Trehalose acidophilous milk and preparation method thereof

A technology of trehalose and yogurt, applied in milk preparations, dairy products, applications, etc., to achieve the effects of inhibiting the decomposition of unsaturated fatty acids, good flavor, and preventing protein denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

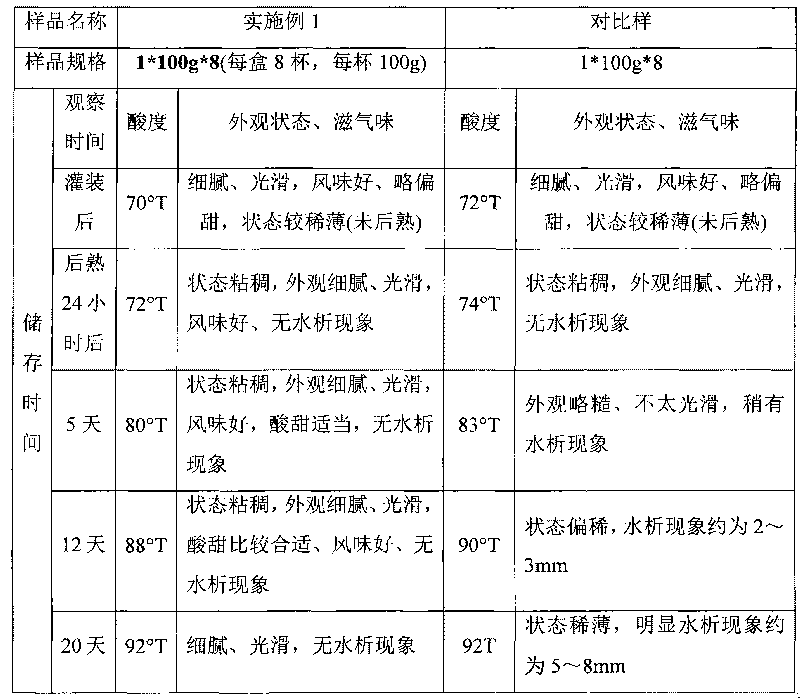

Examples

Embodiment 1

[0029] Embodiment 1 Containing trehalose original probiotic yoghurt and production method thereof

[0030] Raw material formula (based on 1000kg):

[0031] Milk for ingredients (total dry 13%) 915.0kg

[0032] Trehalose 20.0kg

[0033] White sugar 60.0kg

[0034] Low Ester Pectin 1.0kg

[0035] Modified starch (hydroxypropyl starch) 4.0kg

[0036] BMY (Basic Strain + Milk Bifido) (CHR HANSEN Cryogenic Strain) 200U

[0037] Lactobacillus longum (CHR HANSEN cryogenic strain) 200g

[0038]Lactobacillus acidophilus (CHR HANSEN cryogenic strain) 10g

[0039] Raw material standards: milk: comply with GB6914 standard; trehalose: purchased from Japan Linyuan Co., Ltd.; white sugar: comply with GB317-1998; Modified starch: purchased from France Roquette Company, waxy corn modified starch;

[0040] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0041] The production method of the trehalose-containing original probiotic yog...

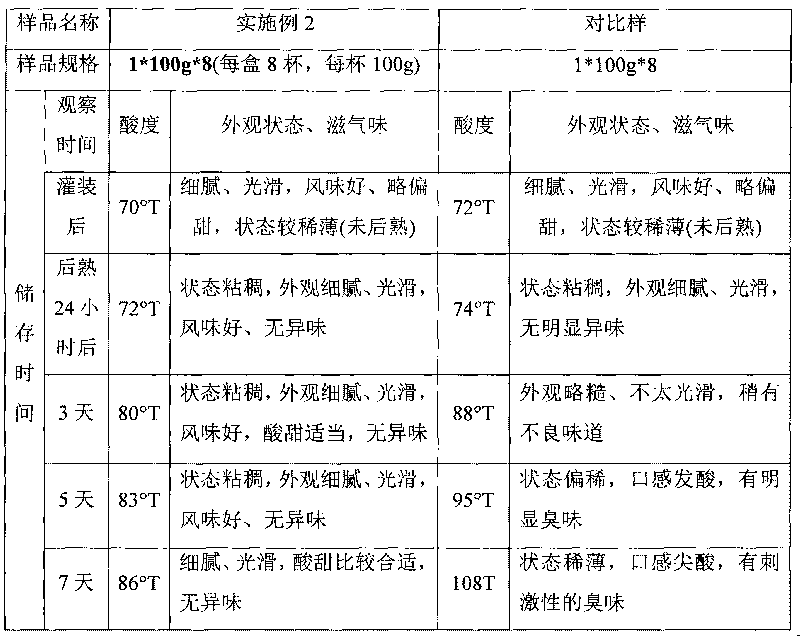

Embodiment 2

[0050] Embodiment 2: unsaturated fatty acid yoghurt and preparation method thereof

[0051] Raw material formula (based on 1000kg):

[0052] Milk for ingredients (total dry 13%) 919.0kg

[0053] Trehalose 40.0kg

[0054] White sugar 40.0kg

[0055] Low Ester Pectin 1.0kg

[0056] Unsaturated fatty acid 0.05kg

[0057] DVS lactic acid bacteria (provided by Danisco) 150DCU

[0058] The performance indicators of each raw material meet the requirements of relevant quality standards

[0059] The production method of the trehalose-containing original probiotic yogurt of the present embodiment mainly includes the following steps:

[0060] Standardize the raw milk, batching (trehalose is added in this process, after trehalose is added to the milk, the material is transformed: shear and stir at 50-60°C for 20-30 minutes), degassing, homogenizing, and sterilizing;

[0061] Lower the temperature to 40°C to 45°C for inoculation, while adding unsaturated fatty acids during the proce...

Embodiment 3

[0067] Example 3, the mouthfeel of yogurt prepared by various amounts of trehalose added

[0068] The following table 3 lists the comparison of the test conditions of different additions of trehalose under the same conditions during the research of the present invention:

[0069] table 3

[0070] The amount of trehalose added (%)

[0071] The amount of trehalose added (%)

[0072] A small amount of addition cannot achieve obvious effects; and if the amount of addition is too large, the fermentation time of the product will be prolonged (mainly affecting the osmotic pressure, thereby affecting the fermentation of the strain), the state will be soft and rough, and the flavor will also have a greater impact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com