Patents

Literature

47results about How to "Precise size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

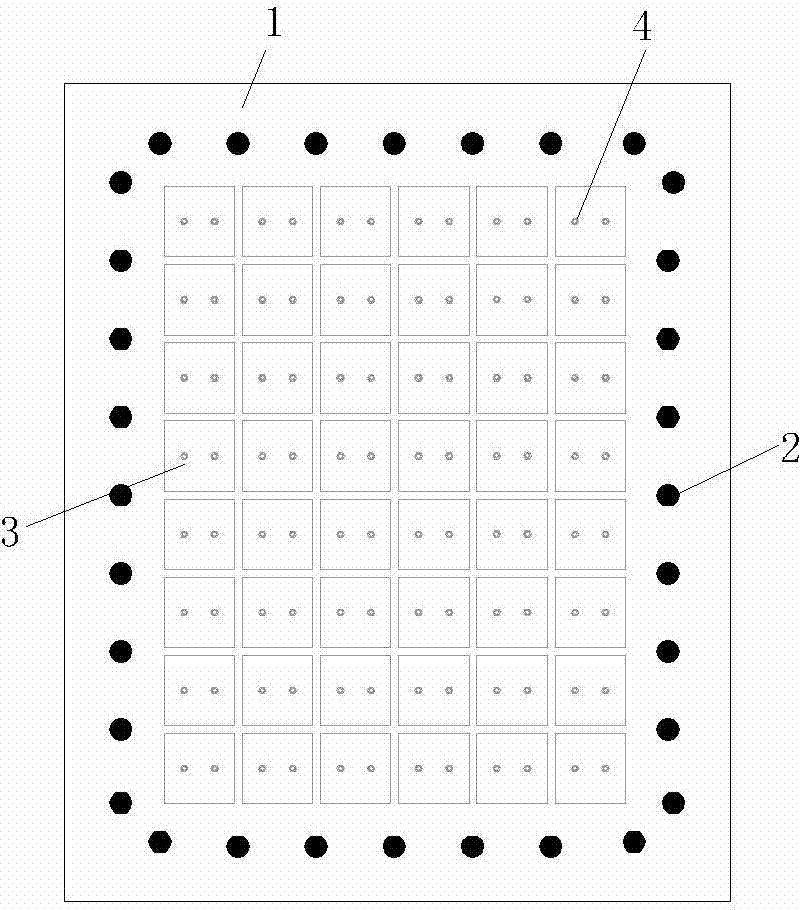

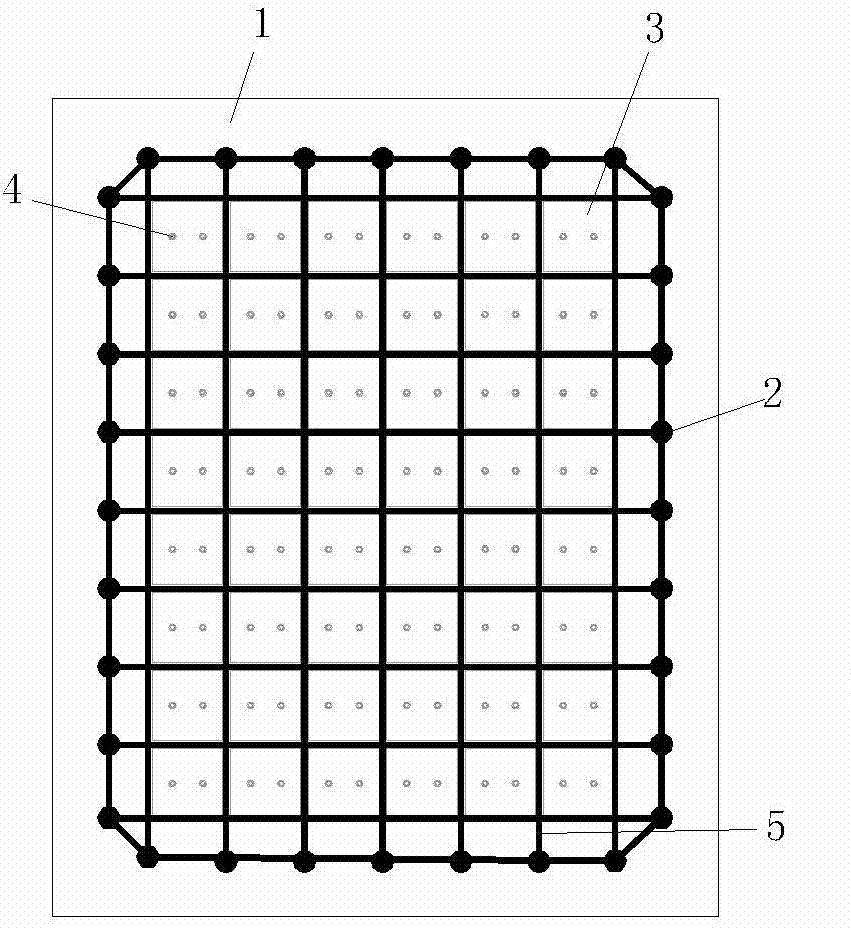

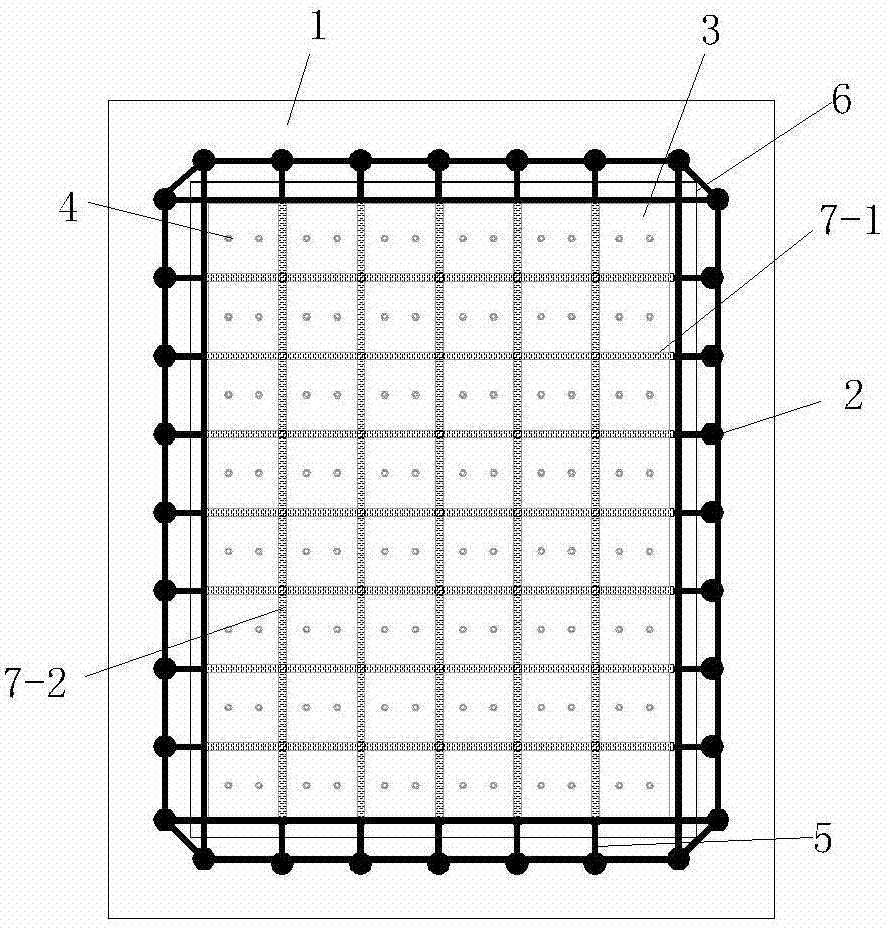

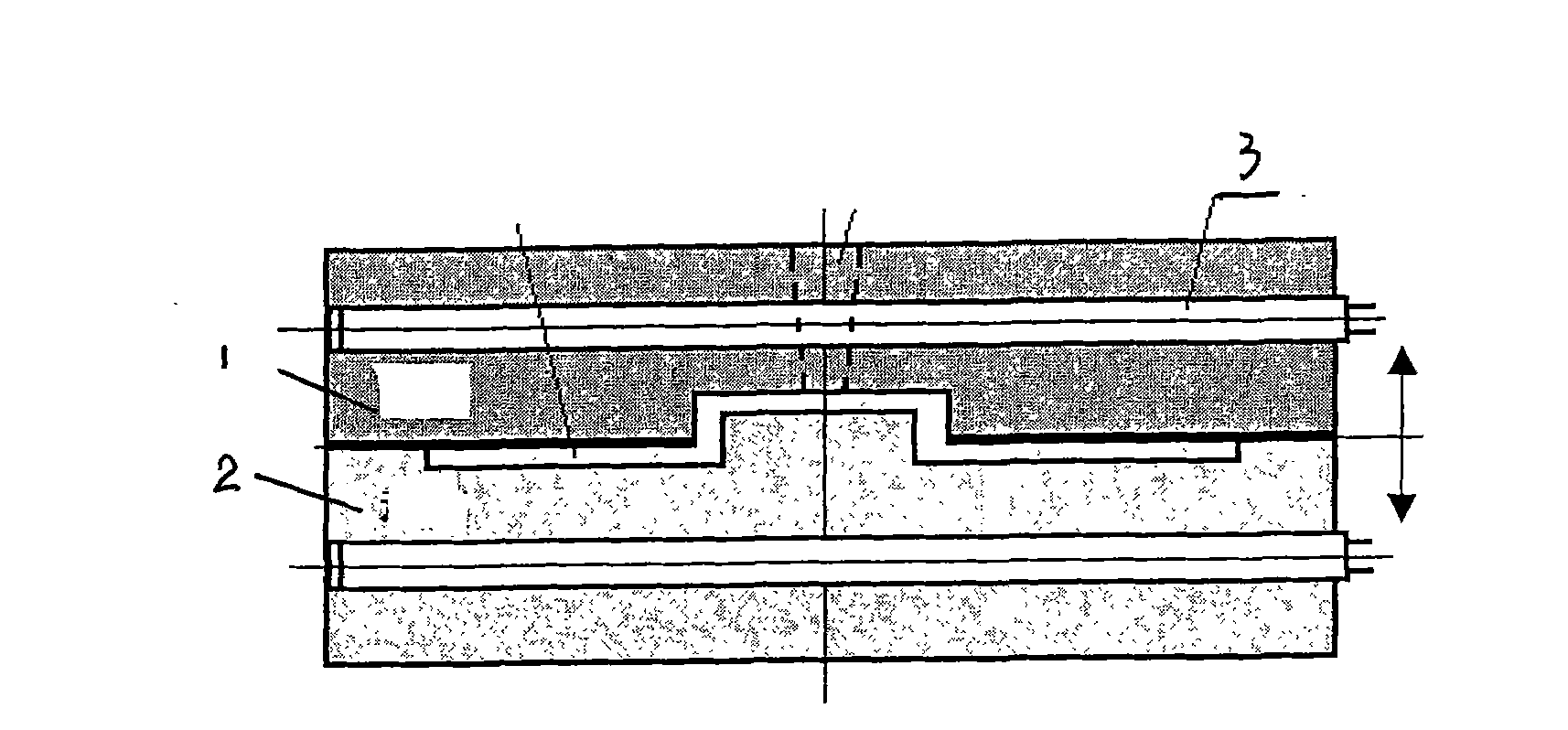

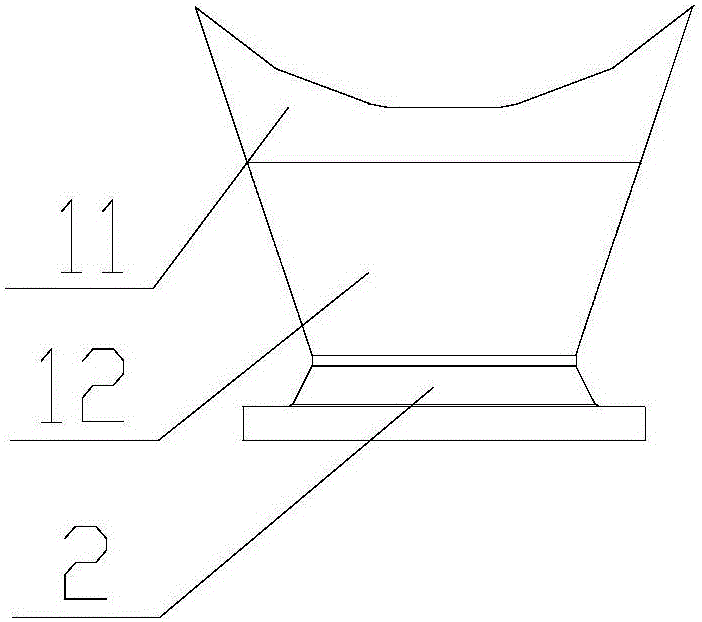

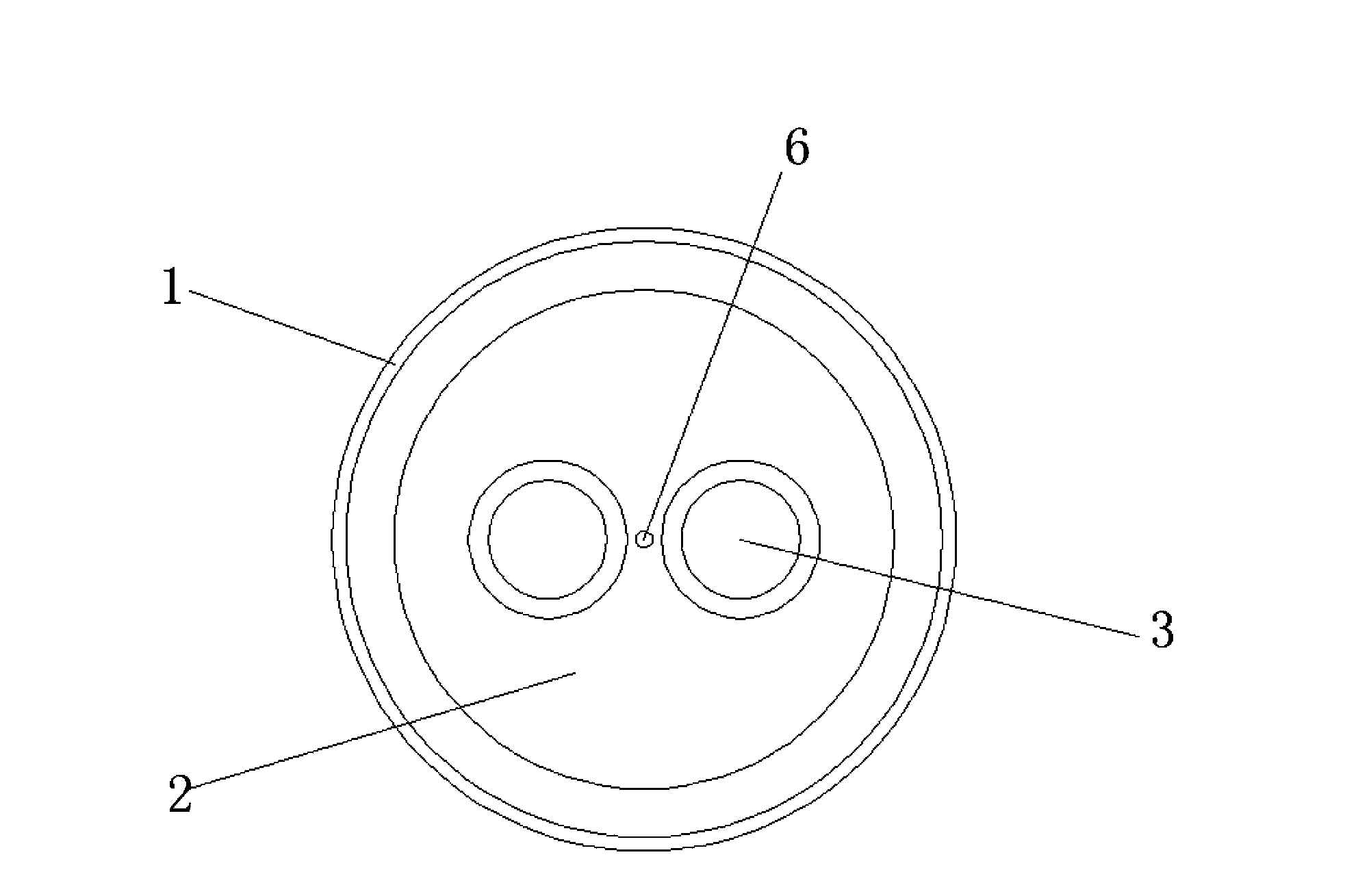

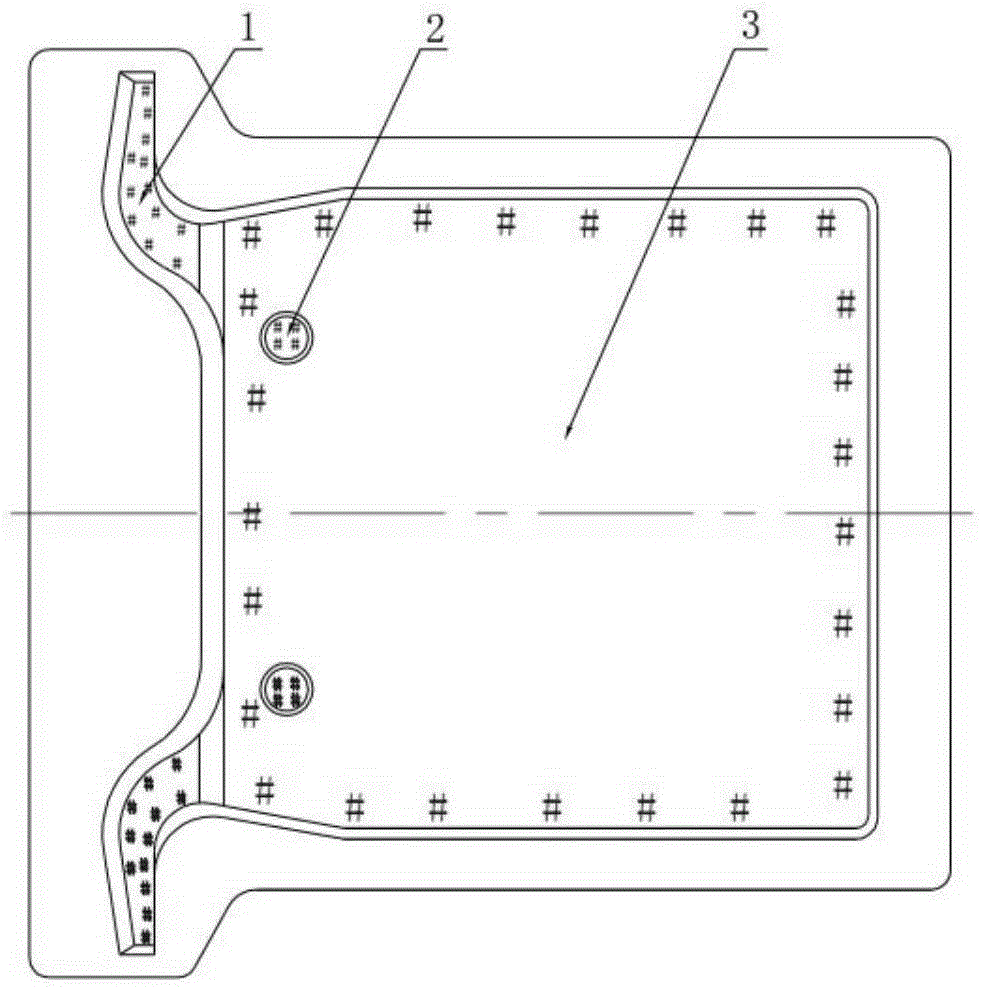

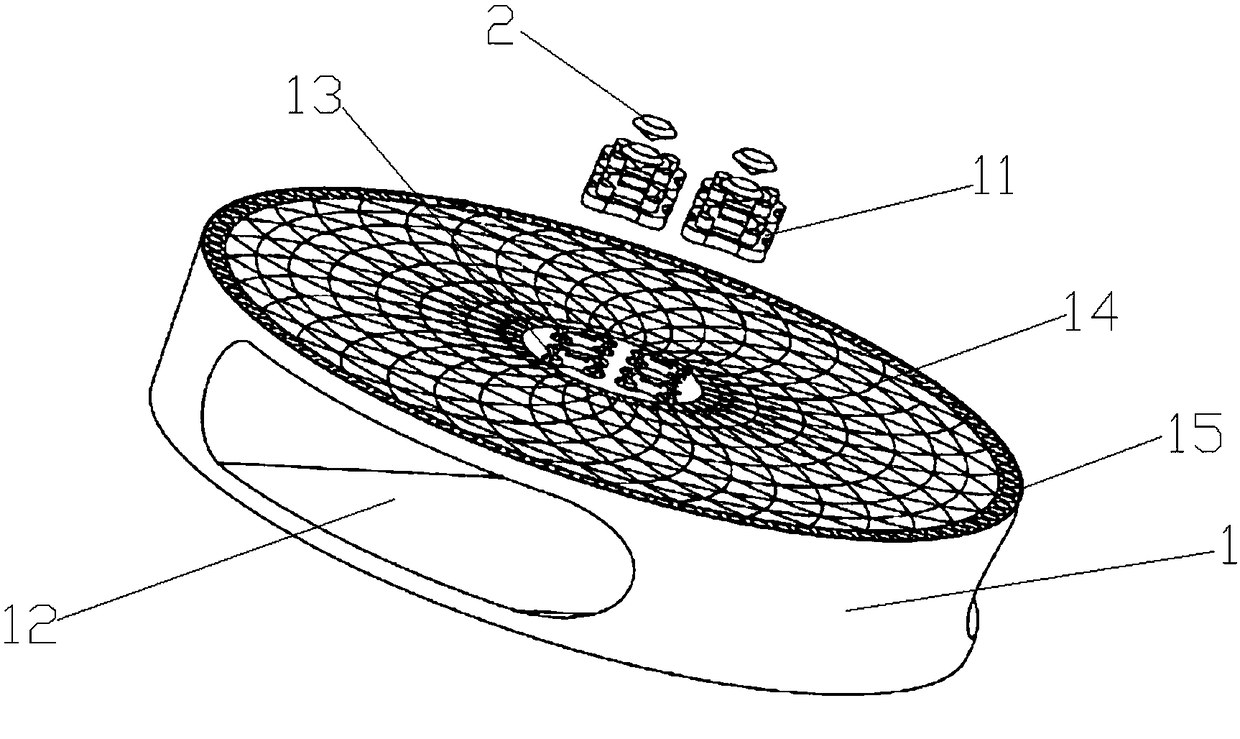

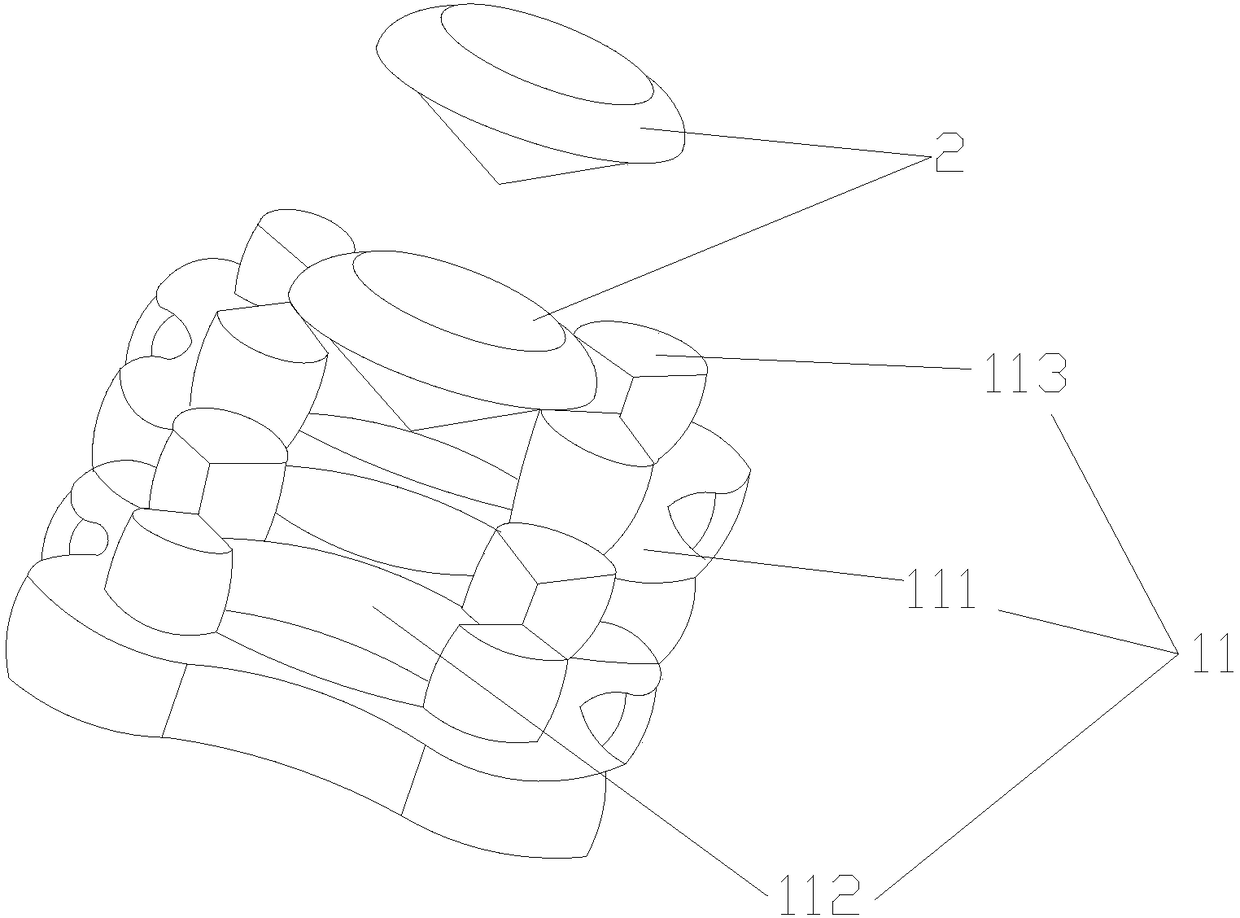

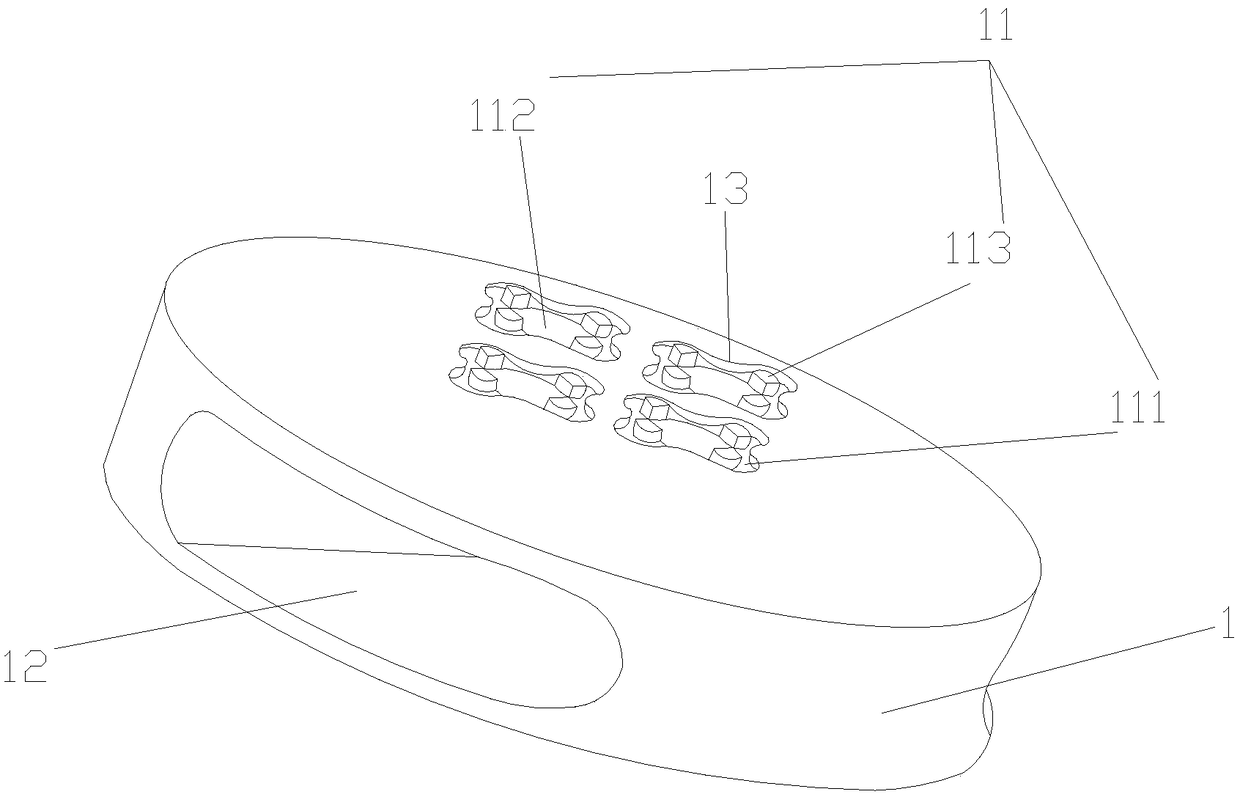

Forming mold and forming method of fiber reinforced composite material grid rib

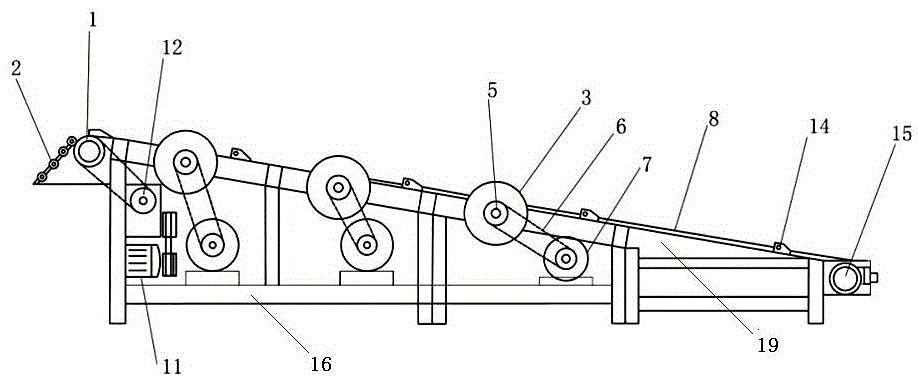

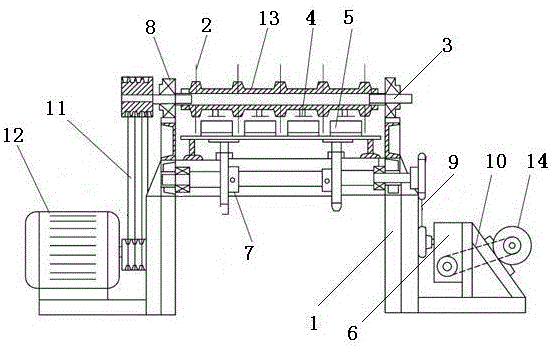

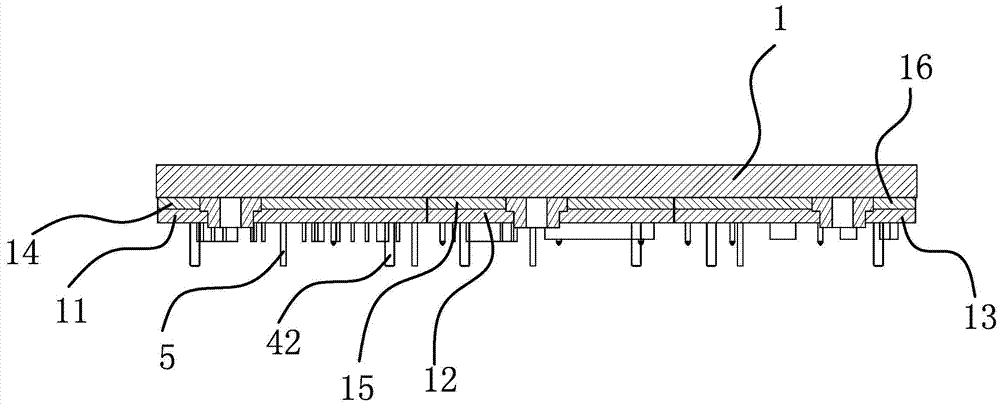

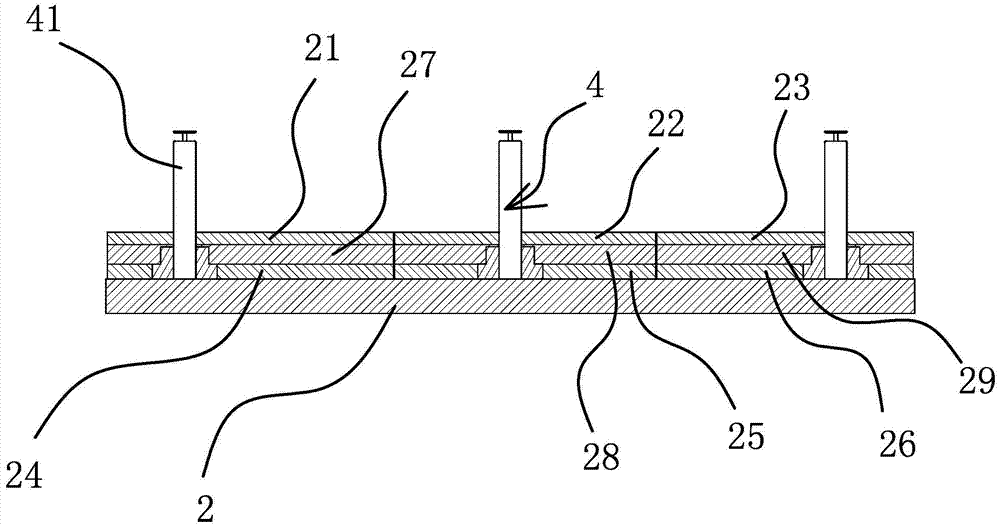

The invention discloses a forming mold and a forming method of a fiber reinforced composite material grid rib. The forming mold comprises a bottom mold, filling molds, compression strips and positioning clamps. The forming method comprises the steps of spreading fiber tows on the mold in longitude and latitude directions to form a fiber grid, and carrying out vacuumizing by virtue of a vacuum mold pressing technique so as to finish dipping and curing forming of the fiber grid. According to the forming mold and the forming method, the fiber reinforced composite material grid rib with any grid size can be fabricated according to the requirement, has a precise size and is stable in performance, and the machining process is environmentally friendly, is easy to handle and is suitable for industrial batch production.

Owner:SOUTHEAST UNIV +1

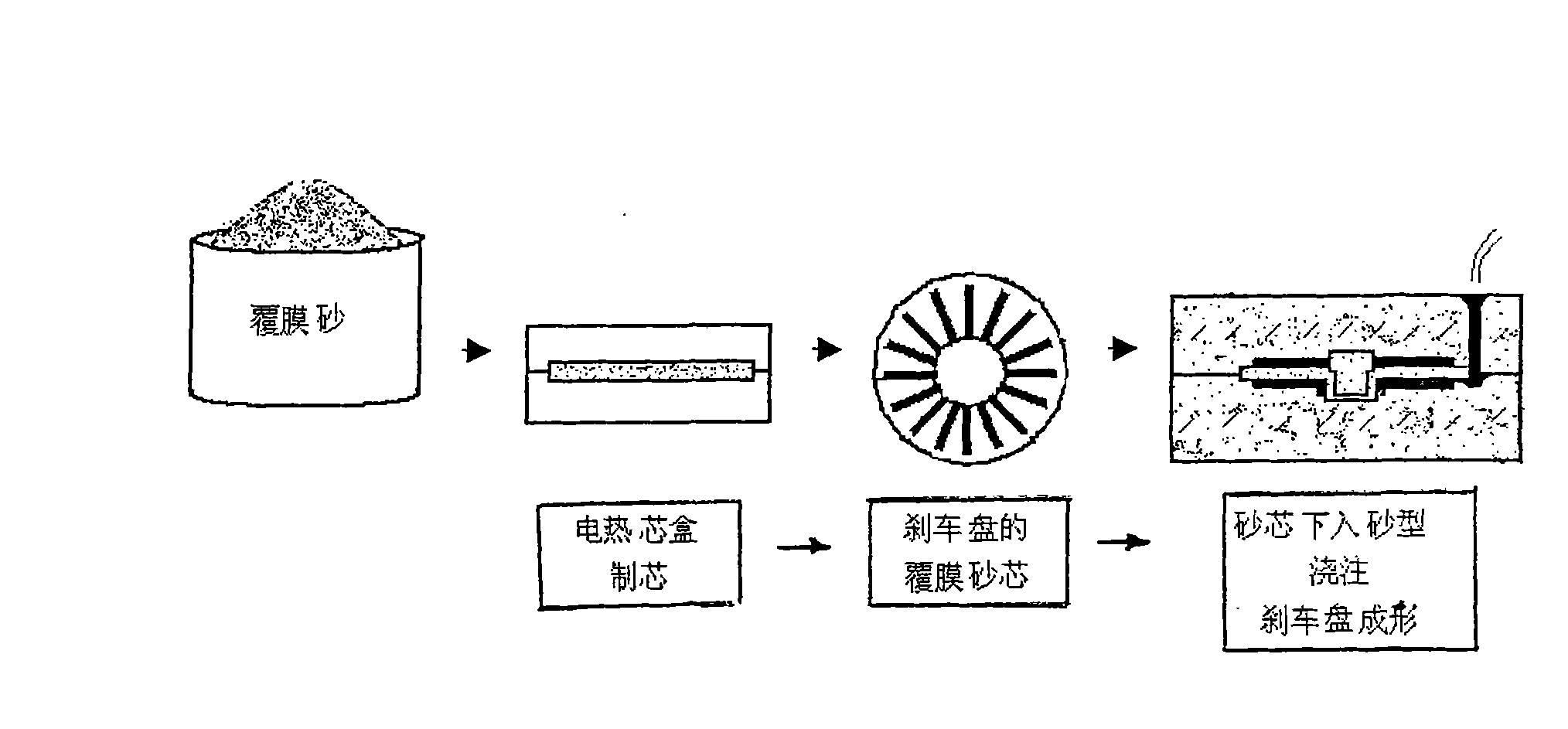

Production technology for casting brake disk air channel with pre-coated sand core method

InactiveCN102107261AGood adhesive effectPrecise sizeFoundry mouldsFoundry coresEnvironmentally friendlyElectric heating

