Patents

Literature

30results about How to "Increase package age" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cap agent with light alkaline particle steel coating

InactiveCN1778493AAvoid secondary oxidationSecondary oxidation will notProcess efficiency improvementChemical reactionRefractory

A light-weight alkaline particle used as the covering agent of steel ladle contains siO2 (18-26 Wt%), CaO (26-34), MgO (6-12), Al2O3 (5-8), Fe2O3 (0.5-2.0), and stabilized C (18-26). Its advantages are low specific bulk weight, high insulating performance, and high effect to prevent oxidization of molten steel and decrease the corrosion to refractory of ladle.

Owner:上海宝谊保温材料有限公司

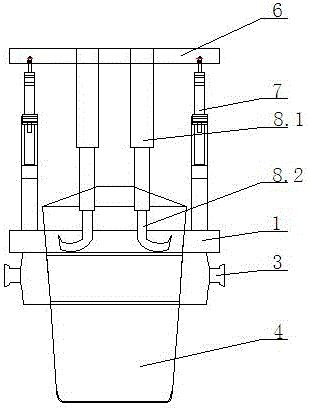

Ladle neck bush pouring technique

The invention discloses a ladle lining casting technology, which comprises the following steps: 1) detaching ladle slag brick, cleaning slag on the ladle wall working layer, reacting layer and deteriorated layer, 2) placing the mould to locate, 3) casting between mould and ladle wall with the same material as working layer, 4) stripping after health preserving, 5) toasting.

Owner:崔东瑞

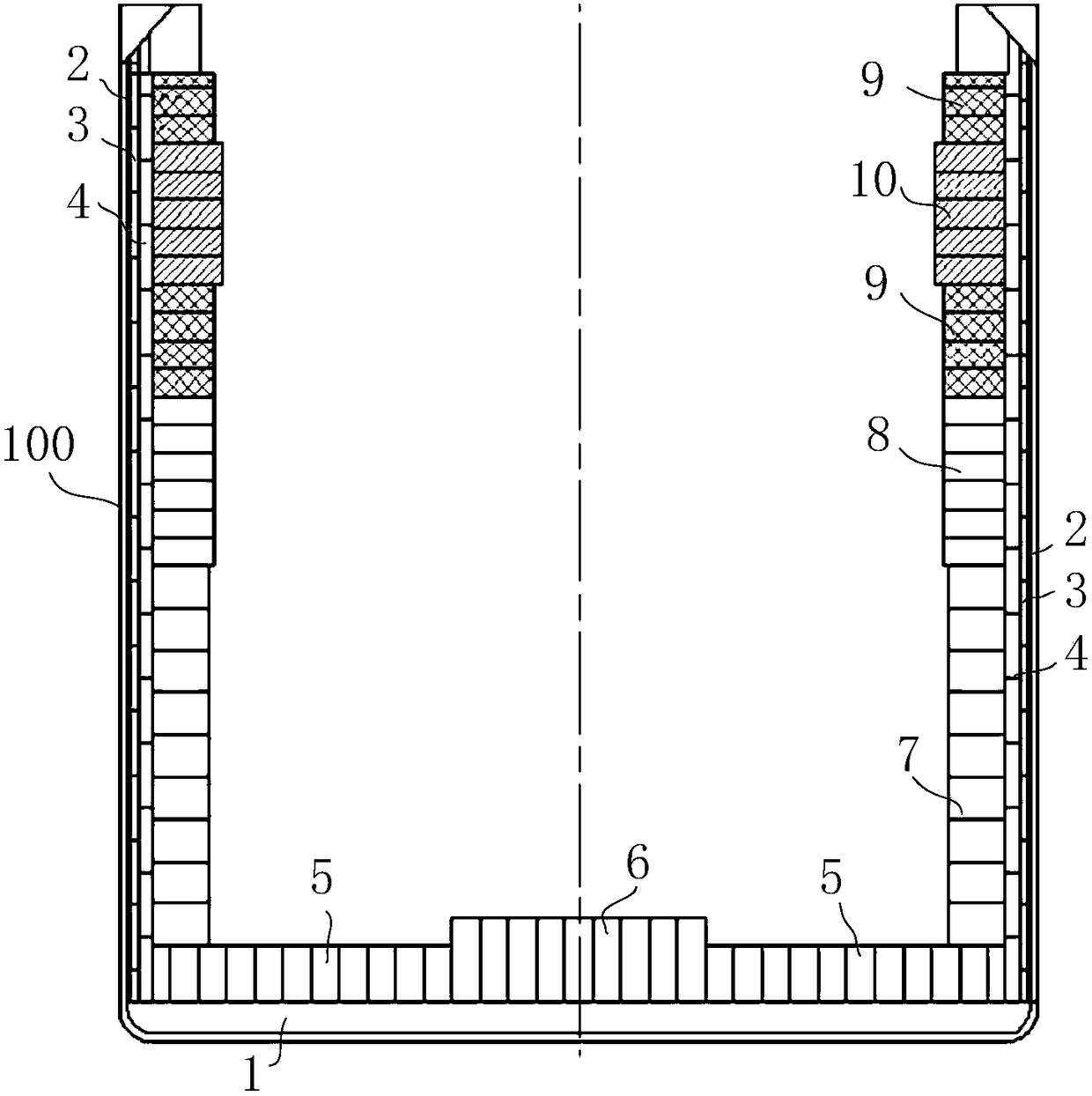

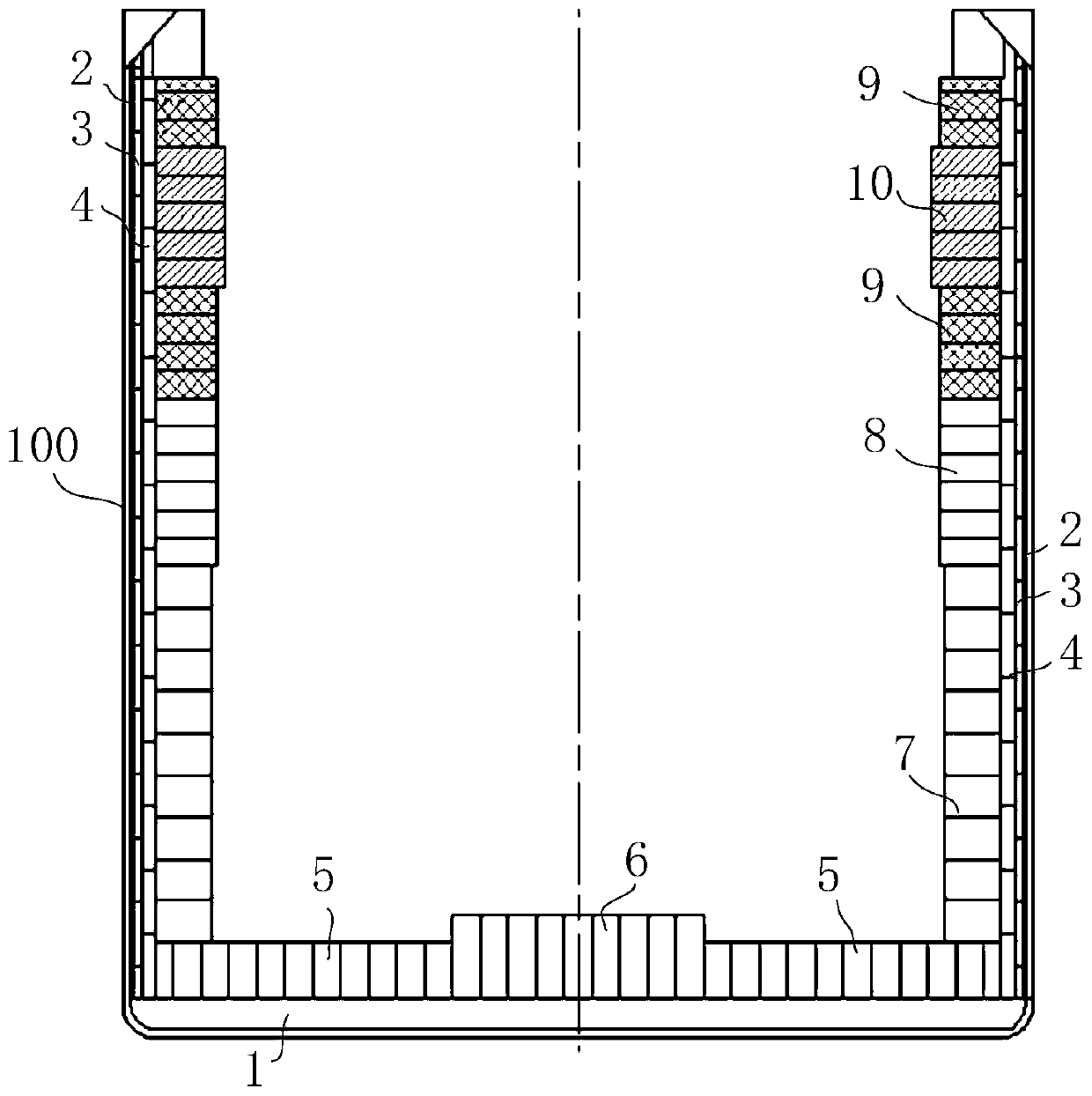

Steel ladle structure and manufacturing method thereof

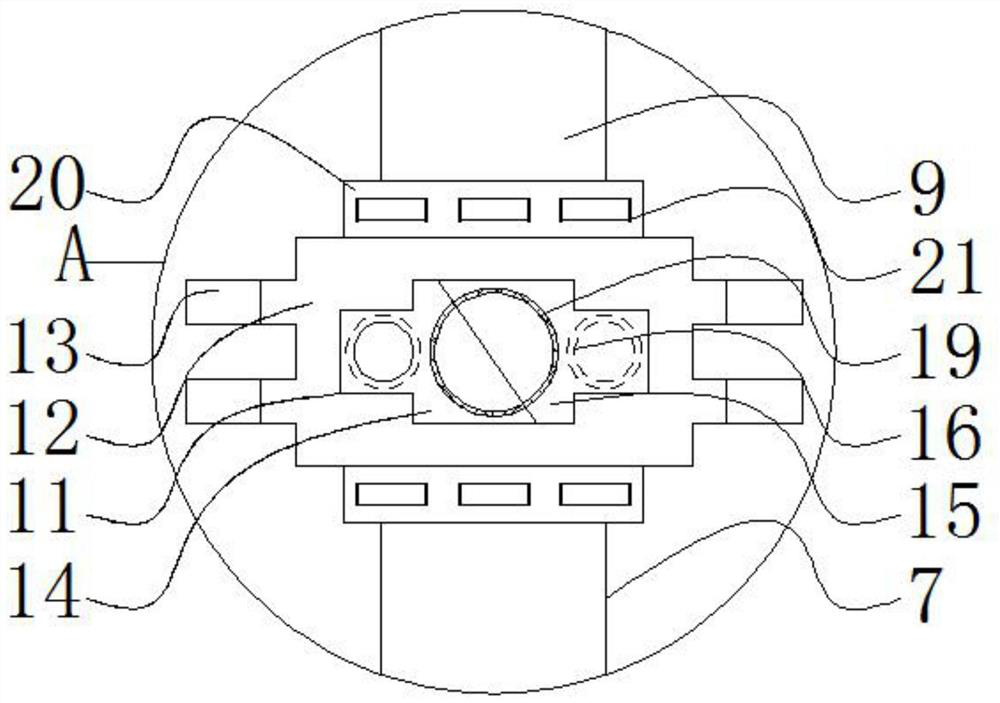

PendingCN110935871AIncrease package ageEffective temperature monitoringMelt-holding vesselsInsulation layerSlag

