Patents

Literature

129results about How to "Strong slag resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light-weight corundum-spinel castable and preparation method thereof

The invention relates to a light-weight corundum-spinel castable and a preparation method thereof. The preparation method includes following steps: (A) employing 60-75 wt% of equal-diameter micro-porous corundum spheres as an aggregate, and employing 8-12 wt% of electric-fused white corundum fine powder, 2-8 wt% of electric-fused magnesite fine powder, 2-8 wt% of magnesium aluminate spinel fine powder, 6-12 wt% of [alpha]-Al2O3 micro powder, 0.5-2.5 wt% of chromium oxide powder and 3-7 wt% of an aluminum silicone gel powder as substrate materials, wherein the aggregate and the substrate materials form a raw material in total; (B) employing organic fibers accounting for 0.02-0.08 wt% of the raw material and a polycarboxylate water reducer accounting for 0.05-0.12 wt% of the raw material as additive materials, pre-mixing the substrate material with the additive materials and adding the aggregate with uniform mixing; (C) adding water accounting for 3-5 wt% of the raw material, stirring the mixture and performing cast moulding; and (D) maintaining the temperature at 110-200 DEG C for 12-48 h, roasting the moulded product at 800-1200 DEG C for 24-72 h to obtain the light-weight corundum-spinel castable. The light-weight corundum-spinel castable is low in apparent porosity, is low in volume density, is low in heat conductivity, is strong in anti-slag-erosion capability and is long in service life.

Owner:WUHAN UNIV OF SCI & TECH

Corundum-spinel pouring material containing nano-magnesium carbonate

The invention relates to a corundum-spinelle lithical concreting material containing nano magnesium carbonate and a preparation method. In the method, the corundum-spinelle lithical concreting material containing nano magnesium carbonate is prepared by taking the currently and commonly used corundum-spinelle lithical concreting material as the base, adding nano magnesium carbonate powder, and adopting high efficient dispersant and proper mixing technique. With the method adopted, not only the adverse impact of magnesium oxide hydration on the concreting material workability caused by adding magnesia to generate spinelle in situ is avoided, but also the dreg resistance and thermal shock resistance of the existing corundum-spinelle lithical concreting material are improved. The corundum-spinelle lithical concreting material containing nano magnesium carbonate prepared by the invention can be widely used in high temperature industries such as steel, nonferrous metal, ceramic, petrochemical and the like, and can also be used for refractory material products such as air bricks which are baked after concreting moulding.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Forsterite-C-contained MgO-SiC-C fire-resistant material and preparation thereof

The invention relates to a forsterite-C-containing MgO-SiC-C material refractory and a method for preparing the same. The technical scheme comprises firstly mixing the 25-40wt% of magnesia particles with a grain size of 3-1mm, 20-35wt% of magnesia particles with a grain size of 1-0mm, 5-40wt% of forsterite-C mixed fine powders and 0-35wt% of magnesia fine powders, adding a 4-10wt% of bonding agent accounting for the weight of the mixed material, stirring or mulling for 10-30 minutes, drying after pressing formation, sintering at a reductive atmosphere with a sintering temperature of 1450-1700 DEG C and a heat preservation time of 4-8 hours, getting the MgO-SiC-C material composite refractory. The MgO-SiC-C material refractory prepared by adding the forsterite and carbon not only can solve the problem of magnesia resource shortage, reduces the production cost, but also the SiC prepared by the reaction of magnesia and carbon at a high temperature can reinforce the conjugation inside the material, and be useful for improving the refractory performance. The invention can also adopt low grade magnesia.

Owner:WUHAN UNIV OF SCI & TECH

Refractory Sialon corundum brick material for blast flurnace and its prepn process

The refractory sialon corundum brick material for blast furnace is prepared with corundum grain and powder 60-75 wt%, metal silicon powder 5-12 wt%, metal aluminum powder 10-15 wt%, titania powder 1-8 wt%, alumina powder 3-9 wt%, silica powder 0-2 wt%, clay 0-2 wt% temporary paper pulp or phnolic resin binding agent 2-5 wt%, and through mixing, forming, drying, sintering at nitrogen atmosphere. The refractory sialon corundum brick material has excellent alkali resistance, excellent slag resistance, high heat shock stability, high wear resistance and excellent molten iron fuse loss resistance. The refractory sialon corundum brick material may be used widely for large and medium sized blast furnaces.

Owner:WUHAN UNIV OF SCI & TECH

MgO-SiC-C refractory material synthesized by forsterite-C and method

The invention relates to MgO-SiC-C refractory material synthesized by forsterite-C and a method. The technical proposal to be adopted is as follows: firstly, forsterite mineral powder and industrial carbon powder are blended according to molar ratio of 1: (1-5); and then the mixture is added with 4 to 10 wt% of bonding agent, stirred or mulled for 10 to 30 minutes, pressed to be formed and dried; and finally under the Ar gas condition, the mixture is sintered in the sintering temperature of 1530 to 1800 DEG C with heat preservation for 2 to 8 hours to obtain MgO-SiC-C refractory material synthesized by forsterite-C. The invention is characterized by comparatively simple processing technique, low producing cost, high producing efficiency, wide raw material source and being capable of reducing energy consumption of high temperature synthesis reaction. The prepared MgO-SiC-C refractory material has the advantages of excellent high temperature performance, anti-corrosion and good durability.

Owner:WUHAN UNIV OF SCI & TECH

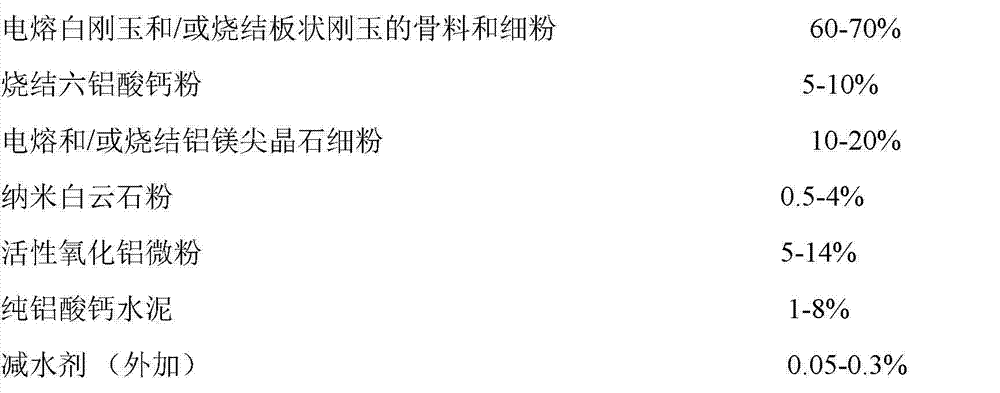

Nano dolomite-containing corundum spinel castable

The invention relates to a nano dolomite-containing corundum spinel castable and a preparation method thereof. On the basis of a corundum spinel castable which is commonly used at present, nano dolomite powder is added, spinel and calcium hexa-aluminate serving as seed crystals are introduced, and a high-efficiency dispersing agent and an appropriate mixing process are adopted, so that the nano dolomite-containing corundum spinel castable is prepared. The adverse effect of hydration of magnesia on the construction performance of the castable when spinel is generated in situ by adding the magnesia is avoided, and the slag resistance and thermal shock resistance of the corundum spinel castable which is used at present are improved; and the prepared nano dolomite-containing corundum spinel castable can be widely applied to the field of high-temperature industry such as steel industry, nonferrous metal industry, ceramic industry and petrochemical industry, and also can be applied to a fireproof material product formed by casting, forming and sintering a permeable brick and the like.

