Method for reducing erosion rate of steel ladle slag line in production of deformed steel bar

A ladle slag line and rebar technology, applied in the field of metallurgy, can solve the problems of reducing the ladle slag line erosion rate, increasing the ladle slag line erosion rate, and increasing the risk of ladle leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

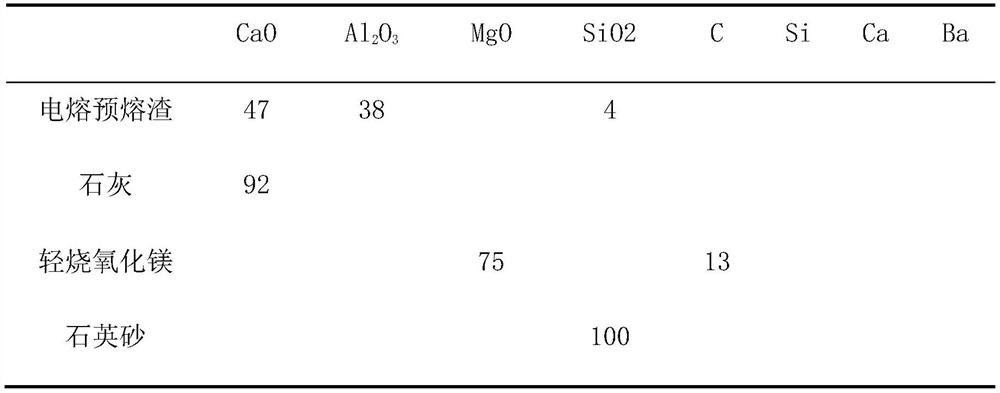

Method used

Image

Examples

example 1

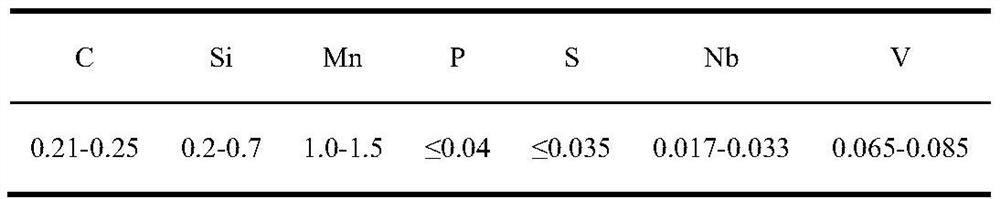

[0020] Example 1: In the first half of April 2021, the process path for producing rebar BOF-AR-LF-CC (BOF-converter, AR-argon station, LF-ladle refining furnace, CC-continuous caster), ladle top slag (FeO +MnO) content of 4.1%, Al 2 O 3 The content is 7.7%, the MgO content is 8%, the basicity (CaO / SiO2) is 1.37, the erosion rate of the ladle slag line brick is 4.7mm / furnace, and the heating rate is 2.2℃ / min. The composition of molten steel is shown in Table 2

[0021] Table 2 Molten steel composition table (unit wt%)

[0022]

[0023] (The conventional production process of rebar is BOF-AR-CC. Under this process condition, the tapping temperature of the converter needs to be high (1640-1660 ° C), and the heat of the converter is seriously insufficient under the condition of low molten iron ratio. If the tapping temperature is increased to 1640 -1660℃, all the consumption indicators of the converter and the safety of furnace conditions will be greatly affected, and the ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com