The invention discloses a steel ladle structure and a manufacturing method thereof. A protective layer is arranged between a ladle body permanent layer and a working layer. The manufacturing method comprises the building steps of (1) building a ladle bottom, specifically, firstly, bottoming in a steel ladle shell by using a semi-light refractory castable, building refractory bricks on the semi-light refractory castable, and building a ladle bottom platform; (2) attaching a heat preservation layer, specifically, tightly attaching two layers of nanometer heat insulation plates to the inner wallof the steel ladle shell; (3) building a protective layer and a working layer, specifically, building protective layer refractory bricks on the ladle bottom platform, then building working layer refractory bricks, and forming a double-ring brick structure; (4) pouring a ladle body permanent layer, specifically, injecting a semi-light castable between the nanometer heat insulation plate and the protective layer bricks every 2-3 layers of double-ring bricks are built, constructing the ladle body permanent layer, and repeating the step until the edge of a steel ladle opening is reached; and (5) punching a hole in the peripheral steel ladle shell of the steel ladle slag line area to install a thermocouple, and connecting a temperature display. According to the invention, the safety of the steel ladle is effectively improved, the heat loss of molten steel is reduced, and the maintenance workload and material consumption of the steel ladle are greatly reduced.

Owner:新余钢铁股份有限公司

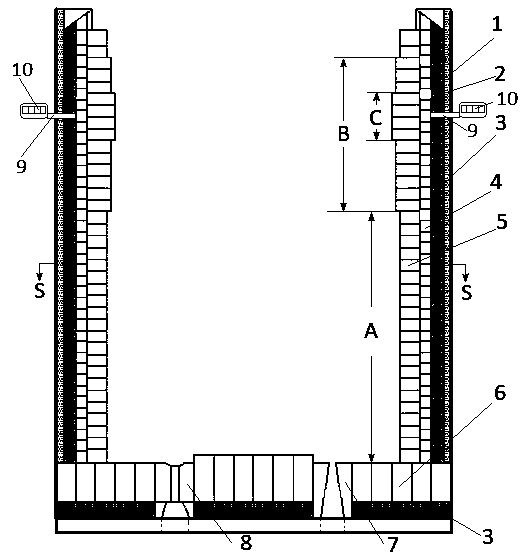

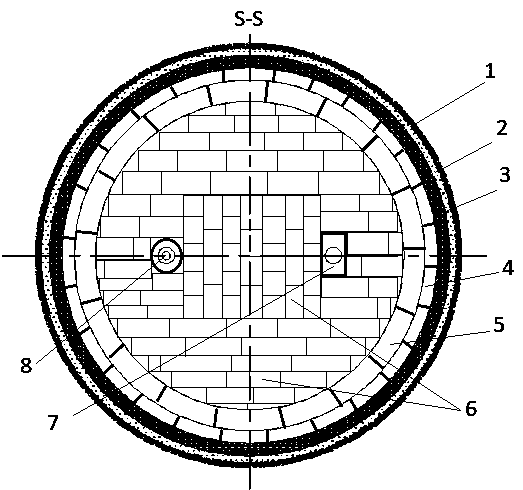

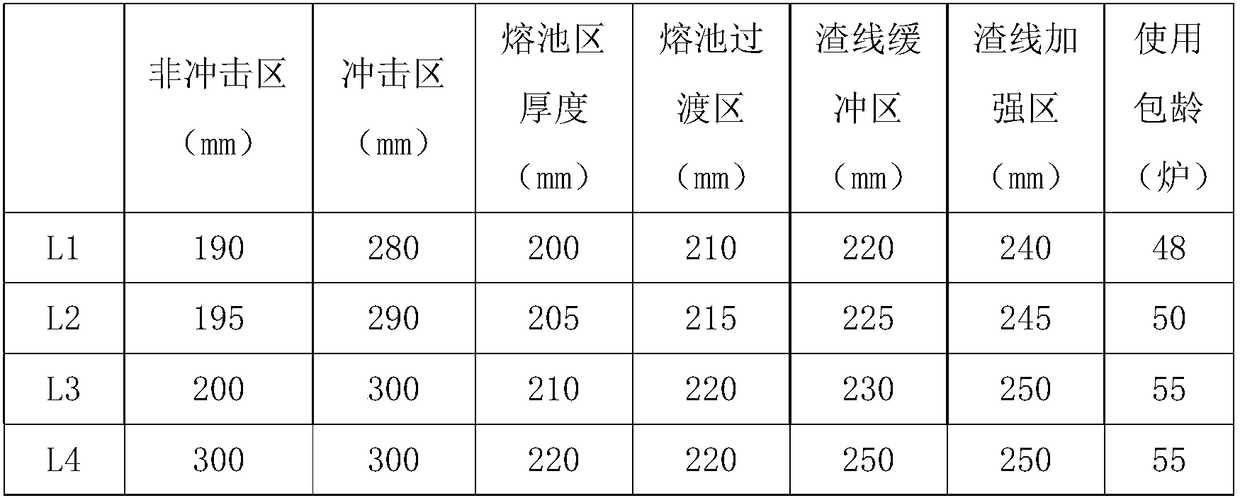

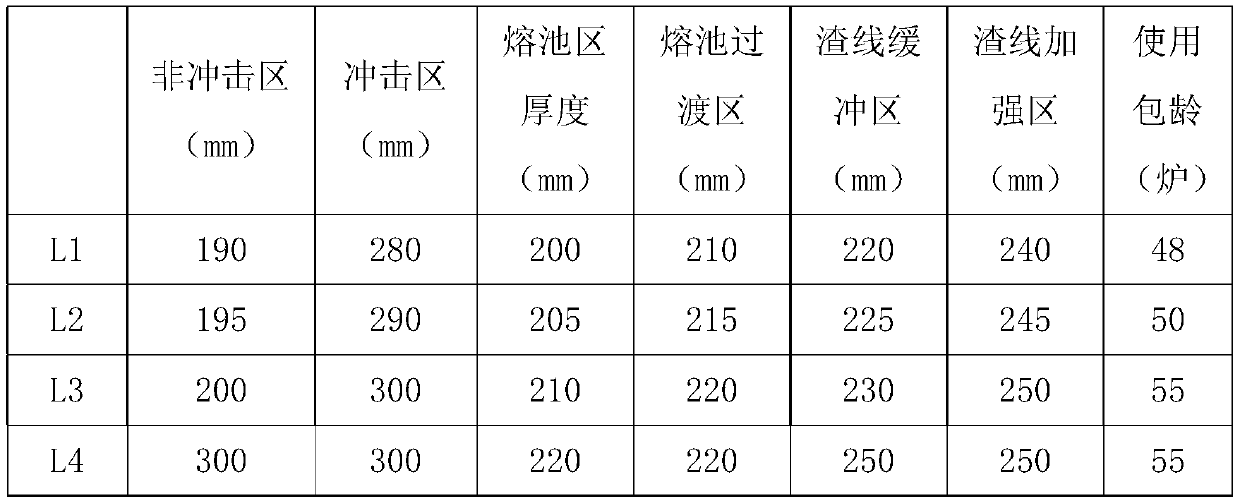

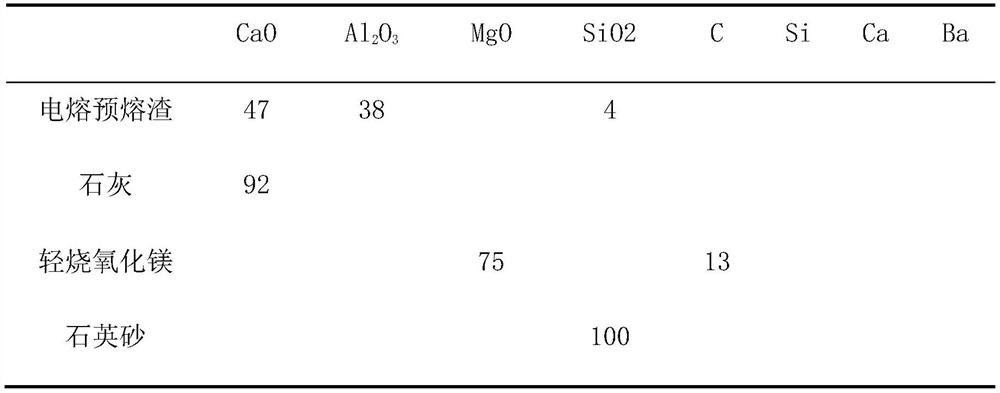

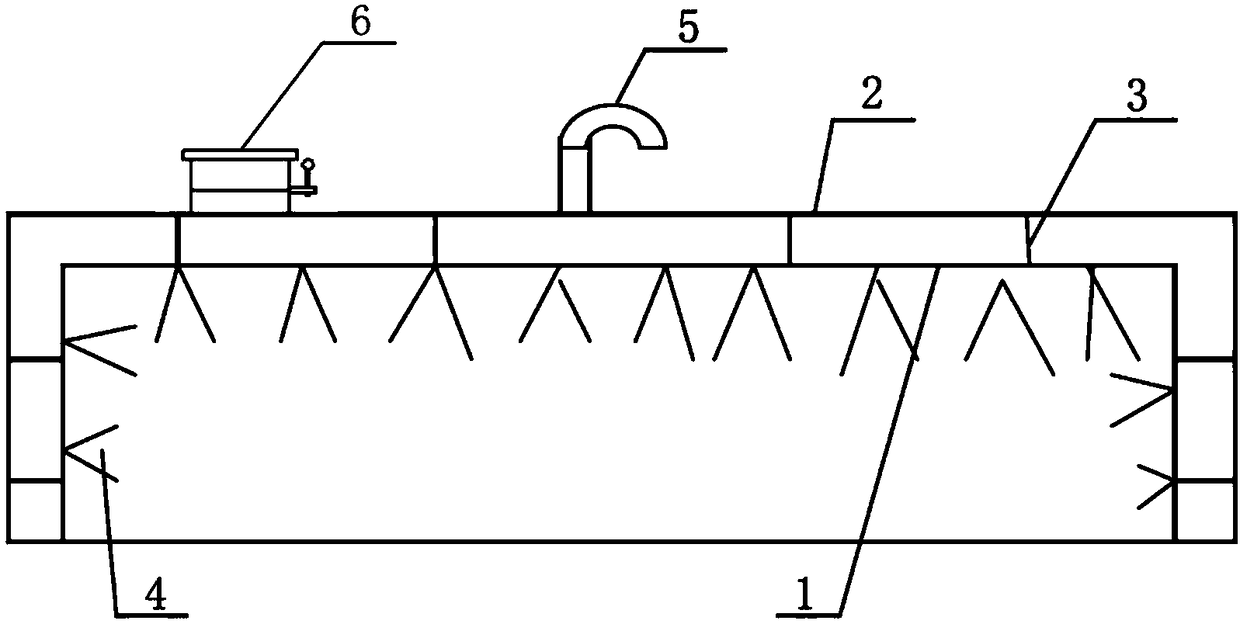

Steel ladle and construction method thereof

The invention discloses a steel ladle. According to different erosion mechanisms and different erosion speeds of all zones inside the steel ladle, a ladle bottom working layer is arranged to be an impacting zone and a non-impacting zone, a ladle wall working layer is arranged to be a bath zone, a bath transition zone and a slag line zone, refractory material specifications of the ladle bottom working layer and the ladle wall working layer are adjusted accordingly, the thickness and height of a refractory material are increased in a zone with the higher erosion speed, an erosion transition beltis formed, the erosion speed of a serious erosion zone is decreased, meanwhile, a slow erosion zone can be indirectly protected, the overall service life of the steel ladle refractory material is prolonged, and the ladle life of the steel ladle is further prolonged effectively. The invention further discloses a construction method of the steel ladle. The using ladle life of the steel ladle constructed by the method can reach 48-55 furnace times, the turnover period of the steel ladle is increased while the ladle life of the steel ladle is prolonged, and the construction cost is reduced.