Owner:山国强

Chromium free refractory material for RH vacuum furnace lining

InactiveCN1715246AExtended service lifeStrong slag resistanceBlast furnace componentsBlast furnace detailsChromium freeZirconia silica

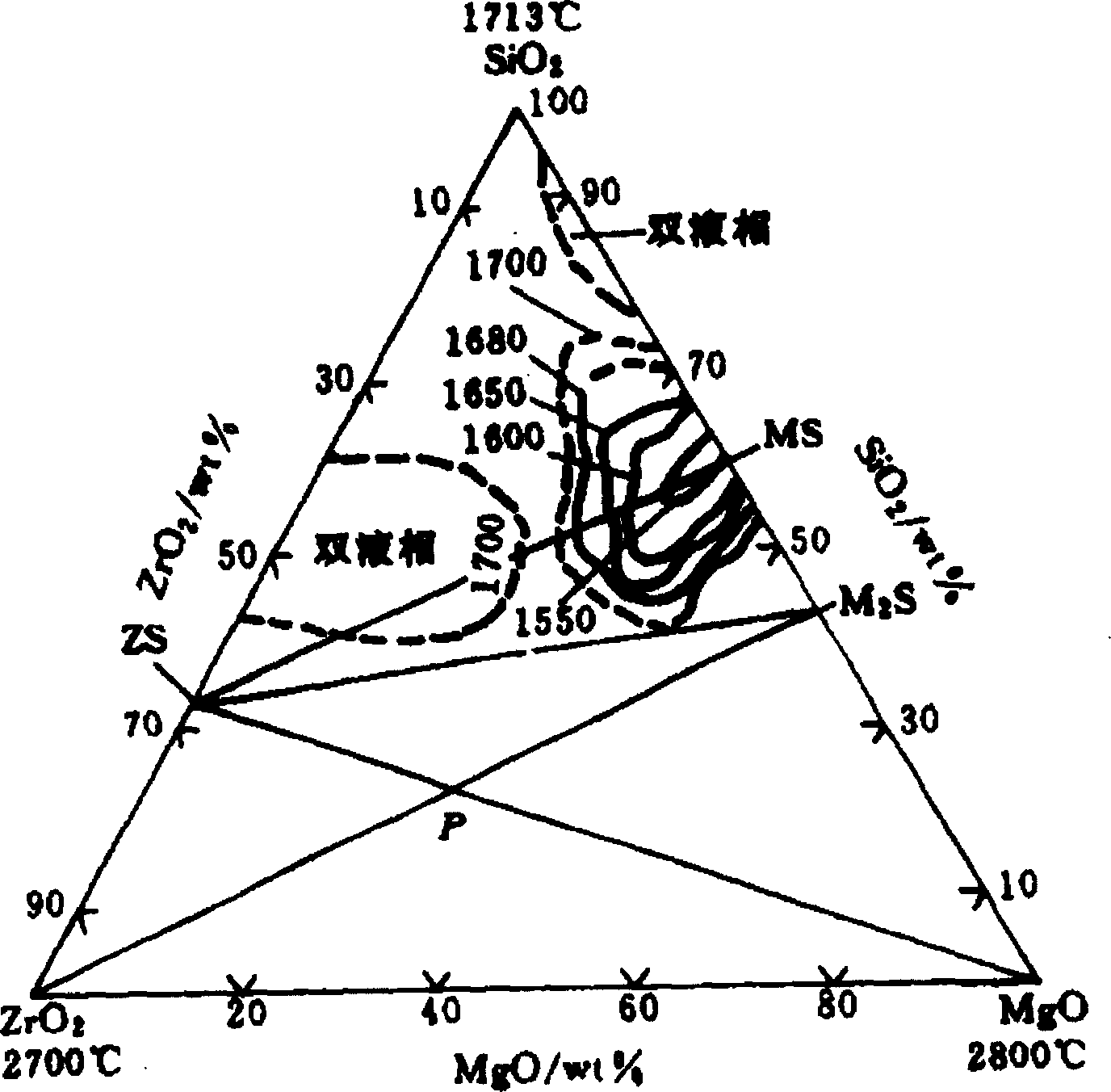

The chromium-free refractory material for RH vacuum furnace lining consists of one or several of magnetize, magnesia zirconia and magnesia zirconia silica 88-97 wt%, fine zirconia powder 1-6 wt%, fine zircon powder 0-9 wt%, and organic binding agent 1-3 wt%. It has the chemical composition of MgO 80-90 wt%, SiO2 1-4 wt%, and ZrO2 7-13 wt%. The organic binding agent is binding agent commonly for refractory material, such as sodium humate, calcium lignosulfonate, dextrin and Arabic gum. The MgO-SiO2-ZrO2 chromium-free refractory material has high slagging resistance and is significant for RH vacuum furnace to obtain long service life.

Owner:BAOSHAN IRON & STEEL CO LTD

Non-phosphorus and low-carbon alumina-magnesia unburned brick for stainless steel ladle and manufacturing method of brick

The invention discloses a non-phosphorus and low-carbon alumina-magnesia unburned brick for a stainless steel ladle and a manufacturing method of the brick. The non-phosphorus and low-carbon alumina-magnesia unburned brick comprises the following components by mass percentage: 15-20% of 5-3mm bauxite, 20-25% of 3-1mm bauxite, 10-15% of bauxite less than or equal to 1mm in particle size, 10-15% of 3-1mm fused magnesite, 5-10% of fused magnesite less than or equal to 1mm in particle size, 10-15% of emery powder, 15-20% of spinel powder, 2-5% of aluminum oxide micropowder less than or equal to 25 micrometers, 0.1-2% of silicon carbide additive, 0.1-2% of wetting agent and a phenolic resin binding agent. Compared with the prior art, the brick and the method have the prominent advantages that a burning technology in the conventional method is omitted, energy sources are saved, the brick is free from phosphorus; aluminum and magnesium perform spinel reaction at the high temperature; and the brick is subjected to machine molding in the absence of the phosphorus, has higher density, avoids pollution of molten stainless steel, and has a longer service life.

Owner:长兴南冶冶金材料有限公司

A kind of refractory castable for ladle

The invention provides a refractory castable for ladle, which is formed by mixing a castable base material and an appropriate amount of additives. The components and weight percentages of the castable base material are: 50-75% of high-aluminum material particles , 10-20% of high alumina powder, 1-10% of magnesia-aluminum spinel powder, 1-20% of electro-baked magnesia fine powder, 1-7% of silicon micropowder; the components and weight percentages of the additives are: Alumina fine powder 0-1%, zircon fine powder 0.1-0.5%, heat-resistant steel fiber 0.2-3%, explosion-proof fiber 0.03-0.2%, sodium tripolyphosphate 0-0.3%, sodium hexametaphosphate 0.1- 0.5%. The invention is a refractory castable for ladle with long service life, strong slag resistance, certain desulfurization effect and low production cost. The molten iron ladle of slag makes it corrode and reduces sticky slag. In addition, the alkaline material has a desulfurization effect.

