A high temperature superconductor temperature monitoring device and method based on non-stick fiber grating temperature sensor

A technology of temperature sensor and optical fiber grating, which is applied in the field of high-temperature superconductor temperature monitoring technology devices, can solve the problems of sample stripping, unstable temperature measurement, and non-reusability, etc., and achieve the effect of stable temperature measurement and saving testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

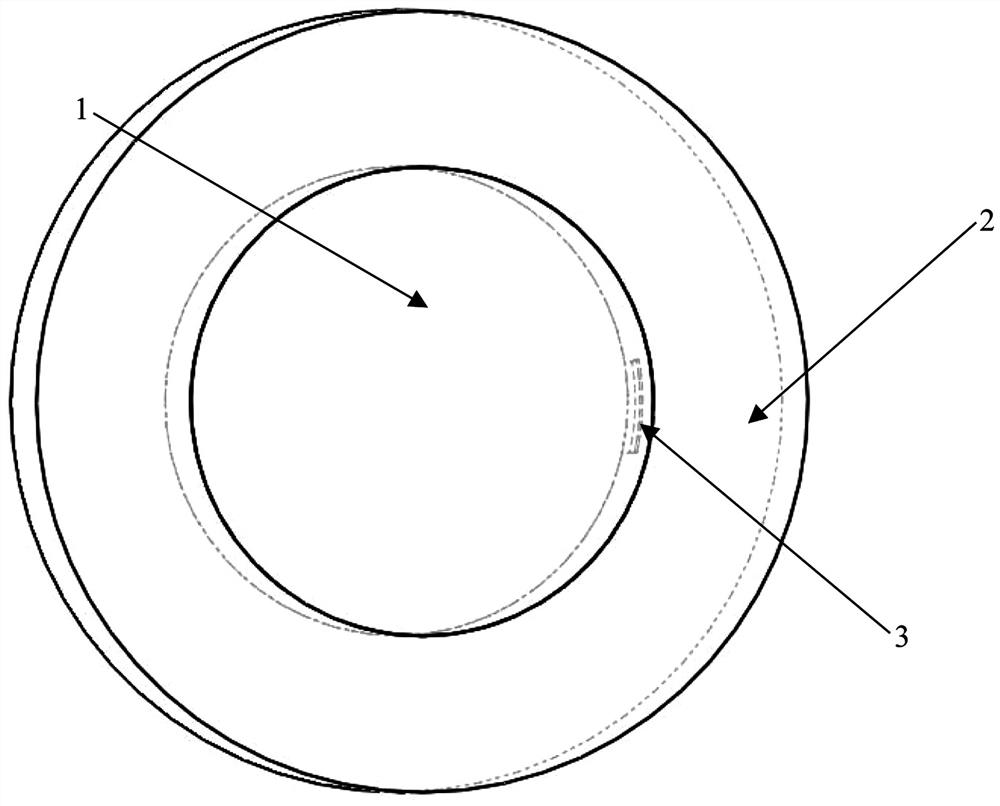

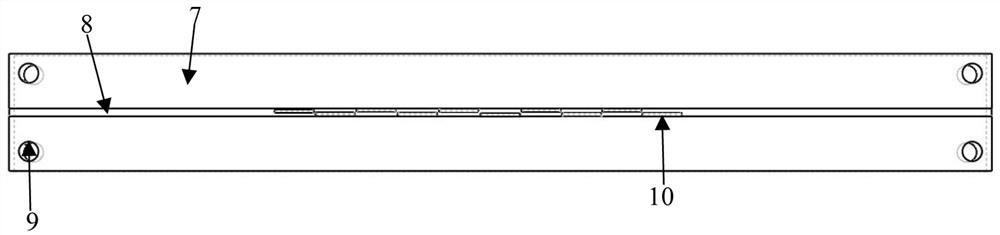

[0043] see Figure 1-7 , a high temperature superconductor temperature monitoring device based on a non-stick fiber grating temperature sensor, which includes a fiber grating temperature sensor 3, the fiber grating temperature sensor 3 is directly embedded in the sample skeleton of the high temperature superconductor whose temperature is to be monitored. By using the temperature monitoring device of the present invention, the fiber grating temperature sensor 3 is embedded into the sample skeleton of the high-temperature superconducting tape or the high-temperature superconducting magnet, instead of directly pasting the fiber grating temperature sensor on the high-temperature superconducting magnet or high-temperature superconductor The surface of the high-temperature superconducting tape can protect the performance of the high-temperature superconducting tape or the high-temperature superconducting magnet from being damaged, thereby improving the measurement accuracy and reliab...

Embodiment 2