Owner:NANJING IRON & STEEL CO LTD

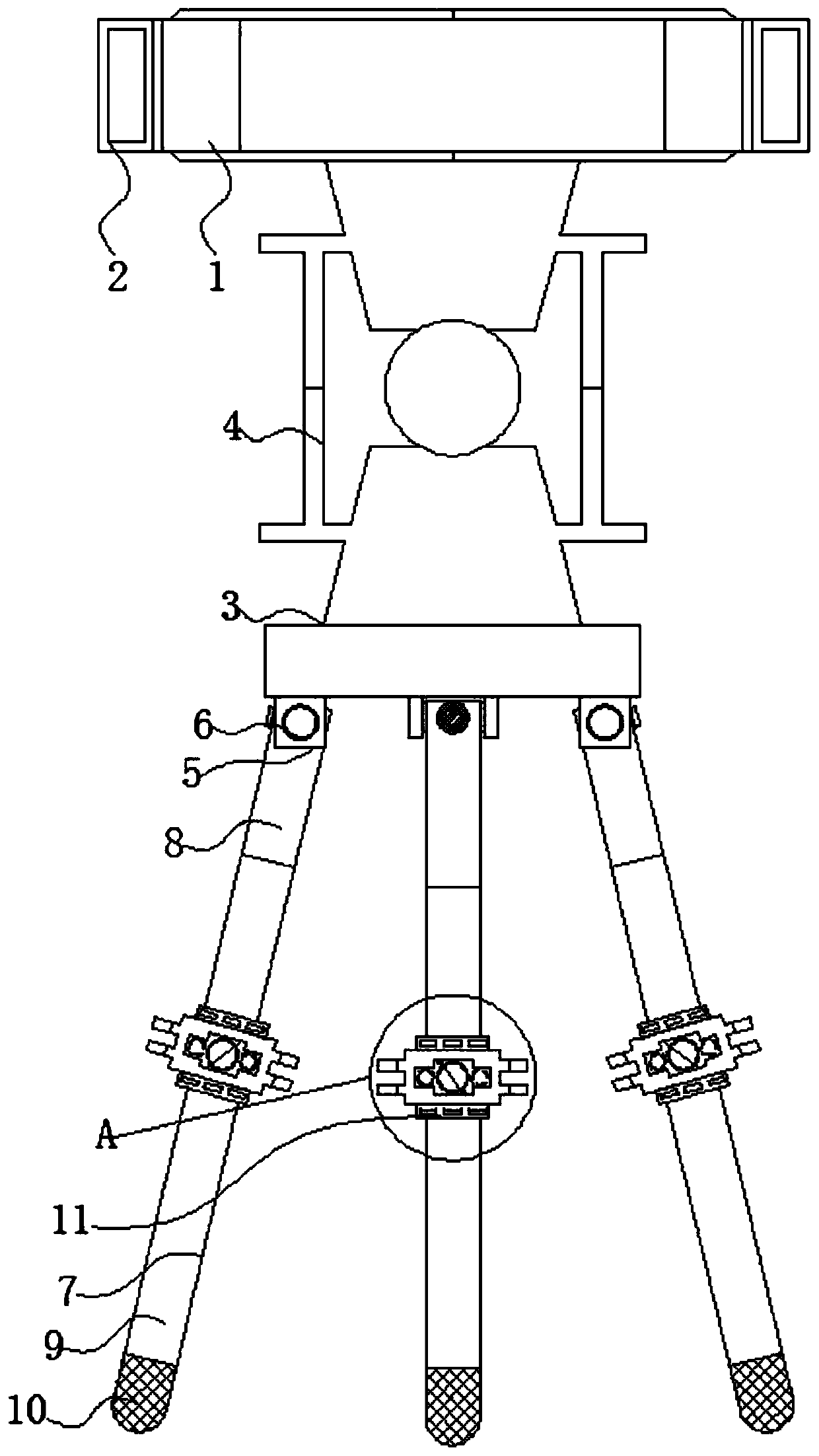

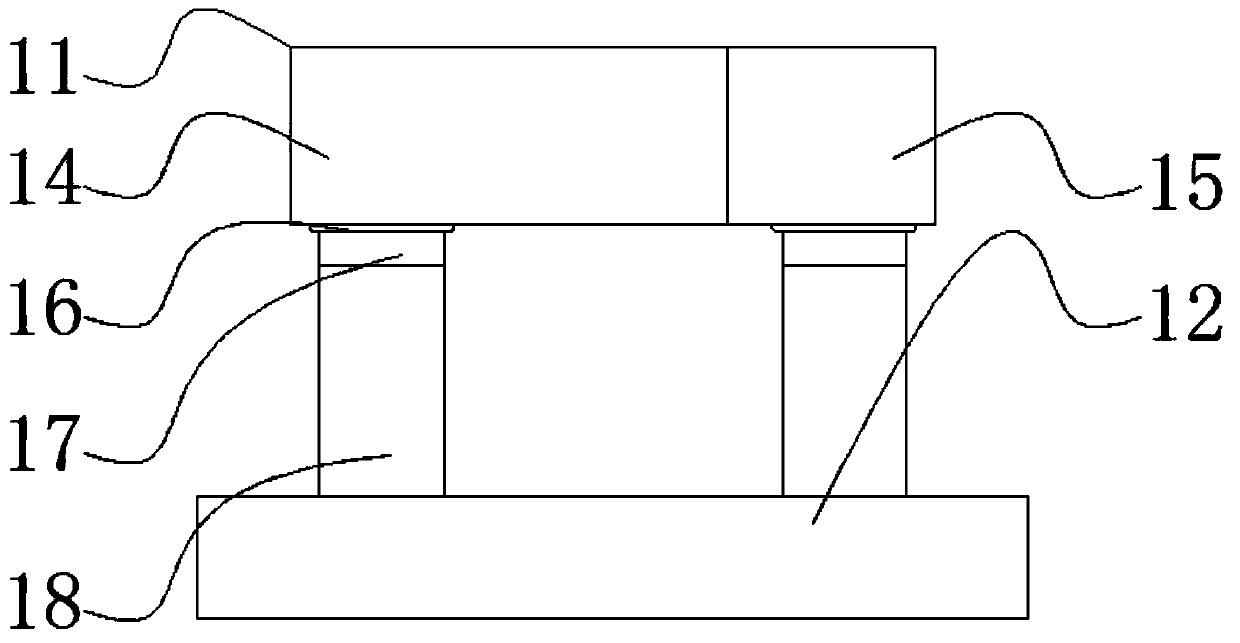

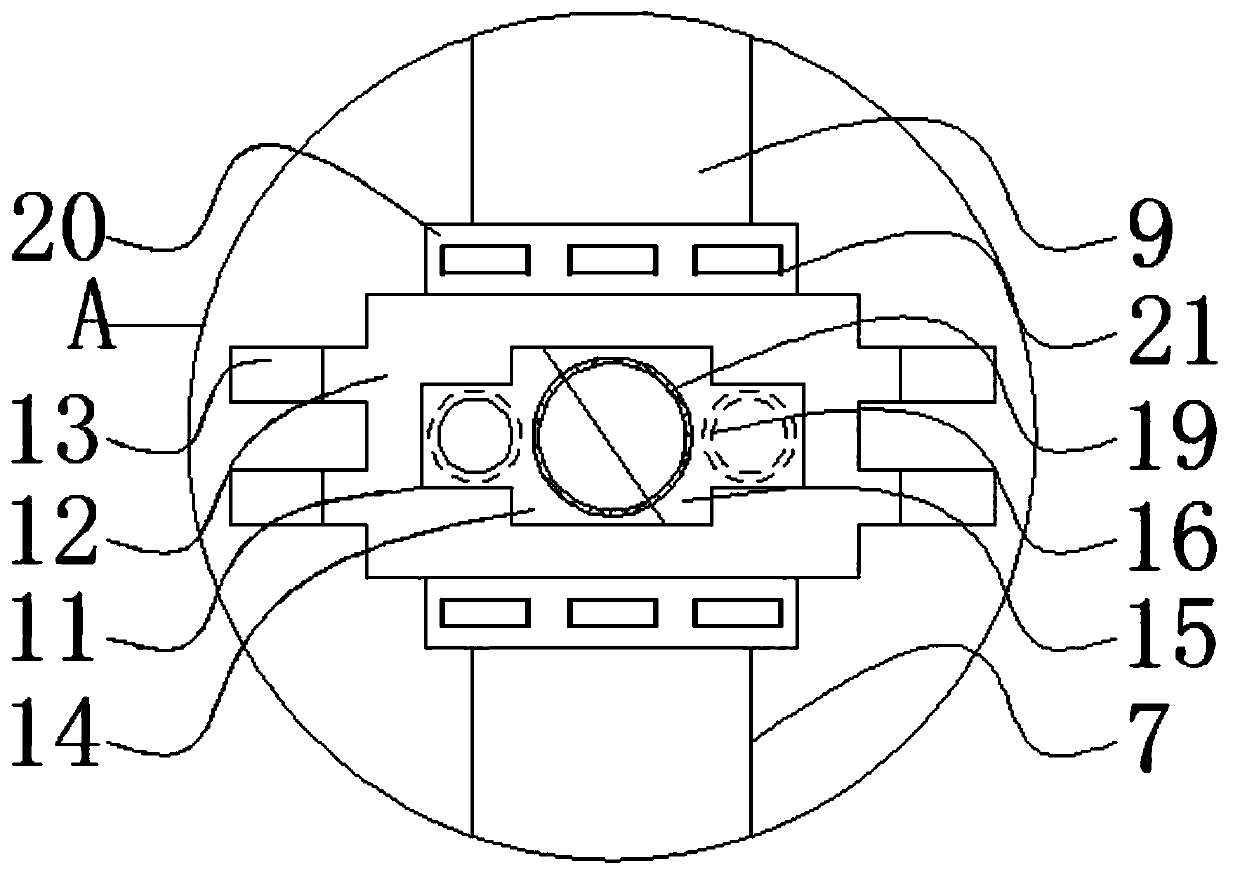

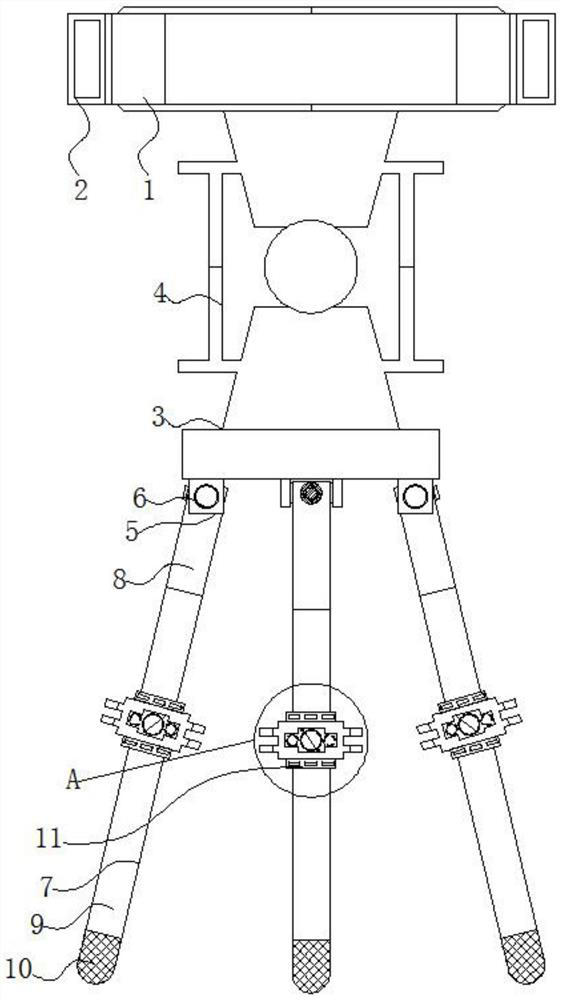

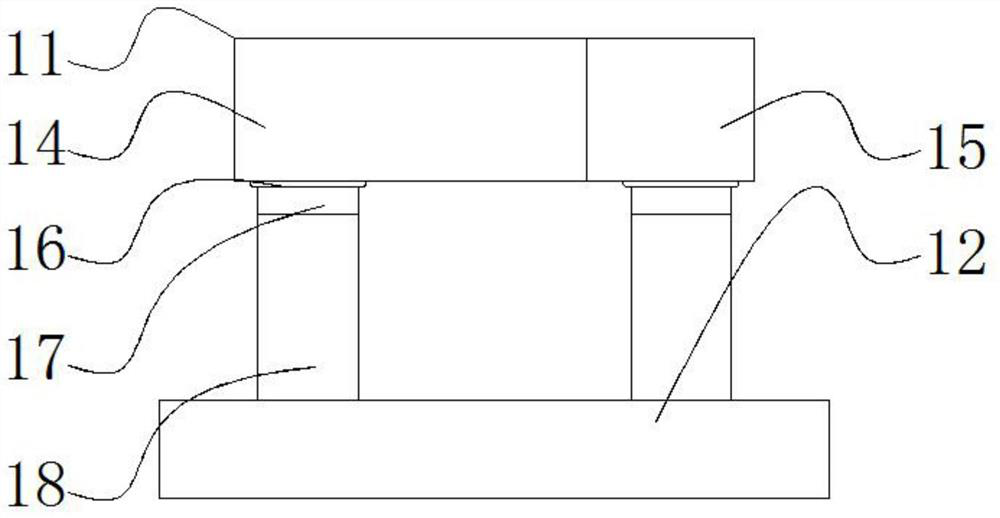

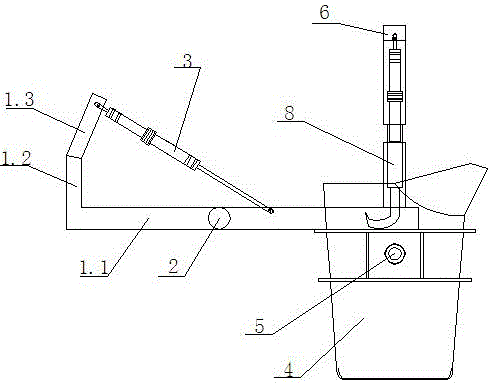

Equipment for measuring internal size of steel ladle by using laser range finder and operation method thereof

ActiveCN111238411AIncrease purchase costReduce cost of measurementUsing optical meansElectromagnetic wave reradiationLaser rangingMaterial consumption

The invention relates to equipment for measuring the internal size of a steel ladle by using a laser range finder and an operation method thereof. The equipment comprises a laser range finding mechanism and a bunching mechanism, and a side connection guardrail frame is arranged at the bottom end of the laser range finding mechanism. The beneficial effects of the equipment are that: According to the equipment for measuring the internal size of the steel ladle by using the laser range finder and the operation method thereof, the size condition of any area in the steel ladle can be measured, theinternal