Patents

Literature

31results about How to "Not prone to separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

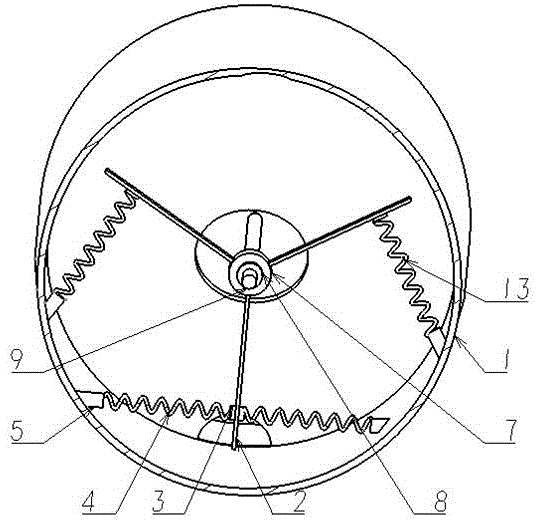

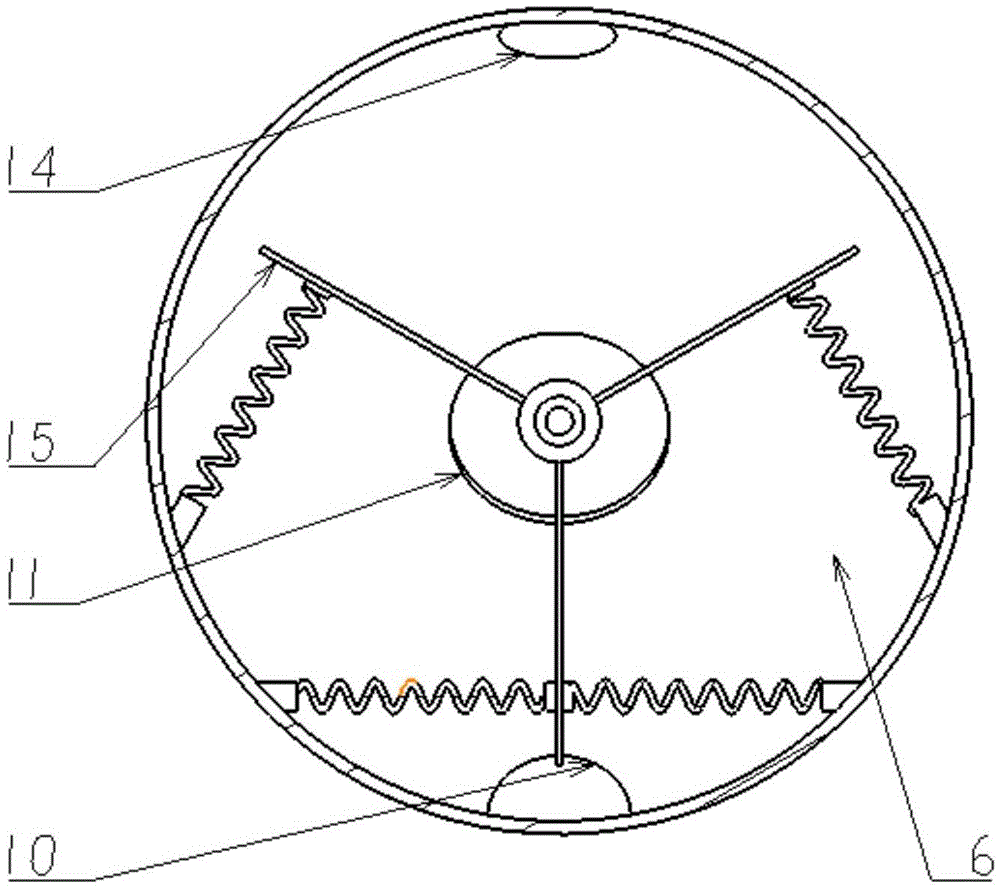

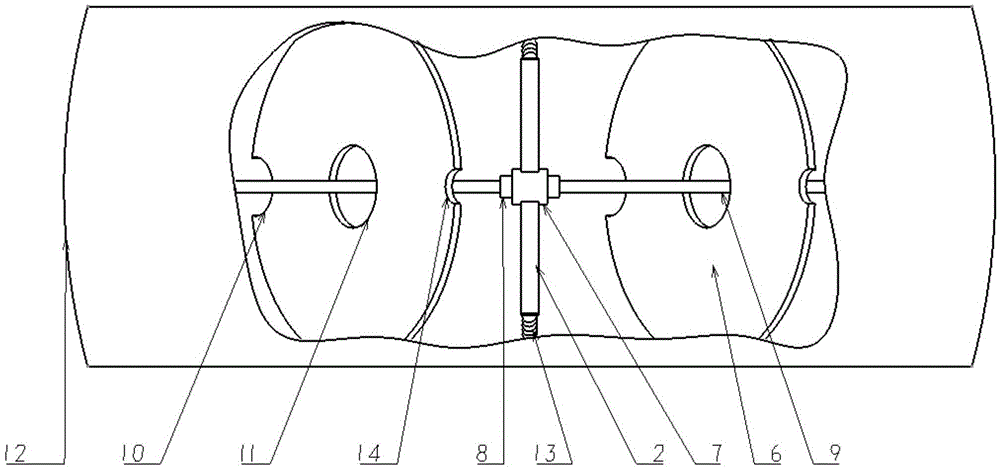

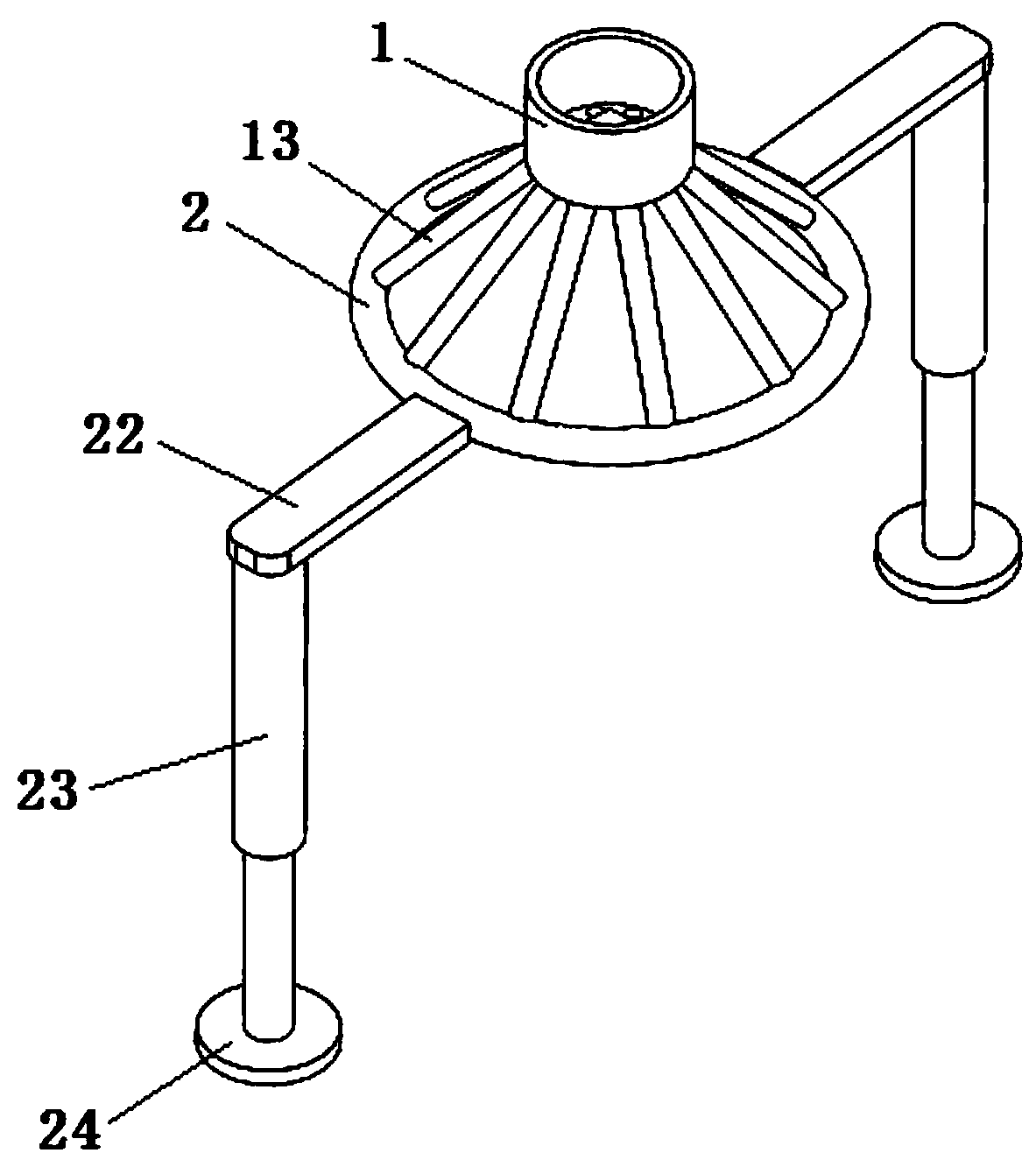

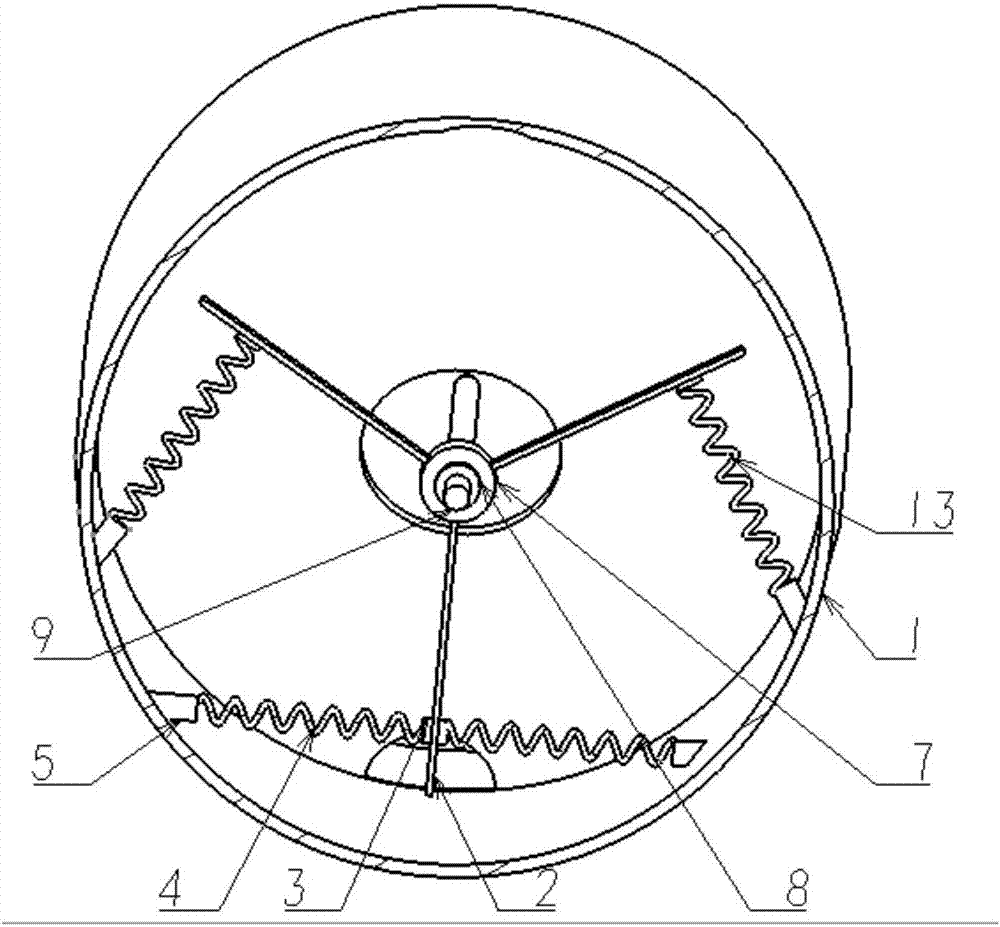

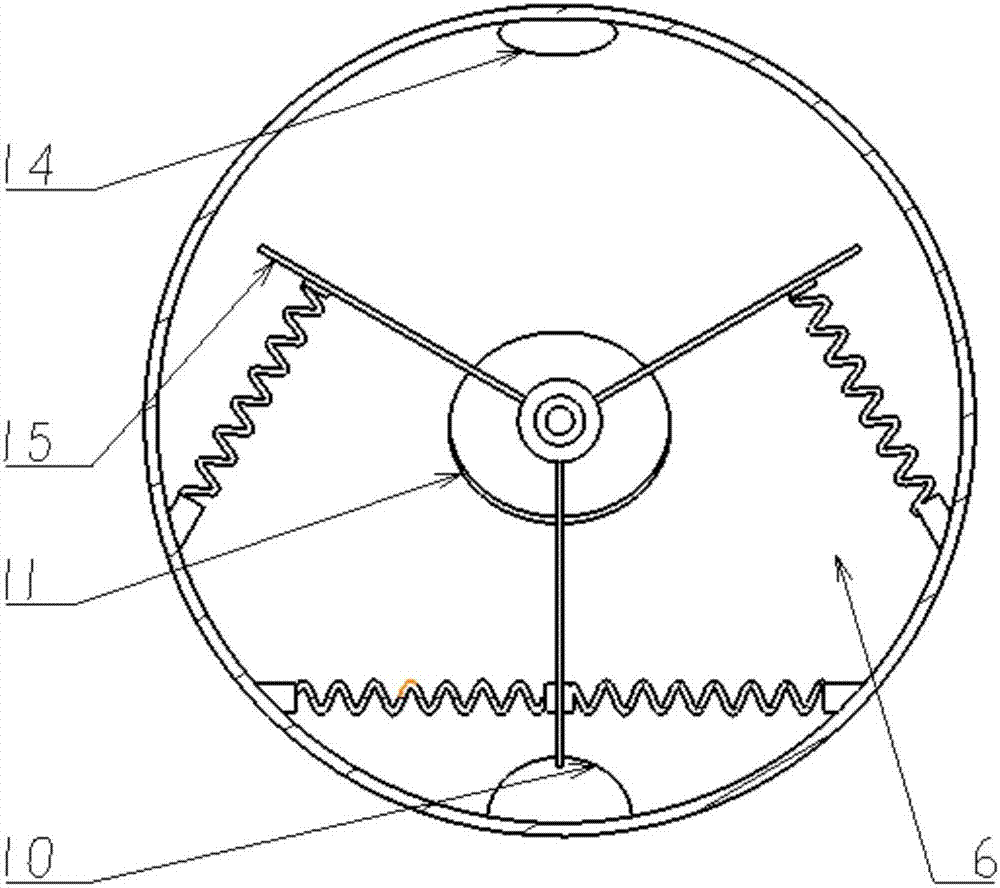

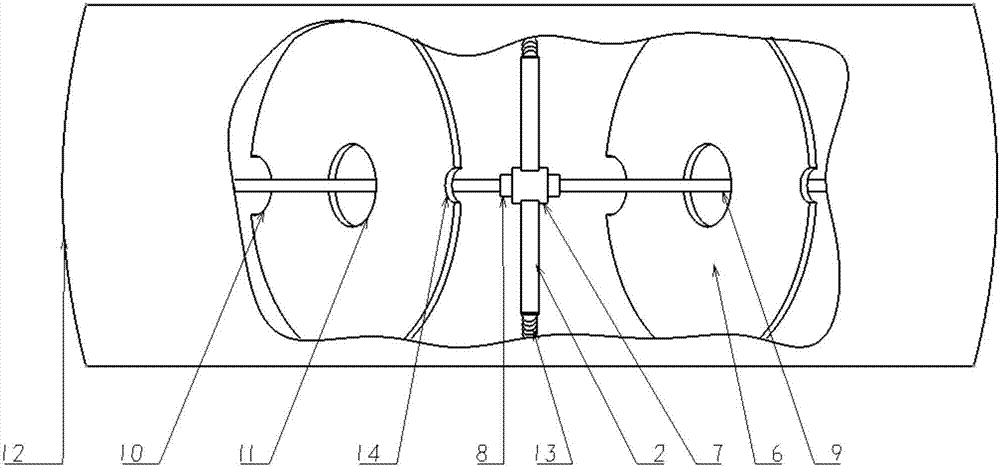

Liquid storage tank capable of preventing liquid from sloshing

InactiveCN105668067AImprove driving safetyImprove connection reliabilityLarge containersLiquid storage tankEngineering

