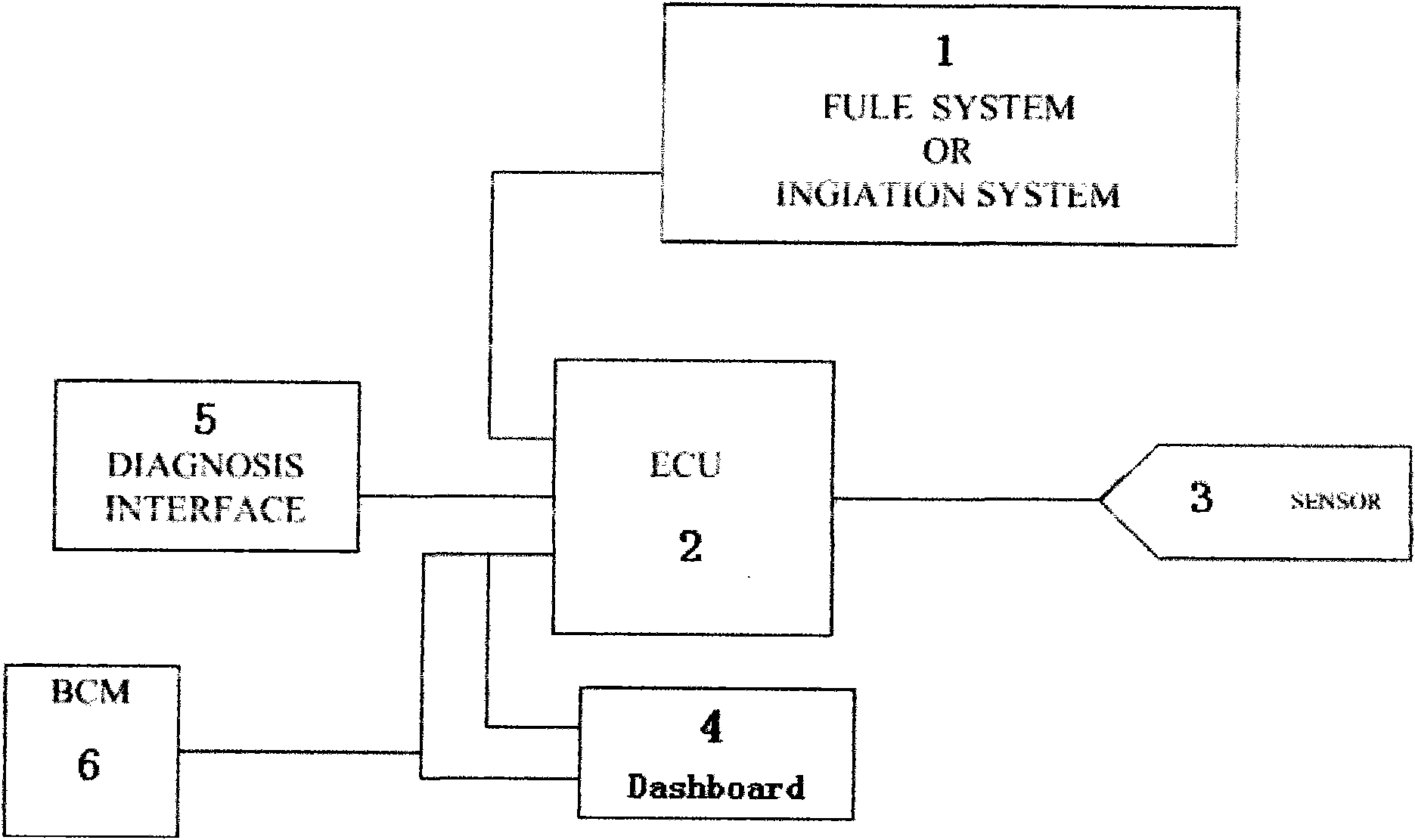

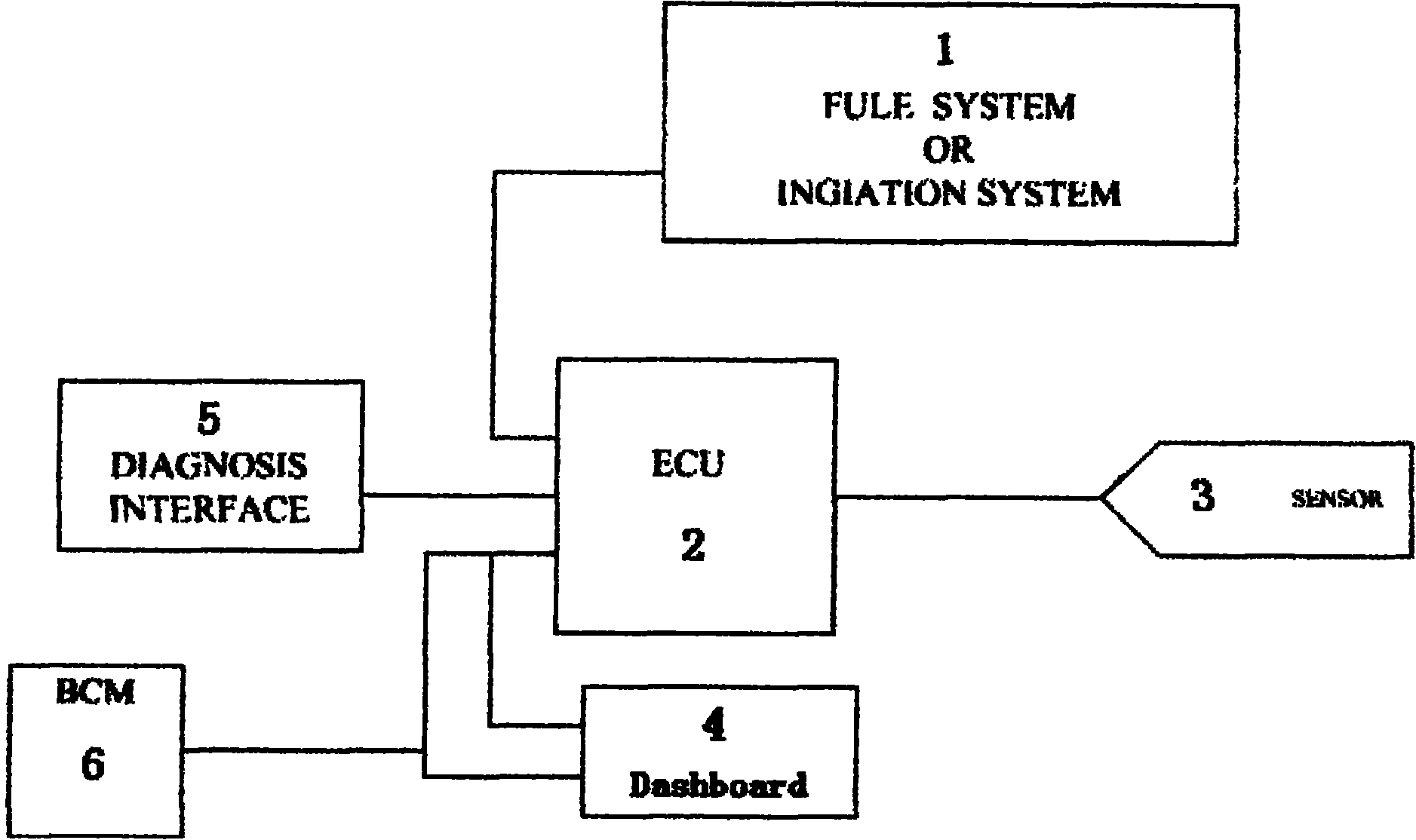

Control circuit for monitoring automobile exhaust system and control method thereof

InactiveCN102011632AEffective temperature monitoringGuaranteed damageInternal combustion piston enginesExhaust treatment electric controlTraffic accidentControl circuit

The invention relates to a control circuit for monitoring an automobile exhaust system and a control method thereof, in particular to the following unit components of an oil supply system or an ignition system, an engine control unit (ECU), a temperature sensor, an instrument display alarm system, a diagnosis interface and a body controller BCM. The circuit can effectively monitor the temperature of the exhaust system, so that when the temperature rise is abnormal, the temperature acquired by the temperature sensor is compared with a preset temperature value of the engine control unit (ECU), three different processing modes, namely early warning, alarming and cut-off of a finished automobile power source, are selectively performed in turn according to a comparison result; therefore, peripheral components of a fore-cab exhaust system are not damaged due to over-temperature melting, and traffic accidents are also avoided.

