Patents

Literature

70results about How to "Reliable molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

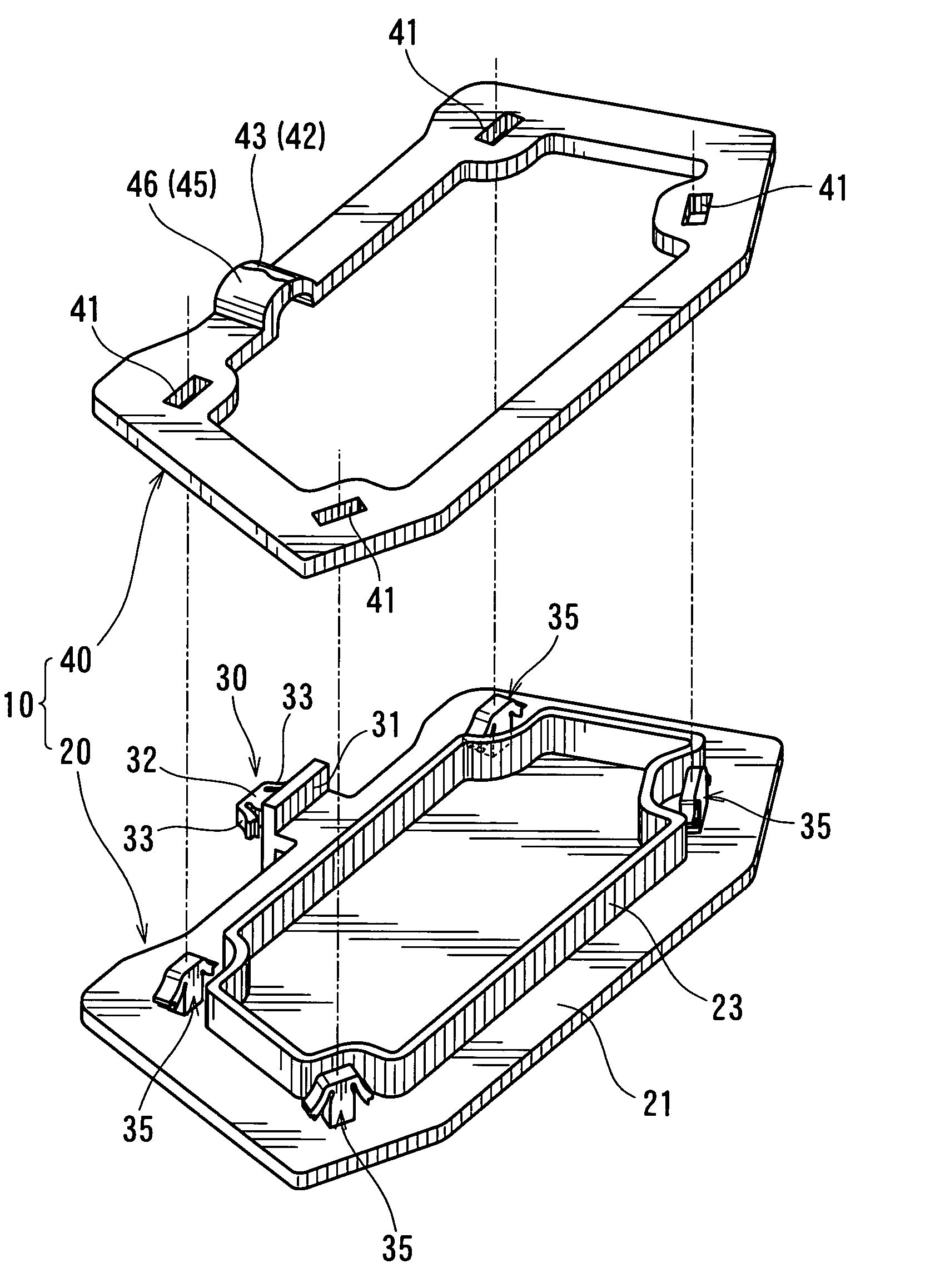

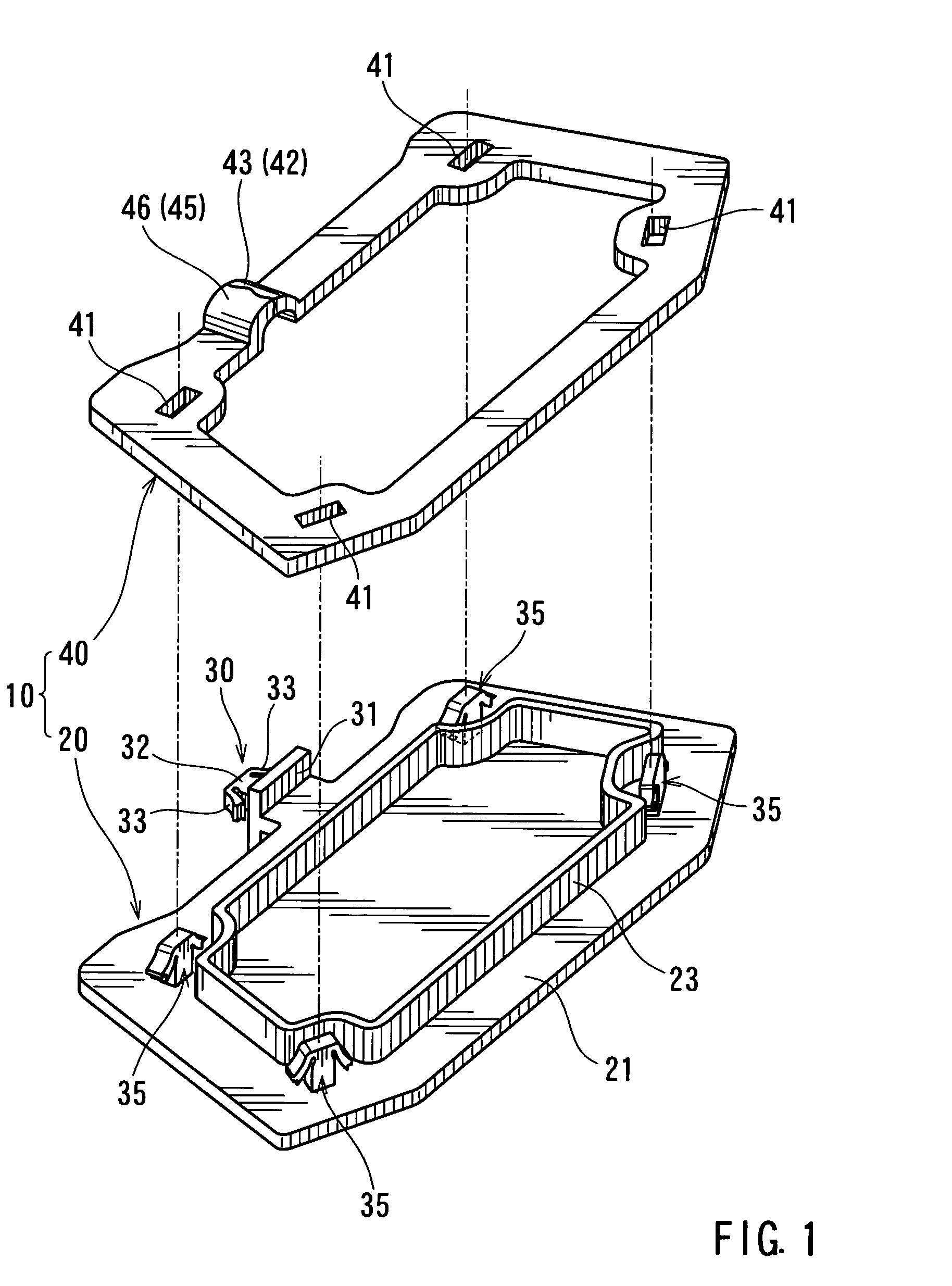

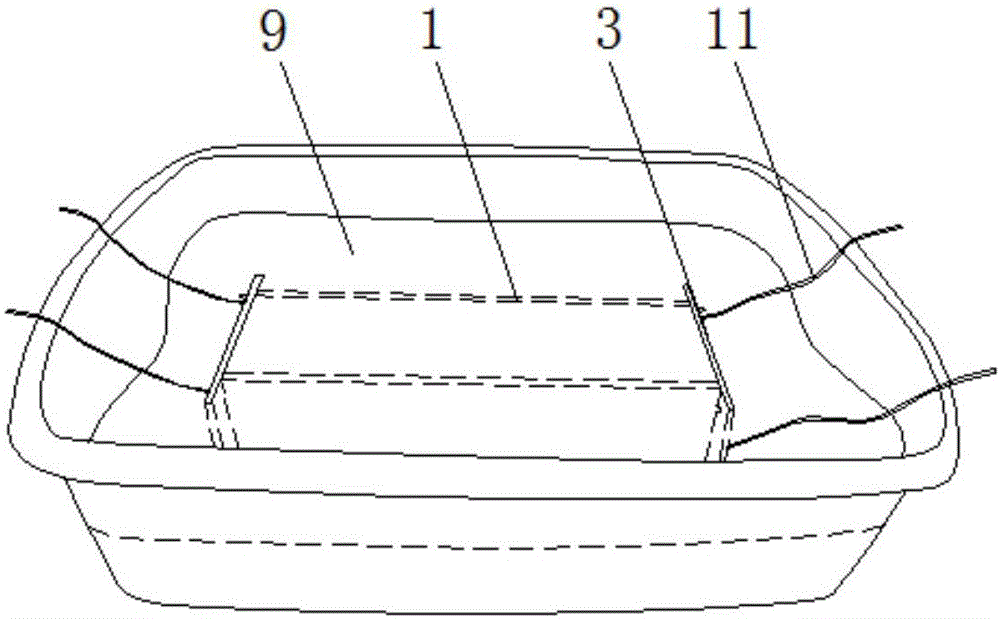

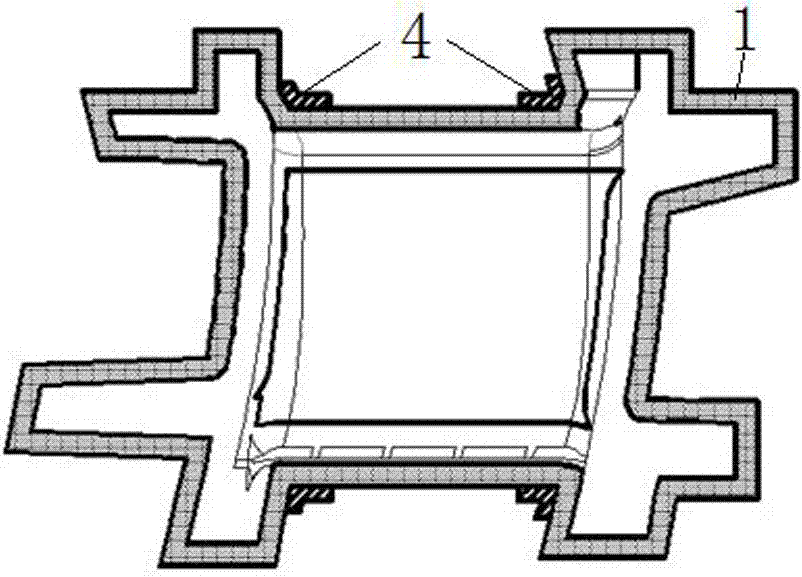

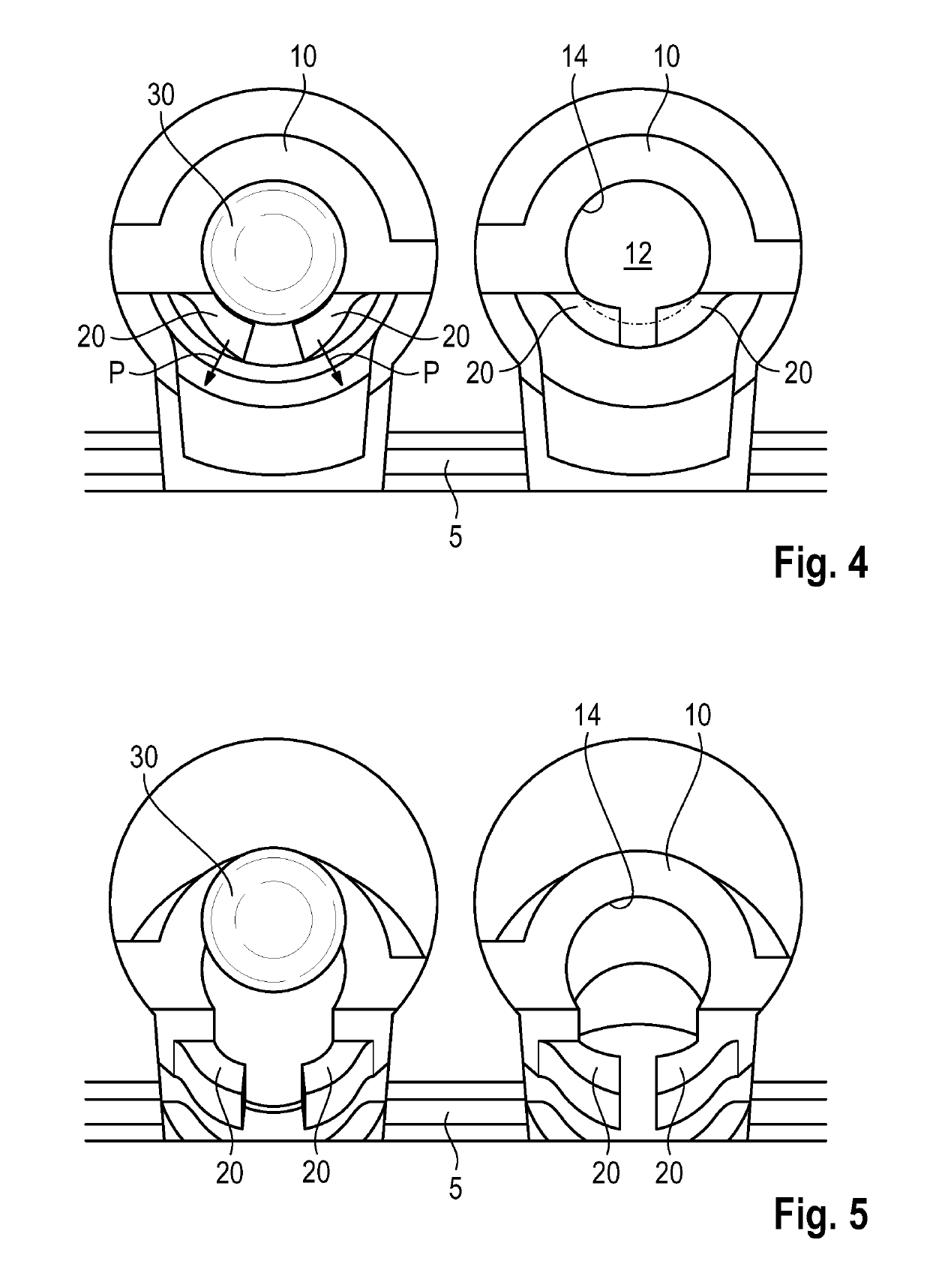

Blocking devices for hollow structures

A blocking device for mounting within a space defined within a hollow structure includes a holder and an expandable member. The holder is adapted to be mounted within the space. The expandable member is supported on the holder and is expandable by heat to form a foam member in order to block or substantially close the space. The holder includes a holder plate extending substantially perpendicular to the longitudinal axis of the space and supporting at least one side of the expandable member. The expandable member includes a constriction absorbing portion that is deformed so as to absorb potential constriction of the expandable member at the beginning of the expansion process of the expandable member.

