Anti-erosion aluminum-magnesium castable

A castable, anti-erosion technology, used in applications, household appliances, casting melt containers, etc., can solve the problem of not greatly increasing the amount of water added, and achieve good corrosion resistance, improved corrosion resistance, and easy construction. The effect of forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An anti-corrosion aluminum-magnesium castable is made of the following raw materials:

[0029] 85 high aluminum material 8-15mm: 18 parts; 85 high aluminum material 5-8mm: 12 parts; 85 high aluminum material 3-5mm: 15 parts; 85 high aluminum material 1-3mm: 15 parts;

[0030] 88 high aluminum material 0-1mm: 10 parts;

[0031] Self-supporting tabular alumina 200 mesh: 11 parts;

[0032] Magnesium aluminum spinel powder: 4 parts;

[0033] 96 fused high-purity magnesia 200 mesh: 6 parts;

[0034] Active Al 2 o 3 Micropowder (CL370): 5 parts;

[0035] Silica powder (951): 3 parts;

[0036] Carbon black N330: 0.5 parts;

[0037] Antioxidant ACAO: 0.5 parts;

[0038] 0.1 part of explosion-proof fiber;

[0039] 0.05 parts of sodium hexametaphosphate;

[0040] ABC 0.1 part.

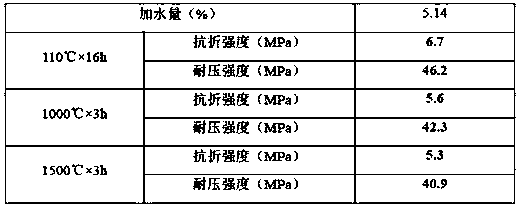

[0041] The performance testing method adopted is carried out in accordance with the current national standards or industry standards. The test results obtained are shown in Table 1. The above-m...

Embodiment 2

[0045] An anti-corrosion aluminum-magnesium castable is made of the following raw materials:

[0046] 85 high aluminum material 8-15mm: 20 parts; 85 high aluminum material 5-8mm: 10 parts; 85 high aluminum material 3-5mm: 14 parts; 85 high aluminum material 1-3mm: 14 parts;

[0047] 88 high aluminum material 0-1mm: 12 parts;

[0048] Self-supporting tabular alumina 200 mesh: 10.7 parts;

[0049] Magnesium aluminum spinel powder: 5 parts;

[0050] 96 fused high-purity magnesia 200 mesh: 4 parts;

[0051] Active Al 2 o 3 Micropowder (CL370): 6 parts;

[0052] Silica powder (951): 2.5 parts;

[0053] Carbon black N330: 1 part;

[0054] Antioxidant ACAO: 0.8 parts;

[0055] 0.1 part of explosion-proof fiber;

[0056] Sodium hexametaphosphate 0.05 part, ABC 0.15 part.

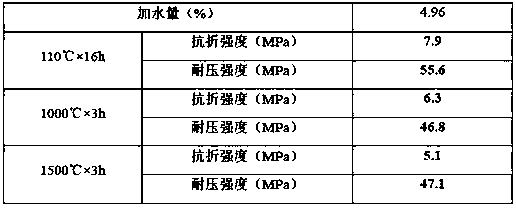

[0057] The performance test method adopted is carried out in accordance with the current national standards or industry standards. The test results obtained are shown in Table 2. The above-mentioned castab...

Embodiment 3

[0061] An anti-corrosion aluminum-magnesium castable is made of the following raw materials:

[0062] 85 high aluminum material 8-15mm: 22 parts; 85 high aluminum material 5-8mm: 8 parts; 85 high aluminum material 3-5mm: 15 parts; 85 high aluminum material 1-3mm: 15 parts;

[0063] 88 high aluminum material 0-1mm: 12 parts;

[0064] Self-supporting tabular alumina 200 mesh: 6 parts;

[0065] Magnesium aluminum spinel powder: 6 parts;

[0066] 96 fused high-purity magnesia 200 mesh: 6 parts;

[0067] Active Al 2 o 3 Micropowder (CL370): 6 parts;

[0068] Silica powder (951): 2 parts;

[0069] Carbon black N330: 1 part;

[0070] Antioxidant ACAO: 1 part;

[0071] Explosion-proof fiber 0.15 parts;

[0072] Sodium hexametaphosphate 0.05 part, ABC 0.15 part.

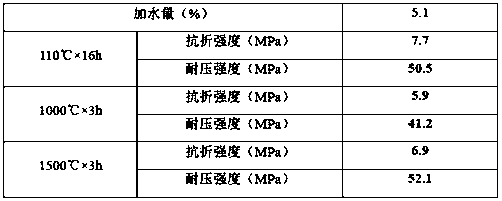

[0073] The performance test method adopted is carried out in accordance with the current national standards or industry standards. The test results obtained are shown in Table 3. The above-mentioned castables are us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com