Owner:CHERY AUTOMOBILE CO LTD

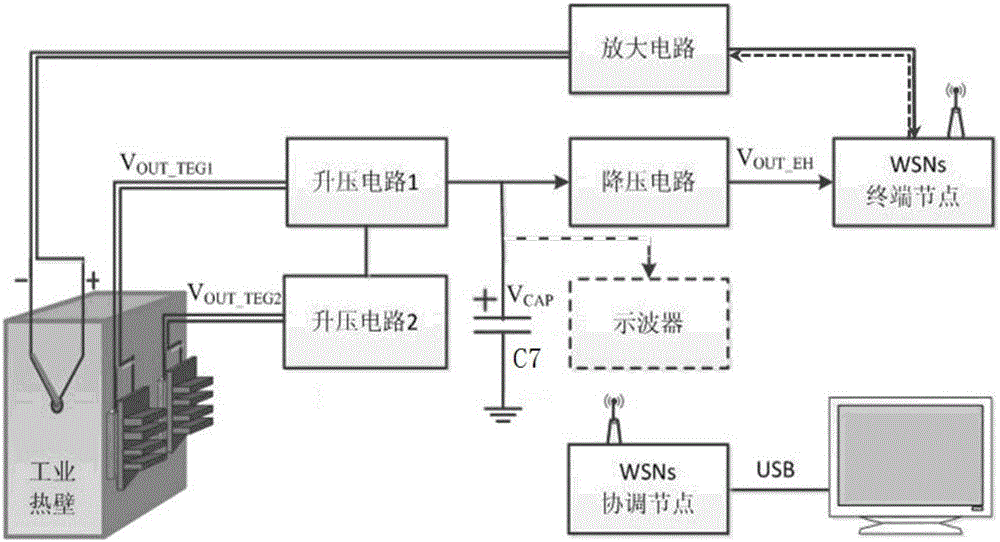

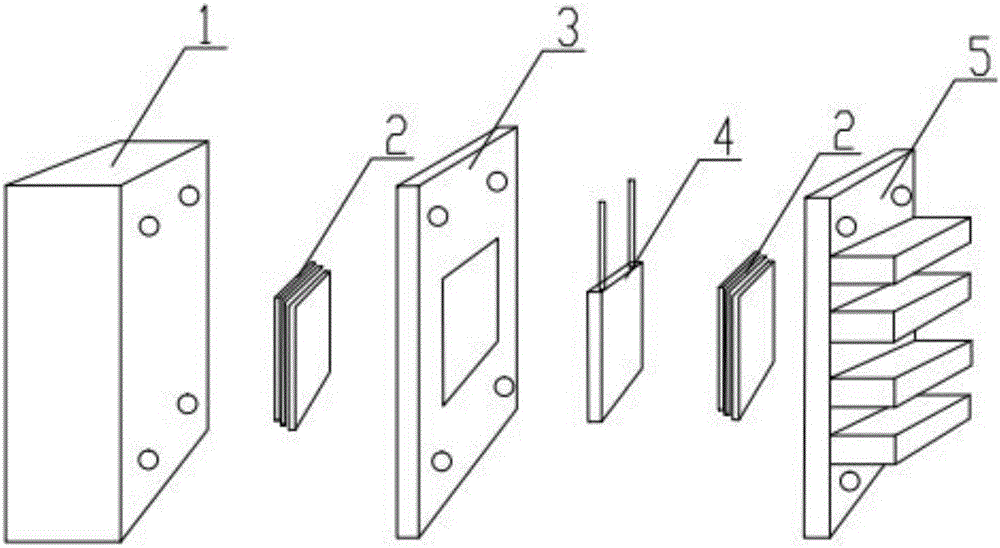

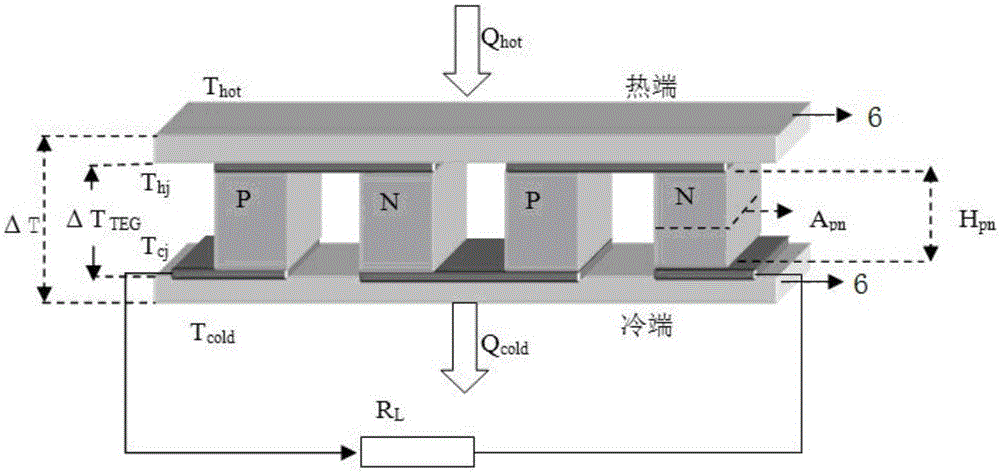

Industrial hot wall temperature wireless sensor network node and industrial hot wall temperature monitoring system

InactiveCN106813791AEffective temperature monitoringSelf-poweredProgramme controlBatteries circuit arrangementsMicrocontrollerCapacitance

The invention relates to an industrial hot wall temperature wireless sensor network node and an industrial hot wall temperature monitoring system, wherein the node and the system relate to the technical field of temperature acquisition devices. The node comprises a plurality of thermoelectric energy acquisition devices, an electric energy conversion circuit, a temperature sensor, a temperature sensor, a signal amplifying circuit, a starting-stopping control circuit and a wireless microcontroller module. The thermoelectric energy acquisition devices are arranged on an industrial hot wall and are used for acquiring heat energy from the industrial hot wall and converting the heat energy to electric energy. The electric energy output end of each thermoelectric energy acquisition device is connected with the electric energy conversion circuit and is then connected with the charging end of a supercapacitor C7. The discharging end of the supercapacitor is connected with the starting-stopping control circuit and the power input end of the wireless microcontroller module. The industrial hot wall temperature wireless sensor network node utilizes thermoelectric energy acquisition for realizing self-powering, thereby realizing high stability in power supplying and effective monitoring to the industrial hot wall temperature.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

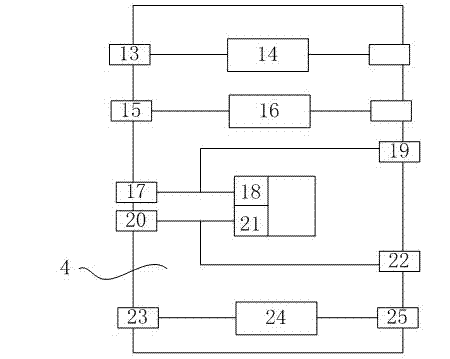

Power monitoring device for batteries of automobile

ActiveCN103358922AEffective voltage monitoringEffective monitoring of currentEmergency protective circuit arrangementsVehicular energy storageFunctional expansionElectrical battery

The invention relates to a power monitoring device for batteries of an automobile. The power monitoring device comprises a device box, and is characterized in that battery detection ends are arranged on the device box, and input ends of the battery detection ends are respectively connected with an input end of a master control unit assembly and an input end of a sub-control unit assembly. A data communication end of the master control unit assembly and a data communication end of the sub-control unit assembly are jointly connected with a battery control assembly, and a signal monitoring end of the battery control assembly is connected with a display assembly. The power monitoring device has the advantages that the master control unit assembly, the sub-control unit assembly and the battery control assembly are effectively matched with one another, so that various technical parameters of voltages, currents, loads, temperatures and the like of the batteries of the automobile can be effectively monitored, safe use degrees of the batteries of the automobile are increased, and troubleshooting can be effectively carried out; the power monitoring device is provided with a bus output end, an address digital output end and a power signal output end in a matched manner, so that monitoring signals can be transmitted conveniently, and necessary guarantee for function extension can be provided.