The invention relates to a production technology for casting brake disk air channel with a pre-coated sand core method, which comprises the following steps: (1) buying a coating film; (2) mounting an electric heating core box on a core injection machine and closing the mould, and quantitatively putting the pre-coated sand in the electric heating core box, wherein the sand injection time of the core injection machine is 5-8 seconds, the electric heating curing temperature is 250-280 DEG C, and the heating curing time is 50-90 seconds; and curing the pre-coated sand in the electric heating core box to form the pre-coated sand core; (3) taking out the pre-coated sand core from the electric heating core box, trimming and checking for use; (4) pouring the pre-coated sand core in a sand mould, wherein the temperature of the molten iron is 1,430 DEG C, and the speed is 3 seconds; and forming a brake disk. The technical process is simple to operate, energy-saving and environmentally-friendly; and the produced product has reliable quality and high yield.

Owner:TIANJIN SHENGXINGXIANG MACHINERY MFG

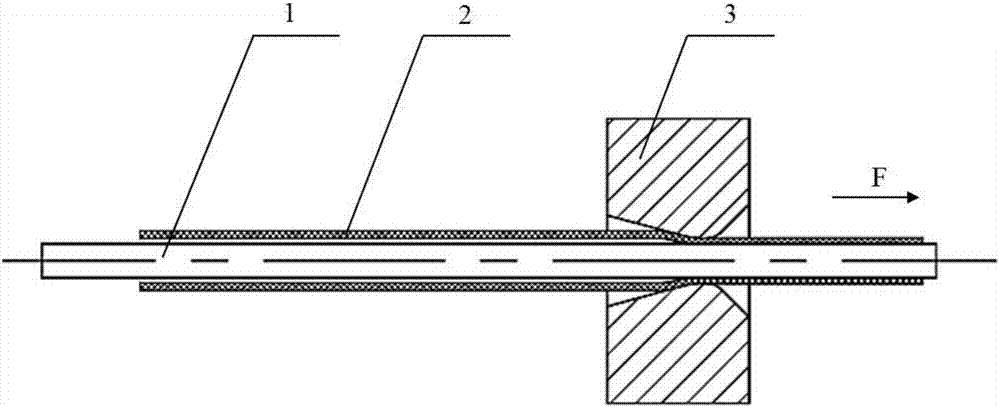

Magnesium alloy microcapillary and preparation method thereof

The invention discloses a magnesium alloy microcapillary and a preparation method thereof and belongs to the field of metal material precision machining. The method comprises the following steps that(1) a magnesium alloy blank is extruded to obtain a seamless extruded pipe blank; (2) the obtained seamless extruded pipe blank is subjected to stress relief annealing; and (3) the annealed seamless extruded pipe blank is subjected to multiple passes of drawing and intermediate annealing, and the magnesium alloy microcapillary is obtained. The magnesium alloy microcapillary prepared through the preparation method provided by the invention is good in surface quality, precise in size, uniform in wall thickness and excellent in mechanical property; the machining method is simple in process, low in cost, high in machining efficiency, and capable of performing large-scale production; and the magnesium alloy microcapillary can be used as a structural component to be applied to the fields of automobiles and electronics, and can also be used as a medical implant used for preparing an intravascular stent.

