Patents

Literature

58results about How to "Guaranteed clean production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

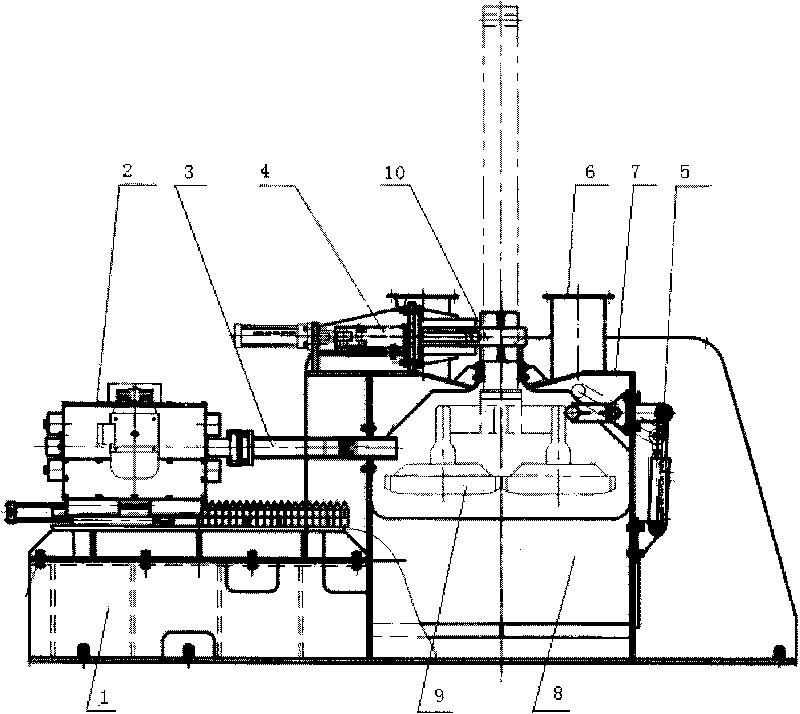

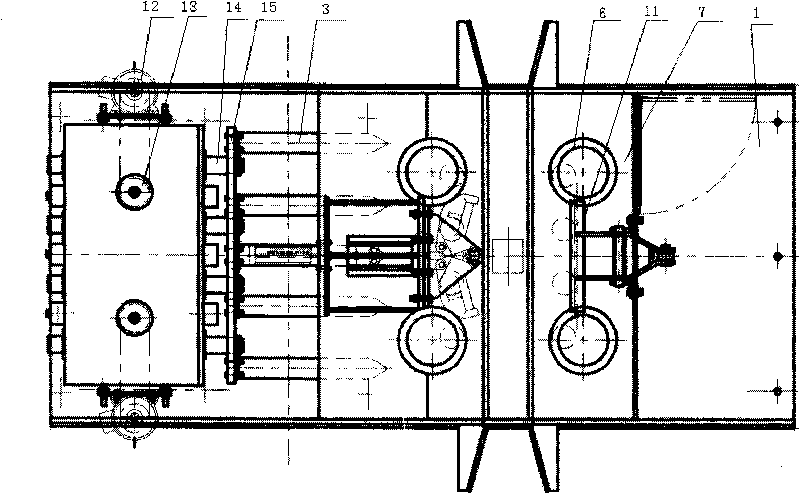

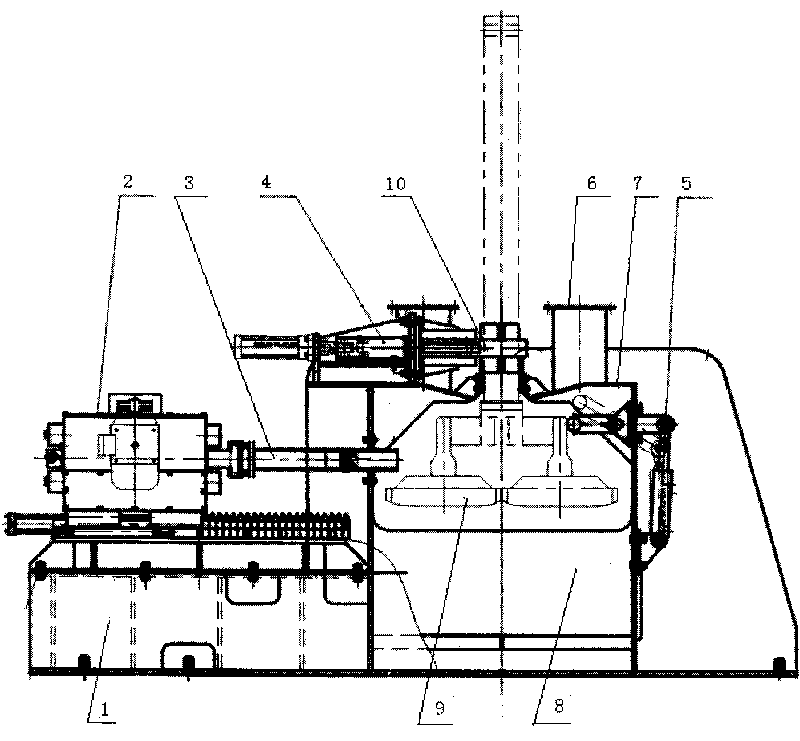

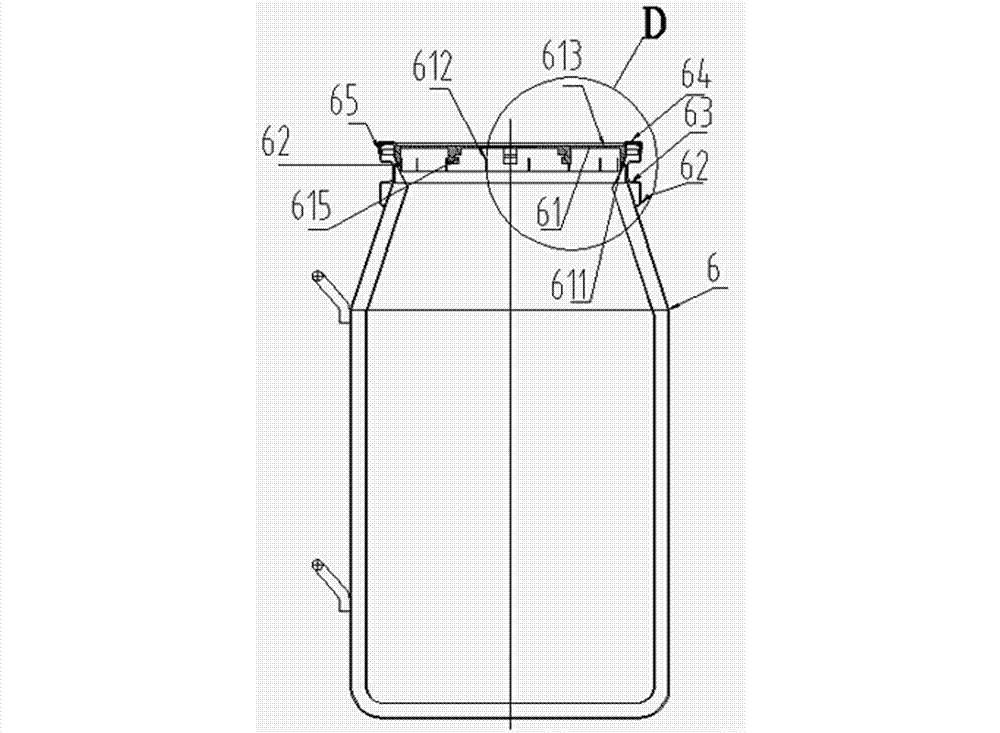

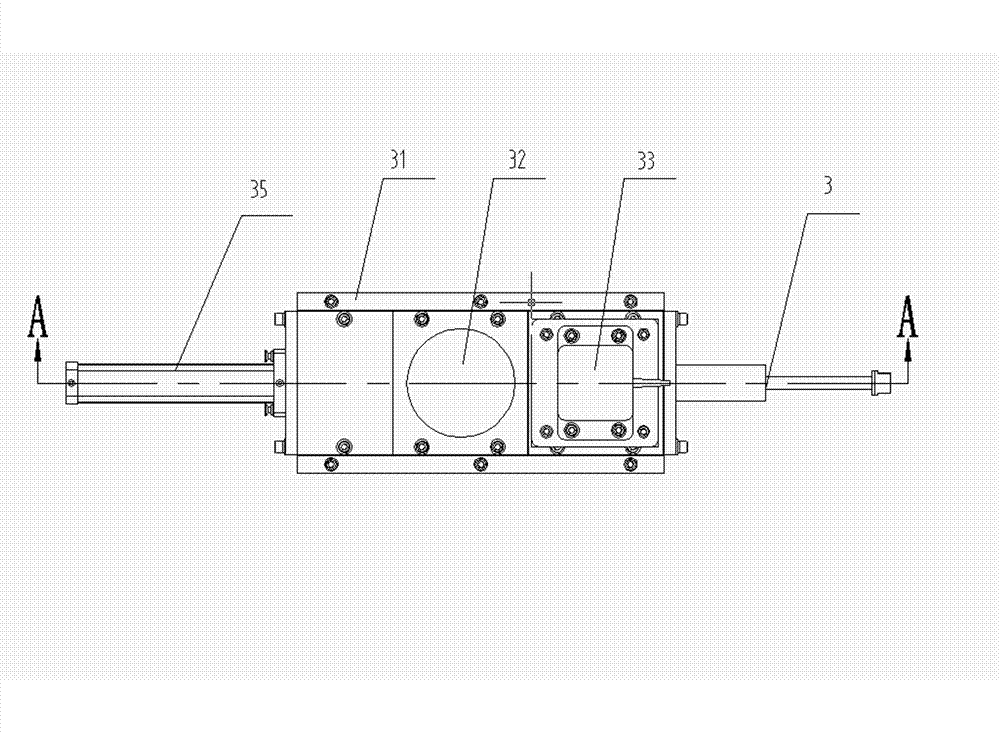

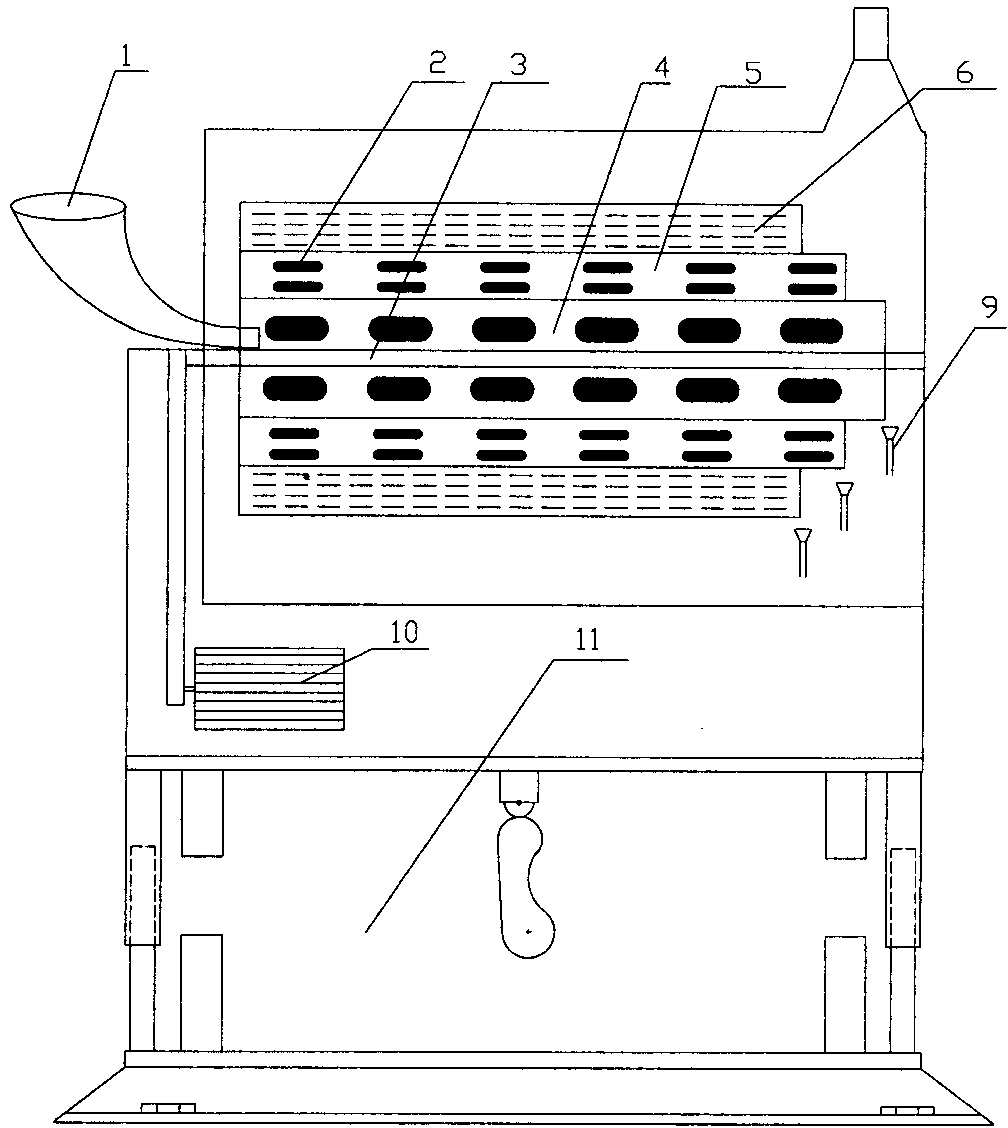

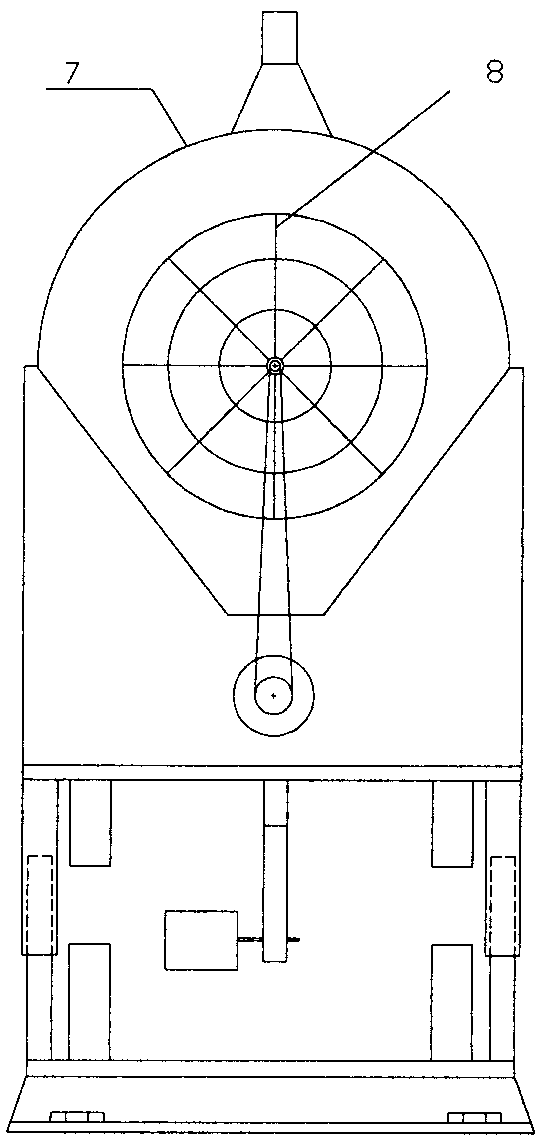

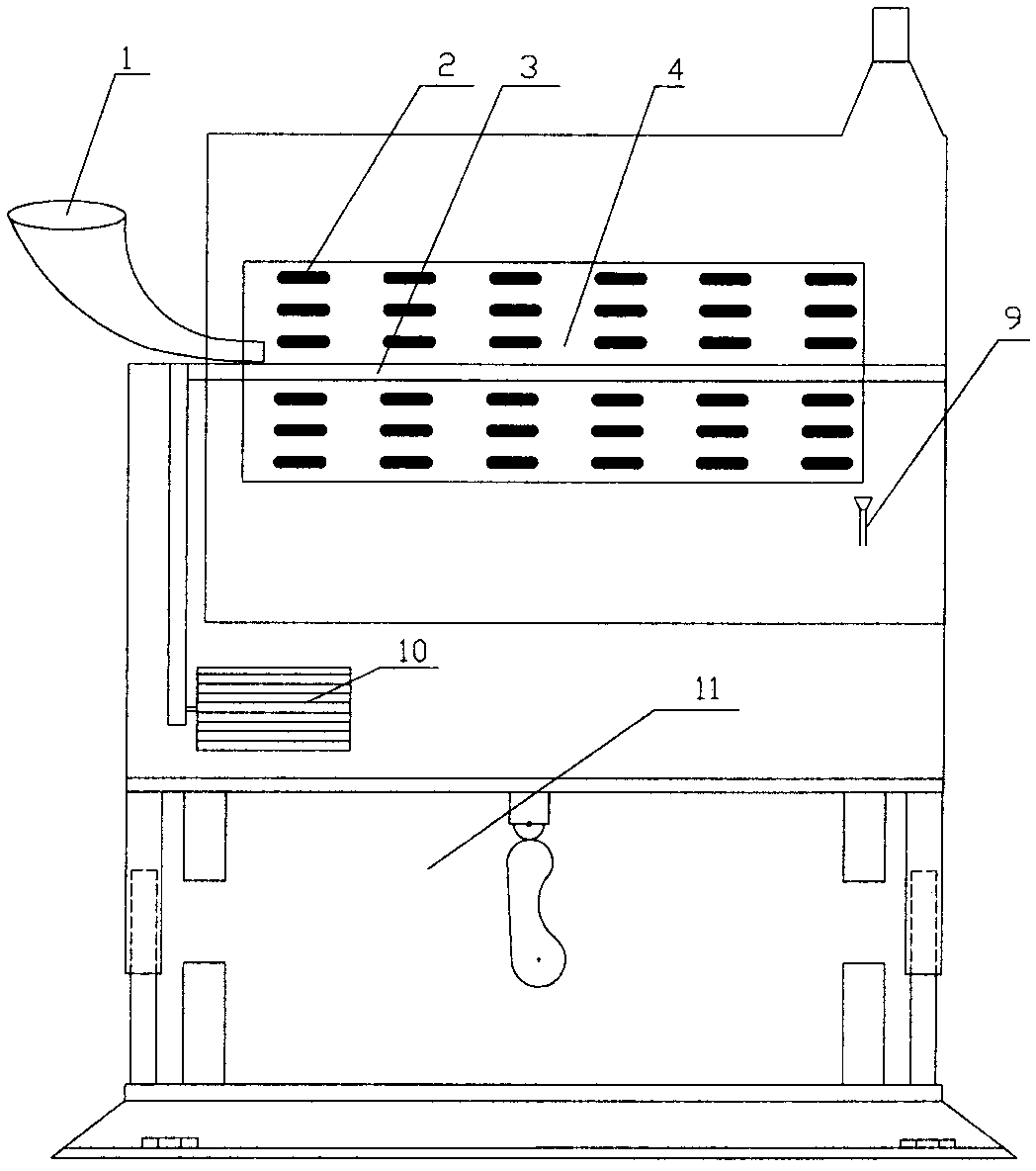

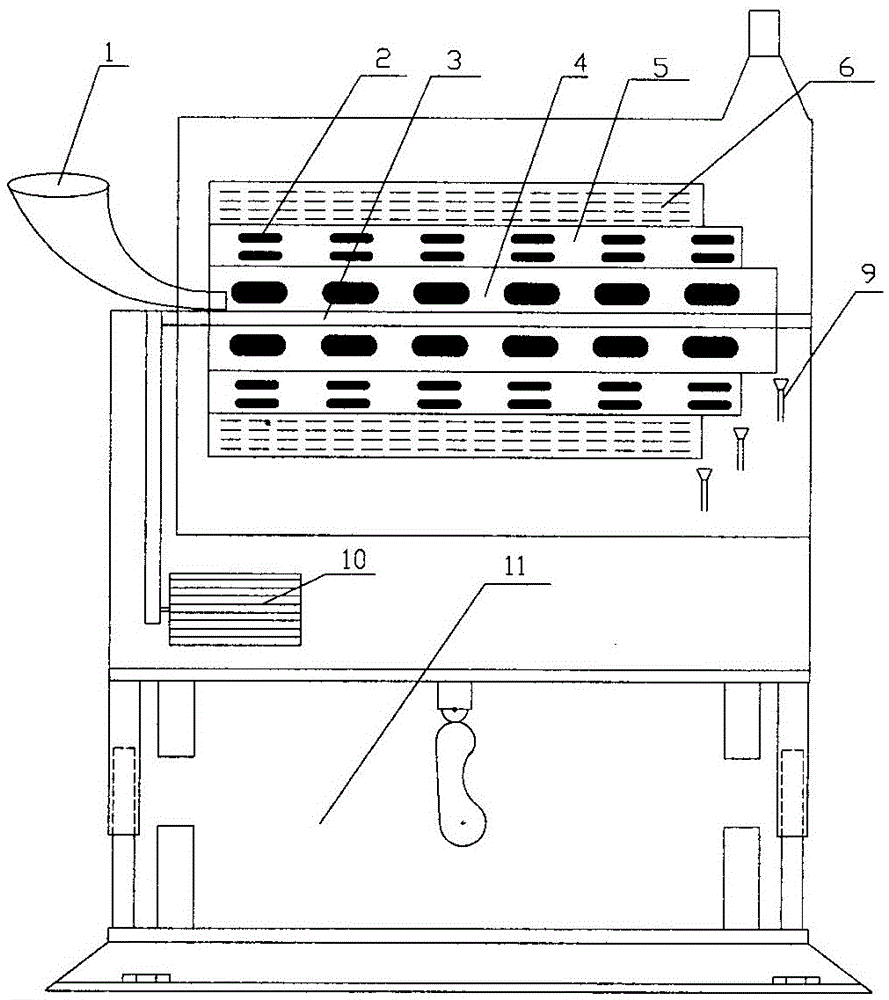

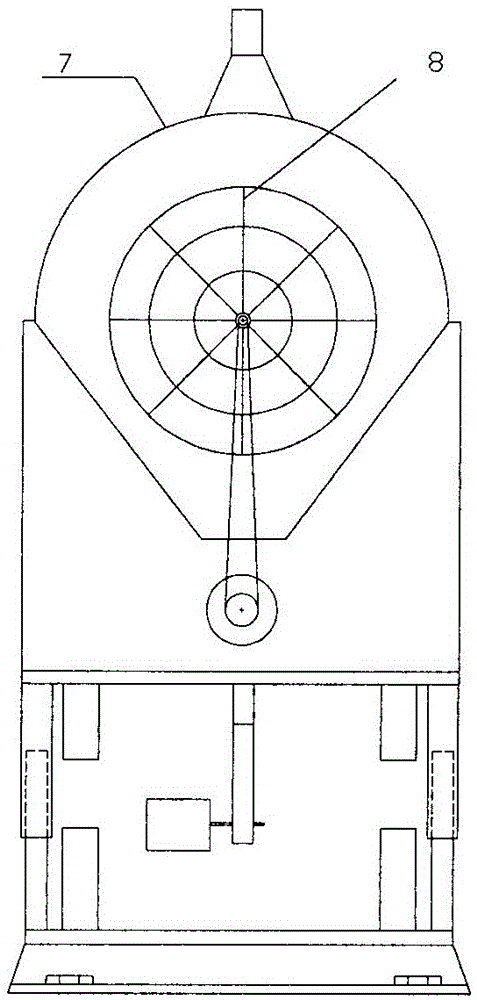

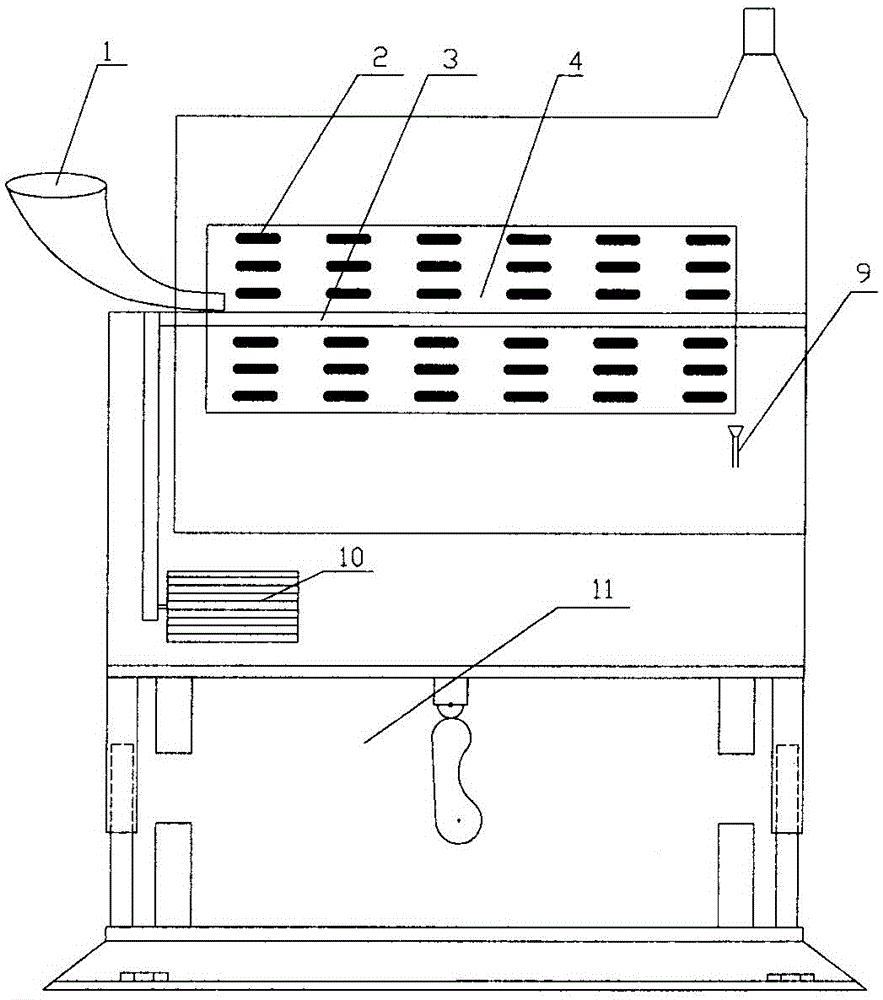

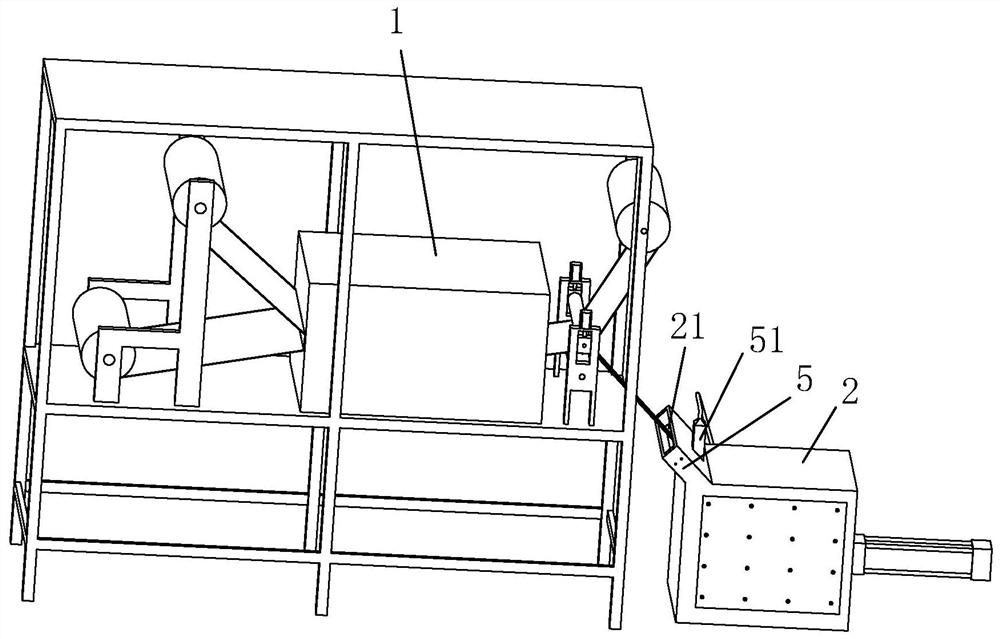

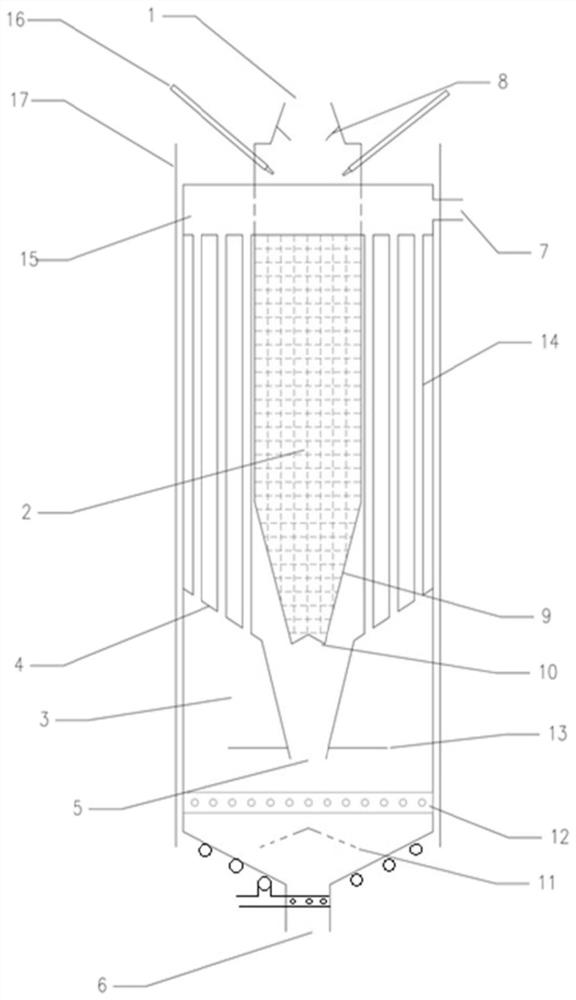

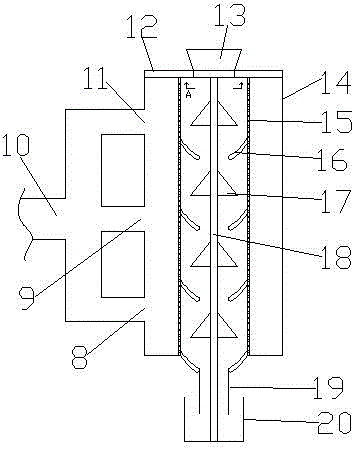

Method and equipment for clearing hot anode scrap electrolytes

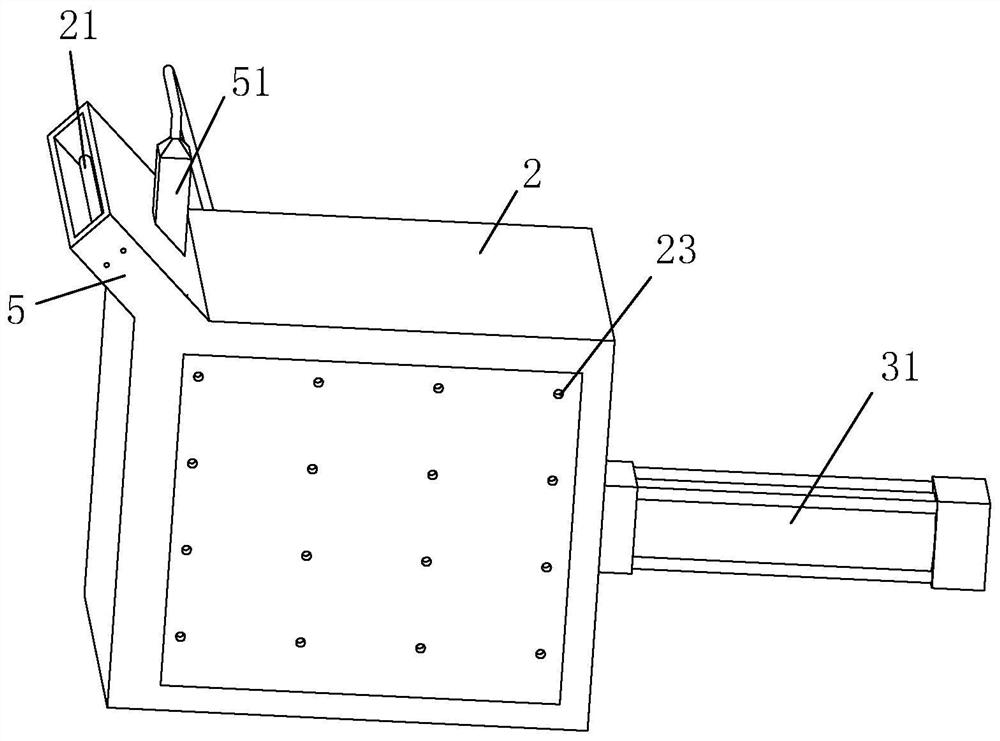

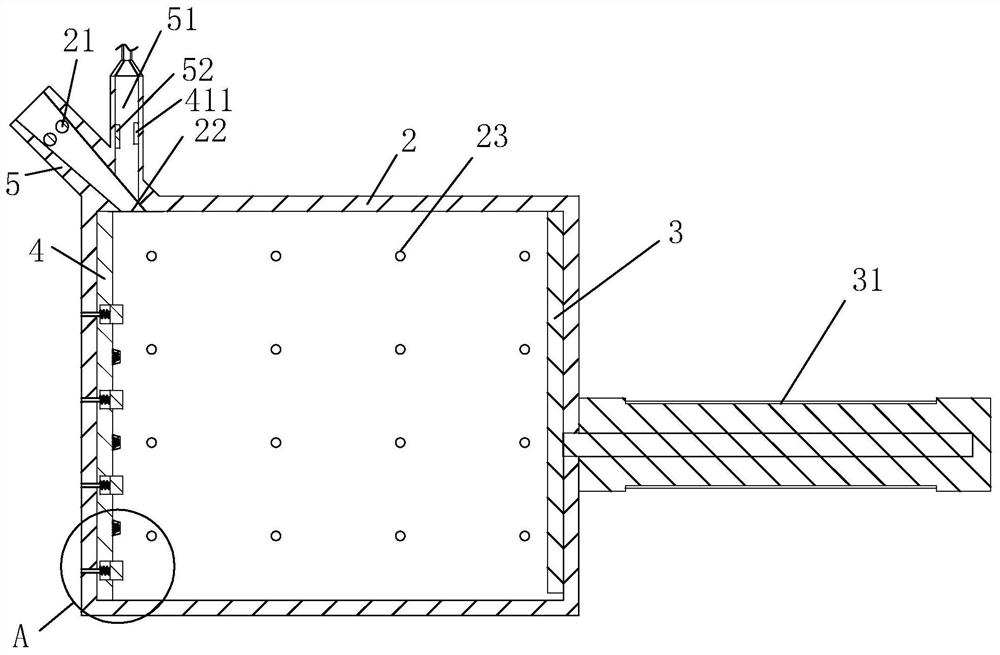

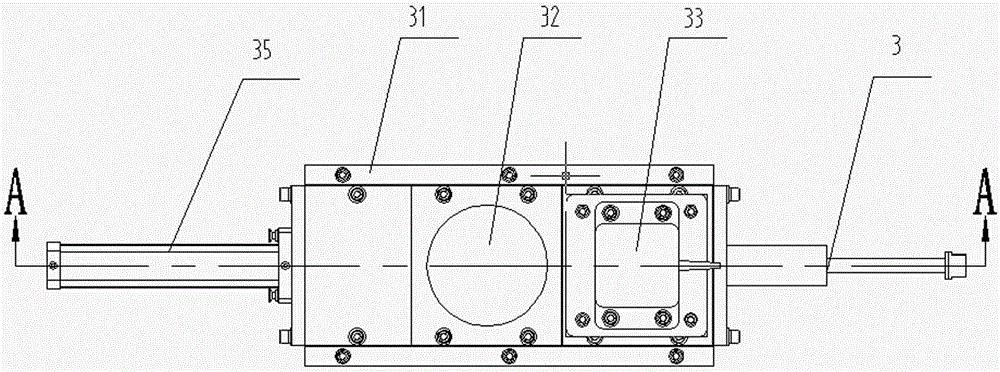

ActiveCN101717966ASave spaceReduce production processCleaning processes and apparatusHydraulic cylinderCrusher

The invention discloses a method and equipment for clearing hot anode scrap electrolytes. A vibrating and beating method is used for clearing hot electrolytes on the surface of an anode scrap. The method comprises the following steps of: conveying a hot anode scrap (9) into heat anode scrap electrolyte clearing equipment through a suspension conveying system; fixing the hot anode scrap (9) through an anode scrap positioning device, driving a vibration box (2) and a scraper knife (3) by a hydraulic cylinder to carry out vibrating and beating clear on the surface of the anode scrap (9), wherein smoke in the clearing process is collected into a smoke processing system through a sealing chamber; and conveying cleared electrolytes into an electrolyte crusher to be crushed through a hopper (8) and a conveyor, wherein the whole clearing process is controlled by a controller PLC. The invention can clear electrolytes on hot anode scraps at a temperature of 150-250 DEG C, and the residual quantity on the surface of the anode scrap after clearing is smaller than 10 percent. The invention reduces working procedures and anode cooling time so as to reduce a use site for anode cooling, and has good clearing effect, simple operation and convenient use.