Owner:石家庄杰泰特动力能源有限公司

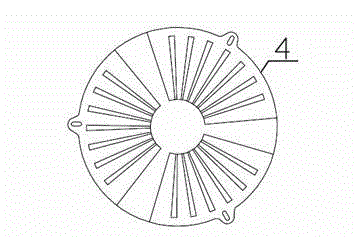

Electromagnetic cooker structure capable of accurately measuring temperature

InactiveCN102980215AEffective temperature monitoringAccurate temperatureDomestic stoves or rangesLighting and heating apparatusNegative temperatureMetal foil

The invention relates to an electromagnetic cooker and particularly relates to an electromagnetic cooker structure capable of accurately measuring temperature. The electromagnetic cooker comprises an electromagnetic cooker lower shell, an electromagnetic cooker upper cover ceramic board, an electromagnetic cooker power board, a main control board, an electromagnetic cooker coil panel, an electromagnetic cooker fan and an NTC (Negative Temperature Coefficient) sensor probe which are matched and connected with one another, wherein the NTC sensor probe is arranged in the middle of the electromagnetic cooker coil panel; the electromagnetic cooker power board, the electromagnetic cooker fan and the NTC sensor probe are all connected with the main control board. The electromagnetic cooker is characterized in that the lower surface of the electromagnetic cooker upper cover ceramic board is coated with a layer of metal foil and the NTC sensor probe is in contact fit with the metal foil. The temperature of the hottest area of the electromagnetic cooker upper cover ceramic board can be effectively monitored; and the temperature can be measured accurately when the cooker is moved, the sectional material of the cooker is changed or the cooker deforms.

Owner:HANGZHOU SINODOD ELECTRIC

A safe and reliable quilt stand

InactiveCN107168404BControl support spaceAvoid lossTemperatue controlTemperature controlComputer engineering

The invention discloses a multifunctional quilt support used for clinic nursing. The multifunctional quilt support comprises two support rods, two connection rods, a heating device, an air supply device and a temperature control device. Each support rod comprises a first telescopic rod, a second telescopic rod and a third telescopic rod. A wing bolt for fastening is arranged at the connection of the third telescopic rod and the first telescopic rod or the second telescopic rod. The first telescopic rods, the second telescopic rods and the third telescopic rods are the same as each other in diameter and are concentric arc-shaped rods. An insertion rod is arranged in the middle position of one of the support rods, and installation holes are arranged in the other support rod. The insertion rod is movably arranged in the installation holes. Each connection rod comprises a first sleeve rod and a second sleeve rod. Connection mechanisms connected with two ends of a corresponding support rod are arranged on two ends of each connection rod. The heating device and the air supply device are arranged in the connection rods. Multiple through holes are arranged in the surfaces of the connection rods. The tempeaure control device comprises a controller, a temperature sensor and a relay.

