Bearing temperature monitoring method and bearing temperature monitoring system

A technology of bearing temperature and monitoring system, applied in the direction of thermometer, thermometer application, thermometer parts, etc., can solve the problems of long maintenance period, large economic loss, downtime maintenance, etc., and achieve the effect of avoiding economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

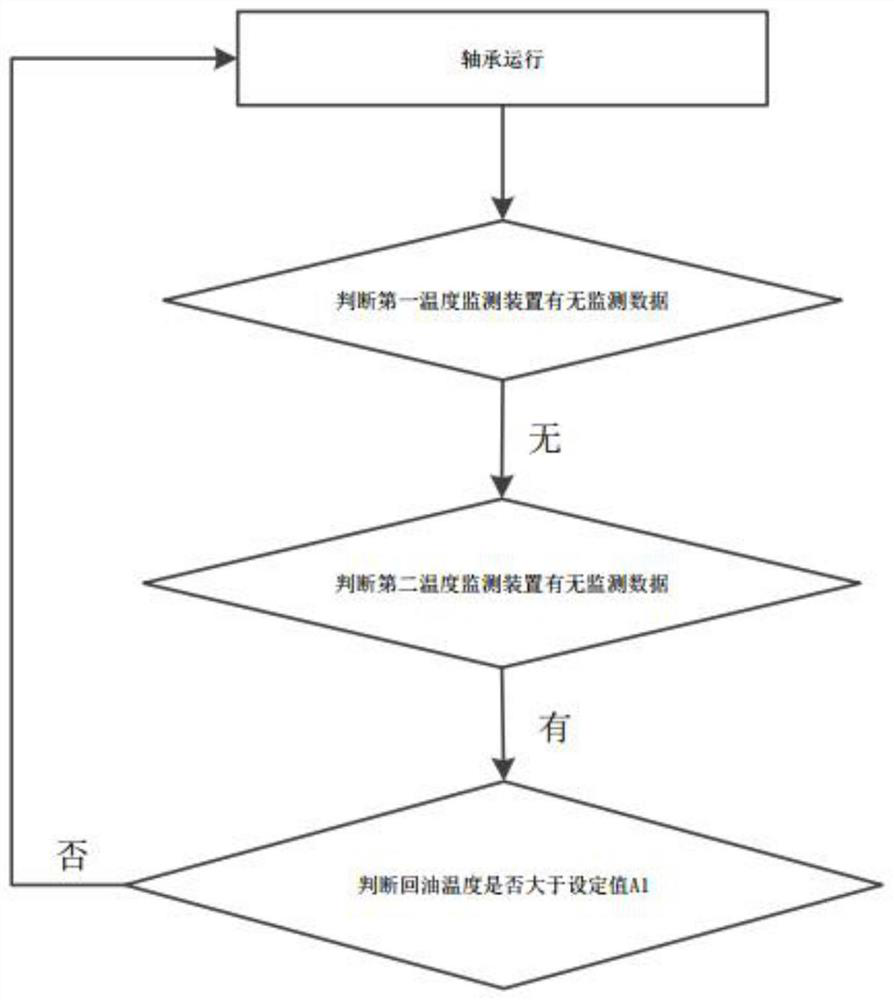

[0033] Such as figure 1 As shown, this embodiment provides a bearing temperature monitoring method for temperature monitoring of radial bearings of high-speed multi-stage centrifugal compressors. The bearing temperature monitoring method provided in this embodiment includes: monitoring the bearing temperature through the first temperature monitoring device, and monitoring the oil return temperature of the bearing lubricating oil through the second temperature monitoring device; when the first temperature monitoring device has no monitoring data, if the return oil temperature Not greater than the set value A1, the bearing continues to run.

[0034] In the bearing temperature monitoring method provided in this embodiment, the bearing temperature is monitored by the first temperature monitoring device, and the bearing oil return temperature is monitored by the second temperature monitoring device. Since the change trend of the bearing lubricating oil return oil temperature is the...

Embodiment 2

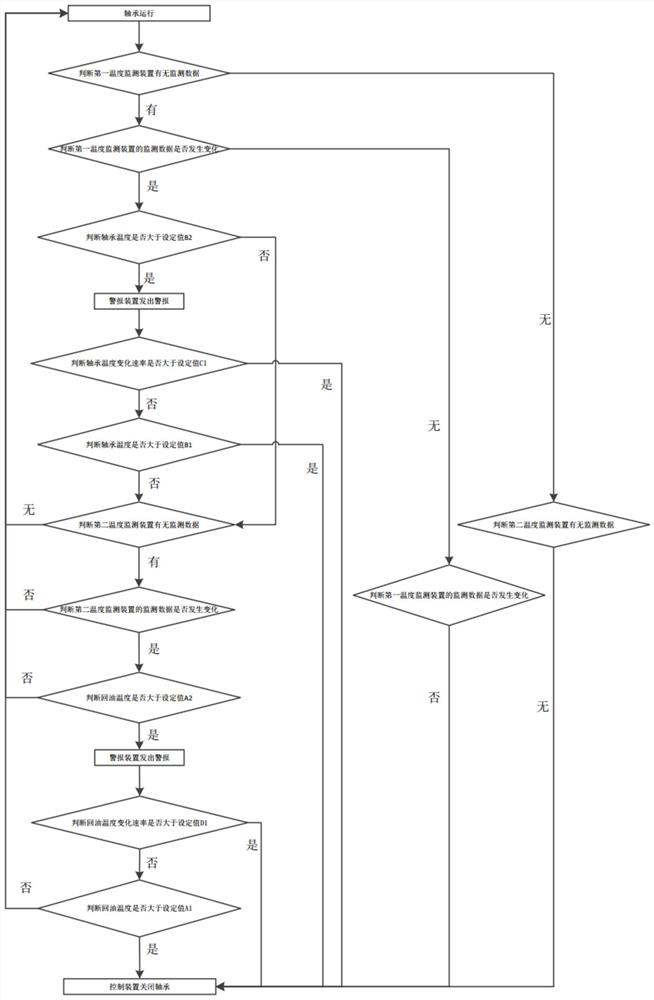

[0037] Such as figure 2 As shown, this embodiment provides a bearing temperature monitoring method, which, on the basis of Embodiment 1, further includes that when the second temperature monitoring device has no monitoring data, if the bearing temperature is not greater than the set value B1, the bearing continues to run.

[0038] In the temperature monitoring method provided in this embodiment, when one of the first temperature monitoring device and the second temperature monitoring device fails, the other can continue to monitor the bearing temperature, so that when the first temperature monitoring device has no monitoring data , if the return oil temperature is not greater than the set value A1, the bearing can continue to run, and when the second temperature monitoring device fails and there is no monitoring data, if the bearing temperature is not greater than the set value B1, the bearing can also continue to run.

[0039] Optionally, as in figure 2 As shown, when the ...

Embodiment 3

[0044] The existing temperature monitoring device for radial bearings of high-speed multi-stage centrifugal compressors uses two temperature-measuring probes buried inside the bearing, one is the main temperature-measuring probe and the other is the spare temperature-measuring probe. The main equipment of the high-speed multi-stage centrifugal compressor is a high-value large-scale equipment with a very long design overhaul period. However, in the actual use of the high-speed multi-stage centrifugal compressor, the service life of the main temperature measuring probe and the spare temperature measuring probe is long The design overhaul period of the main equipment of the high-speed multi-stage centrifugal compressor is often lower than that of the main equipment of the high-speed multi-stage centrifugal compressor. The main body of the high-speed multi-stage centrifugal compressor is often intact, but both the main temperature measuring probe and the backup temperature measuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com