condition of the steel ladle can be simply simulated, the melting loss degree of the area is judged by comparing with relevant parameters when the steel ladle is on line, the internal condition of the steel ladle can be simply simulated through the method, the refractory material melting loss degree of the steel ladle and the steel weighing amount condition of the steel ladle can be calculated, and an original method for optimizing manual measurement by using the rod is adopted; finally, ladle service monitoring and ladle lining size control data and information can be provided for steel ladle service monitoring, a foundation is laid for saving refractory material consumption and prolonging the ladle life, major accidents of steel ladle furnace penetration are effectively prevented and safe operation and smooth production of steel ladle service are guaranteed.

Owner:TANGSHAN GUOLIANG SPEICAL REFRACTORY MATERIAL

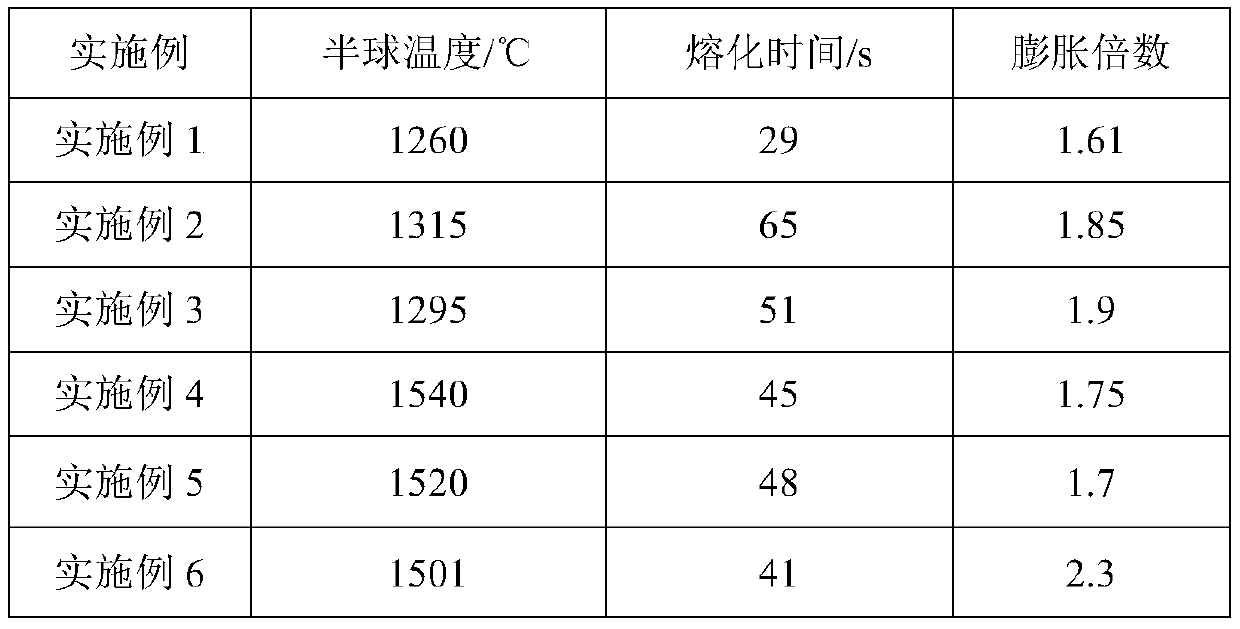

Ladle covering agent prepared through utilizing blast furnace slag

ActiveCN103173592AImprove reducibilityNo carbon increaseProcess efficiency improvementSlagSolid particle