Owner:朱福生

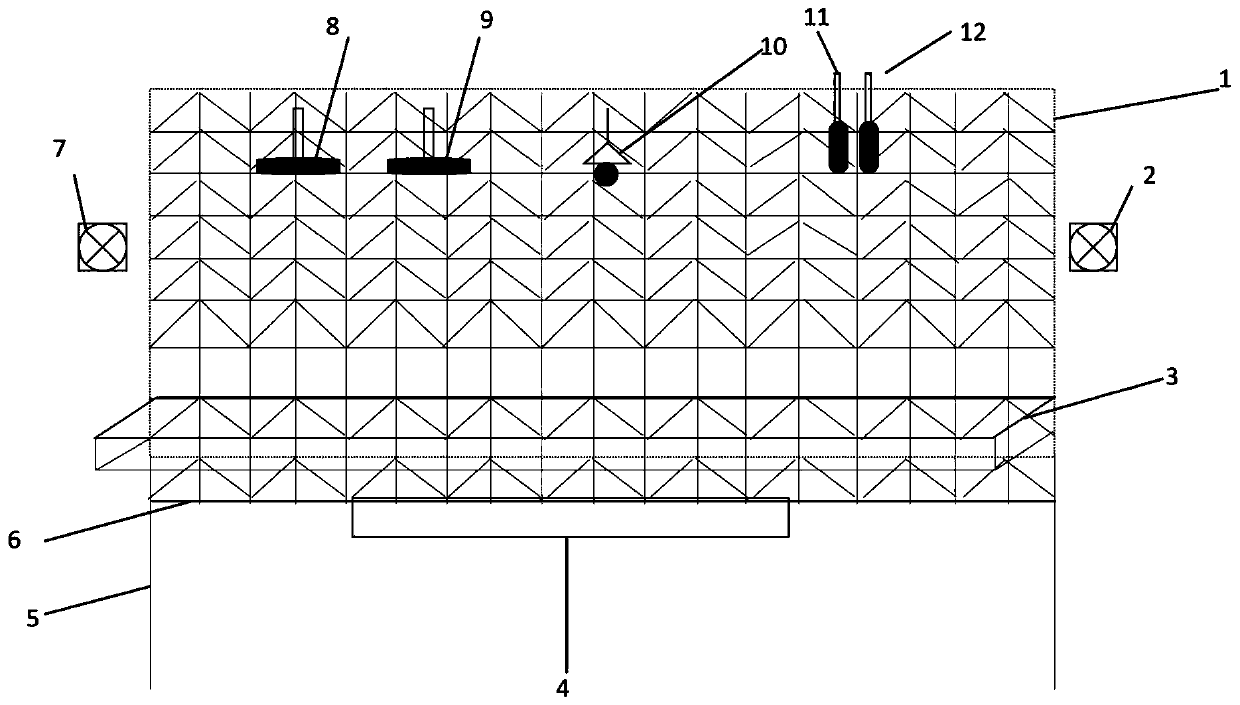

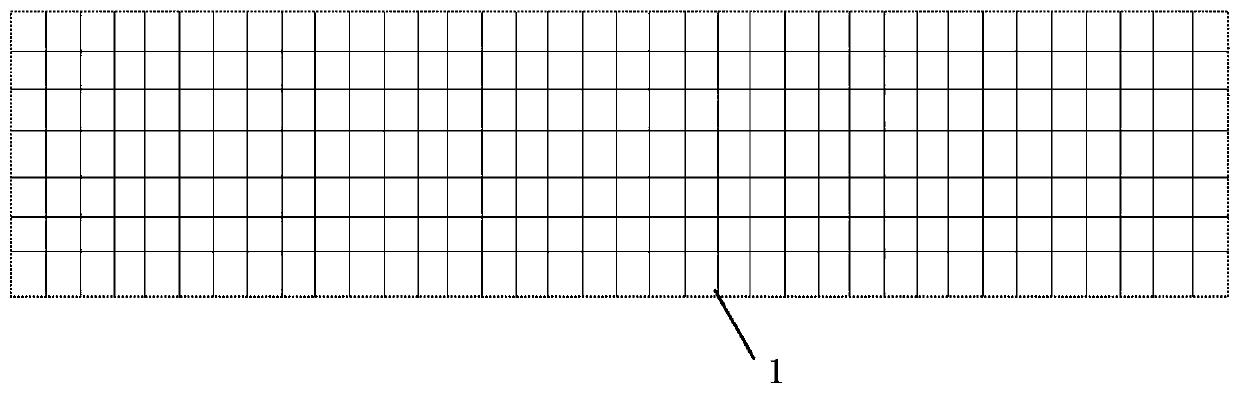

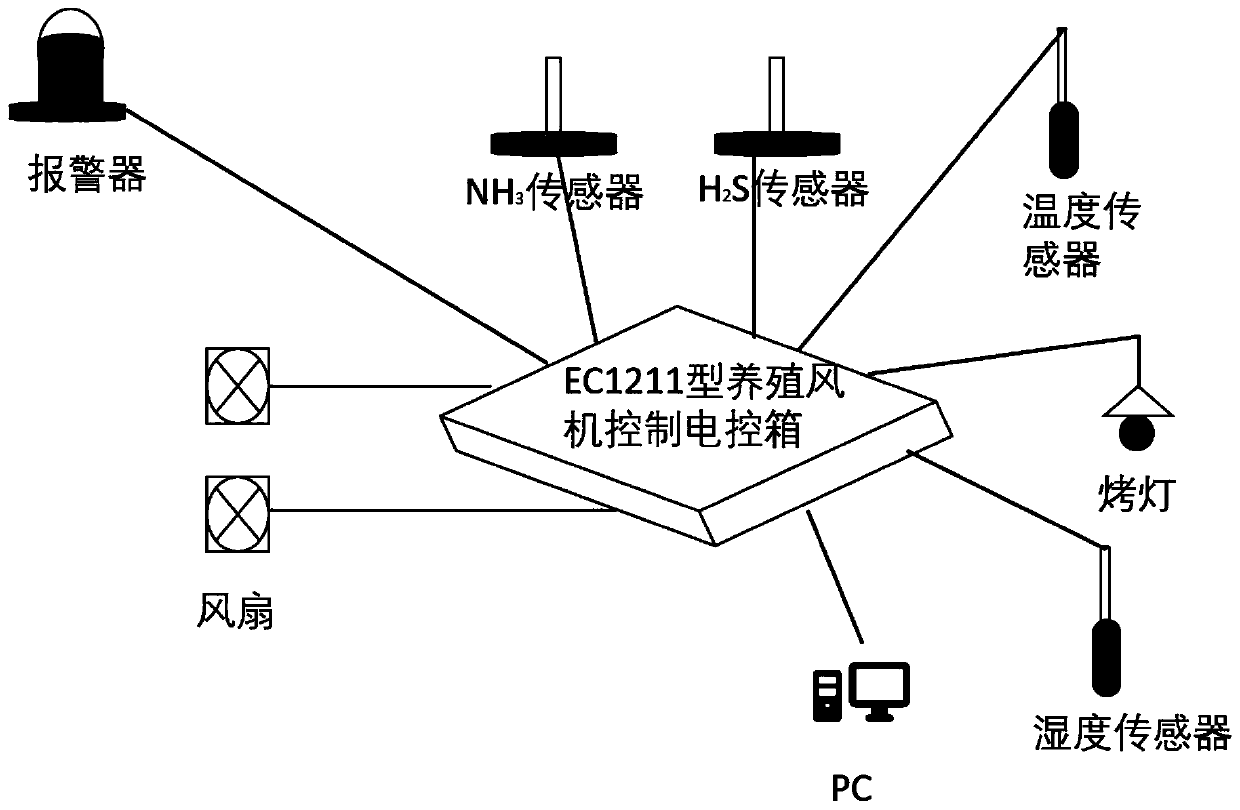

Intelligent vibrating chicken coop

InactiveCN110250036AEasy landingConstant motionMeasurement devicesBird housingsCooking & bakingPeriodic excitation

The invention discloses an intelligent vibrating chicken coop. The chicken coop comprises a coop body, a trough, a vibrating plate, supporting legs, fans, a control electric-control cabinet, a baking lamp, an alarm apparatus and sensors. According to the coop, through a vibrating unit on the surface of bottom rubber, simple harmonic periodic excitation is provided, so that the coop body periodically vibrates, and then fouling in the coop falls to the ground; more importantly, chickens are motivated to move constantly, thus the muscle of the chickens is increased within a short time, so that the chickens have strong bodies, attractive appearance, chewy meat, and meet the requirements of the market for high-quality and high-technology chicken products.