Owner:CENT SOUTH UNIV

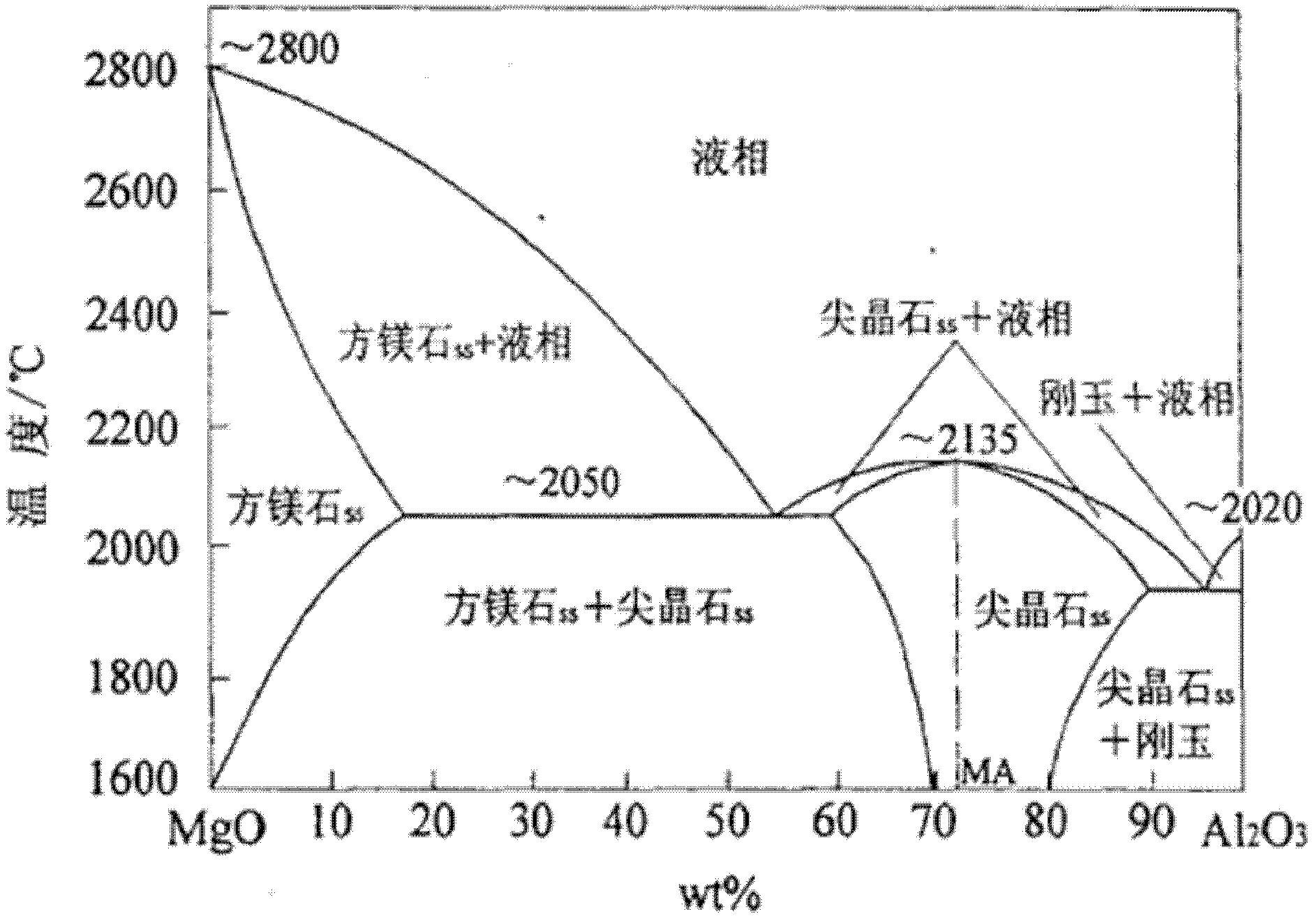

Aluminum-spinel-magnesia composite refractory as well as preparation method and application thereof

The invention belongs to the field of refractory, and discloses an aluminum-spinel-magnesia composite refractory as well as a preparation method and an application thereof. The aluminum-spinel-magnesia composite refractory comprises a raw material and an additional inorganic binding agent, wherein the raw material comprises the following components by weight: 60-94% of magnesia, 5-30% of magnesium-rich spinel or magnesium-aluminum spinel and 1-15% of metal aluminum powder, and the inorganic binding agent is 1-5% of the raw material. The aluminum-spinel-magnesia composite refractory is mainly used for substituting for magnesite-chrome bricks in an RH refining surface. The refractory can be thermally prepared at low temperature, so that energy consumption in the preparation process is lowered and the environmental pollution is reduced; and in the using process, part of the added aluminum powder is oxidized and forms a CA2 protective layer together with the calcium oxide in the slag so that the anti-slag permeability is improved.

Owner:江苏诺明高温材料股份有限公司

Al4SiC4/SiC composite refractory materials and preparation method thereof

The invention relates to a composite refractory material of Al4SiC4 and SiC and a method for preparing the same. The technical proposal is as follows: firstly, 50 to 65 weight percent of clay and 35 to 50 weight percent of industrial carbon powder are mixed; and the mixture is added with 3 to 10 weight percent of bonding agent to be stirred for 5 to 25 minutes, is pressed to be shaped, and is dried for 12 to 36 hours under the condition of between 60 and 110 DEG C or naturally dried for 24 to 48 hours indoors; and secondly, the mixture is sintered for 2 to 6 hours under argon atmosphere and under the condition of between 1,600 and 1,800 DEG C, and is cooled naturally to obtain the composite material of the Al4SiC4 and the SiC. The composite refractory material has the characteristics of rich raw material resource, low production cost and easy industrialized production. The composite refractory material of the Al4SiC4 and the SiC prepared by the method not only has excellent performance, but also can prolong the service life, is suitable for a novel furnace lining material for nonferrous metal and iron and steel smelting equipment, particularly suitable for producing ladle inside lining and refining furnace lining of clean steel such as low carbon steel, ultra-low carbon steel and so on, and is favorable for improving the quality of steel.

Owner:WUHAN UNIV OF SCI & TECH

Blast furnace stemming for repairing and protecting iron notch

The invention discloses a blast furnace stemming for repairing and protecting an iron notch, which belongs to the field of refractory materials. According to the invention, the blast furnace stemming comprises the following components in parts by weight: 10-20 parts of corundum, 5-15 parts of homogenizing material, 10-20 parts of coal gangue, 10-25 parts of pyrophyllite, 10-20 parts of composite clay, 10-35 parts of composite powder, 5-20 parts of vanadium-titanium-iron powder, 1-8 parts of silicon nitride iron, 0.1-0.5 parts of wetting agent and 15-22 parts of addition bonding agent, whereinthe composite powder is the mixture of oxide and nonmetal carbide. The blast furnace stemming for repairing and protecting the iron notch, disclosed by the invention, has the advantages of no generation of toxic black smoke, no fractured iron, strong slag resistance, particular suitability for being used in the blast furnace in the later stage and capability of obviously prolonging the service life of the blast furnace; and problems of the traditional stemming, like poor adaptability, large quality fluctuation, short service life, serious pollution and the like, are effectively solved.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

