A kind of steel ladle and its masonry method

A masonry and steel ladle technology, which is applied to metal processing equipment, manufacturing tools, casting molten material containers, etc., can solve the problems of tight supply of ladles, low use requirements, centralized off-line and other problems, and achieve slow erosion, prolong service time, Improve the effect of package age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

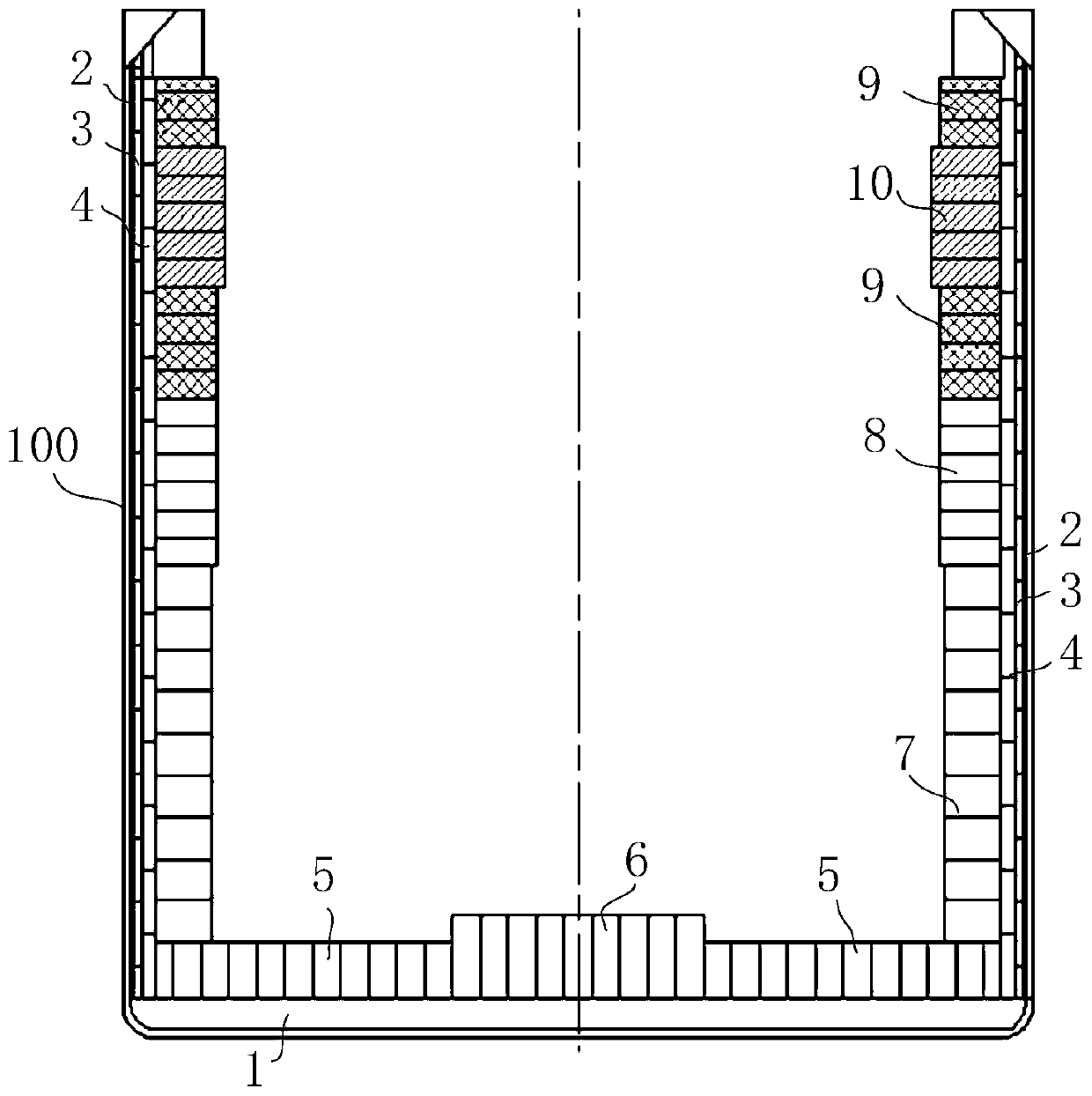

[0019] Below in conjunction with accompanying drawing, take masonry 110 ton ladle as example, the realization mode of the present invention is described further.

[0020] like figure 1 First paste the insulation layer 2, in the fully dismantled ladle 100, stick the insulation layer 2 close to the inner wall with an adhesive, beat the insulation layer 2 evenly with tools such as a small hammer, so that it is closely combined with the inner wall. Compared with silicate heat insulation boards, ceramic heat insulation boards for insulation layer 2 have a better insulation effect, and the thickness of insulation layer 2 is controlled at 10mm, that is, the thickness of ceramic heat insulation boards is 10mm.

[0021] Then pour the bottom permanent layer 1 at the bottom of the ladle. Because the corundum castable has high temperature resistance strength after solidification, it can significantly improve the safety of the bottom of the ladle. Therefore, the permanent layer 1 of the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com