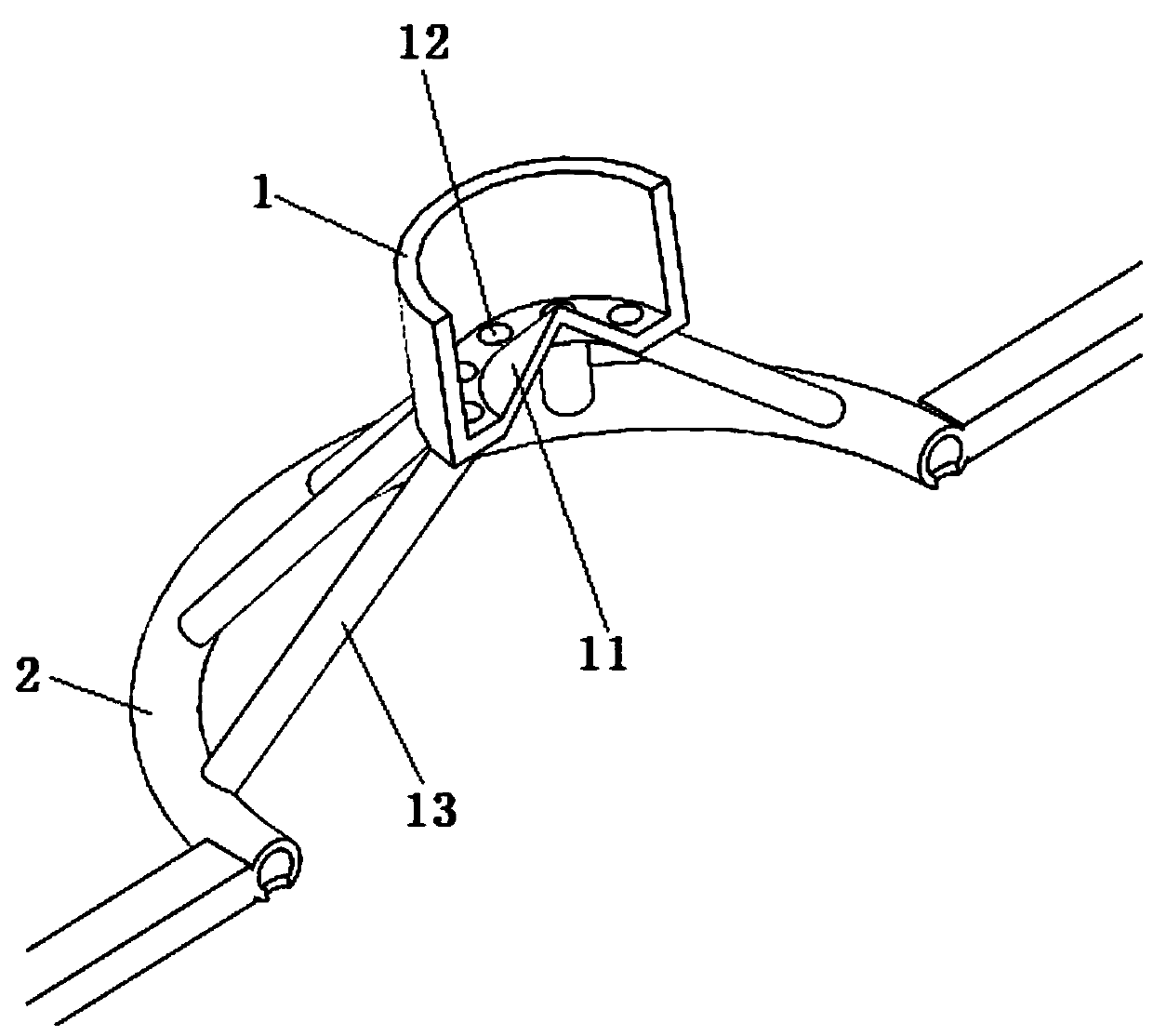

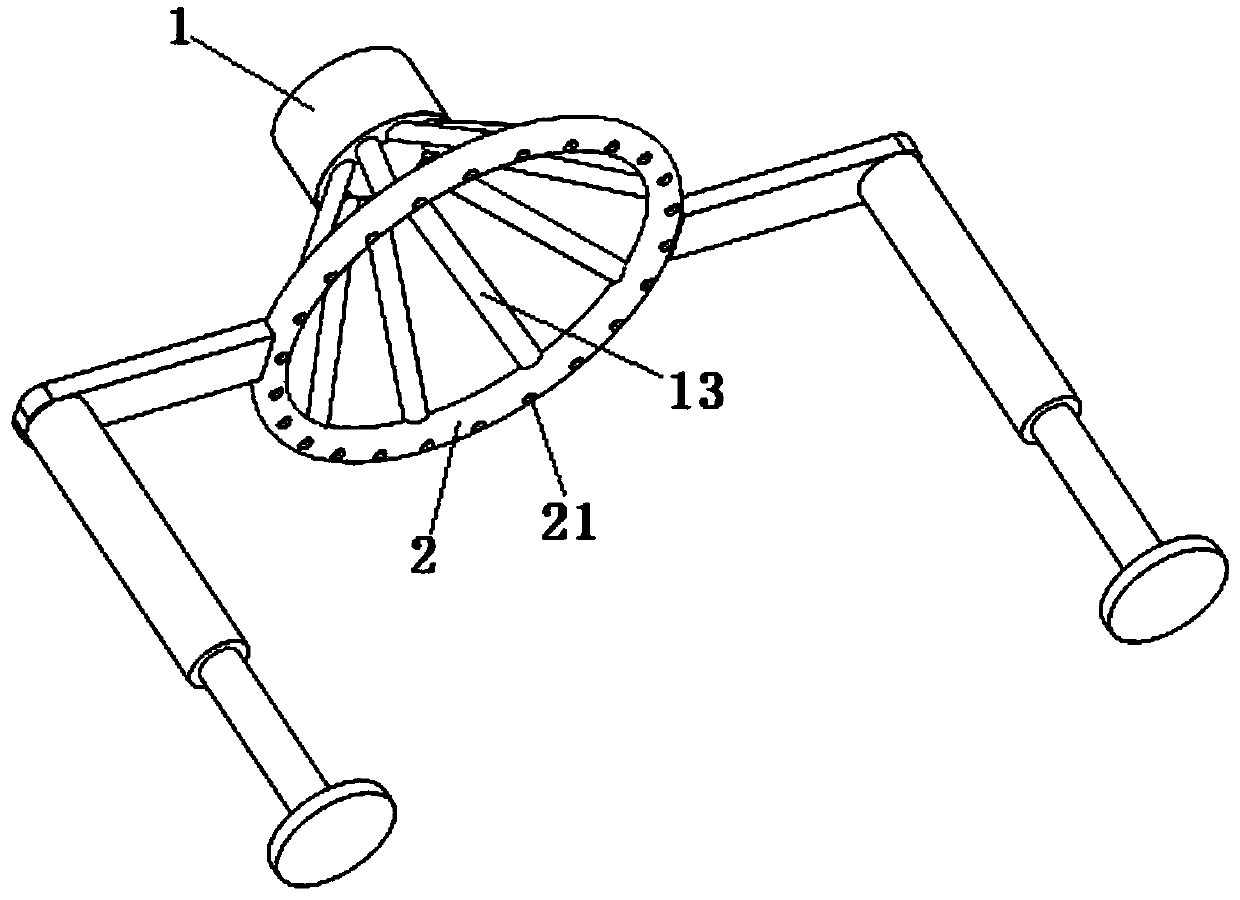

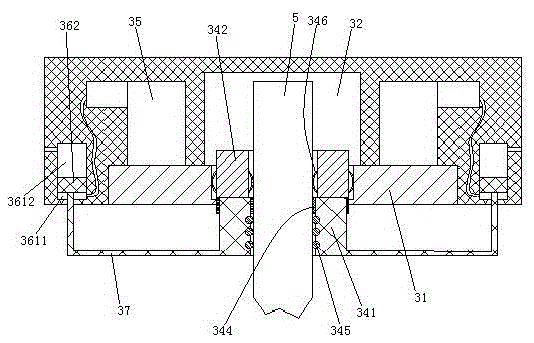

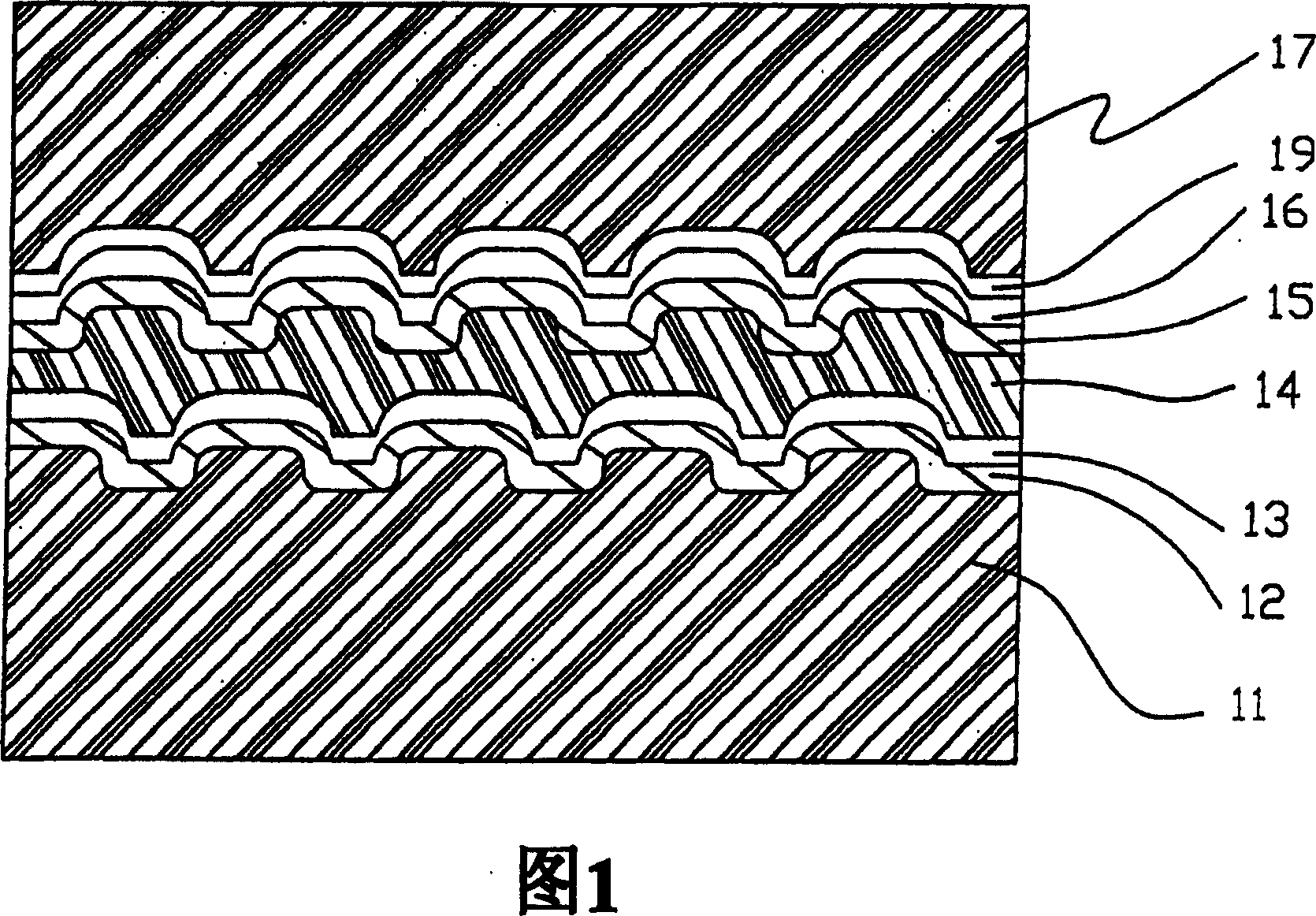

The invention discloses a liquid storage tank capable of preventing liquid from sloshing and aims at solving the problem that a liquid storage tank in the prior art is poor in anti-sloshing effect. The liquid storage tank capable of preventing the liquid from sloshing comprises a main liquid storage tank body, two sealing heads, a longitudinal shaft, n anti-sloshing plates and n+1 blade anti-sloshing devices, and n is a natural number greater than or equal to one. The main liquid storage tank body is sequentially welded to the two sealing heads located at the front end and the back end of the main liquid storage tank body to form a liquid storage tank body. The longitudinal shaft is installed in the liquid storage tank body. The two ends of the longitudinal shaft are welded to the centers of the two sealing heads. The n anti-sloshing plates are installed on the longitudinal shaft in a sleeving mode. The peripheries of the anti-sloshing plates are in welded connection with the inner wall of the main liquid storage tank body. The n-1 blade anti-sloshing devices are installed on the longitudinal shaft between the two anti-sloshing plates in a sleeving mode through blade anti-sloshing device shaft sleeves. Two blade anti-sloshing devices are installed in the positions, between the sealing heads and the anti-sloshing plates and between the anti-sloshing plates and the sealing heads, of the longitudinal shaft in a sleeving mode through the blade anti-sloshing device shaft sleeves. The blade anti-sloshing device shaft sleeves are rotationally connected with the longitudinal shaft. The other ends of the n+1 blade anti-sloshing devices are welded to the inner wall of the main liquid storage tank body through four tank body spring seats.

Owner:JILIN UNIV

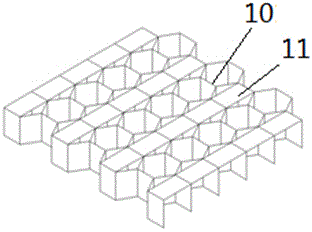

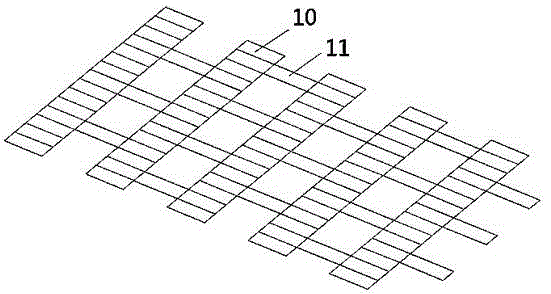

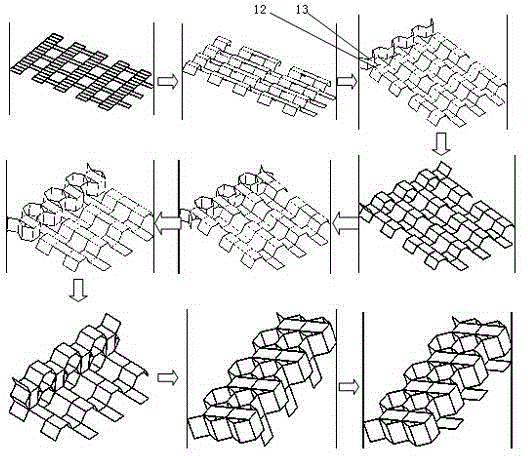

Cellular board core formed through folding and forming method thereof

ActiveCN104085134AResolving Shape UncertaintySolve the problem of loss of compressive performancePaper/cardboard articlesLayered productsStructural engineeringMechanical engineering

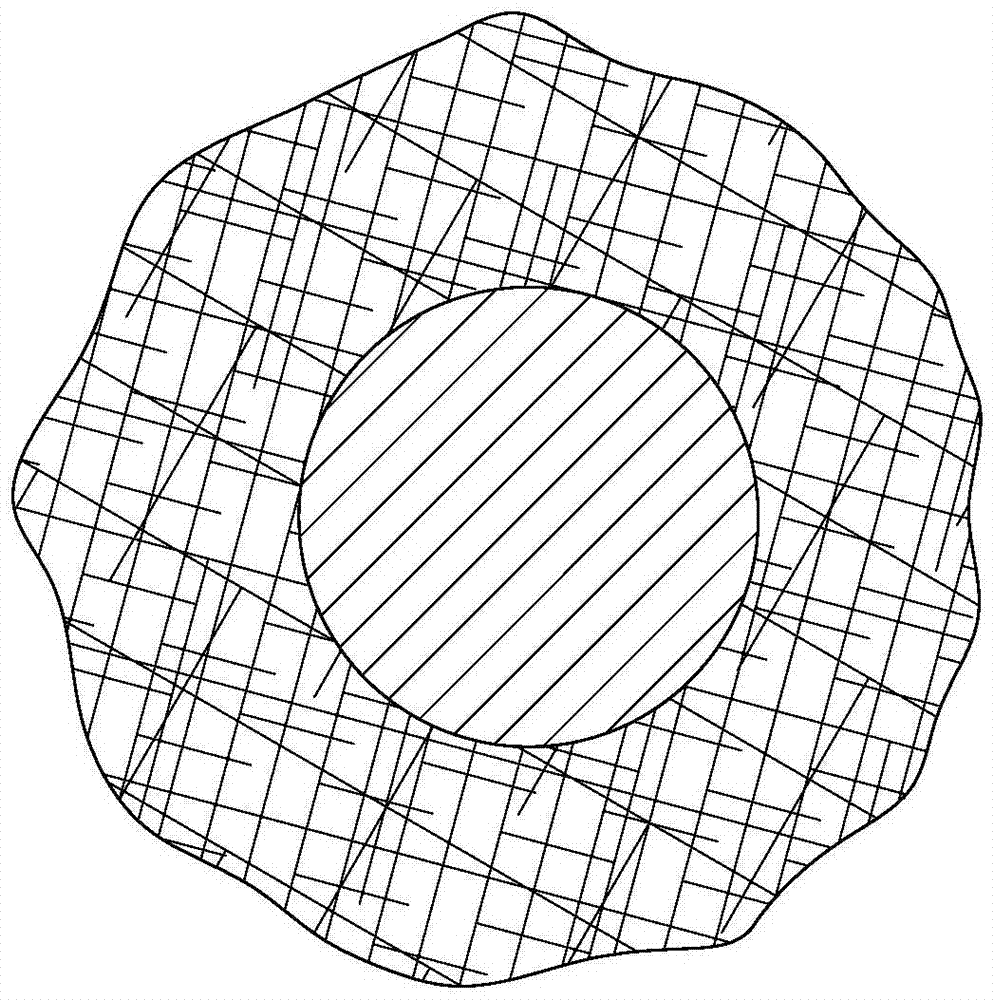

The invention relates to a cellular board core formed through folding and a forming method thereof. The cellular board core formed through folding comprises an upper end board, a lower end board and a cellular core, wherein the cellular core is of a polygonal, cellular and net structure and formed by folding and bonding the whole sheet material, and plane blocks allowing the end boards to be bonded to are arranged on the end faces of the core of the polygonal, cellular and net structure formed by folding the whole sheet material. The cellular core is formed by folding the whole sheet in order, so that the problems of an uncertain shape of the core caused by insufficient stretch and / or excessive stretch during stretch forming of the cellular core and loss of compressive property of a cellular board due to the uncertain shape of the core are solved. The cellular board core formed through folding has the advantages of being stable and reliable in forming, higher in integral strength and unlikely to generate a divergence phenomenon.