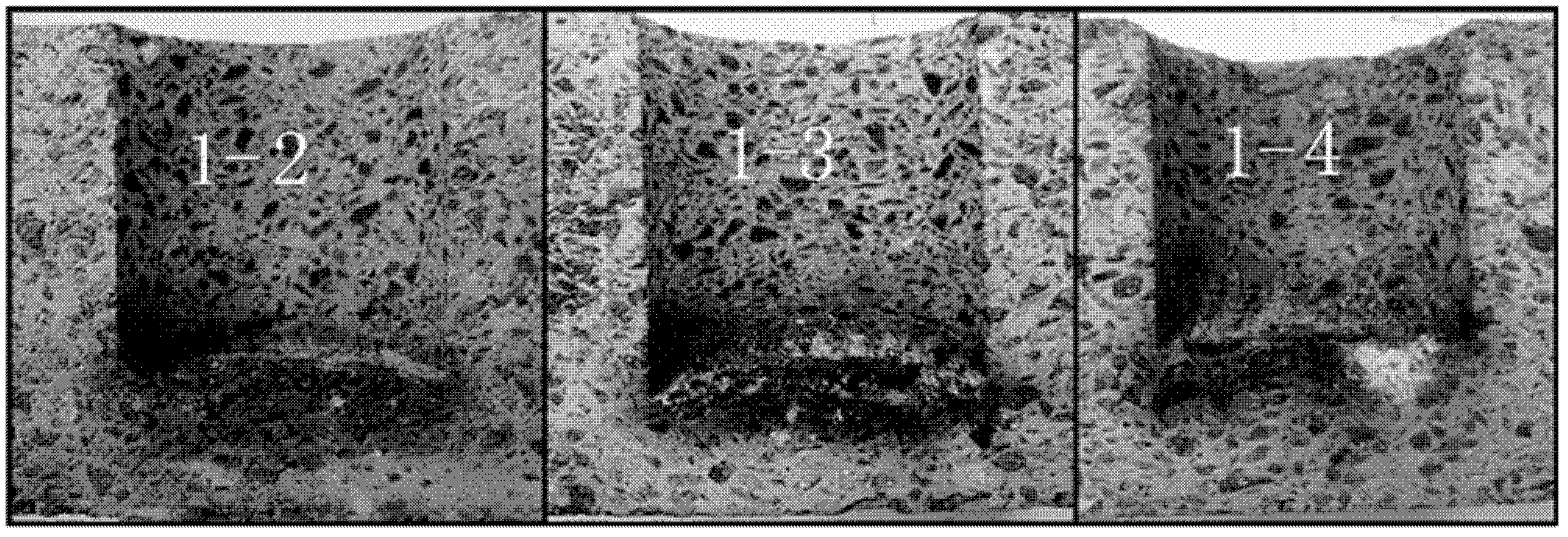

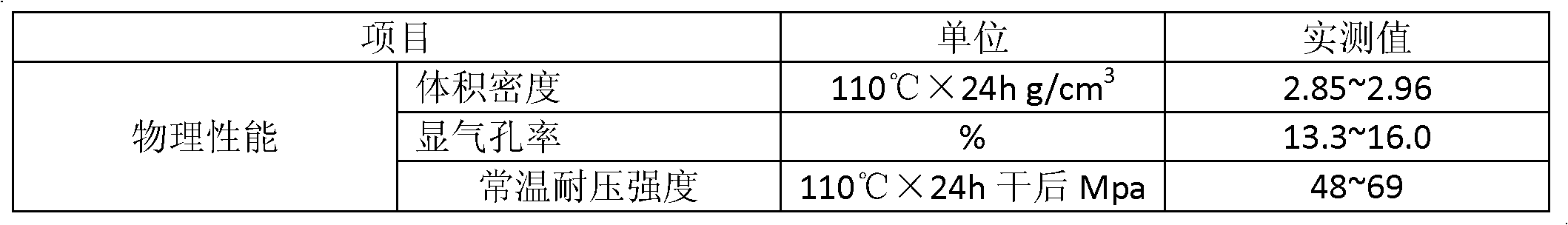

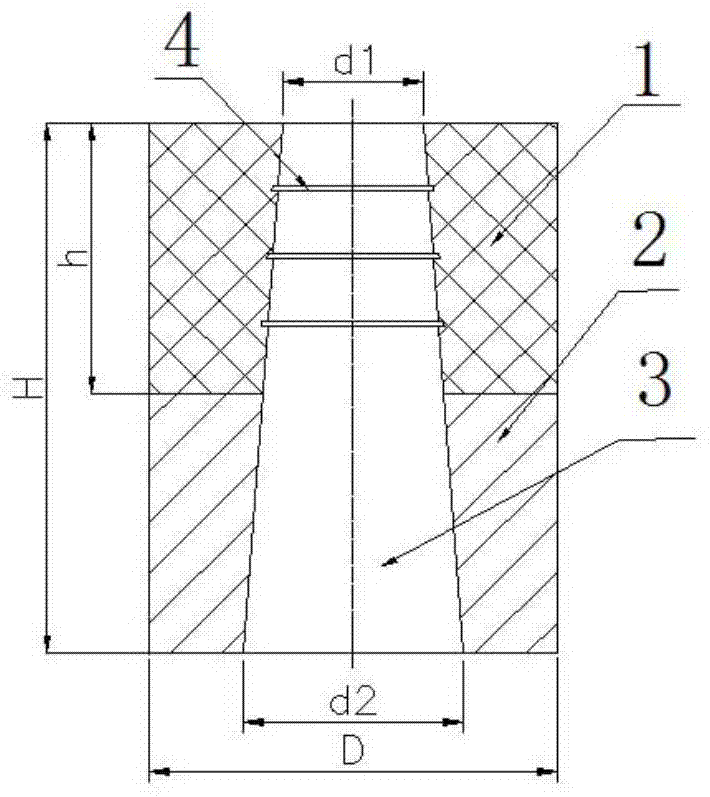

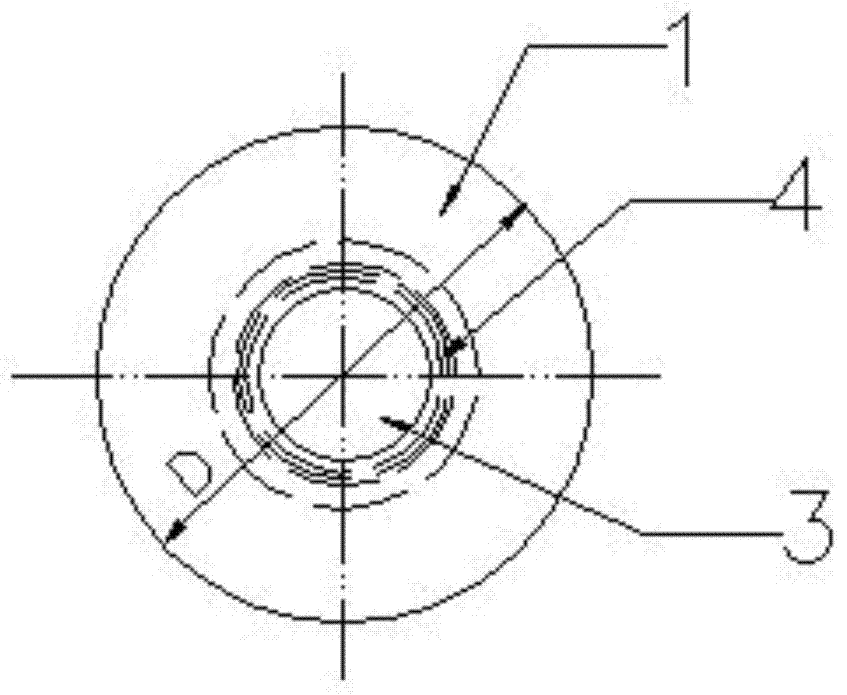

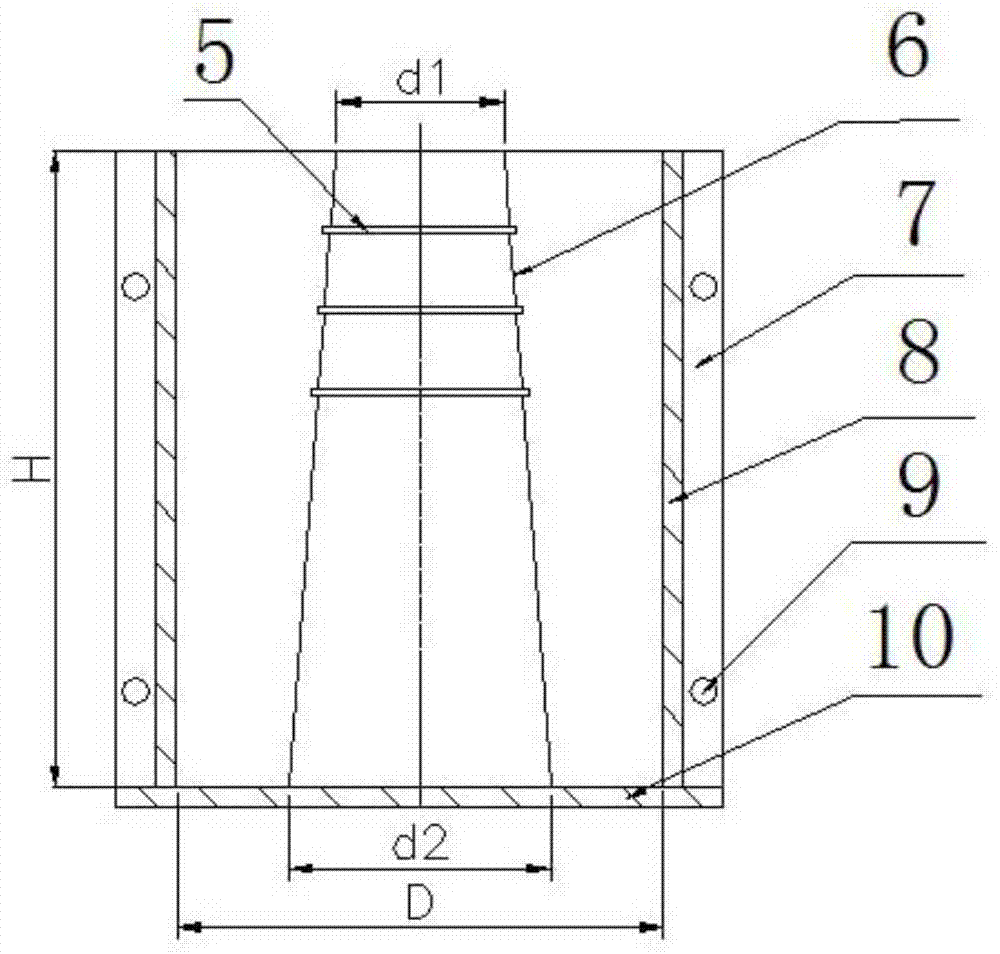

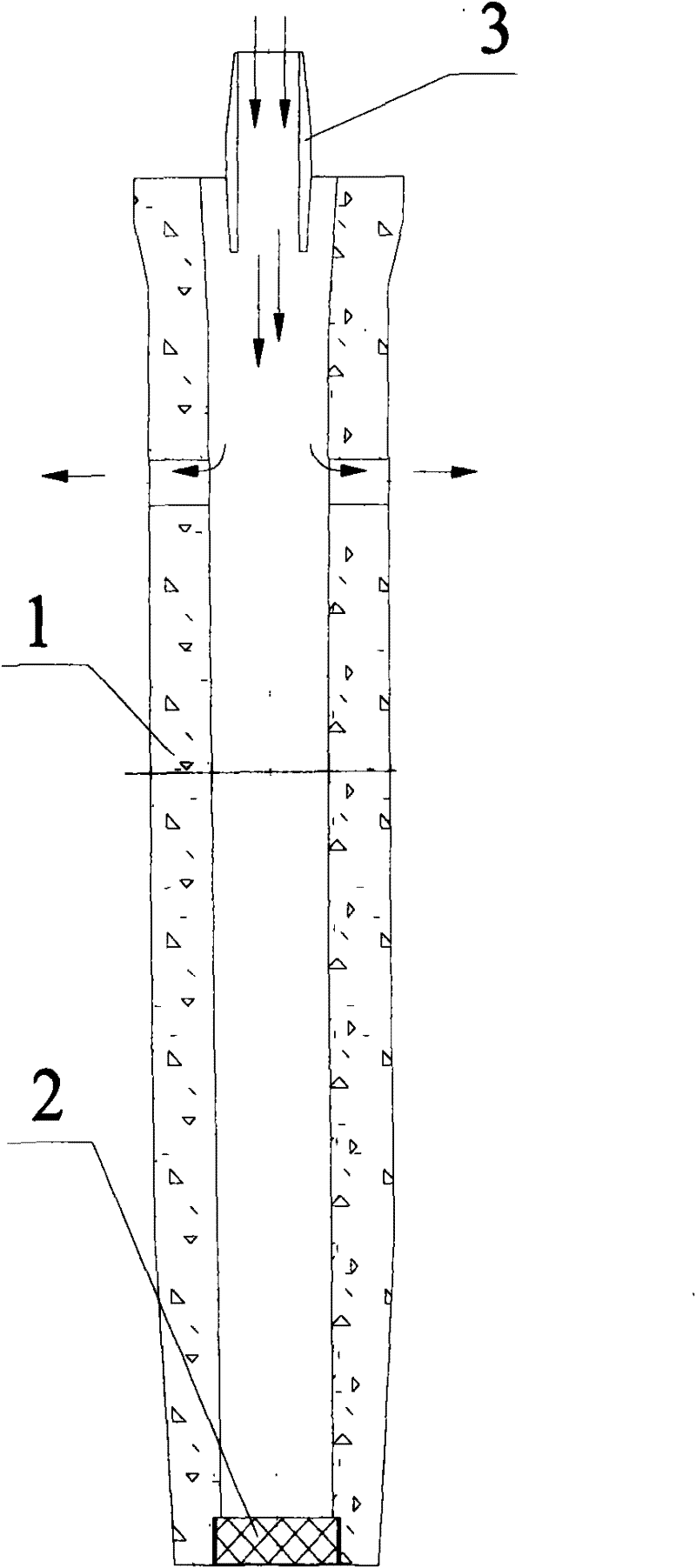

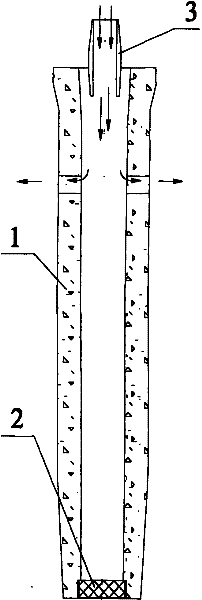

Composite long-life low-cost steel ladle air brick base brick and manufacturing method thereof

The invention relates to a composite long-life low-cost steel ladle air brick base brick. The composite long-life low-cost steel ladle air brick base brick comprises a base brick body, the base brick body comprises an upper body and a lower body which are molded by once casting of different cast materials. The upper body is 260 to 300 mm high, and the inner wall of the upper body is circumferentially provided with grooves uniformly distributed along the height direction. By the composite long-life low-cost steel ladle air brick base brick, cost performance is superior to that of an existing composite air brick base brick, corrosion speed is lower to more than 0.5 mm per furnace year on year, and service life is prolonged by more than ten times.

Owner:SHANDONG IRON & STEEL CO LTD

Tundish magnesia coating material prepared by using waste magnesium aluminum spinel as raw material and method

ActiveCN110282991ASolve the problem that it is difficult to turn over the bag and the color is blackSolve problems such as easy peelingCeramic materials productionClaywaresBrickPlasticizer

The invention belongs to the technical field of unshaped refractory materials, and specifically relates to a tundish magnesia coating material prepared by using waste magnesium aluminum spinel as a raw material and a method. The waste magnesium aluminum spinel is obtained in two ways: waste magnesium aluminum spinel bricks or preformed units produced in a production process of a refractory material enterprise are prepared into the waste magnesium aluminum spinel with the particle diameter of 3-0 mm through sorting and crushing; waste magnesium aluminum spinel bricks or preformed units after use by steel mills are prepared into the waste magnesium aluminum spinel with the particle diameter of 3-0 mm through deslagging, sorting and crushing; the waste magnesium aluminum spinels obtained through the two ways are mixed according to the ratio of (1.5:1) to (1:1.5), and then are sieved to obtain waste magnesium aluminum spinel particles of two kinds of particle diameters of 3-1 mm and 1-0 mm; the waste magnesium aluminum spinel particles are taken as a raw material to be added with a binder, a plasticizer, a water reducer, an anti-knock agent, and the like at the same time to develop the tundish coating material which is stable in performance, high in strength, excellent in construction performance and low in cost; the cyclic utilization of waste refractory materials is realized; the enterprise production cost is lowered.