Owner:KYOWA SANGYO +1

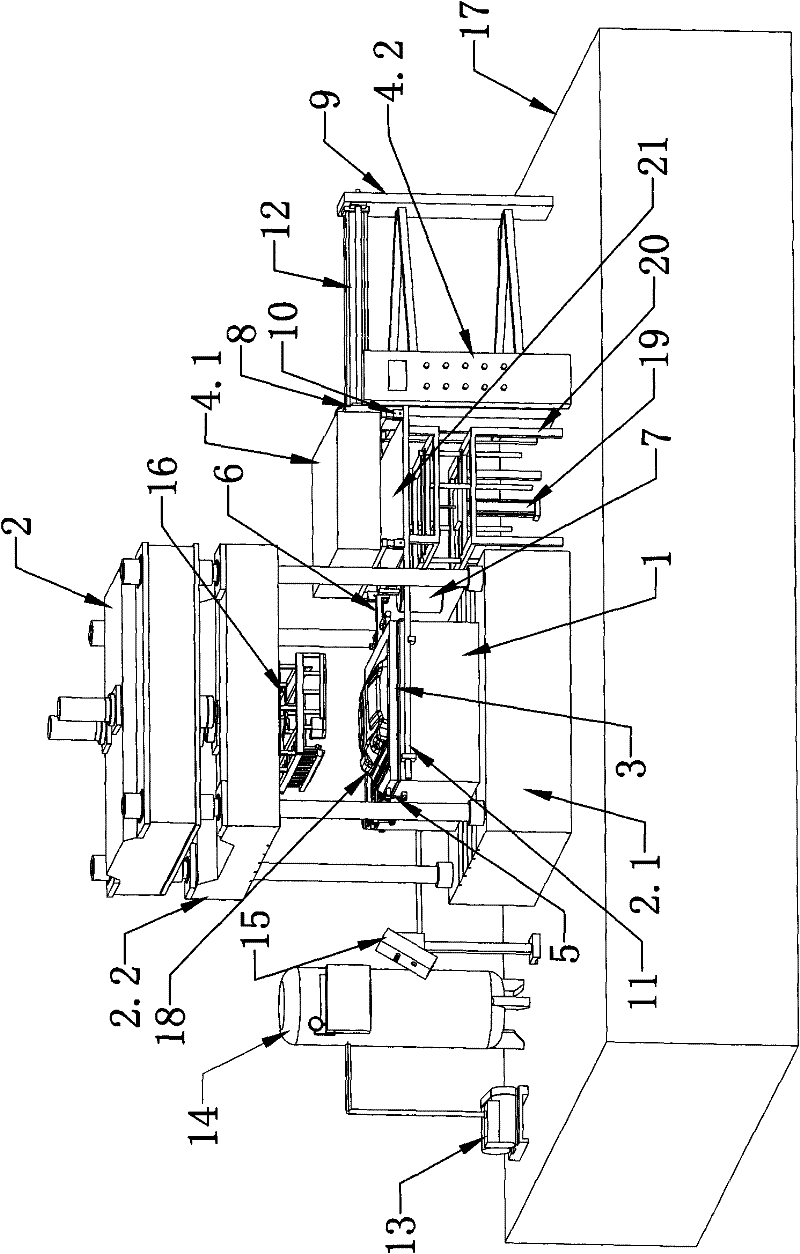

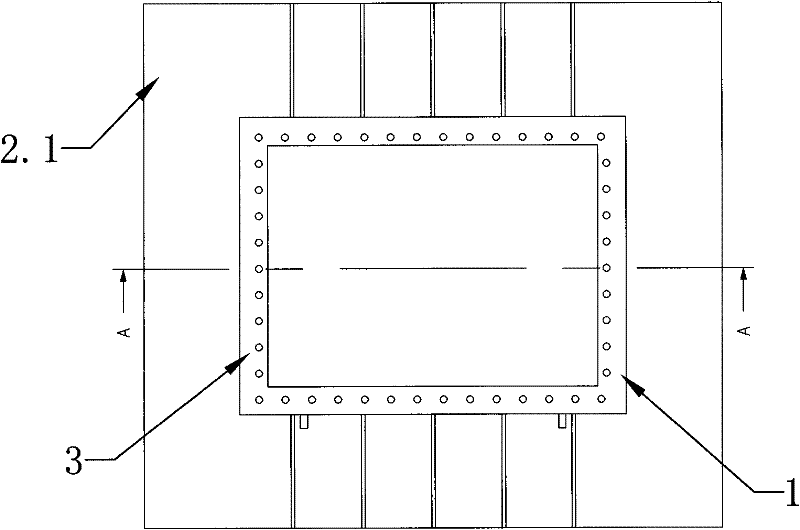

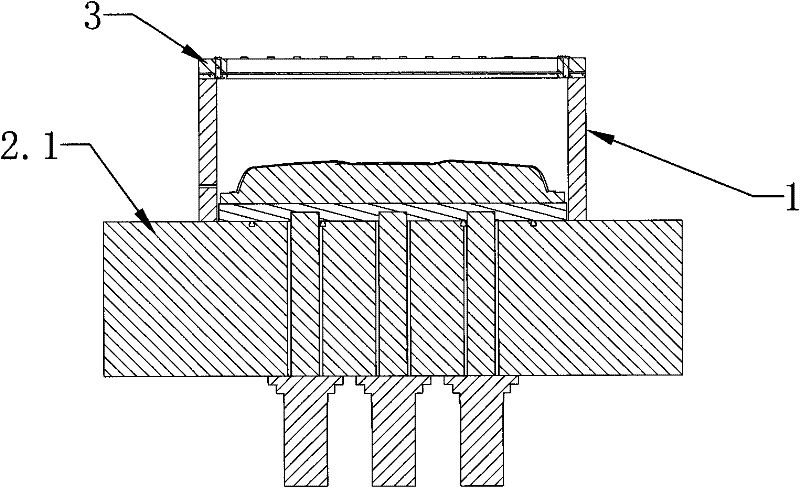

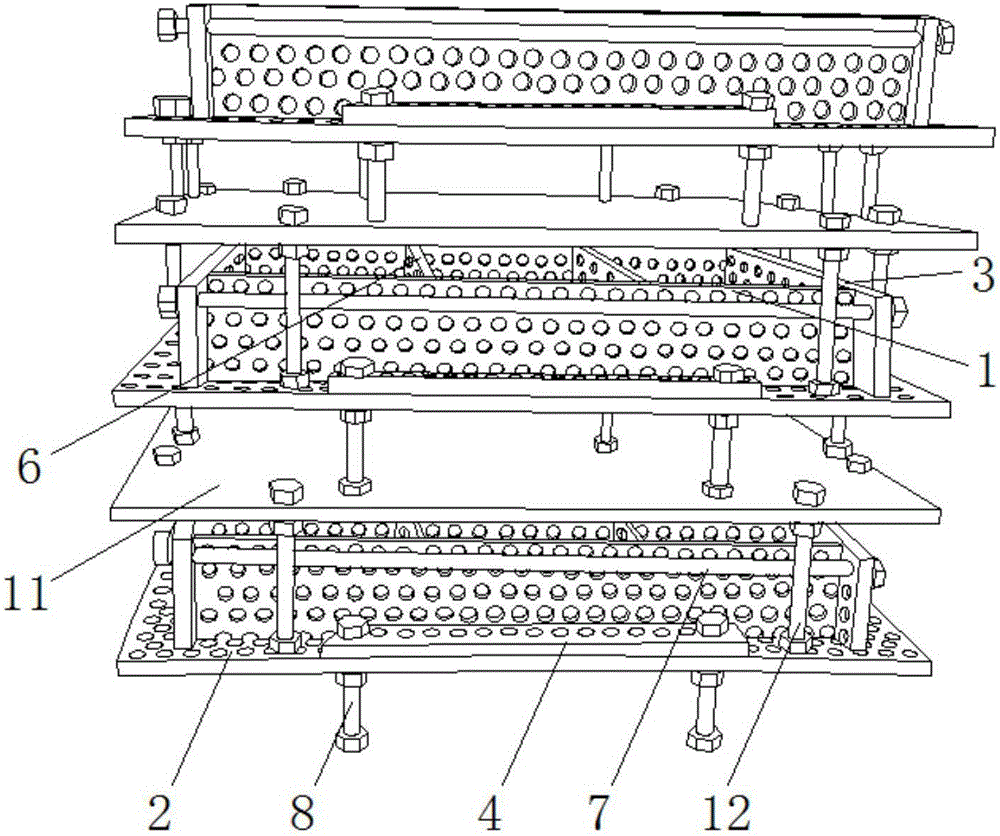

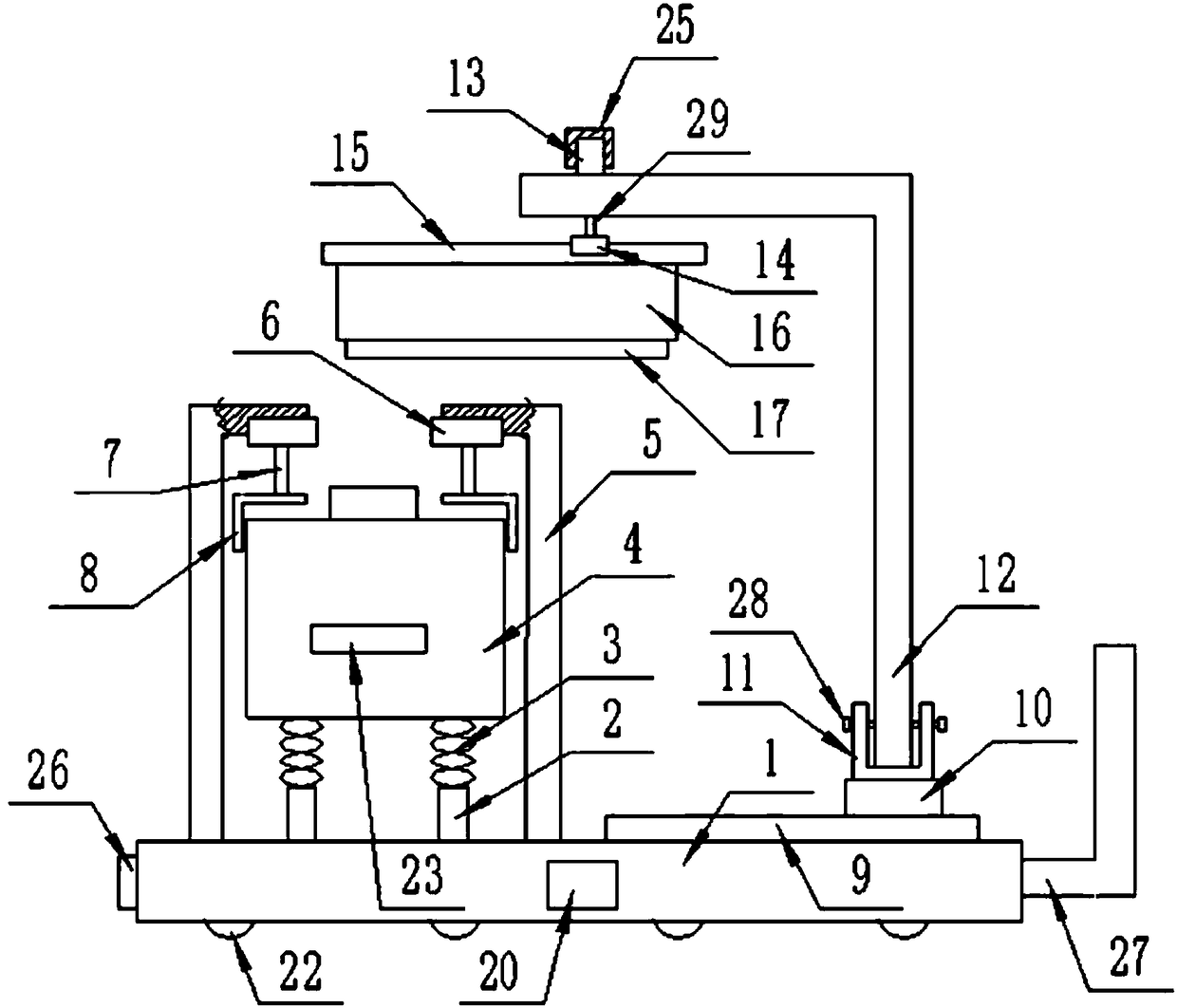

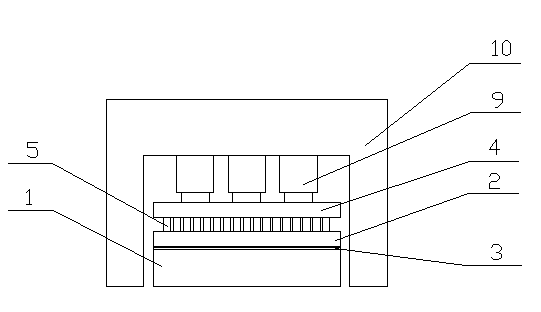

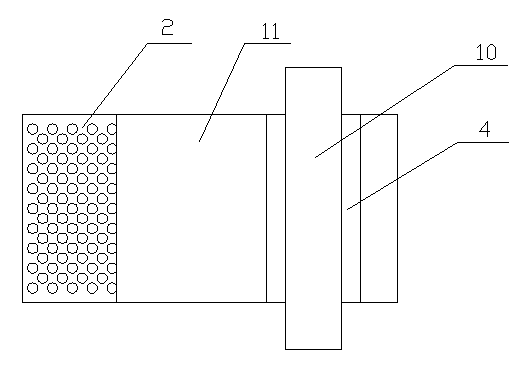

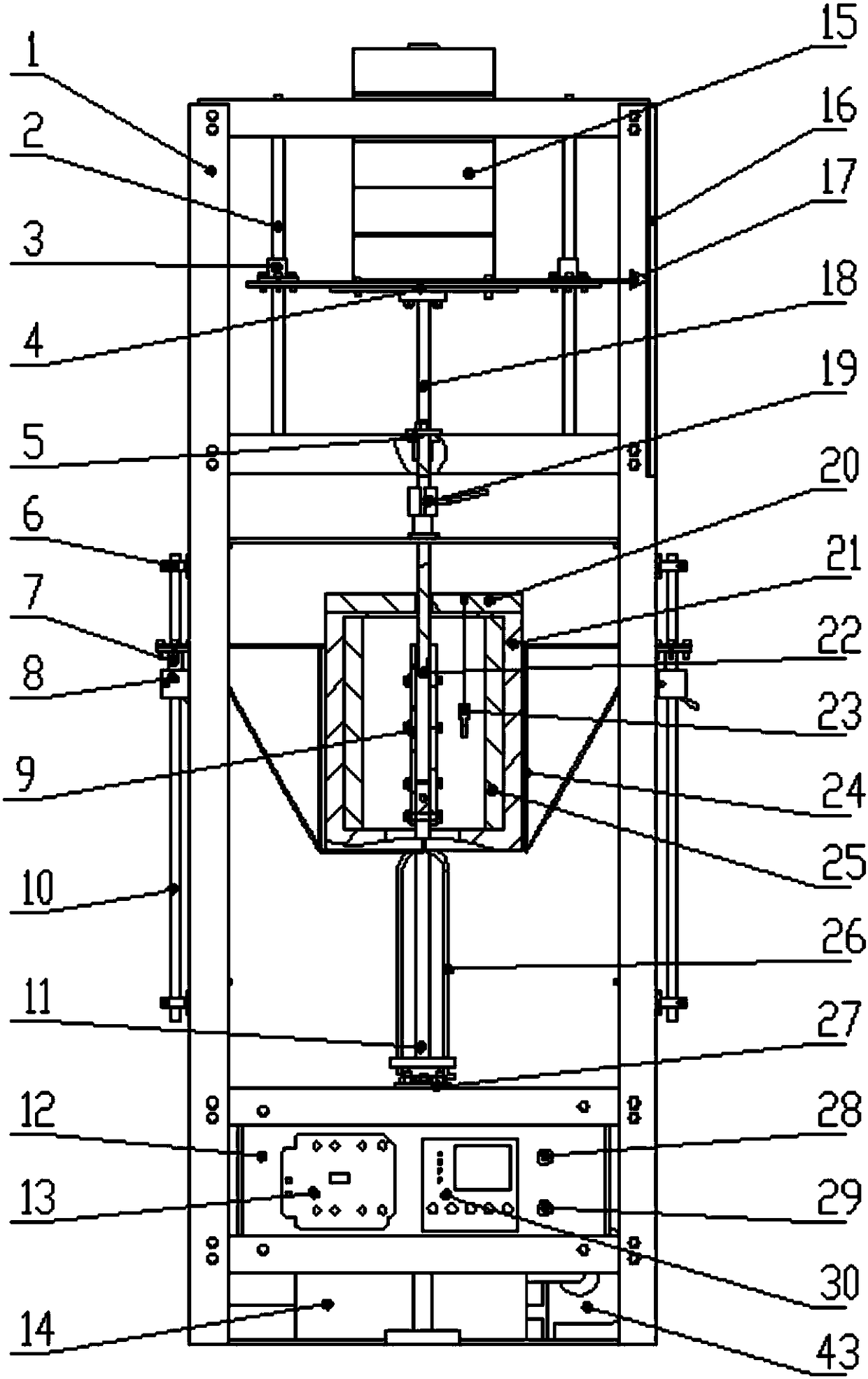

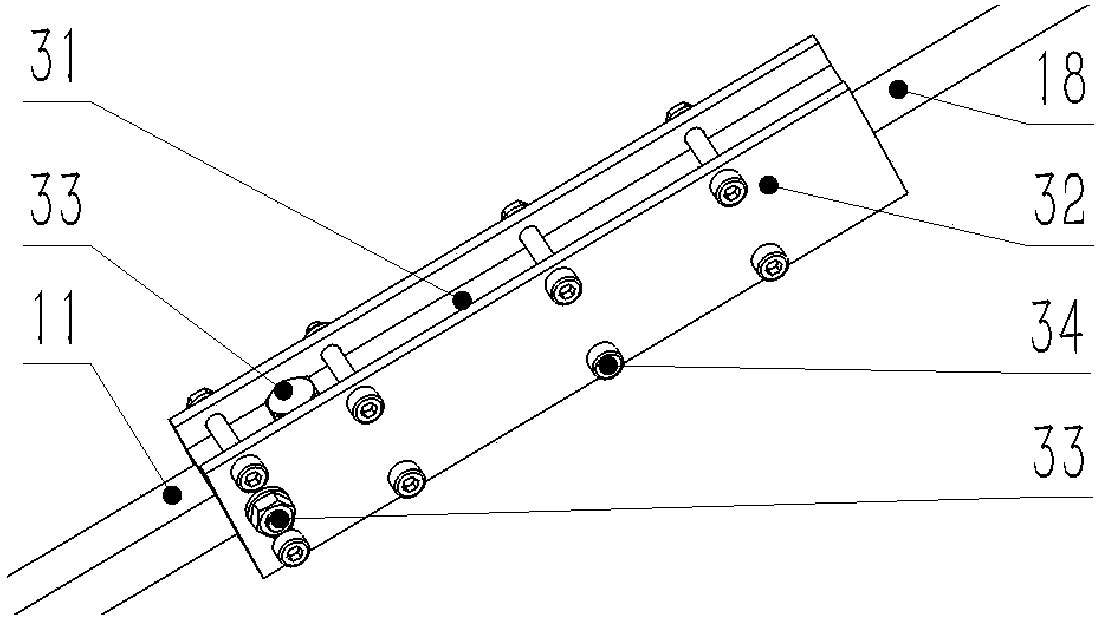

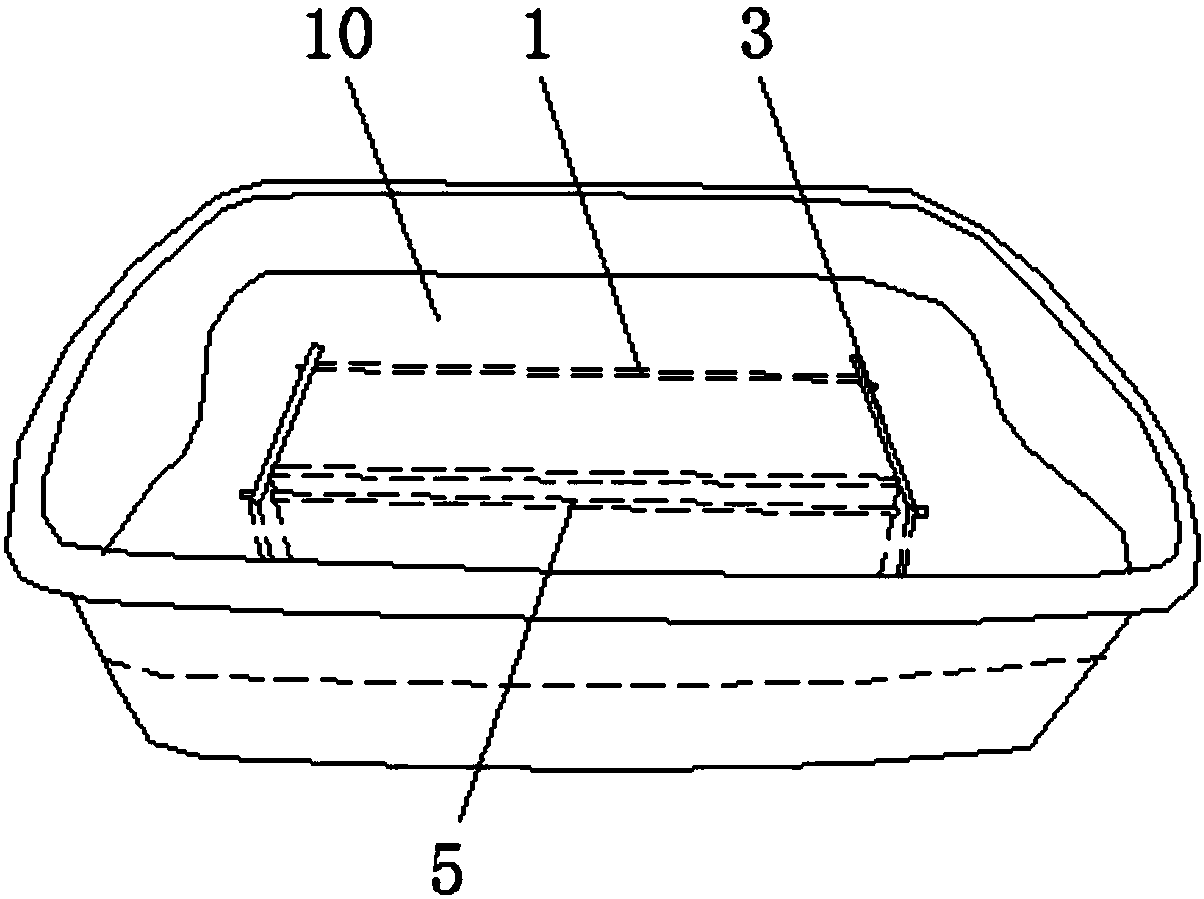

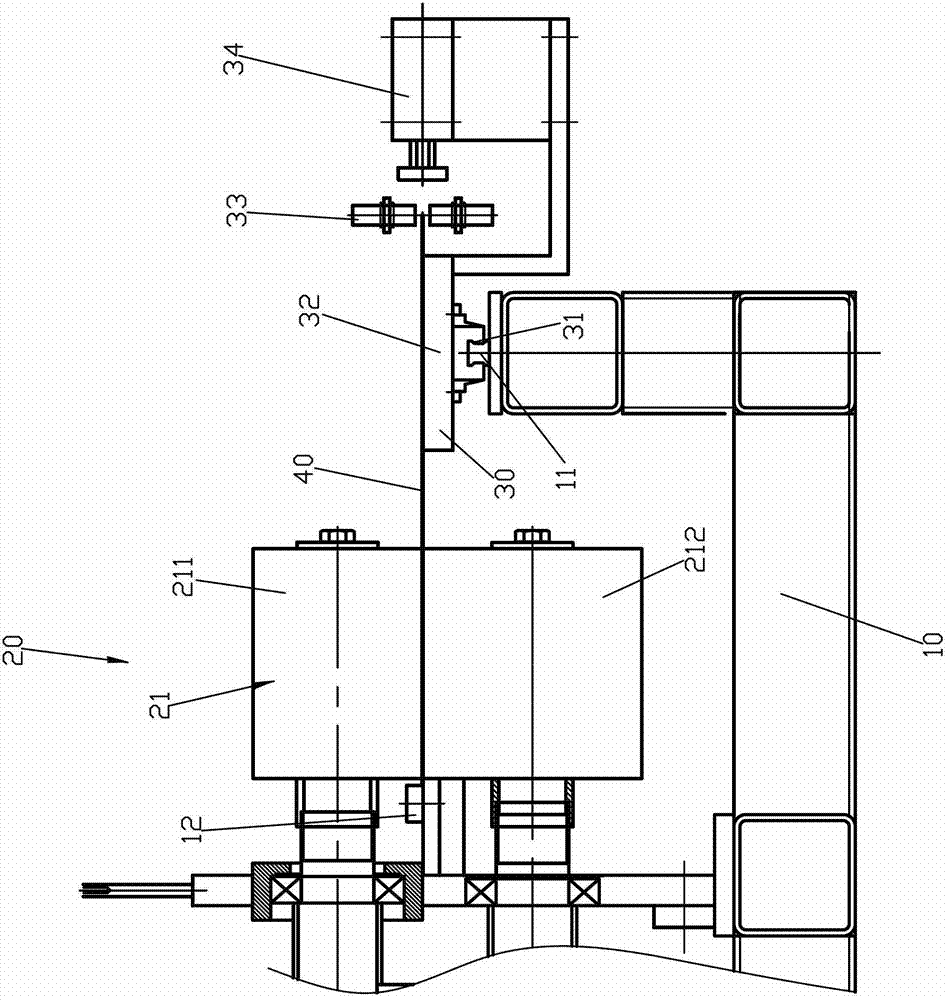

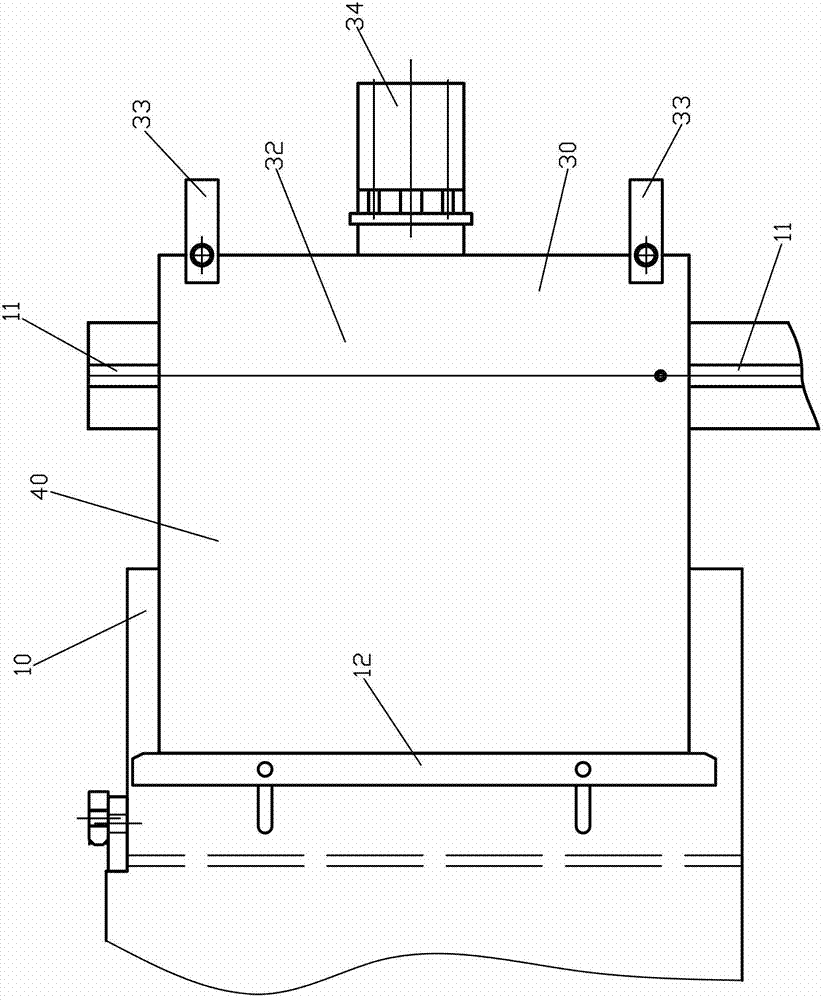

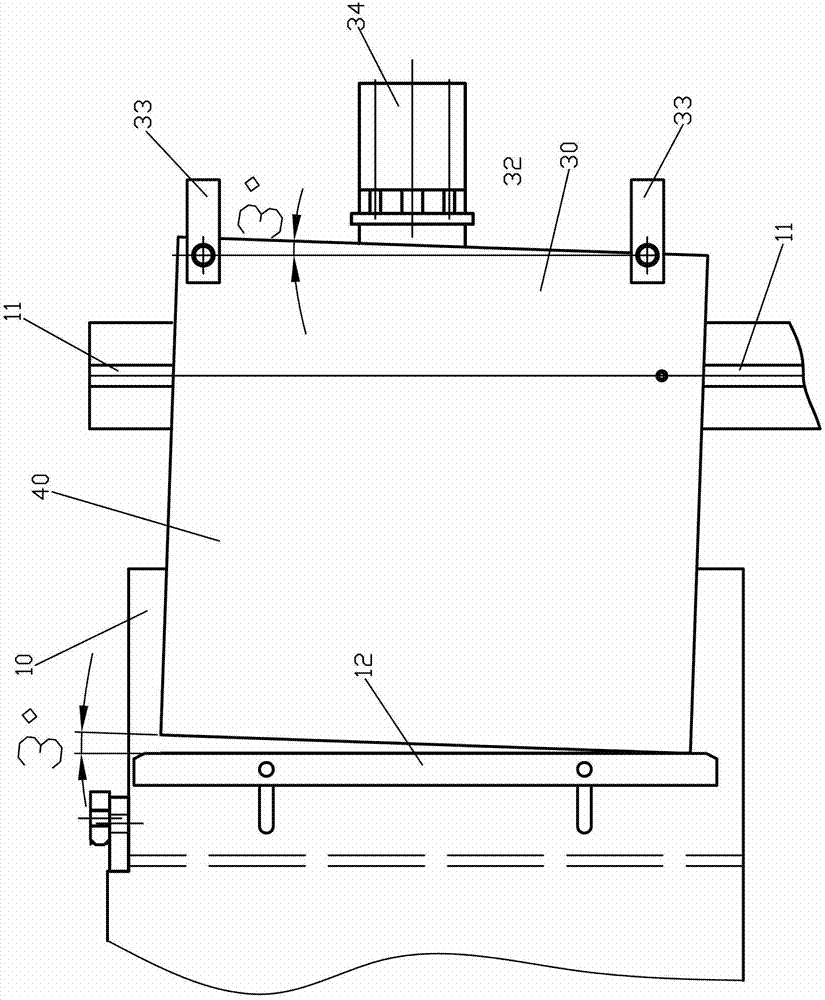

Vacuum adsorption forming device

ActiveCN102189675AReliable moldingRealize continuous productionDomestic articlesVacuum extractionEngineering

The invention discloses a vacuum adsorption forming device which can be suitable for mass production of formed pieces through polypropylene cavity plates. The device comprises a vacuum extraction module, a vacuum box, a hydraulic machine and a heating module, wherein the vacuum extraction module is connected with the vacuum box; the vacuum box is arranged on a fixed plate of the hydraulic machine; a load bearing lifting module which is used for arranging molds and can vertically lift or lower the molds is arranged in the vacuum box; a press frame which can fix a polypropylene cavity plate at the opening of the vacuum box is arranged at the opening of the vacuum box; the heating module is arranged on one side of the hydraulic machine and comprises a heating unit and a moving unit which canbe used for moving the heating unit to the upper side of the fixed polypropylene cavity plate to heat the polypropylene cavity plate and can be deviated from the polypropylene cavity plate after the polypropylene cavity plate is heated; and the heating unit is connected with the moving unit.

