Organic sulfur removal reactor

A technology of reactor and organic sulfur, which is applied in the removal of gas pollutants, the purification of selected absorbent solid gas, the purification of catalytic conversion of impurities, etc., which can solve the problems of large amount of equipment materials and large space occupation, etc. Achieve uniform gas distribution, save space, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

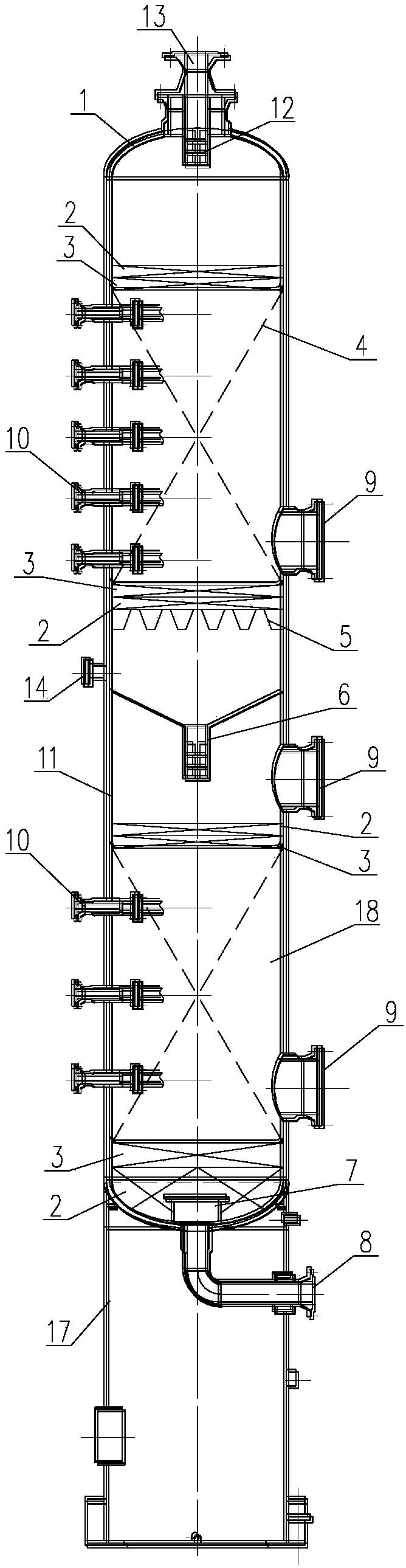

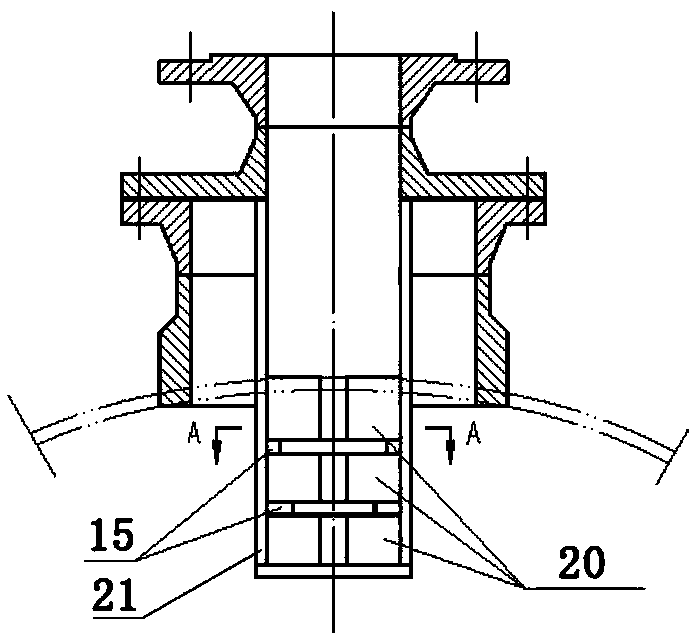

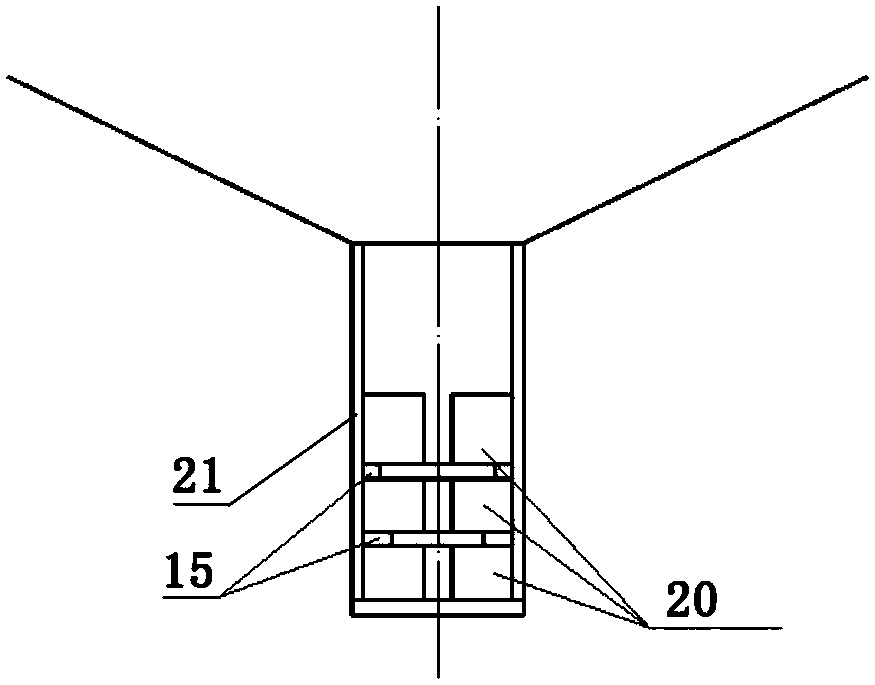

[0031] See figure 1 , an organic sulfur removal reactor, comprising a skirt 17, a cylinder 11 arranged on the skirt 17 and upper and lower heads, the cylinder 11 is sequentially equipped with a hydrogenation reaction catalyst bed 4, and then Distributor 6 and adsorbent bed 18, cylinder body 11 has several thermometer connection pipes 10 and manhole 9; upper head 1 is provided with air inlet 13 and inlet gas distributor 12, lower head is provided with gas outlet 8 and collector gas ring7. A sampling port 14 is provided on the side of the cylinder 11 .

[0032] See figure 1 , The upper and lower parts of the hydrogenation reaction catalyst bed 4 and the adsorbent bed 18 are respectively filled with 2 to 3 layers of ceramic balls with different d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com