Owner:洛阳震动机械有限公司

Environmental protection type transparent solid glue and preparation method thereof

ActiveCN102321443AColor transparentHigh hardnessNon-macromolecular adhesive additivesN-vinyl-pyrrolidone polymer adhesivesSodium stearatePreservative

The present invention discloses environmental protection type transparent solid glue. The glue comprises the following components, by weight, 40-50 parts of deionized water, 6-10 parts of an activator, 0.5-2 parts of an antifoaming agent, 15-20 parts of a lubricant, 20-30 parts of a moisturizing agent, 6-10 parts of sodium stearate, 20-30 parts of polyvinylpyrrolidone and 0.2-1 parts of a preservative. In addition, the present invention further provides a preparation method for the environmental protection type transparent solid glue. Compared to the prior art, the environmental protection type transparent solid glue provided by the present invention has characteristics of transparent color, high hardness, good moisture retention, smooth coating without dreg dropping, good oxidation resistance, environmental protection and no toxicity.

Owner:JIANGSU XINGDA STATIONERY GRP

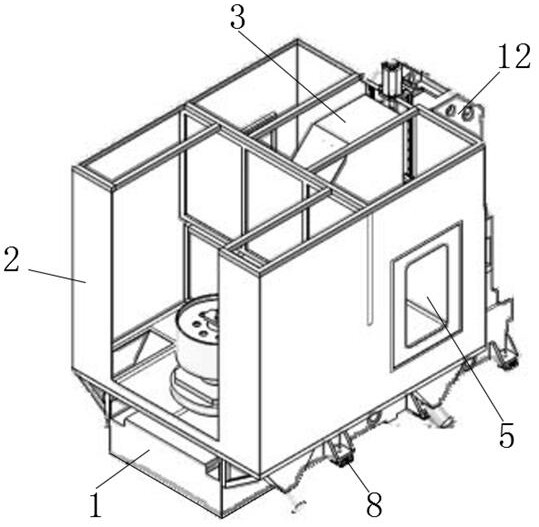

Packaging machine capable of being applied to sampling industry

ActiveCN102730212ASimple structureEasy to controlClosure with auxillary devicesCans/barrels/drumsControl systemProcess engineering

The invention discloses a packaging machine capable of being applied to the sampling industry. The packaging machine comprises a machine frame, wherein a sample inlet mechanism, an automatic cover pressing device, a sample discharge mechanism, a conveying mechanism and a control system are mounted on the machine frame; a plurality of sealable charge buckets are arranged on the conveying mechanism; the motion trails