Owner:NINGBO SUNLIGHT MOTOR PARTS

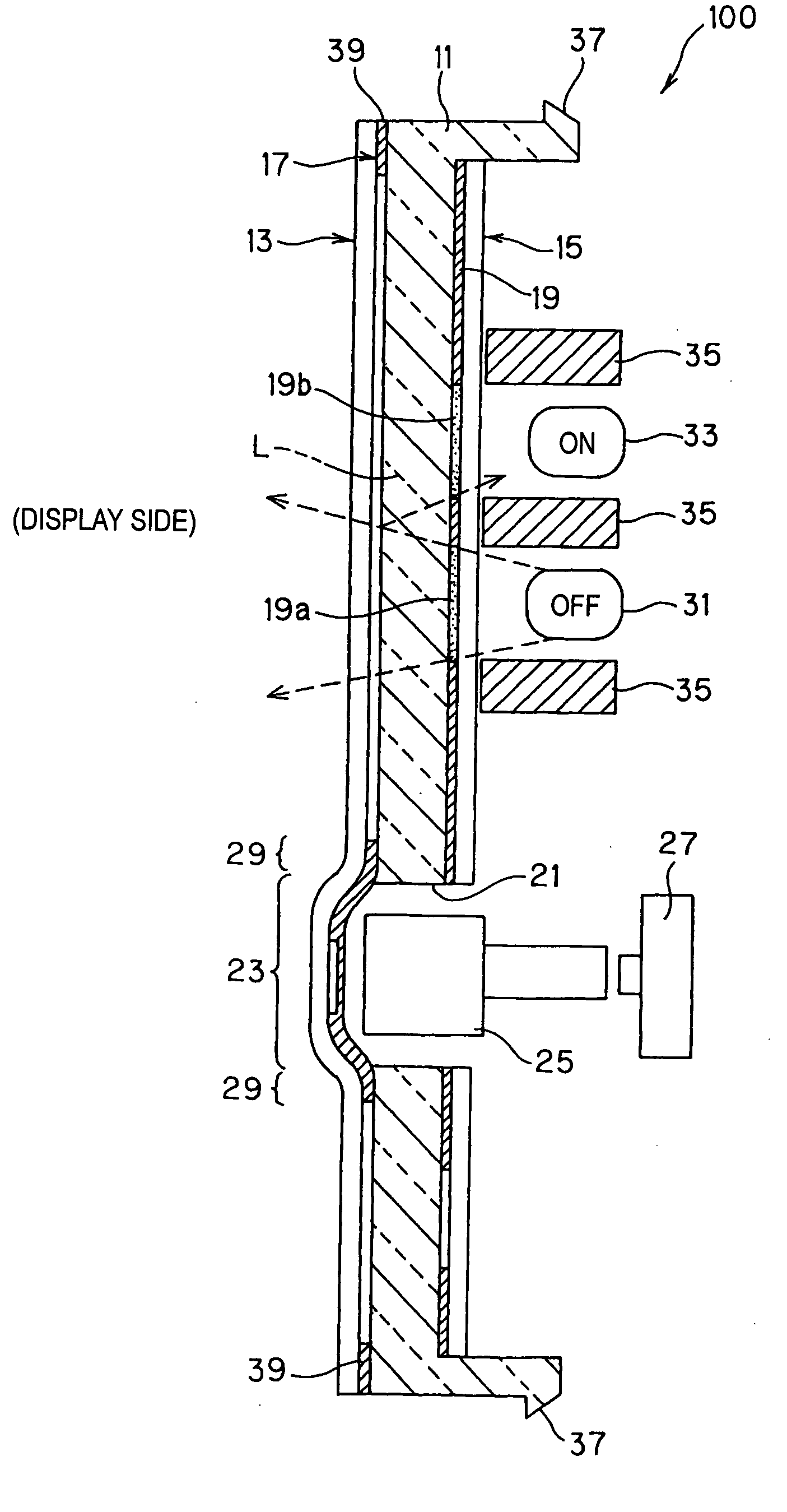

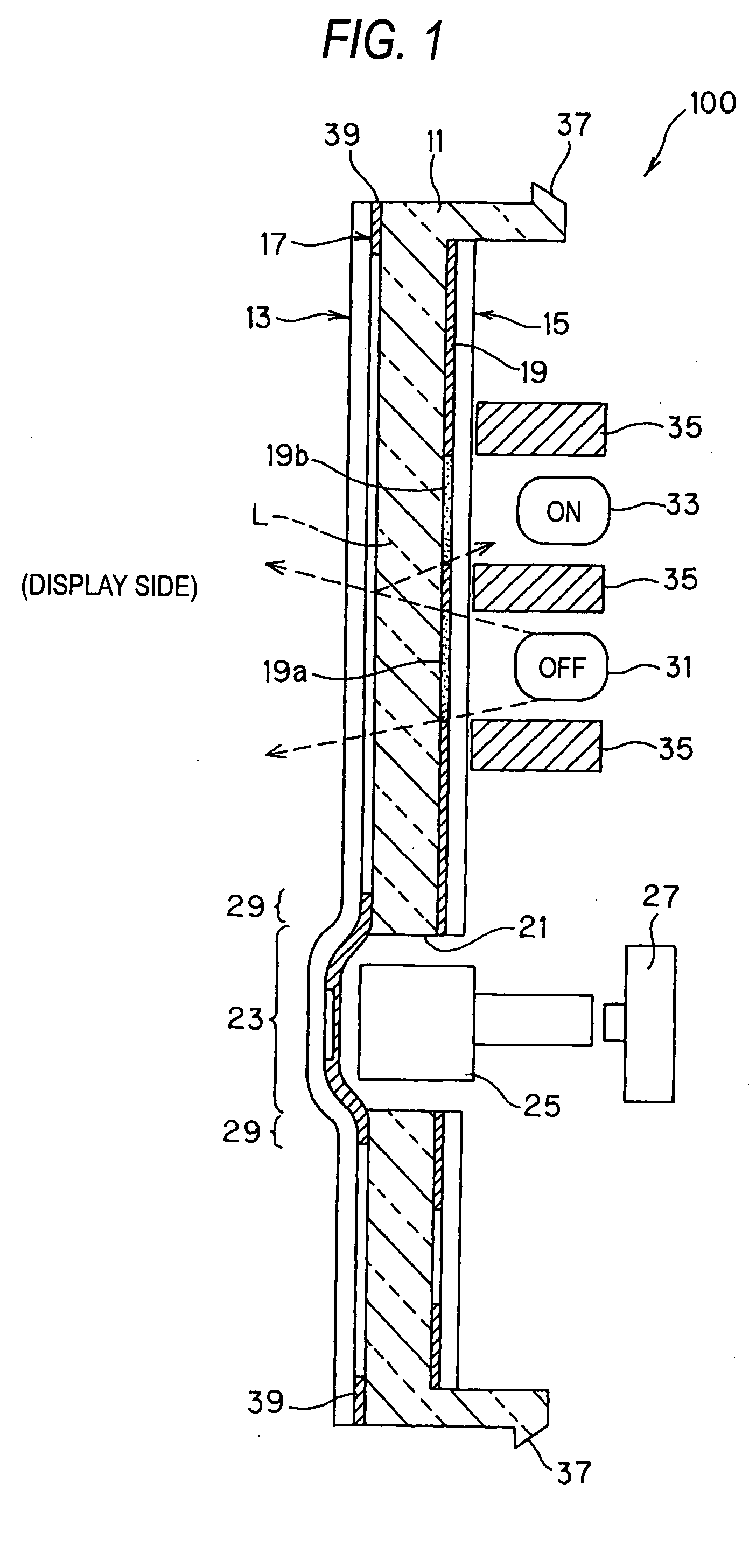

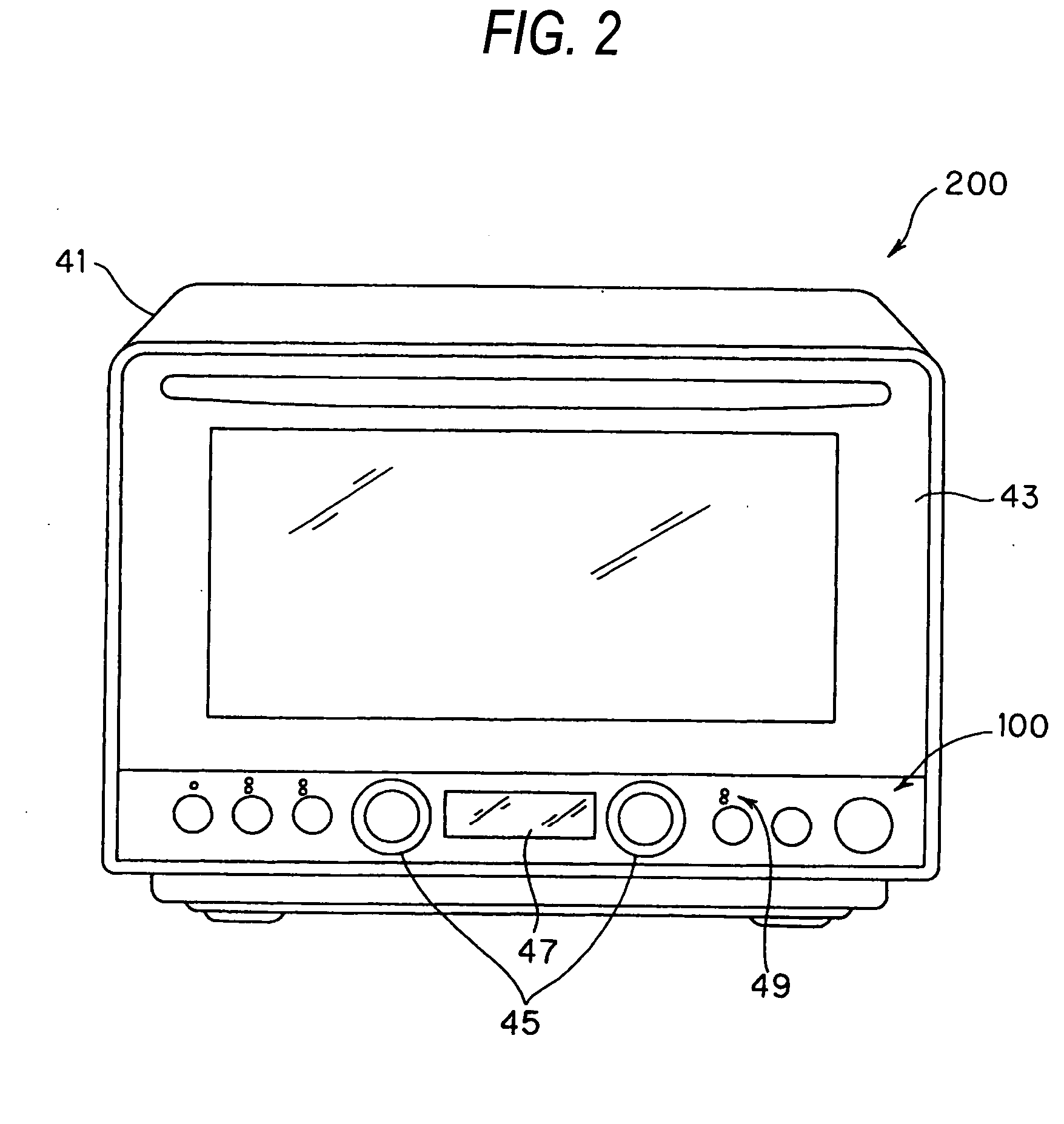

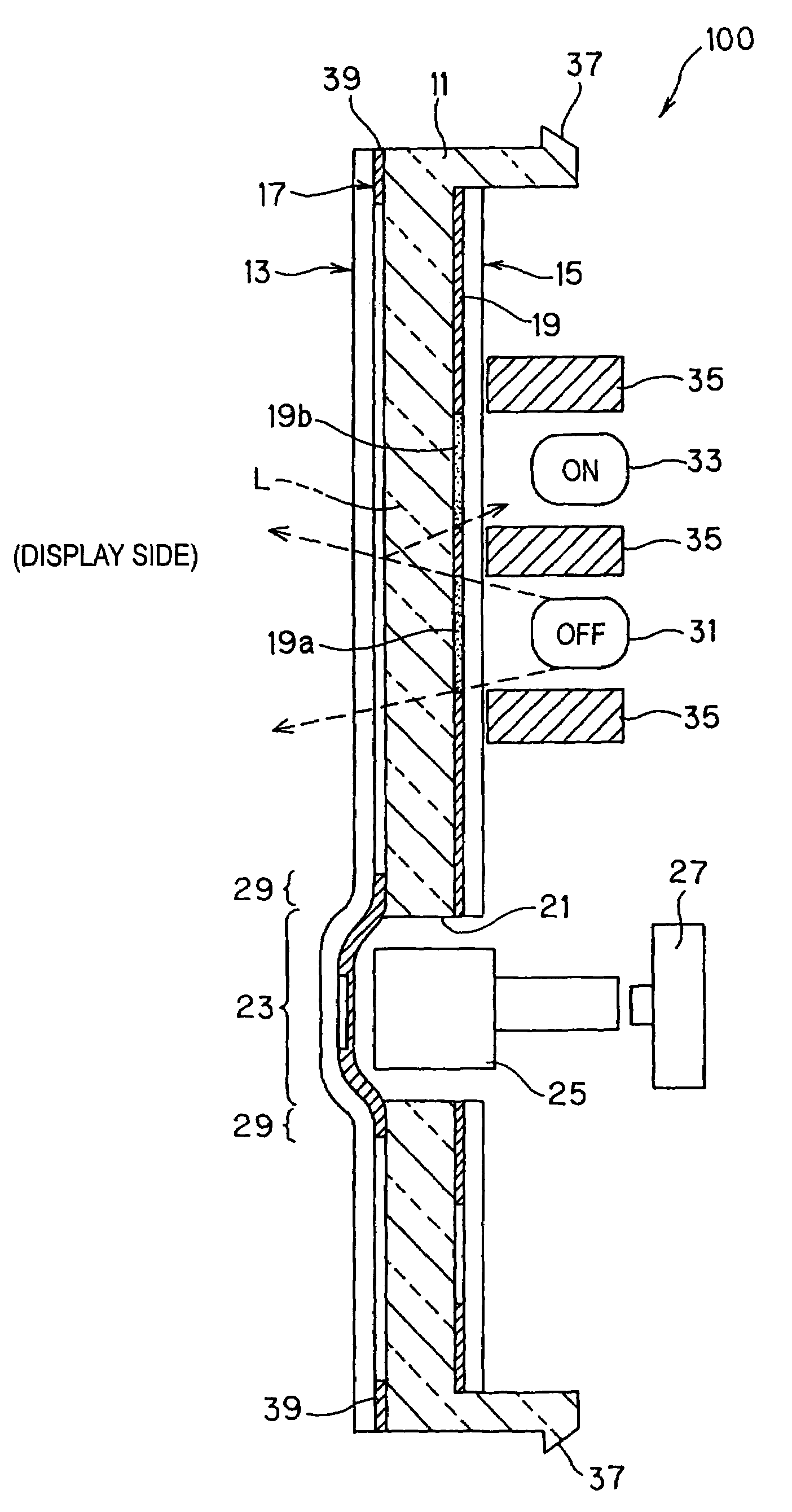

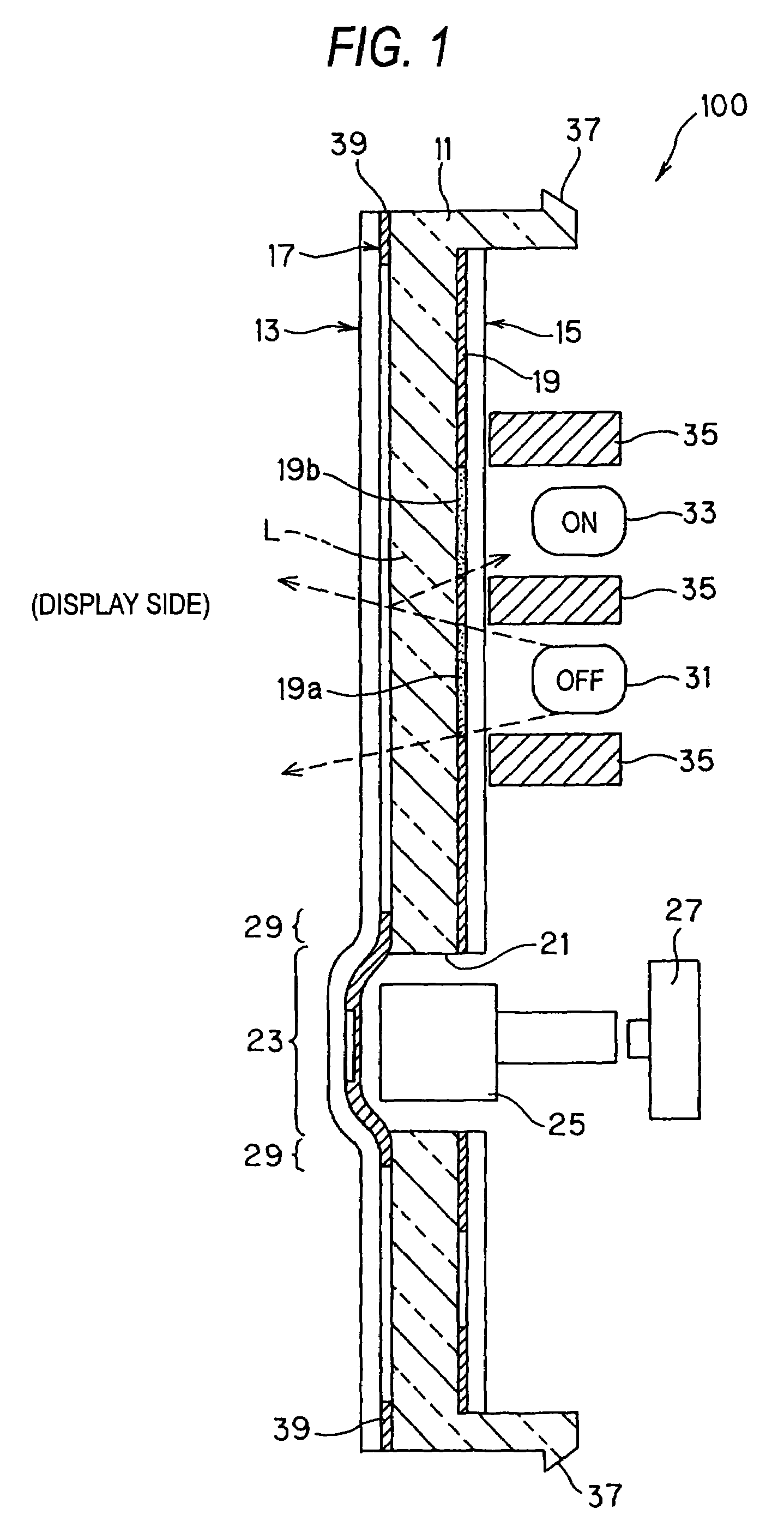

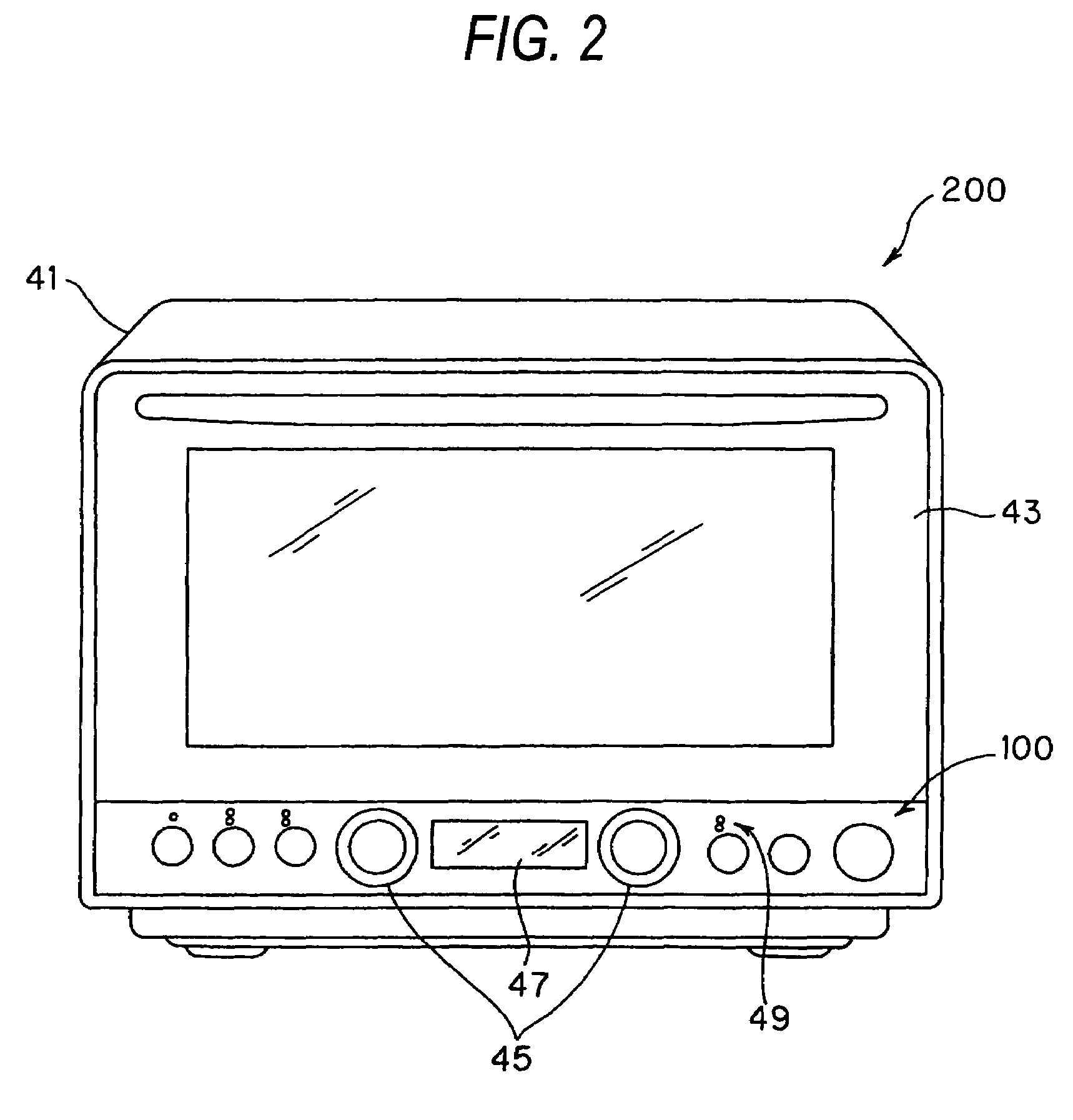

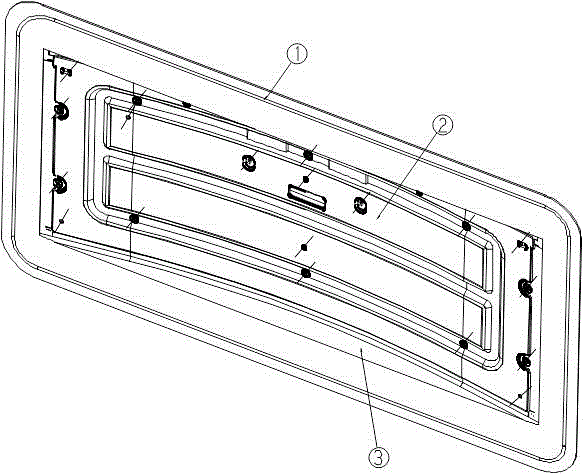

Display panel, control display panel and method for integrally molding insert material

ActiveUS20050183305A1Simple structureEasy to operateAdvertisingCathode-ray tube indicatorsElectronic equipmentElectrical and Electronics engineering

Owner:PANASONIC CORP

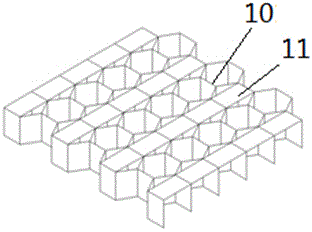

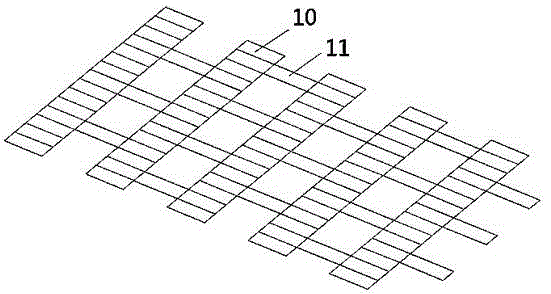

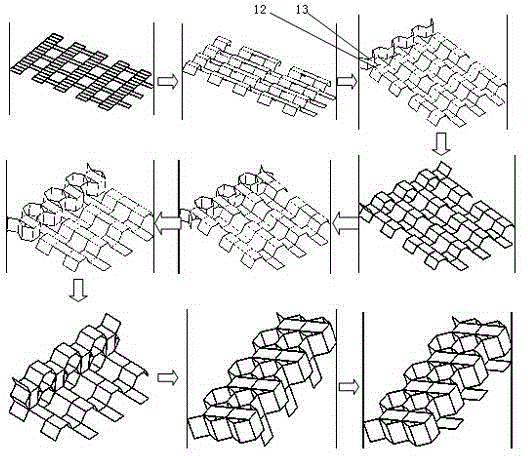

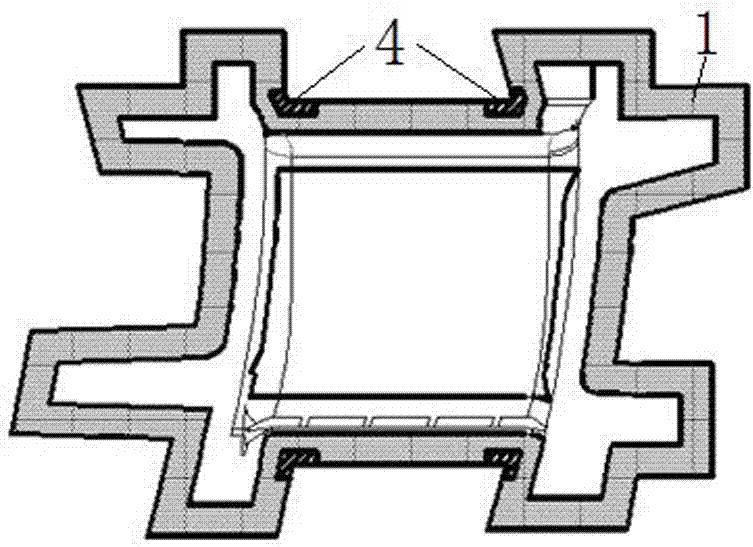

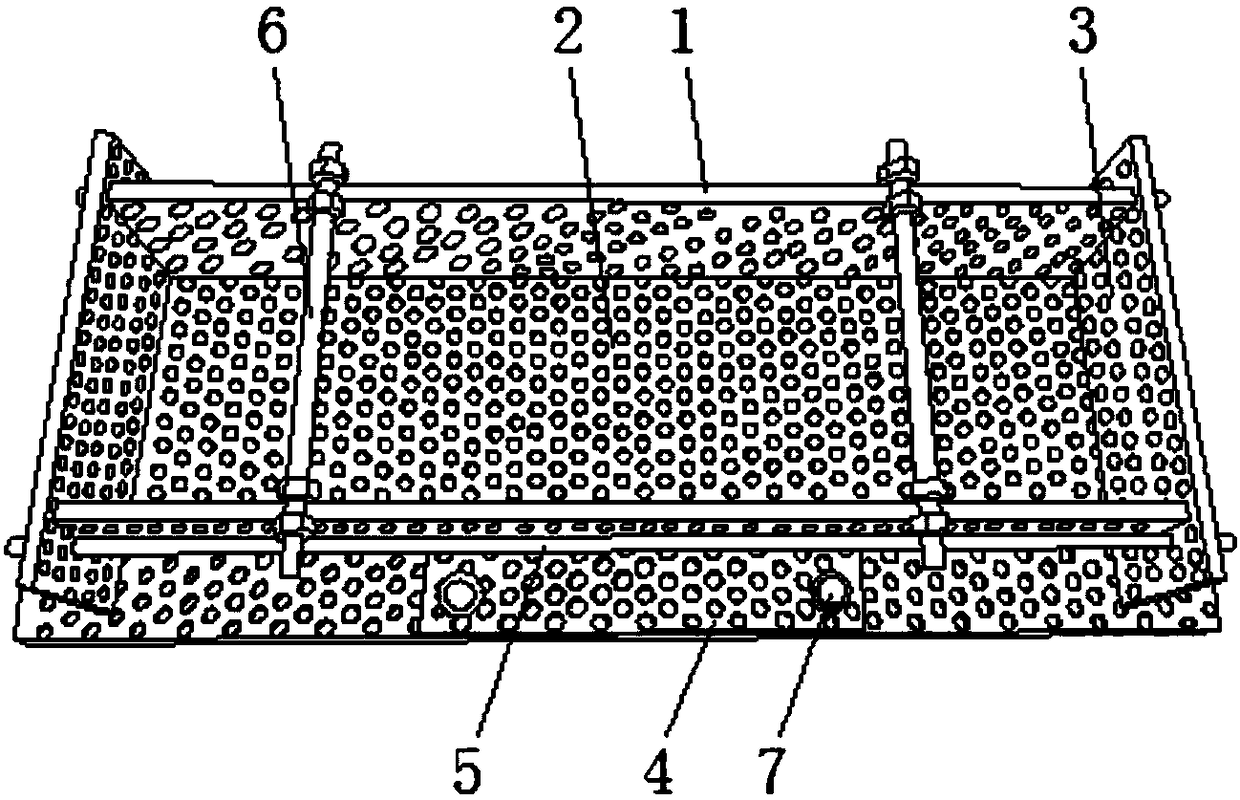

Cellular board core formed through folding and forming method thereof

ActiveCN104085134AResolving Shape UncertaintySolve the problem of loss of compressive performancePaper/cardboard articlesLayered productsStructural engineeringMechanical engineering

The invention relates to a cellular board core formed through folding and a forming method thereof. The cellular board core formed through folding comprises an upper end board, a lower end board and a cellular core, wherein the cellular core is of a polygonal, cellular and net structure and formed by folding and bonding the whole sheet material, and plane blocks allowing the end boards to be bonded to are arranged on the end faces of the core of the polygonal, cellular and net structure formed by folding the whole sheet material. The cellular core is formed by folding the whole sheet in order, so that the problems of an uncertain shape of the core caused by insufficient stretch and / or excessive stretch during stretch forming of the cellular core and loss of compressive property of a cellular board due to the uncertain shape of the core are solved. The cellular board core formed through folding has the advantages of being stable and reliable in forming, higher in integral strength and unlikely to generate a divergence phenomenon.