Owner:芜湖创联新材料科技有限公司

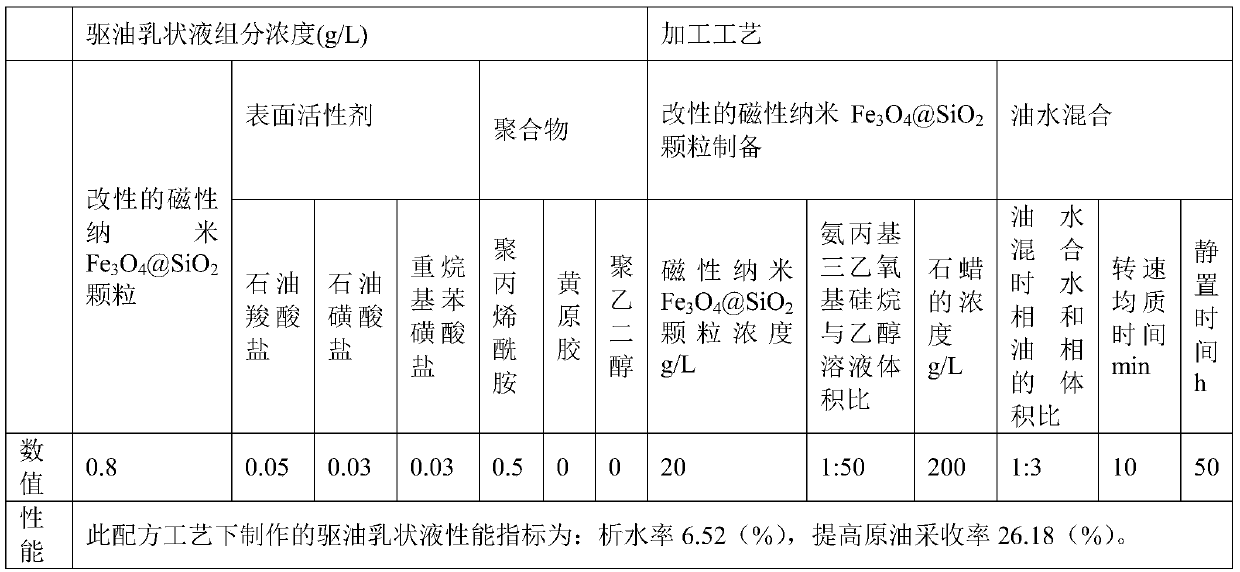

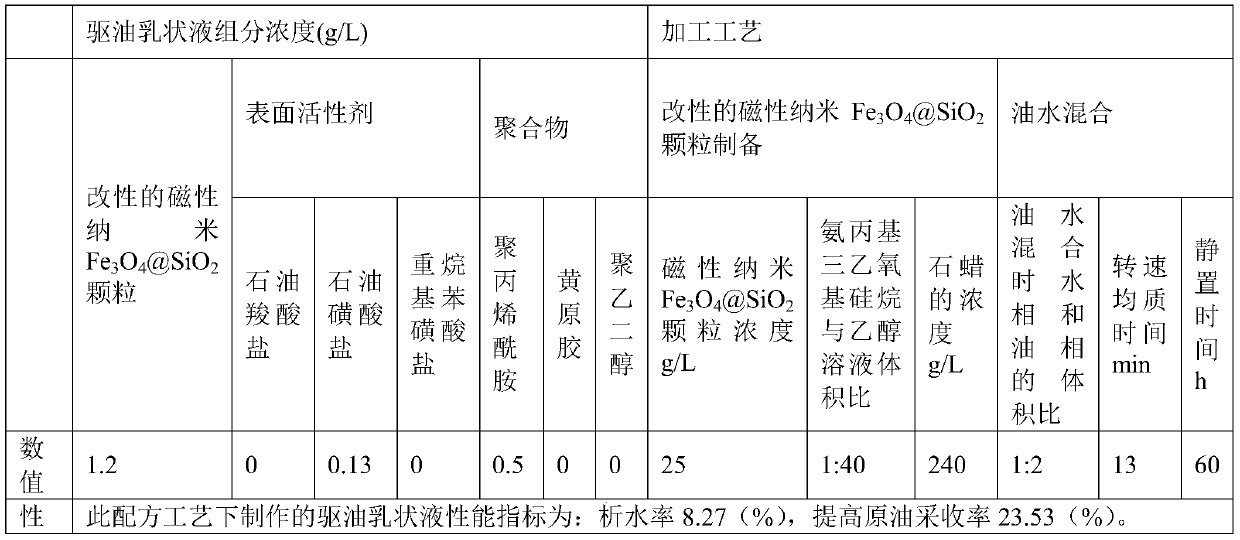

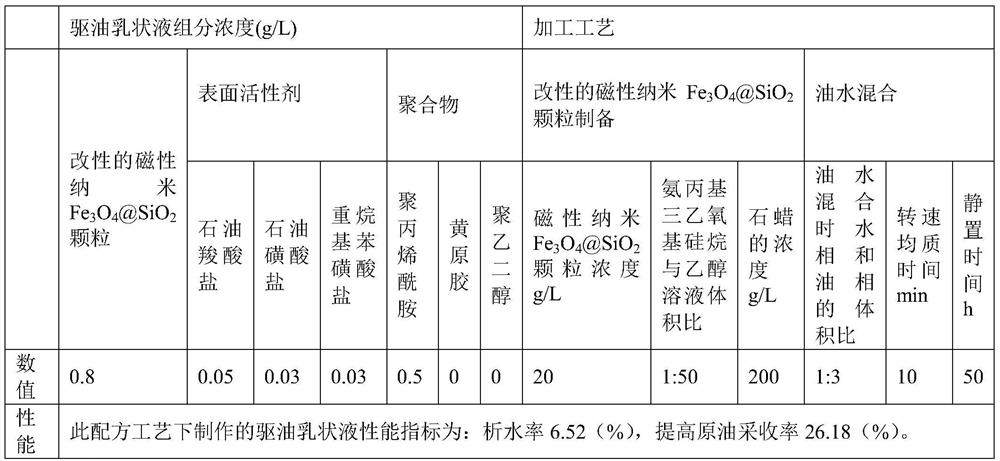

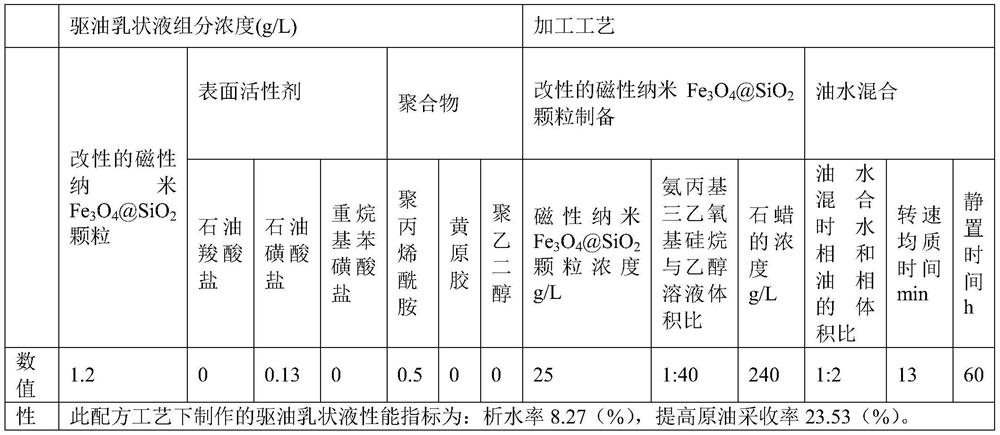

Oil displacement emulsion stabilized by magnetic nanoparticles

The invention relates to the technical field of oil-gas field development, and discloses an oil displacement emulsion stabilized by magnetic nanoparticles. The oil displacement emulsion aims to solvethe problems that thermal stability of an existing oil displacement emulsion is poor and oil-water separation is prone to occurring. The oil displacement emulsion is prepared from: modified magnetic nano Fe3O4@SiO2 particles, a surfactant and polymers. A preparation method comprises the steps that a, the modified magnetic nano Fe3O4@SiO2 particles, the surfactant, the polymers and deionized waterare mixed into an aqueous phase solution, and ultrasonic mixing is performed for 30-60 min to form a mixed solution; and b, an oil phase is added to the mixed solution, a rotation speed is homogenizedfor 10-15 min to obtain a uniformly mixed oil-water system, the oil-water system is allowed to stand at a room temperature for 24h-72h, and the excess oil phase and water phase are separated to obtain a finished product. The oil displacement emulsion stabilized by the magnetic nanoparticles has good stability under high temperature and high salt conditions, and the oil displacement emulsion can significantly improve the recovery ratio of low permeability oil reservoirs.

Owner:ZHEJIANG OCEAN UNIV

Cardboard starch gum activating agent and cardboard starch gum

InactiveCN101054501AImprove stress resistanceStrong puncture resistanceStarch adhesivesCardboardPlasticizer

The invention relates to a cardboard starch glue activating agent and cardboard starch glue. Said activating agent includes following matters by weight (wt.%): 65-75% of sepiolite powder, 10-20% of light calcium powder, 1-5% of sand pulp plasticizer, 3-6% of sodium carboxymethylcellulose, 1-5% of custer sugar. Said starch glue has 1-6% of activating agent. The starch glue produced by inventive activating agent is non-poisonous and harmless and is not tending to the phenomenon of water gel separation, and has a good bonding capacity, a simple producing craft, a stable product quality, a small pollution. The cardboard has a big pressure resistance, a fast car speed, a powerful puncturing resistance.

Owner:邹栋华 +3

Method for preparing NdFeB/PPS injection moulding particle material

InactiveCN101281811AImprove performanceNot prone to separationInorganic material magnetismAlcoholMetallurgy

The present invention relates to a method for producing a high-performance NdFeB / PPS injection molded grain material, which comprises the following steps: dissolving 0.5-2 parts (by weight) of coupling agent in alcohol, adding 100 parts (by weight) of NdFeB magnetic powder, mixing, drying at 40-60 DEG C, grinding and crushing, and then sieving, to obtain coupled NdFeB magnetic powder; dissolving 0.5-2 parts (by weight) of polyvinyl alcohol in deionized water to form clear solution, adding the coupled NdFeB magnetic powder and PPS resin at a certain proportion into the solution, mixing, and drying thoroughly, grinding and crushing, and sieving the dry compound into grains; compounding the grain material, and then cutting, to obtain the NdFeB / PPS injection molded grain material. The NdFeB / PPS injection molded grain material produced doesn't have the phenomenon of separation between NdFeB magnetic powder and PPS resin in the compounding process, can prevent oxidation of the magnetic powder at high temperature, and therefore greatly improves the performance of the injection molded grain material; the producing method is simple and easy to operate.

Owner:ZHEJIANG UNIV OF TECH

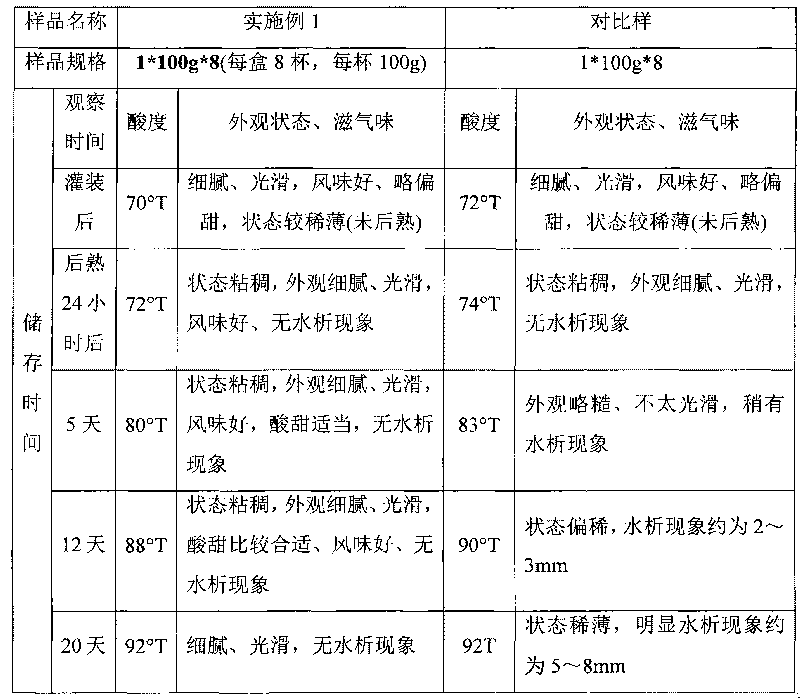

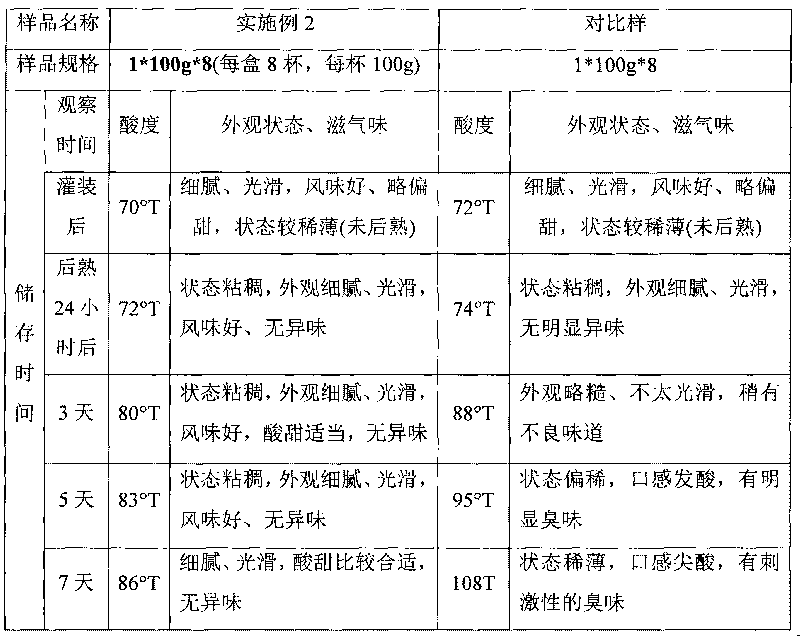

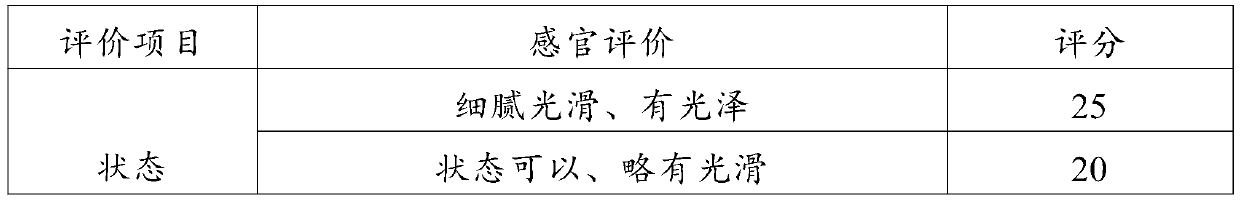

Trehalose acidophilous milk and preparation method thereof

InactiveCN101731333APrevent hydrogen bondingNot prone to separationMilk preparationFlavorDecomposition