of the charge buckets on the conveying mechanism are connected in series with the sample inlet mechanism, the automatic cover pressing device and the sample discharge mechanism in sequence; and the bucket covers of the charge buckets are pressed to the tops of the charge buckets through the automatic cover pressing device, and mineral samples in the charge buckets are packaged in a sealed way. The packaging machine has the advantages of simple structure, easiness in control process, high running reliability, low fault rate, good sealing property and the like.

Owner:长沙通发高新技术开发有限公司

Waste concrete recycling and screening device

InactiveCN103071624AAvoid pollutionAvoid wastingSievingGas current separationMixed materialsEngineering

The invention discloses a waste concrete recycling and screening device, which mainly comprises a first screening device, a second screening device and vibration devices, wherein the first screening device has a multi-layer rotary screen structure; the second screening device has a single-layer rotary screen structure; the first screening device and the second screening device are connected through conveying equipment; lower parts of the first and second screening devices are provided with the vibration devices; and the first and second screening devices can move vertically along the vibration devices to vibrate. A problem that meshes of the screening devices are blocked is solved and the screening efficiency is improved. A mixture of coarse aggregate (stones), fine aggregate (sand) and hardened mortar recycled from waste concrete is effectively screened, and the separated and screened stones and sand have performance similar to natural stones and sand and can be reutilized in newly mixed concrete; and sand in small grain size (less than 1.25mm) of the hardened mortar and powder in grain size of less than 0.16mm of the hardened mortar can be screened out totally to serve as a cement mixed material or an admixture of premixed concrete, so that waste resources are recycled.