Owner:肖洋

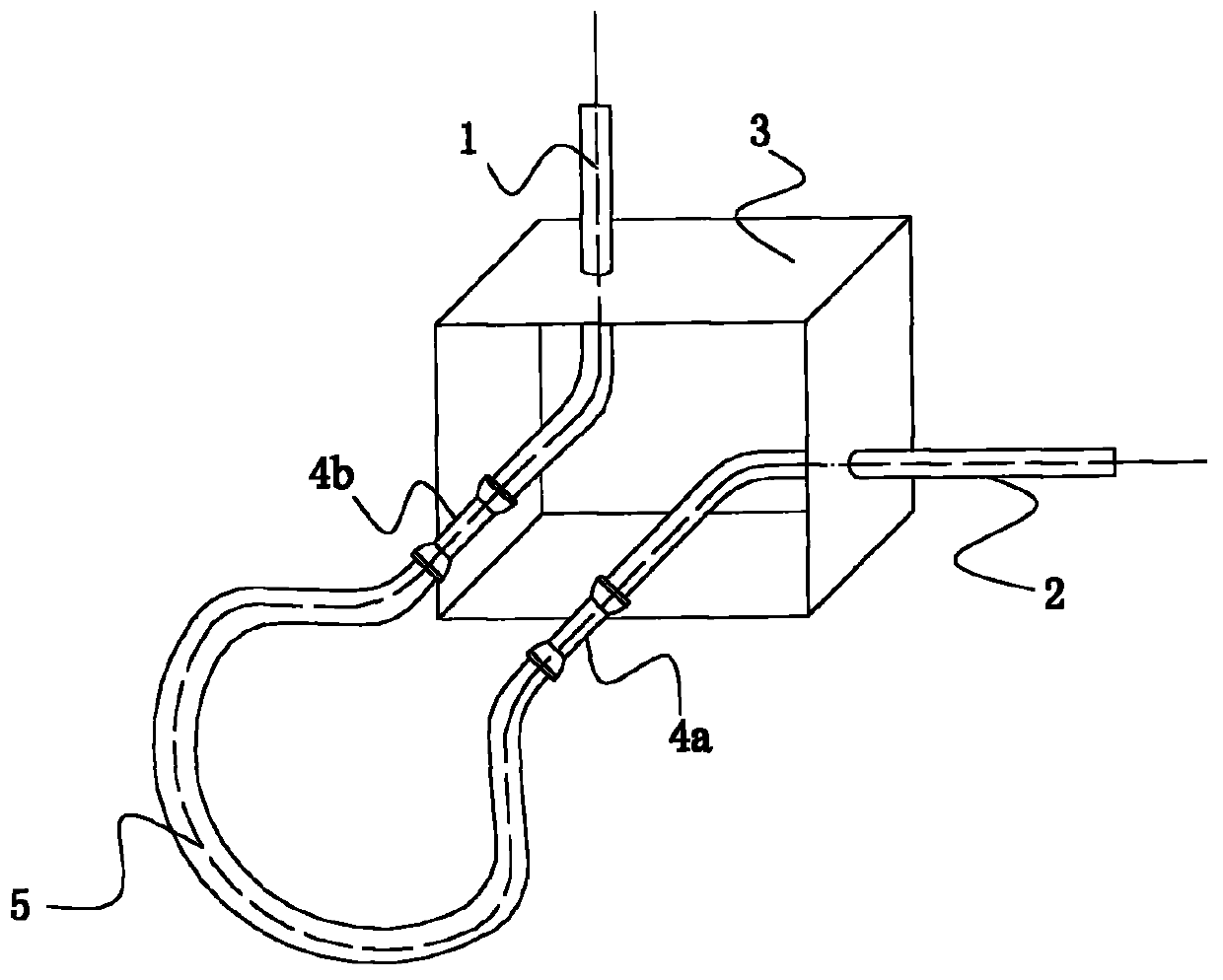

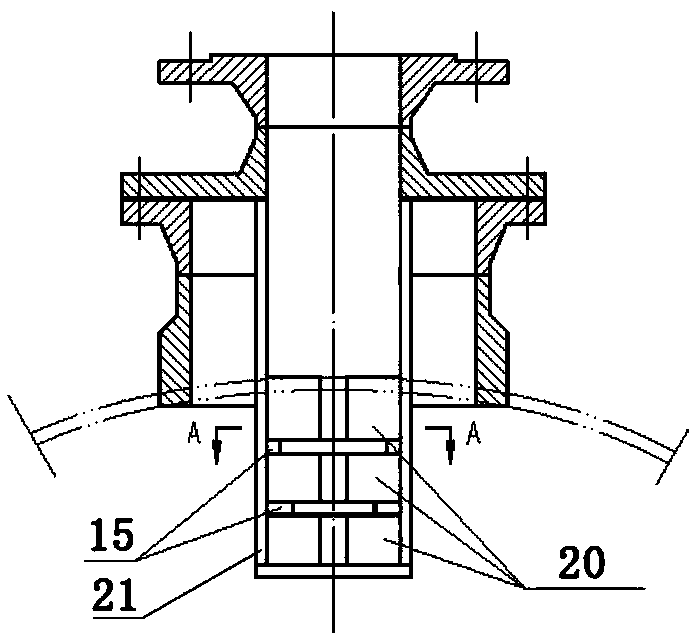

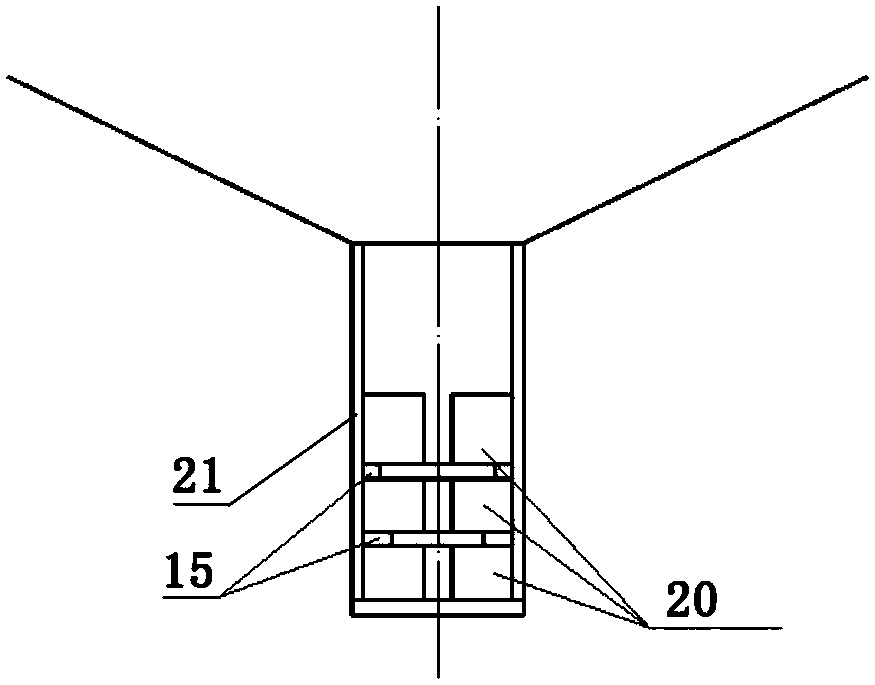

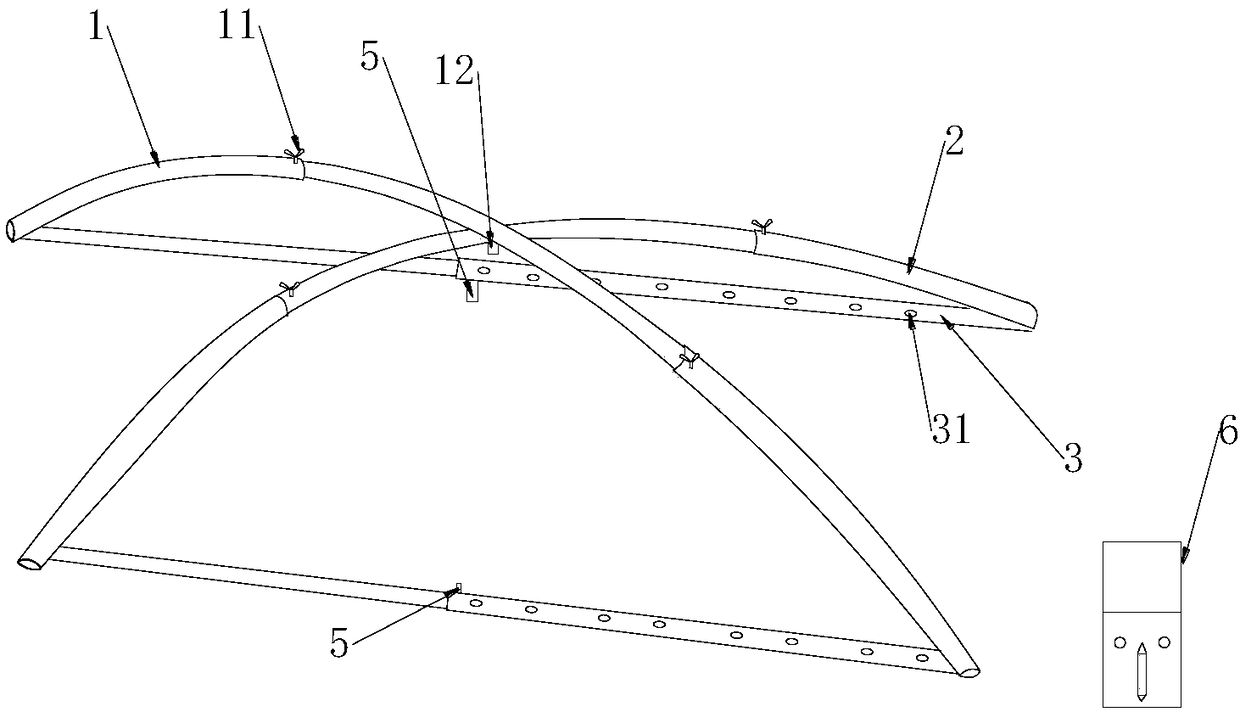

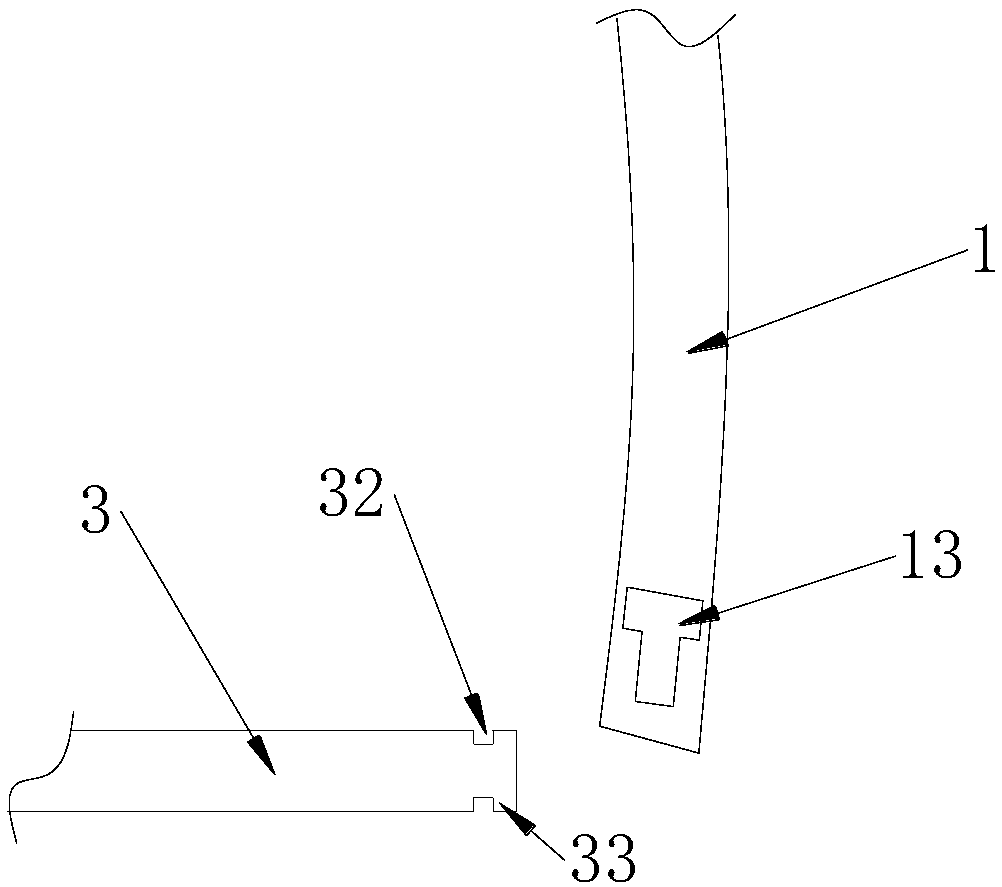

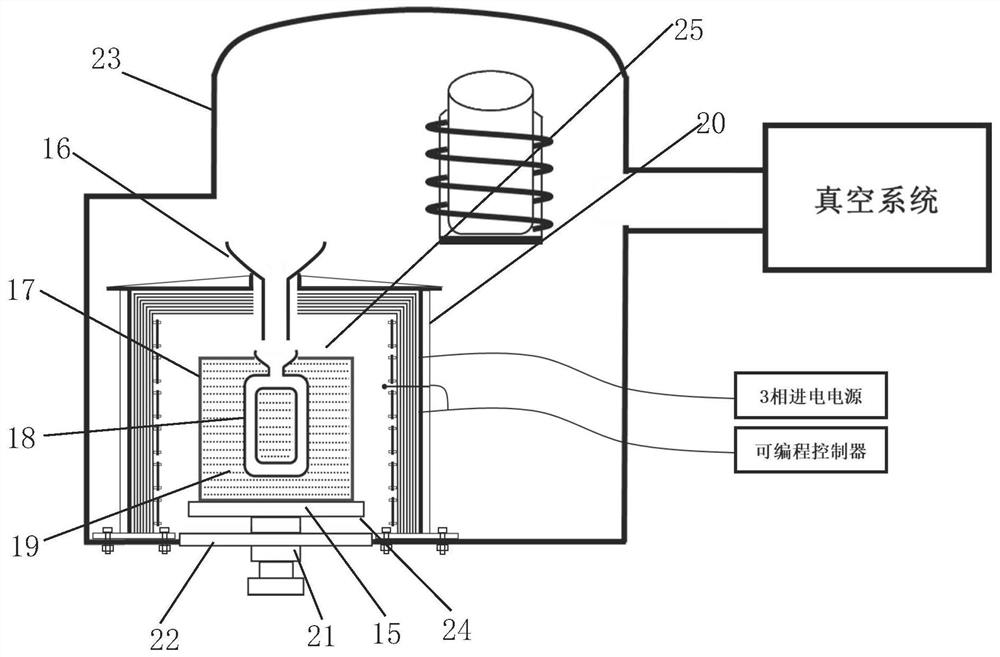

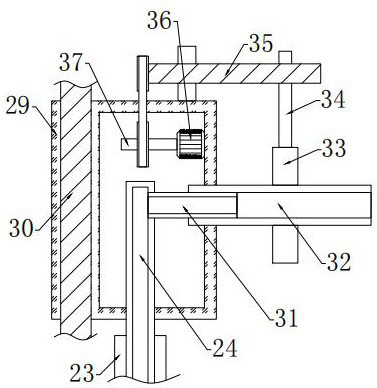

Method and device for realizing shell heating and heat preservation in vacuum casting equipment

The invention relates to a method and device for realizing shell heating and heat preservation in vacuum casting equipment. The device comprises a heat preservation bag used for heating or heat preservation of a shell device and a centrifugal tray device. The heat preservation bag is arranged in the vacuum casting equipment, a second opening is formed in the bottom of the heat preservation bag, and a first opening is formed in the bottom of the vacuum casting equipment and aligned with the second opening. The centrifugal tray device is used for carrying the shell device, and the centrifugal tray device and the vacuum centrifugal casting equipment are independent of each other. When the centrifugal tray device carrying the shell device enters the vacuum centrifugal casting equipment from the first opening, the shell device just enters the heat preservation bag through the second opening, and the centrifugal tray device and the first opening can be assembled in cooperation to achieve vacuum sealing of the first opening. Shell heating and heat preservation can be conducted in the vacuum casting equipment, the centrifugal tray device and the shell device can be independently carried and assembled conveniently, and the technological requirements of centrifugal casting can be met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Inner circulation low temperature grain storage system and method

ActiveCN107246715BEffective temperature monitoringAvoid inaccurate temperature monitoringAgriculture tools and machinesMechanical apparatusThermal insulationControl engineering

The invention discloses an internal circulation low-temperature grain storage system and method. The system includes: a granary, at least one vent is provided at the bottom, an electric window is provided on the wall, an electric valve is provided at the vent, one vent and one One end of the root insulation pipe is connected, and the other end of the insulation pipe is connected with a circulation fan, and a ventilation ground cage is provided on the ground of the granary; the ventilation equipment includes at least one centrifugal fan, at least one circulation fan and at least one air conditioner; the grain situation detection unit, It includes a plurality of grain pile temperature sensors and a temperature and humidity sensor in the warehouse; an intelligent ventilation unit, which includes a first server and an intelligent control cabinet, the first server communicates with a small weather station outside the warehouse, and is automatically controlled by the intelligent control cabinet The operation of ventilation equipment and the opening and closing of electric valves. The invention can timely and intelligently regulate when the temperature of the grain pile and the temperature and humidity in the warehouse deviate from the safe grain storage range, which reduces the labor intensity of the warehouse manager and greatly reduces the warehouse management cost.