Owner:BEIJING UNIV OF TECH

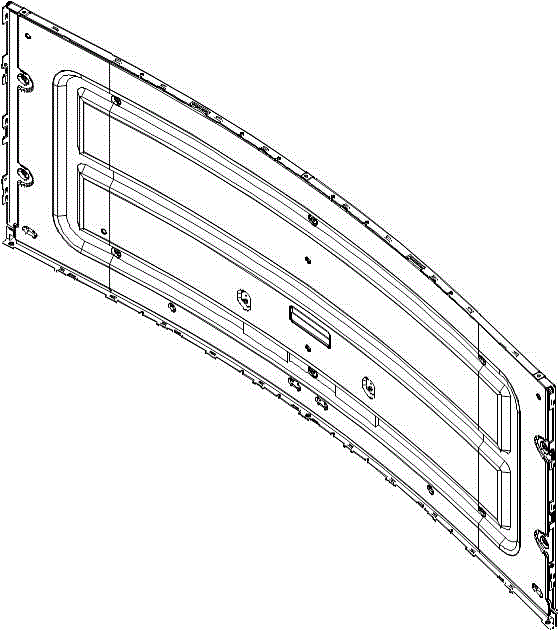

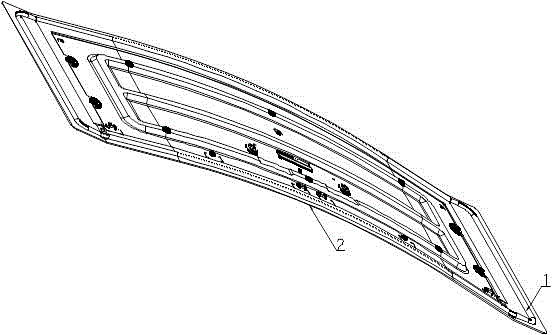

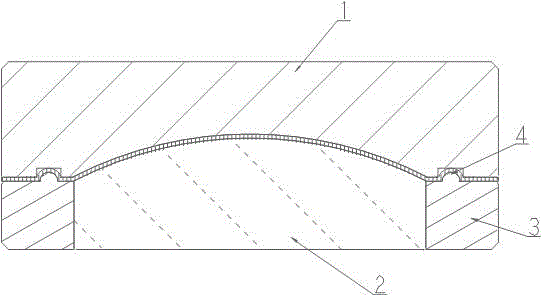

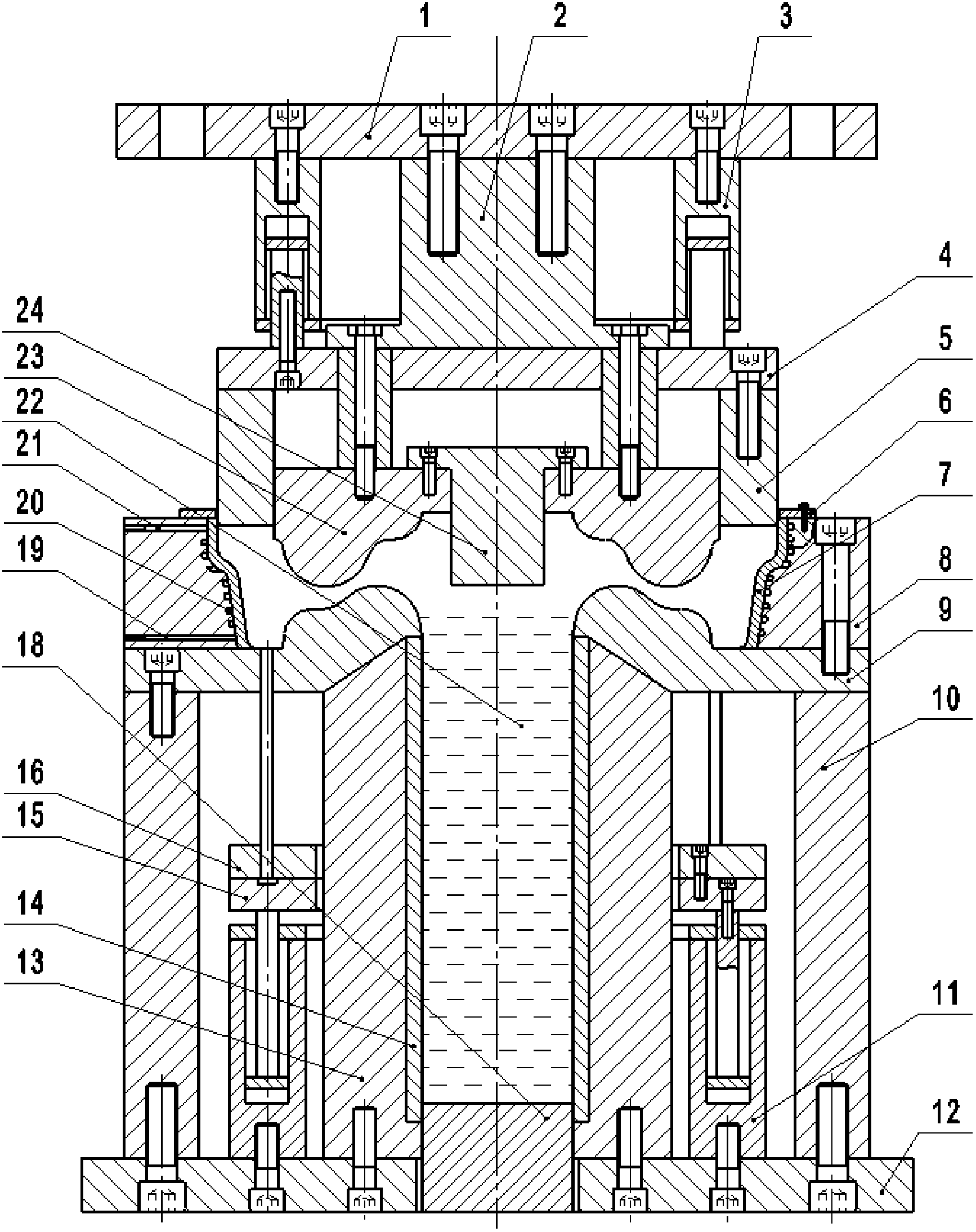

Curved-surface LED display backboard stamping die machining method

The invention relates to a curved-surface LED display backboard stamping die machining method. The method is characterized in that used raw materials are sheets, the sheets are formed into curved-surface sheet bodies on first project curved surfaces, and other subsequent processes such as trimming, convex hull shaping, clamp hook forming, hole stamping, engraving, burr pressing, little bending, engraving, sprouting and complete-cycle bending are all finished on the formed curved-surface sheet bodies. During curved-surface forming, a male die, a female die and a pressure plate are provided, the working surface is a curved surface, pressing ribs are arranged on the die pressure plate, stretching and curved-surface stabilization are facilitated, and accordingly production efficiency is increased, and waste is reduced.

Owner:JIANGSU FANRUN ELECTRONICS

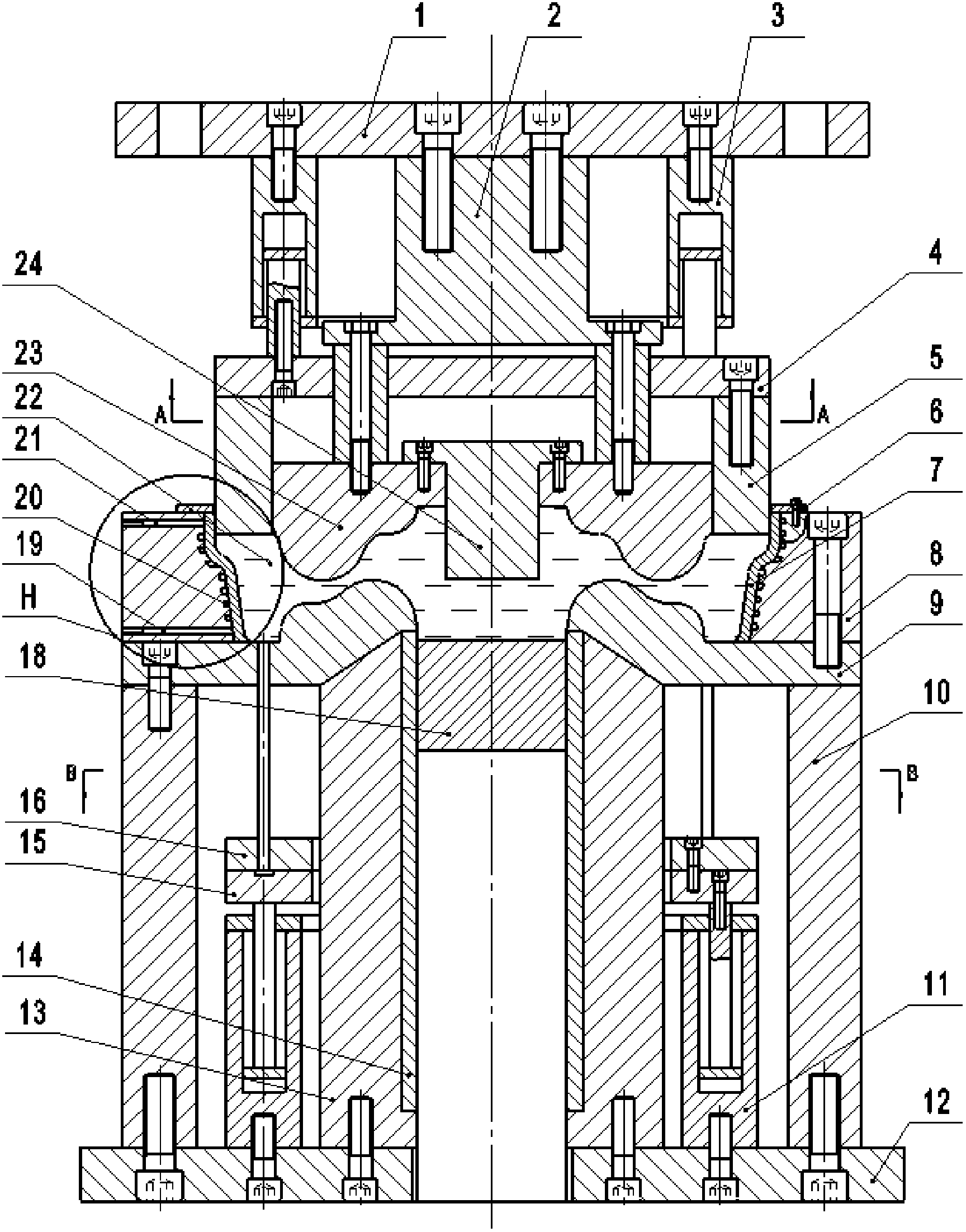

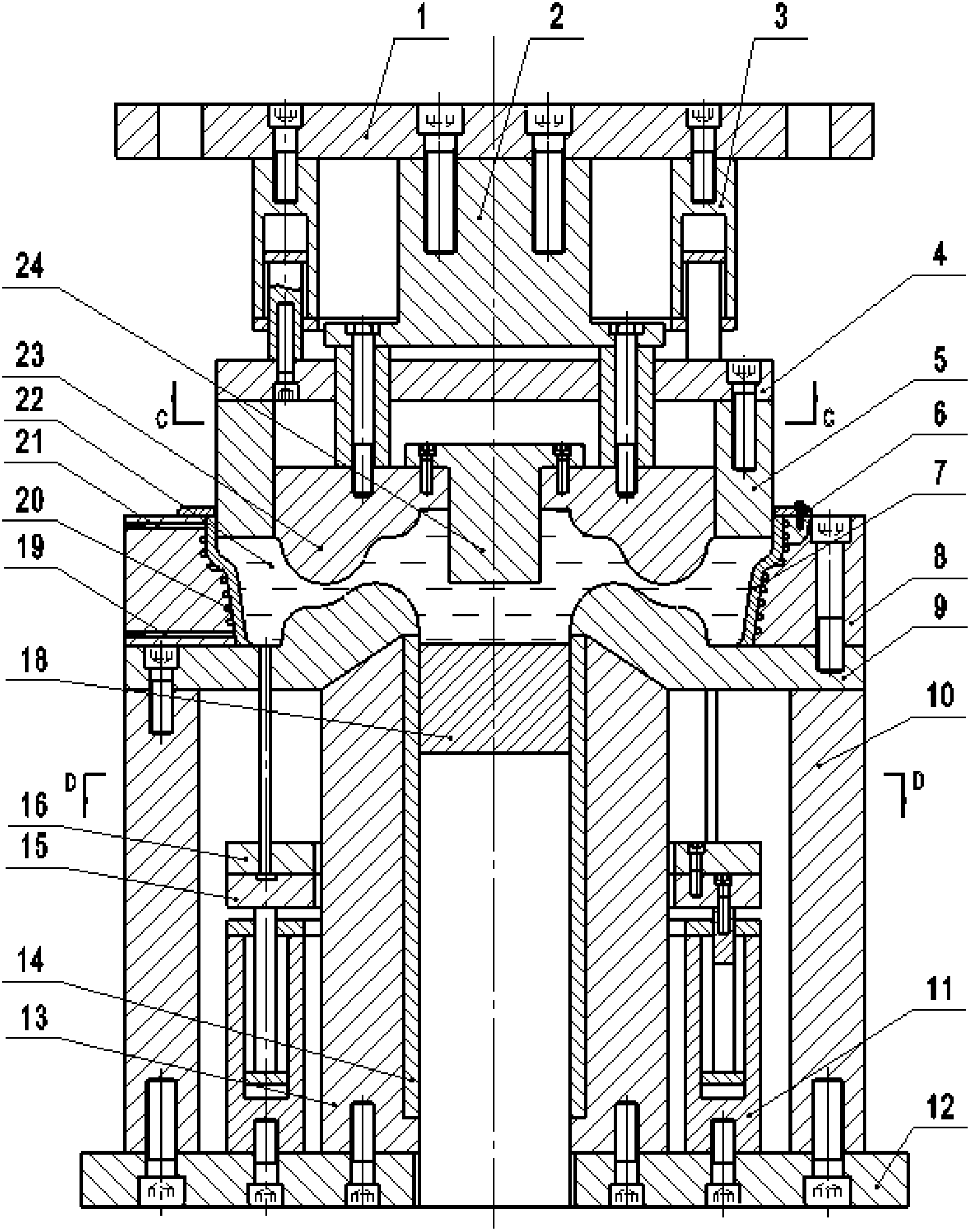

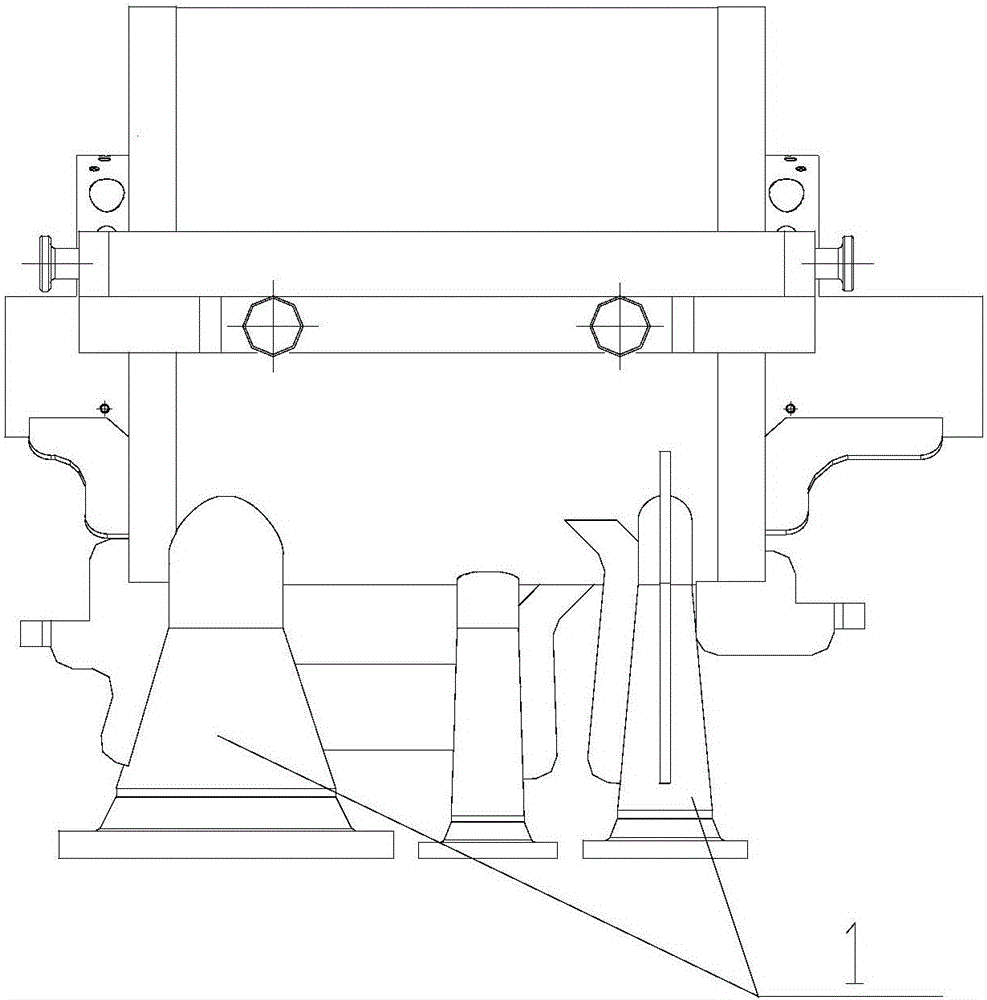

S-shaped spoke plate track wheel blank cast and casting method thereof

The invention relates to casting of an S-shaped spoke plate track wheel blank, in particular to an S-shaped spoke plate track wheel blank cast and a casting method thereof. By the high-quality S-shaped spoke plate track wheel blank cast and the casting method thereof, a sand mould and a dead head is unneeded for casting. The cast comprises two independently moving pressing heads including a rim pressing head and a lower pressing head, and the rim pressing head belongs to a top mould and is capable of moving vertically relative to a spoke plate top mould and a shaft hole core. Wheel molten steel achieves mould filling under the action of the lower pressing head and then is subjected to feeding, plastic deformation and solidification at the positions of a hub and a rim under the high pressure action of the lower pressing head and the rim pressing head respectively, and other portions of a wheel are solidified under the pressure. A lower mould liner is mounted on the inner surface of a lower mould sleeve, a cooling duct is arranged on the boundary, and circulating cooling liquid is fed for forced cooling when a tread is solidified, so that tread structure is refined. An interior liner is mounted on a central hole step of a pressing chamber wall so as to protect the pressing chamber wall. The obtained wheel is compact in structure, and process yield can reach 90%.