The invention provides a ladle covering agent prepared through utilizing blast furnace slag. The ladle covering agent is composed of 30-40 parts by weight of blast furnace slag, 26.7-40 parts by weight of limestone, 15-20 parts by weight of vermiculite and 5-15 parts by weight of fluorite, wherein the total weight part of the above raw materials is 100. The main raw materials of the ladle covering agent have the advantages of low cost, suitable melting point, short fusing time and good spreadability; and limestone decomposes at 800-1200DEG C, foams and expands, vermiculite expands at a high temperature, and the friction force among solid particles is lower than the inner friction force among powders, so the spreadability and the heat insulating property are good. The ladle covering agent can prevent the secondary oxidation and too large temperature decrease of molten steel, and has a certain impurity adsorption and inclusion capability to purify the molten steel because of the appropriate alkalinity. The ladle covering agent has no carbon, does not carburize the molten steel, and is in favor of the component control of the production process.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

Unfired magnesia carbon brick as well as preparation method and application thereof

InactiveCN113943145AExtended service lifeThe number of vacuum smelting furnaces has increasedMelt-holding vesselsBrickRefractory

The invention belongs to the technical field of refractory materials, and relates to an unfired magnesia carbon brick as well as a preparation method and application thereof. The unfired magnesia carbon brick comprises the following components of: 2% to 6% of C, 87% to 92 % of MgO, 1% to 5% of SiO2, 1% to 3 % of CaO and 1% to 3 % of Al2O3. In actual production, the unfired magnesia carbon brick provided by the invention is used in a VOD steel ladle, so that the consumption of a refractory material of the steel ladle can be reduced, the service life of the steel ladle is prolonged, the number of vacuum smelting furnaces of the steel ladle is increased to 15 from 3, the service life of the steel ladle is increased to 80 furnaces from 28 furnaces, meanwhile, the production cost is reduced, and the purity of molten steel is favorably controlled. The unfired magnesia carbon brick comprises carbon, magnesium oxide, silicon dioxide, calcium oxide and aluminum oxide in specific quantities, the components are simple and easy to obtain; and when the unfired magnesia carbon brick is used in the VOD steel ladle, the erosion resistance, oxidation resistance and thermal shock resistance of the steel ladle can be remarkably improved.

Owner:邯郸市翰润达耐火材料有限公司

Stainless steel smelting method for improving content of MgO in slag of gas oxygen refining converter and LF (ladle furnace)

ActiveCN102912085AIncrease the content of MgOReduce erosionManufacturing convertersProcess efficiency improvementSocial benefitsSlag

The invention discloses a stainless steel smelting method for improving the content of MgO in slag of a gas oxygen refining converter and an LF (ladle furnace). The method comprises the following steps: a, preparing a magnesium-calcium refractory material with particle size of 3-15mm and a magnesium-calcium refractory material with the particle size less than 3mm; b, adding the magnesium-calcium refractory material with the particle size of 3-15mm into the gas oxygen refining converter to serve as a bottom magnesium-calcium refractory material; adding the magnesium-calcium refractory material with the particle size of 3-15mm once more during the converting period I, so as to keep the content of MgO in the slag within 9-11%; c, during the smelting and slagging process of the refining LF, adding lime, a slagging agent and the magnesium-calcium refractory material with the particle size less than 3mm together, so as to control the content of MgO in the slag within 7-9%; and d, proceeding to the continuous casting procedure. The method disclosed by the invention can improve the content of MgO in the slag, at the same time, improves the content of CaO, reduces erosion to the furnace lining, and prolongs the furnace life of the converter as well as the ladle life of the LF. The method disclosed by the invention has low requirements on a crushing appliance, lowers the production cost, and has higher economic and social benefits.

Owner:SICHUAN JINGUANG IND GRP

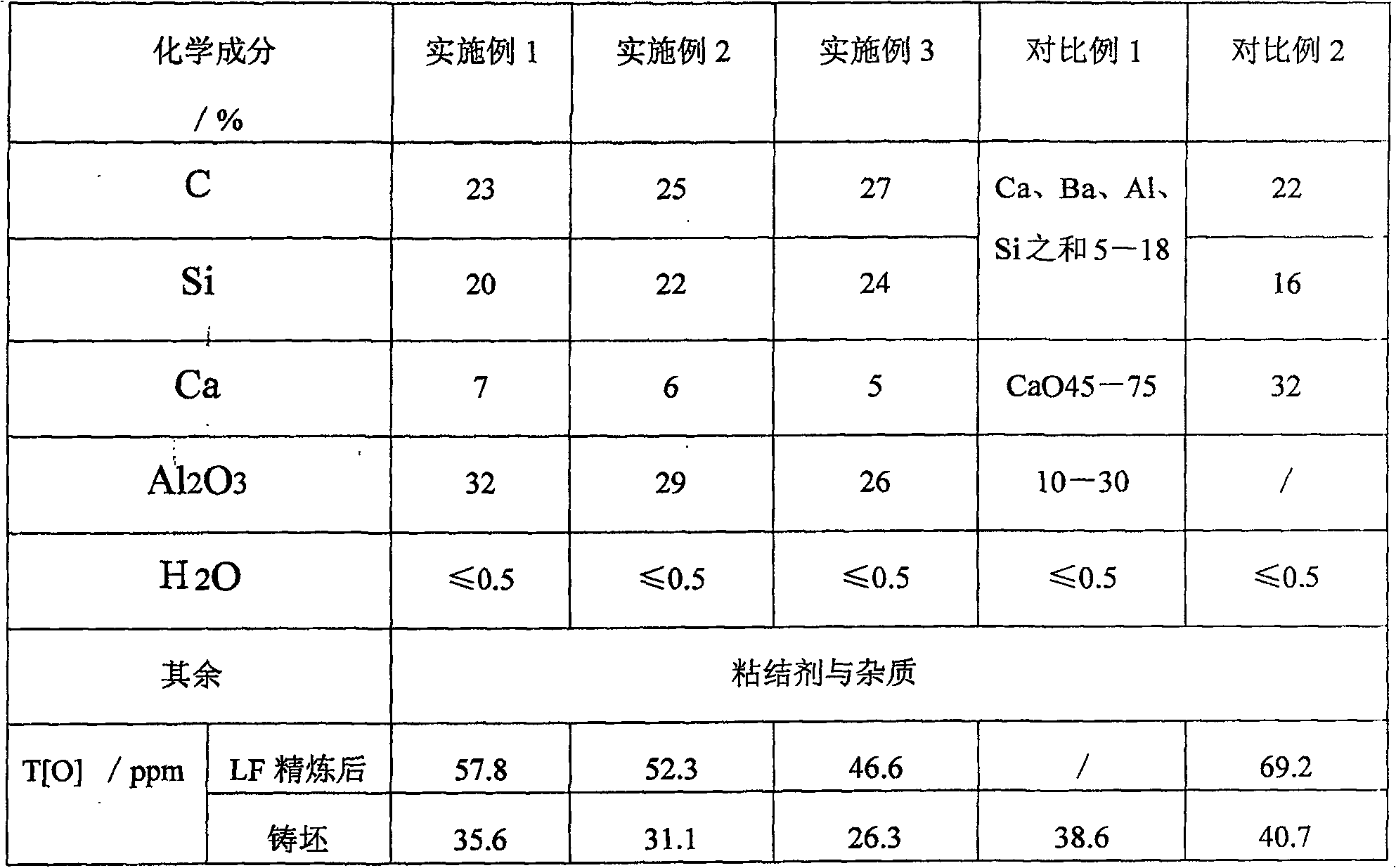

Molten steel composite purifying agent for secondary refining and preparing method

InactiveCN100547085CReduce the [O] content[O] content decreasedProcess efficiency improvementFerrosiliconManganese

The compound purificant of external refining of molten steel and production method pertains to the field of smelting ferroalloy, in particular to the purificant dislodging impurity of molten steel and the purificant production method in external refining. The purificant comprises graphite, ferrosilicon, calcium-silicon and bauxite, according to the percentage of weight, is composed of the following components: the carbon content is from 18 per cent to 32 percent, the content of silicon is from 15 percent to 26 percent, the content of iron is from 3 percent to 8 percent, the content of calcium is from 3 percent to 10 percent, the content of aluminum oxide is from 26 percent to 38 percent, the content of water is less than or equal to 0.75 percent, and the remainder is the impurity and adhesion agent. The method producing the compound purificant of molten steel includes these steps of matching material, crashing, mixing, grain-making, drying, checking, piling and bagging, the purificant becomes graininess, and the grain size ranges from 3 mm to 30 mm. The method has the advantages of the extensive material, the convenient machining, the safety and reliability in production, storage and use, the strong capability of purifying molten steel, the low oxygen content of molten steel, promoting slag foaming, favorable submerged-arc operating in fining furnace, improving the thermal efficiency and the ladle age, the excellent effect of desulfurize, improving the recycle rate of manganese and silicon, saving the use of alloy.