Owner:芜湖创联新材料科技有限公司

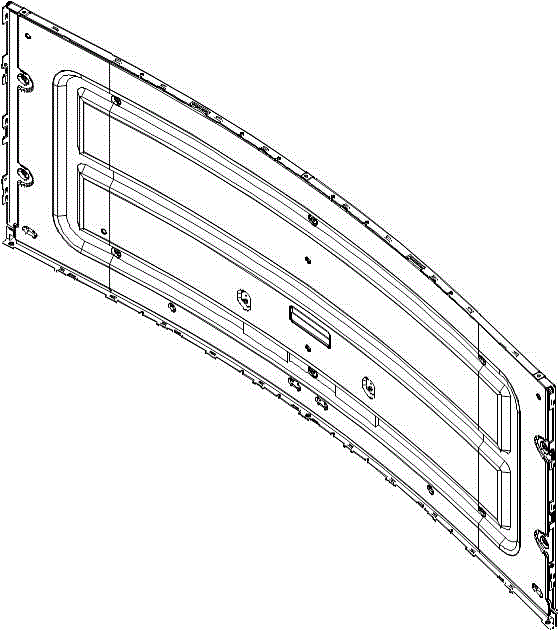

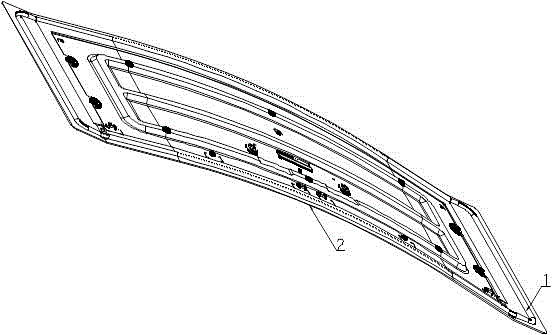

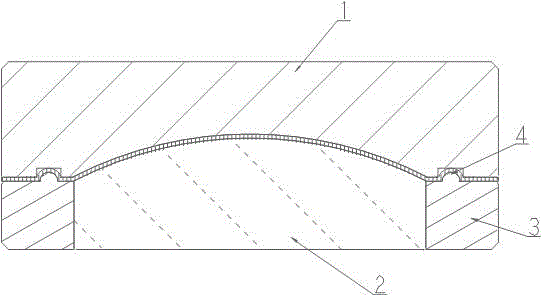

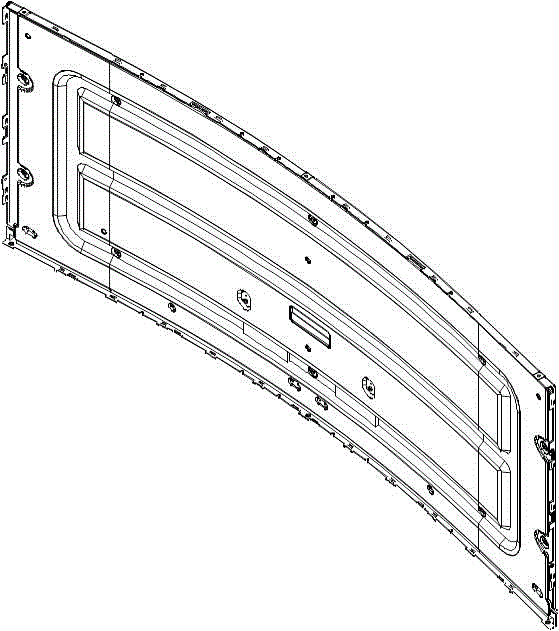

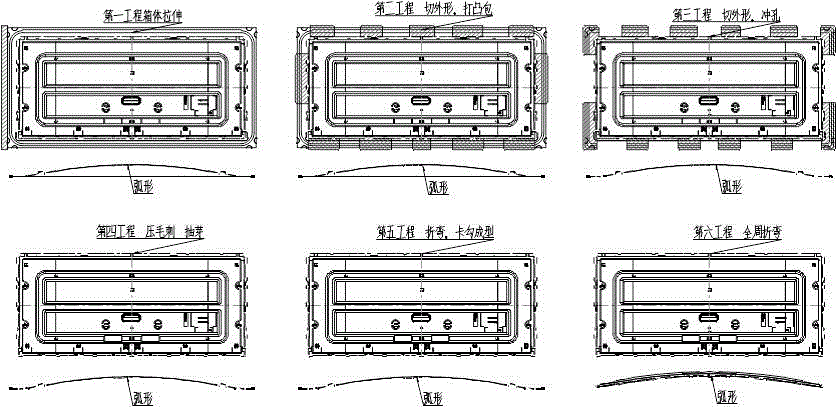

Curved-surface LED display backboard stamping die machining method

The invention relates to a curved-surface LED display backboard stamping die machining method. The method is characterized in that used raw materials are sheets, the sheets are formed into curved-surface sheet bodies on first project curved surfaces, and other subsequent processes such as trimming, convex hull shaping, clamp hook forming, hole stamping, engraving, burr pressing, little bending, engraving, sprouting and complete-cycle bending are all finished on the formed curved-surface sheet bodies. During curved-surface forming, a male die, a female die and a pressure plate are provided, the working surface is a curved surface, pressing ribs are arranged on the die pressure plate, stretching and curved-surface stabilization are facilitated, and accordingly production efficiency is increased, and waste is reduced.

Owner:JIANGSU FANRUN ELECTRONICS

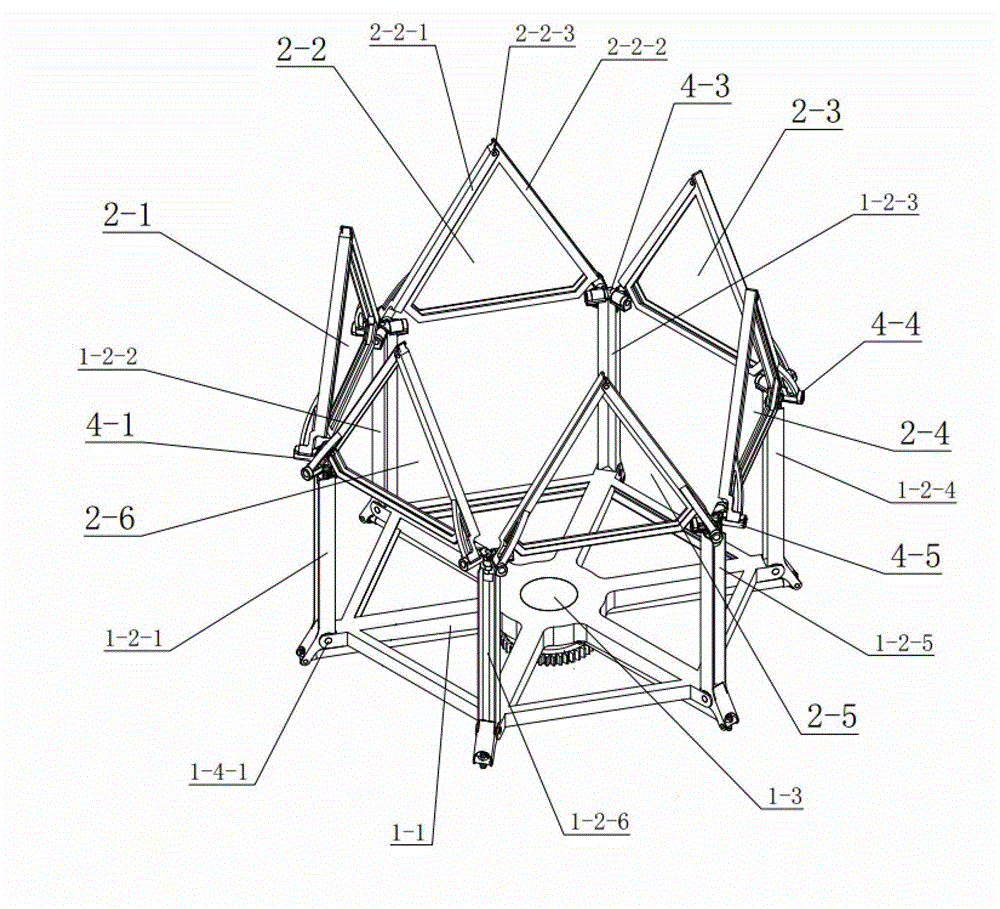

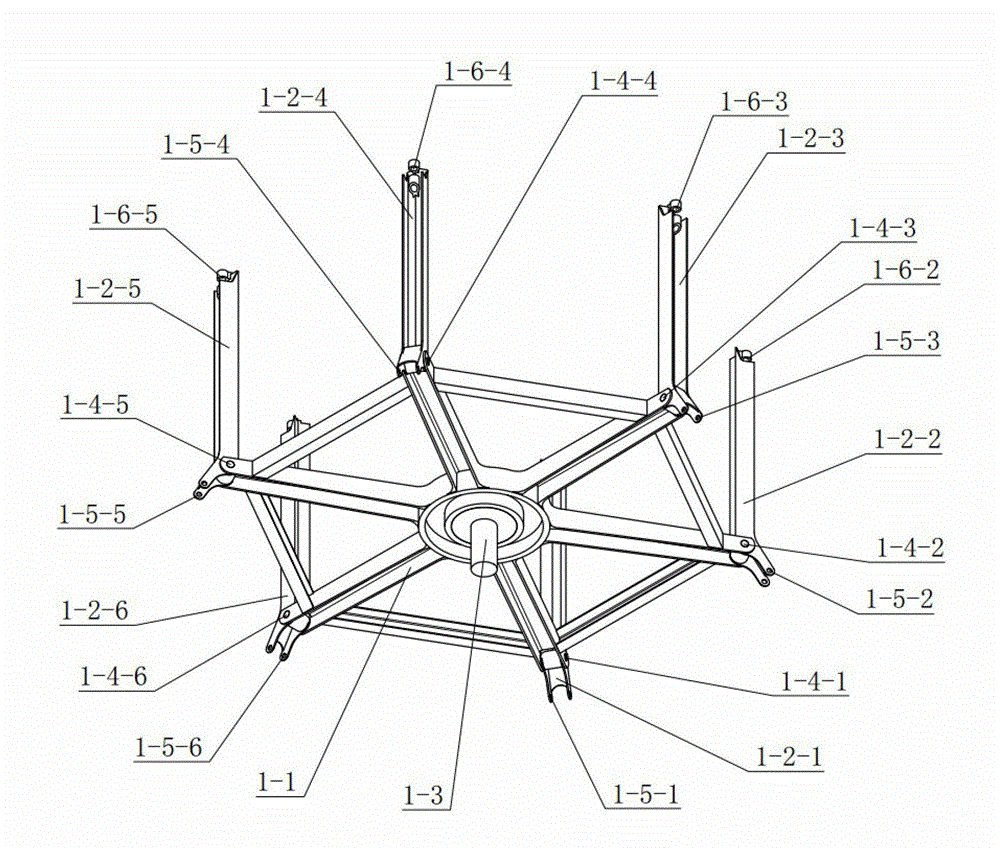

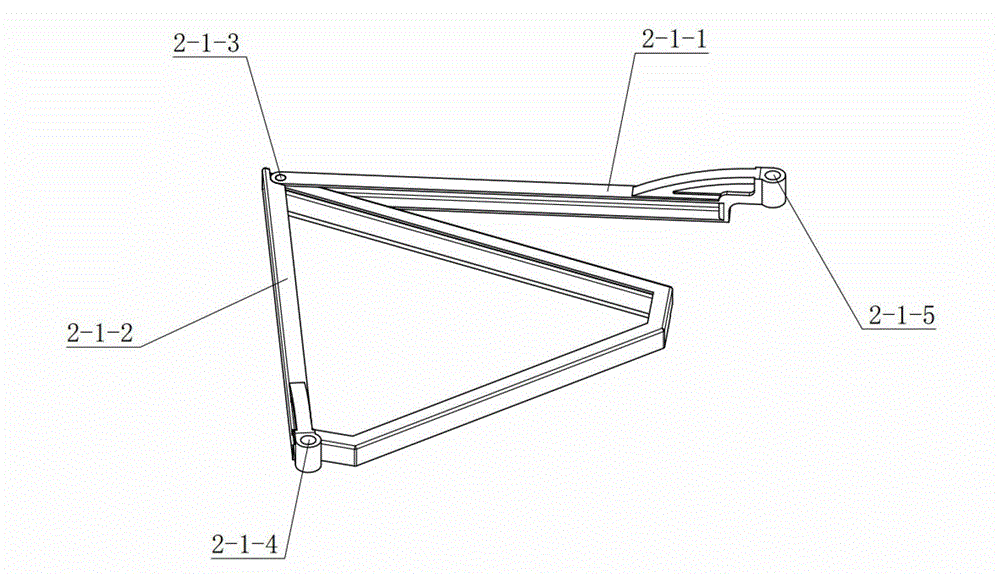

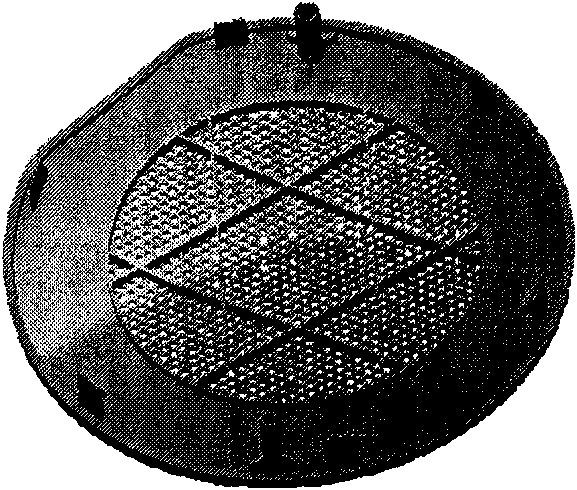

Topology-changing packaging robot mechanism

ActiveCN102717924AImplement topology transformationReliable moldingPackagingCartonMulti degree of freedom

A topology-changing packaging robot mechanism is composed of a main mechanism, a sealing cover mechanism, a transmission mechanism and a multi-degree of freedom articulated mechanism. According to the principle of edge molding of food packaging cartons, the edges are equivalent to rod pieces, vertex angles of a carton are equivalent to hinges, and a packaging molding task of the mechanism is achieved through transmission of a transmission gear. The packaging robot mechanism can change topology, finishes packaging operation tasks by one time, is simple in structure and stable and reliable in molding, greatly reduces procedures of multi-work-station multi-module packaging machinery operation, improves packaging operation efficiency, and simultaneously meets requirements of people for variable modes of food packaging.

Owner:GUANGXI UNIV

Method for manufacturing plastic mould of automobile door plate loudspeaker mask

The invention discloses a method for manufacturing a plastic mould of an automobile door plate loudspeaker mask. The method comprises the following steps: (A) selecting a plastic component structure:a left decoration component and a right decoration component of the automobile door plate loudspeaker mask; (B) selecting a mould structure: (a) designing a die cavity of the mould; (b) designing a die core: adopting the following methods: adding a belting pile in a hook shape on the die core; polishing the face of the die cavity before processing the texture; and increasing the thickness of an installation clamping position; (c) designing a parting face and a template; (d) designing a sprue; (e) designing an ejection system; and (f) cooling: cooling and solidifying the plastic components quickly; injecting PP into the die cavity by an injection molding machine, recovering an ejector bar to a position where the mould is closed under the action of a recovery bar and a return spring and completing the mould. The invention has easy method, simple and convenient operation, high strength, high temperature resistance, high accuracy, strong degree of durability, stable performance and good insulation property, reduces a large number of time and expenses consumed by repairing the mould and saves various costs by more than 50% in the design and processing of the mould.

Owner:WUHAN JIAMENG PLASTIC PROD

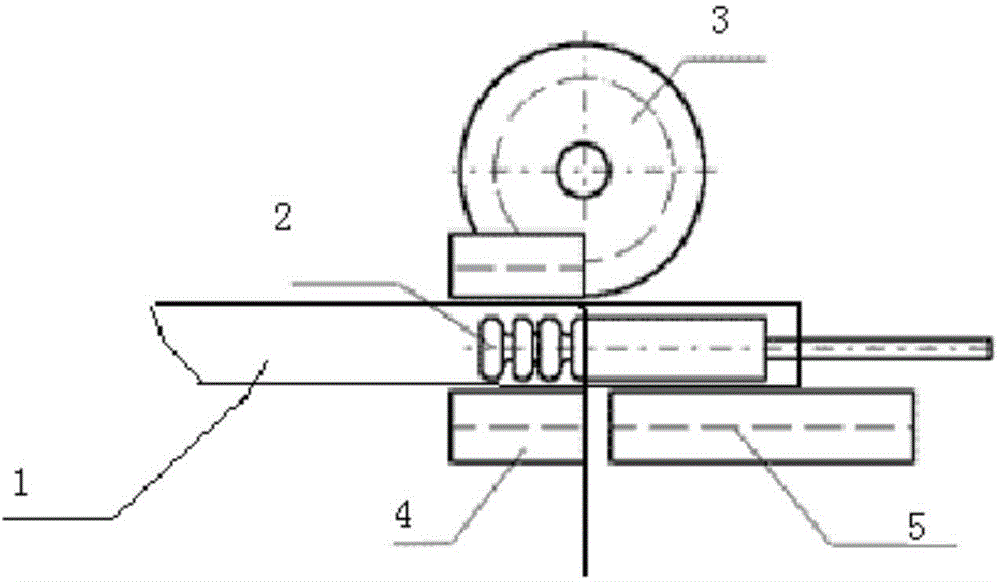

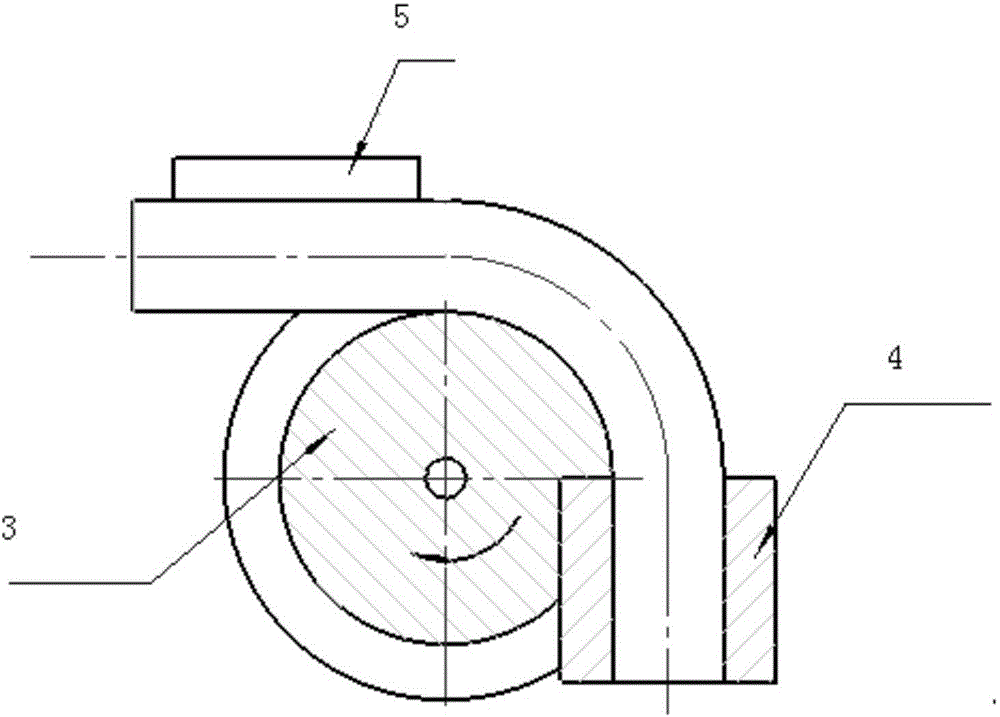

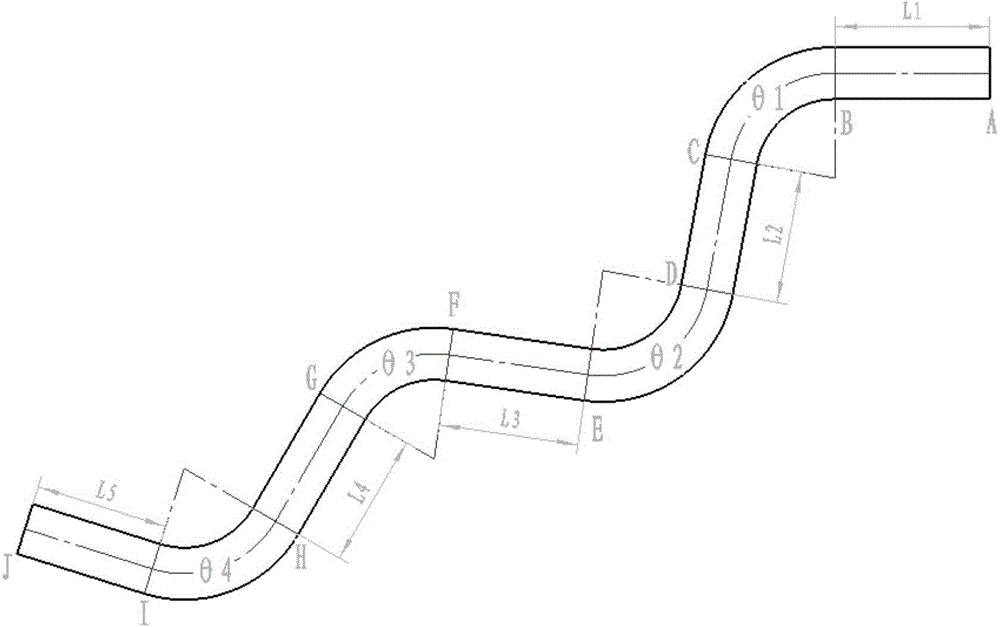

Calculating method for feeding of thin-walled bent copper pipes

ActiveCN104525659ASmall difference in axial lengthRemove materialMetal working apparatusSpecial data processing applicationsEngineeringBend radius

The invention relates to a calculating method for feeding of thin-walled bent copper pipes. The method comprises the following steps: bending a plurality of copper pipes of different lengths and different specifications at a certain angle on a pipe bending machine, setting the initial lengths of the copper pipes as L0, setting a pipe bending radius as R, measuring the actual lengths L of the bent copper pipes along the center lines of the bent copper pipes, and calculating the average value LAverage of the actual lengths of the bent copper pipes of all specifications. Therefore, the pipe bending elongation Delta is equal to LAverage-L0; and when the pipe bending angle is Theta, the pipe bending elongation Delta Theta is equal to (180-Theta)Delta / 90, and the lengths LN' of the bending points of the Nth segments of the bent copper pipes are equal to L1+(180-Theta1)PiR / 180-(180-Theta1)Delta / 90+L2 + ...... + (180-ThetaN-1)PiR / 180-(180-ThetaN-1)Delta / 90+LN. The axial lengths of the central lines of the bent copper pipes produced according to the method have little difference; the pipe bending is simple; and the accuracy is high.

