Crisp sandwich toffee and preparation technology thereof

A sandwich cream and preparation technology, which is applied in the confectionary industry, confectionary, food science, etc., can solve the problems of lack of chewing feeling, short shelf life, poor taste, etc., and achieves the convenience of industrial production, simple production process, and emulsification system stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

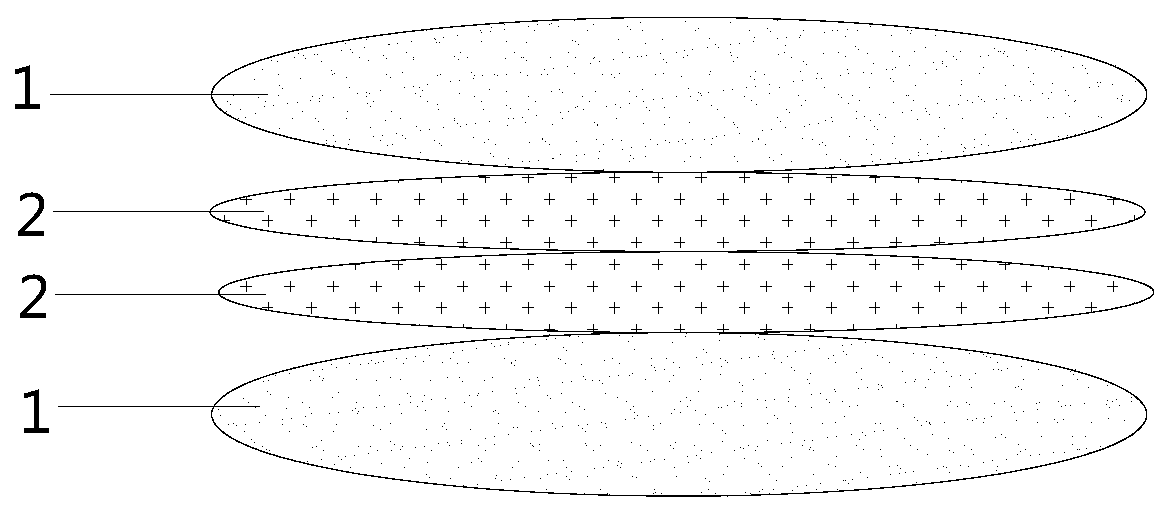

[0025] Such as figure 1 As shown, a crispy type sandwich toffee, the crispy type sandwiched toffee is formed by compounding a creamy crispy layer 1 and a sandwich layer 2, the inside of the creamy crispy layer 1 is uniformly formed with pores, and the creamy crispy layer 1 The raw material is composed of the following mass fractions, cocoa butter substitute 0.1-0.5%, whey powder 10-30%, milk powder 10-30%, white sugar 10-30%, lactose 3-8%, and the balance is water.

[0026] In this embodiment, the butterfat crispy layer 1 is composed of the following raw materials in mass fractions, cocoa butter substitute 0.-0.5%, whey powder 20%, milk powder 20%, white sugar 20%, lactose 5%, and the balance is water.

[0027] The sandwich layer 2 is composed of solid particles, which include walnut kernels, peanuts, barley, oatmeal and the like.