Owner:瑞泰马钢新材料科技有限公司

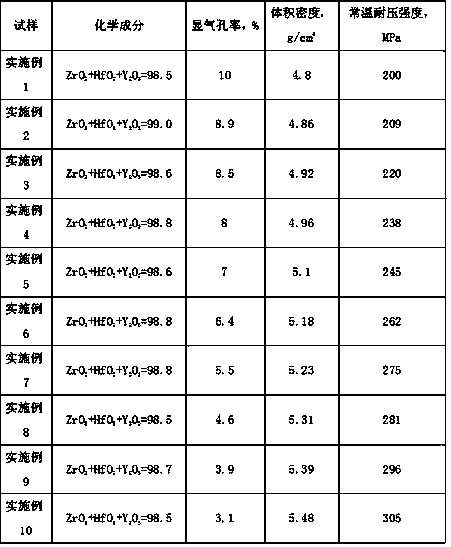

Compact high-purity zirconium oxide refractory product

The invention belongs to the technical field of refractory materials, and provides a compact high-purity zirconium oxide refractory product. The compact high-purity zirconium oxide refractory productcomprises the following raw materials: particles, fine powder and granulation powder, wherein the particles account for 20%-40% of the total mass of the whole refractory product, the fine powder accounts for 5%-15% of the total mass of the whole refractory product, and the granulation powder accounts for 55%-75% of the total mass of the whole refractory product; and the granulation powder also contains a part of an external binding agent, and the content of the binding agent accounts for 3-5% of the total mass of the granulation powder. The compact high-purity zirconium oxide refractory product has the characteristics of low firing temperature, low porosity, high density, high mechanical strength and excellent slag resistance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Castable for gun patching of blast furnace lining and preparation method for castable

The invention discloses castable for gun patching of a blast furnace lining and a preparation method for the castable. The castable is prepared from raw materials, i.e., 10wt% to 15wt% of bauxite particles, 40wt% to 50wt% of brown fused alumina particles, 10wt% to 20wt% of silicon carbide fine powder, 15wt% to 25wt% of corundum fine powder, 0.5wt% to 2wt% of metal silicon powder, 0.5wt% to 2wt% of pelleted pitch, 2wt% to 7wt% of alpha-Al2O3 micropowder and 0.2wt% to 2wt% of silica micropowder, and silica sol, of which the weight percentage is 8% to 15% that of the raw materials, wherein the silica sol serves as a binder. The method comprises the steps of proportionally preparing the raw materials, adding the raw materials in a stirrer, carrying out uniform stirring and mixing, and then, adding the silica sol as a gun patching wetting medium and the binder, thereby obtaining the castable for gun patching of the blast furnace lining. The castable is superior in slag resistance, high in strength, good in bonding performance and quick in construction and can be integrated with a patched face of the blast furnace lining through binding; and the preparation method is simple in operation, exposed furnace wall linings can be subjected to gun-patching lining forming under the circumstances that a stock level of a blast furnace is lowered, and the blast furnace lining is rapidly patched in a large area.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Refractory castable for molten iron tank

The invention provides a refractory castable for a molten iron tank. The refractory castable comprises the following components in percentage by weight: 50-65 percent of high-alumina particles, 10-30 parts of high-alumina powder, 1-10 percent of quartz sand, 1-20 percent of diaspore clay fine powder, 3-7 percent of calcium aluminate cement, 1-7 percent of silicon fine powder, 0-4 percent of alumina fine powder, 1-3 percent of zirconium silicate powder, 0.2-2 percent of heat-resistant steel fiber, 0.05-0.3 percent of metal aluminum powder and 0-0.3 percent of sodium tripolyphosphate. The refractory castable for a molten iron tank has the advantages of long service life, high slag resistance and low production cost, is suitable for a molten iron tank for receiving acid slag with high viscosity, is prevented from being eroded, and contributes to reducing adhesive slag.

Owner:山国强

Anti-slag-adhesion spray coating

ActiveCN107235733AExcellent high temperature resistance and anti-sticking slag performanceGood slag resistanceSilica fumeSlag

The invention relates to an anti-slag-adhesion spray coating, which comprises the following raw materials in weight percent: 10%-13% of bauxite granules in grain size of 0-1mm, 20%-24% of bauxite powder in grain size of 325-800 meshes, 13%-18% of silica powder in grain size of 280-325 meshes, 35%-45% of silica powder in grain size of 600-1000 meshes, 1.5%-2.5% of metal silicon powder in grain size of 180-260 meshes, 0.5%-3% of zirconium oxide in grain size of 325-400 meshes, 2%-5% of silicon carbide in grain size of 180-280 meshes, 1.5%-3% of silica powder, 0.2%-0.5% of sodium tripolyphosphate, 0.3%-0.5% of sodium hexametaphosphate and 35%-40% of water. The anti-slag-adhesion spray coating has an excellent anti-slag-adhesion effect, a slag pot and a slag ladle are free from slag adhesion and the service life of the slag pot and the slag ladle is greatly prolonged.

Owner:巩义市金利炉料厂

MgO-SiC-C material synthesized by forsterite-C and method for preparing same

The invention relates to an MgO-SiC-C material synthesized by forsterite and C and a method for making the same. The method adopts the following technical proposal that: according to molar ratio, 1 to 4 mol of forsterite mineral powder and 3 to 6 mol of C powder are mixed, and a bonding agent occupying 4 to 10 percent of the mass percentage content of the mixed materials is added; the mixture is stirred or ground for 10 to 30 minutes, and is dried after press forming; then, sintering is carried out under a reducing atmosphere at a temperature of between 1,450 and 1,700 DEG C with the heat preservation time of between 2 and 8 hours, thereby obtaining an MgO-SiC-C composite material. The industrial carbon powder raw material adopted by the method has wide sources, and the forsterite mine has abundant resources, thereby not only effectively solving the problem of magnesia resource shortage, but also having low production cost; moreover, the made MgO-SiC-C composite material can maintain excellent properties and reduce corrosion wear, thereby prolonging service life.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing regenerative magnesia-carbon bricks

The invention belongs to the technical field of a refractory material, and discloses a method for preparing regenerative magnesia-carbon bricks. The method comprises the following technical flow steps: piling in classification; sorting; removing impurities; preprocessing; pulverizing; dehydrating; screening; packing; and molding the bricks. Regeneration grains can be used for producing regenerated magnesia carbon bricks, aluminum-magnesium-carbon bricks, aluminum carborundum carbon bricks, tundish dry materials, aluminum-magnesium-carbon fireclay and slag-pot unfired bricks. The regeneration use rate of the carbonic crushed bricks can reach as high as 100 percent. The method saves resources, clears garbage and protects the environment.