Owner:顿汉布什(中国)工业有限公司

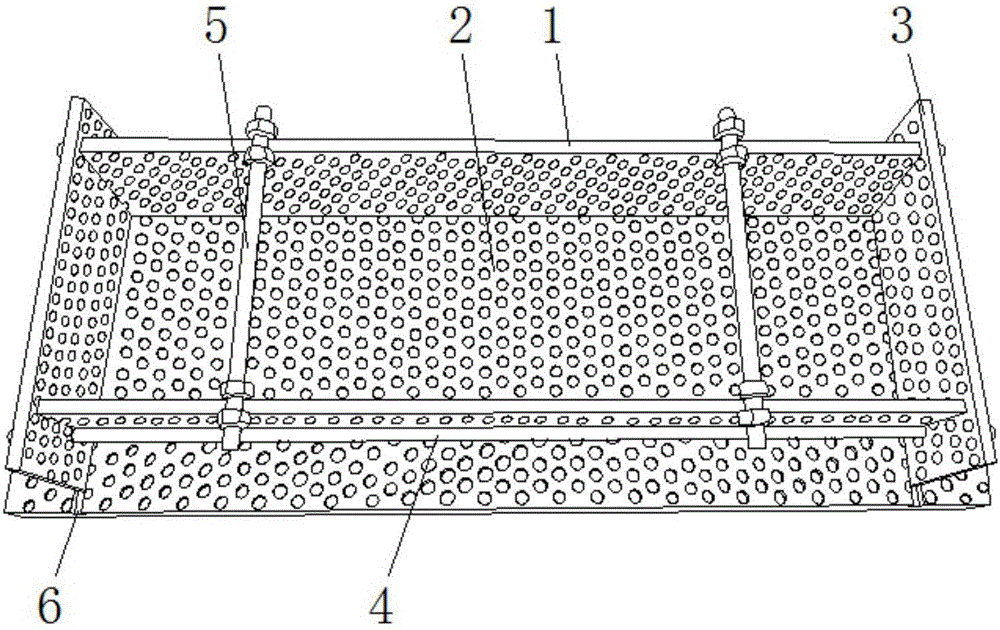

Manufacturing method of biological soil fixation test beam used for constructional engineering

InactiveCN105806688AImprove permeabilityLow costPreparing sample for investigationChemical solutionFixation test

The invention discloses a manufacturing method of a biological soil fixation test beam used for constructional engineering.The manufacturing method includes the following steps that materials are prepared, wherein the materials comprise longitudinal side plates, a bottom plate and end plates; 2, the longitudinal side plates, the bottom plate and the end plates are assembled; 3, a lightweight mold needed for cutting of geotechnical cloth is manufactured, and the geotechnical cloth is cut according to the size; 4, two transverse screws are detached; 5, the cut geotechnical cloth is placed in a rectangular model cavity, and sandy soil is added to a cavity defined by the geotechnical cloth; 6, the distance between the two longitudinal side plates is fixed through the two transverse screws; 7, bacteria are poured into a test piece, and the whole mold is placed in a chemical solution; 8, the rectangular biological soil fixation beam is formed after the reaction is completed.A large number of mechanical performance tests such as the anti-bending performance test need to be conducted on the beam which is produced through the method and needed for building a house before practical engineering application, basic data and scientific reference are provided for practical application of the technology, and safety and reliability of an infrastructure and the house are guaranteed.

Owner:重庆市綦江区全兴建筑工程有限公司

Baked cake

InactiveCN1812719AExcellent Industrial Production EfficiencyImprove taste qualityDough treatmentLeguminous plant bakery productsFlavorGluten

A baked cake that is a hollow stick-shaped baked cake obtained by baking a dough containing ungelatinized flour and flour having been gelatinized in water, wherein the dough is substantially free from active gluten. Namely, a hollow stick-shaped baked cake having favorable molding properties, having high meltability in mouth and showing no powdery texture. This baked cake can contain a large amount of a flavor material to improve preferences. Thus, a hollow stick-shaped baked cake of a novel type having highly uniform properties and showing few bliters which is suitable for mass production and processing can be provided without resort to any special apparatus or complicated process.

Owner:EZAKI GLICO CO LTD

Ceramic die shell capable of eliminating casting hot crack defects of section-variable parts and molding method thereof

ActiveCN107008857AImprove structural strengthReduce resistanceFoundry mouldsFoundry coresMolten steelUltimate tensile strength

The invention discloses a ceramic die shell capable of eliminating casting hot crack defects of section-variable parts and a molding method thereof. The ceramic die shell is provided with a casting cavity matched with a section-variable part design structure; corresponding hot spot areas are arranged in the casting cavity according to coagulation properties of molten steel in the casting cavity in the casting process; concave grooves are formed in positions corresponding to the hot spot areas on the external surface of the ceramic die shell; the width and the length of the concave grooves correspond to the hot spot areas in the casting cavity. Through the ceramic die shell, the structure strength is ensured; meanwhile, the thickness of the ceramic die shell can be effectively, reliably and differentially controlled; the shrinkage stress of the hot spot positions is effectively eliminated; the generation of hot crack defects is avoided.

Owner:DONGFANG TURBINE CO LTD

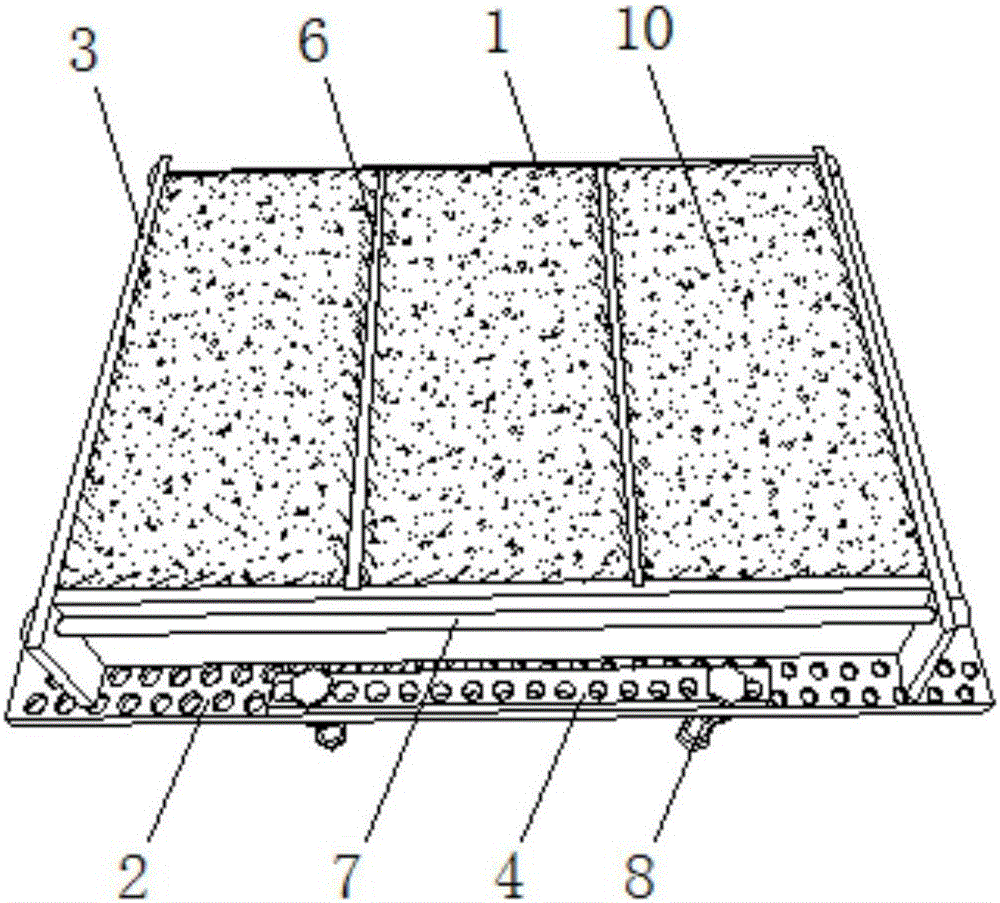

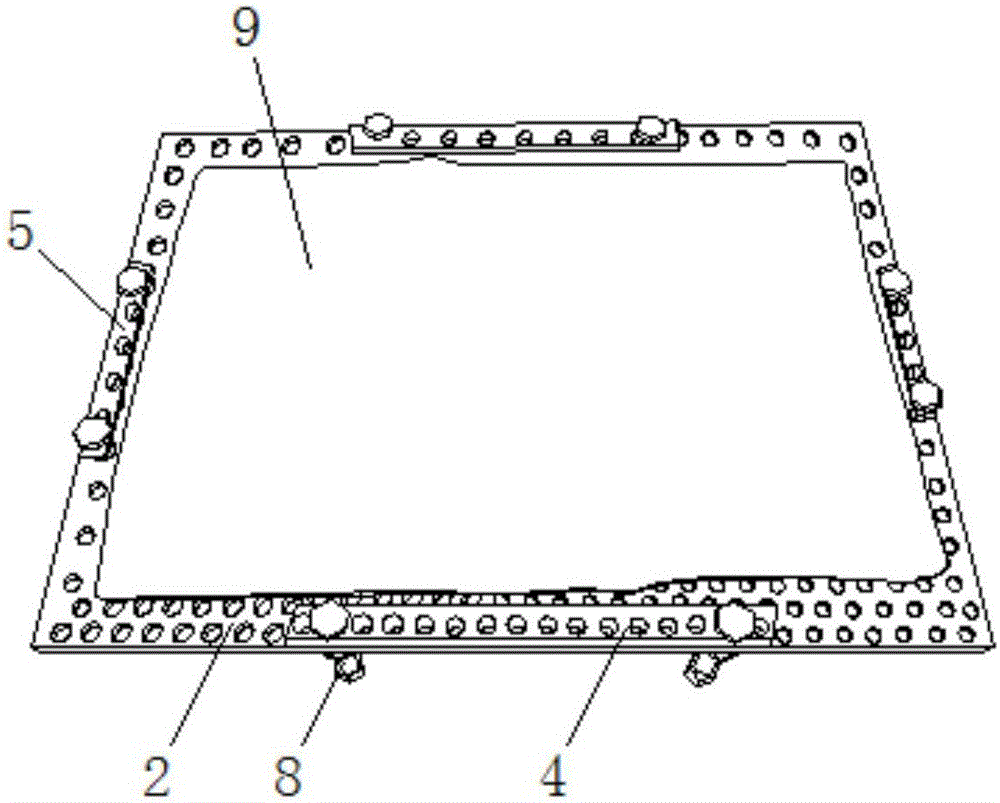

Method for batched formation of square beams for biological soil reinforcement

ActiveCN105804318AImprove permeabilityGood soil fixation effectGirdersJoistsChemical solutionChemical reaction

The invention discloses a method for batched formation of square beams for biological soil reinforcement. The method for batched formation of the square beams for biological soil reinforcement comprises the following steps that (1) materials required by a mold are prepared; (2) cut organic glass plates provided with holes are assembled; (3) a light mold required for tailoring of geotechnical cloth is manufactured, and the geotechnical cloth is tailored according to the sizes of light materials; (4) the geotechnical cloth is placed in square beam mold cavity units, and sandy soil is added into cavities defined by the geotechnical cloth; (5) prepared bacteria are poured into test piece molds; (6) the two or four wetted test piece molds are placed in a container side by side, and a plurality of layers of mold sets are arranged according to the actual condition; (7) the multiple layers of mold sets are soaked in a chemical solution; and (8) the square beams for biological soil reinforcement are formed after a reaction. According to the method for batched formation of the square beams for biological soil reinforcement, by means of the flatness of the surface of organic glass and the good water permeability of the holes, cuboid test pieces formed after the chemical reaction are angular, high in surface flatness, uniform in texture and stable in mechanical property, and a scientific research test for testing the bending performance can be conducted in the later stage conveniently.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

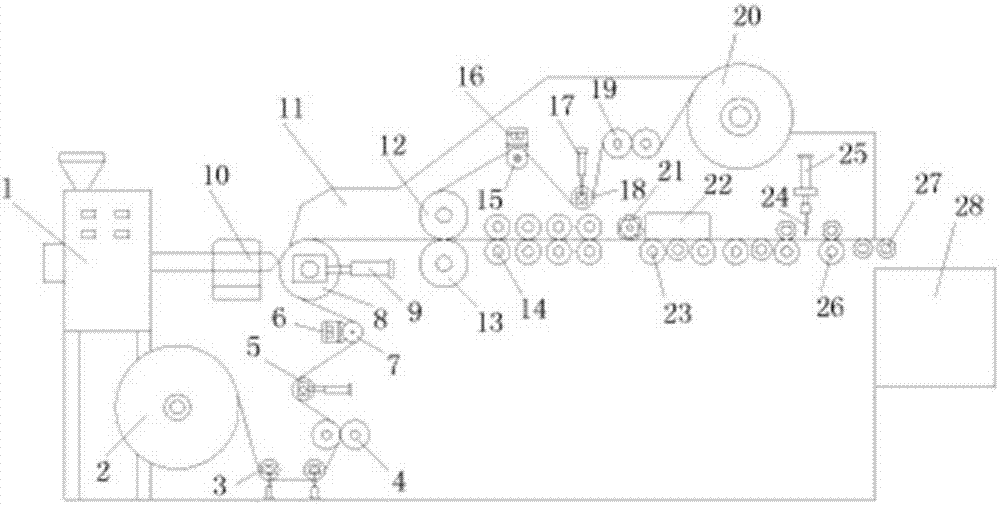

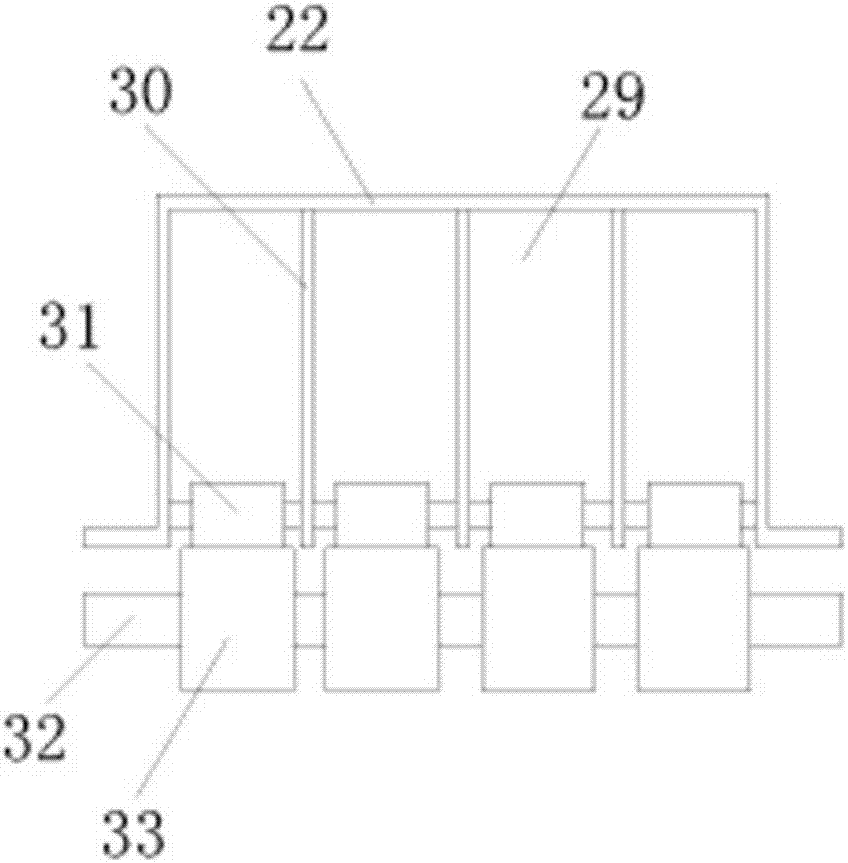

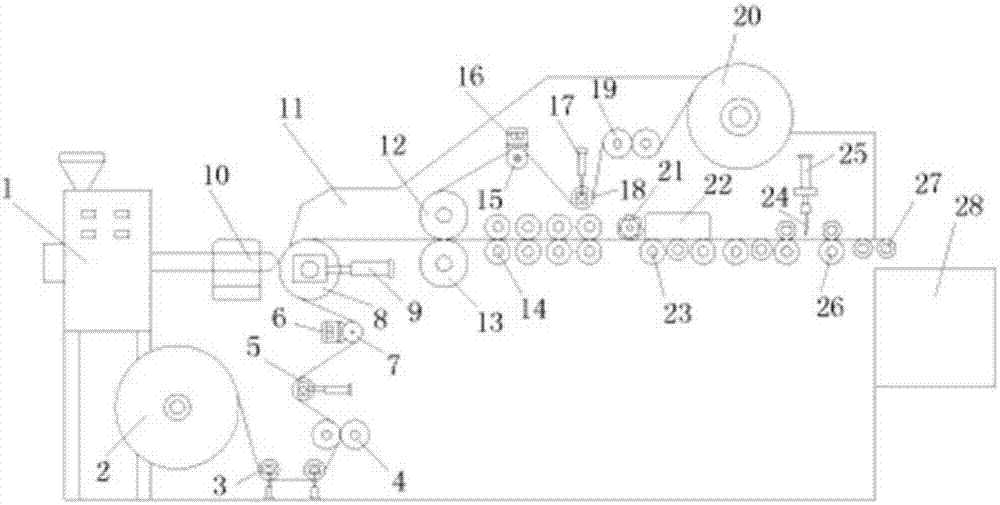

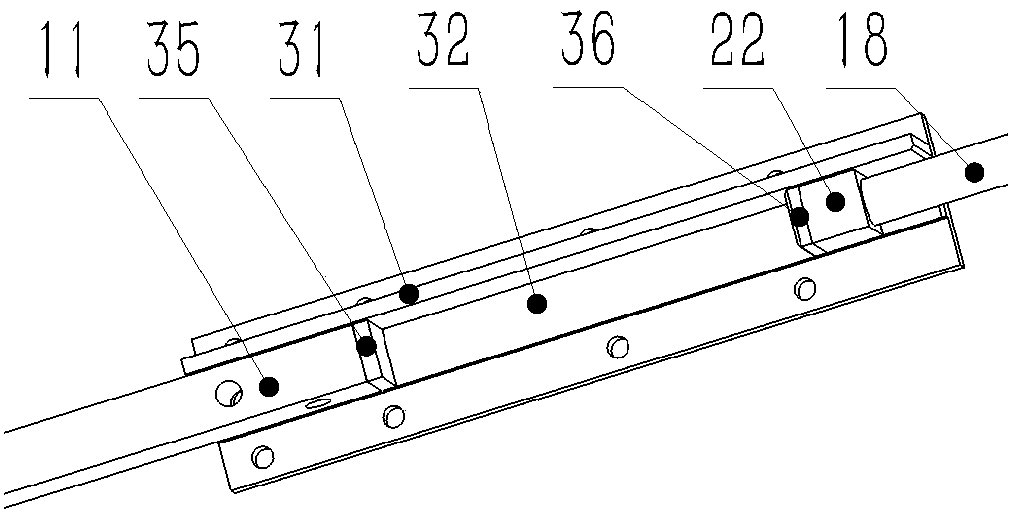

Butyl adhesive tape production line device used for automobiles

PendingCN108003811AReliable moldingReduce process flowFilm/foil adhesivesFlat articlesL&D processEngineering

The invention discloses a butyl adhesive tape production line device used for automobiles. The device comprises a rack, a backing unreeling and feeding mechanism, a top film paper unreeling and feeding mechanism, a gumming mechanism, a compound mechanism, a cutting mechanism, a detaching mechanism and a trimming mechanism, wherein the backing unreeling and feeding mechanism comprises a backing unreeling roller and a backing clamping roller; the top film paper unreeling and feeding mechanism comprises a top film paper unreeling roller and a top film paper clamping roller; the gumming mechanismcomprises a butyl rubber extruding machine; the butyl rubber extruding machine is communicated with a gumming die head through a gum conveying pipe; a gumming roller corresponding to the gumming die head is mounted on the rack; an electric gumming telescopic rod for driving the gumming roller to get close to the gumming die head is mounted on the rack; and the compound mechanism is provided with apressure roller mechanism, the cutting mechanism, the detaching mechanism and the trimming mechanism in sequence. According to the device, the process flow is greatly reduced, the production efficiency is improved, the production process is carried out by adopting automatic equipment, extra manpower is not needed, and the manpower cost is reduced.

Owner:江苏新长宜科技有限公司

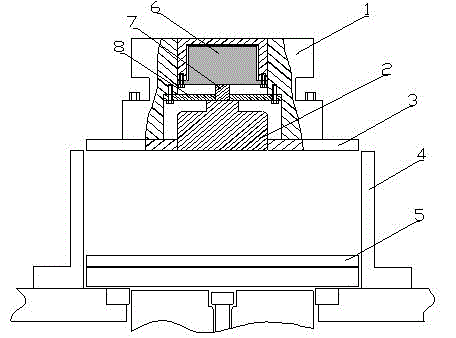

Intelligently-controllable electromagnetic telescopic injection molding car lamp mold

ActiveCN108237655AEasy to pourEasy to shake evenlyDomestic articlesElectric controlUltimate tensile strength

The invention discloses an intelligently-controllable electromagnetic telescopic injection molding car lamp mold. The intelligently-controllable electromagnetic telescopic injection molding car lamp mold comprises a strip bearing base, two sets of supporting stand columns are fixedly connected with the center of the upper surface of the strip bearing base, the upper surface of each supporting stand column is sleeved with an extrusion spring, the injection molding car lamp mold is arranged on the upper surfaces of the two sets of extrusion springs, two sets of L-shaped supporting frames are correspondingly arranged on the edges of the upper surface of the strip bearing base and the upper surface of the injection molding car lamp mold, a strip sliding opening is machined in the upper surfaceinside each L-shaped supporting frame, a sliding block is arranged in each strip sliding opening, an electric control push rod is fixedly connected to the lower surface of each sliding block, and a telescopic extrusion mechanism is arranged at one end of the upper surface of the strip bearing base. The car lamp mold has the beneficial effects that casting is convenient, a casing mold can be conveniently and evenly shaken, bubbles in raw materials can be conveniently removed through control over the extrusion degree, molding is reliable, manual operation intensity is reduced, and moving is convenient.

Owner:太仓法斯特汽车配件有限公司

Die mechanism of vibration molder with slide block on middle part and operation method thereof

ActiveCN102744766AReduce the amount of compressed airAvoid Lamellar Crack DefectsCeramic shaping apparatusMolding machineRefractory

