Nano silica sol combination hearth self-flowing material and preparation method thereof

A nano-silica sol, self-flowing material technology, applied in the field of refractory materials, can solve the problems of poor integrity, poor corrosion resistance, thermal conductivity mismatch, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

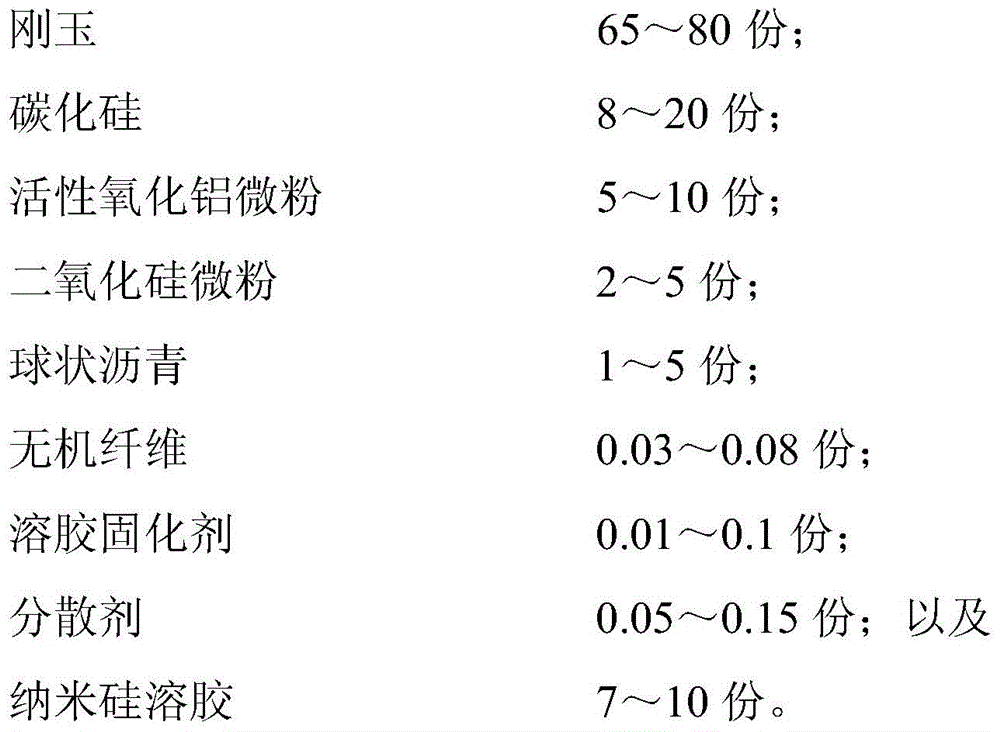

Method used

Image

Examples

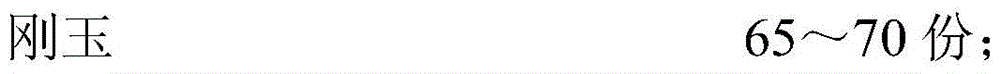

Embodiment 1

[0053] The preparation process of the described nano-silica sol combined with hearth self-flowing material is as follows:

[0054]In the high-efficiency forced mixing equipment, set the stirring time to 5-8 minutes, the rotor speed to 500 rpm, and the turntable speed to 180 rpm. At room temperature, add 80.0 parts of brown corundum, 10.0 parts of silicon carbide, 5.0 parts of activated alumina micropowder, 3.0 parts of silica micropowder, 2.0 parts of spherical pitch, 0.05 part of inorganic fiber, 0.02 parts of sol curing agent, 0.05 parts of dispersant, uniformly mixed, then added 7.0 parts of nano-silica sol, after uniform mixing to obtain the nano-silica sol combined hearth self-flowing material of the present invention.

Embodiment 2

[0056] The preparation process of the described nano-silica sol combined with hearth self-flowing material is as follows:

[0057] In the high-efficiency forced mixing equipment, set the stirring time to 5-8 minutes, the rotor speed to 500 rpm, and the turntable speed to 180 rpm. At room temperature, add 75.0 parts of brown corundum, 15.0 parts of silicon carbide, 5.0 parts of activated alumina micropowder, 3.0 parts of silica micropowder, 2.0 parts of spherical pitch, 0.05 part of inorganic fiber, 0.02 parts of sol curing agent, 0.05 parts of dispersant, uniformly mixed, then added 7.4 parts of nano-silica sol, after uniform mixing to obtain the nano-silica sol combined hearth self-flowing material of the present invention.

Embodiment 3

[0059] The preparation process of the described nano-silica sol combined with hearth self-flowing material is as follows:

[0060] In the high-efficiency forced mixing equipment, set the stirring time to 5-8 minutes, the rotor speed to 500 rpm, and the turntable speed to 180 rpm. At room temperature, add 72.0 parts of brown corundum, 15.0 parts of silicon carbide, 8.0 parts of activated alumina micropowder, 3.0 parts of silica micropowder, 2.0 parts of spherical pitch, 0.05 part of inorganic fiber, 0.02 parts of sol curing agent, 0.05 parts of dispersant, uniformly mixed, then added 7.5 parts of nano-silica sol, after uniform mixing to obtain the nano-silica sol combined hearth self-flowing material of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com