Owner:申久祝

Castable for steel ladle integral casting working lining

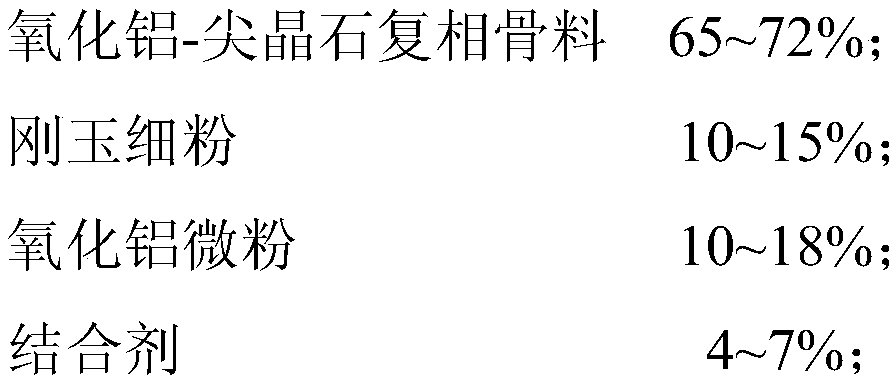

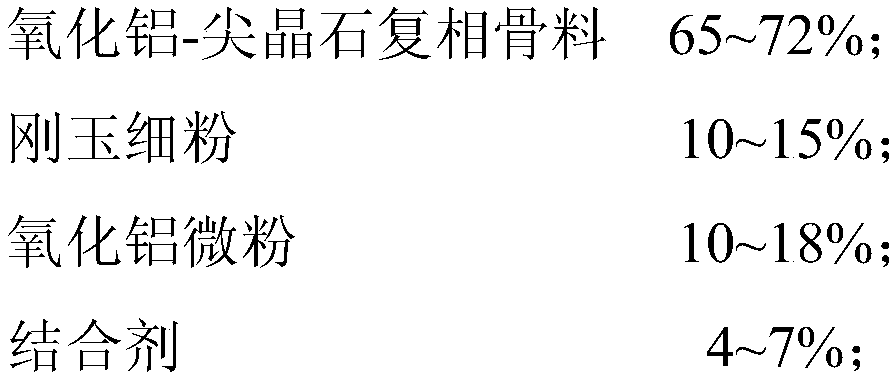

The invention discloses a castable for a steel ladle integral casting working lining. The castable is prepared by mixing raw materials including, by weight, 65-72% of aluminum oxide-spinel complex phase aggregates, 10-15% of corundum fine powder, 10-18% of alumina micro-powder, 4-7% of binding agents, 0.1-1% of additional dispersing agents, 0.01-0.1% of additional detonation inhibitors and 0.01-0.2% of additional bleeding prevention agents. Aluminum oxide-spinel complex phase materials serve as the aggregates to prepare the castable for the steel ladle integral casting working lining, and thecastable is excellent in slag corrosion resistance and penetration resistance, low in cost, good in thermal shock resistance, slight in expansion and long in service life and solves the problems of poor slag corrosion resistance and penetration resistance as current castables for steel ladle integral casting working linings extensively use corundum or alumina as an aggregate.

Owner:WUGANG REFRACTORY CO LTD

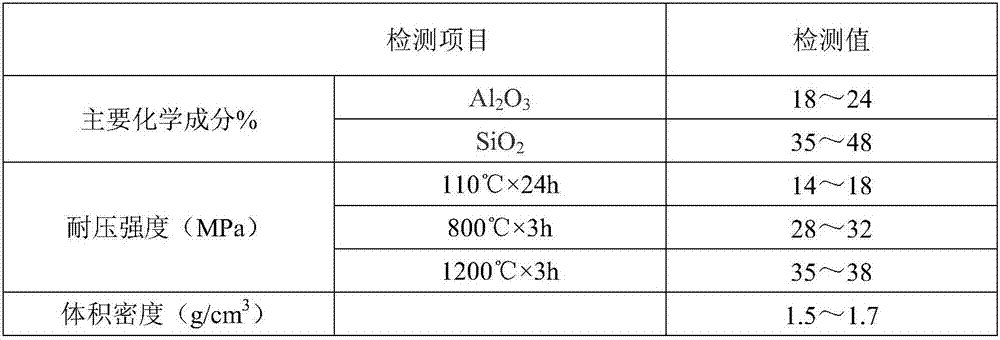

Infrared temperature measuring pipe for continuously measuring temperature of molten steel and components, and preparation method thereof

InactiveCN102221408ASmall heat capacityImproved thermal shock stabilityRadiation pyrometrySlagThermal transmittance

The invention relates to an infrared temperature measuring pipe for continuously measuring temperature of molten steel and components, and a preparation method thereof. An internal hole of a temperature measuring pipe body is a shoulder hole; a heat conduction block is embedded in a hole with greater diameter at the lower end of the temperature measuring pipe body; a connecting pipe is fixed at the upper end of the temperature measuring pipe body; one part of the connecting pipe is arranged in the temperature measuring pipe body; and the other part of the connecting pipe is arranged outside the temperature measuring pipe. Chrome corundum fireproof casting materials of the pipe body has better thermal shock resistance, excellent slag resistance, stable high-temperature volume and high high-temperature strength; a heat conduction block is made of alumina-carbon and is processed by high temperature, thereby having high thermal conductivity, small thermal capacity and large blackness. Allraw materials used for manufacturing the temperature measuring pipe do not emit smoke gas and volatile during the temperature raising process; therefore, an optical passage of the temperature measuring pipe is always at a clean state, thus thoroughly solving the problem that the optical passage of the existing alumina-carbon based temperature measuring pipe can be polluted by the smoke gas and the volatile easily; and the veracity of the temperature measurement is ensured, and the response speed and the stability are improved.

Owner:ANHUI HEPURE CERAMIC

Low-creep andalusite composite refractory brick and preparation method and application thereof

The invention provides a low-creep andalusite composite refractory brick, which comprises main materials and additives. The main materials include, by weight, 6-12% of large particles of bauxite clinker, 14-27% of large particles of mullite, 14-27% of small particles of andalusite, 14-30% of small particles of mullite, 15-27% of fine powder of andalusite, 5-14% of kaolin micro-powder, 5-10% of mullite micro-powder and 2-5% of silica micro-powder. The mass of the additives is 4.5-5.5% of mass of the main materials. The invention also provides a preparation method and application of the above low-creep andalusite composite refractory brick. The low-creep andalusite composite refractory brick has reasonable combination of ingredients and has good thermal shock property, good thermostability and high refractoriness under load. Therefore, service life of a carbon baking furnace having flue walls lined with the low-creep andalusite composite refractory brick is prolonged.

Owner:济源市金峰耐火材料有限公司

Furnace bottom ramming material of RH refining furnace

The invention relates to a furnace bottom ramming material of an RH refining furnace. The furnace bottom ramming material consists of a dry material and an additional anchoring agent, wherein the dry material consists of the following components in percentage by weight: 70-80% of fused magnesite, 5-10% of magnesia-alumina spinel, 1-5% of Al2O3 micro-powder and 1-10% of metal powder, wherein the fused magnesite and the magnesia-alumina spinel are refractory aggregates, the Al2O3 micro-powder and the metal powder are refractory powder, the anchoring agent is an inorganic salt, and the addition amount of the anchoring agent is 1-5% of the weight of the dry material. A preparation method of the furnace bottom ramming material comprises the following steps: preparing various raw materials according to formula requirements, and preparing a dry-powder material in a forced stirring machine; putting the uniformly mixed material into a moisture-proof woven bag; storing and transporting the material at cool and dry places; and when the material is used, adding water and stirring. The furnace bottom magnesia-alumina spinel ramming material of the RH refining furnace, provided by the invention, reaches the same high-temperature performance and the same site construction conditions with a magnesium-chromite ramming material. The furnace bottom ramming material can replace the conventional magnesium-chromite ramming material and has strong environmental-friendliness property.

Owner:洛阳利尔功能材料有限公司

Anhydrous environment-friendly taphole clay

InactiveCN107285750APromote environmental protectionSmall midline rate of changeBlast furnace componentsBlast furnace detailsModified carbonSlag

The invention discloses anhydrous environment-friendly taphole clay which comprises the following components in parts by weight: 8-20 parts of a waste skateboard material of not more than 5mm, 5-10 parts of high-alumina bauxite of 3-5mm, 10-20 parts of coke of not more than 3mm, 8-12 parts of black corundum of not more than 1mm, 10-15 parts of silicon carbide of not more than 1mm, 4-8 parts of kyanite powder, 8-12 parts of Guangxi mud, 5-8 parts of asphalt powder, 4-7 parts of graphite powder, 5-10 parts of silicon carbide powder, 2-5 parts of silicon nitride powder, 0.3-0.6 part of aluminum ashes and 12-16 parts of ethylene glycol-modified carbon-containing resin. The anhydrous environment-friendly taphole clay has the advantages of being good in environmental protection property, small in linear change rate in using process, stable in volume, free of a fracture taphole, easy to open, high in slag resistance, relatively small in operation intensity, high in adaptability to blast furnace condition, is especially suitable for a relatively large blast furnace, can play a key role in maintenance of the depth of the taphole.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