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

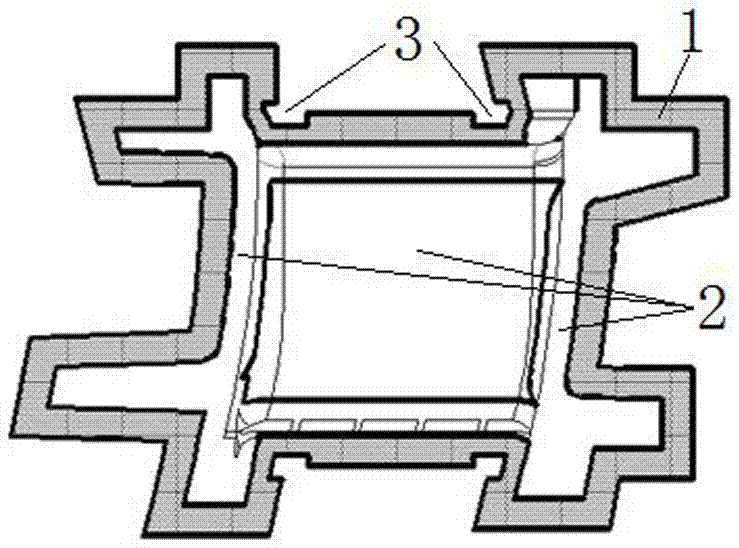

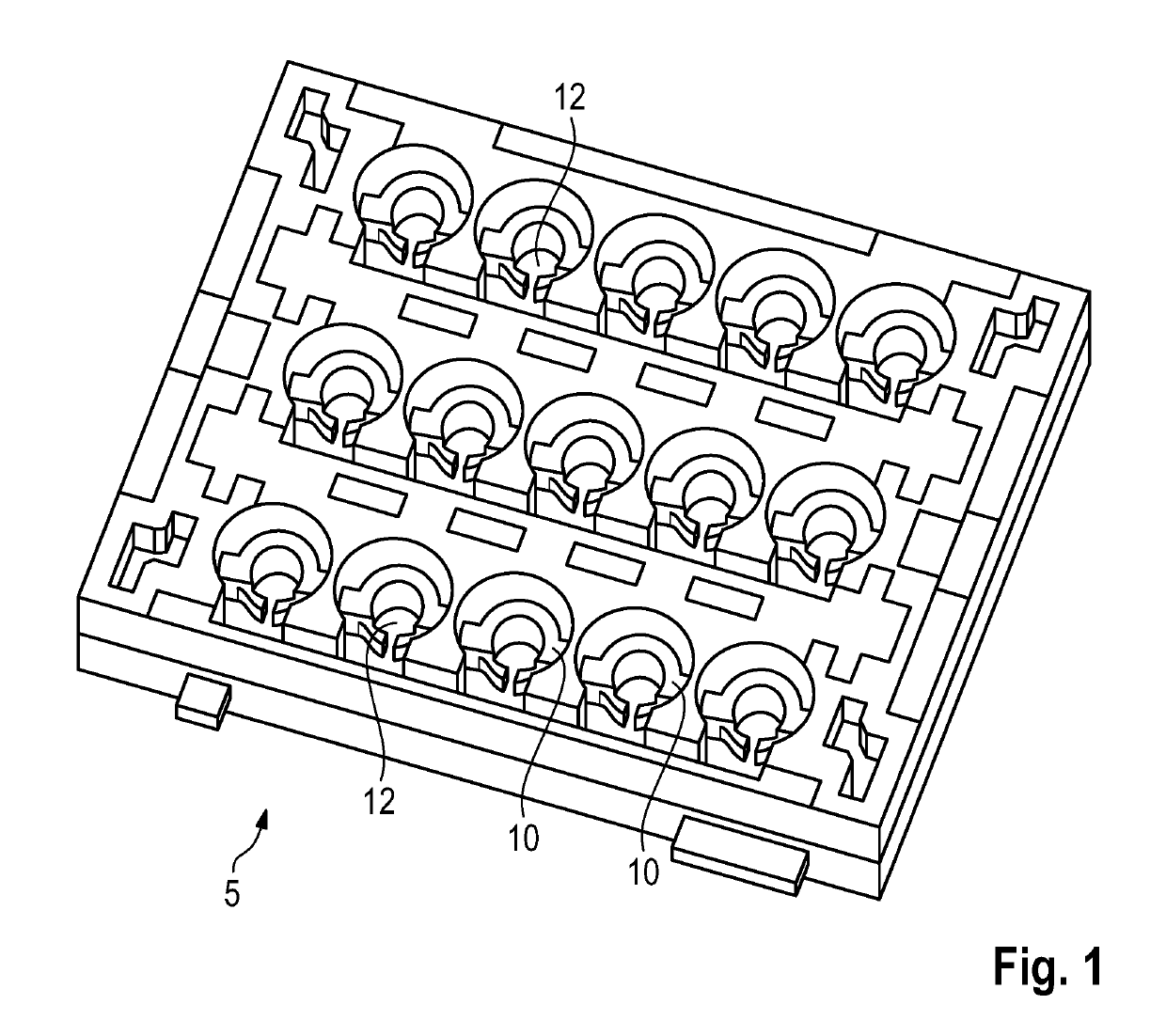

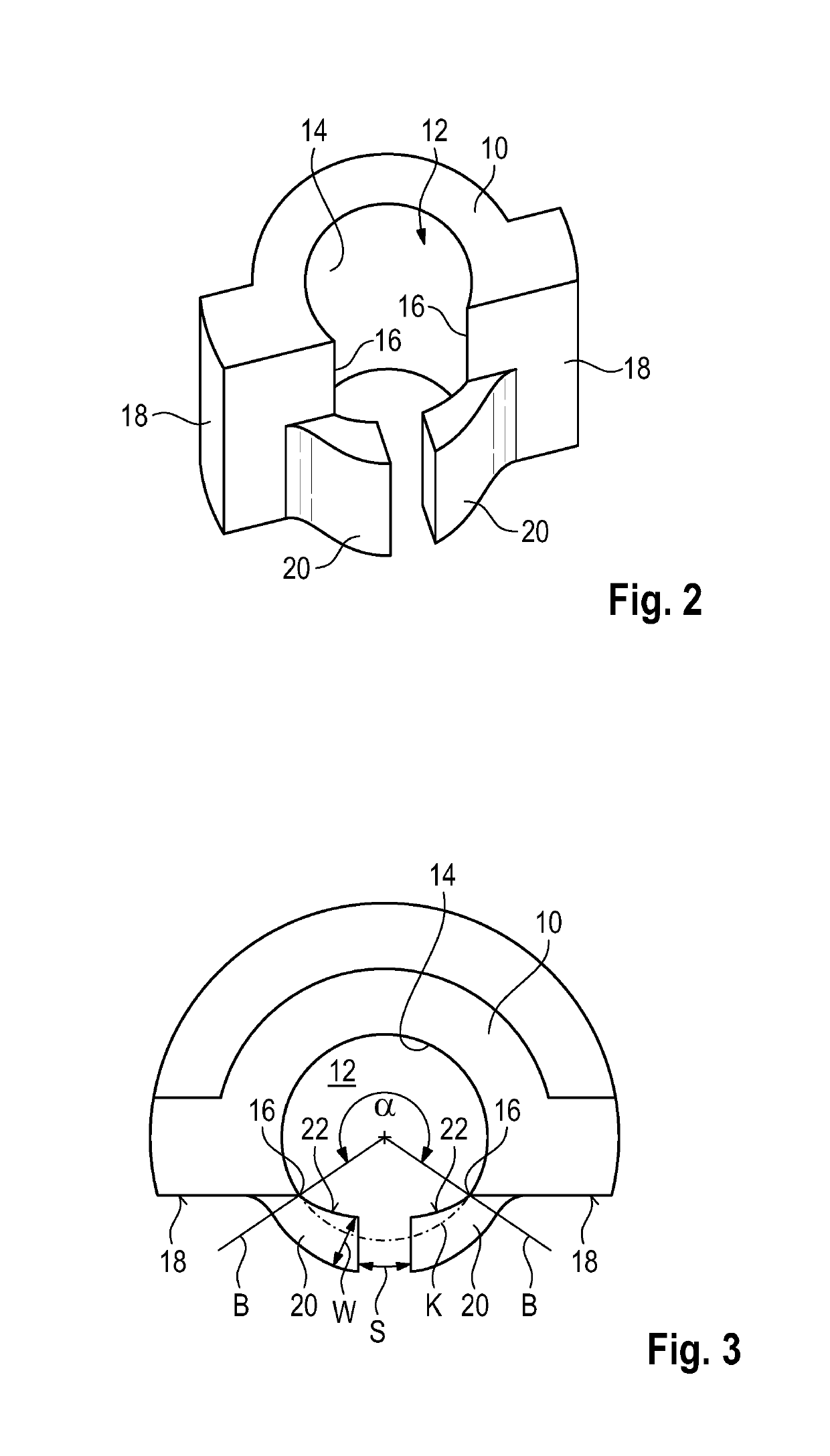

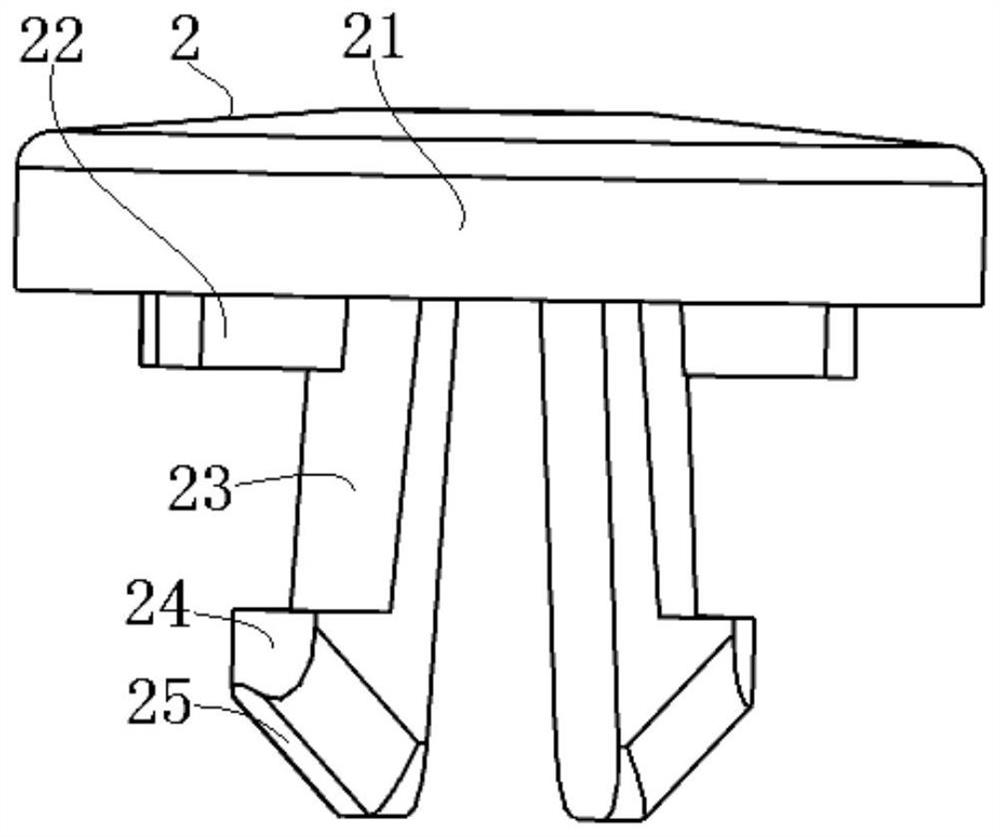

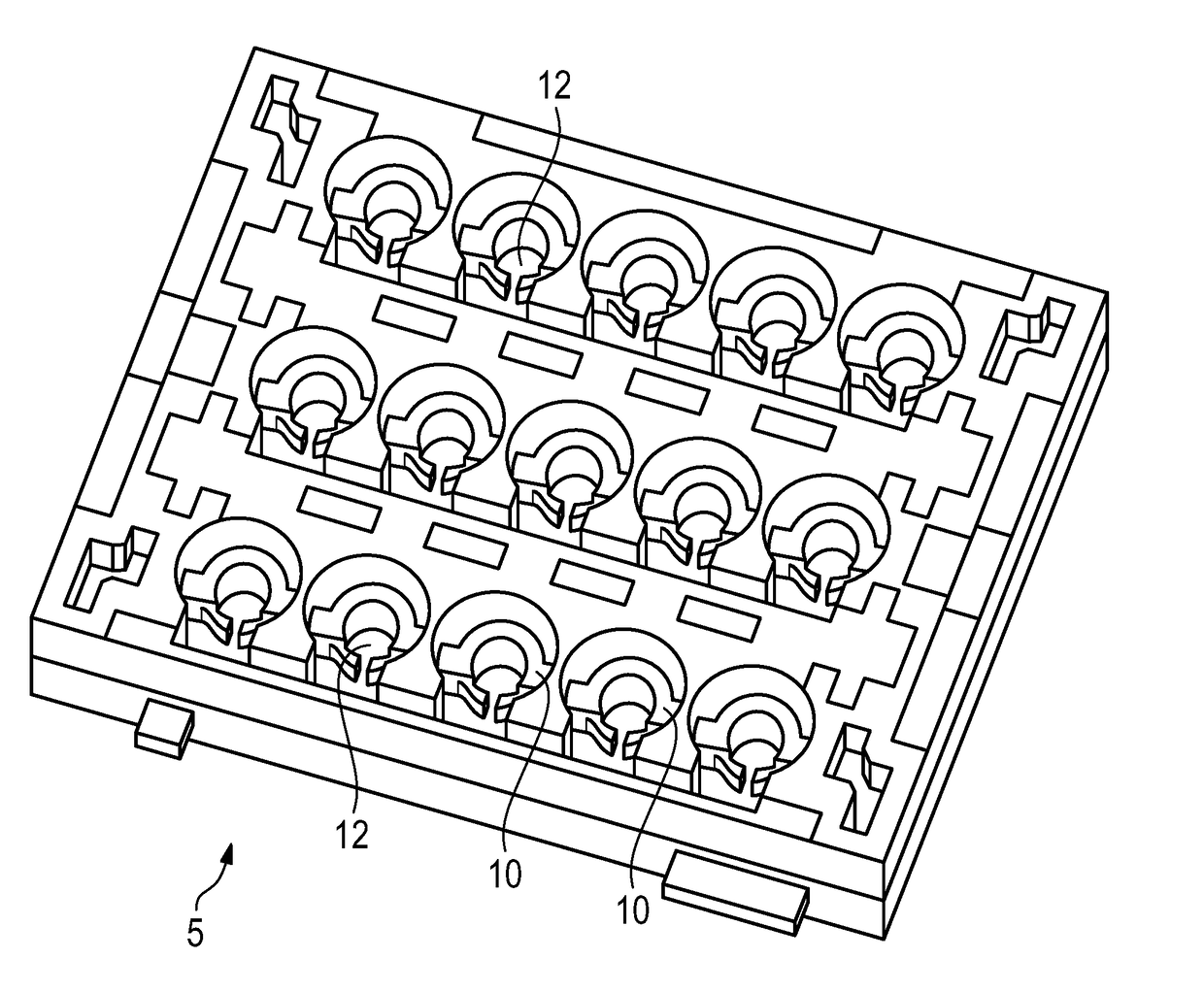

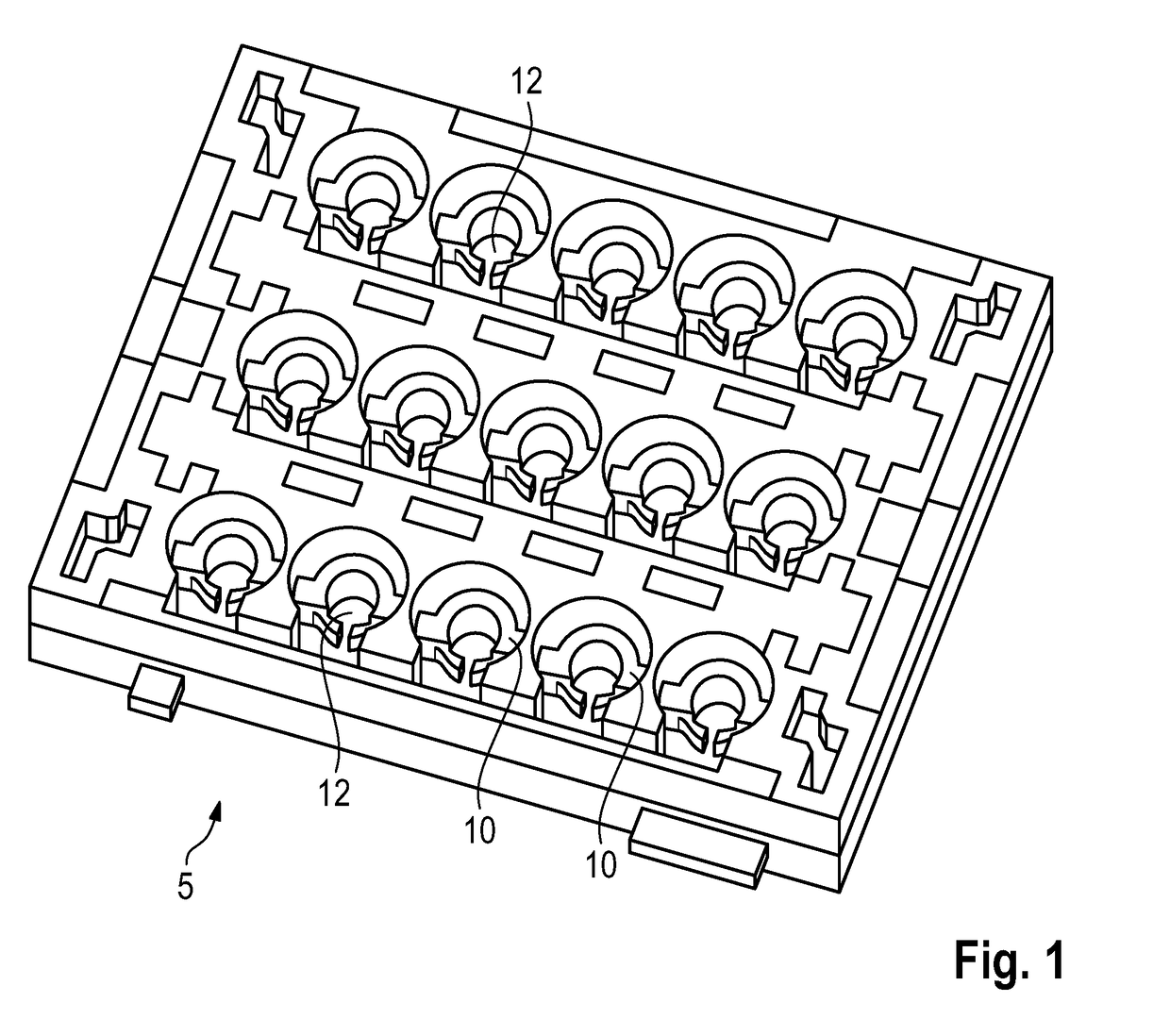

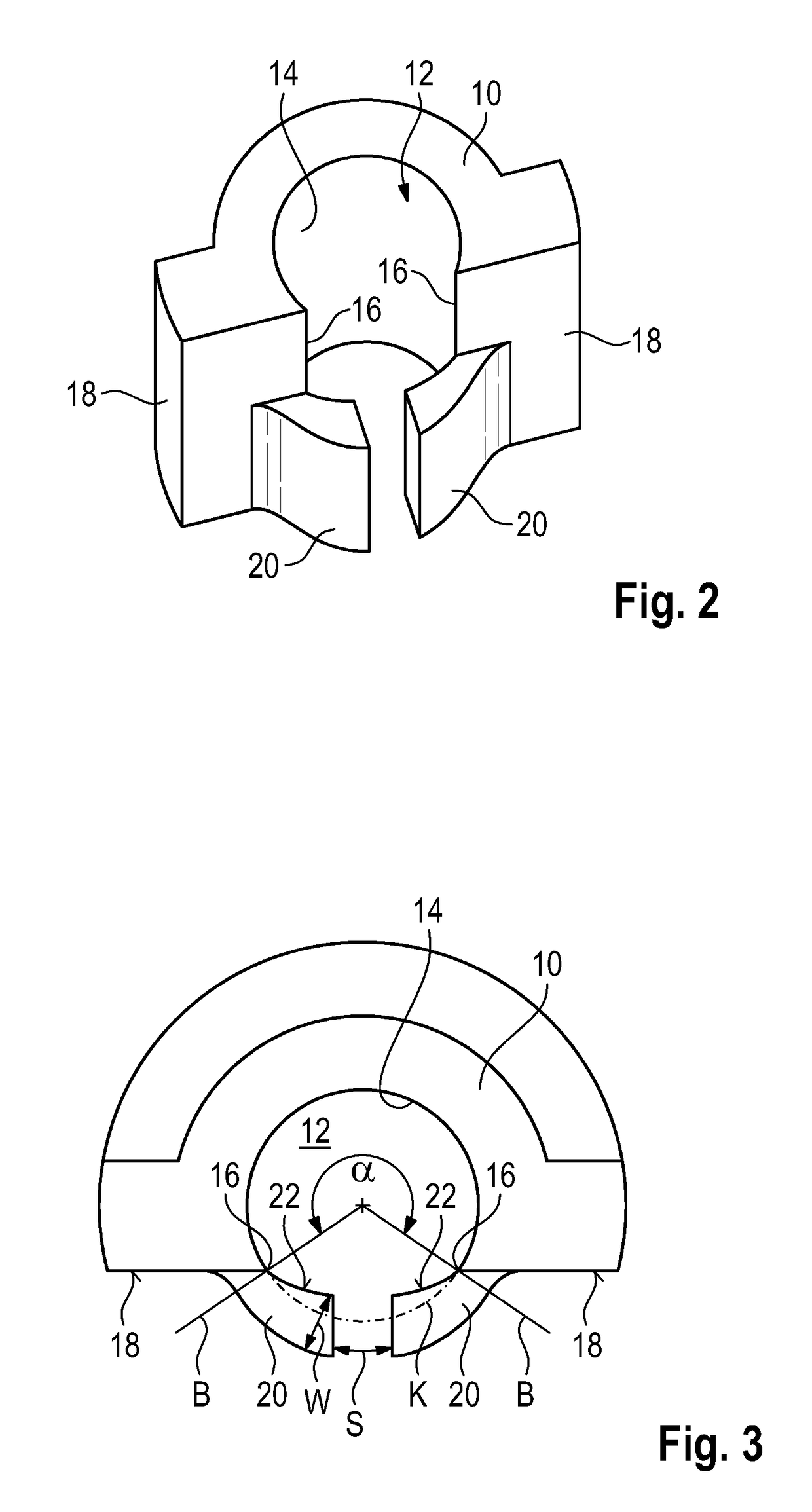

Insulating body for a plug connector

ActiveUS10404002B2Improve installation securityLittle effortCoupling device detailsElectrical and Electronics engineeringAngular range

An insulating body for a plug connector is provided, having at least one seat for a contact, the seat being open in the peripheral direction and surrounding a receiving space for the contact over an angular range which is greater than 180 degrees and smaller than 300 degrees, and wherein at least one peripheral edge of the seat has a guide web provided thereon which is elastic in the radial direction of the seat and which has a wall thickness that is greater at the free end than in the region of the connection to the seat.

Owner:HARTING ELECTRIC GMBH & CO KG

Display panel, control display panel and method for integrally molding insert material

ActiveUS7598926B2Simple structureEasy to operateAdvertisingCathode-ray tube indicatorsEngineeringElectrical and Electronics engineering

Owner:PANASONIC CORP

Method for efficiently forming hollow bricks through high-pressure microorganism solid soil

The invention discloses a method for efficiently forming hollow bricks through high-pressure microorganism solid soil. The method comprises the following steps that 1, a material needed by a die is prepared; 2, organic glass plate with holes is assembled; 3, a light die is manufactured, and geotechnical cloth is tailored according to the size; 4, two transverse screw rods are disassembled; 5, a PVC pipeline is installed in a rectangular die cavity; 6, sandy soil is added to a cavity defined by the geotechnical cloth, and a geotechnical cloth top cover is sewn; 7, by means of the two transversescrew rods, the distance between two longitudinal side plates is fixed; 8, prepared bacteria are poured into a test piece, and then the whole die is placed in a chemical solution, and located under the pressure of two standard atmospheric pressures; and 9, after reacting is carried out for 3 days, biology solid soil hollow bricks are formed. Compared with traditional hollow bricks, the hollow bricks formed efficiently through the high-pressure microorganism solid soil does not need to be inserted and formed at a high temperature, air pollution is reduced, the environment is protected, and themethod is an ecological environment-friendly method.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

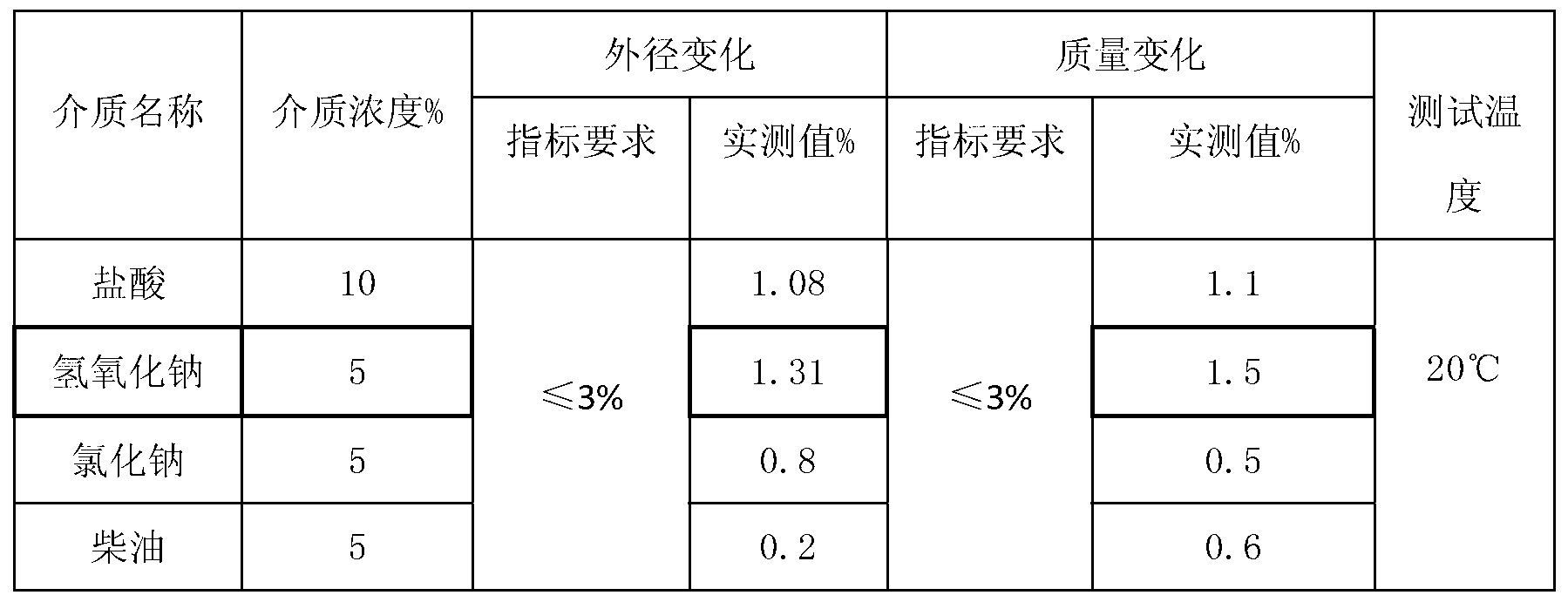

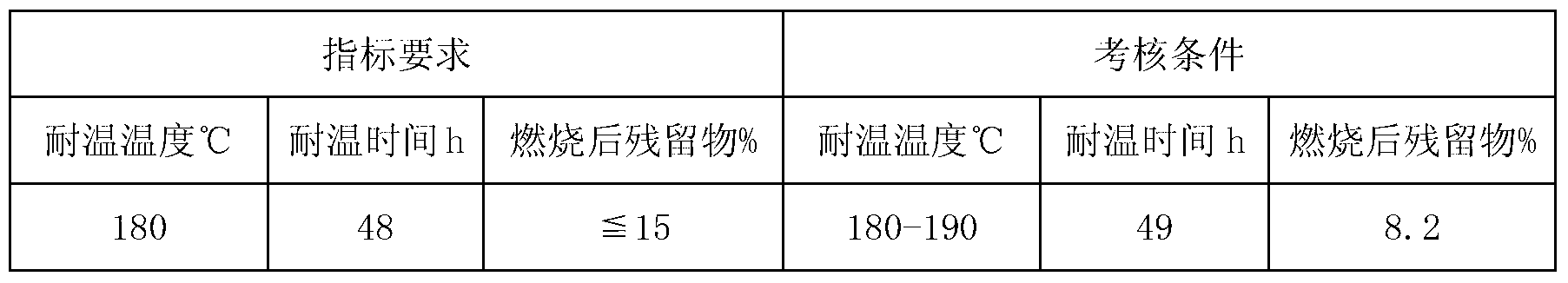

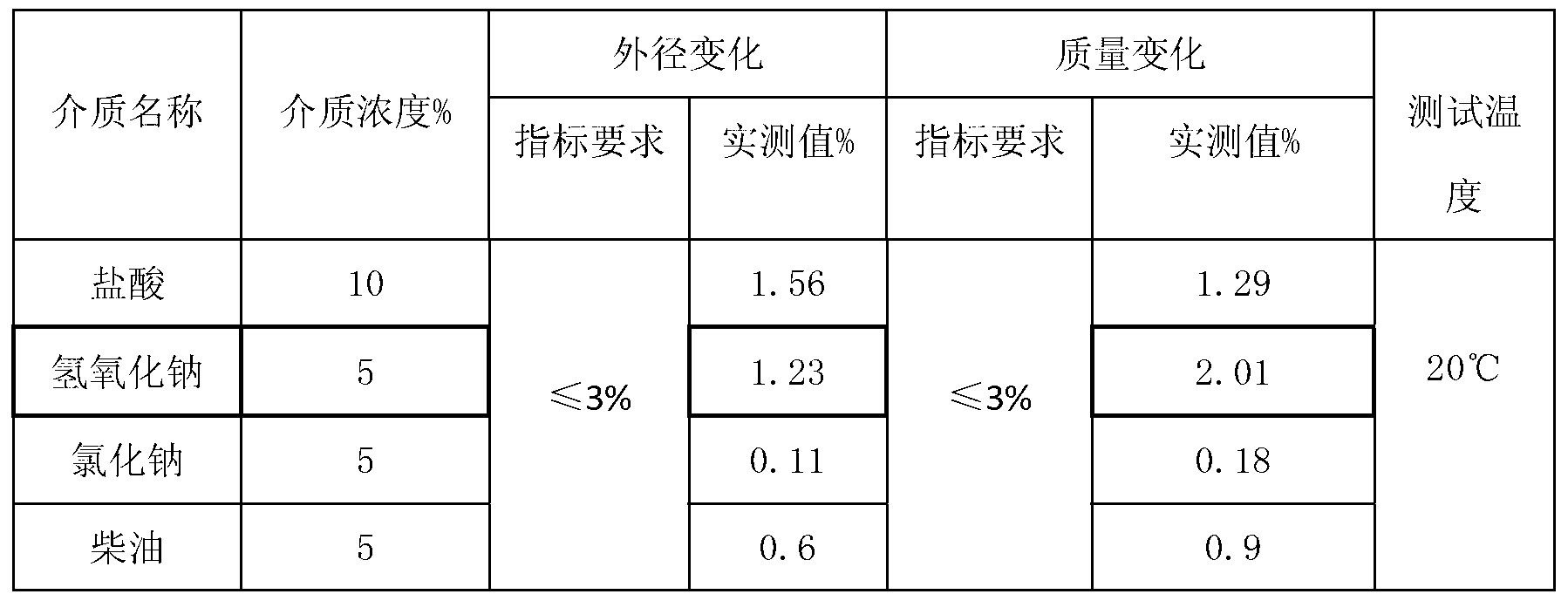

Coating layer for fracturing bomb propulsive agents and preparation method therefor

The invention discloses a coating layer for fracturing bomb propulsive agents and a preparation method therefor. The method comprises steps: by weight, 78.7%-86.2% of silicone modified epoxy resin, 4.3%-7.9% of hydroxyl-terminated polybutadiene, 0.86%-1.6% of organosilicone water repellent and 8.6%-11.8% of polyamide curing agents are prepared, mixed evenly, and defoamed for 10-15 min under vacuum to obtain gel materials, the gel materials are sprayed on the propulsive agent coating surface which is to be coated, and placed at the room temperature for 2-8 h to obtain the coating layer for fracturing bomb propulsive agents. The coating layer has good performances of resistance to water, resistance to oil, resistance to acid, alkali and salt solutions, resistance to high temperature, resistance to high pressure and resistance to dropping, and has a good compatibility with the propulsive agents. The coating layer has good flowability, with a viscosity of 300-1000 cps, is suitable for pouring, spraying, brushing and other coating and molding technologies, and is advantaged by simple technology, convenience and reliable molding.