The invention relates to the filed of dairy products, in particular to trehalose acidophilous milk and a preparation method thereof. Based on 100 weight parts of acidophilous milk raw materials, the trehalose acidophilous milk comprises 0.5 to 7 weight parts of trehalose, preferably 2 to 5 weight parts of trehalose. The trehalose is added into the acidophilous milk, serves as a sweetener and has obvious effects of preventing starch ageing and protein denaturation, inhibiting decomposition of unsaturated fatty acid and the like; and the trehalose acidophilous milk has good quality and also has good flavor and mouthfeel.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Water resistant carton adhesive

InactiveCN104293238ASimple structureImprove liquidityNon-macromolecular adhesive additivesStarch adhesivesAdhesiveWater quality

The invention discloses a water resistant carton adhesive which is prepared from the following raw materials in parts by weight: 65-75 parts of water, 28-34 parts of sweet potato powder, 12-16 parts of calcium carbonate, 1-2 parts of sodium hydroxide, 2-3 parts of keto-aldehyde polyvinyl alcohol compound, 3-4 parts of sepiolite powder, 1.2-1.6 parts of bridging agent, 0.15-0.18 part of sodium carboxymethyl cellulose, 0.10-0.12 part of water quality stabilizer and 0.26-0.36 parts of borax; the water resistant carton adhesive is prepared according to the following steps: pouring water into a container, regulating the temperature of the water to 33-45 DEG C, adding sodium hydroxide and uniformly stirring; then adding the sweet potato powder, and continuously stirring to be sticky; adding calcium carbonate and borax and stirring for 13-20 min; adding the water quality stabilizer and stirring for 5-10min; adding the sepiolite powder, the keto-aldehyde polyvinyl alcohol compound, the bridging agent and sodium carboxymethyl cellulose, uniformly stirring, standing and cooling. The water resistant carton adhesive disclosed by the invention has strong adhesive ability and good waterproof performance.

Owner:HEFEI DONGCAI PRINTING TECH

High-strength corrugated case binder and production method thereof

InactiveCN109852341AHigh strengthHigh bonding strengthNon-macromolecular adhesive additivesProtein adhesivesCardboardMaterials science

The invention discloses a high-strength corrugated case binder. The high-strength corrugated case binder is produced from the following raw materials of, in parts by weight, 30-40 parts of soybean protein isolate, 10-15 parts of modified phenolic resin, 6-8 parts of modified lignin, 150-200 parts of NaOH aqueous solution and 9-11 parts of citric acid. The invention furthermore discloses a production method of the high-strength corrugated case binder. According to the binder, the soybean protein isolate is adopted as a binder main body, the modified phenolic resin is adopted as a cross-linkingagent of the soybean protein isolate, and degraded soybean protein is linked, so that higher binding strength and better water resistance are obtained; by adding the modified lignin, the contents of free formaldehyde and free cresol in the phenolic resin are reduced; and the produced binder is high in binding strength and good in binding performance, the phenomenon of water and binder separation is not liable to happen, the production method is simple, technology conditions are low, a bound board is high in compressive resistance and high in puncture resistance, and the quality of a produced corrugated case can be guaranteed.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Anti-mildew carton adhesive

InactiveCN104277738AHigh bonding strengthStrong puncture resistanceNon-macromolecular adhesive additivesStarch adhesivesEpoxyCellulose

The invention discloses an anti-mildew carton adhesive, which is prepared from the following raw materials in parts by weight: 65-75 parts of water, 9-12 parts of rice starch, 22-30 parts of sticky rice starch, 12-16 parts of calcium carbonate, 1-2 parts of sodium hydroxide, 3-4 parts of epoxy resin, 0.12-0.16 part of a naphthalene sulfonate formaldehyde condensation compound, 1.5-1.8 parts of carboxymethyl cellulose, 0.3-0.5 part of borax, and 1.5-1.7 parts of a preservative. A preparation method comprises the following steps: pouring water into a container, and regulating the temperature of water to be 50-70DEG C; adding rice starch into water, then evenly stirring and adding sticky rice starch, and stirring to be thick, to obtain an emulsion A; adding calcium carbonate into the emulsion A, and stirring to obtain an emulsion B, wherein the stirring time lasts 10-20min; adding sodium hydroxide, epoxy resin, naphthalene sulfonate formaldehyde condensation compound, carboxymethyl cellulose, borax and preservatives into the emulsion B, evenly stirring, and then standing and cooling. The anti-mildew carton adhesive is strong in adhesion power and difficultly generates mildew.

Owner:HEFEI DONGCAI PRINTING TECH

Easy-to-coat carton adhesive

InactiveCN104277736AHigh bonding strengthStrong puncture resistanceNon-macromolecular adhesive additivesStarch adhesivesSodium bicarbonatePolyvinyl alcohol

The invention discloses an easy-to-coat carton adhesive. The easy-to-coat carton adhesive is prepared from the following raw materials in parts by weight: 100-120 parts of water, 20-30 parts of corn starch, 10-15 parts of calcium carbonate, 2-3 parts of alum, 2-3 parts of light magnesium oxide, 0.42-0.46 part of aluminum sulfate, 0.36-0.38 part of polyvinyl alcohol, 1-2 parts of sodium bicarbonate, 0.7-0.8 part of potassium permanganate and 0.6-0.8 part of borax. The easy-to-coat carton adhesive is prepared according to the following steps: pouring water into a container and adjusting water temperature to 56-64 DEG C; pouring corn starch into the water, continuously stirring to a viscous state, then adding calcium carbonate and potassium permanganate, and stirring for 15-18min to obtain an emulsion A; and adding alum and light magnesium oxide into the emulsion A, stirring for 6-8min, then adding aluminum sulfate, polyvinyl alcohol and sodium bicarbonate, uniformly stirring, then adding borax, stirring for 20-25min, standing and cooling. The easy-to-coat carton adhesive disclosed by the invention is strong in adhesive capacity and easy to coat, and can improve the compressive strength and flexural strength of carbons.

Owner:HEFEI DONGCAI PRINTING TECH

Carton adhesive with good waterproof effect

InactiveCN105349051AOptimize structureImprove fluidity and permeabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCorn starchChemistry

A carton adhesive with a good waterproof effect is formed by, by weight, corn starch, potassium permanganate, borax, sodium hydroxide, a ketoaldehyde polyvinyl alcohol compound, a bridging agent, a water quality stabilizer, a catalyst, carboxymethylcellulose sodium, an antifoaming agent, a curing agent and deionized water. The weights of the waterproof carton adhesive are reasonably selected, and proper steps are adopted to blend, so the structure of the adhesive is improved, the fluidity and the permeability of the adhesive are enhanced, and the endophilicity of the adhesive with paper fibers is improved, thereby the adhesive has high adhesion strength, good waterproof property, good toughness of an adhesive film, and difficult appearing of the water-adhesive separation phenomenon; and the adhesive prepared in the invention is nontoxic and harmless, and has the advantages of simple process due to stirring being a main step in the whole blending process, low technological conditions, stable product quality, and large compressive resistance and strong puncturing resistance of cardboards obtained after adhering by using the adhesive.

Owner:FUYANG HAOJIE IND & TRADE CO LTD

Method for preparing NdFeB/PPS injection moulding particle material

InactiveCN100593828CImprove performanceNot prone to separationInorganic material magnetismAlcoholMetallurgy

The present invention relates to a method for producing a high-performance NdFeB / PPS injection molded grain material, which comprises the following steps: dissolving 0.5-2 parts (by weight) of coupling agent in alcohol, adding 100 parts (by weight) of NdFeB magnetic powder, mixing, drying at 40-60 DEG C, grinding and crushing, and then sieving, to obtain coupled NdFeB magnetic powder; dissolving 0.5-2 parts (by weight) of polyvinyl alcohol in deionized water to form clear solution, adding the coupled NdFeB magnetic powder and PPS resin at a certain proportion into the solution, mixing, and drying thoroughly, grinding and crushing, and sieving the dry compound into grains; compounding the grain material, and then cutting, to obtain the NdFeB / PPS injection molded grain material. The NdFeB / PPS injection molded grain material produced doesn't have the phenomenon of separation between NdFeB magnetic powder and PPS resin in the compounding process, can prevent oxidation of the magnetic powder at high temperature, and therefore greatly improves the performance of the injection molded grain material; the producing method is simple and easy to operate.

Owner:ZHEJIANG UNIV OF TECH

Carton adhesive for high-speed production

InactiveCN104277737AHigh bond strengthImprove carton bonding qualityNon-macromolecular adhesive additivesStarch adhesivesChemistryAdhesive

The invention discloses a carton adhesive for high-speed production. The carton adhesive comprises the following components in parts by weight: 90-100 parts of water, 36-40 parts of cassawa starch, 1-2 parts of caustic soda, 0.6-0.8 part of sodium borate, 1-2 parts of sepiolite powder, 0.12-0.16 part of naphthalenesulfonate formaldehyde condensates, 0.15-0.18 part of sodium carboxymethylcellulose and 0.60-0.72 part of a stabilizer. According to the raw material ratio, the carton adhesive for high-speed production is prepared by the following steps: adjusting the temperature of water to be 36-44 DEG C, adding caustic soda and stirring until the caustic soda is completely dissolved; adding sepiolite powder, and stirring for 15-18 minutes; adding sodium borate, sepiolite powder, naphthalenesulfonate formaldehyde condensates, sodium carboxymethylcellulose and a stabilizer in the process of stirring for 15-18 minutes; and standing and cooling to obtain the carton adhesive for high-speed production. The carton adhesive for high-speed production disclosed by the invention is high in adhesive capacity, and high in bonding quality, and can meet the requirements of high-speed production.

Owner:HEFEI DONGCAI PRINTING TECH

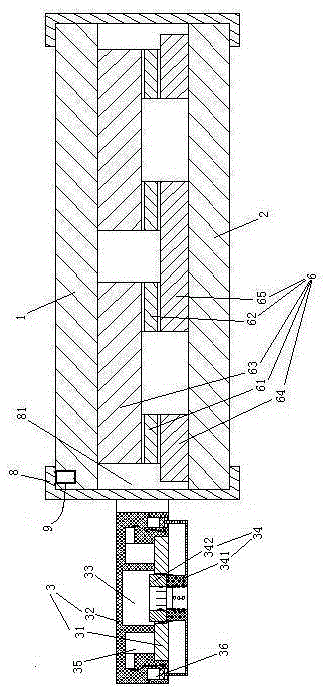

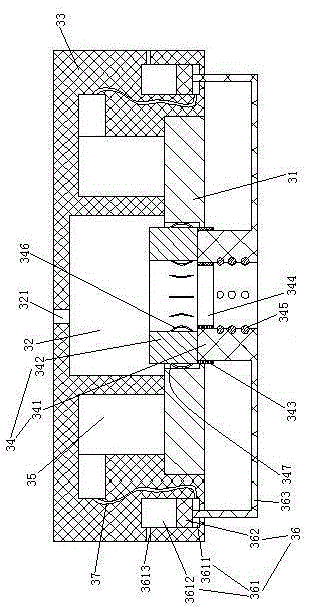

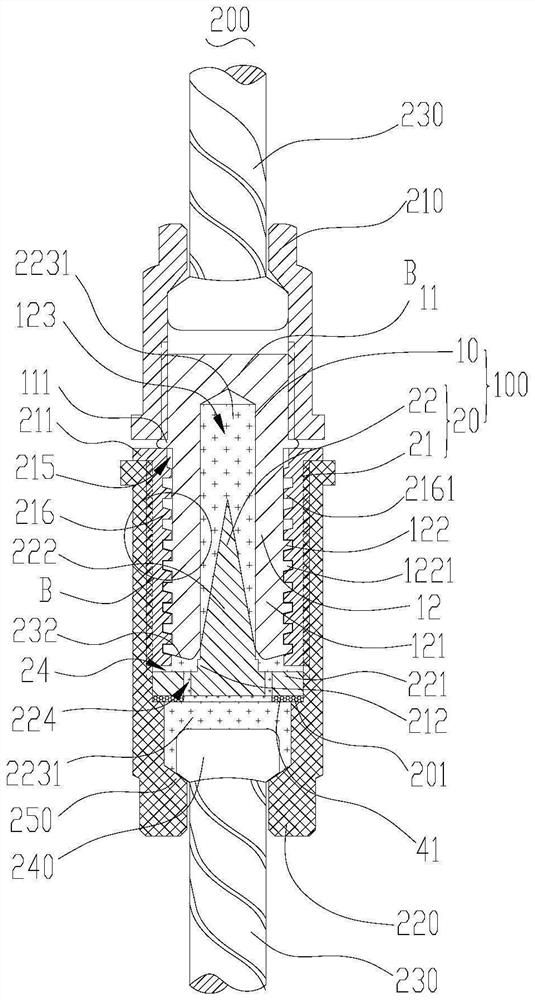

Thermoelectric power generation sheet with overload protection power supply terminal

The invention relates to a thermoelectric power generation sheet. A thermoelectric power generation sheet with an overload protection power supply terminal comprises a power supply terminal, wherein the power supply terminal comprises an insulation body and a wiring copper foil, wherein the wiring copper foil is arranged in the insulation body, the wiring copper foil is electrically connected with a thermoelectric power generation unit and provided with a wiring hole passing through the interior of the insulation body, a wiring sleeve is connected to the wiring hole in a sliding way and comprises an insulation segment and a conductive segment, the insulation segment is arranged along the axial direction of the wiring sleeve, the conductive segment props against the wiring copper foil, an air cavity and an overload response air cylinder are arranged in the insulation body, the air cavity is used for heating through heat generated by the wiring copper foil, and the overload response air cylinder is used for driving through gas expansion in the air cavity and driving the conductive segment to be staggered from the wiring copper foil. The invention provides the thermoelectric power generation sheet which can be automatically disconnected during overload and can be automatically connected after normality and is provided with the overload protection power supply terminal, and the problem that a traditional thermoelectric power generation sheet cannot be automatically powered off after overload and cannot be automatically recovered after normality is solved.