Owner:BEIJING JIAOTONG UNIV

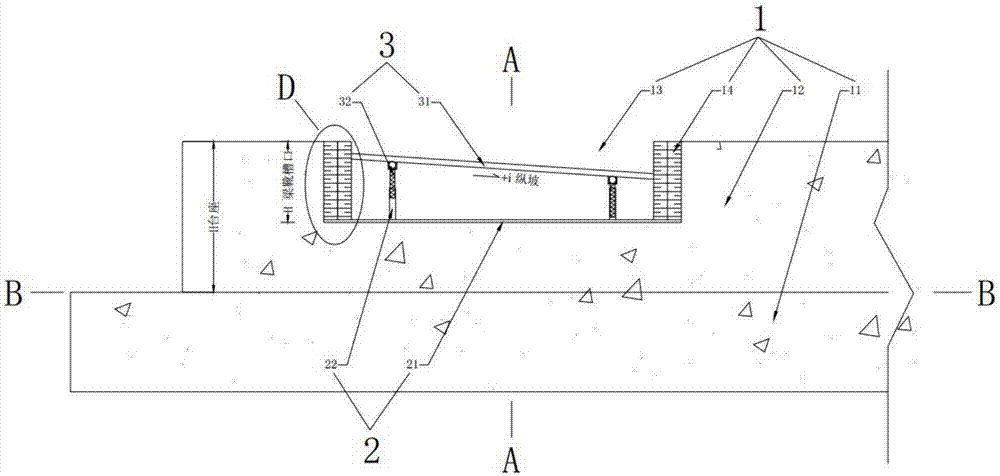

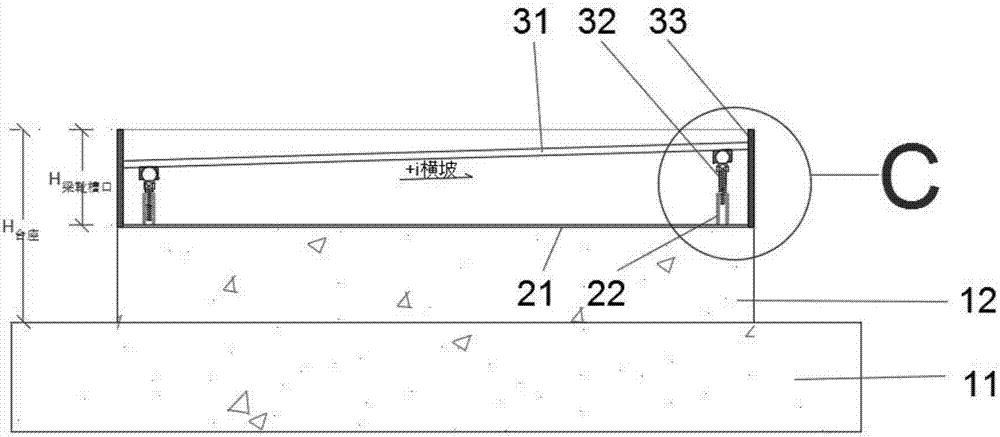

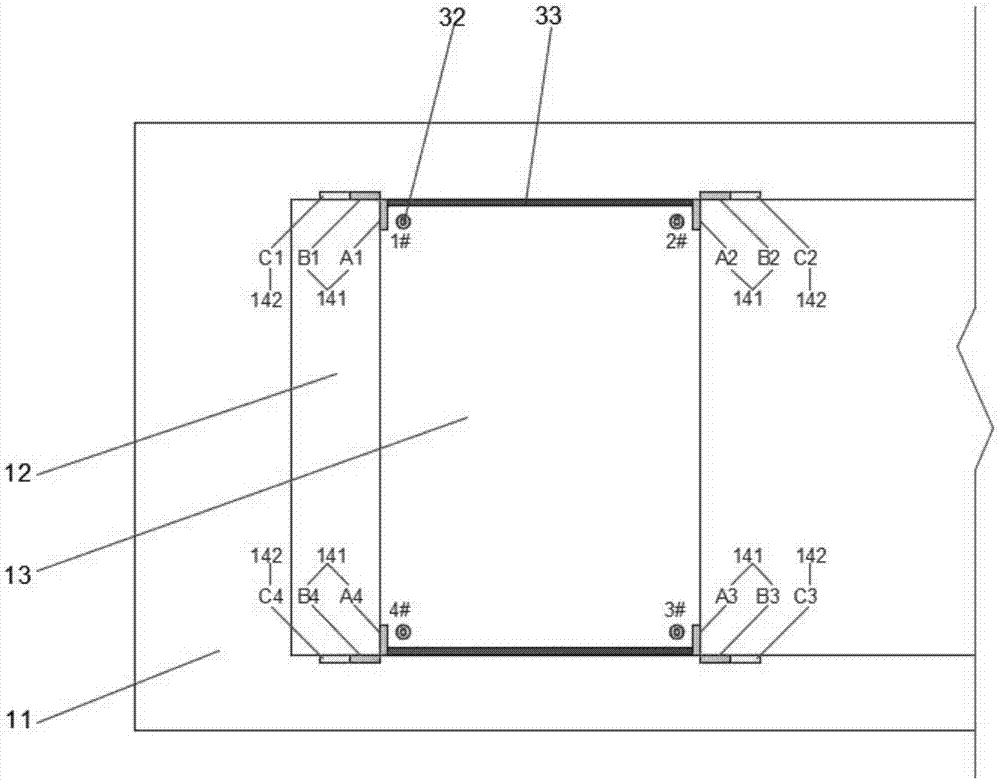

Prefabrication device and prefabrication method of prefabricated beam shoe

InactiveCN107310025AEasy to adjustPrecise sizeMould separation apparatusBridge structural detailsHead jointsPrefabrication

The invention provides a prefabrication device and prefabrication method of a prefabricated beam shoe. The method is achieved through the device which is characterized in that ball head joint bearing screws welded at the four corners of the bottom surface of a steel template are connected with internal thread sleeves fixed to the bottom of a beam shoe embedding groove of a box beam prefabrication pedestal; and the ball head joint bearings can incline by any angle in all directions, so that when the ball head joint bearing screws at the four corners extend and retract up and down, the steel template and the top surface of the pedestal can be driven to form vertical and horizontal gradients and sizes which meet the requirement of the beam shoe. According to the device, manufacturing and mounting can be carried out at the same time during pedestal construction, the device is applicable to the beam shoes with different vertical and horizontal gradient and size requirements during box beam prefabrication, an adjustment method is convenient to implement, and the size is reliable.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

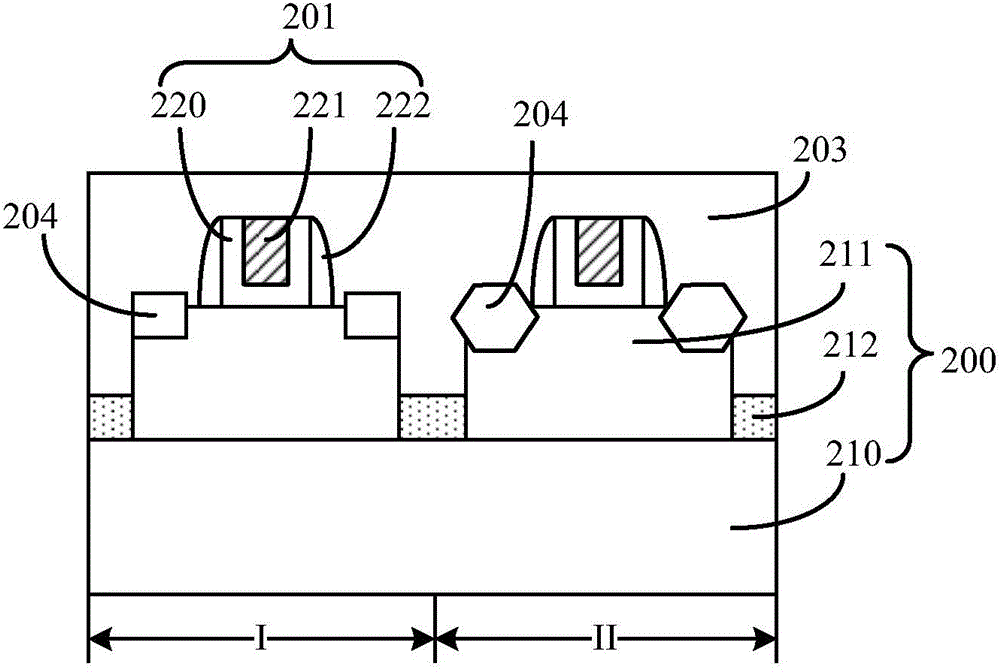

Method for forming semiconductor device

ActiveCN104979201APrecise sizeGood lookingSemiconductor/solid-state device manufacturingPower semiconductor deviceSemiconductor device modeling

A method for forming a semiconductor device comprises a step of providing a substrate whose surface has gate structures, wherein two sides of each gate structure has an interconnection region respectively, portions, in the interconnection regions, of the substrate have source regions and drain regions positioned at two sides of the corresponding gate structure respectively, and surfaces of the substrate and the gate structures have a first dielectric layer; a step of forming a barrier layer on the surface of the first dielectric layer, wherein the material of the barrier layer is different from that of the first dielectric layer, and the pattern of the barrier layer at least penetrates one interconnection region; a step of forming a first patterned layer with a first opening on the first dielectric layer and the surface of the barrier layer, wherein the first opening exposes the positions of the interconnection regions; a step of taking the first patterned layer and the barrier layer as mask layers, and etching the first dielectric layer until the surface of the substrate in the interconnection regions is exposed, so as to form source-drain grooves; a step of forming gate through holes in the first dielectric layer for exposing tops of the gate structures; and a step of forming source-drain conductive structures in the source-drain grooves and forming gate plugs in the gate through holes. The formed semiconductor device is good in appearance and has improved performances.

Owner:SEMICON MFG INT (SHANGHAI) CORP

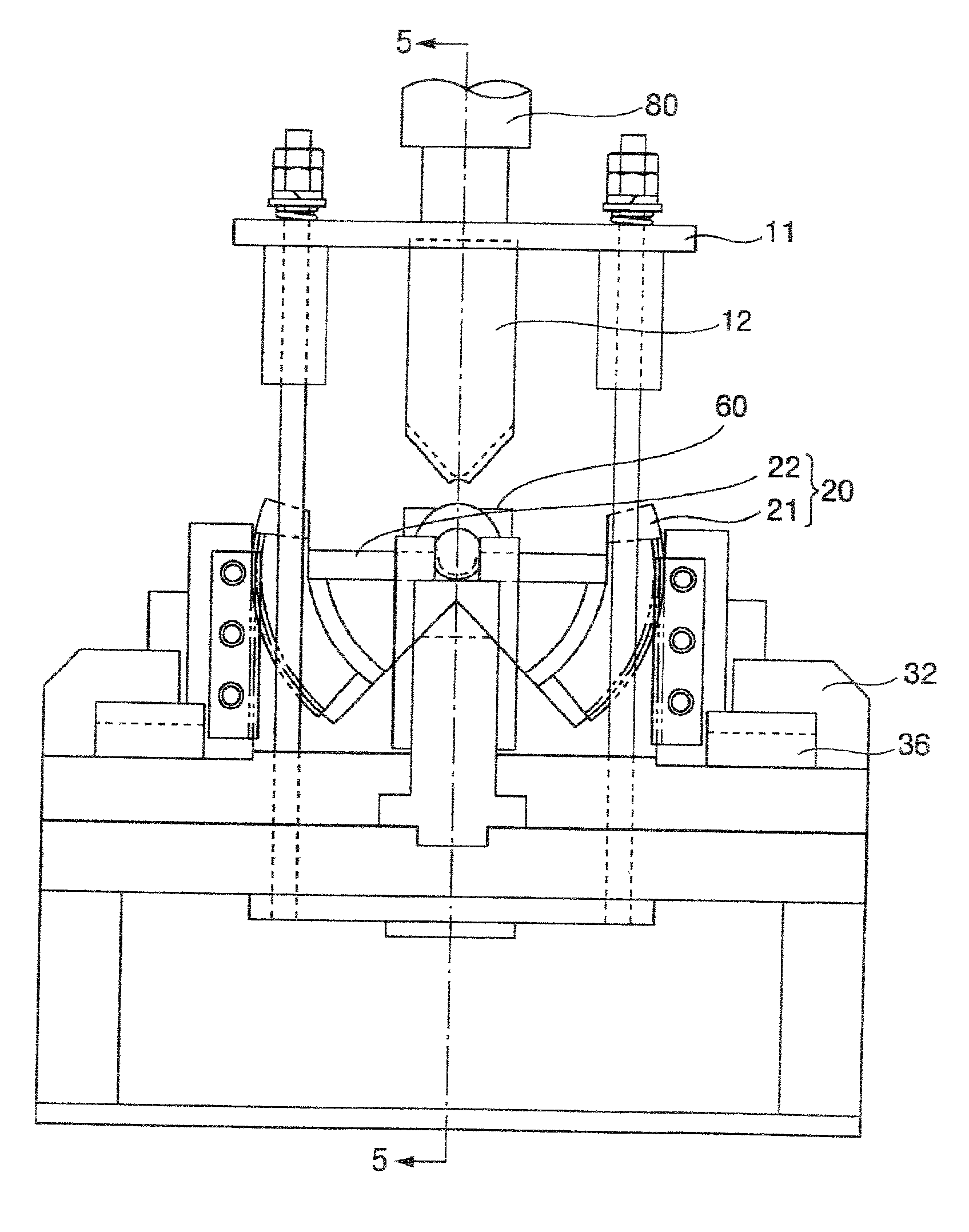

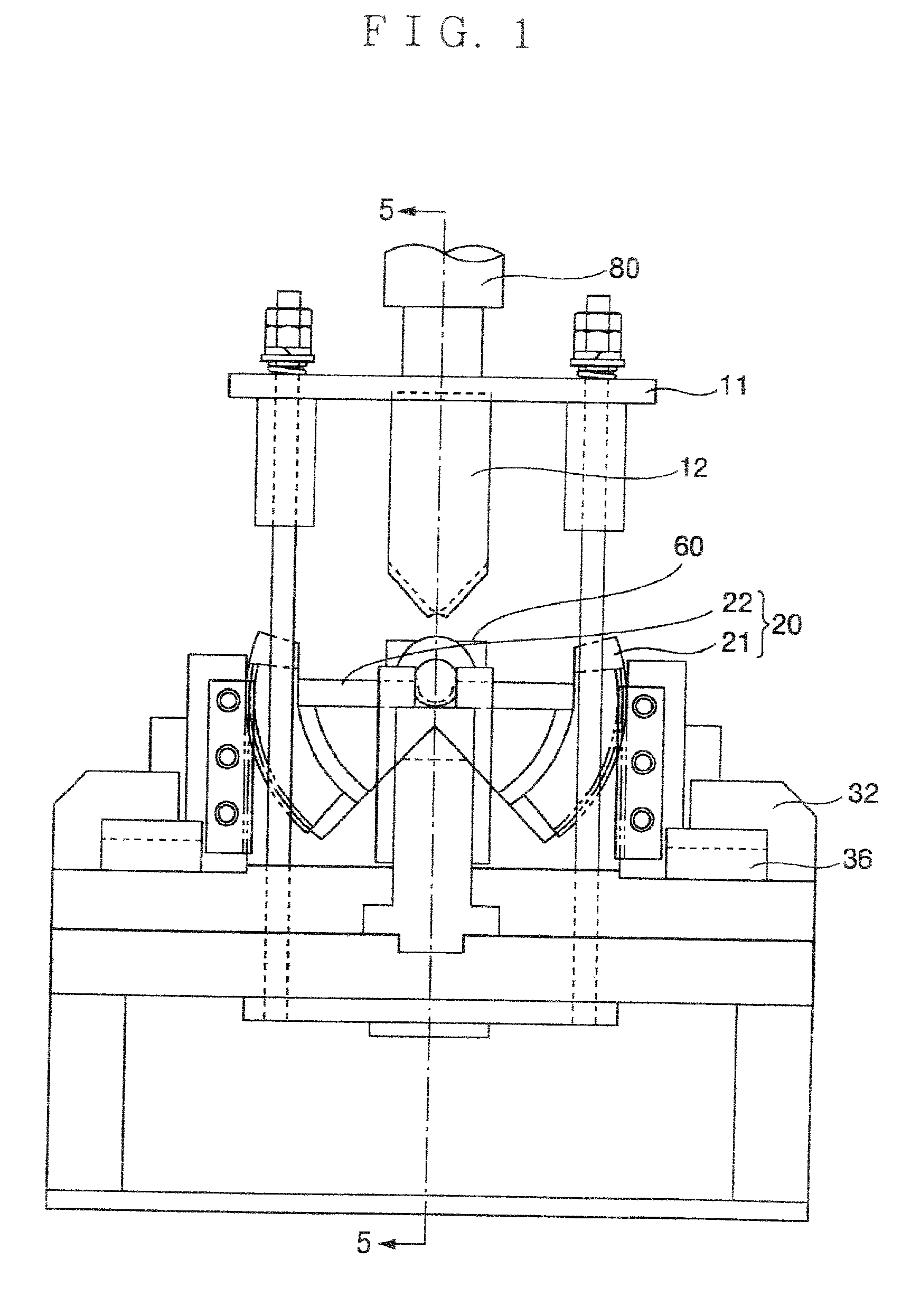

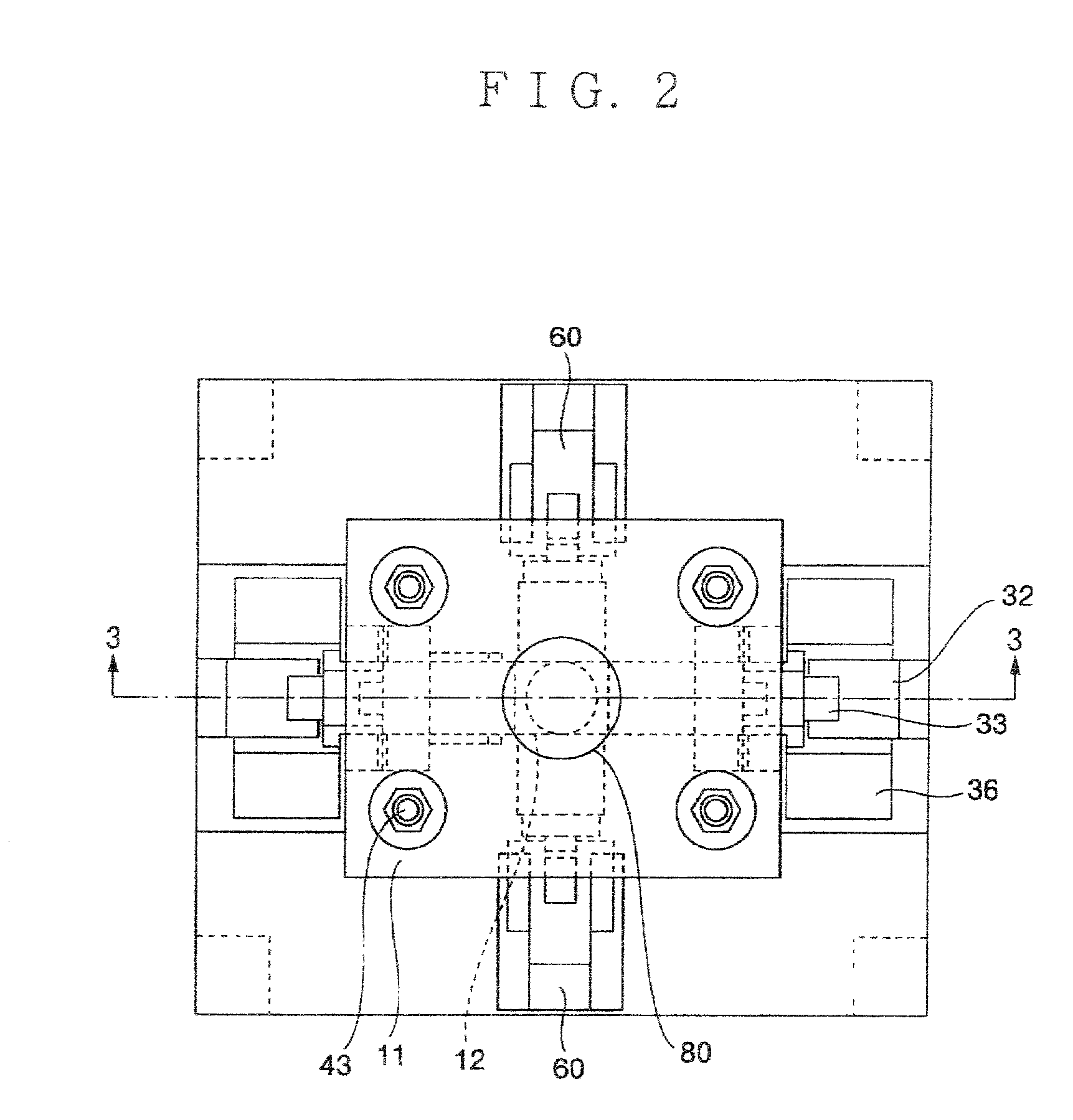

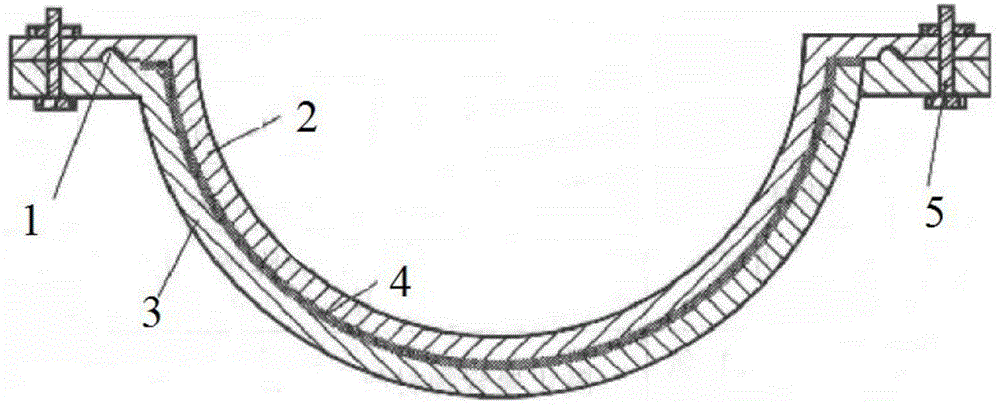

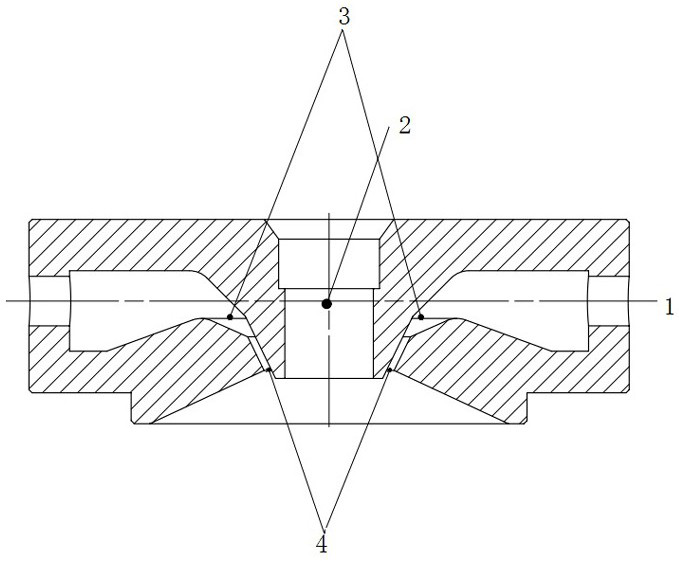

Apparatus and method for manufacturing thick-walled bent pipe

InactiveUS20020129636A1Precise sizeSimple structureFluid pressure measurement using elastically-deformable gaugesStatic/dynamic balance measurementManufacturing engineeringManufactured apparatus