Owner:XIAN MODERN CHEM RES INST

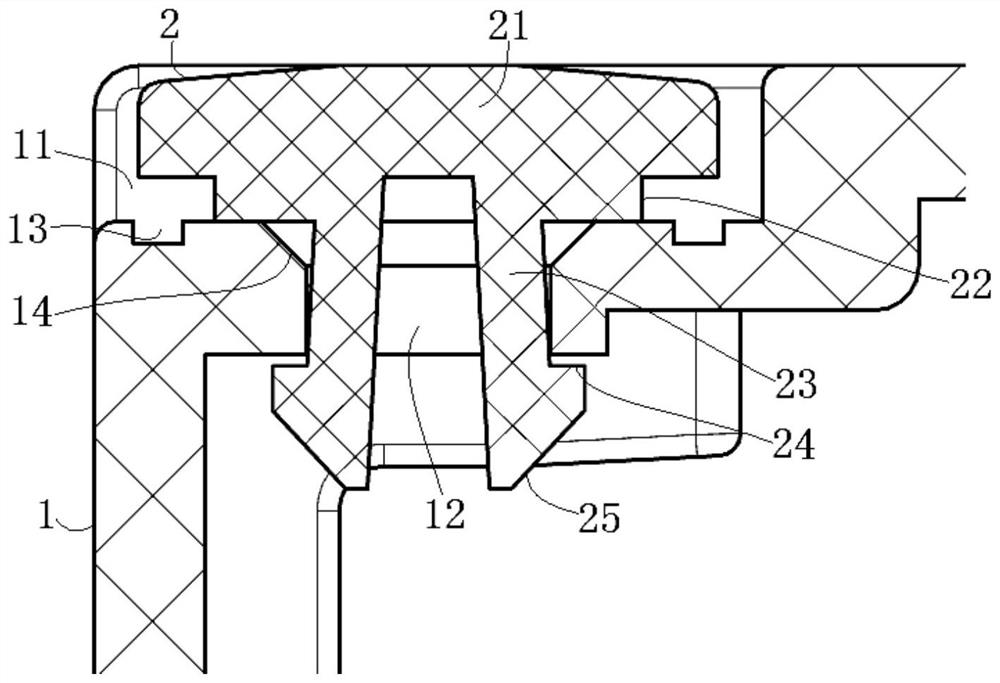

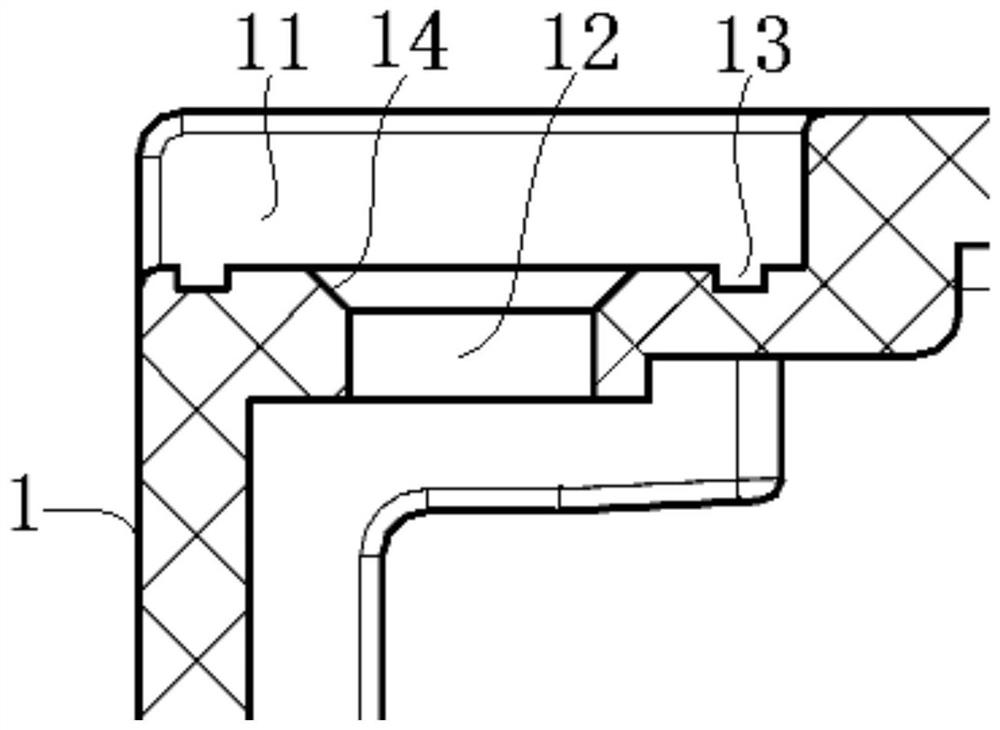

Air hole structure on relay shell

PendingCN112271108APrevent intrusionGood technical effectRelay ventilation/cooling/heatingRelay bases/casings/coversEngineeringStructural engineering

The invention discloses an air hole structure on a relay shell. The structure comprises a base hole formed in the relay shell and capable of communicating the inside with the outside of the shell, anda plug capable of shielding the outer end part of the base hole is assembled in the base hole on the relay shell. The plug is matched with the base hole, so that an air hole of which the air passageis of a non-straight passage structure is formed in the relay shell. Pollutants can be effectively prevented from directly intruding into the relay shell through the air holes, the air channel is notprone to being blocked, and the relay shell can be manufactured and formed in a simple, easy and economical mode.

Owner:SICHUAN HONGFA ELECTROACOUSTIC

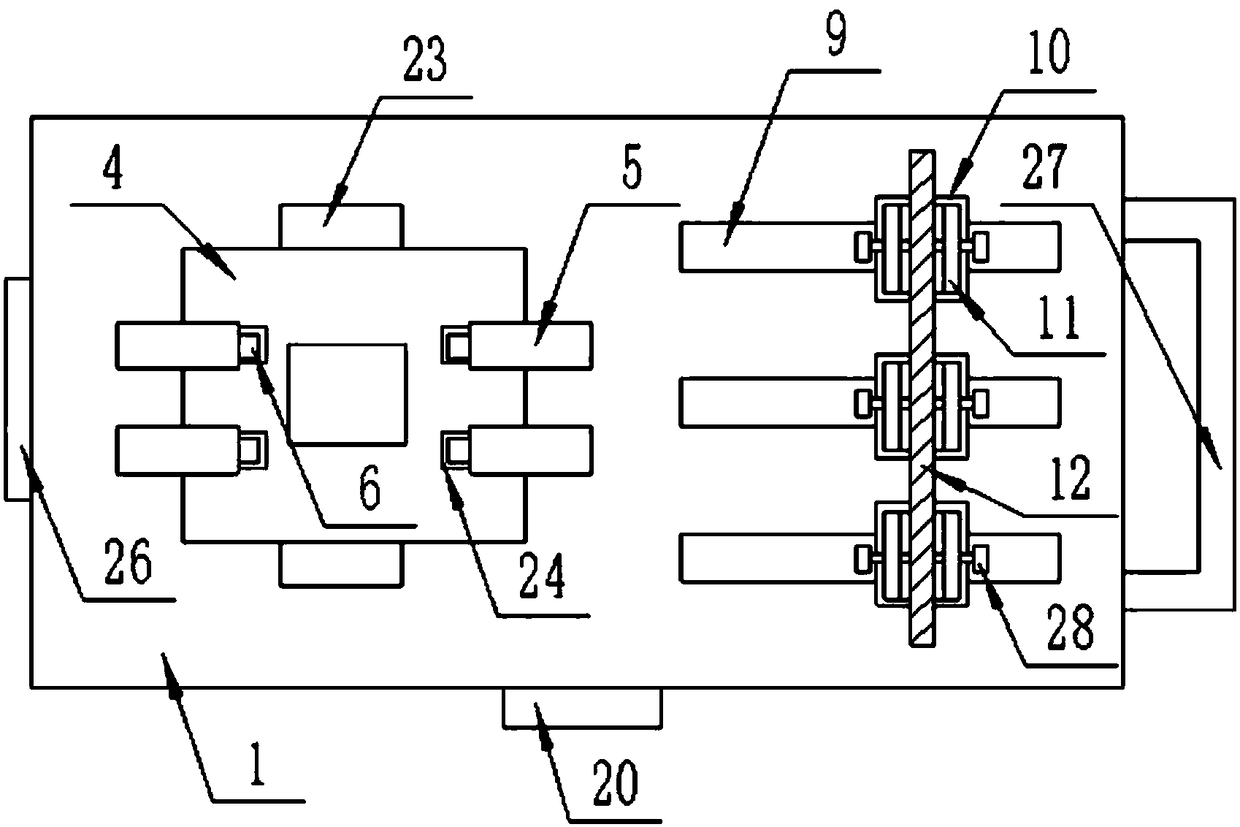

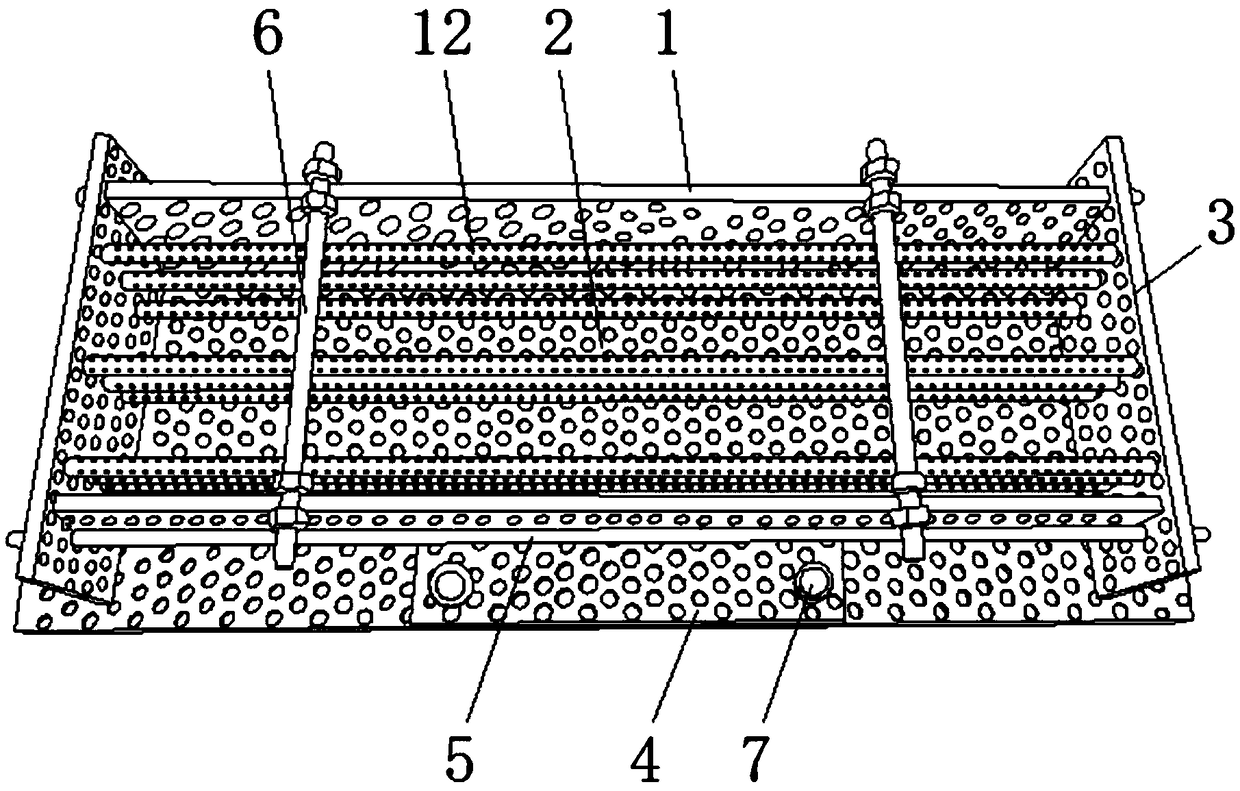

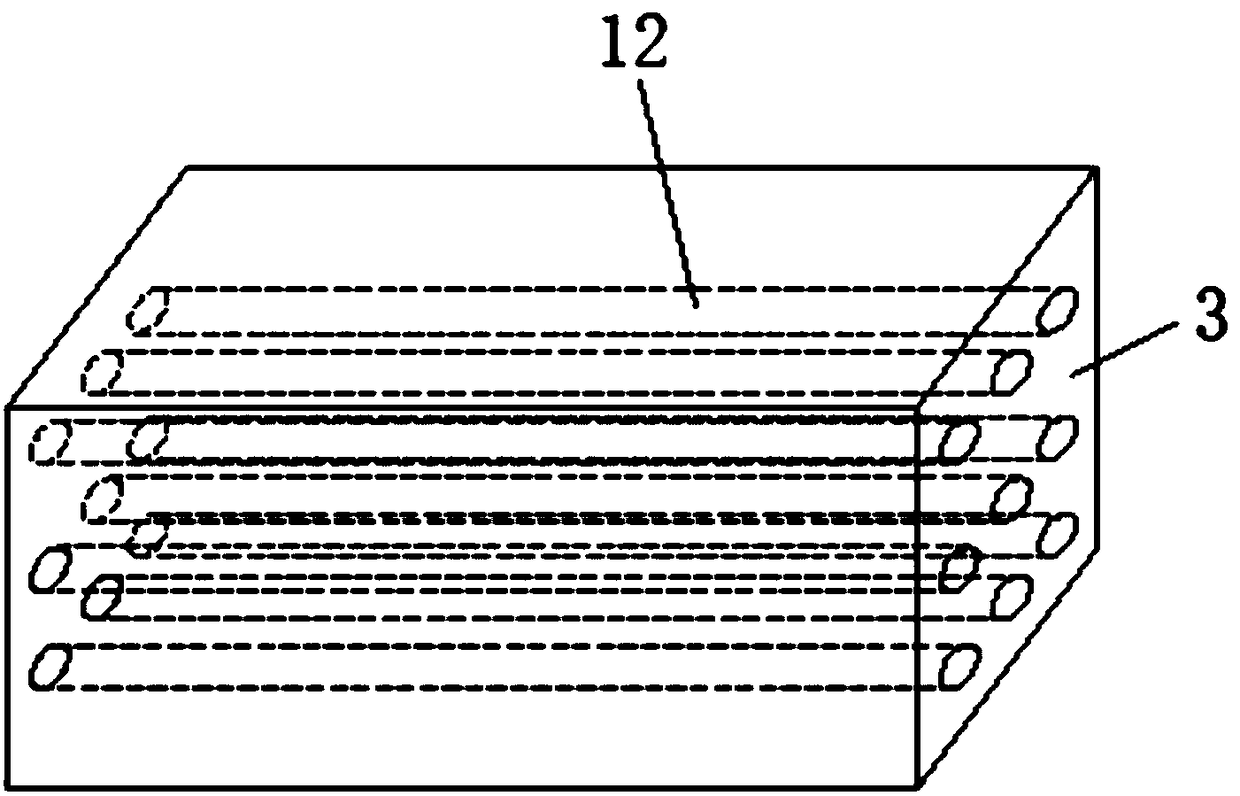

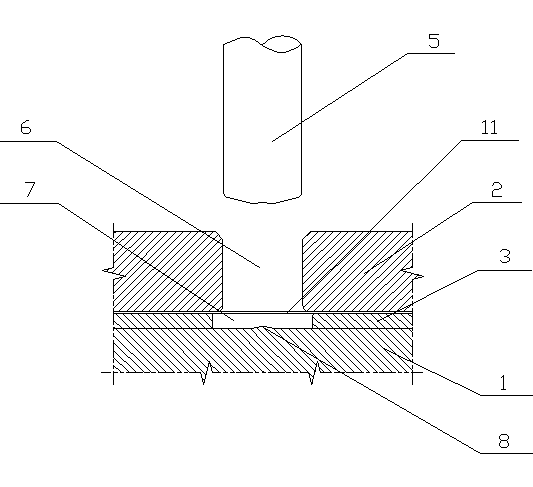

Stamping tool of plate-shell type evaporator plate bundle element

The invention discloses a stamping tool of a plate-shell type evaporator plate bundle element, belonging to the field of punch forming machinery. The stamping tool comprises a bottom platform, an upper die, a lower die, a punch plate bundle, a hydraulic driving device and a portal frame, wherein the hydraulic driving device is fixedly arranged at the lower end of the portal frame, the punch plate bundle is fixedly arranged at the lower end of the hydraulic driving device, the upper die is arranged below the punch plate bundle, and the upper die is provided with a plurality of uniformly distributed upper die through holes; punches of the punch plate bundle are arranged in the upper die through holes, the lower die is arranged on the bottom platform and is provided with a plurality of uniformly distributed lower die through holes, and the lower dies are arranged between the bottom platform and the upper die. The stamping tool of the plate-shell type evaporator plate bundle elementis high in stamping efficiency, reliable in forming and high in finished product rate.

