Efficient production method of polyurethane elastic fiber

A polyurethane elasticity and production method technology, applied in the field of polyurethane elastic fiber material manufacturing, can solve problems such as high raw material prices, restricting industrial application prospects, and reducing production costs, so as to suppress the growth of subsequent aggregation viscosity and efficiently produce polyurethane elastic fibers , reduce the viscosity and the effect of viscosity growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

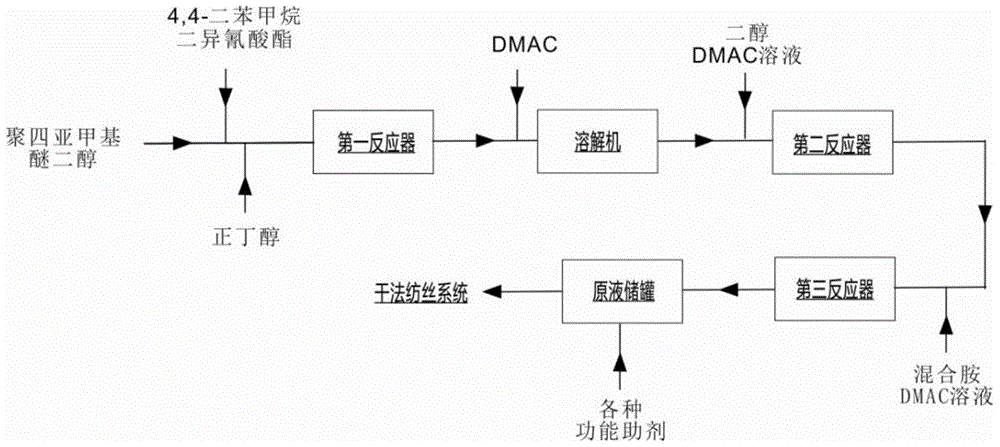

[0027] Step ① Send 407.95g of polytetramethylene ether glycol, 91.55g of 4,4-diphenylmethane diisocyanate, and 0.5g of n-butanol to the first reactor at the same time, and the reaction time is 2hr to obtain the prepolymer (PP) ;

[0028] Step ② Transport 500g of prepolymer and 596.5g of N,N-dimethylacetamide (DMAC) solvent to the high-speed dissolving machine at the same time, and fully dissolve PP under the action of high-speed shear force to obtain prepolymer solution (PPs);

[0029] Step ③ Transfer 1096.5g of prepolymer solution and 21.5g of ethylene glycol DMAC (concentration: 4%) solution to the second reactor at the same time, and make it undergo a chain extension reaction under the condition of rapid stirring to obtain the part containing -NCO-terminated polyurethane polymer solution;

[0030] Step 4. Transport the polyurethane polymer solution containing part-NCO end groups to the third reactor, and simultaneously feed 244.98g of mixed amines (including 0.83g of prop...

Embodiment 2

[0034] Step ① Send 407.95g of polytetramethylene ether glycol, 91.55g of 4,4-diphenylmethane diisocyanate, and 1.0g of n-butanol to the first reactor at the same time, and the reaction time is 2hr to obtain a prepolymer (PP) ;

[0035] Step ② Transport 500g of prepolymer and 565.4g of N,N-dimethylacetamide (DMAC) solvent to the high-speed dissolving machine at the same time, and fully dissolve PP under the action of high-speed shear force to obtain prepolymer solution (PPs);

[0036] Step ③ Transfer 1065.4g of prepolymer solution and 28.7g of ethylene glycol DMAC (concentration: 4%) solution to the second reactor at the same time, and make it undergo a chain extension reaction under the condition of rapid stirring to obtain the part containing -NCO-terminated polyurethane polymer solution;

[0037] Step 4. Transport the polyurethane polymer solution containing part-NCO end groups to the third reactor, and simultaneously feed 248.62g mixed amines (including 0.87g propylenedia...

Embodiment 3

[0041] Step ① Send 407.95g of polytetramethylene ether glycol, 91.55g of 4,4-diphenylmethane diisocyanate, and 1.5g of n-butanol to the first reactor at the same time, and the reaction time is 2hr to obtain the prepolymer (PP );

[0042] Step ② Transport 500g of prepolymer and 548.5g of N,N-dimethylacetamide (DMAC) solvent to the high-speed dissolving machine at the same time, and fully dissolve PP under the action of high-speed shear force to obtain prepolymer solution (PPs);

[0043] Step ③ Transfer 1048.5g of prepolymer solution and 30.8g of ethylene glycol DMAC (concentration: 4%) solution to the second reactor at the same time, and make it undergo a chain extension reaction under the condition of rapid stirring to obtain the part containing -NCO-terminated polyurethane polymer solution;

[0044] Step ④ transports the polyurethane polymer solution containing part-NCO end groups to the third reactor, and simultaneously feeds 254.73g mixed amines (comprising 0.95g propylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com