An apparatus and a method for manufacturing a thick-walled bent pipe with a simple structure at low production cost, which has durability and can manufacture an elbow material for piping with higher size accuracy, are provided. For this purpose, the manufacturing apparatus is a manufacturing apparatus comprising a presser die (12) and a lower die (20), in which the lower die (20) includes a pair of bottom dies (21, 22) having meshing means (30), and a pair of the bottom dies (21, 22) are allowed to rotate opposite to each other by the meshing means (30), in connection with a descent of the presser die.

Owner:TOKIWA SEIKI

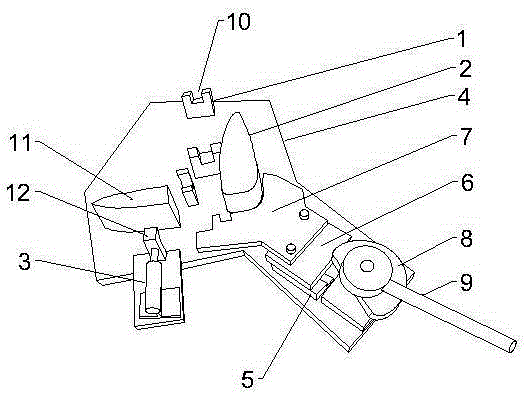

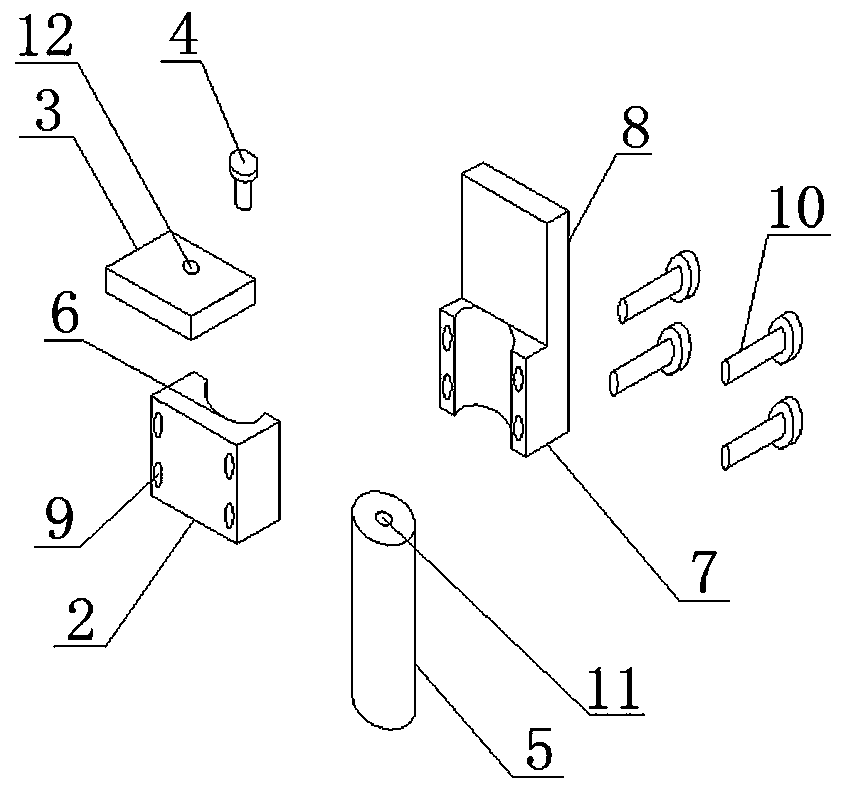

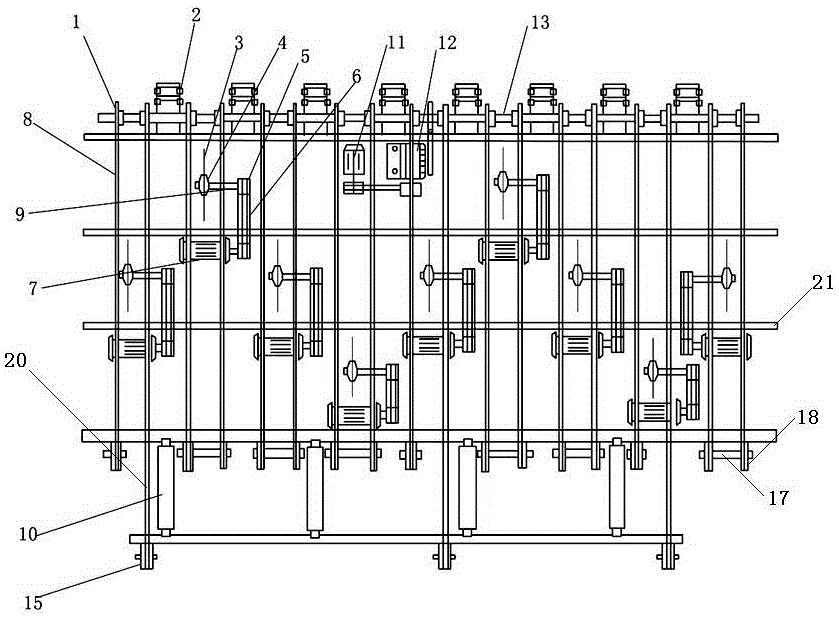

Welding clamp for aviation chair handrail

ActiveCN105290673AGood welding effectPrecise sizeWelding/cutting auxillary devicesAuxillary welding devicesHandrailEngineering

The invention provides a welding clamp for aviation chair handrail. The welding clamp for aviation chair handrail comprises a supporting block and a limiting block. One end of a base extends to form a pressing seat, a sliding groove is formed in the top of the pressing seat, and a sliding seat is movably assembled on the sliding groove. A pressing block is arranged at one end of the top of the sliding seat, a cam disc is arranged on the pressing seat at the other end of the sliding seat, and a control handle is arranged on the cam disc. The base is provided with the limiting block matched with the pressing block, the supporting block is arranged on one side of the limiting block, and a U-shaped clamping groove is formed in the top of the supporting block. A positioning block is arranged on one side of the supporting block, press pincers are arranged on one side of the positioning block, a pressing plate is arranged on a telescopic rod of the press pincers and provided with an inwards concaved arc surface, and the arc surface is located on one side of the positioning block. After the scheme is adopted, manual positioning is not needed, the welding effect is good, the size is accurate, a skewing phenomenon is avoided, the labor intensity of workers is greatly relieved, and the quality of products is improved.

Owner:HUZHOU MEISHENG MACHINERY

Method for casting large-scale bucket tooth casting by using lost foam

InactiveCN104874731AReduce manufacturing costPrecise sizeFoundry mouldsFoundry coresFinenessHigh surface

The invention discloses a method for casting a large-scale bucket tooth casting by using a lost foam. The method can be used for producing the large-scale bucket tooth with the weight greater than 90Kg. EPS bead granule pre-frothing is used for moulding, and a coating with the thickness of 1.6-2.4mm is applied, and then the casting mould is dried for 16h. A sink head is designed as an open sink head during box burying; modeling sand fully placed after an upper end is horizontal and is compacted through vibration. A blank lost foam pattern is roasted to obtain a model empty-shell after a vacuum pump is turned on; finally molten steel enters the casting from a casting system, and negative pressure stops after lasting for 15 minutes. The obtained casting has the beneficial effects of high surface fineness, high technological yield, and low cost; the method allows industrialization popularization and can bring huge economic benefit.

Owner:TIANJIN WILL LONG SCI &TECH CO LTD

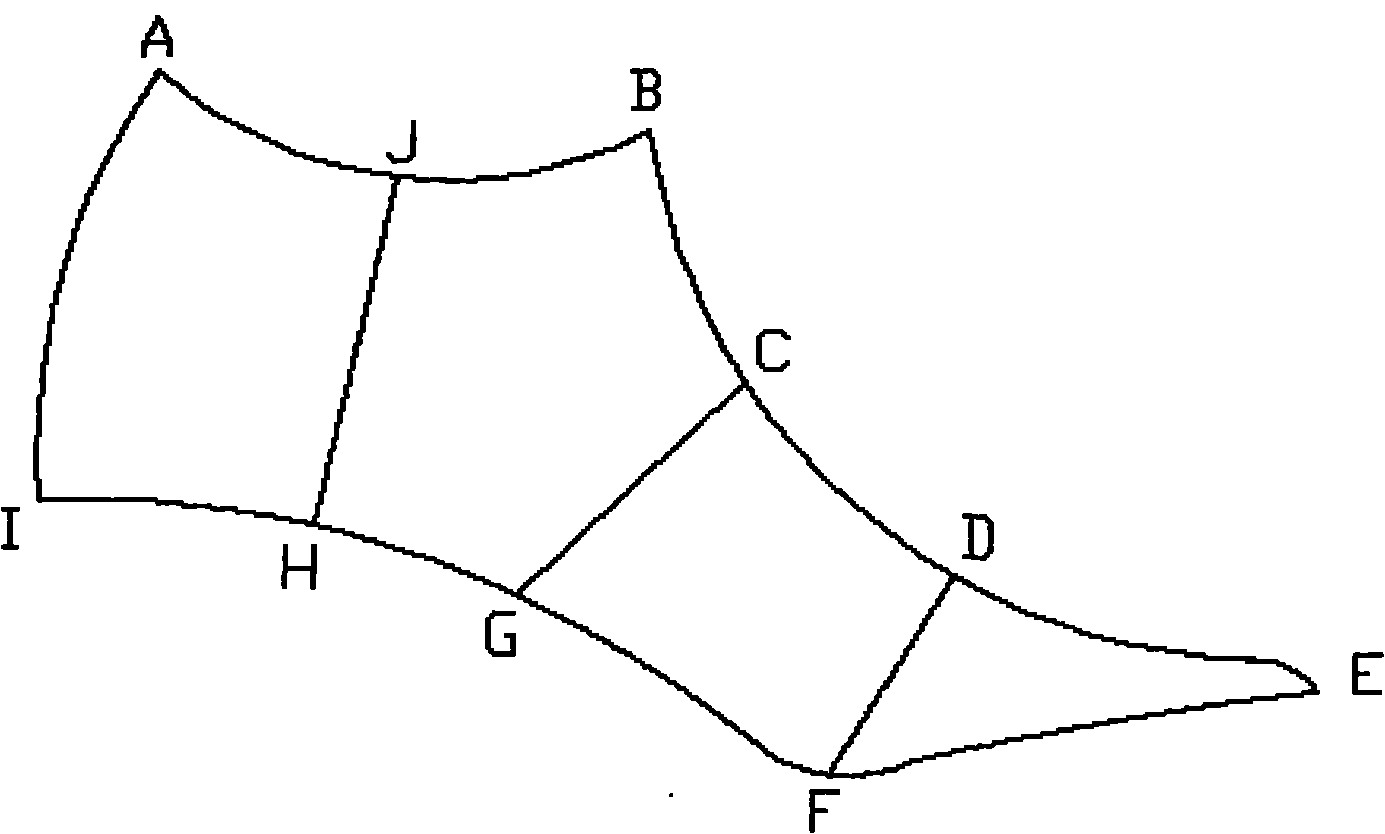

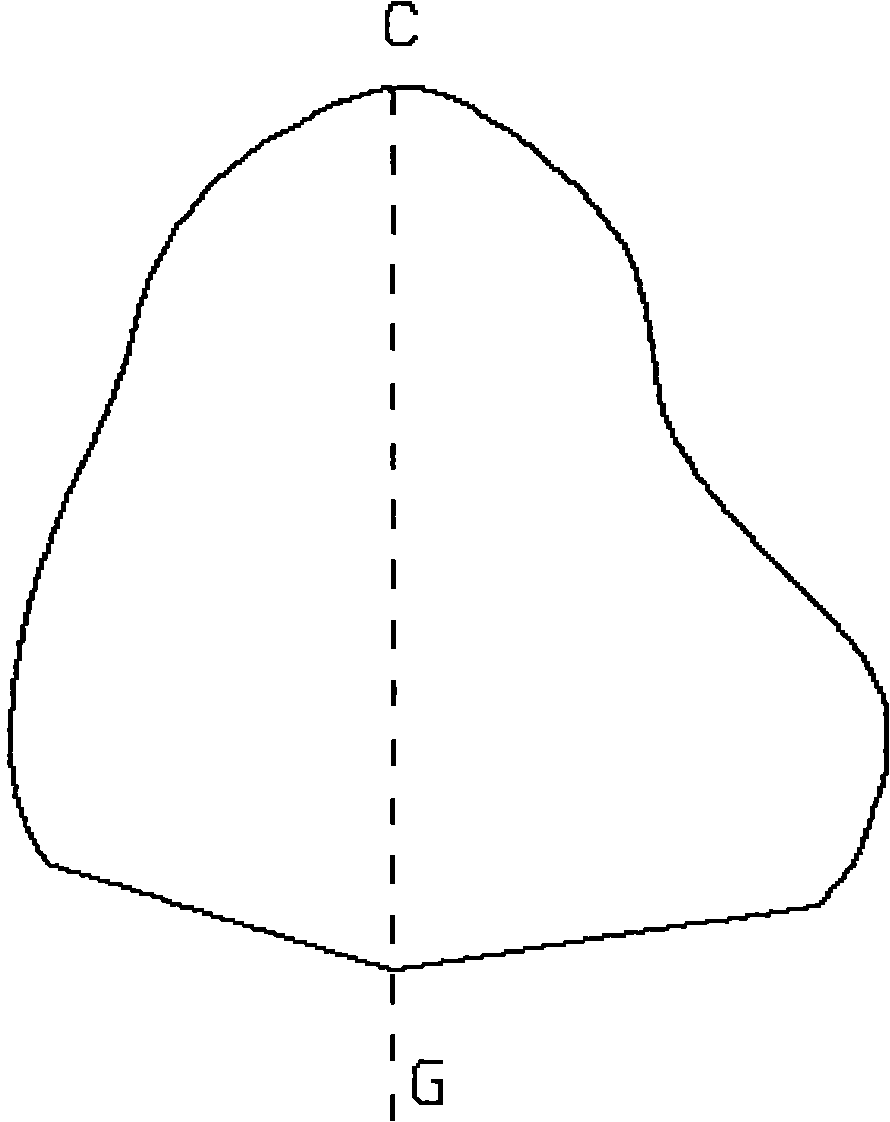

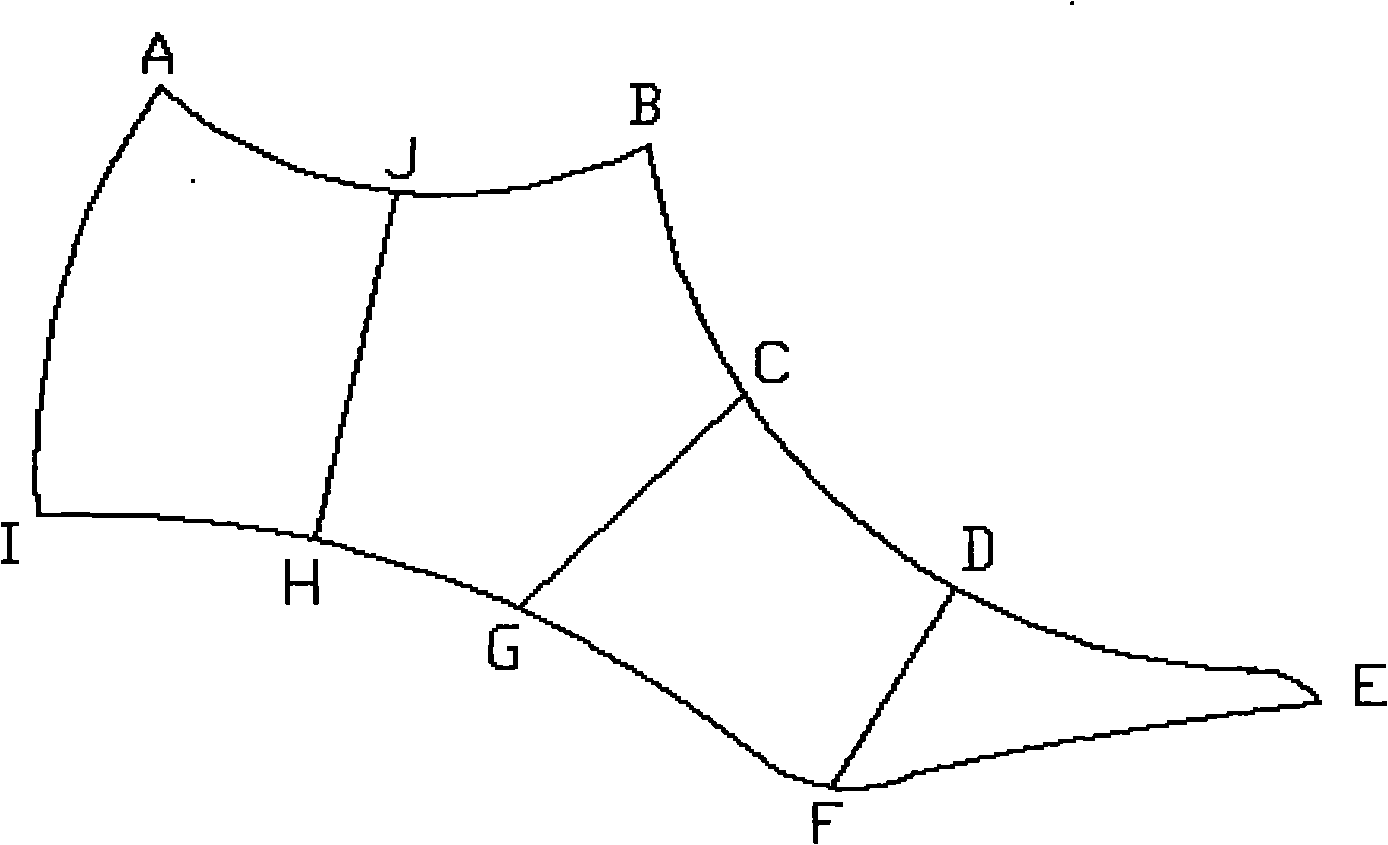

Digital standard sample last

The invention provides a digital standard sample last, wherein an entire last, a vertical section last and a cross section last are provided with digital standard samples; and the digital standard sample consists of a length of the last, a circumference of the last, a width of the last, and a size of the last body. The length of the last includes the length of a last bottom sample, a margin, positions of toes end points, the position of convex points of the thumb, the position of the convex points of the little finger, the position of the first metatarsophalangeal, the position of the fifth metatarsophalangeal, the position of the flank, the position of the heel center, and a rear tolerance. The circumference of the last includes: a metatarsophalangeal circumference, an instep circumference, a blanket circumference and a flank circumference; the width of the last includes a basic width, an inner width of the thumb, an outer width of the little finger, the inner width of the first metatarsophalangeal, the outer width of the fifth metatarsophalangeal, the outer width of the flank and a full width of the heel center; and the size of the last body includes the height of tiptoe, the thickness of head part, the height of the convex points of the heel, the height of the rear body, a protruding degree of the front palm, a concave degree of arch, the width of a last top, the length of the last top, and the inclined length of the last. The digital standard sample last is provided to designers of shoes by a convenient and rapid using method, so that the time of designing master lasts, upper samples and soles are saved and the designing process is simplified.