Owner:浙江万谷半导体有限公司

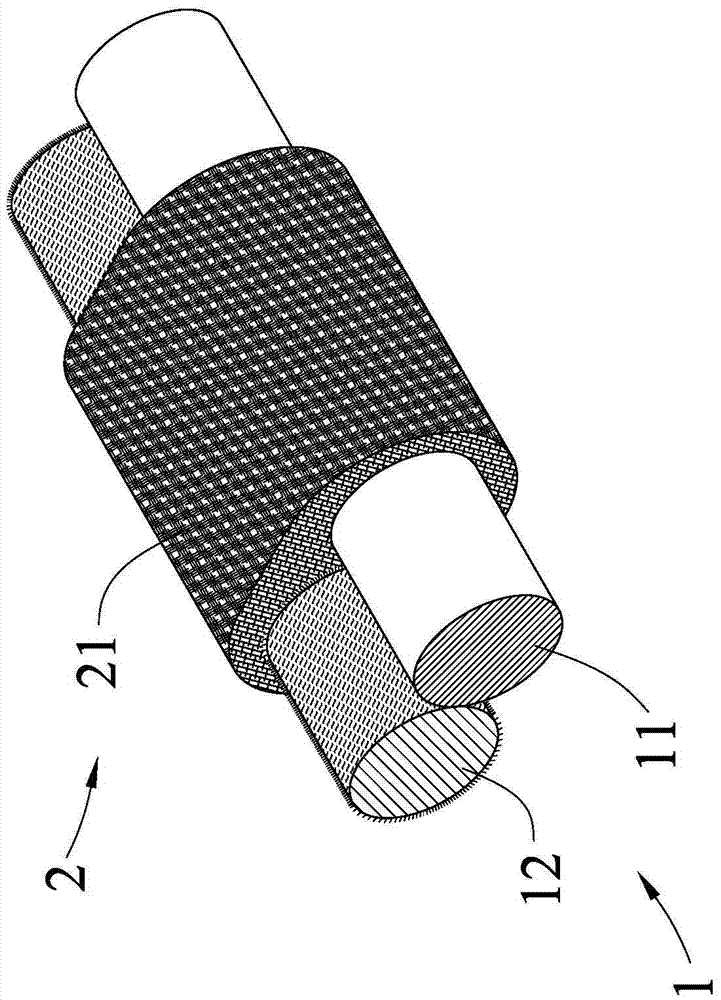

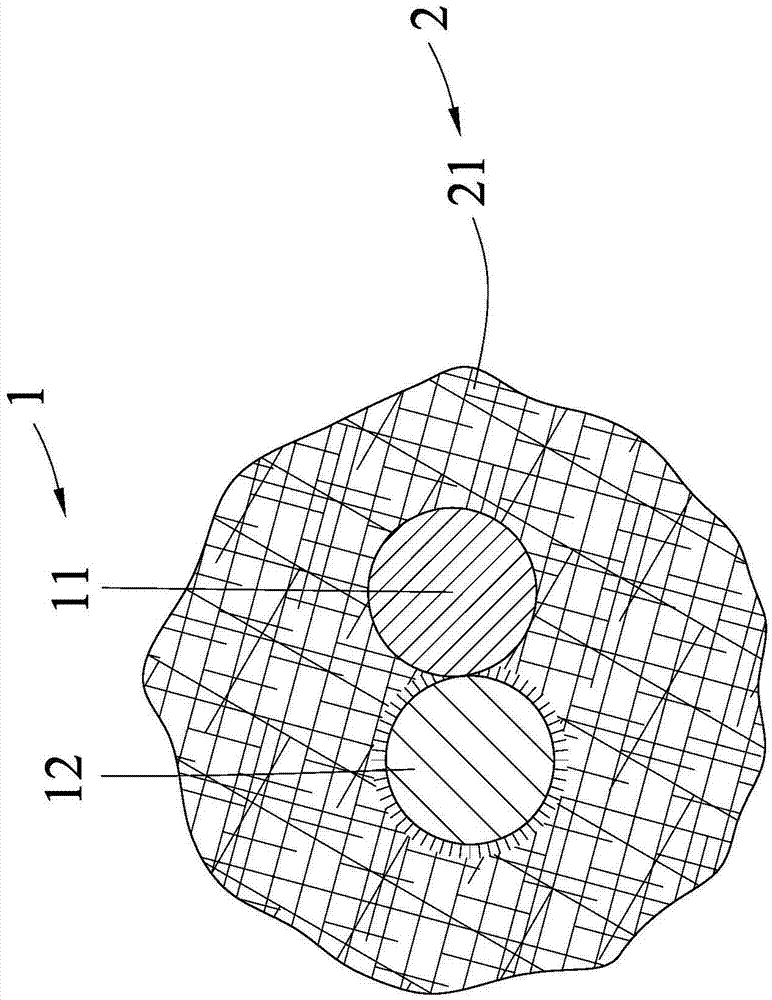

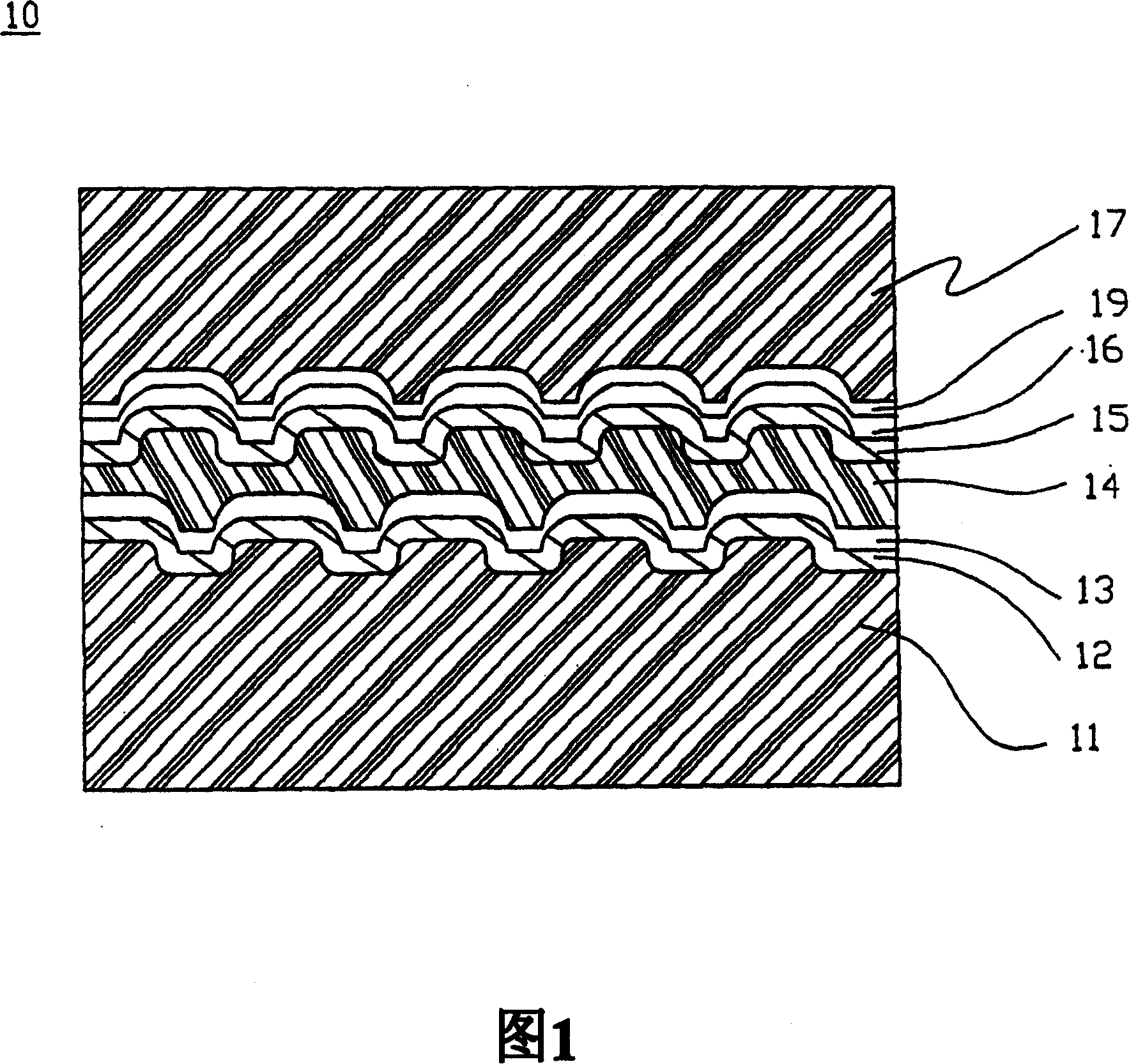

Highly-tenacious cut-resistant core spun yarn

The invention relates to a highly-tenacious cut-resistant core spun yarn. The highly-tenacious cut-resistant core spun yarn is mostly composed of a shaft core part and a wrapping part. A second core yarn of the shat core part has better friction coefficient due to a jumping fiber surface in the surface layer. During the process of making into yarns, first and second core yarns are mutually and closely attached to each other so that tensile strength is increased. The yarn is not easy to break. Effects of effectively increasing production efficiency and improving quality are obtained. The better friction coefficient of the second core yarn enables the wrapping part to be closely wound around the first and second core yarns. No separation occurs. Second core yarns of the shaft core part and short fibers of the wrapping part have highly-tenacious and good mechanical strength. The structure of the core spun yarn has excellent cut-resistant and anti-tensile strength so that a finished product made by the structure of the core spun yarn is puncture-proof, abrasion-resistant and cutting-resistant. Therefore, the highly-tenacious cut-resistant core spun yarn can be made into a highly-progressive product.

Owner:NAM LIONG ENTERPRISE

Water-resistant carton adhesive

InactiveCN104277735AHigh bonding strengthStrong puncture resistanceNon-macromolecular adhesive additivesStarch adhesivesCarboxymethyl celluloseCarton

The invention discloses a water-resistant carton adhesive, which is prepared from the following raw materials in parts by weight: 75-85 parts of water, 20-24 parts of tapioca, 12-16 parts of calcium carbonate, 2-3 parts of a hydrochloric acid, 3-4 parts of sepiolite powder, 0.12-0.16 part of a napsylate-formaldehyde condensate, 0.15-0.18 part of carboxymethyl cellulose, 0.40-0.60 parts of borax, and 0.40-0.60 part of urea formaldehyde resin. The water-resistant carton adhesive is prepared through the following steps: pouring water into a container, and adjusting the temperature of the water to 56-64 DEG C; adding tapioca, and constantly stirring until the obtained product is sticky; adding calcium carbonate, and stirring for 15-18 min; adding a hydrochloric acid, and stirring for 6-8 min; and adding borax and urea formaldehyde resin, uniformly stirring, adding sepiolite powder, a napsylate-formaldehyde condensate and carboxymethyl cellulose, uniformly stirring, standing, and cooling, so that the water-resistant carton adhesive is obtained. The water-resistant carton adhesive disclosed by the invention is strong in adhesive capacity, and is safe, and environmental-friendly.

Owner:HEFEI DONGCAI PRINTING TECH

Adhesive for corrugated paper and processing method thereof

PendingCN109777325AHigh strengthImprove moisture resistanceNon-macromolecular adhesive additivesOil/fat/wax adhesivesPolyvinyl alcoholAdhesive

The invention discloses an adhesive for corrugated paper and a processing method thereof. The adhesive comprises the following raw materials in parts by mass: 10-15 parts of oxidized starch, 15-20 parts of polyvinyl alcohol, 1-3 parts of cooked tung oil, 5-10 parts of silicon resin, 3-5 parts of silicon dioxide, 1-2 parts of isocyanate, 3-6 parts of lactobionic acid, 2-4 parts of magnesium carbonate and 1-2 parts of sodium hydroxide. The processing method comprises the following steps: 1, according to the mass parts, adding the oxidized starch, the polyvinyl alcohol, the magnesium carbonate and the sodium hydroxide into a reaction kettle; 2, and adding the silicon dioxide, the isocyanate and the lactobionic acid into the reaction kettle according to the mass parts; 3) adding the cooked tung oil and the silicon resin into the reaction kettle in parts by mass; 4, cooling the mixture obtained in the step 3 to 10-30 DEG C at normal temperature to obtain the corrugated paper adhesive. The corrugated paper adhesive has the advantages that the strength and the moisture resistance of the corrugated paper are better improved, and the phenomenon of water and adhesive separation is not easy to occur, the bonding strength is high, the bonding property is good, the market use requirements are met, and the product is beneficial to popularization.

Owner:国腾彩色纸品(鹤山)有限公司

Packaging box adhesive

InactiveCN109439214AImprove stress resistanceImprove moisture resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyAntioxidant

The invention discloses a packaging box adhesive. The packaging box adhesive is prepared from components by weight as follows: 30-50 parts of epoxy resin, 30-50 parts of maleic resin, 30-50 parts of 2-imidazolidone, 30-50 parts of an ethylene-acetic acid copolymer, 10-20 parts of butyl rubber, 20-40 parts of epoxidized soybean oil, 15-30 parts of a castor oil hydrogenation mixture, 10-20 parts ofboiled tung oil, 8-12 parts of tripropargyl trimesate, 8-12 parts of water-soluble polyethylene ethylene glycol wax, 8-12 parts of isopropanol, 8-12 parts of silicon resin, 0.8-1.2 parts of an antioxidant, 1-3 parts of a tackifier and 2-20 parts of deionized water. The packaging box adhesive has the characteristics of high adhesion, pressure resistance, dampproof capacity and high-temperature resistance.

Owner:贵州众旺包装有限公司

Corrugated carton adhesive

InactiveCN104277739AHigh bond strengthSimple processNon-macromolecular adhesive additivesStarch adhesivesChemistryAdhesive

The invention discloses a corrugated carton adhesive which is prepared from the following raw materials in parts by weight: 45-55 parts of water, 28-34 parts of sweet potato powder, 12-16 parts of calcium carbonate, 2-3 parts of hydrochloric acid, 3-4 parts of meerschaum powder, 0.12-0.16 part of naphthalene sulfonate formaldehyde condensate, 0.15-0.18 part of sodium carboxymethyl cellulose and 0.10-0.12 part of white granulated sugar. The corrugated carton adhesive is prepared from the following steps: pouring water into a container, and regulating the water temperature to 56-64 DEG C; adding the sweet potato powder, and stirring to a viscous state; adding the calcium carbonate, and stirring for 15-18 minutes; adding the hydrochloric acid, and stirring for 6-8 minutes; and adding the meerschaum powder, naphthalene sulfonate formaldehyde condensate, sodium carboxymethyl cellulose and white granulated sugar, stirring uniformly, standing and cooling. The corrugated carton adhesive has the advantages of high adhesive capacity, high safety and environmental protection.