Owner:马鞍山中冶钢铁冶金高新技术有限公司

Stainless steel smelting method for improving content of MgO in slag of gas oxygen refining converter and LF (ladle furnace)

ActiveCN102912085BIncrease the content of MgOReduce erosionManufacturing convertersProcess efficiency improvementCalcium in biologySocial benefits

The invention discloses a stainless steel smelting method for improving the content of MgO in slag of a gas oxygen refining converter and an LF (ladle furnace). The method comprises the following steps: a, preparing a magnesium-calcium refractory material with particle size of 3-15mm and a magnesium-calcium refractory material with the particle size less than 3mm; b, adding the magnesium-calcium refractory material with the particle size of 3-15mm into the gas oxygen refining converter to serve as a bottom magnesium-calcium refractory material; adding the magnesium-calcium refractory material with the particle size of 3-15mm once more during the converting period I, so as to keep the content of MgO in the slag within 9-11%; c, during the smelting and slagging process of the refining LF, adding lime, a slagging agent and the magnesium-calcium refractory material with the particle size less than 3mm together, so as to control the content of MgO in the slag within 7-9%; and d, proceeding to the continuous casting procedure. The method disclosed by the invention can improve the content of MgO in the slag, at the same time, improves the content of CaO, reduces erosion to the furnace lining, and prolongs the furnace life of the converter as well as the ladle life of the LF. The method disclosed by the invention has low requirements on a crushing appliance, lowers the production cost, and has higher economic and social benefits.

Owner:SICHUAN JINGUANG IND GRP

A kind of steel ladle and its masonry method

The invention discloses a steel ladle. According to different erosion mechanisms and different erosion speeds of all zones inside the steel ladle, a ladle bottom working layer is arranged to be an impacting zone and a non-impacting zone, a ladle wall working layer is arranged to be a bath zone, a bath transition zone and a slag line zone, refractory material specifications of the ladle bottom working layer and the ladle wall working layer are adjusted accordingly, the thickness and height of a refractory material are increased in a zone with the higher erosion speed, an erosion transition beltis formed, the erosion speed of a serious erosion zone is decreased, meanwhile, a slow erosion zone can be indirectly protected, the overall service life of the steel ladle refractory material is prolonged, and the ladle life of the steel ladle is further prolonged effectively. The invention further discloses a construction method of the steel ladle. The using ladle life of the steel ladle constructed by the method can reach 48-55 furnace times, the turnover period of the steel ladle is increased while the ladle life of the steel ladle is prolonged, and the construction cost is reduced.

Owner:NANJING IRON & STEEL CO LTD

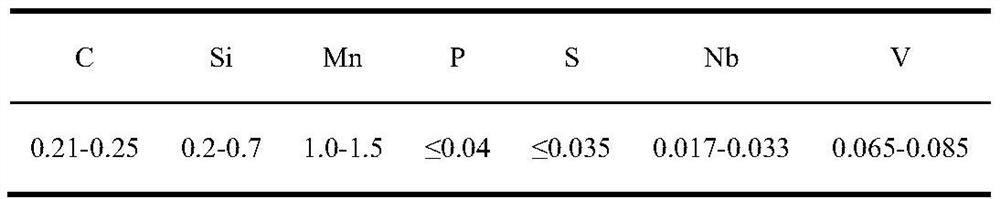

Method for reducing erosion rate of steel ladle slag line in production of deformed steel bar

PendingCN114535555AReduce erosion rateGood foaming effectMelt-holding vesselsProcess efficiency improvementBrickSlag

According to the method for producing the deformed steel bar and reducing the erosion rate of the steel ladle slag line, the content of Al2O3 in steel ladle top slag is controlled to be about 15%, the content of MgO is controlled to be about 10%, the content of (FeO + MnO) is controlled to be 2.6% or below, the alkalinity (CaO / SiO2) is controlled to be 1.8-2.0, the foaming performance of the steel ladle top slag can be effectively improved, the submerged arc effect is improved, and the service life of the steel ladle top slag is prolonged. The heating rate is increased, the smelting period is shortened, and the influence of electric arc on slag line bricks is reduced. In addition, by increasing the content of MgO, the solution loss rate of magnesia in the slag line magnesia carbon brick can be effectively inhibited, the erosion rate of the slag line brick is reduced, and the ladle life of a steel ladle is prolonged.

Owner:广西钢铁集团有限公司 +1

Ladle covering agent prepared through utilizing blast furnace slag

ActiveCN103173592BImprove reducibilityNo carbon increaseProcess efficiency improvementSlagSolid particle

The invention provides a ladle covering agent prepared through utilizing blast furnace slag. The ladle covering agent is composed of 30-40 parts by weight of blast furnace slag, 26.7-40 parts by weight of limestone, 15-20 parts by weight of vermiculite and 5-15 parts by weight of fluorite, wherein the total weight part of the above raw materials is 100. The main raw materials of the ladle covering agent have the advantages of low cost, suitable melting point, short fusing time and good spreadability; and limestone decomposes at 800-1200DEG C, foams and expands, vermiculite expands at a high temperature, and the friction force among solid particles is lower than the inner friction force among powders, so the spreadability and the heat insulating property are good. The ladle covering agent can prevent the secondary oxidation and too large temperature decrease of molten steel, and has a certain impurity adsorption and inclusion capability to purify the molten steel because of the appropriate alkalinity. The ladle covering agent has no carbon, does not carburize the molten steel, and is in favor of the component control of the production process.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

Anti-erosion aluminum-magnesium castable

InactiveCN111548129AImprove high temperature performanceImprove anti-scourabilityMelt-holding vesselsCeramicwareFiberSodium phosphates

The invention relates to an anti-erosion aluminum-magnesium castable comprising the following raw materials in parts: 85 high-aluminum materials, 88 high-aluminum materials, self-supporting tabular corundum, fused magnesite, magnesium aluminate spinel, aluminum oxide micro-powder, silicon micro-powder, nano carbon black, an anti-erosion agent ACAO, explosion-proof fibers, a water reducing agent and sodium hexametaphosphate. The anti-erosion aluminum-magnesium refractory castable disclosed by the invention is excellent in application and construction performance on a steel ladle, is easy to construct and shape, and can meet the requirements of no cracking during demolding and baking, scouring erosion resistance, oxidation resistance and ladle life improvement; a formed steel ladle is not subjected to secondary repair, the steel passing amount reaches 12,000 tons or more, the castable can be continuously used after sleeve beating and pouring, and the anti-erosion aluminum-magnesium castable has the characteristics of high scouring erosion resistance, long service life and the like, and has a good application prospect.

Owner:TANGSHAN GUOLIANG SPEICAL REFRACTORY MATERIAL

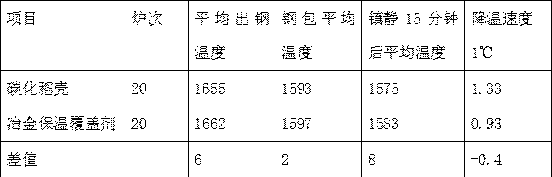

Molten steel heat preservation covering agent capable of achieving heat supplementing

ActiveCN113337670ASatisfy process needsCost controlProcess efficiency improvementSteelmakingLithium oxide

The invention discloses a molten steel heat preservation covering agent capable of achieving heat supplementing. The covering agent is a first-layer covering agent or comprises the first-layer covering agent and a second-layer covering agent at the same time, wherein the first-layer covering agent is composed of one or more of dry quenching furnace fly ash, blast furnace fly ash or coke screen underflow, and further comprises expanded perlite, expanded vermiculite, aluminum silicate fibers, dolomite and ferrosilicon powder; and the second-layer covering agent is composed of one or more of light-burned dolomite, lime, lithium peroxide or sodium peroxide, boron nitride, magnesium hydroxide or magnesium borate. The covering agent for hot metal ladles, steel ladles and tundishes is provided to overcome the limitation that due to the fact that an existing covering agent is poor in heat preservation performance, the temperature of molten iron and molten steel is greatly reduced, and the surfaces are prone to crusting; and the requirement of the steelmaking technology is met.

Owner:武汉钢铁有限公司

Cast steel riser covering agent as well as preparation and using method thereof

The invention belongs to the field of metallurgy, and relates to a cast steel riser covering agent as well as a preparation and using method thereof. The cast steel riser covering agent comprises thefollowing components of, with the total mass units being 100 parts, 15-40 parts of aluminum electrolysis waste cathode carbon block, 10-35 parts of dolomite, 10-25 parts of vermiculite, and 20-40 parts of aluminum electrolysis waste silicon carbide-silicon nitride bricks. During preparing, firstly, crushing and grinding the dried raw materials, wherein the particle size is not more than 2 mm; weighing the raw materials according to the composition quality of the raw materials, uniformly stirring, and drying to obtain the cast steel riser covering agent. During using, a steel ladle is added into the cast steel riser covering agent to form a slag layer, so that the thickness of the slag layer is 6-8 cm, the liquid surface of the steel ladle does not leak red, and the slag layer is not crusted. By using the cast steel riser covering agent, the heat loss at the top of the riser can be solved, the solidification speed of molten steel in the riser can be prolonged, the feeding capacity of the molten steel in the riser is improved, the process yield of the casting is guaranteed, the height of the riser is reduced, the molten steel is saved, and finally the cost is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Alkaline granule steel ladle covering agent

InactiveCN1151901CLow fixed carbon contentLow Reducible Oxide ContentProcess efficiency improvementMetallurgyMolten steel

The composition of coverflux contains (wt) SiO2 10%-20%, Al2O3 1%-5%, CaO 50%-60%, MgO 5%-12%, Fe2O3 1%-3%, MnO 0.01%-0.1% and fixed carbon 0%-1%. Said coverflux possesses proper melting point and good heat-insulating property, can prevent secondary oxidation of molten steel, and can prolong ladle life.