Owner:温州市鹿艺鞋材有限公司

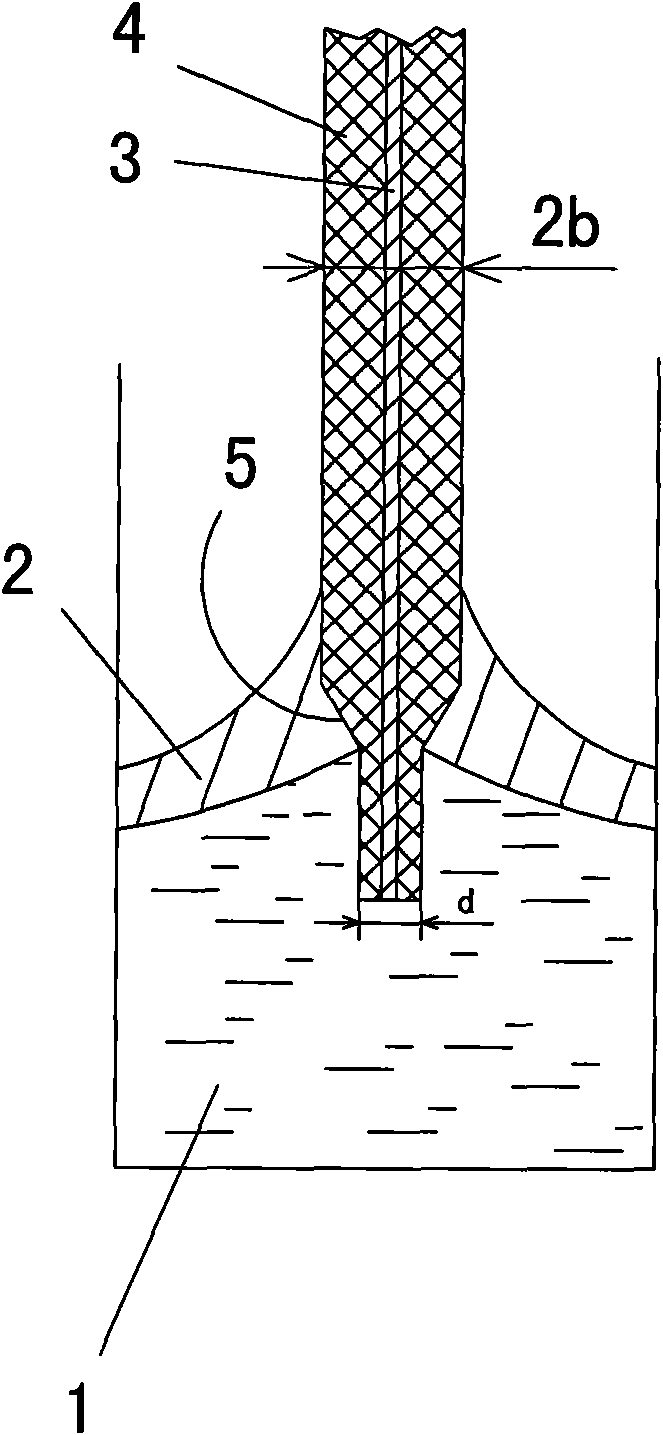

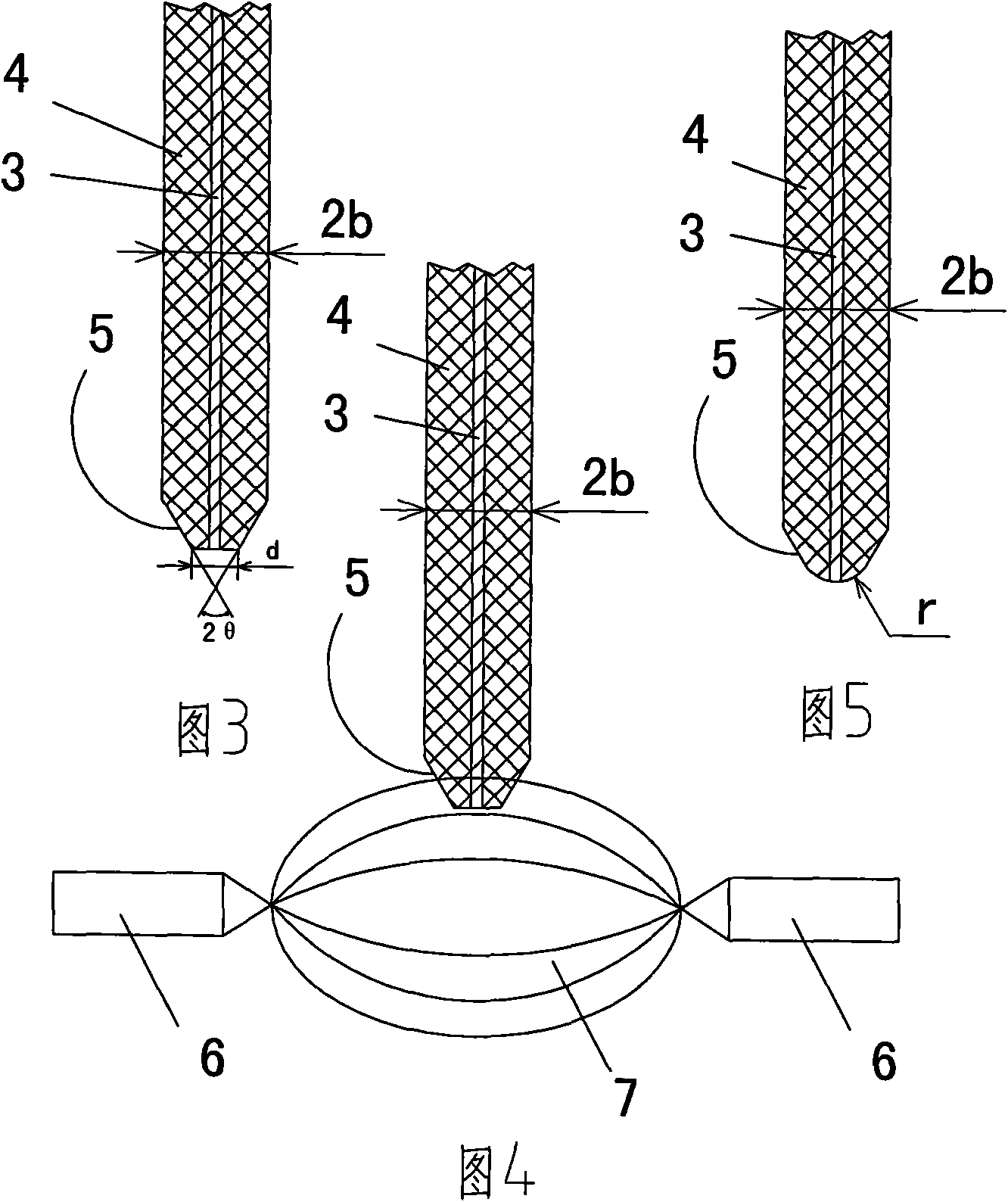

Method for making optical fiber spherical-surface micro lens in three steps of corrosion, cutting and hot melting

The invention relates to a method for making an optical fiber spherical-surface micro lens in three steps of corrosion, cutting and hot melting, which comprises the following steps of: (1) corrosion: corroding the end parts of an optical fiber by using acid liquor to diminish the diameters of outer layers on the end parts of the optical fiber and forming a conical surface transition shape at a non-corrosion part; (2) flat end surface cutting: cutting off small-diameter parts formed on the end parts of the optical fiber so that the ends of the optical fiber is of a regular circular truncated cone shape after the cutting; and (3) formation of the optical fiber spherical-surface micro lens by utilizing electrodes for hot melting on the ends of the optical fiber, wherein the corrosion time in the step (1) is the ratio of the difference of the radius b of the covered outer side of the non-corroded optical fiber and the curvature radius of the optical fiber spherical-surface micro lens formed in the step (3) to the corroding speed v of the optical fiber. Compared with the prior art, the method has the advantages of convenience, accurate size and artificial control on the curvature radius of the spherical-surface micro lens.

Owner:大连艾科科技开发有限公司

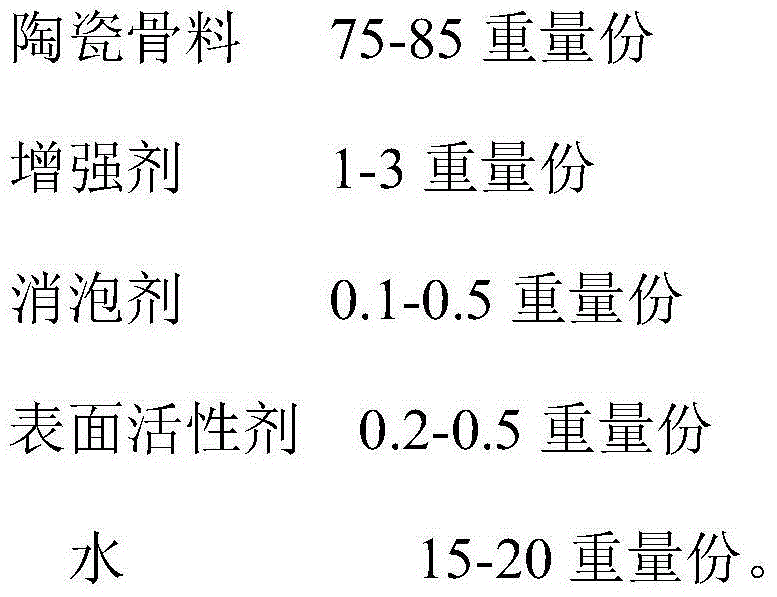

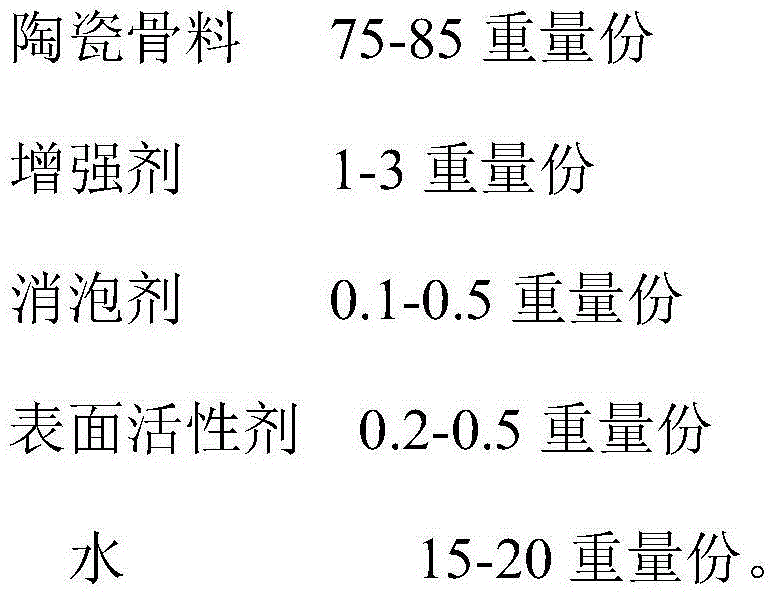

Ceramic mould for carbon fiber reinforcement resin matrix composite forming and preparation method thereof

The invention discloses a ceramic mould for carbon fiber reinforcement resin matrix composite forming and a preparation method thereof. Compared with the prior art, the ceramic mould for carbon fiber reinforcement resin matrix composite forming and the preparation method thereof have the advantages that the ceramic mould can be used in all carbon fiber composite forming technology except mould pressing, the mould preparation technology is simple, direct forming can be achieved, many times of mould turning is avoided, and the size is more accurate; ceramic materials of a special structure are adopted, reinforcing fiber materials are added, and compared with common mould materials such as metal and glass fiber reinforcement plastic, the advantages of being good in flame retardant property, low in thermal expansion coefficient, resistant to high temperature, chemical corrosion and wear, high in strength and hardness, long in usage period, low in cost and the like are achieved; high-quality enamel layers are adopted so that the surface glossiness is high, the product aftertreatment process is reduced, and the production efficiency is improved.

Owner:WUHU HONGMA NEW MATERIAL

Composite material for making baffle at bottom of automobile

The invention relates to a composite material which is used to manufacture automobile bottom deflectors; the composite material consists of UP resin P171-903B, flexible resin P193-01, fiber glass, low profile additive H814-902, styrene, BYK996, 501 anti-oxidant, heavy calcium carbonate, PBTB, MgO, conductive carbon black powder, Al(OH)3 and zinc stearate. The density of the prepared automobile bottom deflector is 1.8, which meets the light-weighted trend of the prior automobile; the deflector plays the roles of buffering and protecting the passenger carriage; meanwhile, the strength-to-weight ratio (the ratio of ultimate tensile strength to density) is higher than that of metal; the corrosion resistance in adverse environment is excellent, the bottom deflector is located at the car bottom; the size is precise, the stability is stable and good strength is kept in a wide temperature range; the inflaming retarding and aging resistance are excellent.