Owner:XUCHANG HENGRUI BUILDING MATERIALS CO LTD

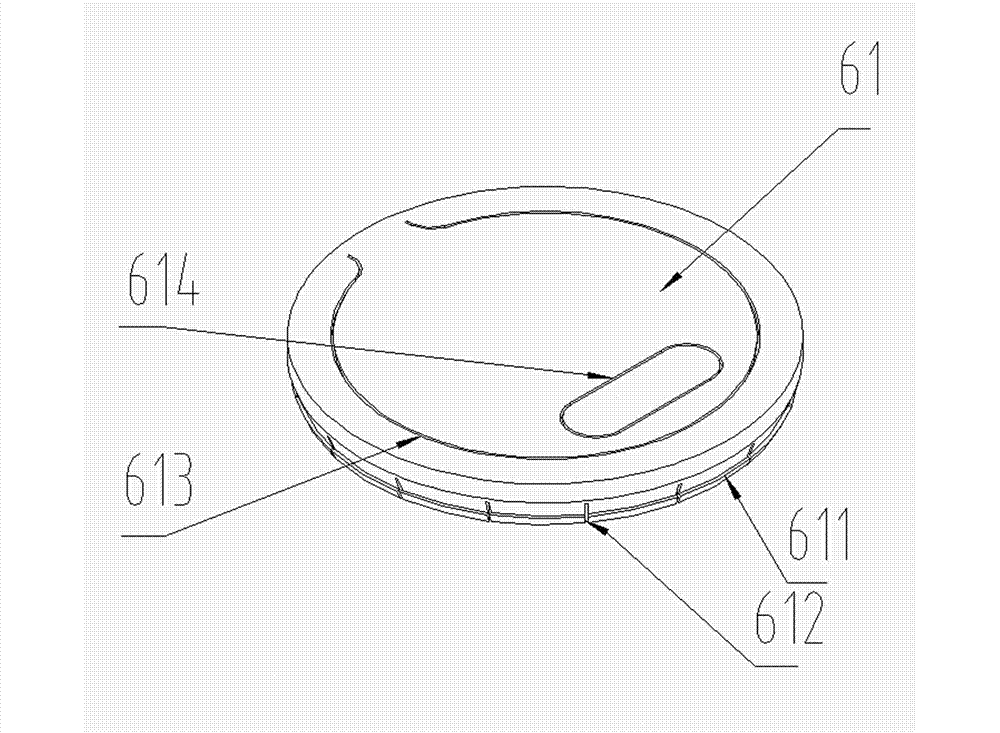

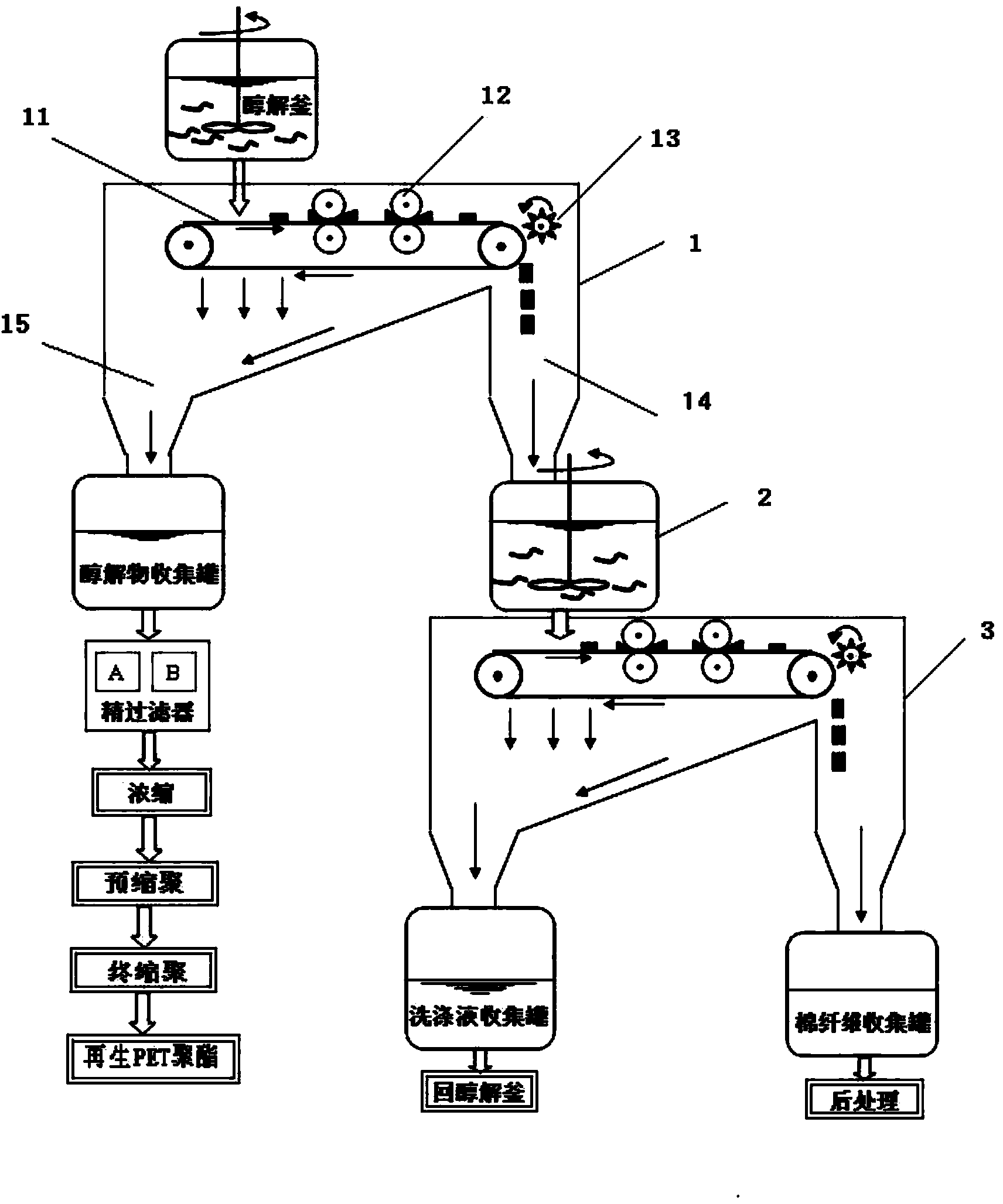

Device and process for continuously separating and recycling waste polyester cotton textiles

InactiveCN104327255AGuaranteed clean productionHigh degree of engineeringPlastic recyclingSolventPolyester

The invention provides a device and process for continuously separating and recycling waste polyester cotton textiles. The device comprises: (1) alcoholysis and polycondensation system, comprising an alcoholysis kettle, an alcoholysis product collecting tank, a fine filter, concentration equipment, a pre-polycondensation kettle and a final polycondensation kettle which are connected in sequence; and (2) a continuous separation system, comprising two sets of continuous separation equipment, an alcoholysis product collecting tank, a cotton fiber collecting and scrubbing tank, a scrubbing solution collecting tank and a cotton fiber collecting tank. The process comprises the following steps: feeding crushed waste polyester cotton textiles into the alcoholysis kettle in which polyester in the crushed waste polyester cotton textiles is subjected to alcoholysis by using ethylene glycol; carrying out continuous separation on mixture of the alcoholysis product and cotton fibers twice to obtain scrubbed cotton fibers and scrubbing solution, wherein both the scrubbed cotton fibers and the scrubbing solution can be recycled; and filtering the separated alcoholysis product, then concentrating and carrying out pre-polycondensation and final polycondensation to obtain regenerated PET polyester. The device and process disclosed by the invention can be used for continuous separation of waste polyester cotton textiles; moreover, the separated polyester and cotton fibers both can be recycled and the solvent also can be recycled.

Owner:SHANGHAI JUYOU CHEM ENG

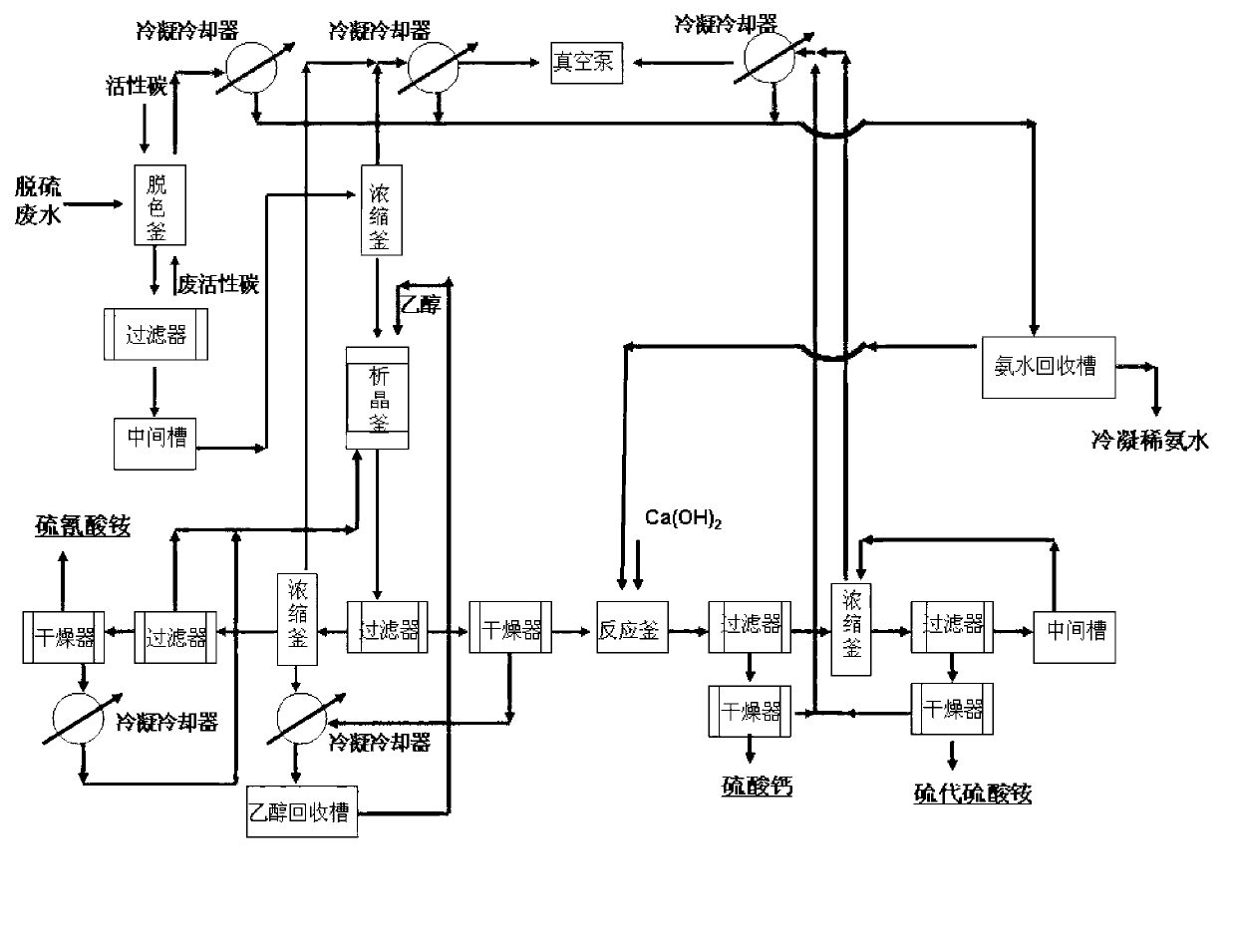

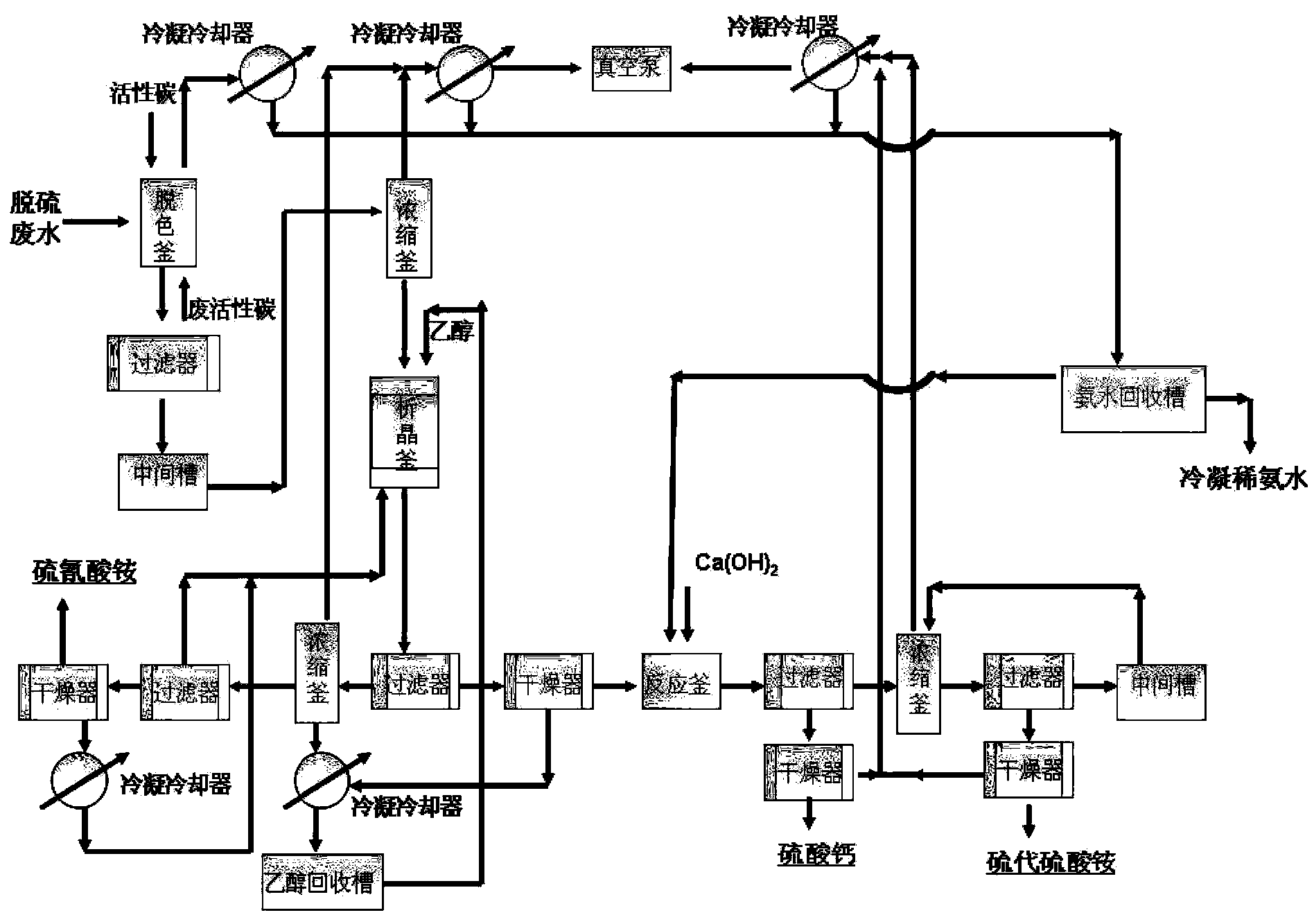

Method for extracting two secondary salts from desulfurized salt-containing waste liquid of coke oven gas

ActiveCN103274367AThorough treatmentNo secondary pollutionThiosulfates/dithionites/polythionitesThiocyanic acidLiquid wasteResource utilization

The invention relates to a method for extracting two secondary salts from a desulfurized salt-containing waste liquid of coke oven gas. The waste liquid treatment and secondary salt extraction process comprises the following steps: decolorizing, removing impurities, performing reduced pressure concentration on the salt-containing filtrate, separating ammonium thiocyanate, concentrating and crystallizing the ammonium thiocyanate ethanol filtrate, drying the ammonium thiocyanate product, separating ammonium sulfate, concentrating and crystallizing the ammonium thiosulfate filtrate, drying the ammonium thiosulfate product and the like. According to the invention, the desulfurized waste liquid is thoroughly treated, the products are high in recovery rate, no mixed salts or waste water is discharged, no secondary pollution is caused, and the process is clean and environment-friendly. Meanwhile, the invention also has the remarkable characteristics of high adaptability, high production elasticity, high resource utilization rate and the like.