Owner:上海宝谊保温材料有限公司

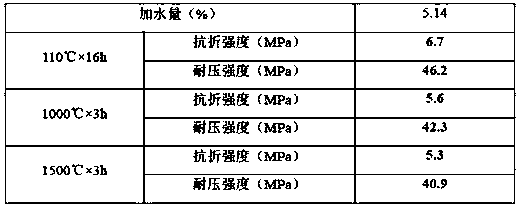

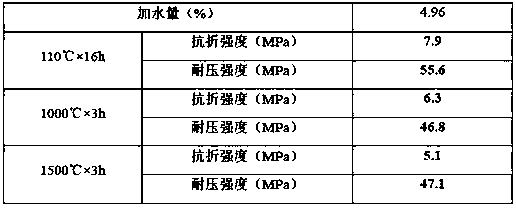

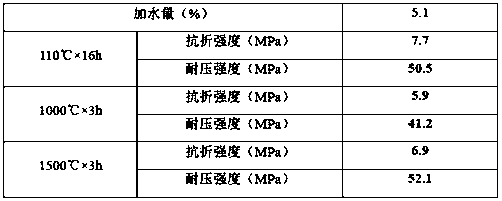

Method for preparing ladle liner permanent layer by adopting perlite composite insulation board

The invention relates to a method for preparing a ladle liner permanent layer by adopting a perlite composite insulation board, which comprises the preparation of a perlite composite insulation board and the arrangement of the perlite composite insulation board on a ladle shell inner wall. The method for preparing the perlite composite insulation board comprises the following steps of: (1) evenlymixing 1 percent by weight of expanded perlite, 0.3-1.2 percent by weight of adhesive and 0.02-0.06 percent by weight of fiber materials under the stirring condition to obtain a mixture; and (2) putting the mixture in a die; pressuring and smoothening the surface; and then, hardening at 15-110 DEG C for 0.2-24h to obtain a perlite composite insulation board. The perlite composite material of the invention adopts environment-friendly natural materials which are nontoxic, tasteless and taintless and have low production cost, low price and good insulation performance; and the insulation board has the advantages of light capacity weight, small conductive coefficient, good stability, strong strength, convenient construction, and the like.

Owner:湖北兴冶特钢实业发展有限公司

Ladle neck bush pouring technique

The invention discloses a ladle lining casting technology, which comprises the following steps: 1) detaching ladle slag brick, cleaning slag on the ladle wall working layer, reacting layer and deteriorated layer, 2) placing the mould to locate, 3) casting between mould and ladle wall with the same material as working layer, 4) stripping after health preserving, 5) toasting.

Owner:崔东瑞

Method for prolonging service life of steel ladle slag line bricks

The invention discloses a method for prolonging the service life of steel ladle slag line bricks. The adopted control method comprises the steps that the thickness of the slag line bricks on the firstlayer to the sixth layer is changed and designed into 210 mm; the thickness of the slag line bricks on the seventh layer is maintained as originally designed 230 mm; the thickness of the slag line bricks on the eighth layer to the twelfth layer is changed and designed into 250 mm; the thickness of the slag line bricks on the seventh layer is maintained as originally designed 230 mm; and the thickness of the slag line bricks on the fourteenth layer is maintained as originally designed 210 mm. By means of the method, on the premise of guaranteeing that the volume of a steel ladle is not changed, that is, the tapping amount of a converter is not changed, the corrosion speed of the slag line bricks is reduced, the use number of the slag line bricks is effectively improved, and the ladle age is increased.

Owner:SD STEEL RIZHAO CO LTD

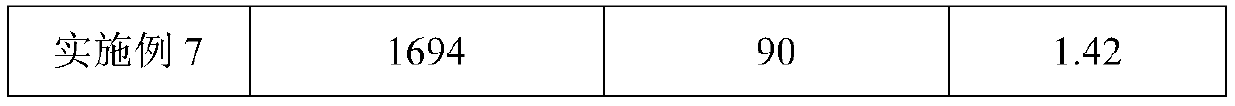

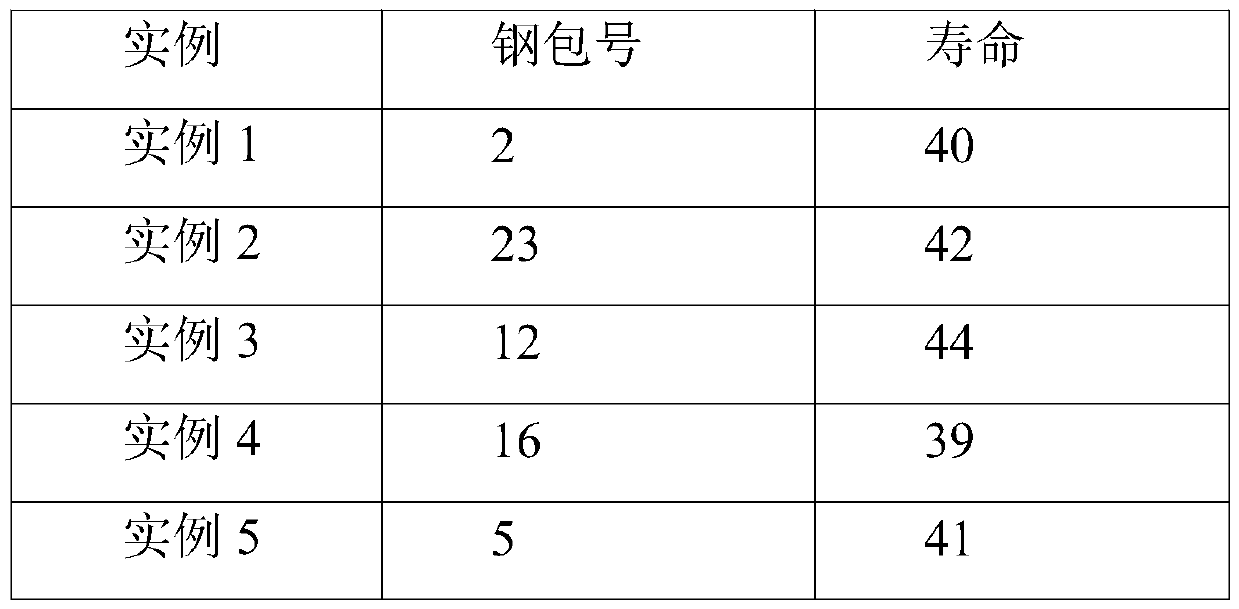

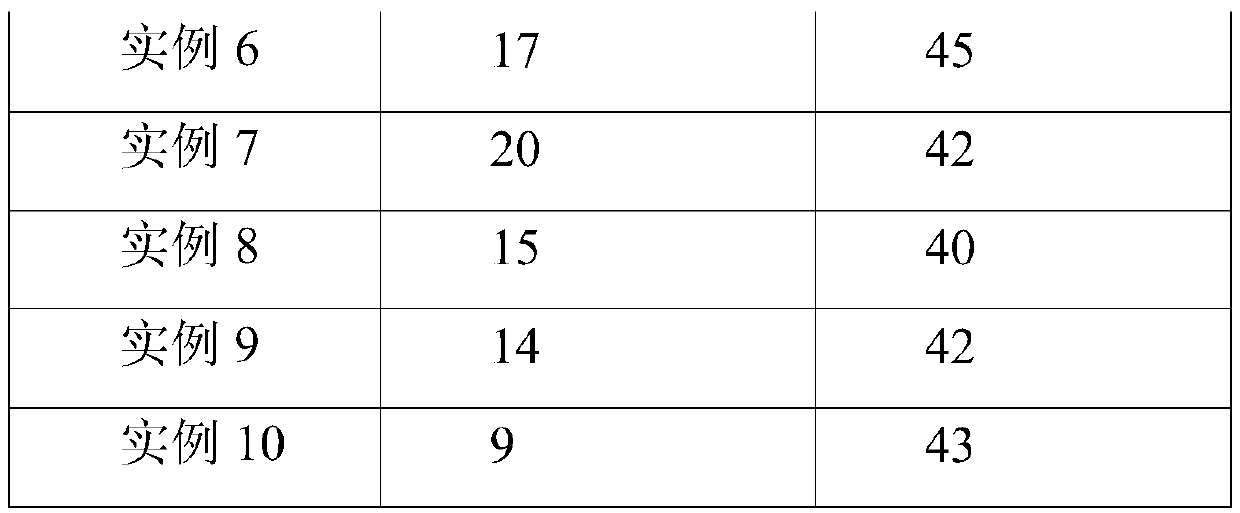

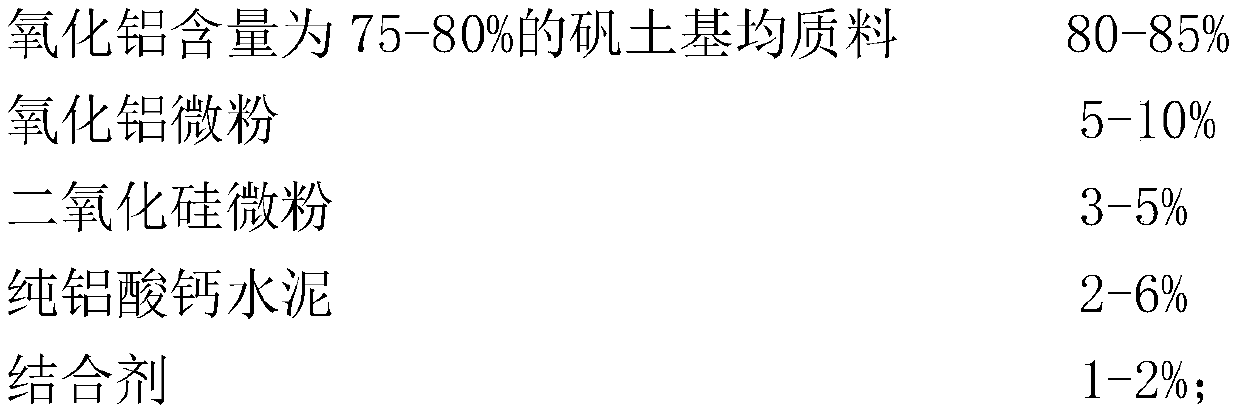

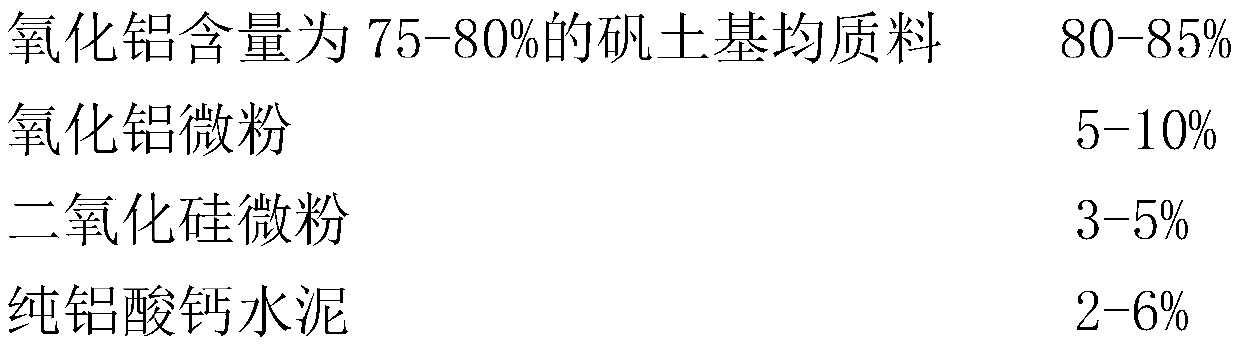

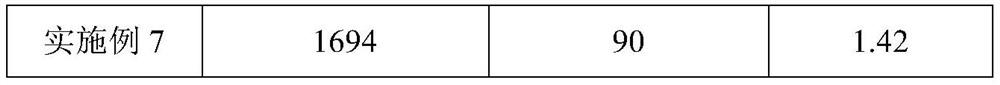

Steel ladle castable taking alumina-based homogenized material as matrix

PendingCN111348901AIncrease package ageSolve crackingMelt-holding vesselsSilicon dioxideCalcium aluminates