Owner:HUBEI YE WEI INTELLIGENT TECH +1

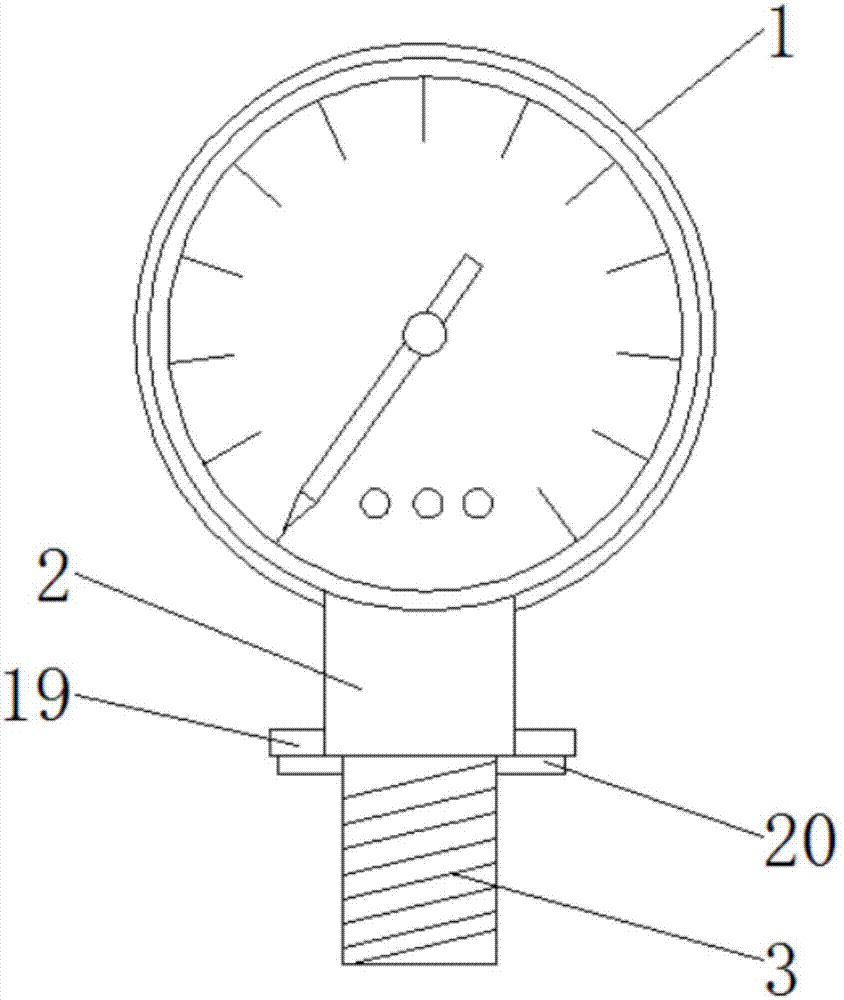

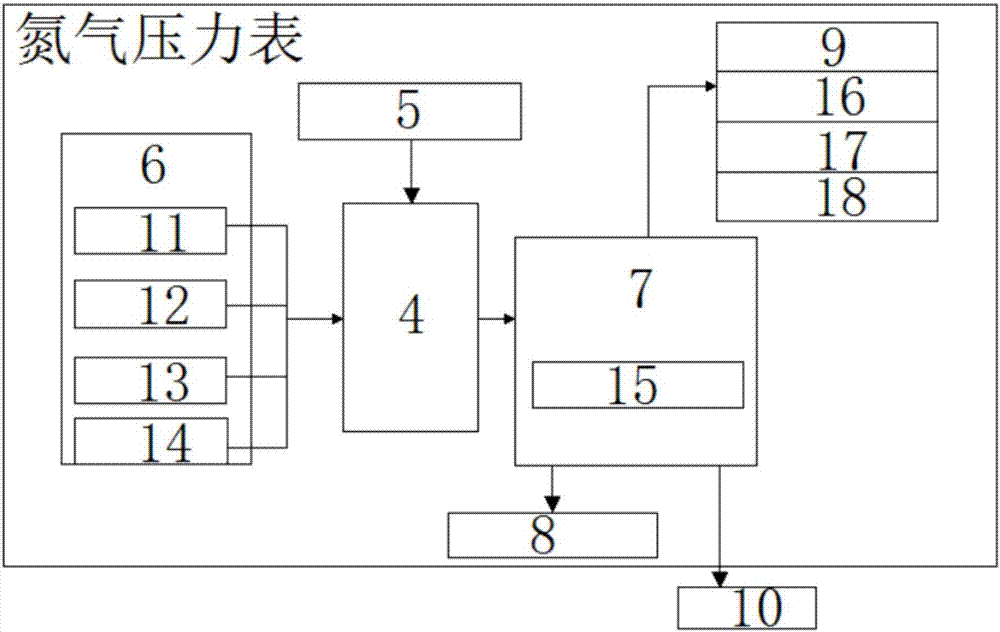

Precise nitrogen pressure gauge

PendingCN107505084ASolve the problem of overpressure alarm functionImprove securityFluid pressure measurementInformation processingThreaded pipe

The invention discloses a precise nitrogen pressure gauge, which comprises a pressure gauge body. A connection sleeve is communicated with the bottom of the pressure gauge body, a threaded pipe is communicated with the bottom of the connection sleeve, and an inner cavity of the pressure gauge body is provided with an information processing unit. The pressure gauge body, the connection sleeve, the threaded pipe, the information processing unit, a power supply module, an acquisition unit, an information feedback unit, a data storage module, a prompt unit, a cell phone APP, a pressure sensor, a temperature sensor, a humidity sensor, an airflow sensor, a signal transmitting module, a buzzer, a red alarm flashing lamp, a green warning lamp, a fixed baffle and a gasket cooperate to solve the problem that the existing precise nitrogen pressure gauge does not have an overpressure alarm function. The precise nitrogen pressure gauge has the advantages of an overpressure alarm function, enhances the safety of the precise nitrogen pressure gauge, and enhances the practicality of the precise nitrogen pressure gauge.

Owner:WUXI CITY KAIFENG PRESSURE GAUGES CO LTD

A high temperature superconductor temperature monitoring device and method based on non-stick fiber grating temperature sensor

ActiveCN112834071BEffective temperature monitoringReliable temperature monitoringThermometers using physical/chemical changesSuperconductor elements usageFiberSuperconducting Coils

The invention provides a high temperature superconductor temperature monitoring device and method based on a non-stick fiber grating temperature sensor. The method embeds the fiber grating temperature sensor into the superconducting tape or superconducting magnet sample skeleton, which can effectively protect the fiber grating temperature sensor, avoid the wavelength distortion of the fiber grating caused by the glue, and make the measurement stable and reliable. . In addition, for the study of the quenching mechanism of high-temperature superconducting tapes, the non-stick fiber grating temperature sensor can be used multiple times to avoid waste and has the characteristics of economical saving. This method can be used together with the sticker fiber grating temperature monitoring technology. Comprehensive temperature monitoring of high temperature superconductors.

Owner:CHINA THREE GORGES CORPORATION

Directional heat dissipation type safety power distribution cabinet

ActiveCN113659478AAvoid failureEffective temperature monitoringSubstation/switching arrangement cooling/ventilationMechanical engineeringPhysics

The invention relates to the technical field of power distribution cabinet equipment, in particular to a directional heat dissipation type safety power distribution cabinet, which comprises a cabinet body, a placing mechanism, aheat dissipation mechanism and a driving mechanism, wherein the placing mechanism is arranged on the inner side of the cabinet body and is fixedly connected with the cabinet body; the heat dissipation mechanism is arranged between the placing mechanism and the cabinet body and is detachably connected with the placing mechanism; the driving mechanism is fixedly connected with the cabinet body and is connected with the heat dissipation mechanism; the heat dissipation mechanism comprises a cooling box, a connecting assembly, and aliquid guide assembly. The liquid guide assembly is arranged between the cooling box and the connecting assembly, the heat dissipation mechanism is arranged, the driving mechanism is used for driving the heat dissipation mechanism to be adjustably connected with the placing mechanism, directional heat dissipation of the device can be achieved, and therefore the situation that part of components break down due to overheating is avoided; and meanwhile, the heat dissipation effectiveness and the heat dissipation efficiency of the device are ensured through the liquid guide assembly.