Owner:张建利

Prepn process of solid glue capable of adhering repetitively

InactiveCN101067071AImprove antioxidant capacityGood moisturizing effectEster polymer adhesivesN-vinyl-pyrrolidone polymer adhesivesSodium stearateEthylene glycol

The present invention discloses preparation process of solid glue capable of adhering repetitively. The solid glue is prepared with polyacrylate 60-75 weight portions, polyglycol 5-8 weight portions, periston 10-15 weight portions and sodium stearate 6-8 weight portions, and through mixing, heating to 78-80 deg.c, maintaining to reaction for 1 hr, and packing at 80 deg.c. The preparation process is simple and clean, and the solid glue is coated to paper for adhering repetitively.

Owner:JIANGSU XINGDA STATIONERY GRP

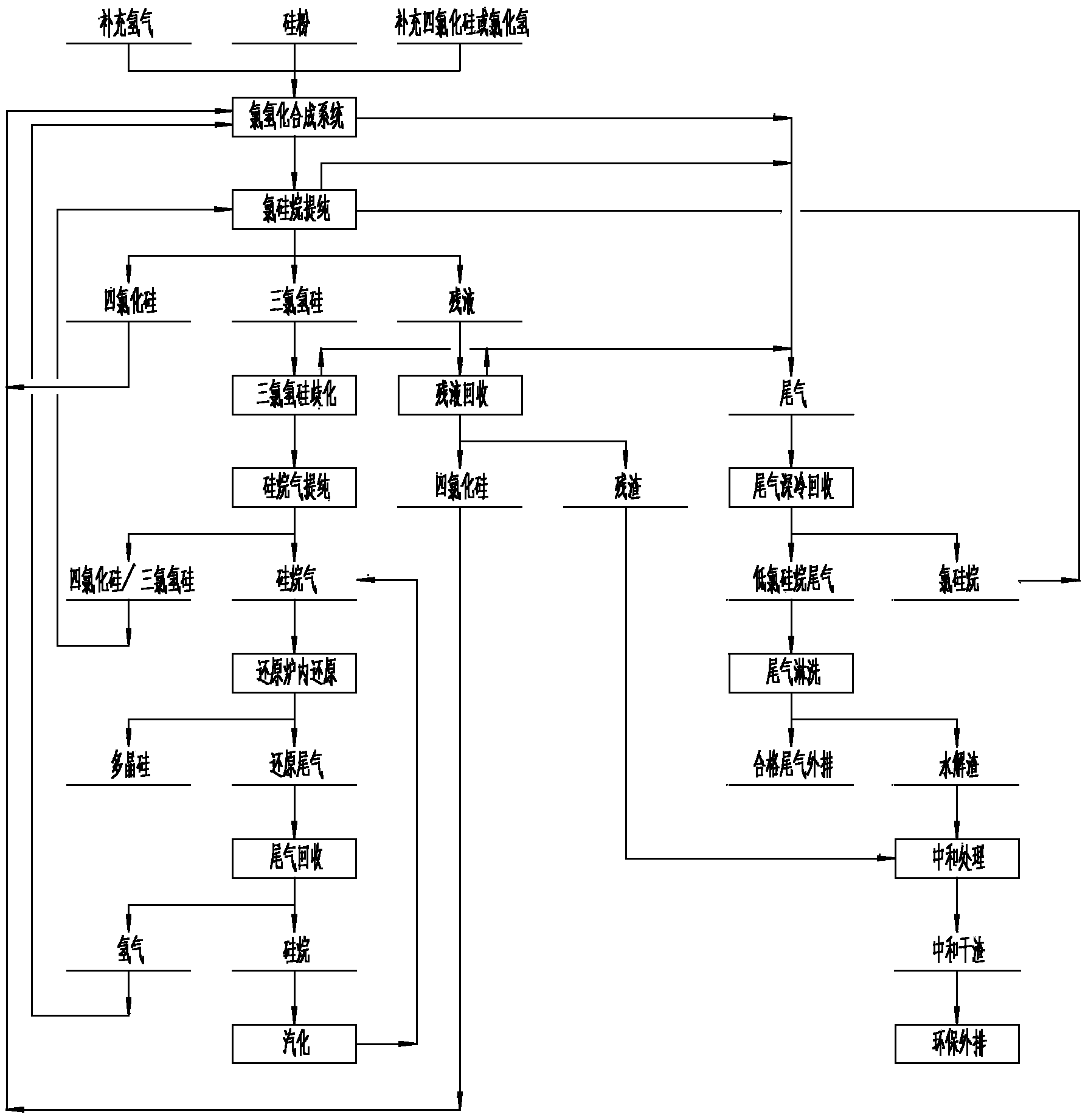

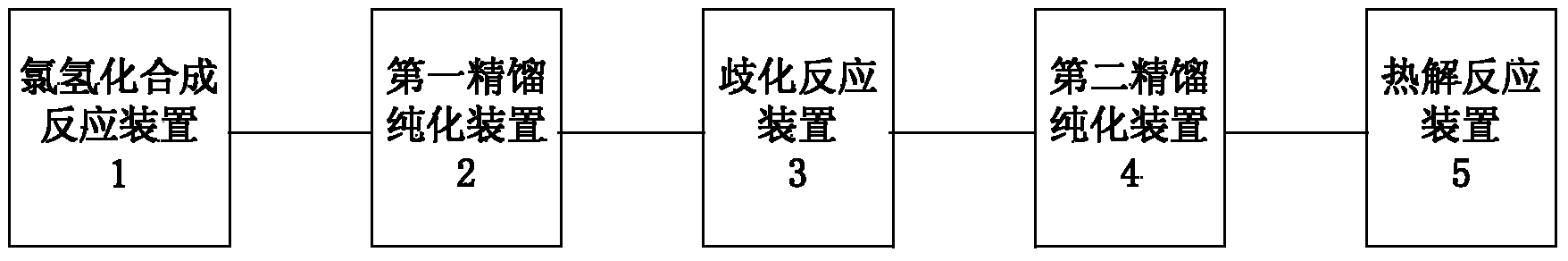

Equipment for purifying trichlorosilane

ActiveCN103449448AImprove efficiencyReduce manufacturing costHalogenated silanesTowerPolycrystalline silicon

The invention discloses equipment for purifying trichlorosilane. The equipment is a first rectifying and purifying device and used for conducting first rectifying and purifying treatment on trichlorosilane so as to obtain purified trichlorosilane and first rectifying residual liquid, wherein the first rectifying and purifying device consists of a first rectifying tower, a second rectifying tower and a third rectifying tower which are connected in series, the rectifying of the first rectifying tower is conducted at the temperature of 60-100DEG C and the pressure of 0.2MPa according to the reflux ratio of (10-50):1; the rectifying of the second rectifying tower is conducted at the temperature of 100-140DEG C and the pressure of 0.5MPa according to the reflux ratio of (20-50):1; the rectifying of the third rectifying tower is conducted at the temperature of 60-80DEG C and the pressure of 0.2MPa according to the reflux ratio of (20-50):1. The equipment can be utilized for effectively purifying the trichlorosilane, and is simple, safe, energy-saving and environment-friendly and low-cost in technique, the purity of the purified trichlorosilane is high, the purified trichlorosilane can be effectively utilized for producing polycrystalline silicon, and the produced waste liquor can be recycled.

Owner:CHINA ENFI ENGINEERING CORPORATION

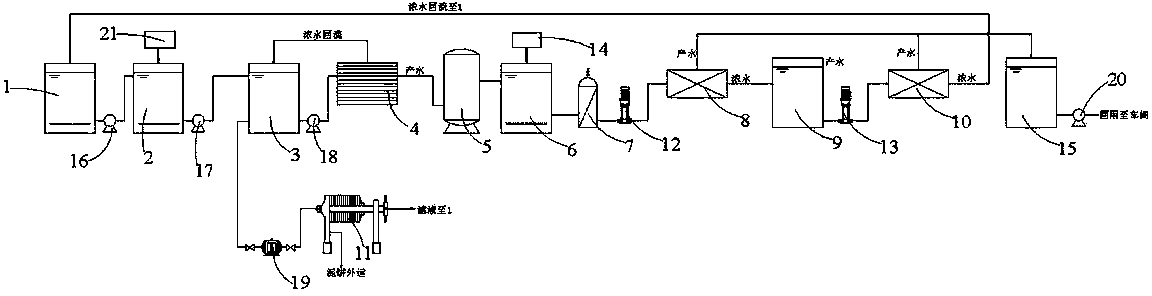

Zero-drainage treatment system and zero-drainage treatment method for nickel plating wastewater in steel workshop

InactiveCN104071925AEasy to removeExtended service lifeWaste water treatment from metallurgical processMultistage water/sewage treatmentFiltrationActivated carbon filtration

The invention belongs to the technical field of sewage treatment systems, and particularly relates to a zero-drainage treatment system for nickel plating wastewater in a steel workshop. The zero-drainage treatment system comprises a collection aeration water tank, a reaction aeration water tank, a concentration water tank, a tubular membrane filtration system, an active carbon filter, a retracement aeration water tank, a security filter, a first-stage RO (reverse osmosis) system, a concentrated water tank, a second-stage RO system, a fresh water tank, a water outlet pump and a plate-and-frame filter press, wherein the reaction aeration water tank is further connected with an alkalifying device, and the retracement aeration water tank is further connected with an acidifying device. Compared with the prior art, the zero-drainage treatment system disclosed by the invention is capable of enabling the wastewater drained from the steel workshop to achieve zero-drainage standards, so as to avoid harm to environment and human health, and enabling the nickel plating wastewater of the steel workshop to be effectively recycled. The invention further discloses a method for using the system for carrying out zero-drainage treatment on the nickel plating wastewater of the steel workshop.

Owner:广东汇金环境科技有限公司

Method for intensively producing refractory material through coal tar pitch needle coke

The invention discloses a method for intensively producing a refractory material through coal tar pitch needle coke. Unutilized QI1 residues of the prior art, coal tar, delayed coking tower side oil products, a modifier and a nickel, vanadium and cobalt removing agent are subjected to separation, sedimentation, purification and oxidization modification to produce a refractory material adhesion agent with high softening point; the refractory material adhesion agent has the performances of high slag resistance, oxidation resistance and thermal shock resistance, is mixed with active agents such as white carbon black, ammonium humate, polyvinyl alcohol, carboxymethyl cellulose and the like and dry pressed to obtain the refractory material for a steel refining furnace, and the refractory material is better than phenolic resin; and the refractory material, carbon black, dimethylbenzene, benzofuran, polyethylene glycol and the like are dissolved, mixed and dissolved so as to obtain a liquid spraying adhesion agent for repairing the steel refining furnace, and the repairing strength of the liquid spraying adhesion agent is better than the repairing strength of common medium temperature pitch. The service lives of equipment such as converters, electric furnaces, calcinators and the like can be prolonged.

Owner:YUNNAN COAL & ENERGY +1

Preparation method of waterborne bass with pressure change resistance and high resilience property

The invention relates to a preparation method of a waterborne bass with pressure change resistance and high resilience property. The method comprises steps as follows: (1) preparation of slurry: 1) preparation of waterborne bass foaming slurry: 10-30 parts of tap water, 2-5 parts of a waterborne dispersant, 1-3 parts of a waterborne crosslinking agent, 3-6 parts of a waterborne stabilizer, 3-6 parts of a waterborne foaming agent, 2-5 parts of a medium-temperature microsphere foaming agent, 20-40 parts of filling powder and 1-2 parts of a thickener are sequentially added to 200-300 parts of waterborne polyurethane resin, the mixture is stirred and mechanically foamed, and the waterborne bass foaming slurry with uniform pores is prepared; 2) preparation of a curing liquid: 85-95 parts of tap water are added to 6-14 parts of a demulsifying curing agent and stirred uniformly, and the curing liquid is obtained; (2) preparation of the waterborne bass: the waterborne bass foaming slurry is uniformly applied to knitted or woven fabric and sequentially subjected to water washing and press drying after being solidified through the curing liquid and finally enters a five-zone stepped heating oven to be foamed and dried, and the waterborne bass is obtained. The waterborne bass is low in cost, safe, environment-friendly and high in pressure change resistance and air permeability.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD

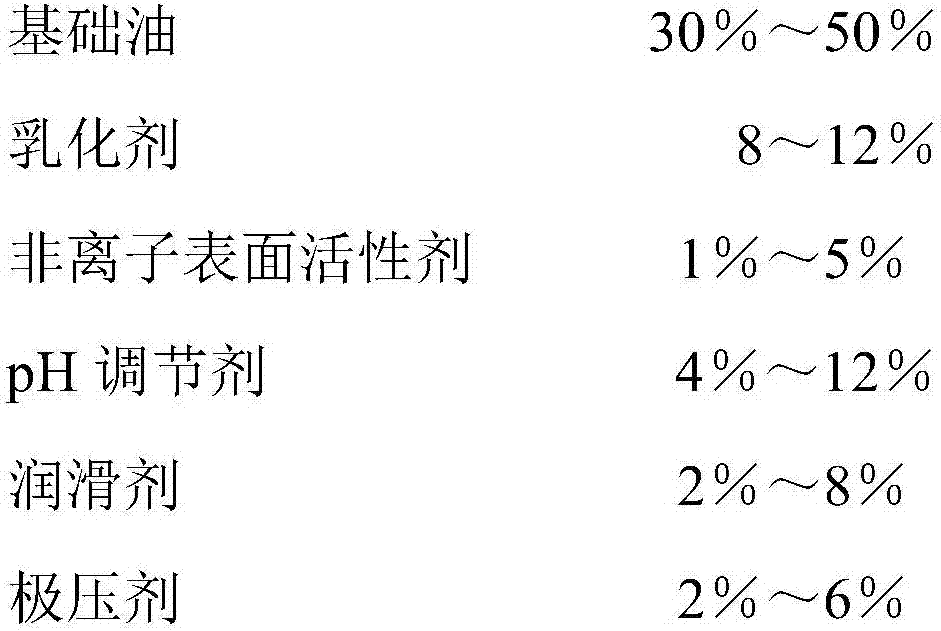

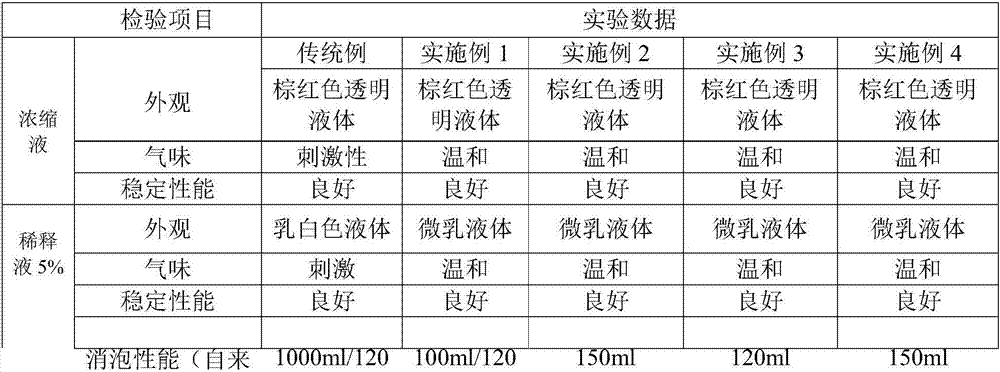

Novel-emulsion-system cutting fluid based on polyisobutylene succinic anhydride and preparation method and application of cutting fluid