[0053] see figure 1 , when using the fiber grating temperature sensor to monitor the temperature of the high-temperature superconducting magnet online, the fiber grating temperature sensor can be embedded into the sample skeleton. like figure 1 As shown, it is a schematic diagram of a round cake-shaped superconducting magnet with a fiber grating temperature sensor embedded in the sample skeleton. figure 1 It is just an example, and in practical applications, the superconducting magnet may also be a magnet with any other structure such as a horseshoe coil. Among them, 1 is a magnet coil skeleton, 2 is a high temperature superconducting magnet coil, and 3 is a fiber grating temperature sensor. From the working principle and electromagnetic knowledge of the high-temperature superconducting coil, it can be known that the surface magnetic field intensity is the largest at the inner side of the high-temperature superconducting magnet coil 2 near the magnet coil bobbin 1, which lea...

Embodiment 3

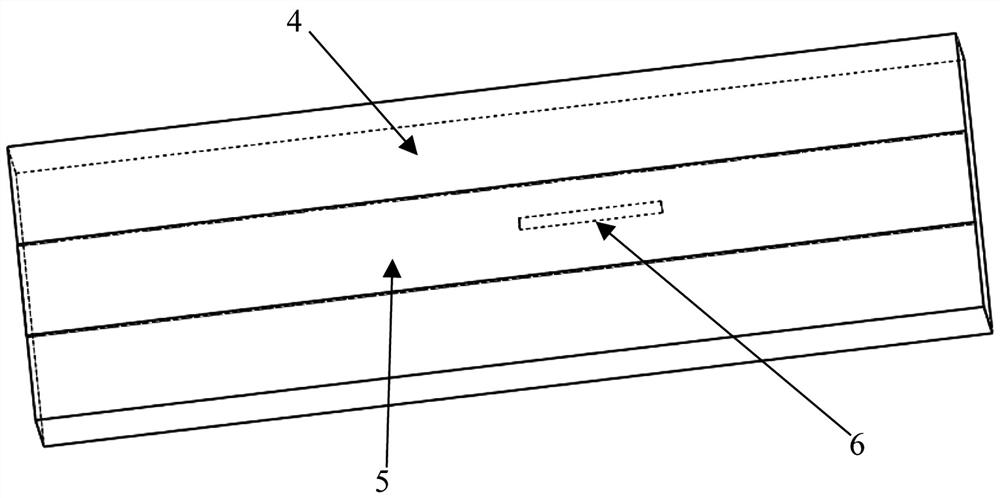

[0055] see figure 2 , for the application of fiber grating temperature sensor to study the quench mechanism and temperature propagation characteristics of high-temperature superconducting tape, the fiber grating temperature sensor can be embedded into the sample skeleton. like figure 2 As shown, a schematic diagram of a superconducting tape sample with a sample skeleton embedded in a fiber grating temperature sensor. Among them, 4 is a G10 sample skeleton, 5 is a high temperature superconducting tape, and 6 is a first fiber grating temperature sensor with a capillary encapsulation structure embedded in the sample skeleton. In order to reduce the temperature delay between the tested superconductor and the fiber grating sensor, the protective sleeve should be made of materials with high thermal conductivity, and its inner diameter should not be too large, and should match the diameter of the optical fiber to facilitate the optical fiber to pass through. At the same time, in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com