Owner:江苏铜变变压器有限公司

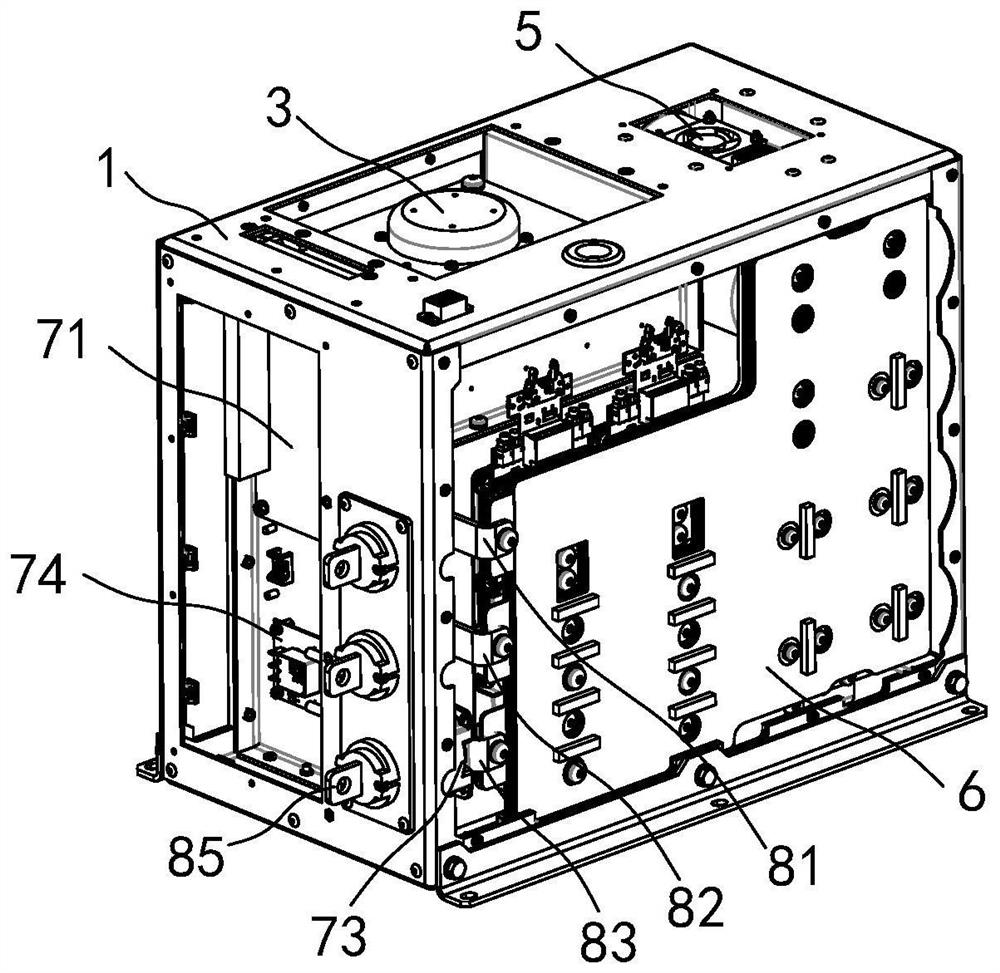

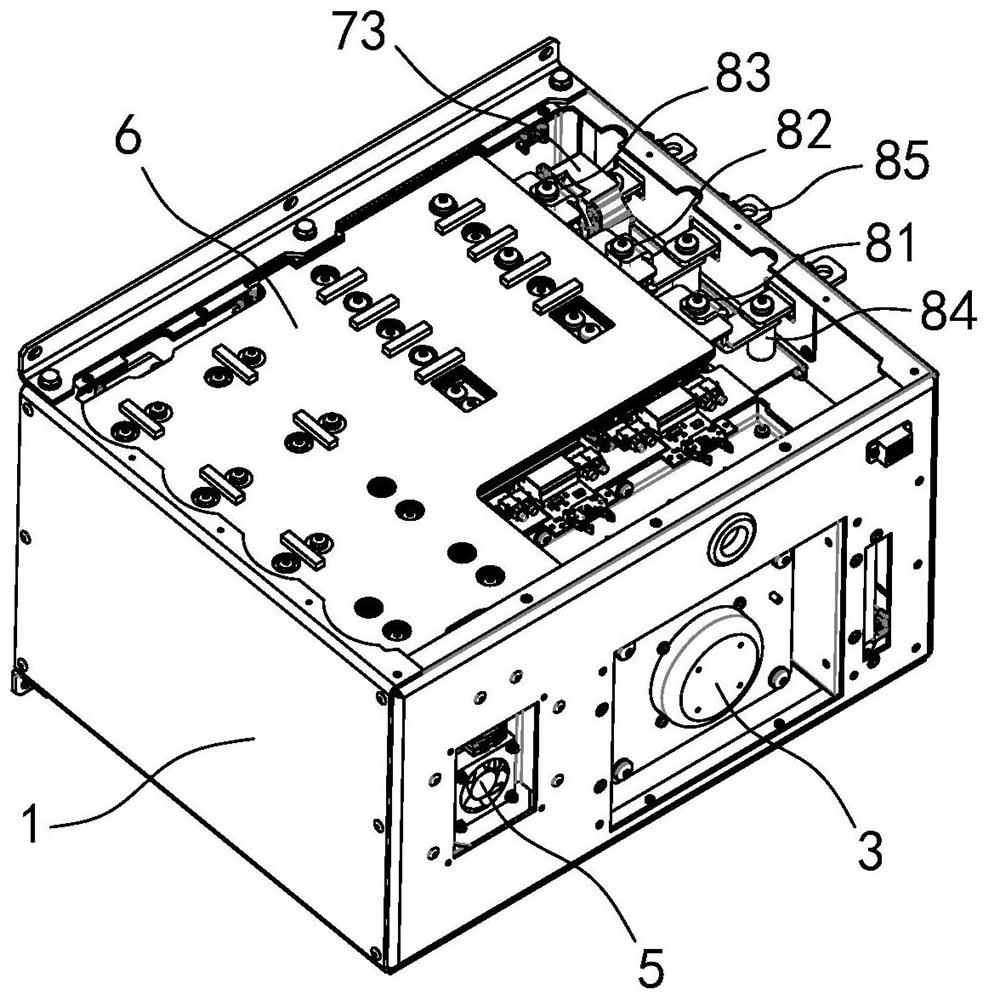

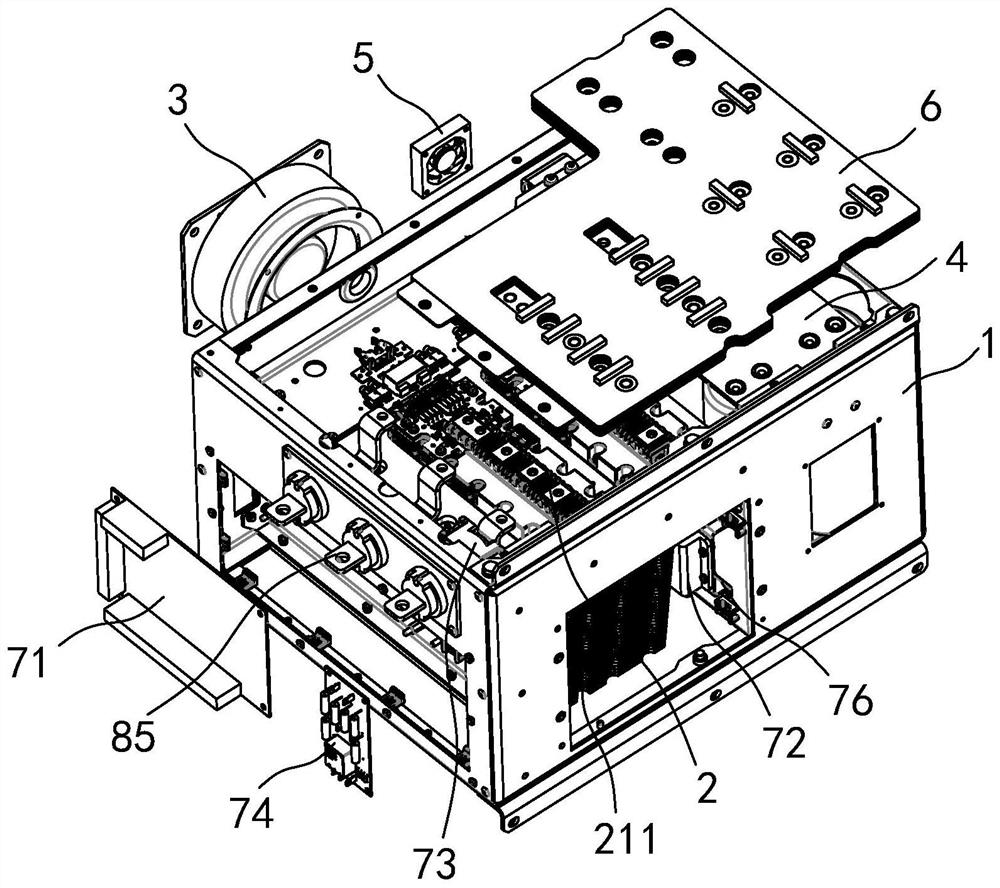

Three-level power module system device and charging system

ActiveCN111049361BAchieve stand-alone installationImprove convenienceModifications for power electronicsPower conversion systemsCapacitanceBusbar

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com