ActiveCN107418673AEmulsion system is stableExcellent infiltration and protectionLubricant compositionEmulsionChemistry

The invention belongs to the field of metal cutting fluids, and discloses a novel-emulsion-system cutting fluid based on a polyisobutylene succinic anhydride and a preparation method and application of the cutting fluid. The cutting fluid comprises base oil, a polyisobutylene succinic anhydride mixture (the mixture is formed by mixing of three polyisobutylene succinic anhydrides which separately have a molecular weight of 200, 400 and 1000, and the mass ratio of the polyisobutylene succinic anhydride with a molecular weight of 200 to the polyisobutylene succinic anhydride with a molecular weight of 400 to the polyisobutylene succinic anhydride with a molecular weight of 1000 is 2:1:1), a non-ionic surfactant, a pH modifier, a lubricant, an extreme pressure agent, an antirusting agent, a corrosion inhibitor, and a bactericide. According to the invention, the polyisobutylene succinic anhydride mixture is used as a main emulsifier of the cutting fluid for the first time, thus the emulsion system is very stable, stinking and bacterium growth are not easily, and the product service life is very long, wherein the cutting fluid can be used for half a year or more; and the cutting fluid has properties such as excellent antirust properties, lubricating performance and low-foam performance. The cutting fluid properties are excellent, thus the cutting fluid can be used in machining center with high speed precision, especially the cutting fluid has outstanding performance in a non-ferrous metal processing aspect, and the cutting fluid is mainly used for aspects such as electronic product tapping, and deep-hole drilling.

Owner:广州国机润滑科技有限公司 +1

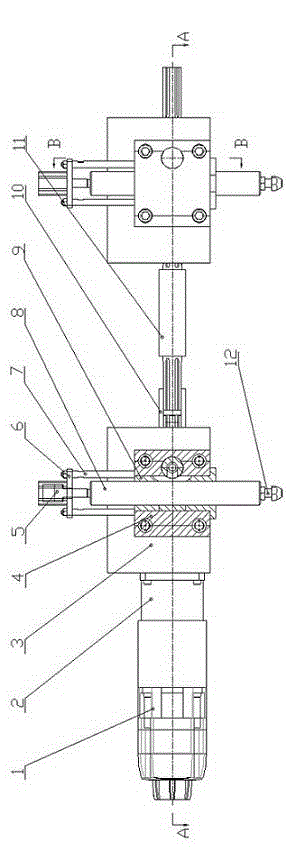

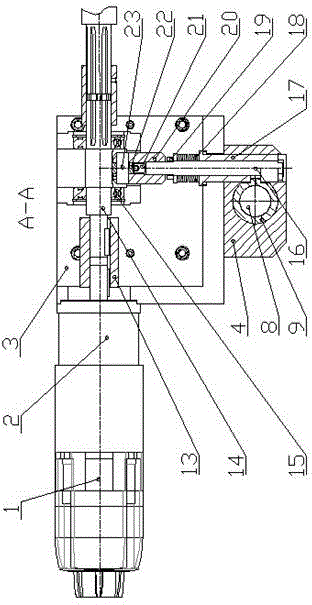

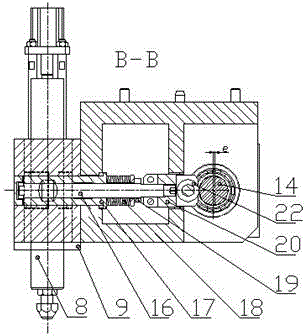

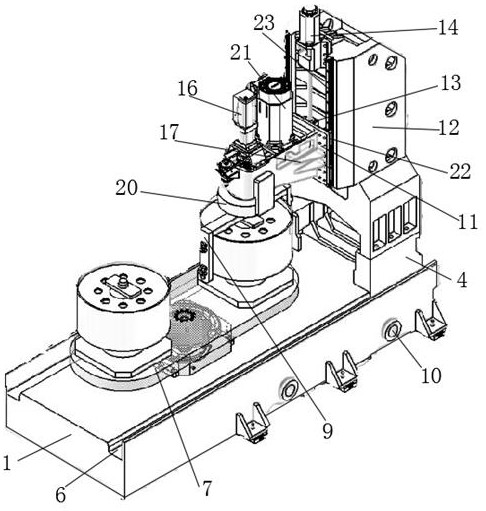

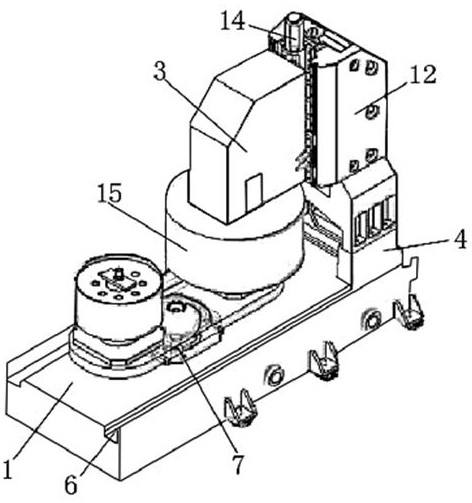

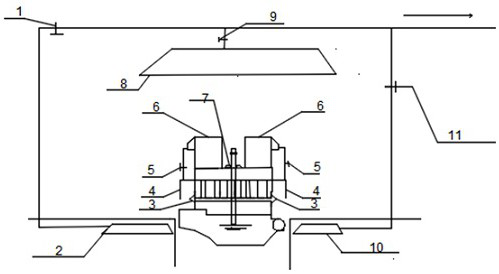

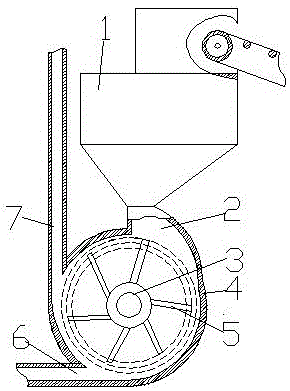

Self-locking pneumoelectric driving auxiliary supporting device

ActiveCN104690580AImprove performanceGuaranteed clean productionWork clamping meansPositioning apparatusMotor driveLocking mechanism

The invention relates to a tool clamp of a combined machine tool, in particular to a self-locking pneumoelectric driving auxiliary supporting device which is composed of a pneumatic supporting mechanism, a spring locking mechanism and an electric unlocking mechanism. A supporting rod (8) in the pneumatic supporting mechanism supports a workpiece, and a jaw formed by a pull rod (16) and a supporting sleeve (17) in the spring locking mechanism elastically locks the supporting rod (8) and then is unlocked through an eccentric wheel (14), so that functions of auxiliary supporting, spring locking and electric unlocking are realized. The self-locking pneumoelectric driving auxiliary supporting device has the advantages that the device is small and adjustable in supporting force, stable and reliable in supporting position, high in workpiece machining accuracy and stable and adjustable in elastic locking force and does not change along with elastic deformation of a supporting face; a motor drives the eccentric wheel (14) to realize unlocking action, and conventional hydraulic driving is replaced, so that clean production is realized. The device can realize multipoint supporting.

Owner:JIANGSU HENGLI MACHINE TOOL

Method for efficiently using converter precipitator dust

InactiveCN106282475AReduce the phosphorus content in the furnacePromote rapid slaggingManufacturing convertersProcess efficiency improvementSlagLiquid surfaces

The invention discloses a method for efficiently using converter precipitator dust, belongs to the technical field of converter steel making methods, and is used for efficient reuse of the precipitator dust. The method is characterized in that the precipitator dust is added along with a chute in the process of extracting vanadium to discharge from semisteel; when the vanadium is extracted to discharge from the semisteel by 1 / 5, a secondary dust removing valve is opened; the chute rotates to add the precipitator dust by one time or two times; after the precipitator dust is added, the precipitator dust is accelerated to melt through front-back movement; the dust removing valve is recovered to a normal state; and after the semisteel is discharged, the iron mixing for converter steel making is prepared. The precipitator dust totally covers the liquid surface of the semisteel to achieve the effect of inhibiting the smoke discharge; the pecipitator dust is molten in a semisteel ladle to form slag to improve the difficulties of making steel slag by the semisteel; and the problems of non-ignition of a converter and explosion venting of an electric field in direct returning of the precipitator dust along with waste steel are solved. The method is an initiate in converter steel making, solves the problem, of capability of effectively using the precipitator dust, not thoroughly solved for a long time, and has the advantages of short flow, high metal yield and low cost.

Owner:HEBEI IRON AND STEEL

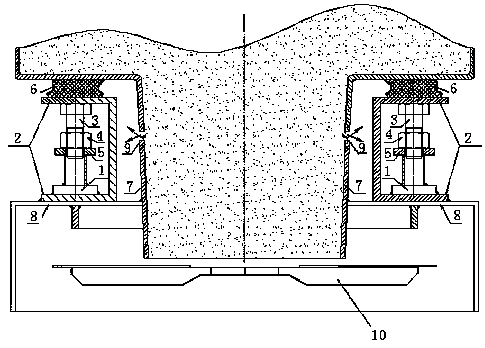

Maerz active lime kiln shell crack sealing device

The invention relates to a Maerz active lime kiln shell crack sealing device, belonging to the technical field of Maerz active lime kiln equipment. The technical solutions are: a sealing plate (2) isarranged on the outside of the kiln shell crack (9), the sealing plate (2) is composed of an upper plate, a lower plate and a side plate, the longitudinal section is U-shaped, the U-shaped opening faces away from the kiln shell, the lower plate of the sealing plate (2) is fixed on the kiln body steel structure (8), a high temperature resistant sealing strip (6) is arranged between the upper plateof the sealing plate (2) and the larger diameter end of the kiln shell, a support assembly (1), a bolt (3), a nut (4) and a washer (5) are arranged between the upper plate and the lower plate of the sealing plate (2), the support assembly (1) is fixed to the lower plate of the sealing plate (2), the bolt (3) is fixed to the support assembly (1) and the bolt (3) is provided with the nut (4) and thewasher (5). The invention has the advantages that the sealing of the cracks in the kiln shell can be realized under the condition that the kiln is not stopped, and the escape of powder ash can be avoided.

Owner:HANDAN IRON & STEEL GROUP +1

Waste concrete recycling and screening device

InactiveCN103071624BAvoid wastingAvoid pollutionSievingGas current separationMixed materialsEngineering

Owner:XUCHANG HENGRUI BUILDING MATERIALS CO LTD

A method for extracting two secondary salts from coke oven gas desulfurization salty waste liquid

ActiveCN103274367BThorough treatmentNo secondary pollutionThiosulfates/dithionites/polythionitesThiocyanic acidLiquid wasteWater discharge

A method for extracting two secondary salts from desulfurized salt-containing waste liquid of coke oven gas. Waste liquid treatment and secondary salt extraction techniques comprise decoloring and decontaminating, decompressing and concentrating the salt-containing filtrate, separating ammonium thiocyanate, concentrating and crystallizing the ammonium thiocyanate ethanol filtrate, drying the ammonium thiocyanate product, separating ammonium sulfate, concentrating and crystallizing the ammonium thiosulfate filtrate, and drying the ammonium thiosulfate product. The invention completely treats desulfurized waste liquid, has high product recycling rate, and produces no mixed salt. The waste water discharge contains no secondary pollution. The technique is clean and environmentally friendly. The invention also has substantial advantages such as high adaptability, scalability, and resource utility rate.

Owner:张建利

Double-station tool for machining outer edges of brakes and machining method of double-station tool

PendingCN112439950AShorten the timeExtended service lifeFeeding apparatusPositioning apparatusBrakeDrive by wire

The invention provides a double-station tool for machining the outer edges of brakes. The double-station tool comprises a machine body, wherein a connecting flange is fixedly connected to the bottom of the machine body; a plurality of chip removal pipes are fixedly connected to the two side walls of the machine body; a shell is fixedly connected to the periphery of the top of the machine body; a double-station cam workbench is fixedly connected to the front end of the upper surface of the machine body; sliding rails are arranged on the two sides of the upper surface of the machine body; a linear drive frame is arranged at the rear end of the upper surface of the machine body and is in sliding clamping connection with the sliding rails; and an air cylinder support is fixedly connected to the top of the linear drive frame. According to the double-station tool for machining the outer edges of the brakes and a machining method of the double-station tool, the two brakes are assembled on thedouble-station cam workbench, one brake is used for machining, and the workpiece installing time is saved; and the linear drive frame works to drive the air cylinder support to push, the linear driveframe slides on the sliding rails, a cross beam is driven to move, the effect of better collecting waste chips generated during machining is achieved, the machining efficiency is greatly improved, and workpiece installing and replacing are more user-friendly.

