High-strength corrugated case binder and production method thereof

A corrugated box, adhesive technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesive types, etc., can solve the problem that the storage time is short, usually about 24 hours, and the kinematic viscosity of the glue decreases. Faster, the adhesive is not stable, etc., to achieve the effect of not easy to separate the water and glue, good bonding performance, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of described high-strength corrugated box adhesive comprises the steps:

[0040] Step 1. Under constant stirring at 150r / min, use the discharge device to slowly add soybean protein isolate into the NaOH solution. After the addition, gradually raise the temperature of the system to 80°C within 25-30min, keep the temperature for 90min, and then cool down to 50°C, adjust the pH of the system to 9-9.5 with citric acid, and naturally cool to room temperature to obtain a soybean protein degradation solution;

[0041] Step 2. React the soybean protein degradation solution with one-third of the modified phenolic resin at 90°C for 10 minutes, then lower the temperature to 65°C, add the remaining modified phenolic resin and modified lignin, continue the reaction for 20 minutes, and cool naturally to room temperature to prepare the adhesive.

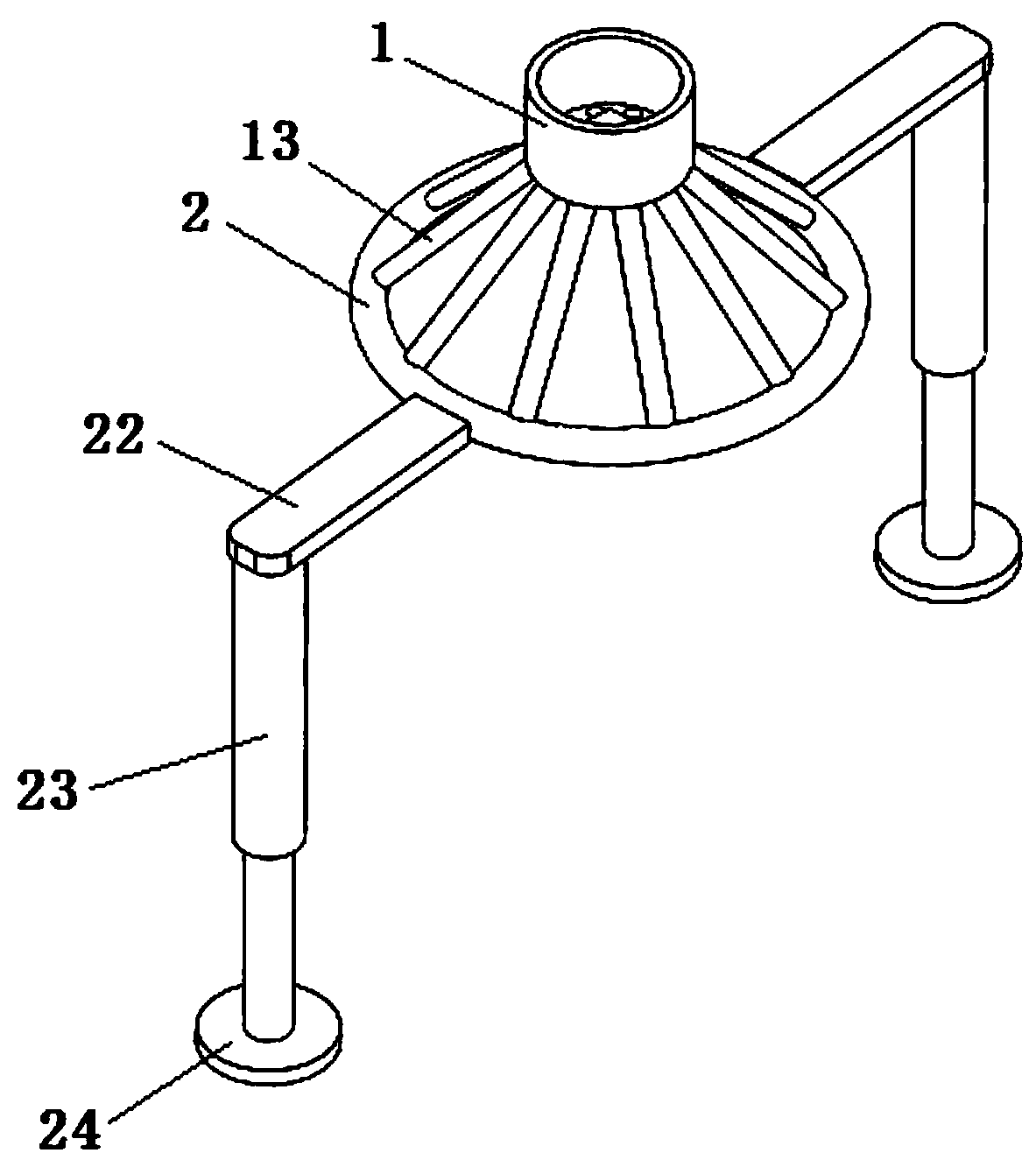

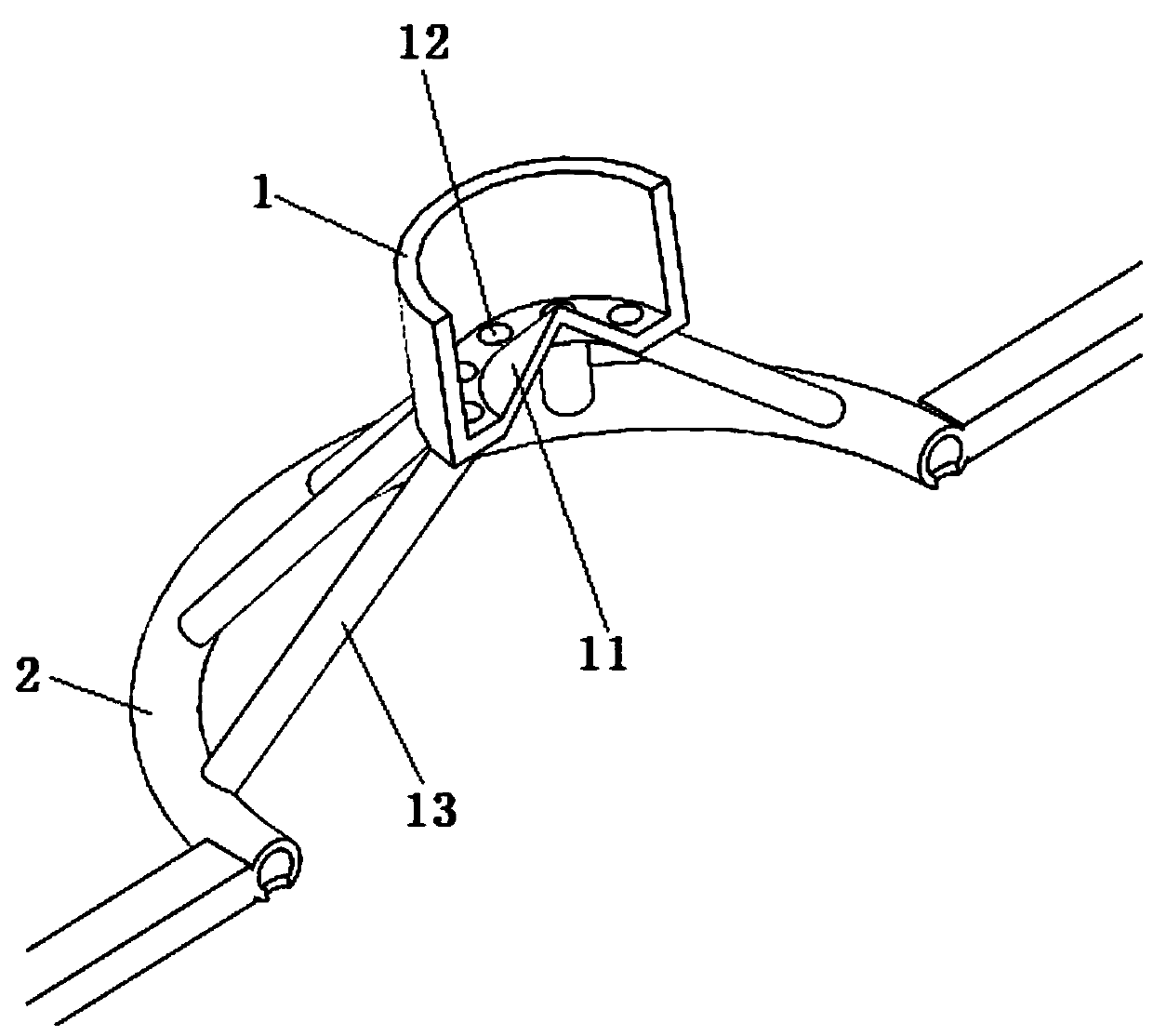

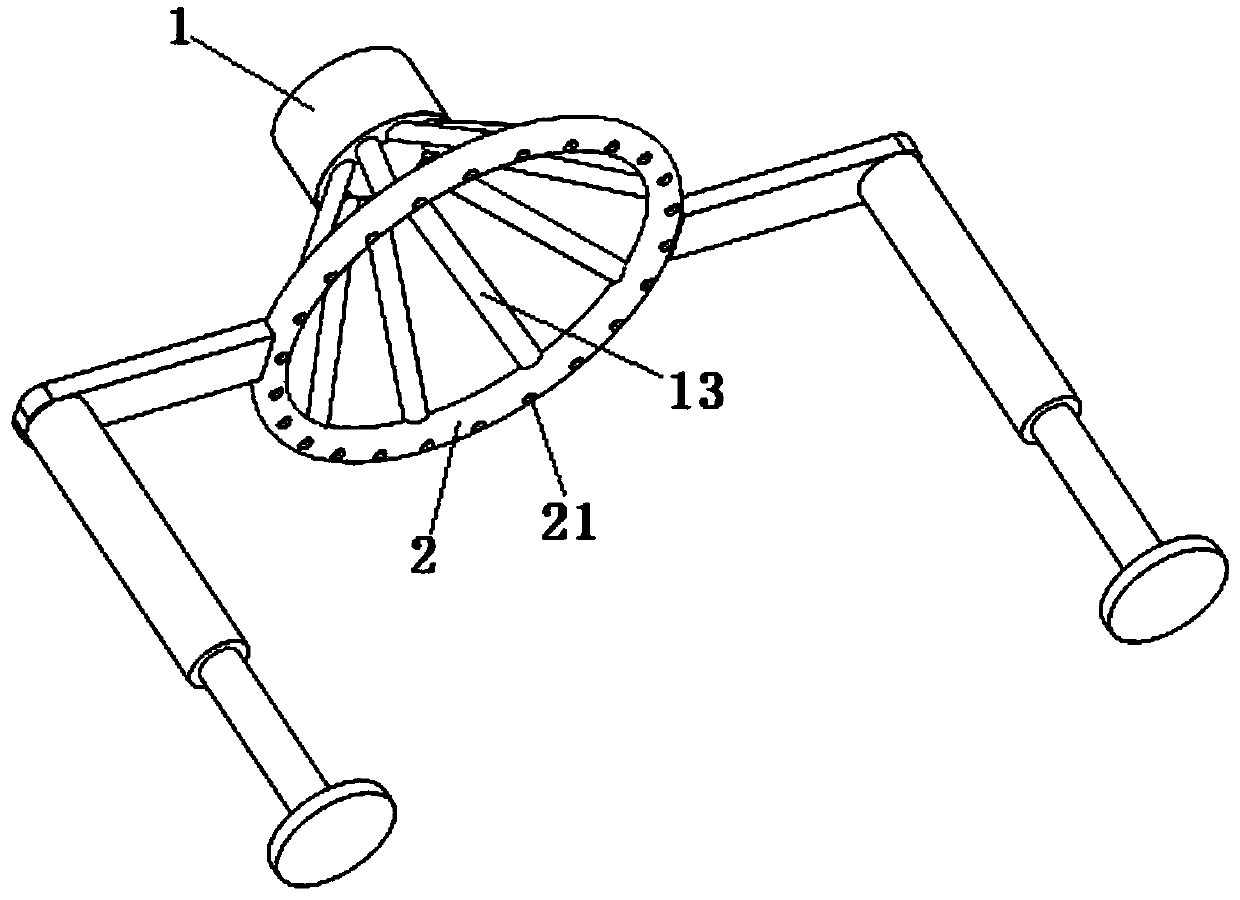

[0042] The discharge device described in step 1, such as Figure 1-3 As shown, including the discharge barrel 1, t...

Embodiment 1

[0046] A high-strength corrugated box adhesive, made of the following raw materials in parts by weight: 30 parts of soybean protein isolate, 10 parts of modified phenolic resin, 6 parts of modified lignin, 150 parts of NaOH aqueous solution, and 9 parts of citric acid;

[0047] The high-strength corrugated box adhesive is made by the following steps:

[0048] Step 1. Slowly add soybean protein isolate into the NaOH solution under constant stirring at 150r / min. After adding, gradually raise the temperature of the system to 80°C within 25 minutes, keep the temperature for 90 minutes, and then cool down to 50°C. Adjust the pH of the system to 9, and naturally cool to room temperature to obtain a soybean protein degradation liquid;

[0049] Step 2. React the soybean protein degradation solution with one-third of the modified phenolic resin at 90°C for 10 minutes, then lower the temperature to 65°C, add the remaining modified phenolic resin and modified lignin, continue the reactio...

Embodiment 2

[0051] A high-strength corrugated box adhesive, made of the following raw materials in parts by weight: 35 parts of soybean protein isolate, 12 parts of modified phenolic resin, 7 parts of modified lignin, 175 parts of NaOH aqueous solution, and 10 parts of citric acid;

[0052] The high-strength corrugated box adhesive is made by the following steps:

[0053] Step 1. Slowly add soybean protein isolate into the NaOH solution under constant stirring at 150r / min. After the addition, gradually raise the temperature of the system to 80°C within 28 minutes, keep the temperature for 90 minutes, and then cool down to 50°C. Adjust the pH of the system to 9.3, and cool naturally to room temperature to obtain a soybean protein degradation liquid;

[0054] Step 2. React the soybean protein degradation solution with one-third of the modified phenolic resin at 90°C for 10 minutes, then lower the temperature to 65°C, add the remaining modified phenolic resin and modified lignin, continue th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com