Owner:上海耀华大中新材料有限公司

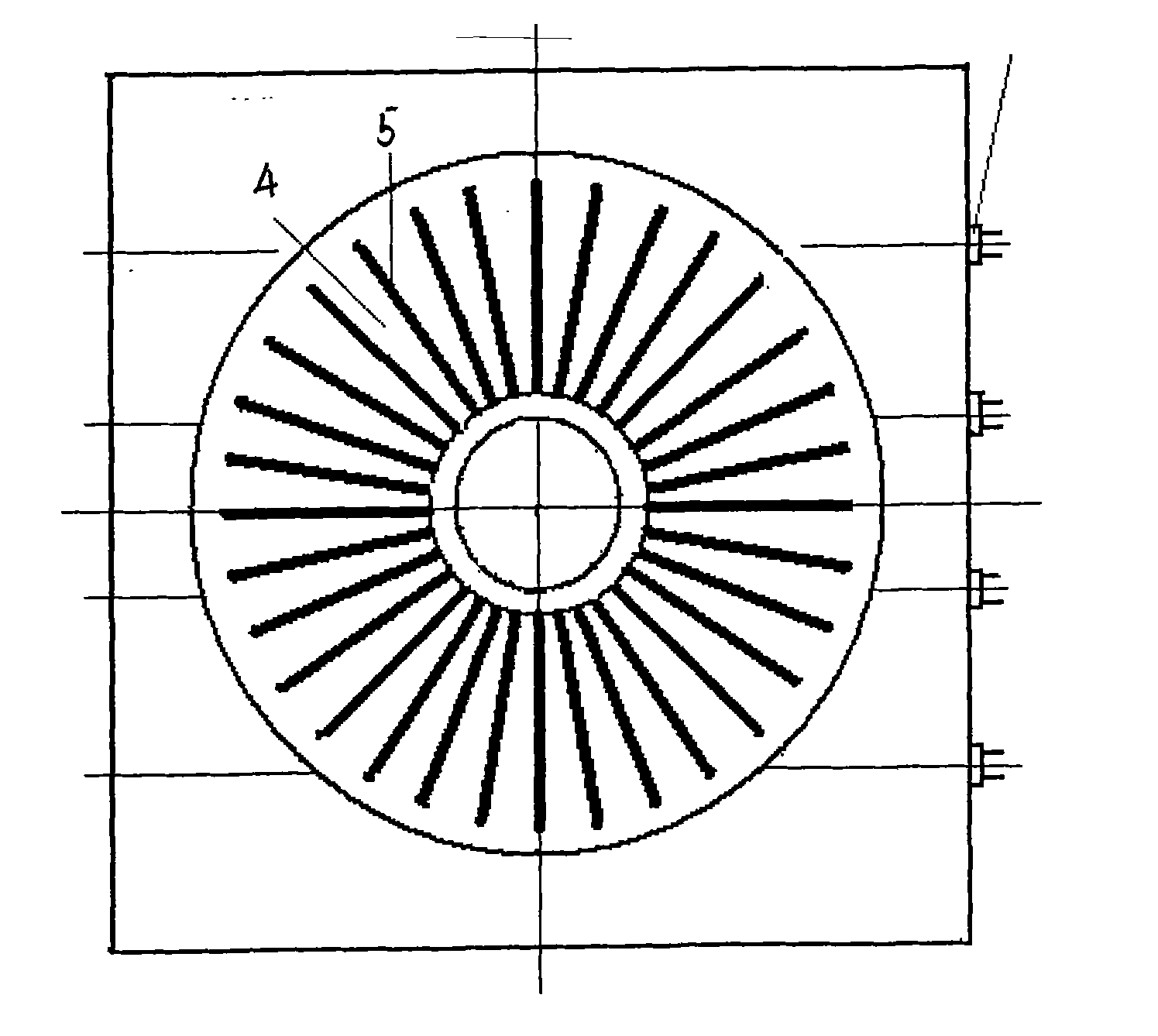

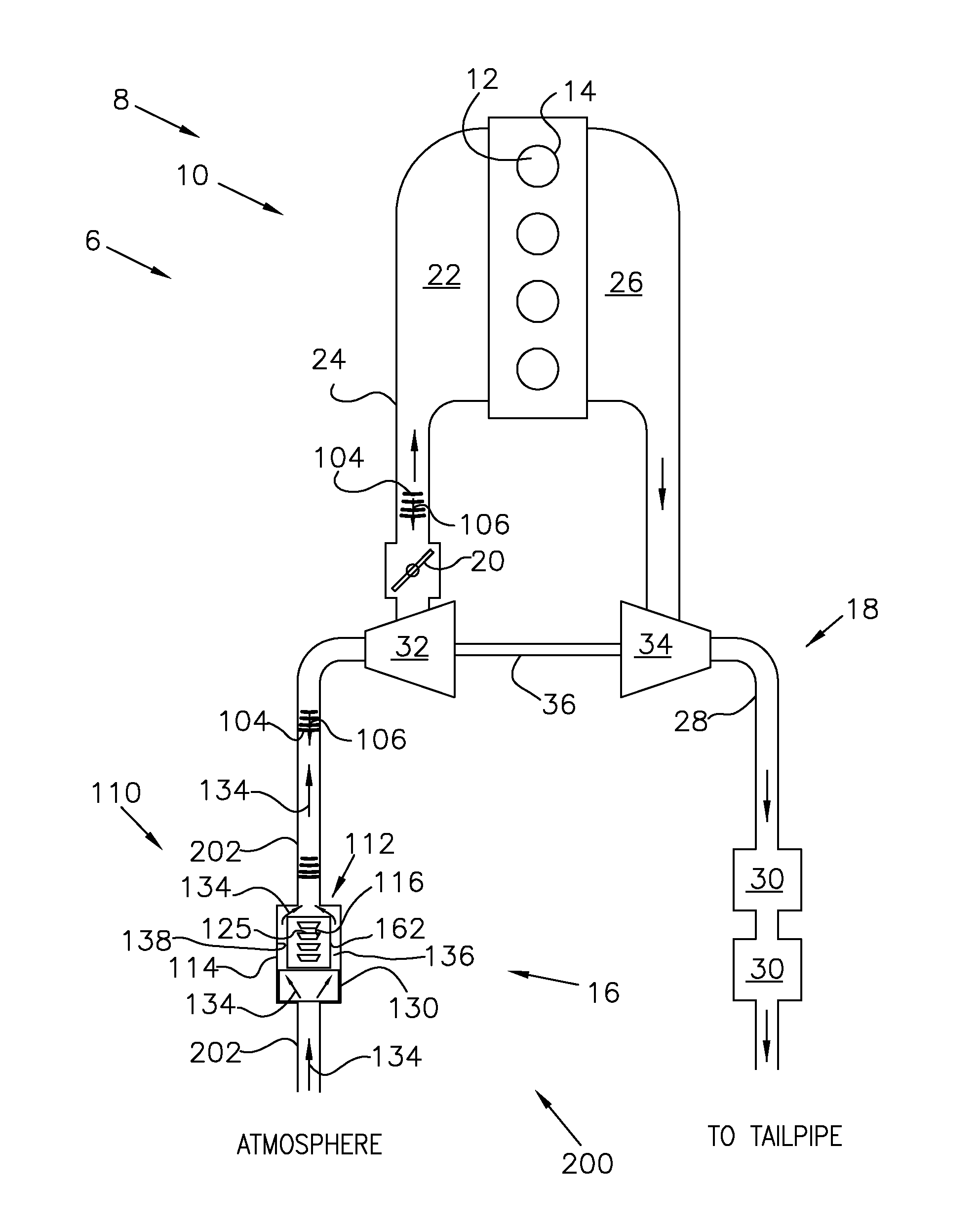

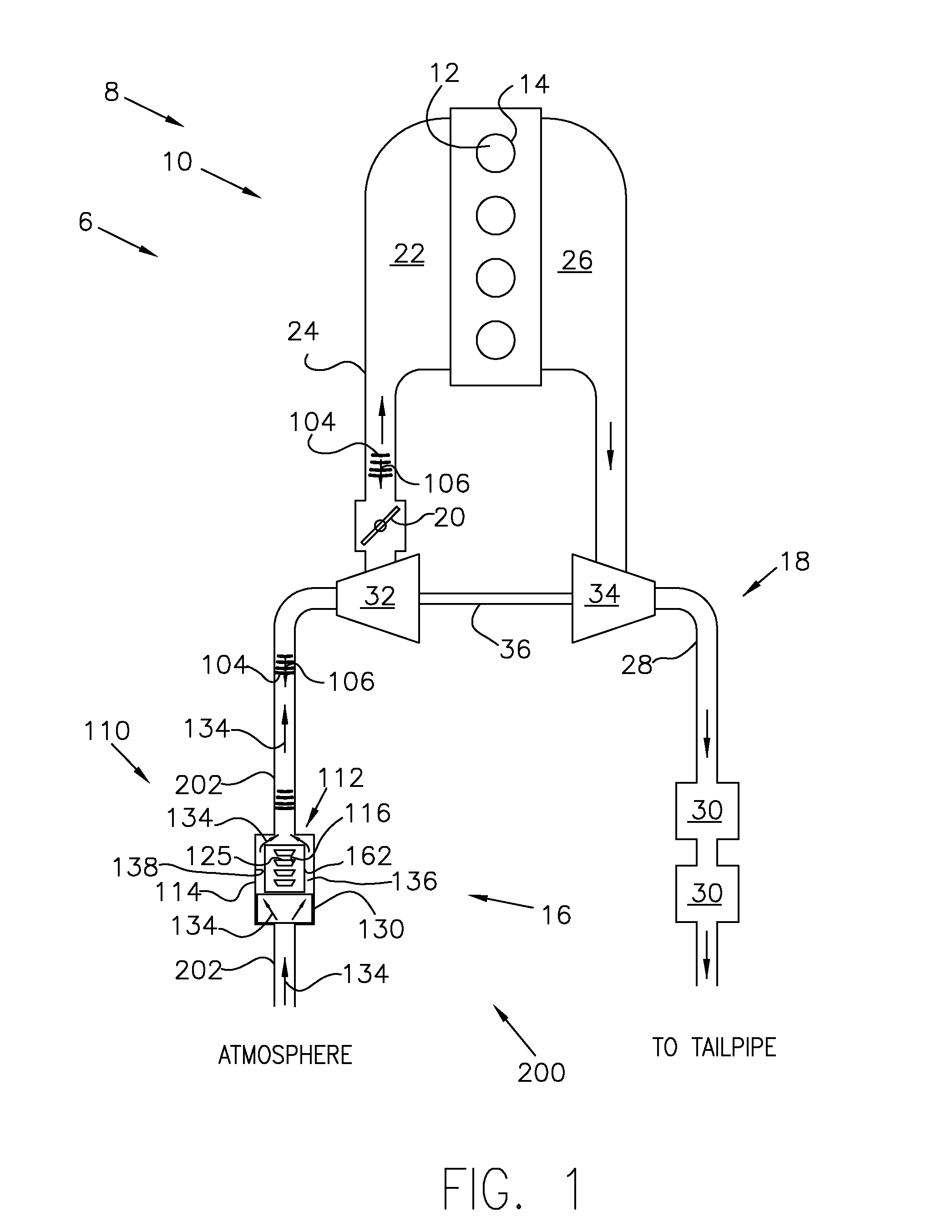

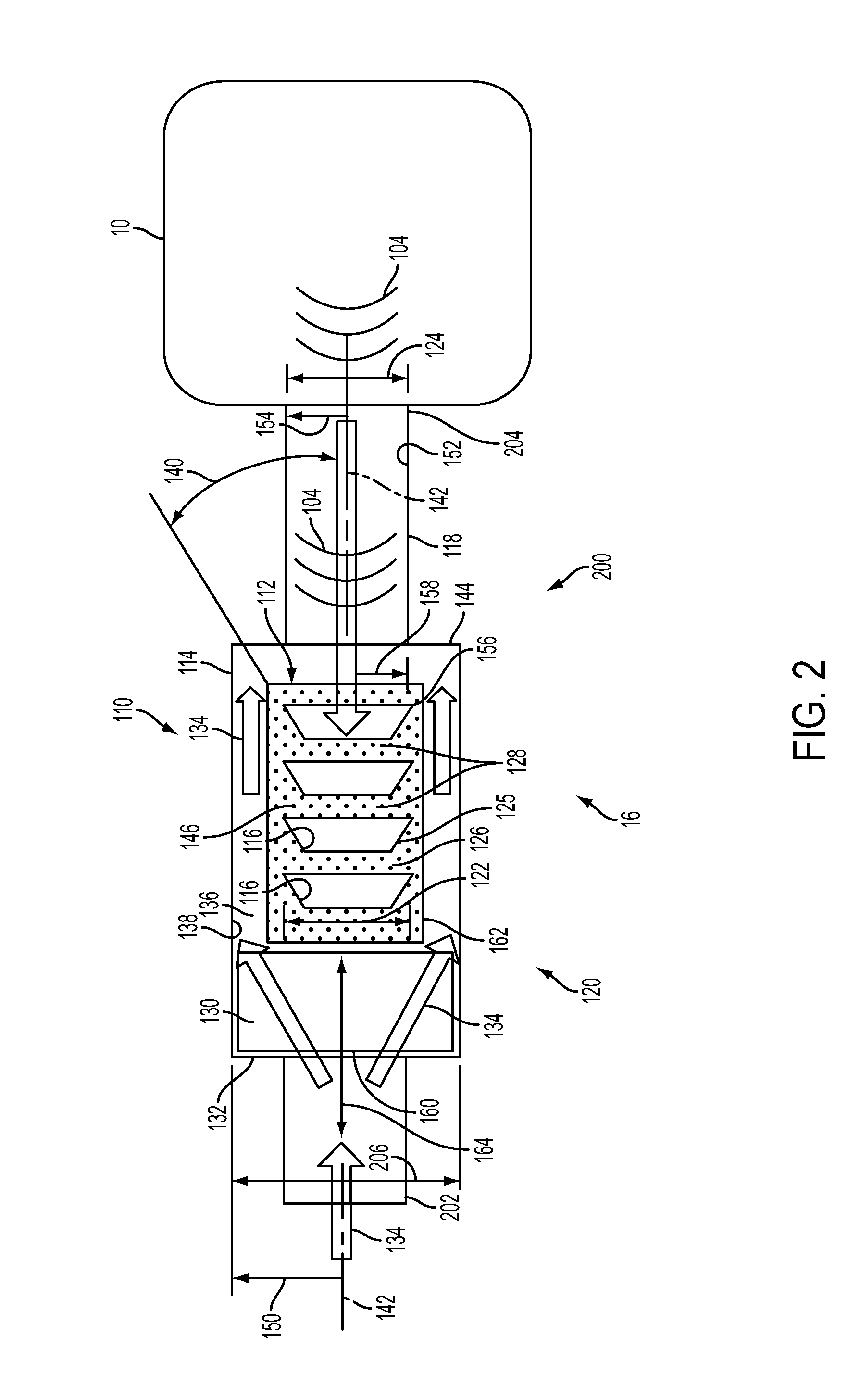

Engine noise attenuation

ActiveUS20150068481A1Low resistancePrecise sizeExhaust apparatusSilencing apparatusEngineeringNoise attenuation

An induction passage noise attenuator and a system are provided. The induction passage noise attenuator may include a series of surfaces arranged within an enclosure upstream from a clean side air duct on an induction inlet for an internal combustion engine. Each surface of the series of surfaces may have a diametric extent being substantially in line with an inner diameter of the clean side air duct.

Owner:FORD GLOBAL TECH LLC

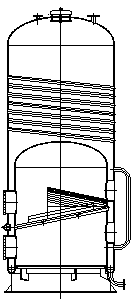

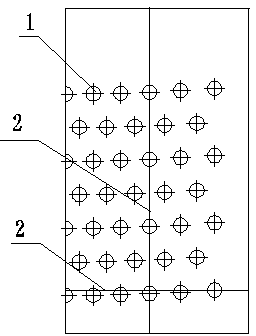

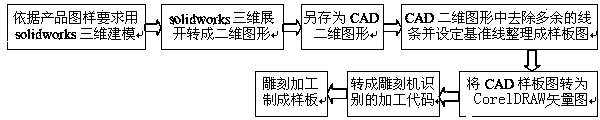

Boiler cylinder body pipe hole face mold and manufacturing method thereof

InactiveCN103624761APrecise sizeAccurate hole sizeOther workshop equipmentEngineeringSeries production

The invention provides a boiler cylinder body pipe hole face mold and a manufacturing method thereof. According to the method, by means of a computer and relative programs, a three-dimensional diagram corresponding to a boiler cylinder body is built in the computer according to requirements for design of boiler cylinder body pipe holes, then the diagram is spread to form a two-dimensional diagram, lines are revised, reference lines of regions are determined according to pipe hole distribution regions, a vector diagram is formed through conversion, a carving program is formed through conversion, hole profile lines and the reference lines are carved on a face mold material, and the pipe hole face mold is manufactured. According to the boiler cylinder body pipe hole face mold manufactured in the method, the size is accurate, the efficiency is high, the cylinder body pipe holes do not need cut for a second time, the face mold can be repeatedly used, and the face mold is suitable for large-scale production.

Owner:ZUNYI YULONG BOILER

Special-shaped pipe forming method

The invention relates to the technical field of manufacturing of centrifugal large compressors, and discloses a special-shaped pipe forming method. The special-shaped pipe forming method comprises the following steps: (S1) a special-shaped pipe for welding a shell of a compressor is segmented according to a preset design; (S2) each section is longitudinally split according to preset two split lines; (S3) a lifting pattern is increased in the radial direction of the split lines to reserve a pressing margin; (S4) plates satisfying the shape and the size after the step (S3) are bent and pressed hop by hop according to predesigned marking lines by using pressing and bending molds; (S5) after two plates are bent to shapes corresponding to two parts of the special-shaped pipe sections, each section is welded according to self longitudinal splicing line; and (S6) all the special-shaped pipe sections are welded to form the whole special-shaped pipe. The special-shaped pipe forming method forms each special-shaped pipe section through segmented lofting, pressing and welding, forms the whole special-shaped pipe through welding all the special-shaped pipe sections, and is simple in operation and precise in size.

Owner:CHONGQING GENERAL IND (GRP) LTD

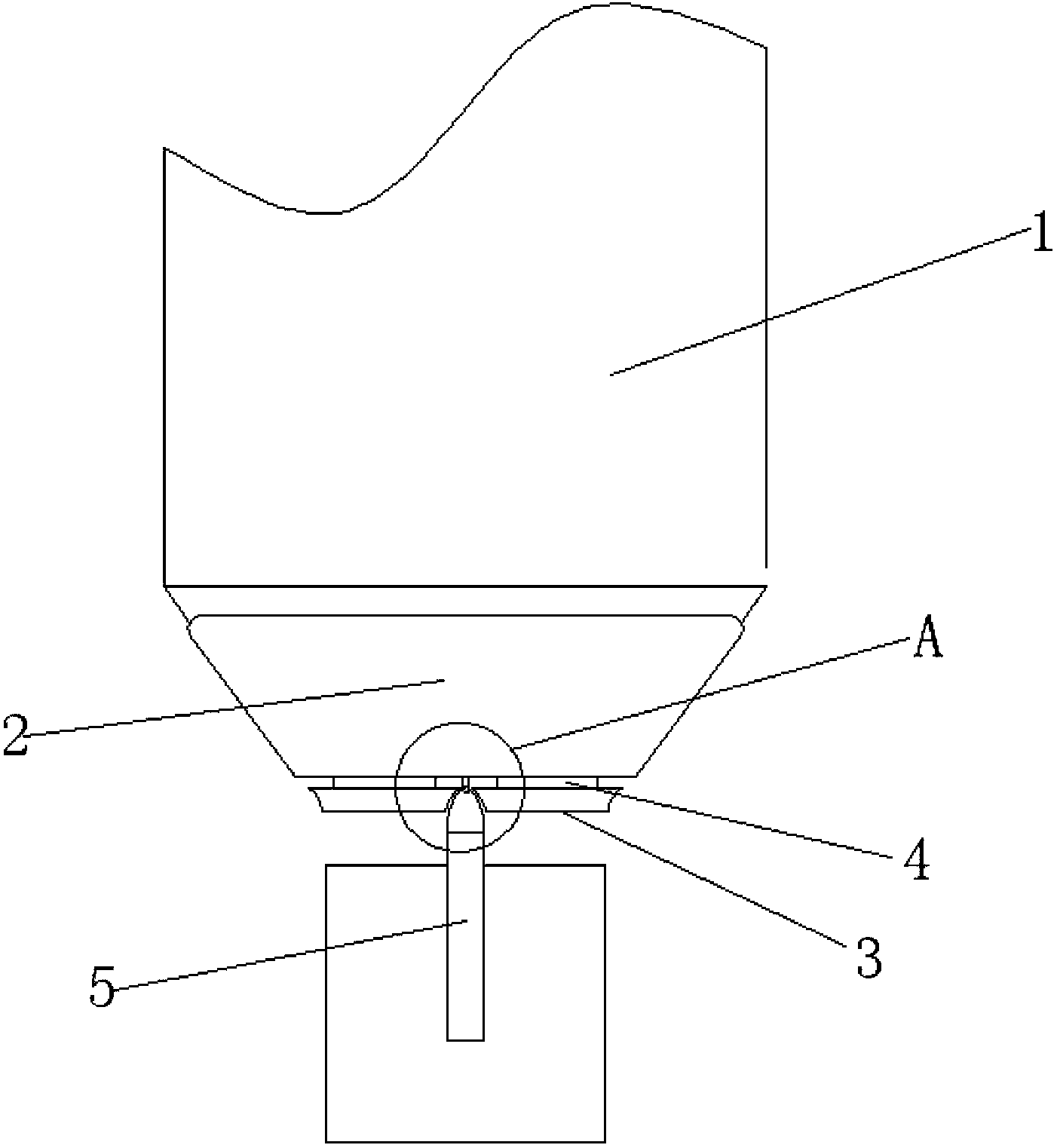

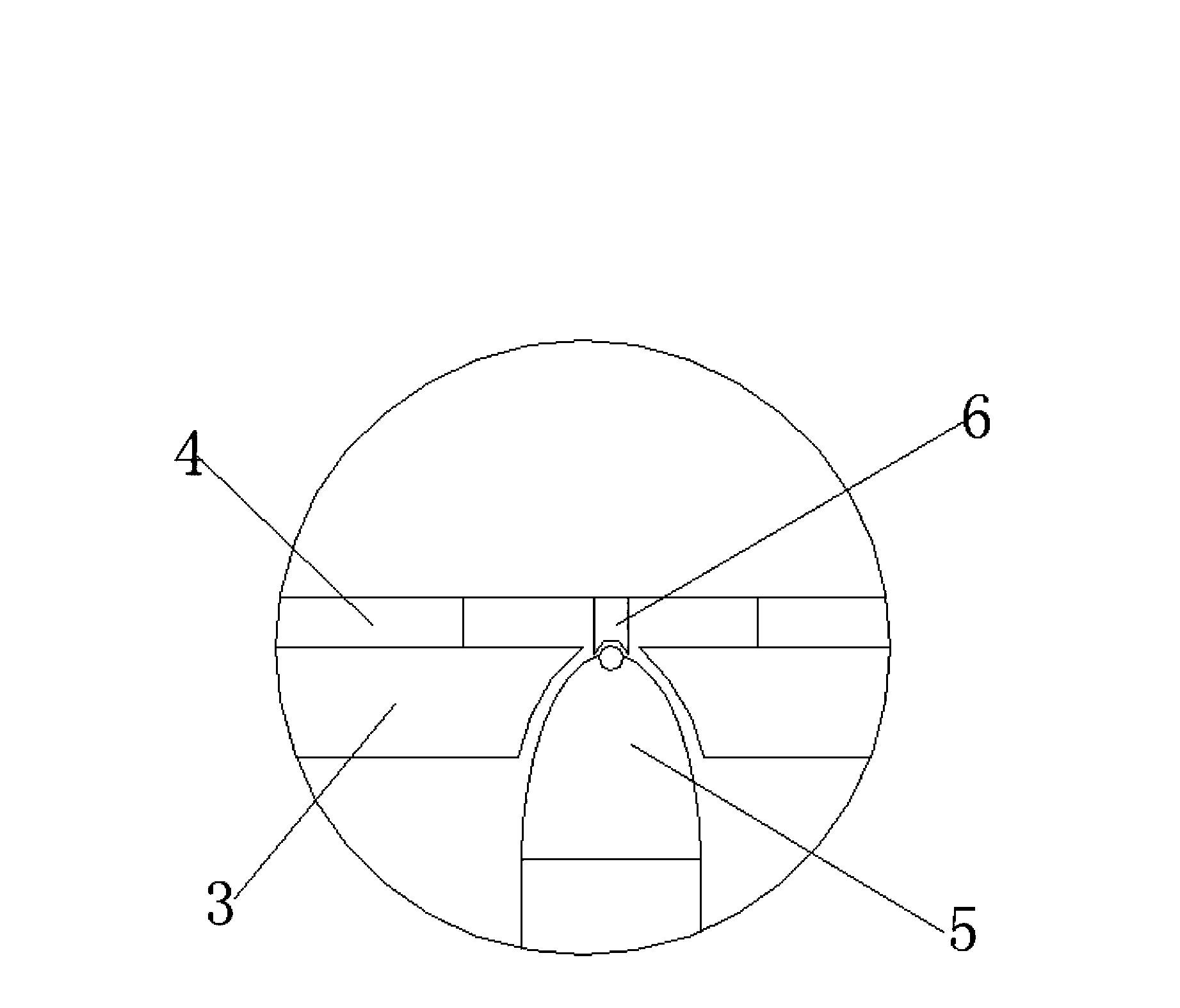

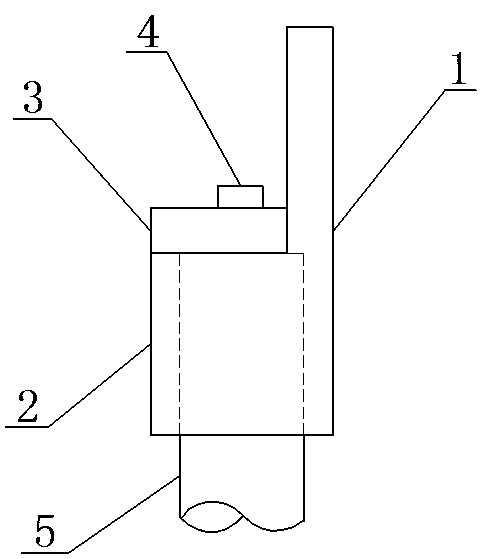

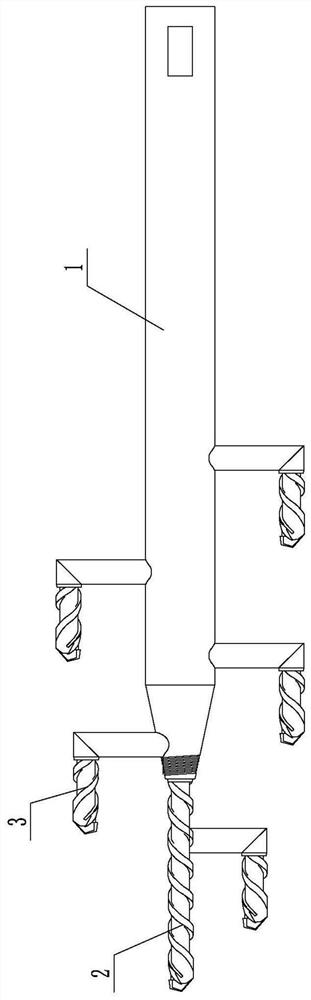

Rotation necking-down device

The invention discloses a rotation necking-down device. The rotation necking-down device comprises a power head, a base and at least two discs. The power head can be driven by an external power device to rotate around the axis of the power head and move up and down with the using direction as a benchmark. The upper end of the base is detachably fixed to the lower end of the power head, each disc is provided with an adjusting device, the upper ends of the adjusting devices are positioned and fixed at the lower end of the base, the lower ends of the adjusting devices are fixedly connected with the upper ends of the corresponding discs, the adjusting devices can adjust the discs in the axial direction and the radial direction of the power head, the discs are located on the same plane and distributed with the axis of the power head as the center, each disc is in a reverse circular platform shape with the peripheral sides concaving towards the center by certain radian, and the discs can rotate around their own axis. The rotation neck-down device can compress an opening of a pipe to neck down the opening of the pipe, the surface of the necked-down pipe is smooth, the size of the necked-down pipe is accurate, and the rotation neck-down device is suitable for necking-down fine machining of various pipes and especially suitable for machining and manufacturing cannonball type or needle tubing type pen heads in the pen manufacturing industry.