Owner:HEFEI DONGCAI PRINTING TECH

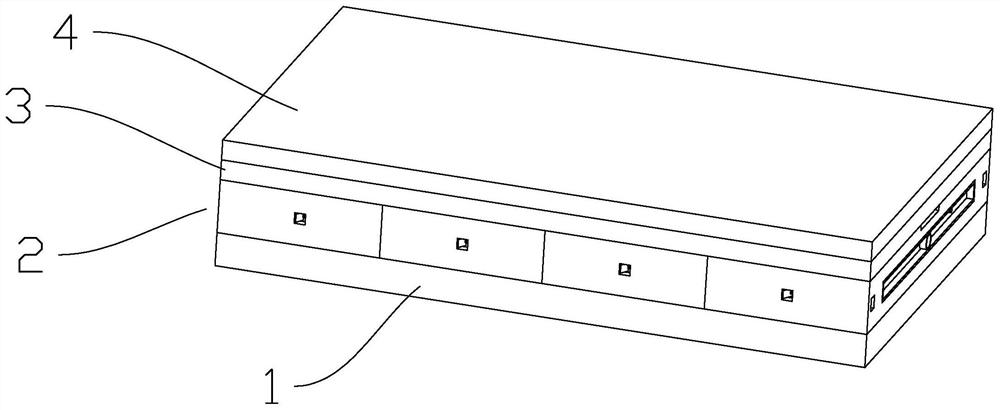

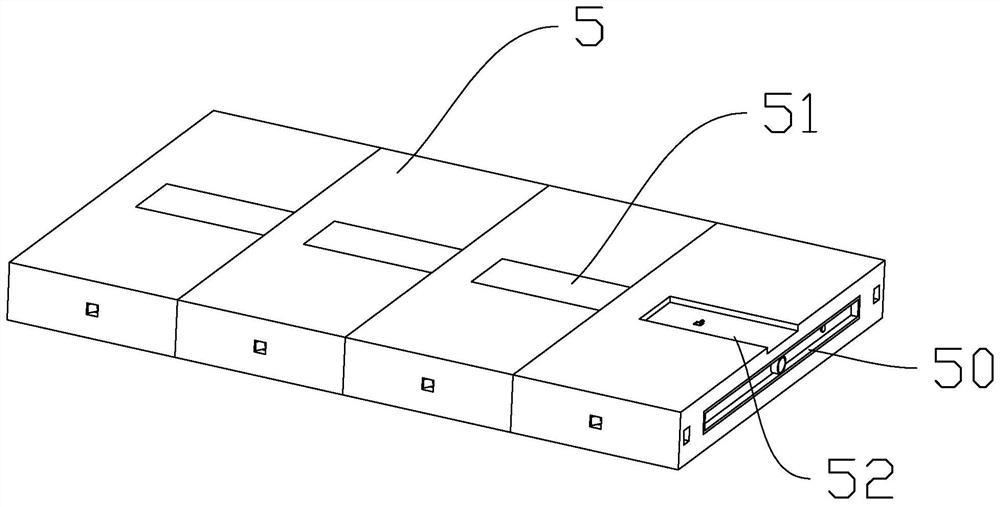

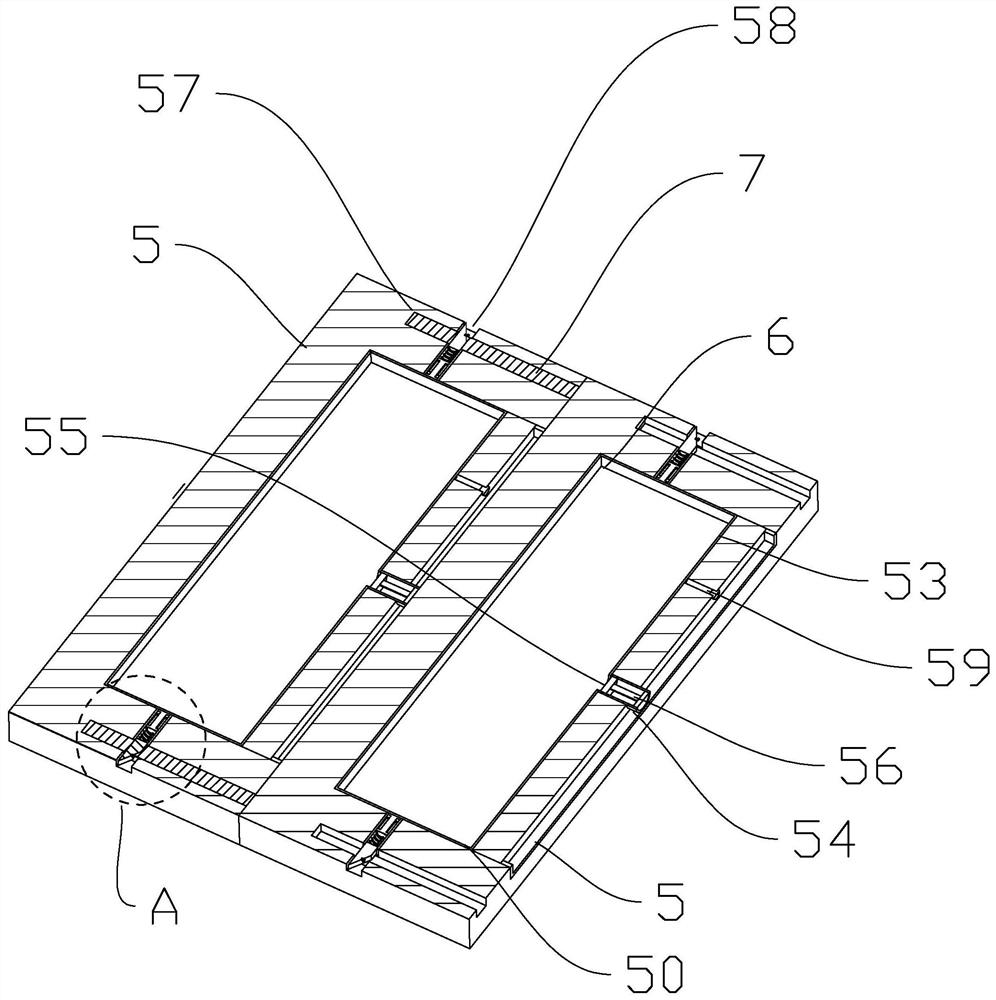

An inverted flat roof composite waterproof and thermal insulation structure and its construction method

ActiveCN112081310BStable structureRealize splicingBuild-up roofsRoof covering insulationsInsulation layerThermal insulation

This application relates to the technical field of roof waterproofing, and discloses an inverted flat roof composite waterproof and thermal insulation structure, which includes a roof layer, thermal insulation layer, waterproof layer and protective layer arranged in sequence. The thermal insulation layer includes a number of interconnected thermal insulation boards. There is an installation slot on one side, and a horizontal plug-in board is provided on the side edge of the insulation board away from the installation slot. On the two side walls of the installation slot, there are plug-in slots that cooperate with the plug-in board, and a fixed plug-in board is arranged in the installation slot. Positioning piece 1 in the horizontal position, the top edge of the insulation board is formed with a horizontal pressure plate, the top outer wall of the installation groove is provided with a transverse groove matching the pressure plate, and the positioning piece 2 for fixing the position of the pressure plate is arranged in the installation groove. The application has the effect of improving the structural stability of the thermal insulation layer.

Owner:浏阳市山田建筑工程有限公司

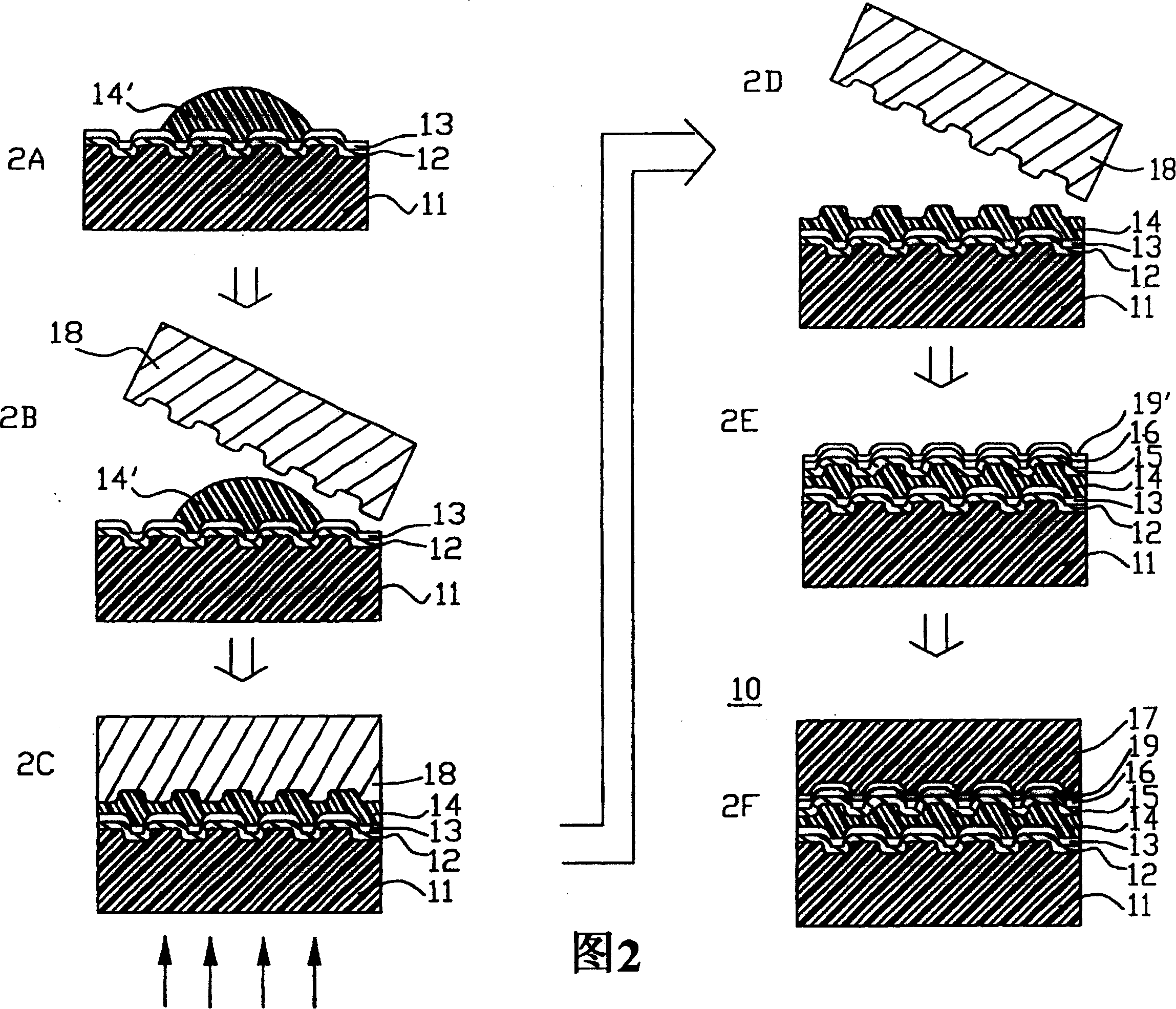

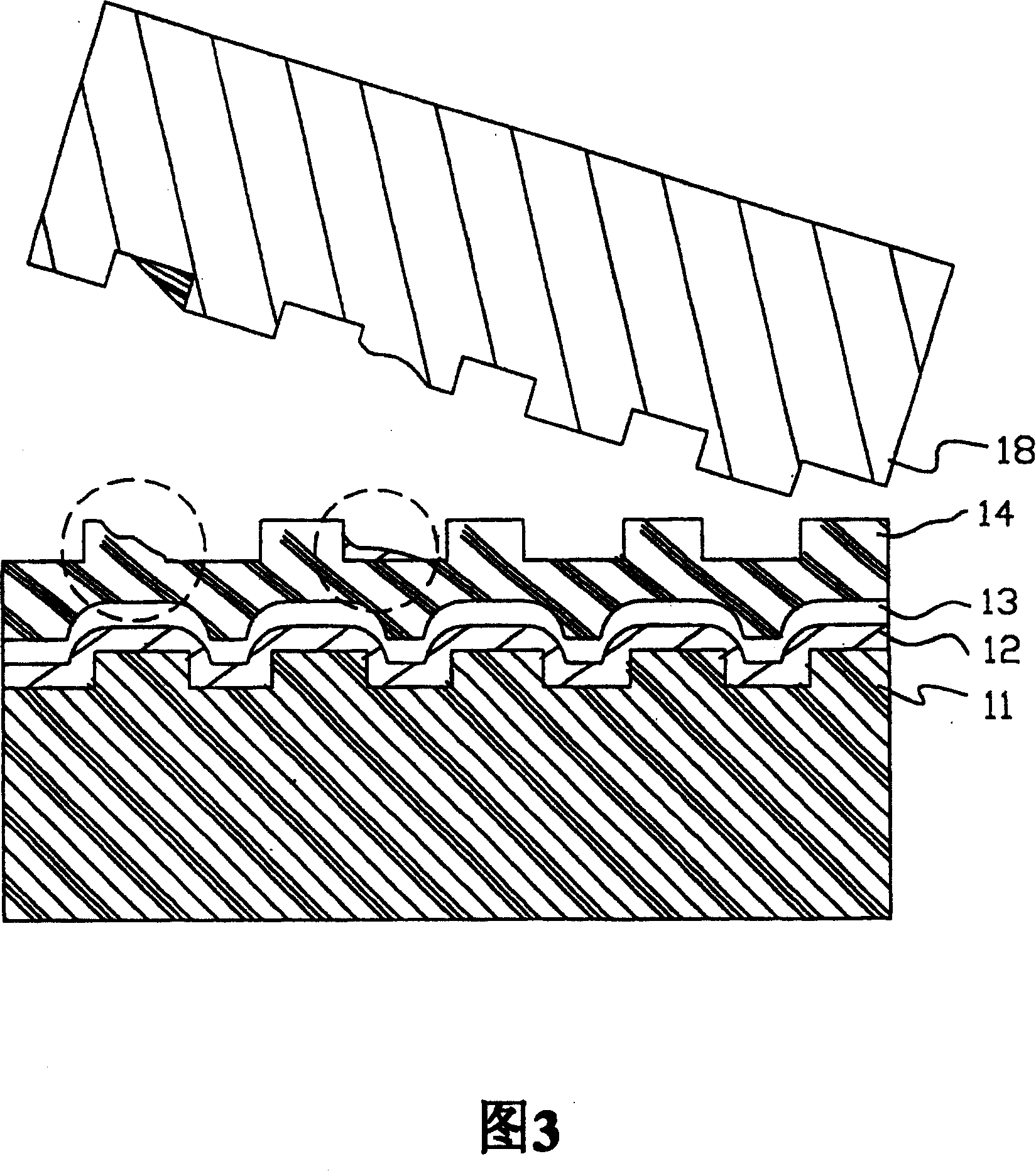

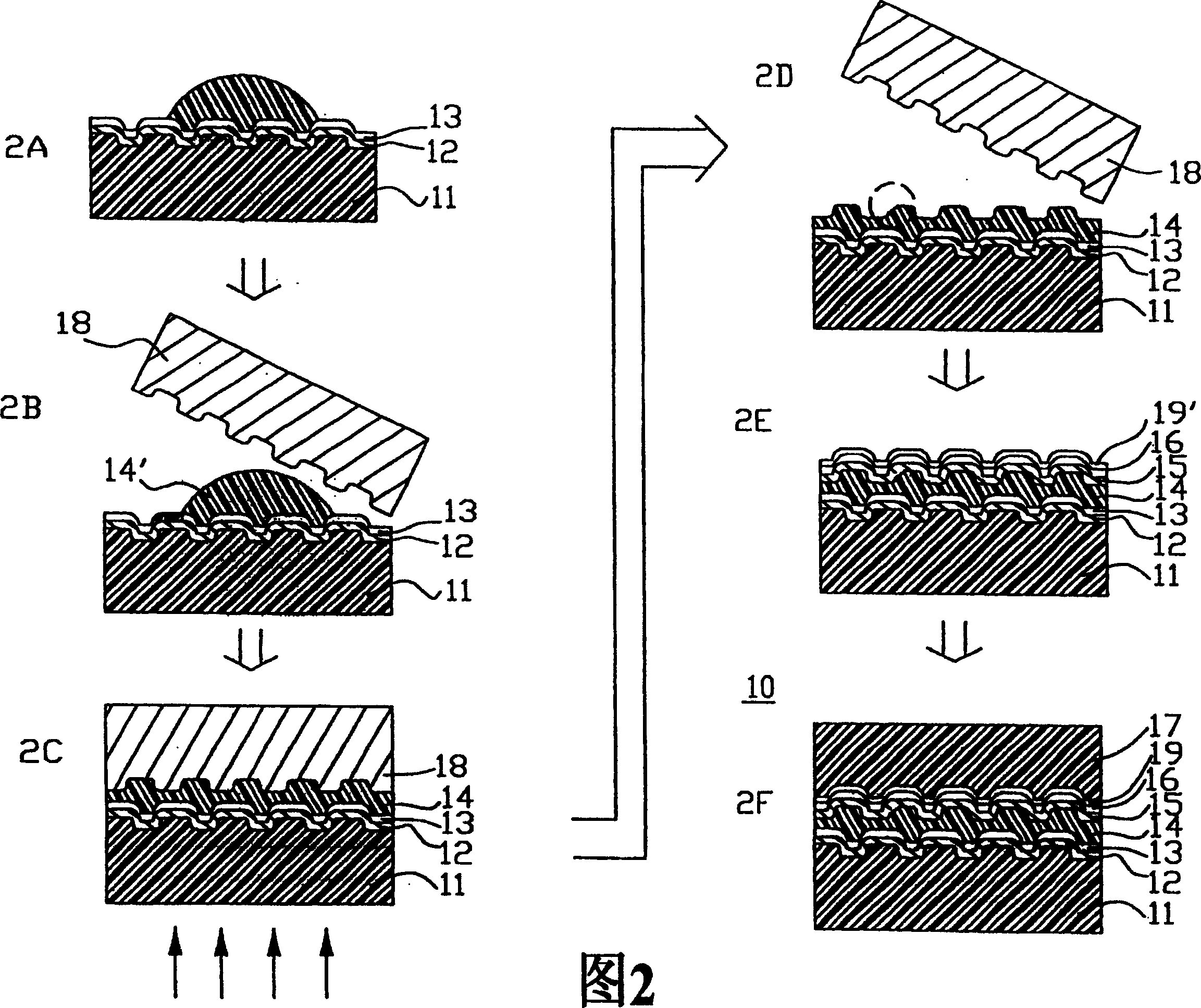

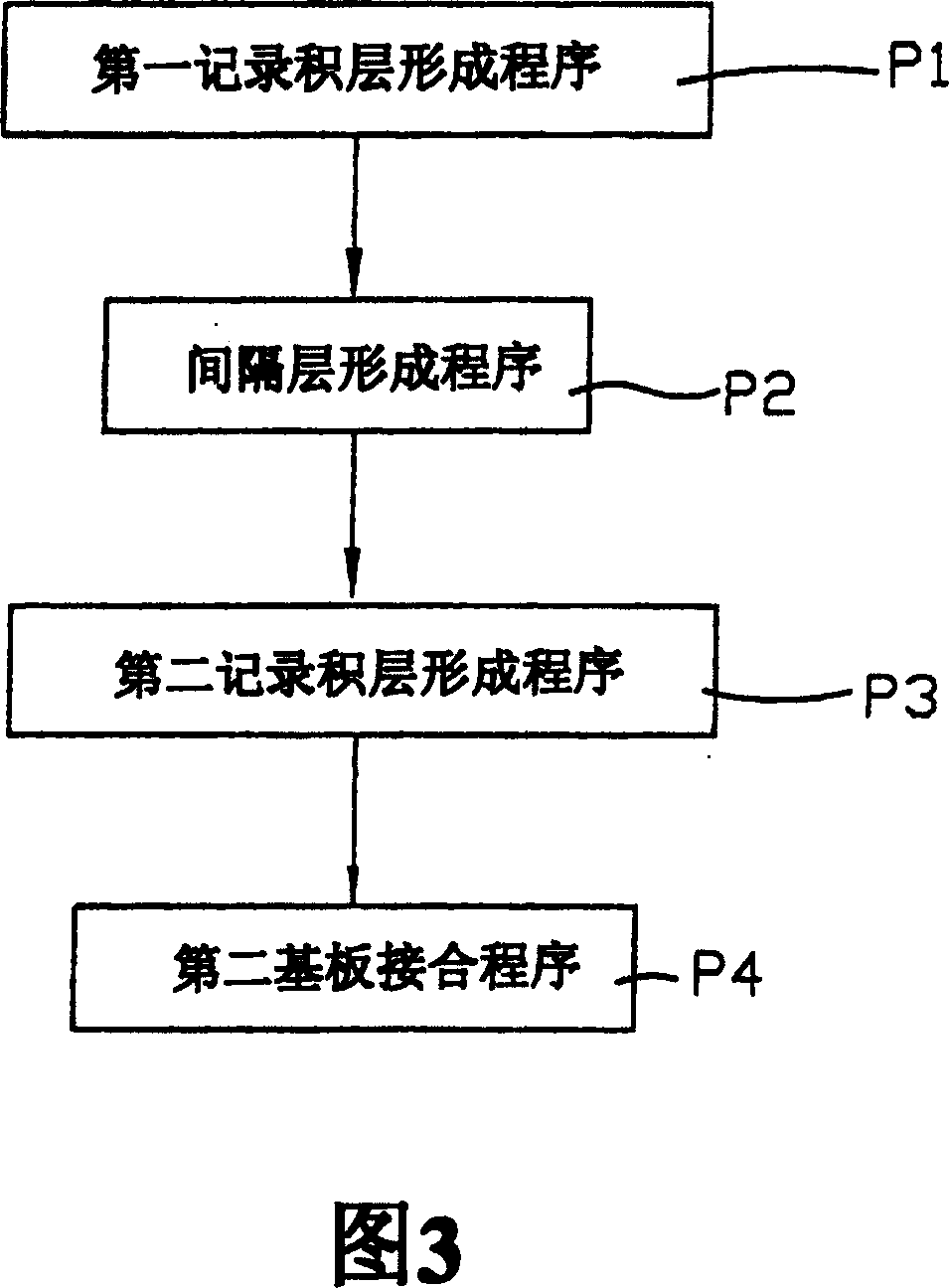

Method of manufacturing templet and optical information storage medium

InactiveCN100372011CNot prone to breakage and peeling problemsReduce adhesionOptical record carrier manufactureEngineeringInformation storage

