Metallurgy heat preservation covering agent

A thermal insulation covering agent and covering agent technology are applied in the field of steelmaking, ironmaking and casting, which can solve the problems of poor operating environment for workers, inability to spread quickly, poor thermal insulation effect, etc., so as to reduce the labor intensity of workers and solve the difficulty of turning slag. , dust and small flame effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

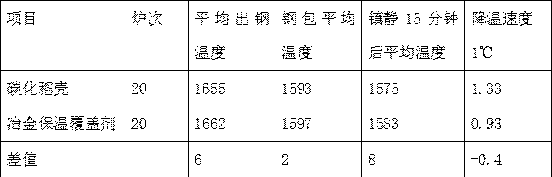

Image

Examples

Embodiment 1

[0016] The metallurgical thermal insulation covering agent is an alkaline covering agent, which contains 30% Ca0 and 15% SiO by weight percentage 2 , 10% Al 2 o 3 , 7%-Na 2 O, 10% C, 5% MgO, 0.5% Fe 2 o 3 , 3% expansion agent, 4% heating agent, and the rest of impurities, the melting point is 1190 ° C, the melting speed is 70-80 seconds, and the alkalinity is 0.4-0.5.

Embodiment 2

[0018] The metallurgical thermal insulation covering agent is an alkaline covering agent, which contains 35% Ca0 and 17% SiO by weight percentage 2 , 15% Al 2 o 3 , 8.5% Na 2 O, 12.5% C, 6% MgO, 0.75% Fe 2 o 3 , 3.5% expansion agent, 4.5% heating agent, and the rest of impurities, the melting point is 1300 ° C, the melting speed is 75 seconds, and the alkalinity of the alkaline covering agent is 0.45.

Embodiment 3

[0020] Metallurgical thermal insulation covering agent, the metallurgical thermal insulation covering agent is an alkaline covering agent, containing 340% Ca0 and 20% SiO by weight percentage 2 , 20% Al 2 o 3 , 10% Na 2 O, 15% C, 7% MgO, 1% Fe 2 o 3 , 4% expansion agent, 5% heat generating agent, and the rest of impurities, the melting point is 1421°C, the melting speed is 80 seconds, and the alkalinity is 0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com