Novel-emulsion-system cutting fluid based on polyisobutylene succinic anhydride and preparation method and application of cutting fluid

A technology of polyisobutenyl succinic anhydride and emulsification system, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of large environmental pollution, low production efficiency, unenvironmental protection, etc., and achieves stable emulsification system, safe use, and maintenance of clean production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

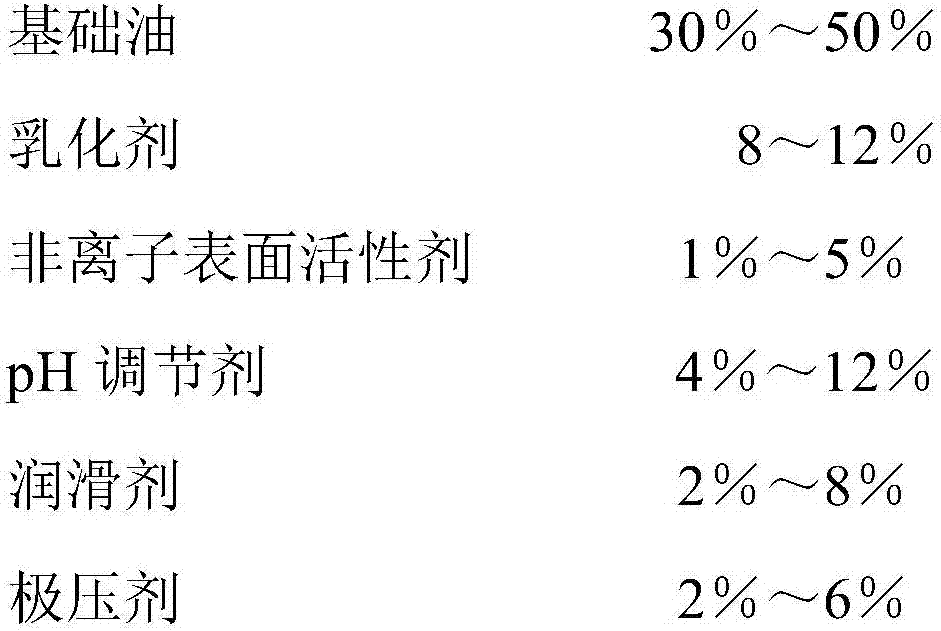

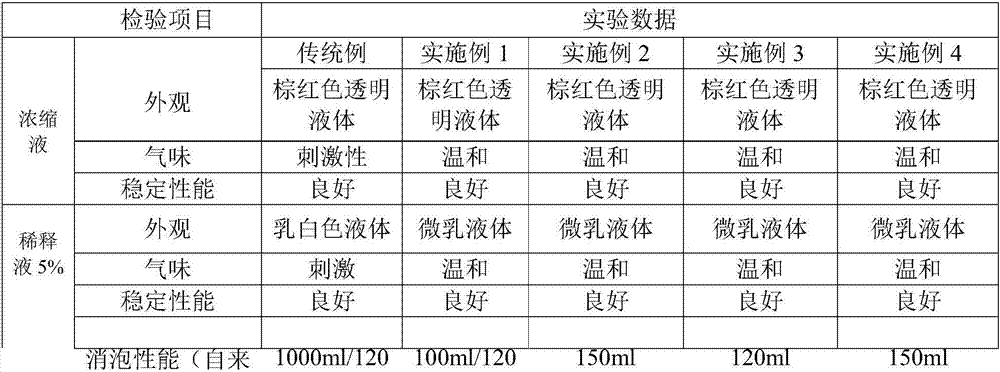

Embodiment 1

[0034]A kind of cutting fluid based on the novel emulsification system of polyisobutenyl succinic anhydride; Comprising the raw material of following percentage by weight: base oil (naphthenic mineral oil) 45%, polyisobutene succinic anhydride mixture 10%, nonionic surfactant (loss Sorbitan oleate) 4%, pH adjuster (a mixture of triethanolamine 5%, diglycolamine 2% and alkylamine 2%) 9%, rust inhibitor (a mixture of polymeric acid and dimeric acid ) 7%, lubricant (trimethylolpropane oleate) 6%, extreme pressure agent (a mixture of chlorinated paraffin 5% and modified phosphate ester 1%) 6%, corrosion inhibitor (phosphate ester) 1% , fungicide (1,2-benzisothiazolin-3-one) 2% and the balance water.

Embodiment 2

[0036] A kind of cutting fluid based on the novel emulsification system of polyisobutenyl succinic anhydride; Comprising the raw material of following percentage by weight: base oil (castor oil) 40%, polyisobutylene succinic anhydride mixture 12%, nonionic surfactant (fatty alcohol polyoxygen Vinyl ether) 5%, pH adjuster (a mixture of 1% triethanolamine, 3% monoethanolamine and 2% alkylamine) 6%, lubricant (stearate) 2%, rust inhibitor (dimer acid and Organic carboxylate mixture) 10%, extreme pressure agent (mixture of sulfurized vegetable oil fatty acid 2% and modified phosphate ester 2%) 4%, fungicide (2-butyl-1,2-benzisothiazoline- 3-keto) 2% and the balance water.

Embodiment 3

[0038] A cutting fluid based on a novel emulsified system of polyisobutenyl succinic anhydride; raw materials comprising the following percentages by weight: base oil (mixed oil of sunflower oil and cottonseed oil) 50%, polyisobutylene succinic anhydride mixture 8%, non-ionic surface Active agent (fatty alcohol polyoxyethylene ether) 3%, pH regulator (2-amino-2-methyl-1-propanol 4%, triethanolamine 4% and monoethanolamine 3% mixture) 11%, lubricant (trimethylolpropane oleate) 3%, rust inhibitor (mixture of dimer acid and organic carboxylate) 10%, extreme pressure agent (mixture of chlorinated paraffin 3% and modified phosphate ester 1%) 4%, slow release agent (phosphate) 1%, bactericide (3-iodo-2-propynyl butyl carbamate) 3% and the balance water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com