Owner:青岛海通制动器有限公司

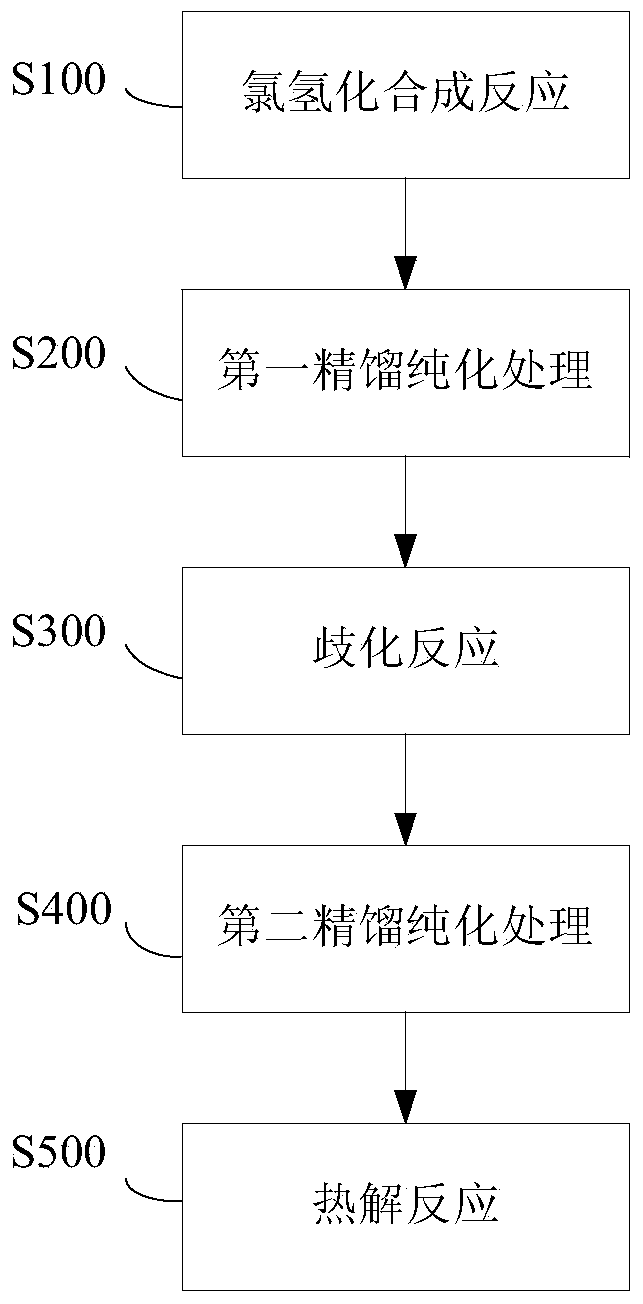

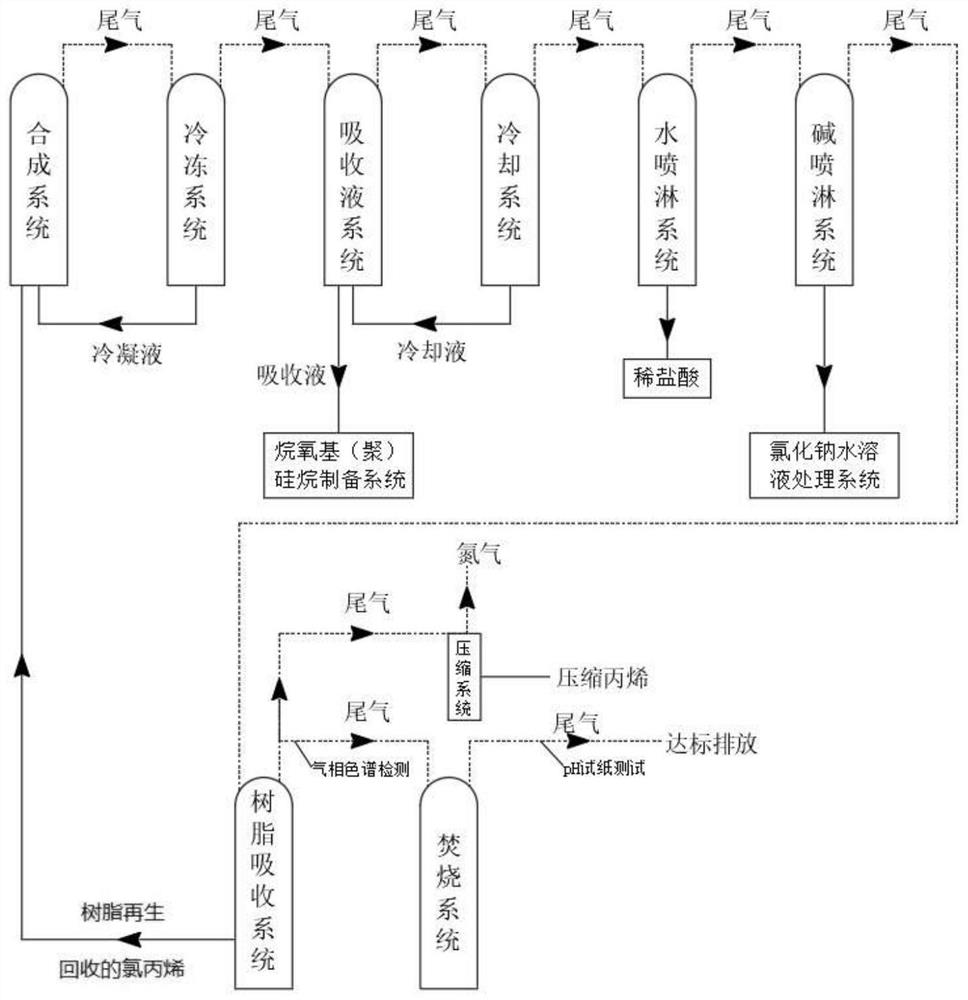

Environment-friendly treatment method for 3-chloropropyltrichlorosilane synthetic tail gas

ActiveCN112473314AEfficient use ofIncrease economic value addedGas treatmentDispersed particle separationThermodynamicsProcess engineering

The invention discloses an environment-friendly treatment method for 3-chloropropyltrichlorosilane synthetic tail gas, and belongs to the technical field of chemical engineering. The environment-friendly treatment method for the 3-chloropropyltrichlorosilane synthesis tail gas comprises the steps of enabling the synthesis tail gas to sequentially pass through a refrigerating system, an absorptionliquid system, a cooling system, a water spraying system, an alkali spraying system and a resin absorption system, and finally, discharging the tail gas after the tail gas is monitored to be qualifiedthrough an incineration system, or obtaining a compressed propylene product through a compression system. All components in the tail gas can be effectively separated from or removed from the tail gasand recycled or subjected to next-step environment-friendly treatment, the environment-friendly problem of a traditional tail gas treatment process is solved, the generation of wastes is effectivelyavoided, the factory environment is improved, and a brand new idea is provided for the treatment method of the synthetic tail gas. In addition, propylene gas in the tail gas can also be made into a product, so that the additional value of byproducts is increased, the production cost of 3-chloropropyltrichlorosilane is reduced, and energy saving and emission reduction are achieved.

Owner:南京曙光新材料有限公司

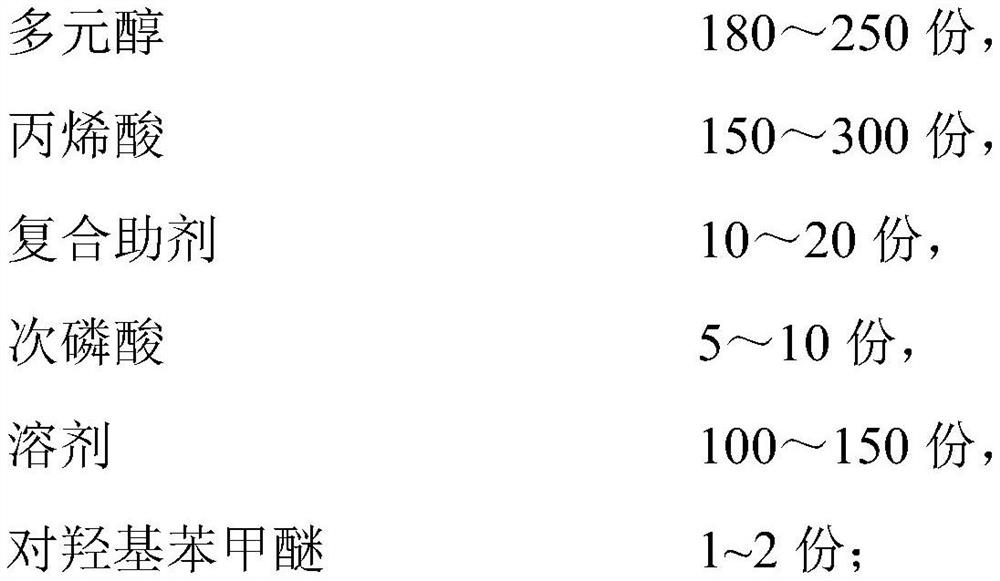

Ultraviolet light curing monomer as well as preparation method and application thereof

The invention provides an ultraviolet light curing monomer, which comprises the following raw materials: polyol, acrylic acid, a composite auxiliary agent, hypophosphorous acid, p-hydroxyanisole and asolvent; wherein the composite auxiliary agent is formed by compounding copper methanesulfonate and methanesulfonic acid, the copper methanesulfonate and methanesulfonic acid are compounded as the composite auxiliary agent, and the solvent is an organic solvent. Copper methanesulfonate of a composite auxiliary agent is used as a polymerization inhibitor, and methanesulfonic acid is used as a catalyst, wherein a catalytic esterification reaction is carried out under an acidic condition, so that the reaction efficiency is improved, and a compound of copper methanesulfonate and methanesulfonic acid is used as the composite auxiliary agent, so that the reaction efficiency is improved, and the product purity is also improved; furthermore, chlorine-containing compounds are completely preventedfrom being used as auxiliaries in the reaction process, stress corrosion of chloride ions to stainless steel equipment is avoided; therefore, the service life of the equipment is prolonged, the use amount of detergent can be greatly reduced, and the environmental goal of clean production is achieved.

Owner:濮阳展辰新材料有限公司

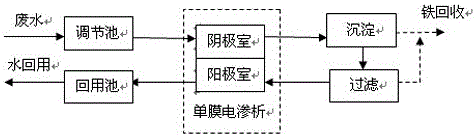

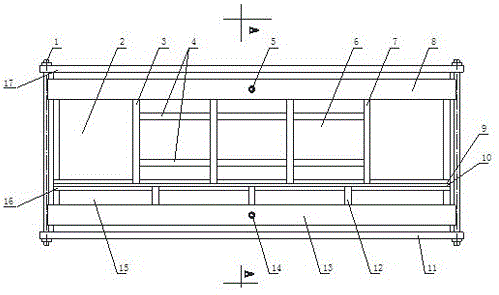

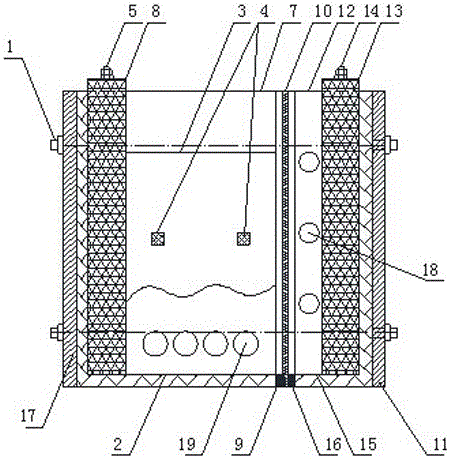

Resourceful treatment process for silicon carbide pickling wastewater

InactiveCN105731696AAchieve separationLower iron levelsCellsPhotography auxillary processesFiltrationWastewater

The invention discloses a resourceful treatment process for silicon carbide pickling wastewater, and the resourceful treatment process mainly adopts a process route of taking single membrane electroosmosis+ precipitation+ filtration as a pickling wastewater resourceful treatment technology. On the premise of not introducing extra chemical agent, separation of acid and metal ions in sulfuric acid pickling wastewater can be effectively realized, so that the iron content in the sulfuric acid pickling wastewater is guaranteed to be reduced to be lower than 10mg / L from 500mg / L, the iron recovery rate is 90% or higher, and the acid recovery rate is 99% or higher. According to the resourceful treatment process, no other impurities are newly introduced, and 3g of concentrated sulfuric acid with concentration being 98% only needs to be added into every liter of the recycled sulfuric acid pickling wastewater, so that the acidity of the recycled sulfuric acid pickling wastewater is supplemented to be 3%, and therefore, wastewater recycling can be realized. Meanwhile, simple substances and / or compounds are generated by the treatment process, so that zero release can be realized, clean production is guaranteed, and resource recycling of wastewater and iron is realized, and therefore, very good economic and environmental benefits are generated.

Owner:HENAN UNIVERSITY

Boric ester base fluid for brake fluid and preparation method thereof

ActiveCN102031179BLow costIncrease productivityGroup 3/13 element organic compoundsBase-materialsOxygenVariable pressure

Owner:BEIJING UNIV OF CHEM TECH

A kind of preparation method of water-based bass with compression resistance and high resilience performance

The present invention relates to a kind of preparation method of the water-based bass with pressure-resisting and high-resilience performance, and the method comprises the following steps: (1) preparing slurry: ① preparing water-based bass foaming slurry: adding 200 to 300 parts of water-based polyurethane resin in turn Add 10-30 parts of tap water, 2-5 parts of water-based dispersant, 1-3 parts of water-based cross-linking agent, 3-6 parts of water-based foam stabilizer, 3-6 parts of water-based foaming agent, 2-5 parts of medium-temperature microsphere hair Foaming agent, 20-40 parts of filling powder, 1-2 parts of water-based thickener, after stirring and mechanical foaming, a water-based bass foaming slurry with uniform cells is obtained; Add 85~95 parts of tap water to 1 part of demulsification curing agent, stir evenly to get the solidified solution; (2) Preparation of water-based base: apply the water-based base foam slurry evenly on the knitted or woven fabric, and solidify with the solidified solution After that, it is washed with water and pressed dry in turn, and finally enters the five-zone stepped heating oven for foaming and drying. The invention has the advantages of low cost, safety and environmental protection, pressure change resistance and strong air permeability.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD

A paper laminating machine

ActiveCN111332013BEasy to collectEasy access collectionPrinting press partsThin membraneProcess engineering

The invention relates to a paper laminating machine, which comprises a laminating body, a waste box is arranged at the tail of the laminating body, a waste guide roller is arranged on the waste opening on the top of the waste box, and a squeezing plate and a collision plate are respectively arranged at both ends of the waste box. , the waste box is provided with a telescopic device that drives the extruding plate to move to the collision plate, and the side of the collision plate close to the extrusion plate is provided with several heat-melting platforms, and a heater is arranged in the heat-melting platform. Squeeze the waste film to increase the collection amount in the waste box, and heat and fuse the waste film after extrusion to maintain the extrusion state and increase the collection amount, which is convenient for the subsequent collection of waste film.