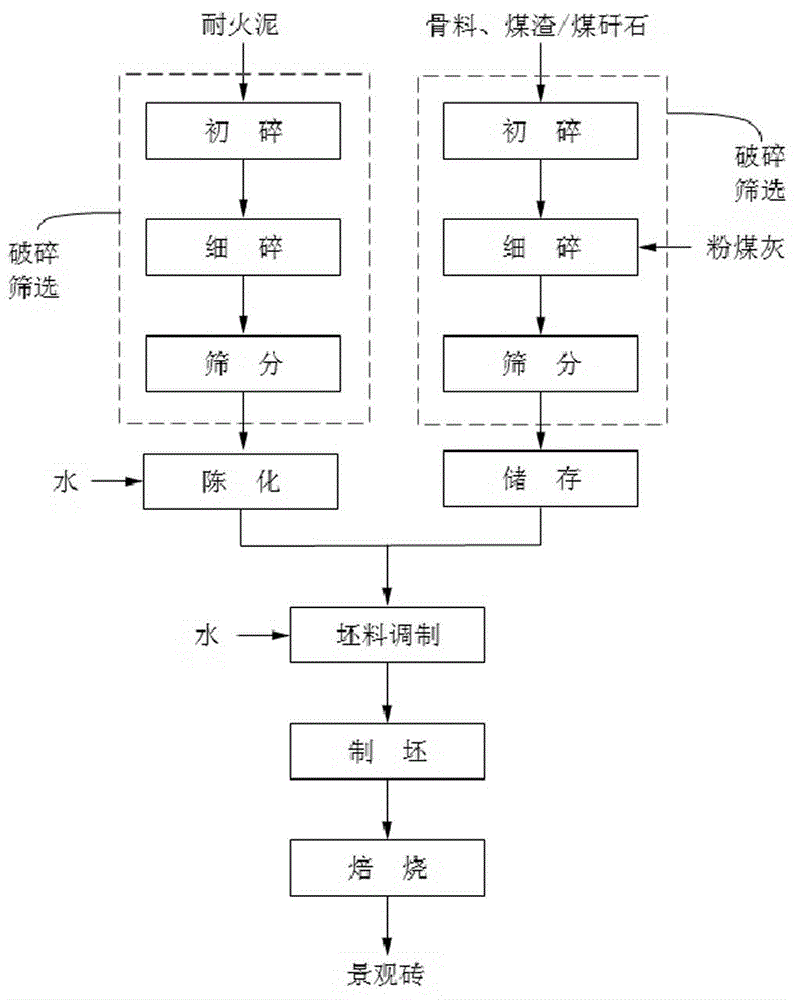

Yellow sintered landscape brick and production method thereof

InactiveCN104556962AImprove firing performanceReduce deformation of finished productFire clayHigh pressure

The invention discloses a yellow sintered landscape brick and a production method thereof. The yellow sintered landscape brick comprises 30 to 50 percent of fire clay and 50 to 70 percent of aggregate, wherein the sum of mass percent of all raw materials is not more than 100 percent. The production method comprises the steps of crushing, screening, blank mixing, blank preparation and roasting. According to the yellow landscape brick, aggregate is adopted as a main material, fire clay is adopted as an auxiliary material, and particularly hard fire clay and / or half-hard fire clay is adopted, so that the plasticity of the aggregate can be realized, and the blank is good in moldability; meanwhile, the raw materials are sintered at a high temperature of a specific range, the fire clay is thermally decomposed and toughened and covers and is bonded to the aggregate to present in faint yellow color and yellow color effects, so that the landscape brick has the characteristics of pure yellow color, relatively high pressure resistance and bending resistance and small deformation. The production method is pure in color, simple in process and stable in product quality.

Owner:楚雄诚鑫工贸有限公司

Method for intensively producing refractory material through coal tar pitch needle coke

The invention discloses a method for intensively producing a refractory material through coal tar pitch needle coke. Unutilized QI1 residues of the prior art, coal tar, delayed coking tower side oil products, a modifier and a nickel, vanadium and cobalt removing agent are subjected to separation, sedimentation, purification and oxidization modification to produce a refractory material adhesion agent with high softening point; the refractory material adhesion agent has the performances of high slag resistance, oxidation resistance and thermal shock resistance, is mixed with active agents such as white carbon black, ammonium humate, polyvinyl alcohol, carboxymethyl cellulose and the like and dry pressed to obtain the refractory material for a steel refining furnace, and the refractory material is better than phenolic resin; and the refractory material, carbon black, dimethylbenzene, benzofuran, polyethylene glycol and the like are dissolved, mixed and dissolved so as to obtain a liquid spraying adhesion agent for repairing the steel refining furnace, and the repairing strength of the liquid spraying adhesion agent is better than the repairing strength of common medium temperature pitch. The service lives of equipment such as converters, electric furnaces, calcinators and the like can be prolonged.

Owner:YUNNAN COAL & ENERGY +1

Low-creep high-rcasting refractory brick and preparation method and application thereof

InactiveCN106187241AResistant to thermal shockImprove thermal shock resistanceBrickThermal stability

The invention provides a low-creep high-rcasting refractory brick. The low-creep high-rcasting refractory brick comprises a main material and an additive, the main material is mainly prepared from, by mass, 20%-40% of flint clay large particles, 20%-35% of flint clay small particles, 15%-25% of flint clay fine powder, 5%-15% of bonding clay fine powder and 5%-15% of bauxite clinker micro powder. The mass of the additive accounts for 4.5%-5.5% that of the main material. The invention further provides a preparation method and application of the low-creep high-rcasting refractory brick. The low-creep high-rcasting refractory brick is reasonable in component matching and has the thermal shock property, good thermal stability and high refractoriness under load, and therefore the service life of a carbon calcinatory with a flame path wall built by the low-creep high-rcasting refractory brick is prolonged.

Owner:济源市金峰耐火材料有限公司

MgO-SiC-C fire resistant pouring material based on forsterite and method for preparing same

The invention relates to a MgO-SiC-C fireproof casting material based on forsterite-C and a preparation method thereof. In the technical proposal, forsterite and C powder are mixed according to the mol ratio of (1 to 4) to (3 to 6), and a binder of 1 to 10 percent of the mixture by weight is added. After the mixture is beaten, moulded and dried, the mixture is synthesized into MgO-SiC-C material for two to eight hours at the temperature of 1450 to 1700 DEG C under the reducing atmosphere. 10-25 weight percent of 10-5mm granule, 15-25 percent weight of 5-3mm granule, 15-25 weight percent of 3-1mm granule, 10-20 weight percent of 1-0mm granule, 25-35 weight percent of 0.1-0mm fine powder are mixed with 2-8 weight percent of the binder, and are beaten uniformly, thus getting the MgO-SiC-C fireproof casting material. The manufacturing cost of the invention is low; the process is simple; and the fireproof casting material prepared has good performance, and is widely applied.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of solar heat absorption composite material

InactiveCN110423131AHigh mechanical strengthStrong thermal shock resistanceSolar heating energyAbsorbing elementsSlagMullite

The invention relates to a preparation method of a solar heat absorption composite material, belonging to the technical field of solar energy. The preparation method prepares the solar energy heat absorption composite material by adding andalusite, silicon carbide and silicon nitride, wherein the andalusite is an aluminosilicate mineral; after the andalusite is heated to 1350 DEG C under normal pressure, the andalusite begins to be converted into acicular mullite parallel to original crystals; the mullized andalusite is resistant to quenching and shock heating, has large mechanical strength, strong thermal impact resistance, strong slag resistance, high load conversion point, extremely high chemical stability and extremely strong chemical corrosion resistance; silicon carbide bonded silicon nitride has good oxidation resistance. In addition to good wear resistance, the silicon carbide in the material has high thermal conductivity and low thermal expansion coefficient, so that the silicon nitride bonded silicon carbide has excellent thermal shock resistance and acts as an obstacle and delay role in the penetration of external erosion media, and the solar heat absorption composite material has good chemical stability.

Owner:宁波宏翌能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com