This invention relates to formwork for manufacturing a light information storage medium. The formwork includes a base plate and a reformed layer, among which, the base plate has multiple pre-carved trenches and the reformed layer is set on the base plate. This invention also discloses a manufacturing method for a light information storage medium.

Owner:PRODISC TECH INC

Adhesive for corrugated boxes

ActiveCN108424723BQuality assuranceHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyCardboard

The invention discloses a corrugated box adhesive, which is made of the following raw materials in parts by weight: 60-80 parts of modified epoxy resin, 10-15 parts of starch, 10-15 parts of epoxy soybean oil, and 1 part of fumed white carbon black. ‑2 parts, 1‑2 parts of trimesin tricarboxylate, 4‑7 parts of antioxidant, 3‑5 parts of cooked tung oil, nanometer Au 30 S(SCH 2 CH 2 CH 3 ) 18 Clusters 0.1‑0.3 parts. The present invention reasonably selects the weight components of the corrugated box adhesive, and adopts appropriate steps for deployment, so that the adhesive has high bonding strength and good bonding performance; the present invention adopts modified epoxy resin and modified Non-toxic starch can enhance the high temperature resistance and adhesion performance of the adhesive. At the same time, the prepared adhesive is non-toxic and harmless, and the phenomenon of water-gel separation is not easy to occur. The preparation method is simple, the process conditions are low, and the product quality is stable. The cardboard obtained after bonding has high pressure resistance and strong puncture resistance, and the quality of the produced corrugated box can be guaranteed.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

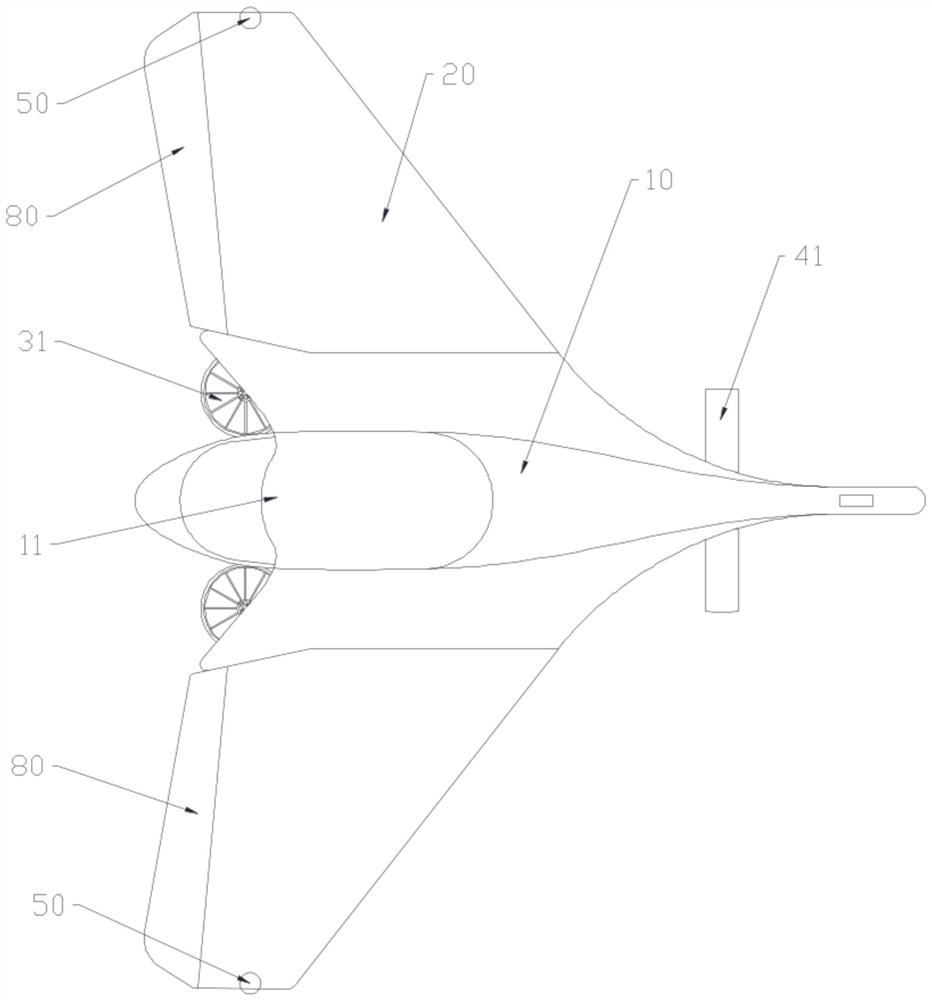

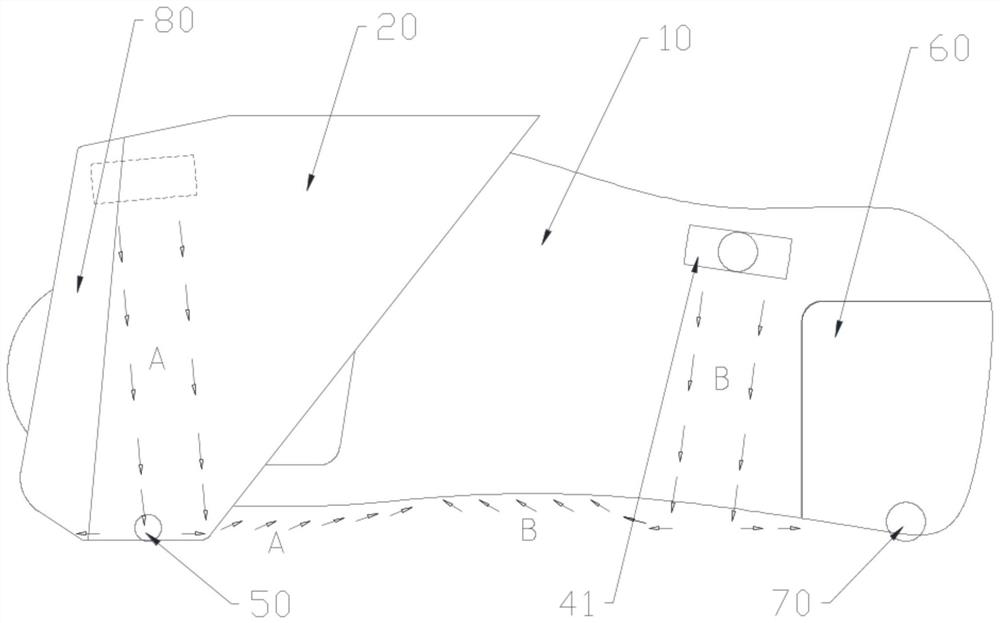

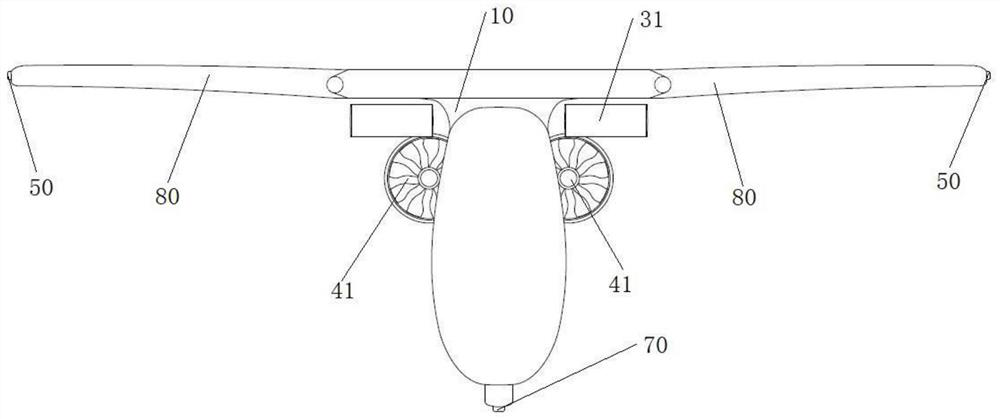

Safe and efficient electric vertical take-off and landing aircraft

PendingCN114104280AFirmly connectedImprove aerodynamic performanceWing adjustmentsVertical landing/take-off aircraftsAviationFlight vehicle

The invention belongs to the technical field of aviation, and particularly relates to a safe and efficient electric vertical take-off and landing aircraft which comprises an aircraft body, a first driving component, a second driving component, a main wing, an aileron, two front take-off and landing devices, an empennage and a rear take-off and landing device. The air driving efficiency can be improved in all flight states, the stall speed is reduced, and the aircraft is prevented from being out of control easily, so that the safety and the reliability of the aircraft are greatly improved.

Owner:常州市锦织机械有限公司

Packaging box adhesive and preparation method thereof

InactiveCN109517561AHigh bond strengthGood bonding performanceEpoxy resin adhesivesRosin adhesivesWaxChemistry

The invention discloses a packaging box adhesive. The packaging box adhesive contains the following components in parts by weight: 30-50 parts of epoxy resin, 30-50 parts of maleic resin, 30-50 partsof 2-imidazolidone, 30-50 parts of an ethylene-acetate copolymer, 10-20 parts of butyl rubber, 20-40 parts of epoxidized soybean oil, 15-30 parts of a castor oil hydrogenated mixture, 10-20 parts of boiled wood oil, 8-12 parts of tripropargyl trimellitate, 8-12 parts of a water-soluble polyethylene acetylene alcohol wax, 8-12 parts of isopropanol, 8-12 parts of silicon resin, 0.8-1.2 parts of an antioxidant, 1-3 parts of a tackifier and 2-20 parts of deionized water. By utilizing the epoxy resin, the high temperature resistance and adhesion property of the adhesive can be improved, meanwhile,the prepared adhesive is non-toxic and harmless, and a water-glue separation phenomenon is unlikely to occur; and the preparation method is simple, low in process condition and stable in product quality, a paper board obtained through adhesion is high in compressive resistance and strong in puncture resistance, and the quality of a product packaging box can be guaranteed. The packaging box adhesive has the characteristics of strong adhesion force, compressive resistance, moisture resistance and high temperature resistance.

Owner:贵州众旺包装有限公司

An oil displacement emulsion stabilized by magnetic nanoparticles

ActiveCN110373171BEnhanced overall recoveryNot prone to separationDrilling compositionOil emulsionActive agent

The invention relates to the technical field of oil and gas field development. Aiming at the problems of poor thermal stability and easy oil-water separation of existing oil-displacement emulsions, an oil-displacement emulsion stabilized by magnetic nanoparticles is disclosed, including: modified magnetic nanoparticle Fe 3 o 4 @SiO 2 Particles, surfactants and polymers, the preparation method of which is: the modified magnetic nano-Fe 3 o 4 @SiO 2 Granules, surfactants, polymers and deionized water are mixed to form an aqueous phase solution, and ultrasonically mixed for 30-60 min to form a mixed solution; b. Add the oil phase to the above mixed solution, and the speed is homogeneous for 10-15 min to obtain a uniform mixture The oil-water system is allowed to stand at room temperature for 24h-72h, and the excess oil phase and water phase are separated to obtain the finished product. The invention provides an oil-displacement emulsion stabilized by magnetic nanoparticles, which has good stability under high-temperature and high-salt conditions, and the oil-displacement emulsion can significantly improve the recovery rate of low-permeability oil reservoirs.

Owner:ZHEJIANG OCEAN UNIV

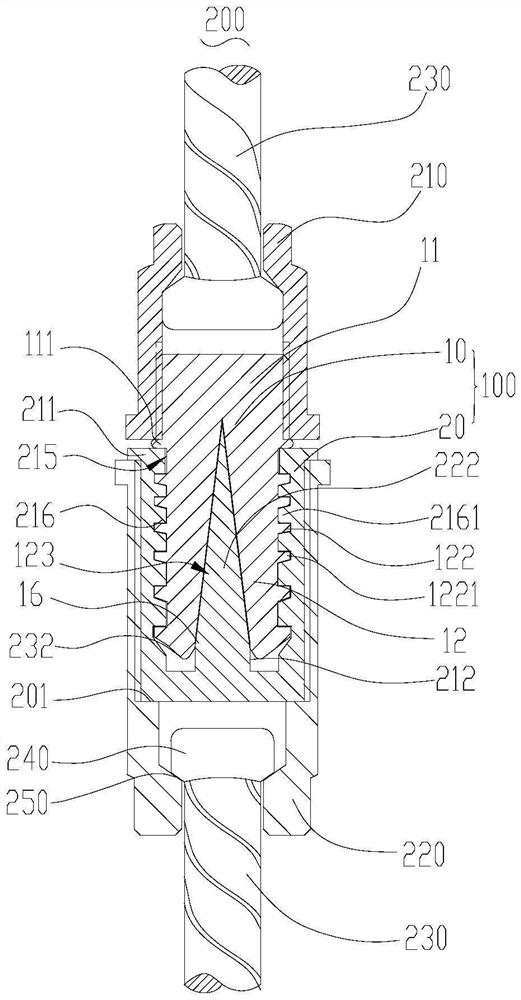

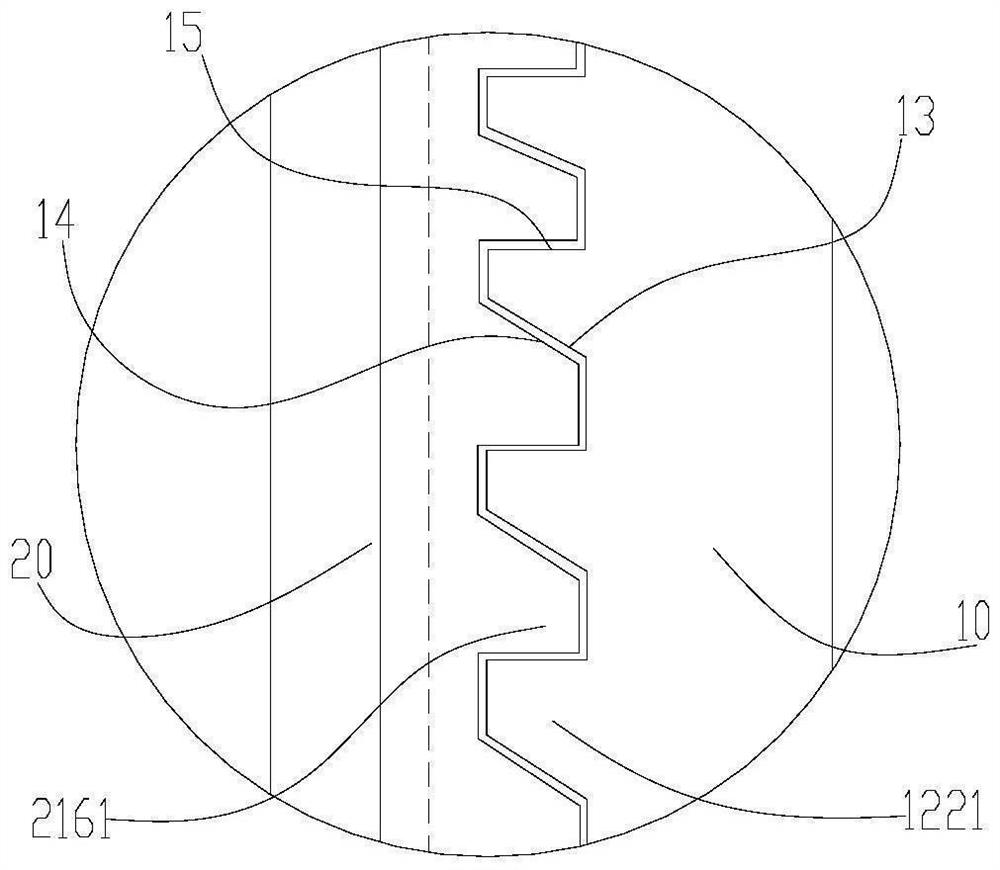

Plug-in structure and precast pile connecting mechanism

PendingCN114427222AImprove connection strengthImprove stabilityBulkheads/pilesArchitectural engineeringStructural engineering