Owner:台州市美琪乐工艺品有限公司

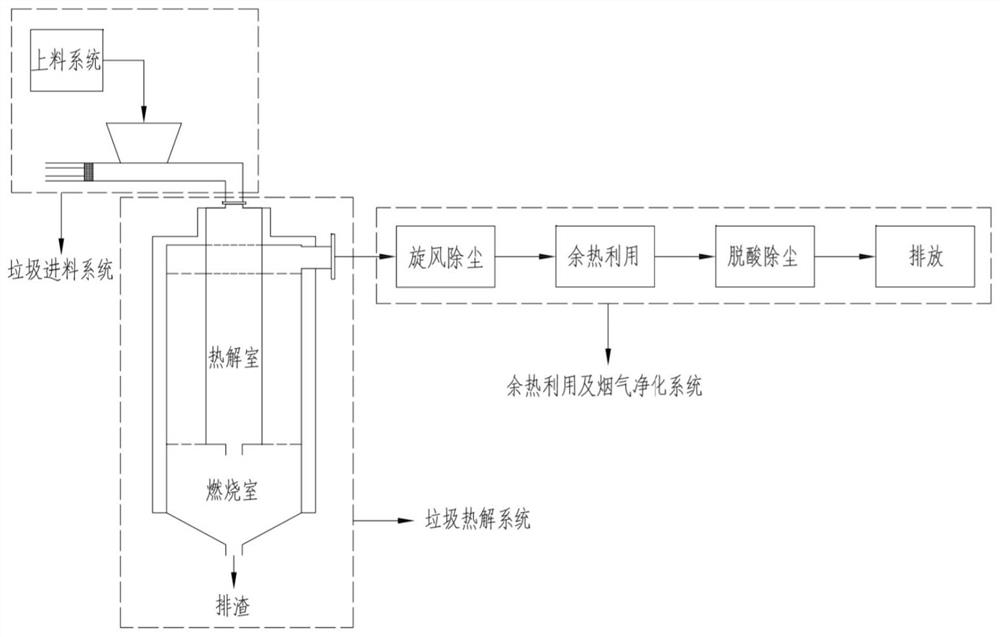

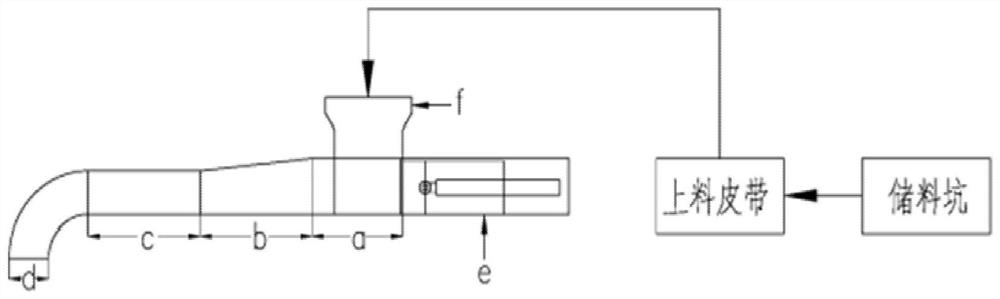

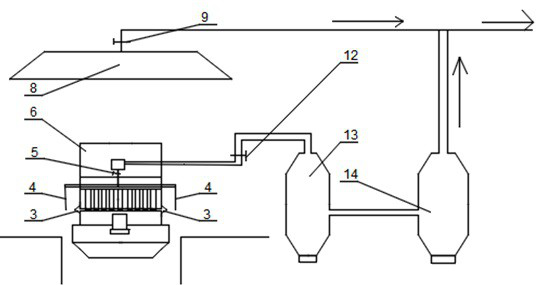

A high-temperature pyrolysis system for domestic waste treatment

ActiveCN112610959BClean and beautiful external environmentAvoid it happening againCombustion technology mitigationIncinerator apparatusCombustion chamberSlag

The invention discloses a high-temperature pyrolysis system for domestic waste treatment, belonging to the field of solid waste harmless disposal, which includes a waste feeding unit, a waste pyrolysis unit, a pyrolysis gas combustion and heat exchange unit, a tail gas treatment unit and There is a sealed cover between the ash discharge unit, the garbage feeding unit and the garbage pyrolysis unit. The integrated garbage pyrolysis and combustion furnace is cylindrical in shape with a height-to-diameter ratio of 2 to 4, and its internal cavity is divided into thermal The pyrolysis chamber and the combustion chamber are equipped with a solid cloth grid. The pyrolysis gas combustion and heat exchange unit includes a plurality of heat exchange tubes arranged around the pyrolysis chamber with the pyrolysis chamber as the center of the circle. The tail gas treatment The unit is connected to the gas collecting hood on the top of the furnace, which is used to treat the tail gas to prevent environmental pollution. The ash discharge unit is connected to the slag discharge port of the garbage pyrolysis and combustion integrated furnace, which can provide a sealed channel for the ash discharge. The high-temperature pyrolysis system of the invention can continuously and stably perform garbage pyrolysis, oxygen-controlled combustion and tail gas treatment, and is environmentally friendly without odor and waste water.

Owner:武汉可立尔环保科技有限公司

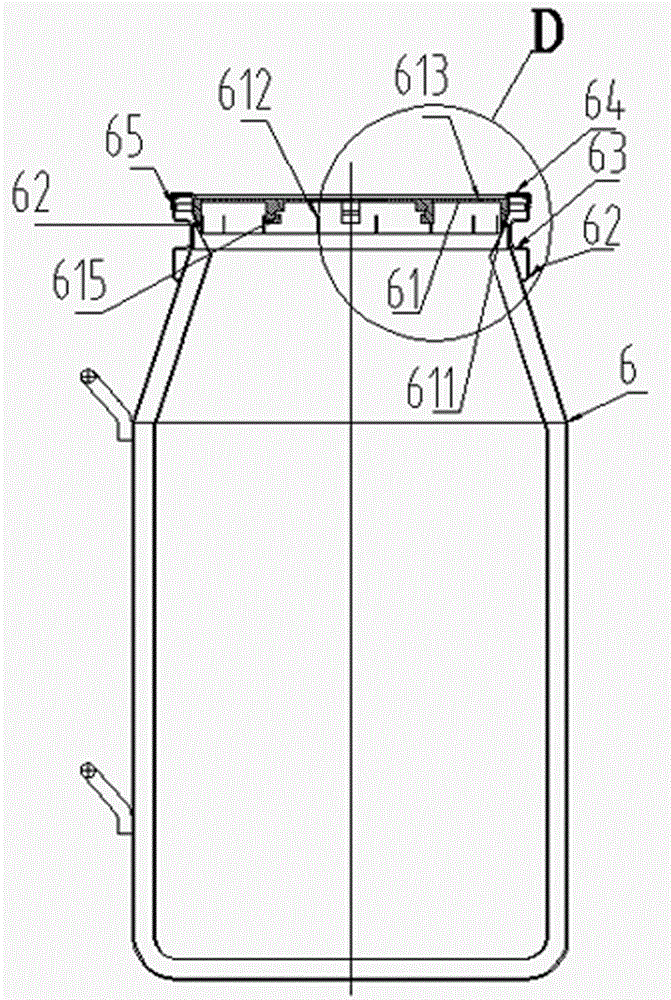

A clean production control method for vertical electric furnace steelmaking

ActiveCN111485059BReduce escapeGuaranteed clean productionDirt cleaningProcess efficiency improvementSteelmakingFlue gas

The invention relates to a clean production control method for vertical electric furnace steelmaking, which belongs to the technical field of metallurgy and environmental protection. The technical solution of the present invention is: to install individual flue gas collection hoods at all the flue gas generating points of the vertical electric furnace; to divide all the flue gas collection hoods into system functions; to carry out secondary classification and independent control of the same functional flue gas collection system; Through different scrap steel cone ratios, different flue gas system control models are formulated; according to different smelting periods, the residual CO in the primary flue gas is burned by adjusting the special valve (5) for secondary combustion, and then the flue gas is treated. The beneficial effects of the present invention are: 100% capture and treatment of vertical electric furnace steelmaking flue gas; reduction of escape of primary flue gas, improvement of airtightness in electric furnace, and reduction of dioxin generation in flue gas; The interlocking control adjustment is more conducive to the energy saving of the system; it can ensure the clean production of the vertical electric furnace steelmaking.

Owner:SHIJIAZHUANG IRON & STEEL

Packaging machine capable of being applied to sampling industry

ActiveCN102730212BSimple structureEasy to controlClosure with auxillary devicesCans/barrels/drumsControl systemProcess engineering

Owner:长沙通发高新技术开发有限公司

Method for intensively producing refractory material binder by coal tar pitch needle coke

The invention discloses a method for intensively producing a refractory material binder by coal tar pitch needle coke, comprising: separating, settling, purifying, oxidizing and modifying the QI1 residue which is not utilized in the prior art, coal tar, byproduct oils of a delay coking tower, a conditioning agent and a nickel, vanadium and cobalt depriving agent, to obtain the refractory materialbinder with high softening point, high slagging resistance, high oxidizability and high thermal shock resistance, mixing the refractory material binder with the activators: white carbon black, ammonium humate, polyvinyl alcohol, carboxymethyl cellulose, etc., and dry-pressing and forming the mixture to obtain the refractory material for a steel furnace with the performance batter than that of thephenolic resins. The refractory material binder is dissolved in the solution of carbon black, xylene, coumarone, polyethylene glycol, etc., to obtain a liquid spray coating type binder for repairing the steel furnace, which has higher repairing intensity than the common medium temperature asphalt does. The refractory material binder can effectively prolong the service life of a converter, an electric furnace, a calciner, etc.

Owner:YUNNAN COAL & ENERGY +1

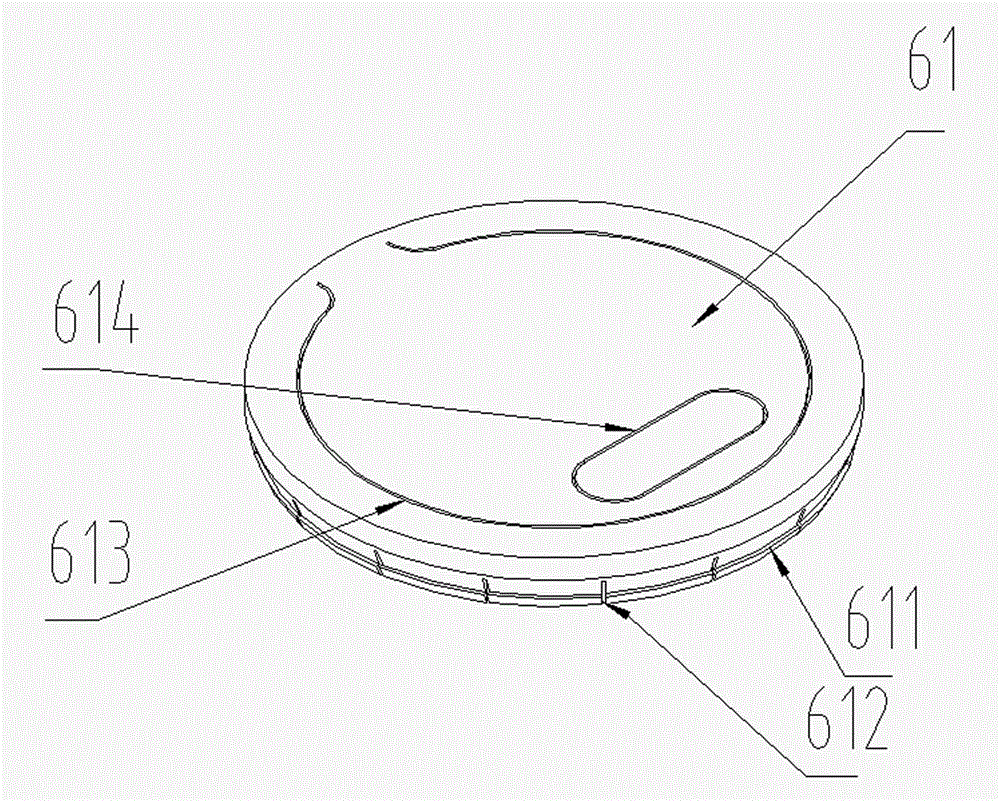

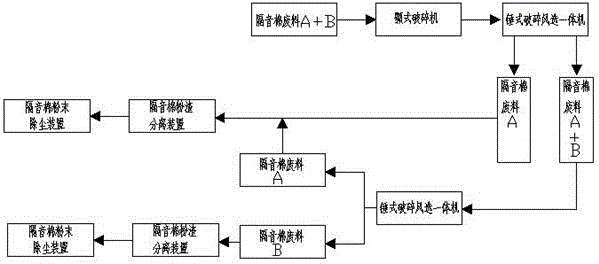

A kind of sound insulation cotton waste recycling method

ActiveCN104760157BIncrease profitAchieve brokenSievingGas current separationEnvironmental resistanceResource recovery

The invention discloses a recycling method for sound-insulation cotton waste and belongs to the technical field of resource recycling. The method comprises the treating steps: performing first-level crushing on the sound-insulation cotton waste, performing second-level crushing on the sound-insulation cotton waste subjected to the first-level crushing, performing first-level air separation on the sound-insulation cotton waste subjected to the second-level crushing, performing third-level crushing on the sound-insulation cotton waste subjected to the first-level air separation, performing second-level air separation on the sound-insulation cotton waste subjected to third-level crushing, separating the sound-insulation cotton waste subjected to second-level air separation and dedusting the separated sound-insulation cotton. According to the method, the continuous crushing, separation, purification and dedusting on the sound-insulation cotton waste are realized; separated rubber and felt can be recycled, so that the engineering degree is high; the dedusting can be further performed after crushing and separation, so that the cleaning production is ensured, and the environment protection is facilitated; a sound-insulation cotton waste indentifying process is not required; and the method has the characteristics of being large in treating amount, easy in industrial application, low in cost, high in efficiency, simple in structure, free of pollution and the like, and the environment pollution is reduced.

Owner:武汉蓝格包装材料有限公司

Preparation process of solid glue capable of adhering repetitively

InactiveCN100503763CImprove antioxidant capacityGood moisturizing effectEster polymer adhesivesN-vinyl-pyrrolidone polymer adhesivesSodium stearateAdhesive glue

Owner:JIANGSU XINGDA STATIONERY GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com