The invention relates to the technical field of refractory castables, and specifically to a steel ladle castable taking alumina-based homogenized material as matrix. The steel ladle castable is prepared by taking the alumina-based homogenized material with the alumina content of 75-80% as an aggregate, and alumina micro-powder, silicon dioxide micro-powder, pure calcium aluminate cement and a binding agent as auxiliary materials, and the content of the alumina-based homogenized material with the particle size larger than 8 mm and smaller than or equal to 25 mm is smaller than or equal to 5%. And the particle size of the binding agent is controlled below 1mm. According to the invention, a raw material grading control technology is combined with a superfine powder technology; the grain composition of the homogeneous material, especially the amount of large particles, is adjusted, so that the overall erosion resistance of the castable is improved, the overall ladle life of a steel ladle is prolonged, the ladle life of an existing steel ladle is prolonged from 110 times to 160 times or above, and more benefits of 4000-6000 tons of steel are brought to users.

Owner:李向威

Molten steel composite purifying agent for secondary refining and preparing method

InactiveCN101157964AReduce the [O] content[O] content decreasedProcess efficiency improvementFerrosiliconManganese

The compound purificant of external refining of molten steel and production method pertains to the field of smelting ferroalloy, in particular to the purificant dislodging impurity of molten steel and the purificant production method in external refining. The purificant comprises graphite, ferrosilicon, calcium-silicon and bauxite, according to the percentage of weight, is composed of the following components: the carbon content is from 18 per cent to 32 percent, the content of silicon is from 15 percent to 26 percent, the content of iron is from 3 percent to 8 percent, the content of calcium is from 3 percent to 10 percent, the content of aluminum oxide is from 26 percent to 38 percent, the content of water is less than or equal to 0.75 percent, and the remainder is the impurity and adhesion agent. The method producing the compound purificant of molten steel includes these steps of matching material, crashing, mixing, grain-making, drying, checking, piling and bagging, the purificant becomes graininess, and the grain size ranges from 3 mm to 30 mm. The method has the advantages of the extensive material, the convenient machining, the safety and reliability in production, storage and use, the strong capability of purifying molten steel, the low oxygen content of molten steel, promoting slag foaming, favorable submerged-arc operating in fining furnace, improving the thermal efficiency and the ladle age, the excellent effect of desulfurize, improving the recycle rate of manganese and silicon, saving the use of alloy.

Owner:马鞍山中冶钢铁冶金高新技术有限公司

Cap agent with light alkaline particle steel coating

InactiveCN100446895CLow in Reducible OxidesLow bulk specific gravityProcess efficiency improvementChemical reactionRefractory

Owner:上海宝谊保温材料有限公司

Metallurgy heat preservation covering agent

InactiveCN111154950AImprove isolationImprove cleanlinessProcess efficiency improvementSlagMolten steel

The invention relates to a metallurgy heat preservation covering agent. The metallurgy heat preservation covering agent is divided into alkaline and acidic types. The alkaline covering liquid comprises the following components of, in percentage by weight, 30%-40% of CaO, 15%-20% of SiO<2>, 10%-20% of Al<2>O<3>, 7%-10% of Na<2>O, 10%-15% of C, 5%-7% of MgO, 0.5%-1% of Fe<2>O<3>, 3%-4% of an expanding agent, 4%-5% of an exothermic agent, and the balance impurities; and the acidic covering agent comprises the following components of, in percentage by weight, 20%-30% of CaO, 30%-50% of Al<2>O<3>,5%-10% of MgO, less than 5% of CaF<2>, 40%-50% of C, 4%-5% of the expanding agent, 2%-4% of exothermic agent and the balance impurities. The metallurgy heat preservation covering agent can prevent secondary oxidation of molten steel, adsorb inclusion floating on the molten steel, does not react with the molten steel, avoid pollution of the molten steel, does not erode the alkaline ladle lining, does not generate slag bonding or form nodules in use, improves the cleanliness of a steel ladle, is favorable for ladle slag turning, simultaneously solves the problems of difficulty in slag turning, is easy to disassembly, reduces labor intensity of workers, and is also favorable for improving ladle life.

Owner:高英

A device for measuring the internal dimensions of a steel ladle using a laser range finder and its operating method

ActiveCN111238411BIncrease purchase costReduce cost of measurementUsing optical meansElectromagnetic wave reradiationLaser rangingRefractory

Owner:TANGSHAN GUOLIANG SPEICAL REFRACTORY MATERIAL

Ladle lidding device

The invention provides a ladle lidding device, and belongs to heat preservation technologies of a ladle. The ladle lidding device comprises an inner hood, an outer hood and a suspending hook; the internal shape of the inner hood coincides with the shape of a ladle opening, and the inner hood is used for covering the ladle opening; the internal shape of the outer hood coincides with the external shape of the inner hood, the edge of the outer hood is connected with that of the inner hood, and a sealed sandwich layer space is formed between the inner hood and the outer hood; the suspending hook is arranged on the outer hood and is used for suspending the ladle lidding device. The ladle lidding device has the advantages that through the principle that the air heat conducting coefficient is small, the ladle lidding device is manufactured, loss of molten iron heat energy is effectively lowered, the steel output temperature is increased, and the steel quality is improved; a desulfurization reaction is easily conducted, the consumption of active lime is reduced, and the cost is lowered; cracking caused by the stress of a refractory material is reduced, the service life of the refractory material is prolonged, and the service life of the ladle is prolonged.

Owner:DAYE SPECIAL STEEL CO LTD

A kind of slag removal device for ladle

The invention provides a technical scheme of a slag removing device for a ladle. The slag removing device comprises a pressing mechanism for tightly pressing a ladle body and a slag hooking mechanism for removing bonded slag in the ladle, wherein the pressing mechanism comprises rotatable supports, each rotatable support is formed by fixed connection of at least two sections of support arms, the support arms located at two ends of each rotatable support are hinged to and connected with a cylinder rod and a cylinder body of each rotatable oil cylinder respectively, and the support arm at one end of each rotatable support tightly presses a trunnion seat of the ladle during working; the slag hooking mechanism comprises a movable support driven by a movable support driving mechanism to move, and hooks for hooking and removing the bonded slag in the ladle are fixed at the lower part of the movable support. According to the slag removing device, the pressing mechanism presses and fixes the ladle in a cleaning pit, and meanwhile, movable oil cylinders are started to drive the hooks, so that the bonded slag in the ladle is removed.

Owner:SHANDONG IRON & STEEL CO LTD

A kind of casting steel riser covering agent and its preparation and use

The invention belongs to the field of metallurgy, and relates to a cast steel riser covering agent and its preparation and use method. The cast steel riser covering agent includes 15 to 40 parts of aluminum electrolysis waste cathode carbon blocks in 100 parts by mass, 10-35 parts of dolomite, 10-25 parts of vermiculite, 20-40 parts of waste silicon carbide-silicon nitride bricks for aluminum electrolysis; during preparation, the dried raw materials are first crushed and ground, and the particle size is not greater than 2mm; Then weigh each raw material according to the composition quality of the raw materials, then stir evenly, and dry to obtain the casting steel riser covering agent. When in use, the cast steel riser covering agent is added to the ladle to form a slag layer, and finally the thickness of the slag layer is 6-8 cm, the liquid surface of the ladle does not leak red, and the slag layer does not crust. By using the casting steel riser covering agent of the present invention, the heat loss at the top of the riser can be solved, and the solidification speed of the molten steel in the riser can be extended, thereby improving the feeding capacity of the molten steel in the riser, ensuring the process yield of castings, and reducing the risk of leakage. The height of the mouth can save molten steel and ultimately reduce the cost.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Tundish covering agent prepared by using blast furnace slag

ActiveCN103170592BIncrease package ageModerate alkalinityRecycling and recovery technologiesAlkalinitySlag

The invention provides a tundish covering agent prepared by using blast furnace slag. The tundish covering agent prepared by using the blast furnace slag comprises the following raw materials, by 100 parts of weight, 30-45 parts of the blast furnace slag, 24.7-40 parts of limestone, 10-20 parts of vermiculite and 10 -20 parts of fluorite. Primary raw materials adopted by the tundish covering agent prepared by using the blast furnace slag are low in cost, appropriate in melting points, short in melting time, and excellent in spreadability and heat retaining property. The tundish covering agent prepared by using the blast furnace slag can prevent molten steel from being secondarily oxidized and temperature drop from being too much, meanwhile, the tundish covering agent prepared by using the blast furnace slag has certain absorption mixing performance, can purify the molten steel, and improves inner quality of casting blank; no carbon exists in the tundish covering agent prepared by using the blast furnace slag, alkalinity is appropriate, recarburization is not generated to the molten steel, alkalinity-resisting materials of a tundish is not corroded, and service life of the tundish is prolonged.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com