Steel ladle structure and manufacturing method thereof

A manufacturing method and ladle technology, applied in ladle manufacturing, ladle structure and its manufacturing fields, can solve problems such as difficulty in accurately judging the erosion of the working layer, hidden safety hazards, and poor working conditions, so as to prevent steel leakage accidents and improve Use safety, improve the effect of package age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

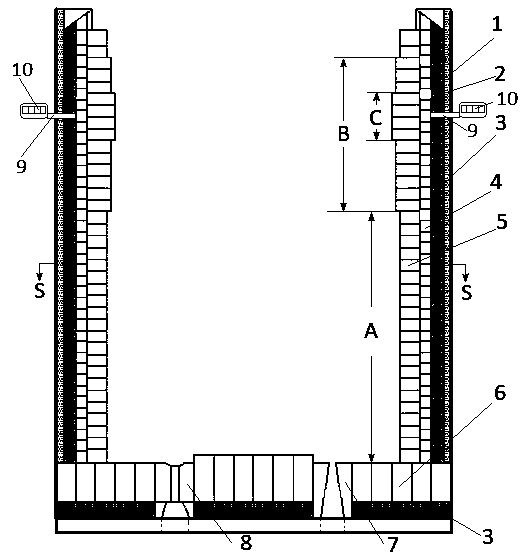

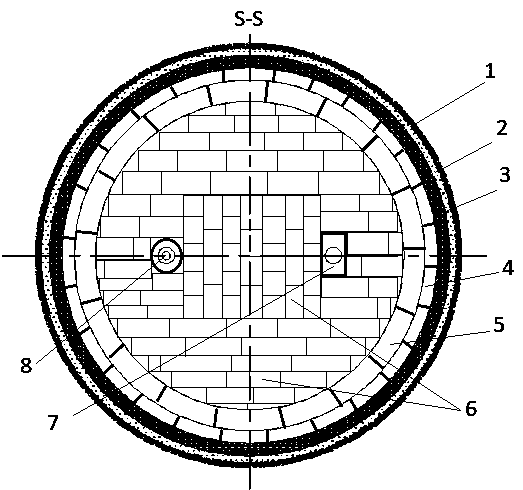

[0034] Embodiment 1: Taking the manufacture of a 120-ton ladle of the present invention as an example, further descriptions are made of the possible ways of the present invention. The 120-ton steel ladle of the present invention is matched with a 100-ton top-bottom combined blowing converter. Such as figure 1 , figure 2 As shown, a ladle shell 1 capable of loading 120 tons of molten steel is made with a steel plate with a thickness of 26mm. The diameter of the ladle is 2.77m and the height is 3.7m. Build the bottom of the ladle in the ladle shell 1, first use semi-light refractory castables to make the bottom, build the permanent layer 3 of the bottom of the ladle, with a thickness of 100mm, after drying, build the bottom refractory brick 6 on it, and build the bottom refractory brick 6. Magnesia-carbon bricks are used, and the thickness of the bottom refractory brick 6 in the center area of 800mm×800mm is required to be 50mm higher than that of other areas with a thickne...

Embodiment 2

[0035] Embodiment 2: Taking the production of a 250-ton ladle of the present invention as an example, further descriptions are made of the realizable manner of the present invention. The 250-ton steel ladle of the present invention is matched with a 210-ton top-bottom combined blowing converter. Such as figure 1 , figure 2 As shown, a steel ladle shell 1 capable of loading 250 tons of molten steel is made with a steel plate with a thickness of 30 mm, the diameter of the clad body is 3.8 m, and the height is 4.7 m. Build the bottom of the ladle in the ladle shell 1, first use semi-light refractory castables to make the bottom, build the permanent layer 3 of the bottom of the ladle, with a thickness of 150mm, after drying, build the bottom refractory brick 6 on it, and build the bottom refractory brick 6. Magnesia-carbon bricks are used, and the thickness of the bottom refractory brick 6 in the central 1000mm×1000mm area is required to be 80mm higher than that of other areas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com