Owner:金沙 +2

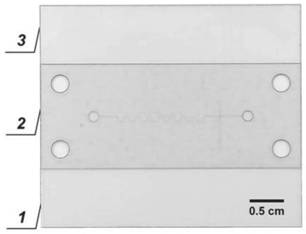

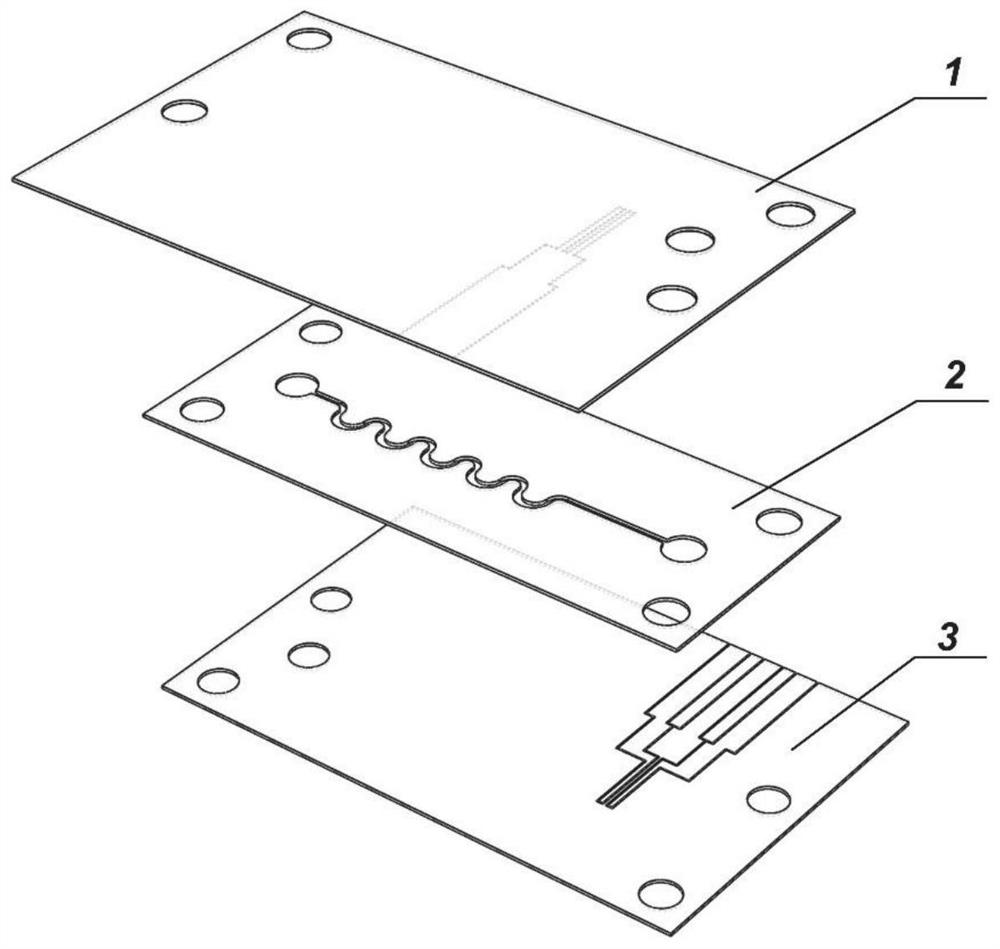

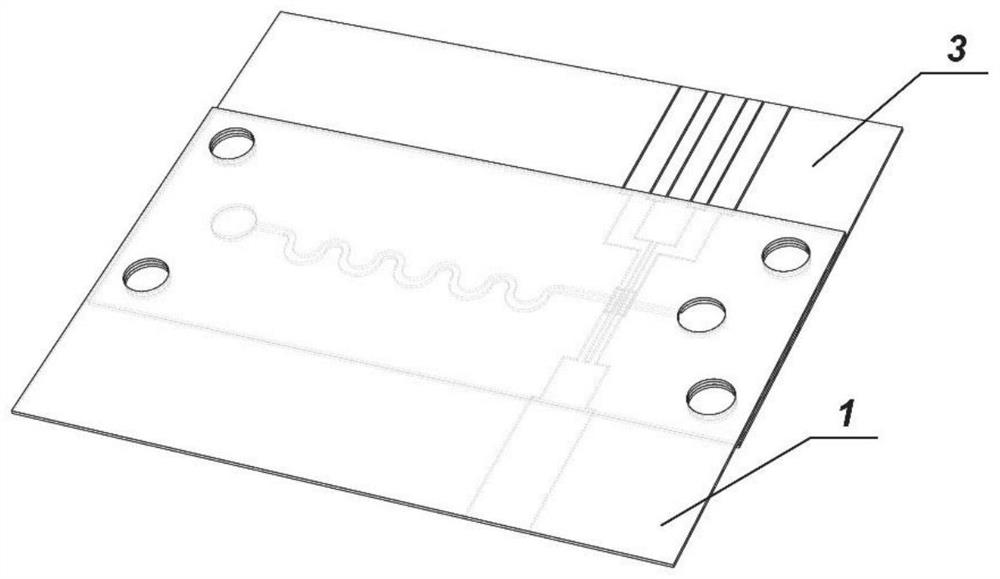

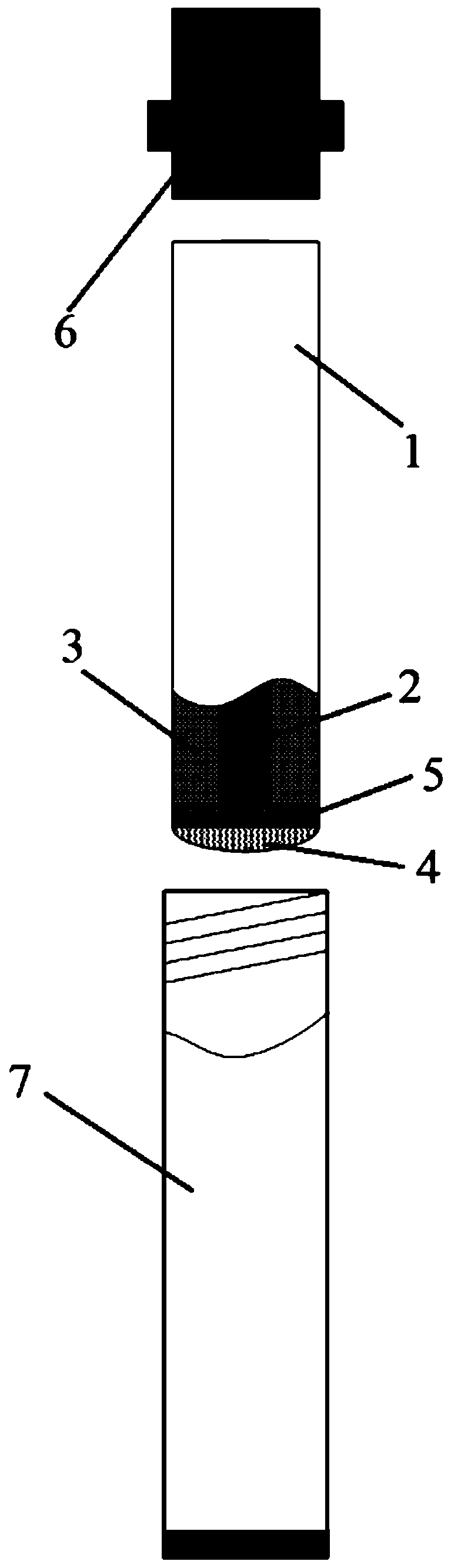

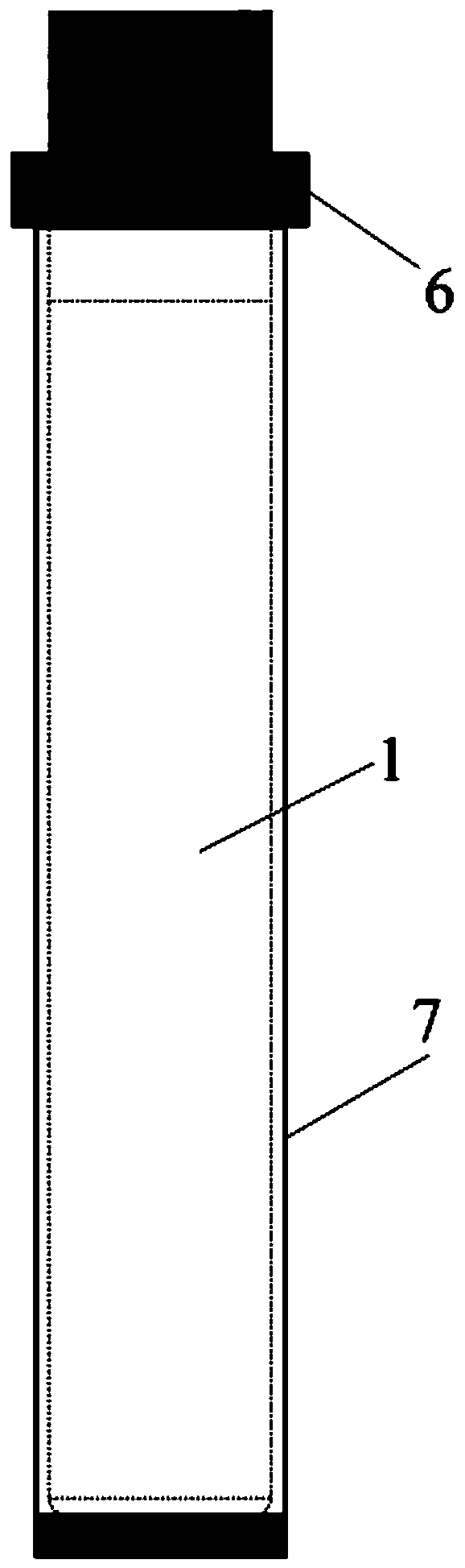

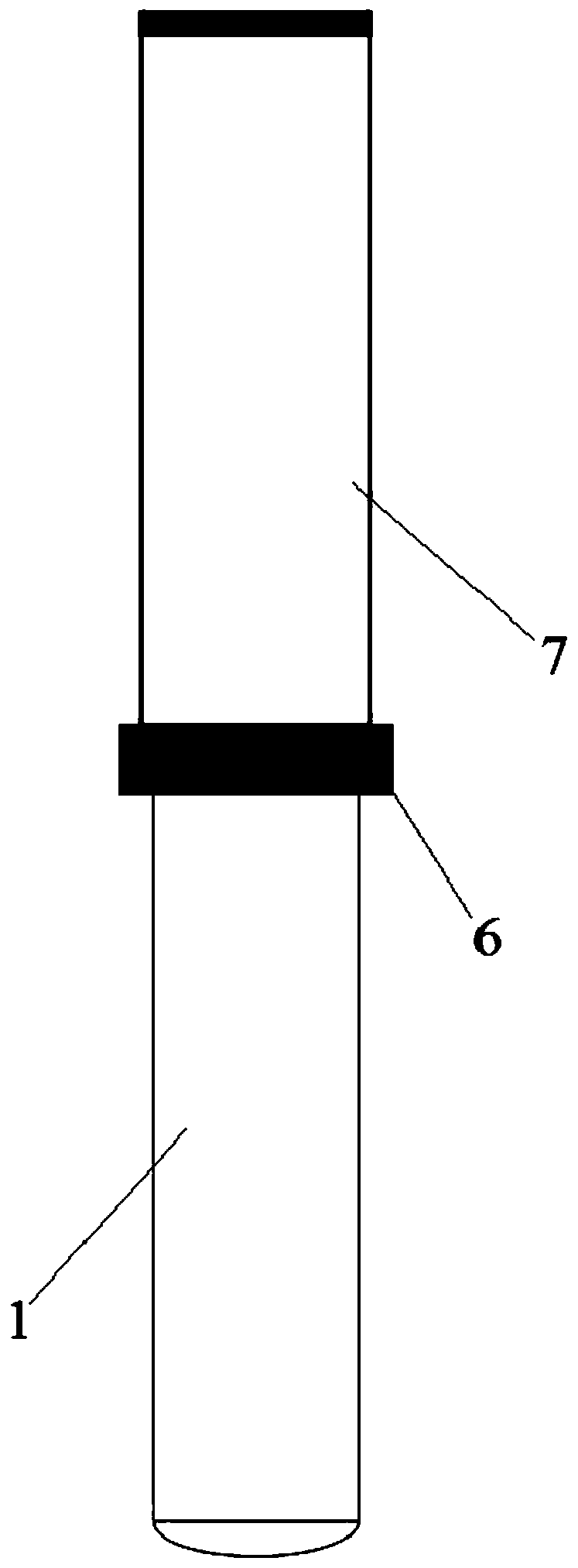

Microfluidic impedance cytometer and preparation method thereof

ActiveCN112730560AEasy accessReliable moldingMaterial analysis by electric/magnetic meansLaboratory glasswaresMicrofluidicsFilm material

The invention provides a microfluidic impedance cytometer and a preparation method thereof. The microfluidic impedance cytometer comprises an upper electrode layer, a flow channel layer and a lower electrode layer, the flow channel layer is provided with a focusing flow channel, the upper electrode layer is provided with an excitation electrode, and the lower electrode layer is provided with an induction electrode. Both the upper electrode layer and the lower electrode layer are made of ITO conductive film materials with PET as a substrate, the flow channel layer is made of AB double-sided tape materials with PET as a substrate, and the upper surface and the lower surface of the flow channel layer are bonded with the upper electrode layer and the lower electrode layer respectively to seal the focusing flow channel. An ITO conductive film is cut, an upper insulation groove is cut in an upper electrode layer, a lower insulation groove is cut in a lower electrode layer, the upper insulation groove surrounds to form an excitation electrode independent of the rest part of the upper electrode layer, and the lower insulation groove surrounds to form an induction electrode independent of the rest part of the lower electrode layer. The excitation electrode and the induction electrode are in butt joint to form a three-dimensional differential electrode, functions of cell counting, volume measurement, focusing position monitoring and the like can be achieved, the preparation process is simple, materials are easy to obtain, and cost is low.

Owner:SOUTHEAST UNIV

Production process method for stamping molds for back boards of liquid crystal displays of curved-surface televisions

The invention relates to a production technology for stamping molds for back boards which are important structural components of liquid crystal displays of curved-surface televisions. The technology is characterized in that firstly, molding is performed on first engineering curved surfaces, subsequent processes such as trimming, convex hull reshaping, hook molding, hole stamping, stamp-marking, burr pressing, little bending, stamp-marking, sprouting, all-around bending and the like are performed on curved surfaces, and the curved surfaces are formed by drawing sheet metal parts into box-shaped bodies with bottoms being curved surfaces in first engineering and then cutting off excess materials; and during drawing of the curved surfaces, drawing pressing ribs are arranged on the molds, and drawing and stabilization of the curved surfaces are facilitated.

Owner:JIANGSU FANRUN ELECTRONICS

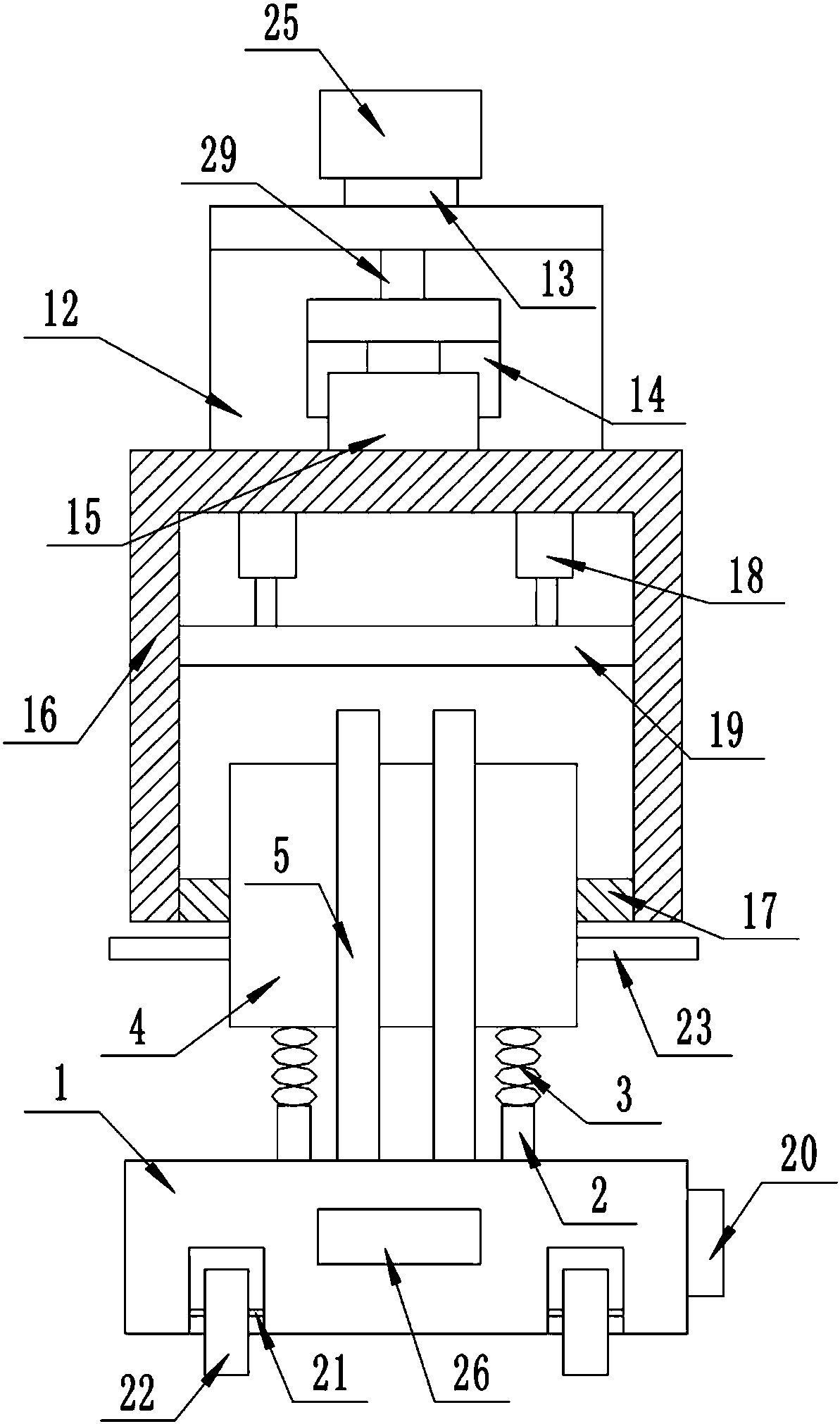

Hot-static pressure molding apparatus

The invention discloses a hot-static pressure molding apparatus, which includes: a pressurizing mechanism, which includes a weight, and a weight bearing board supporting the weight, the weight supplies a driving force downwardly, so that under gravity of the weight, the weight bearing board can move down in the vertical direction; a mold includes a pressing rod, a plurality of long side plates, and a top rod, wherein the long side plates are detachably and sealedly connected to form a cylinder of a sealed cavity; the top of the pressing rod is fixedly connected to the weight bearing board; thebottom of the pressing rod is stretched into the cylinder through an opening in the upper end of the cylinder to form a movable top of the sealed cavity; the top end of the top rod is stretched intothe cylinder through an opening in the lower end of the cylinder to form a fixed bottom of the sealed cavity; a heating mechanism includes a heating furnace, that is arranged in the sealed structure and can move vertically, and can be used for heating materials. The apparatus solves the problem that a hot-press shaping apparatus makes big noise, causes pollution on oil, causes fluctuation in pressure value, is limited in compression travel, cannot uniformly heat a mold, is high in energy consumption and cost and has difficulty in demolding.

Owner:NORTHEASTERN UNIV

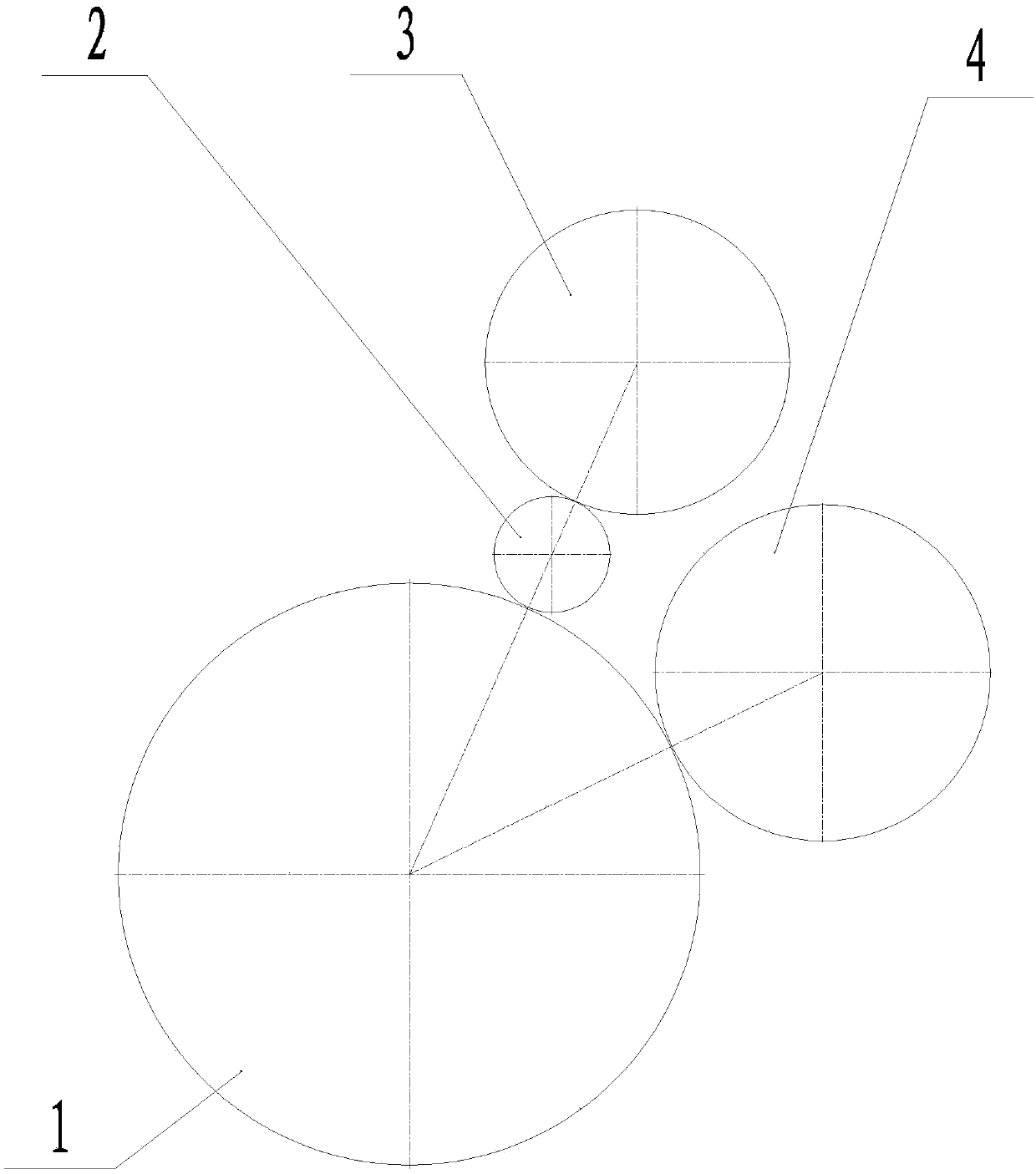

Corrugated board forming device

InactiveCN103753869ASimple structureReliable moldingMechanical working/deformationPaper/cardboard wound articlesMechanical devicesEngineering

The invention belongs to the technical field of packaging mechanical devices, and relates to a composite device, in particular to a corrugated board forming device. The corrugated board forming device comprises a lower corrugated roller, an upper corrugated roller, a supporting roller and a shaping roller, wherein the lower corrugated roller, the upper corrugated roller, the supporting roller and the shaping roller are arranged on a wall board. The upper corrugated roller and the shaping roller make rolling contact with the lower corrugated roller. The upper corrugated roller is arranged on one side of the top end of the lower corrugated roller. The supporting roller is attached to the upper corrugated roller. The axis of the lower corrugated roller, the axis of the upper corrugated roller and the axis of the supporting roller are on the same straight line. The shaping roller is arranged below the upper corrugated roller. Reliable forming of a corrugated board can be effectively achieved through the additional shaping roller; rolling instead of secondary minification is needed when the corrugated board is rolled by the lower corrugated roller and the shaping roller after being rolled by the upper corrugated roller and the lower corrugated roller, abrasion to the rollers is small, the high and low edges and the inclined edges of the corrugated board can be effectively eliminated after the corrugated board pass through the shaping roller, and the aims of being environmentally friendly and saving energy can be achieved without any heat energy.

Owner:朱丹华

Forming method of biofixed soil strip beams for flexural tests

ActiveCN105865863BImprove permeabilityImprove soil fixation effectPreparing sample for investigationMaterial strength using steady bending forcesChemical solutionShaped beam

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Insulating body for a plug connector

ActiveUS20180337484A1Simple technologyImprove installation securityCoupling device detailsAngular rangeEngineering

An insulating body for a plug connector is provided, having at least one seat for a contact, the seat being open in the peripheral direction and surrounding a receiving space for the contact over an angular range which is greater than 180 degrees and smaller than 300 degrees, and wherein at least one peripheral edge of the seat has a guide web provided thereon which is elastic in the radial direction of the seat and which has a wall thickness that is greater at the free end than in the region of the connection to the seat.

Owner:HARTING ELECTRIC GMBH & CO KG

Metal bar inner core type self-propagating welding pen and preparation method thereof

ActiveCN110280892ALow priceEasy to implementAlumino-thermic welding apparatusCopperUltimate tensile strength

The invention discloses a metal bar inner core type self-propagating welding pen and a preparation method thereof. The welding pen comprises a papery agent pipe, a clamping end and a pen barrel. A metal (iron, copper and the like) bar inner core is arranged in the middle of the agent pipe. The space between the metal bar inner core and the agent pipe is filled with a thermite. Components comprise, by weight, 60.0%-75.0% of CuO powder, 15.0%-25.0% of Al powder, 4.0%-6.0% of CaF2 powder, 0.5%-1.5% of B powder, 4.0%-8.0% of SiO2 powder, 2.0%-5.0% of Fe powder and 2.5%-6.0% of NiO powder. When the welding pen is used, high heat released by the thermite is used for melting the metal bar inner core, and generated molten metal serves as deposited metal for welding. By means of the metal bar inner core type structure, the strength of the agent pipe is improved, a reaction is more stable, and metal losses in the reaction process are reduced.

Owner:WUHAN UNIV

Cold roll forming equipment of single board

ActiveCN103028638APrevent deviationLow costMetal-working feeding devicesPositioning devicesRoll formingEngineering

The invention discloses cold roll forming equipment of a single board. The cold roll forming equipment comprises a machine platform, a cold roll forming device, a control device, a guide platform, a detection device, a pushing mechanism, an electromagnetic sucking disk and a guide seat, wherein the single board is put on the guide platform; the machine platform is provided with at least one guide rail and one fixing baffle plate, the guide platform is connected to the machine platform in a sliding way, the guide seat and the guide rail are matched, and the guide platform slides along the direction of the guide rail through the matching of the guide seat and the guide rail; and the control device is also in signal connection with the electromagnetic sucking disk, a position detection device and the pushing mechanism, and the control device can be used for controlling the electromagnetic sucking disk to adsorb the single board or release the adsorption, judging whether deviation needs to be corrected or not according to single board position data obtained by the position detection device and controlling the pushing mechanism to push the single board so that the single board can be leaned against the fixing baffle plate for correcting the deviation. The cold roll forming equipment disclosed by the invention has the following advantages that automatic deviation correcting and feeding is adopted before the forming of the single board, and accurate follow-up guide is adopted during the forming of the single board.

Owner:XIAMEN ZHENGLIMING METALLURGICAL MACHINERY

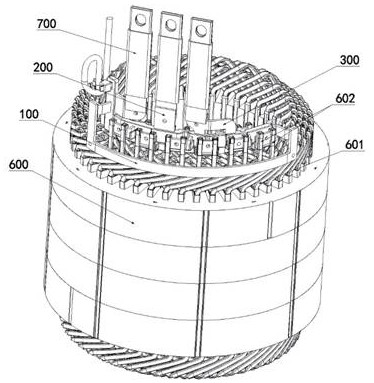

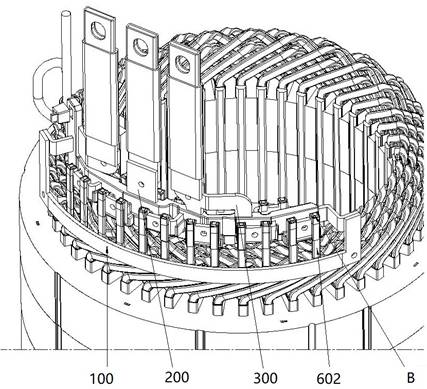

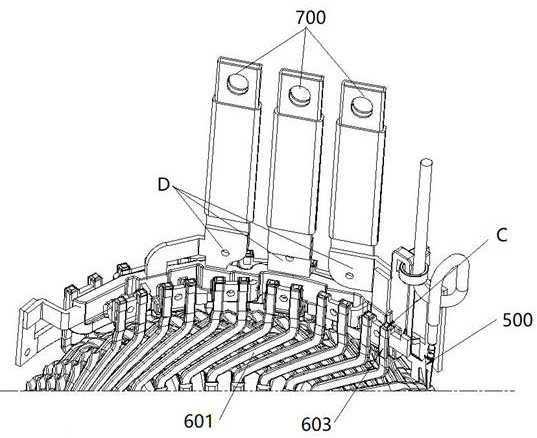

Busbar of flat wire motor and flat wire motor

ActiveCN112186934ASimple structureSimple structure and firm structureWindings insulation shape/form/constructionSingle bars/rods/wires/strips conductorsElectrical conductorBusbar

The invention discloses a busbar of a flat wire motor, which comprises a first-phase busbar, a second-phase busbar and a third-phase busbar, and is characterized in that the first-phase busbar, the second-phase busbar and the third-phase busbar respectively comprise a main body part, and a first wiring part and a second wiring part which are respectively positioned on two sides of the main body part; the first wiring part is connected with a first outgoing line conductor located at the outermost corresponding phase of the stator winding, and the second wiring part is connected with a second outgoing line conductor located at the innermost corresponding phase of the stator winding; and one or two of the main body parts of the first-phase busbar, the second-phase busbar and the third-phase busbar are arranged between the first outgoing line conductor and the second outgoing line conductor. The invention solves the problem that the busbar is difficult to arrange due to the fact that the internal space of a winding of an existing flat wire motor is small.

Owner:恒大恒驰新能源汽车研究院(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com