Cellular board core formed through folding and forming method thereof

A honeycomb panel and sandwich technology, applied in the field of sandwich panel manufacturing, to achieve the effect of small contact area, high overall strength and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

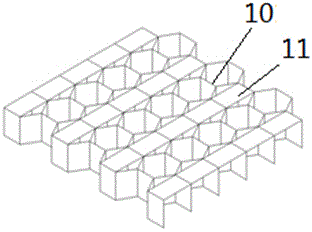

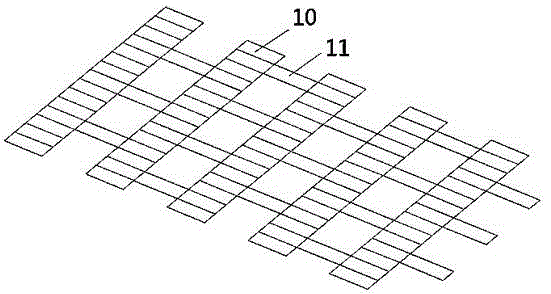

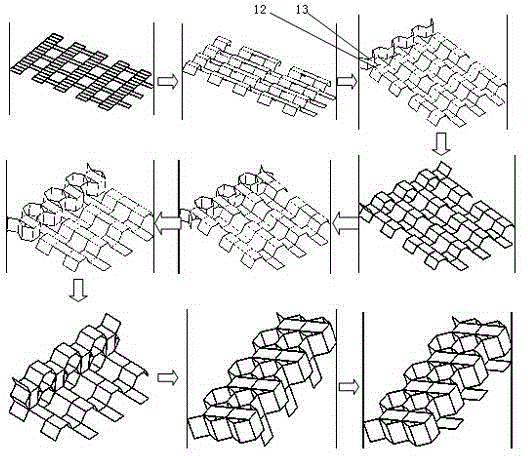

[0045] The honeycomb sandwich core is a sandwich formed based on the combination of hexagonal honeycomb structures. When the whole thin cardboard is unfolded, it is attached figure 2 For the piece of flat paper shown, the entire sheet of thin cardboard is punched and creased according to the folded position, and then folded in sequence to form a hexagonal honeycomb structure, and a hexagonal honeycomb structure is formed on one or both ends of the hexagonal honeycomb structure. There are a plurality of evenly distributed planar blocks 11 for bonding end plates, and the planar blocks 11 are evenly distributed on both ends of the hexagonal honeycomb structure 10 .

[0046] The plane blocks 11 are rectangular, and each plane block covers one end surface of a honeycomb unit cell, and the plane blocks are naturally formed by bending a whole sheet of thin cardboard.

[0047] Using the manufacturing method of the folded and formed honeycomb panel core, the polygonal honeycomb networ...

Embodiment 2

[0062] The folding method is consistent with the first embodiment.

[0063] Embodiment three

Embodiment 3

[0065] The folding method is consistent with the first embodiment.

[0066] Embodiment Four

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com