The invention provides an inserting structure and a precast pile connecting mechanism. The inserting structure comprises a first sleeve, a second sleeve, an inserting rod, an elastic sleeve, a limiting piece and a tensile piece, and the inserting rod is fixedly installed on the first sleeve; a first latch group arranged in the axial direction is arranged on the outer circumferential wall of the insertion rod, and a second latch group matched with the first latch group is arranged on the inner circumferential wall of the limiting piece; the elastic sleeve is sleeved with the limiting piece, the elastic sleeve and the limiting piece are both contained in the second sleeve, the tensile piece is fixedly connected to the second sleeve, and the elastic sleeve can elastically expand so that the inserting rod can be inserted into the limiting piece. The first latch group and the second latch group are meshed with each other under the elastic contraction of the elastic sleeve; wherein the inserting rod comprises a connecting part and an inserting part which are arranged in the axial direction and fixed to each other, the connecting part is used for being connected with the first sleeve, a first groove extending in the axial direction is formed in the inserting part, the inserting part comprises a plurality of fins, and the fins are arranged in a surrounding mode and enable the inserting rod to contract in the radial direction.

Owner:JIAXING XINCHUANG CONCRETE PROD +1

Trehalose yogurt and preparation method thereof

The invention provides trehalose yogurt and a preparation method thereof. The trehalose yogurt is prepared from the following raw materials in parts by weight: 90-95 parts of milk, 5-7 parts of trehalose, 2-3 parts of corn maltodextrin and 3-4 parts of starter. According to the trehalose yogurt and the preparation method thereof, the content of trehalose in yogurt can be increased, the yogurt stability can be improved, and application of white granulated sugar can be avoided.

Owner:合肥民祯健康科技有限公司

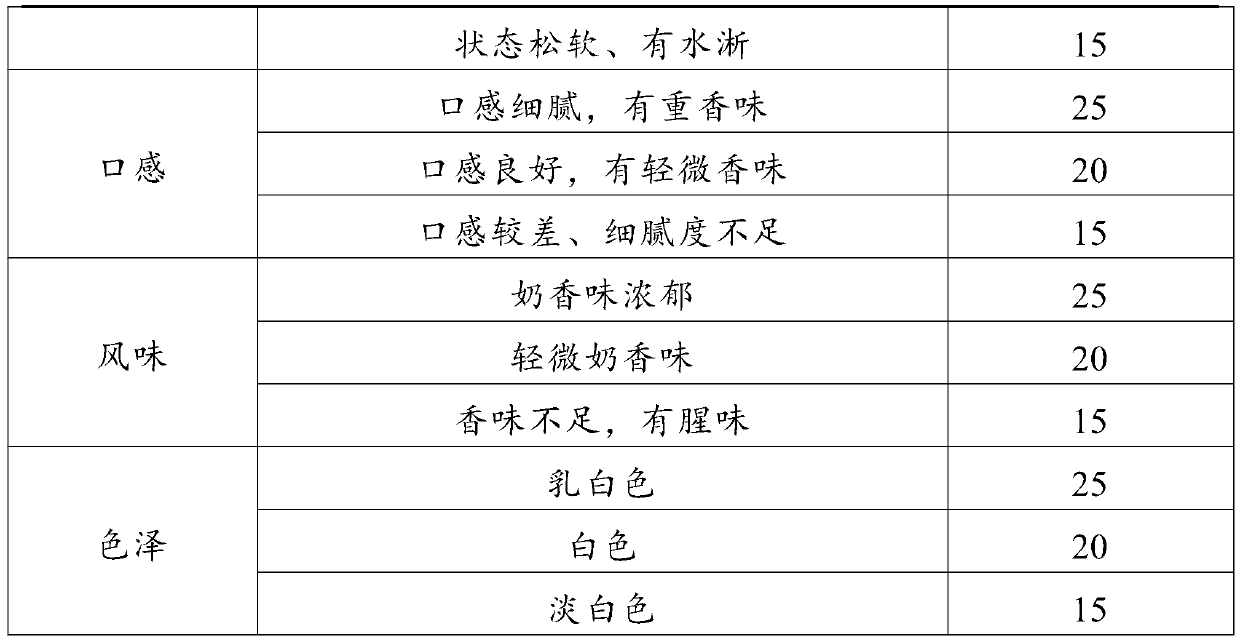

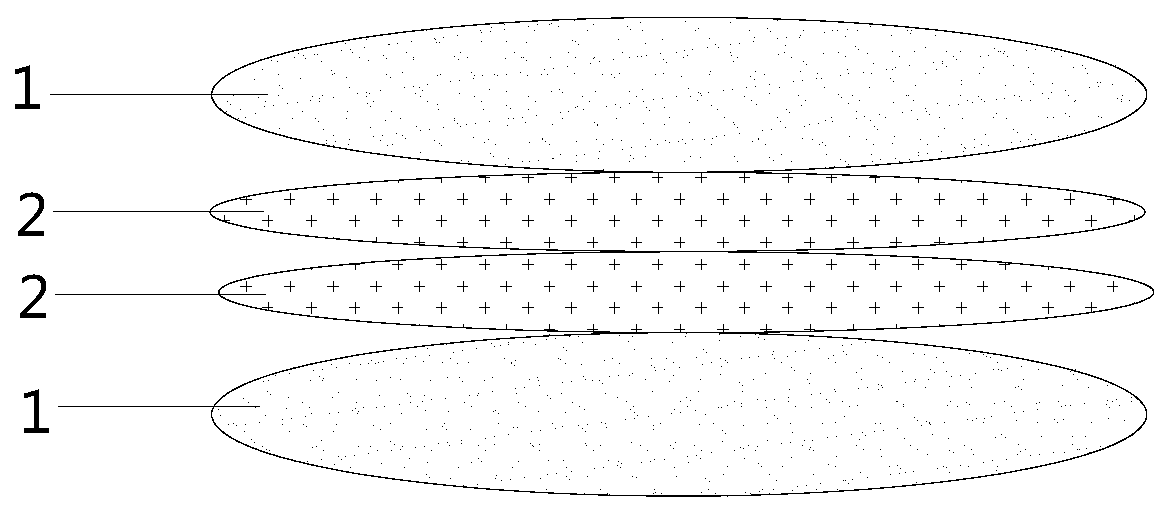

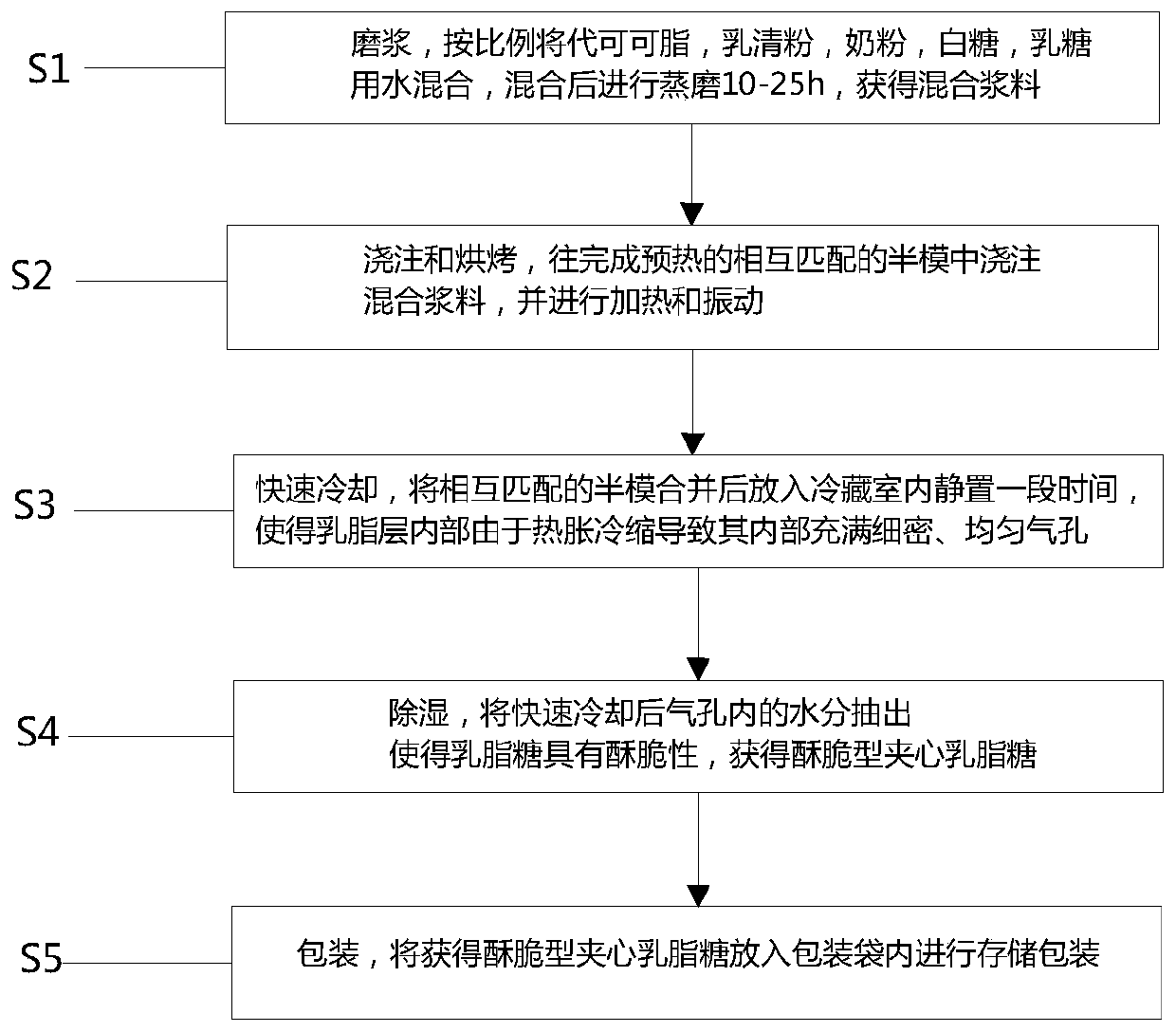

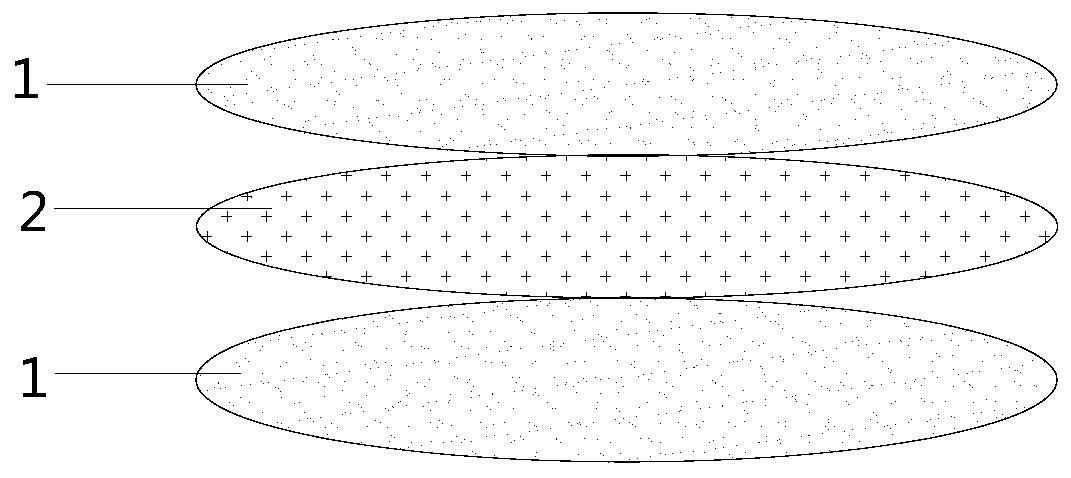

Crisp sandwich toffee and preparation technology thereof

InactiveCN110140792AEmulsion system is stableReplenish energyConfectionerySweetmeatsButter cocoaChemistry

The invention belongs to the technical field of candy production, and particularly relates to crisp sandwich toffee and a preparation technology thereof. The preparation technology of the crisp sandwich toffee disclosed by the invention comprises the following steps of mixing a cocoa butter replacer, whey powder, milk powder, white sugar and lactose with water in a certain proportion, then performing steaming and grinding to obtain mixed pulp, then casting the mixed pulp into molds, performing baking, performing quick cooling, and then performing a dampness removing technology so as to obtainthe crisp sandwich toffee. Through the technology, an emulsifying system of the toffee is stable, and an oil-water separation phenomenon is not easy to appear; besides, due to baking and cold storagetechnologies, fine, tight and uniform bubbles exist in the toffee, after dampness removal, fine, tight and uniform air holes exist in the toffee, and the toffee has crisp properties and scorch aroma;through adding solid matter, the toffee is formed into the sandwich toffee, and the toffee is more delicious and is loved by consumers; and the production technology is simple, low in cost and convenient in industrial production.

Owner:晋江市金伯诺食品有限责任公司

Method of mfg. of form and optical information storage medium

InactiveCN100342440CImprove yieldReduce manufacturing costOptical record carrier manufactureOptical storageInformation storage

This invention relates to formwork used in the production of an optical storage medium. The formwork includes a base plate and a reformed layer, among which, the base plate has multiple pre-carved trenches and the reformed layer is set on the base plate. This invention also discloses a manufacture method for a light information storage medium.

Owner:PRODISC TECH INC

Liquid storage tank against liquid sloshing

InactiveCN105668067BImprove driving safetyImprove connection reliabilityLarge containersLiquid storage tankEngineering

The invention discloses a liquid storage tank capable of preventing liquid from sloshing and aims at solving the problem that a liquid storage tank in the prior art is poor in anti-sloshing effect. The liquid storage tank capable of preventing the liquid from sloshing comprises a main liquid storage tank body, two sealing heads, a longitudinal shaft, n anti-sloshing plates and n+1 blade anti-sloshing devices, and n is a natural number greater than or equal to one. The main liquid storage tank body is sequentially welded to the two sealing heads located at the front end and the back end of the main liquid storage tank body to form a liquid storage tank body. The longitudinal shaft is installed in the liquid storage tank body. The two ends of the longitudinal shaft are welded to the centers of the two sealing heads. The n anti-sloshing plates are installed on the longitudinal shaft in a sleeving mode. The peripheries of the anti-sloshing plates are in welded connection with the inner wall of the main liquid storage tank body. The n-1 blade anti-sloshing devices are installed on the longitudinal shaft between the two anti-sloshing plates in a sleeving mode through blade anti-sloshing device shaft sleeves. Two blade anti-sloshing devices are installed in the positions, between the sealing heads and the anti-sloshing plates and between the anti-sloshing plates and the sealing heads, of the longitudinal shaft in a sleeving mode through the blade anti-sloshing device shaft sleeves. The blade anti-sloshing device shaft sleeves are rotationally connected with the longitudinal shaft. The other ends of the n+1 blade anti-sloshing devices are welded to the inner wall of the main liquid storage tank body through four tank body spring seats.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com