Composite long-life low-cost steel ladle air brick base brick and manufacturing method thereof

A breathable brick and composite technology, which is applied in the field of steel-making refractories, can solve the problems of reduced production cost, low service life, aggravated erosion of breathable bricks and breathable brick base bricks, etc., and achieves the effect of reducing production cost and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

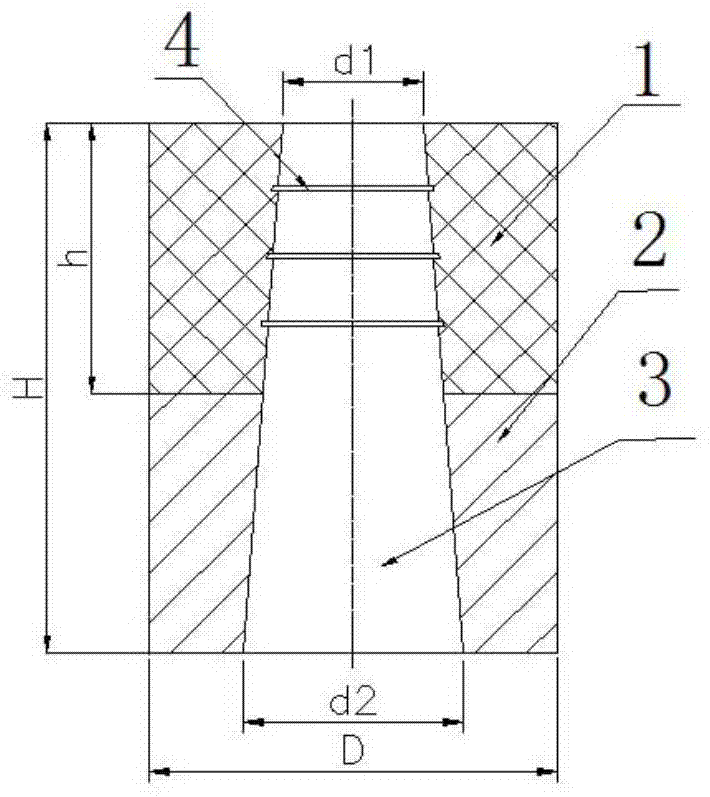

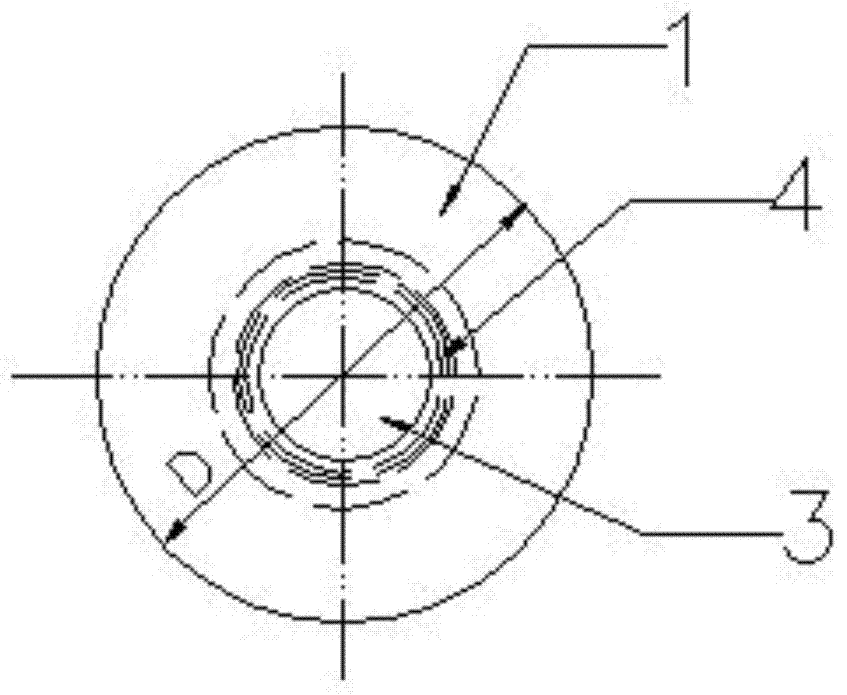

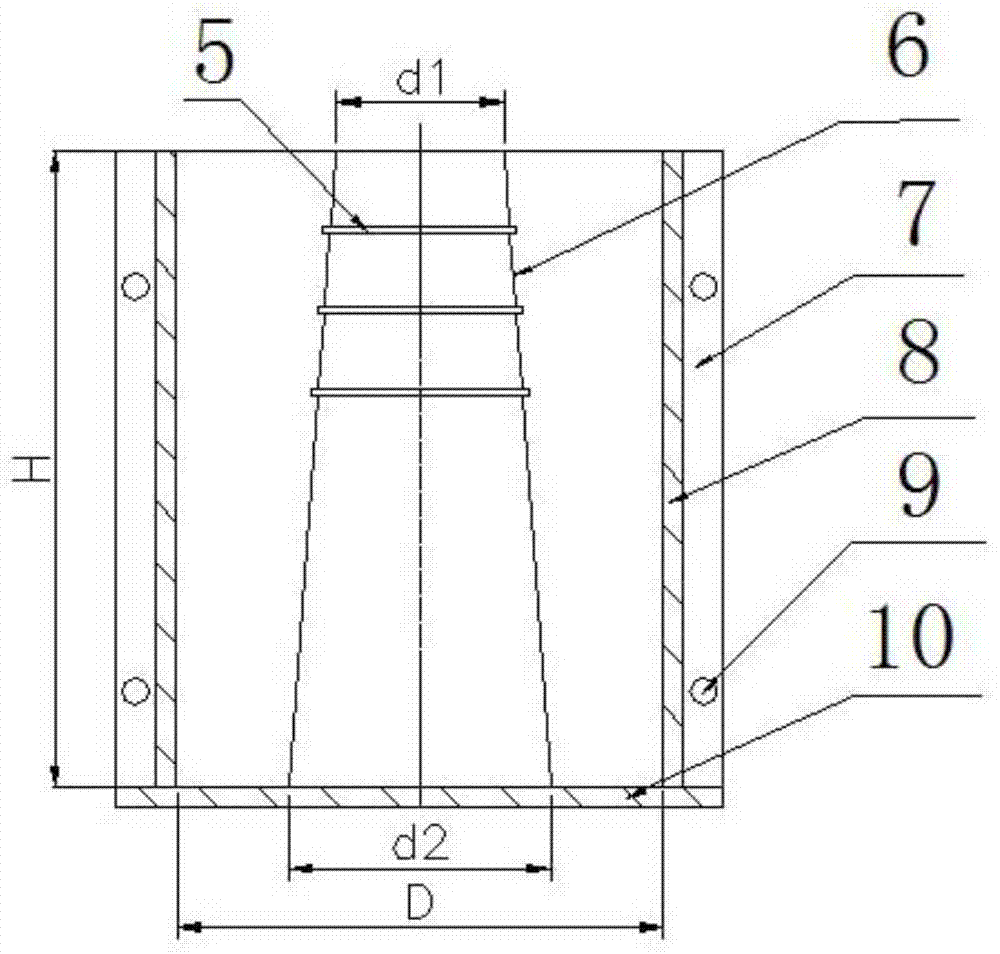

[0056] A composite high-life, low-cost ladle permeable brick seat brick, the structure of which is as follows figure 1 , 2 As shown, including the seat brick body, the seat brick body is cylindrical as a whole, and the middle part of the seat brick body is provided with a mounting hole 3 passing through the seat brick body. The lower port diameter d2 is 195mm. The block body includes an upper body 1 and a lower body 2. The upper body 1 and the lower body 2 are formed by one-time casting with different castable materials. The upper body 1 is casted with high-purity chromium magnesium mullite corundum castable. h is 300mm, the lower body 2 is casted with chrome magnesium mullite corundum castable, the inner wall of the upper body is horizontally provided with grooves 4 uniformly distributed along the height direction along the circumferential direction, the number of grooves 4 is 5, and the depth of the grooves 4 is Consistent with the width, both are 6mm.

[0057] The outer ...

Embodiment 2

[0081] A composite high-life, low-cost ladle permeable brick seat brick, the same as Example 1, the difference lies in:

[0082] The diameter d1 of the upper port of the truncated cone is 150mm, and the diameter d2 of the lower port of the truncated cone is 220mm. The block body includes an upper body 1 and a lower body 2. The height h of the upper body 1 is 260 mm. The inner wall of the upper body is horizontally provided with grooves 4 uniformly distributed along the height direction along the circumferential direction. There are 3 grooves 4 and 4 grooves. The depth and width are the same, both are 10mm.

[0083] The high-purity chrome-magnesium-mullite corundum castable used in the upper body, the raw material components are as follows, all in percent by weight: 18% fused white corundum with a particle size 2 o 3 Micropowder 3.0%, fused spinel micropowder with particle size 2 o 3 Micropowder 5.0%, active SiO 2 Micropowder 1.2%, pure calcium aluminate cement 4.0%, wood ca...

Embodiment 3

[0098] A composite high-life, low-cost ladle permeable brick seat brick, the same as Example 1, the difference lies in:

[0099] The diameter d1 of the upper port of the truncated cone is 135mm, and the diameter d2 of the lower port of the truncated cone is 205mm. The block body includes an upper body 1 and a lower body 2. The height h of the upper body 1 is 270 mm. The inner wall of the upper body is horizontally provided with grooves 4 uniformly distributed along the height direction along the circumferential direction. There are 4 grooves 4 and 4 grooves. The depth and width are the same, both are 8mm.

[0100]The high-purity chrome-magnesium-mullite corundum castable used in the upper body, the raw material components are as follows, all in weight percentage: 17% fused white corundum with a particle size 2 o 3 Micropowder 4.0%, fused spinel micropowder with particle size 2 o 3 Micropowder 4.0%, active SiO 2 Micropowder 1.0%, pure calcium aluminate cement 3.75%, wood cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com