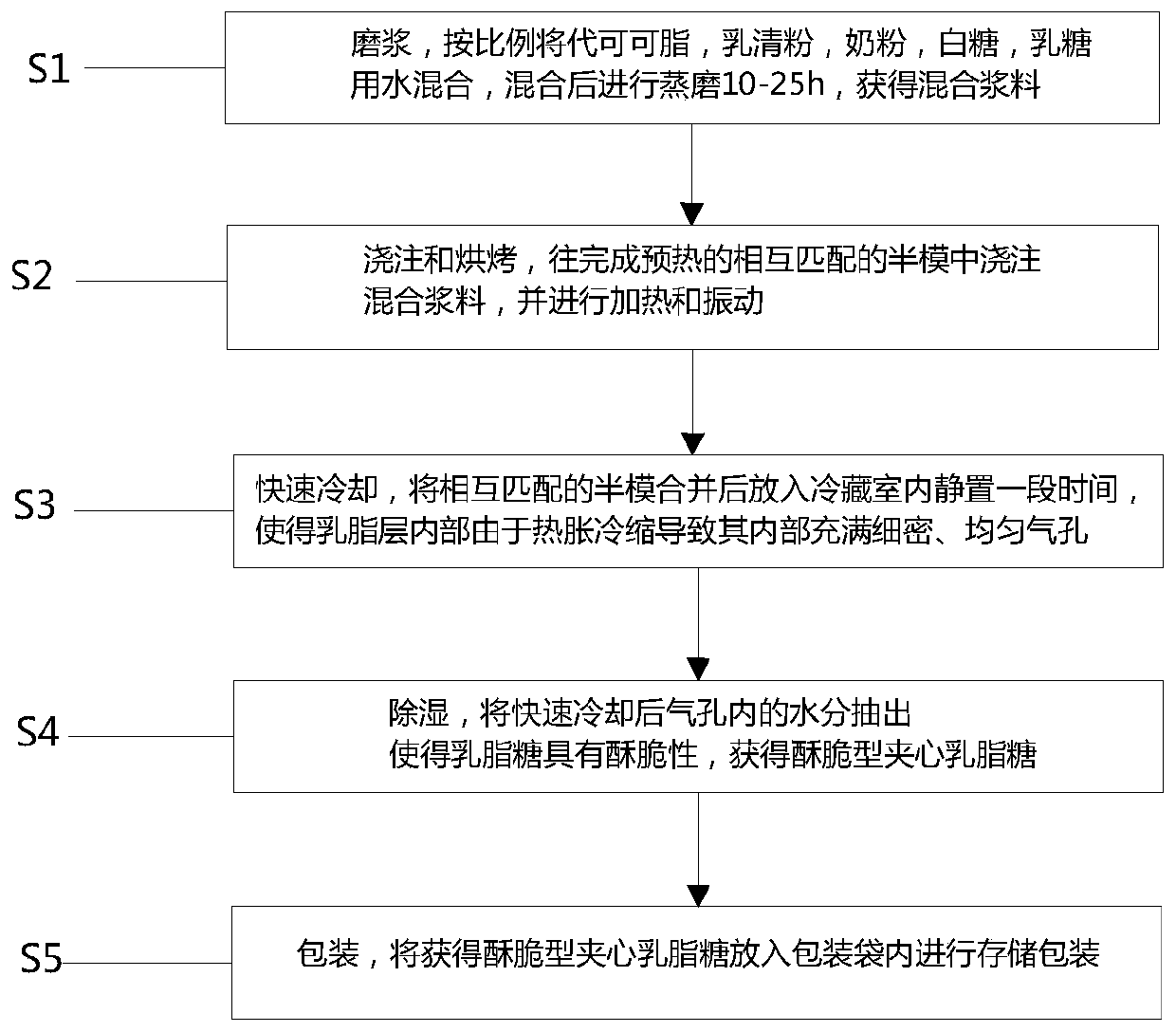

[0028] Such as figure 2 Shown, a kind of preparation technology of crisp type sandwich toffee, manufacture above-mentioned crisp type sandwich ...

Embodiment 2

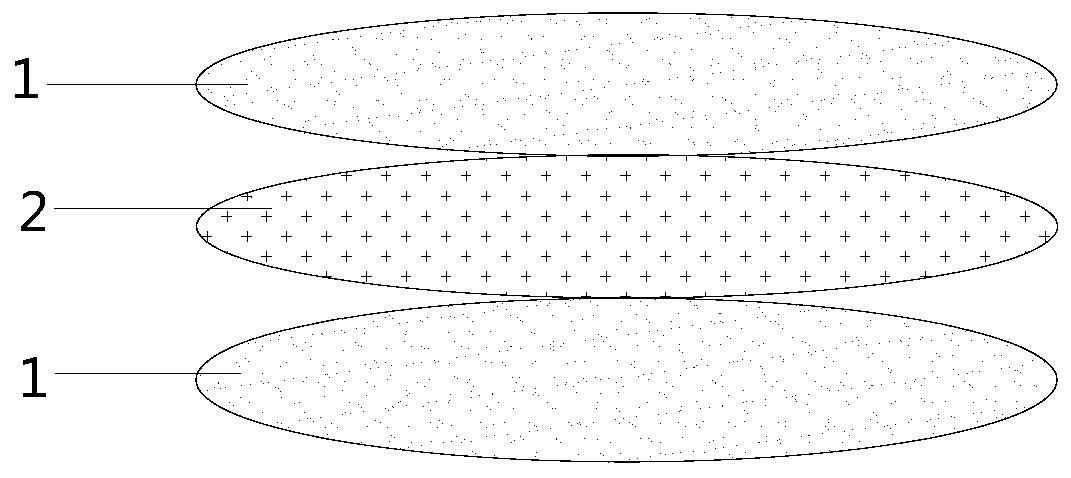

[0041] Such as image 3 As shown, a kind of crispy sandwich toffee, the crispy sandwich toffee is composed of creamy crispy layer 1 and sandwich layer 2, and pores are uniformly formed in the creamy crispy layer 1, and the creamy crispy layer 1 is composed of the following The composition of raw materials in mass fraction is 0.1% of cocoa butter substitute, 10% of whey powder, 10% of milk powder, 1-30% of white sugar, 3% of lactose, and the balance is water.

[0042] The sandwich layer 2 is composed of solid particles, which include walnut kernels, peanuts, barley, oatmeal and the like.

[0043] Such as figure 2 Shown, a kind of preparation technology of crisp type sandwich toffee, manufacture above-mentioned crisp type sandwich toffee, its process is as follows:

[0044] S1: Refining, mixing cocoa butter substitute, whey powder, milk powder, white sugar, and lactose with water in proportion, steaming and milling for 10-25 hours after mixing, to obtain a mixed slurry;

[0...

Embodiment 3

[0056] Such as image 3 As shown, a kind of crispy sandwich toffee, the crispy sandwich toffee is composed of creamy crispy layer 1 and sandwich layer 2, and pores are uniformly formed in the creamy crispy layer 1, and the creamy crispy layer 1 is composed of the following The raw material composition of mass fraction is 0.5% of cocoa butter substitute, 30% of whey powder, 30% of milk powder, 30% of white sugar, 8% of lactose, and the balance is water.

[0057] The sandwich layer 2 is composed of solid particles, which include walnut kernels, peanuts, barley, oatmeal and the like.

[0058] Such as figure 2 Shown, a kind of preparation technology of crisp type sandwich toffee, manufacture above-mentioned crisp type sandwich toffee, its process is as follows:

[0059] S1: Refining, mixing cocoa butter substitute, whey powder, milk powder, white sugar, and lactose with water in proportion, steaming and milling for 10-25 hours after mixing, to obtain a mixed slurry;

[0060] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com