Owner:LOTUS STATIONERY

Method for casting steel anode template through composite sand mould

InactiveCN105268926APrecise sizeDense tissueFoundry mouldsFoundry coresSodium silicateSelf hardening

The invention discloses a method for casting a steel anode template through a composite sand mould. The method includes the following steps that (1) chromite sand, modified sodium silicate and organic ester are used for preparing chromite moulding sand, chromite moulding sand of 10-15 mm is laid on the big plane of an anode template model, chromite moulding sand is arranged on the portions of all lugs and a centre hole, and quartz sand replaces chromite sand to prepare quartz sodium silicate moulding sand to be injected into other portions and is compressed; (2) self hardening, mould drawing, shaping and put down of a centre hole sand core are conducted, then a cavity is formed, and portions without chromite moulding sand are coated with zircon powder alcohol-based coatings twice; (3) molten steel is cast into the cavity, and sand is discharged after heat preservation is conducted; and (4) a riser is cut off, full annealing treatment, cleaning and grinding are conducted, and then the steel anode template can be obtained. By the adoption of the composite sand mould, the lugs and the centre hole of the anode template are not prone to sintering through the chilling action of the chromite sand, so that no iron coated sand is generated, and the sand adhering defect is avoided as a whole. The dimension is precise, and the big plane is compact in texture.

Owner:武钢集团襄阳重型装备材料有限公司

Anti-drop connection armor clamp for terminal

PendingCN108767506AEasy to manufacturePrecise sizeClamped/spring connectionsMechanical engineeringEngineering

Owner:JIANGSU ZHONGTIAN TECH CABLE ACCESSORIES CO LTD

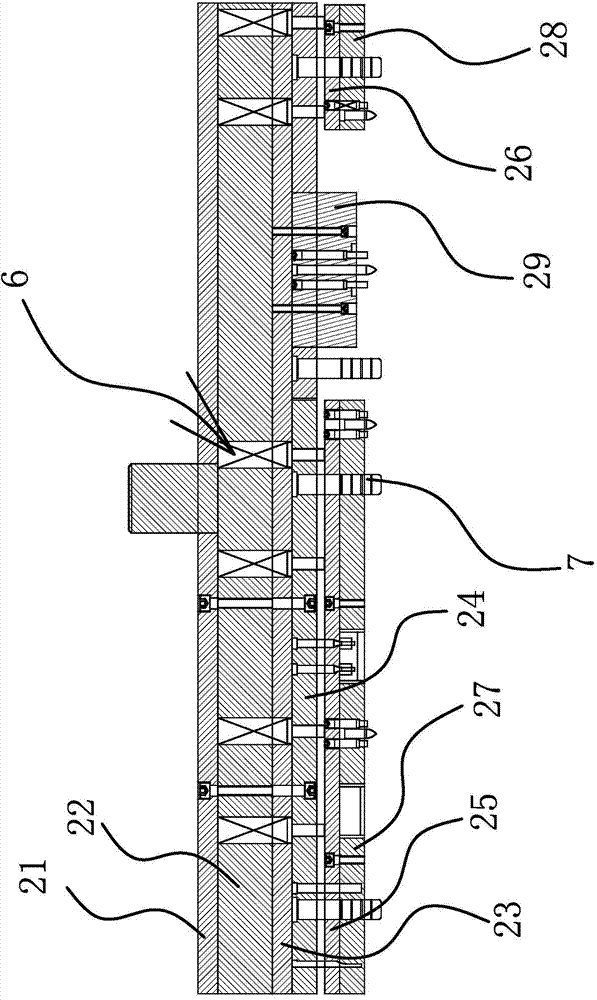

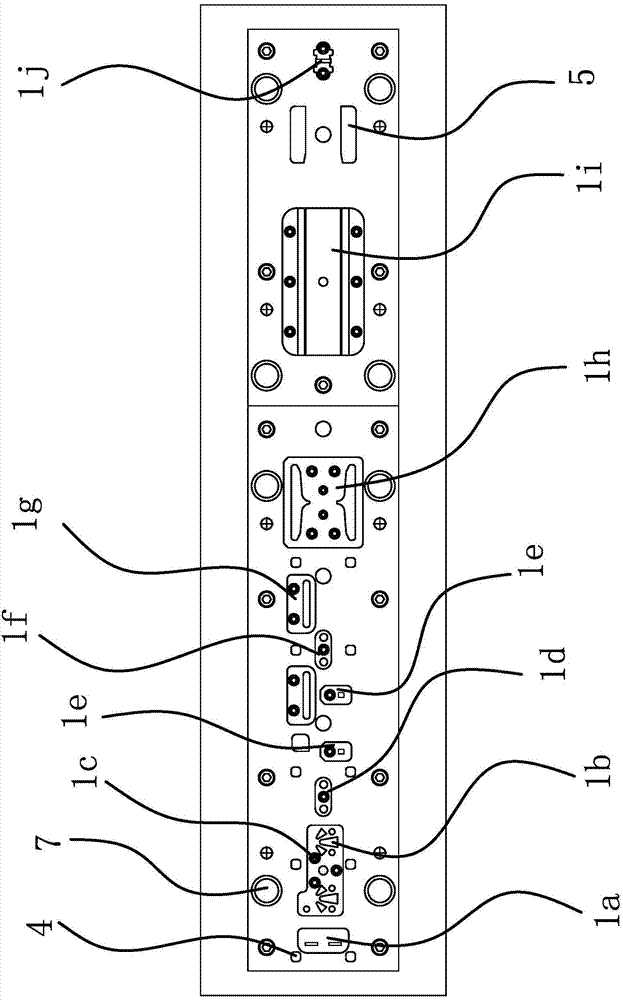

Spring clamp progressive die

The invention provides a spring clamp progressive die, and belongs to the technical field of dies. The spring clamp progressive die solves the technical problems that an existing spring clamp is low in die production efficiency and the like. The spring clamp progressive die comprises an upper die base, a lower bottom plate and a plurality of guide columns arranged on the upper die base. The lower bottom plate is sequentially provided with a corner cutting insert, a first convex point insert, a punching insert, a first stretching insert, a second convex point insert, a second stretching insert, a first scrap insert, a second scrap insert, a bending forming insert and a material cutting insert. The upper die base is sequentially provided with a first spring pressing plate, a forming lug and a second spring pressing plate, wherein the first spring pressing plate is matched with the corner cutting insert, the first convex point insert, the punching insert, the first stretching insert, the second convex point insert, the second stretching insert, the first scrap insert and the second scrap insert, the forming lug is matched with the bending forming insert, and the second spring pressing plate is matched with the material cutting insert. The spring clamp progressive die has the advantages of being high in efficiency, stable in quality.

Owner:ZHEJIANG FEILI TECH

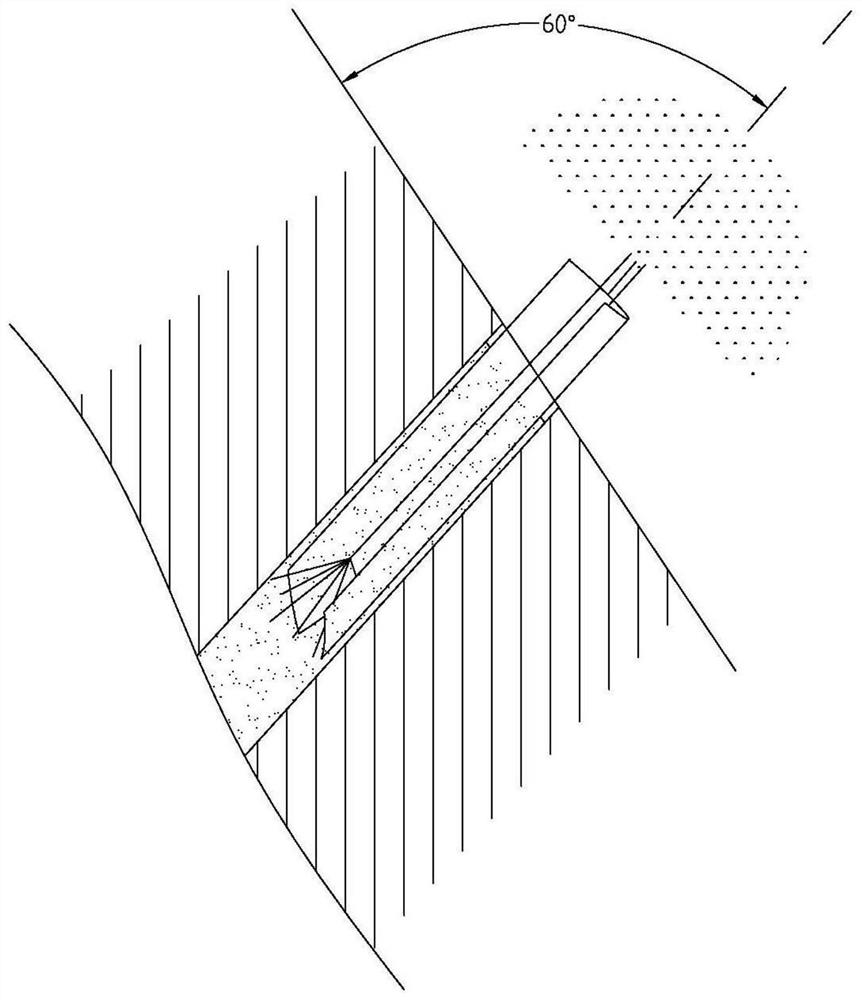

Slope surface punching, planting and greening method

PendingCN112273126APrecise sizeImprove construction accuracyPlantingCultivating equipmentsAgricultural engineeringBiology

The invention discloses a slope surface punching, planting and greening method. The method comprises the steps that slope cutting treatment is conducted on a surface soil layer of a slope surface; a special drill bit is used for punching holes in the cut slope surface to form circular planting holes; during punching, the holes face downwards and form an included angle of 55-65 degrees with the slope surface, and the holes are arranged up and down to form a shape like a Chinese character "pin"; a PVC pipe is divided into two parts in the axis center line direction, a notch is formed in one endof the cut PVC pipe to form a growth groove, the end, provided with the growth groove, of the PVC pipe is obliquely inserted into the planting hole, the growth groove is exposed, and a semicircular opening of the PVC pipe faces upwards to form a water collecting groove; a drought-resistant water-retaining agent is scattered at the bottom of the planting hole, container seedlings with soil balls are fed into the bottom of the planting hole through a water collecting pipe, and mellow soil is backfilled; and after planting, the seedlings are watered and continuously tended for two years, and theseedlings are well watered, managed and protected according to the soil moisture content in March, July, August and November every year. According to the method, water and soil loss can be effectivelyprevented, and the effective greening area is increased.

Owner:宝鸡市林业科技信息中心

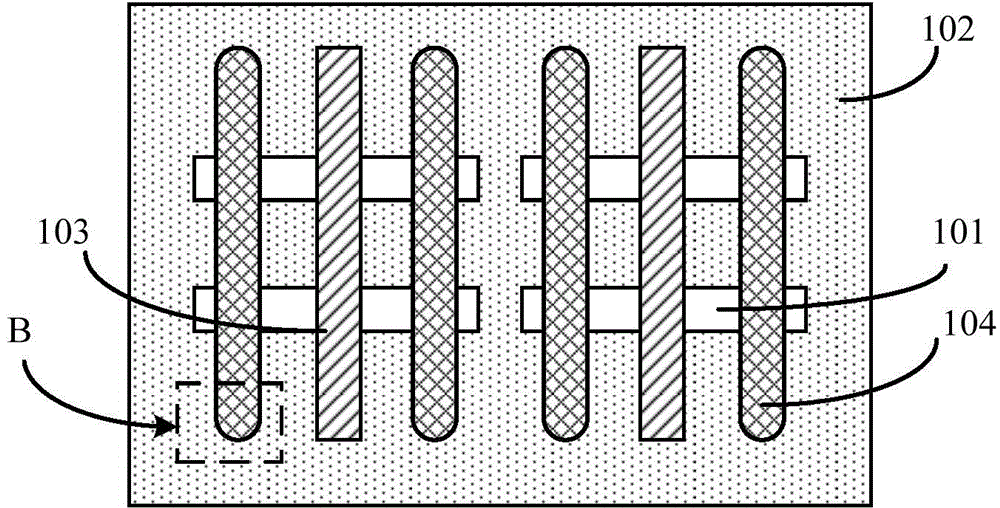

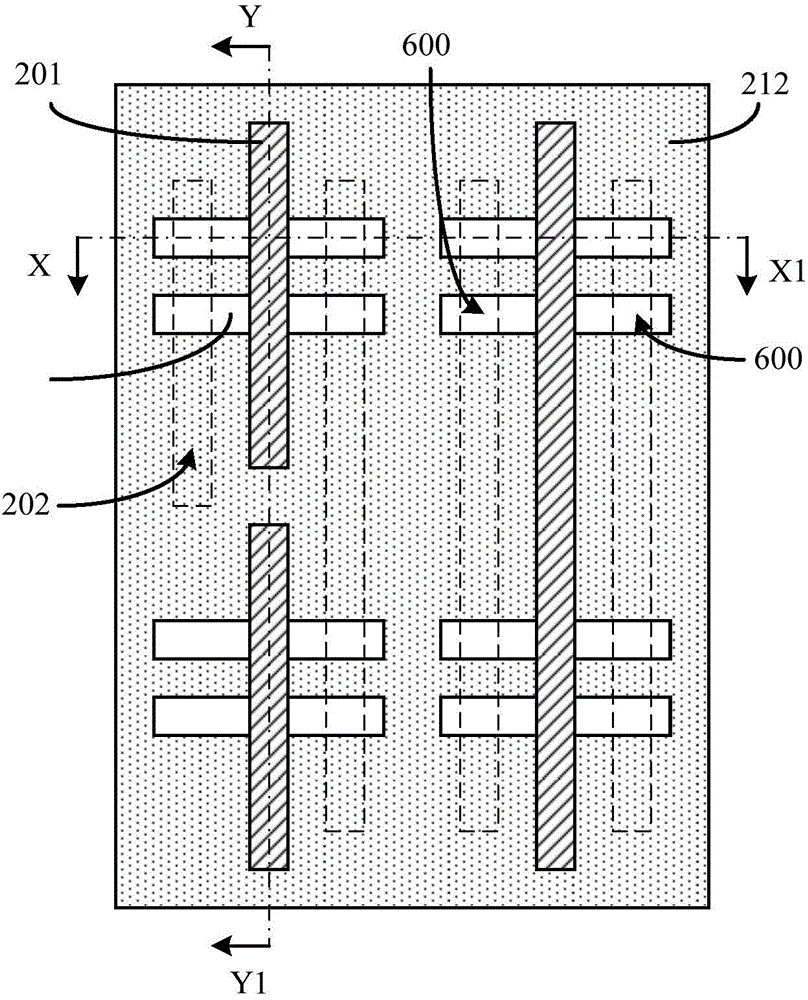

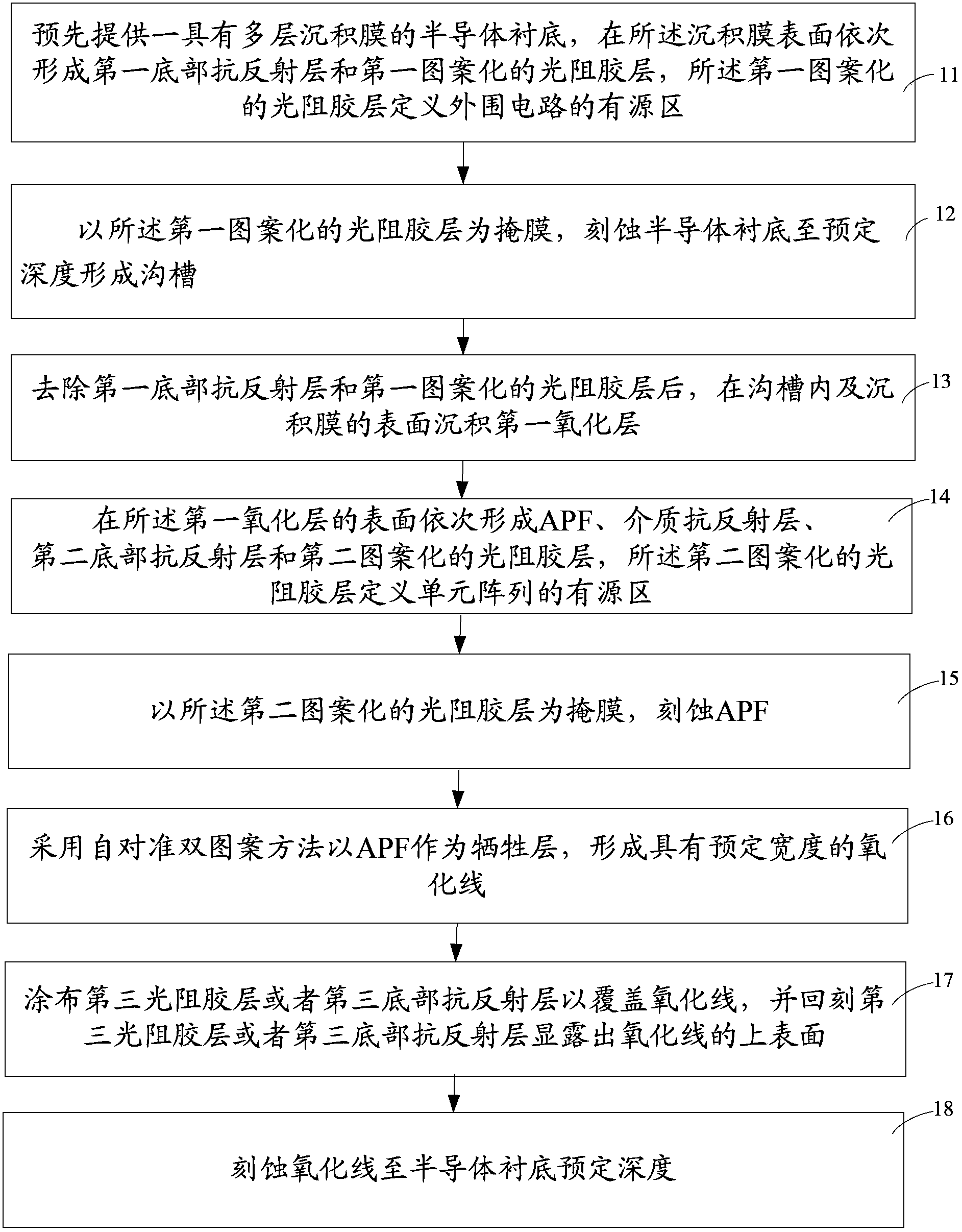

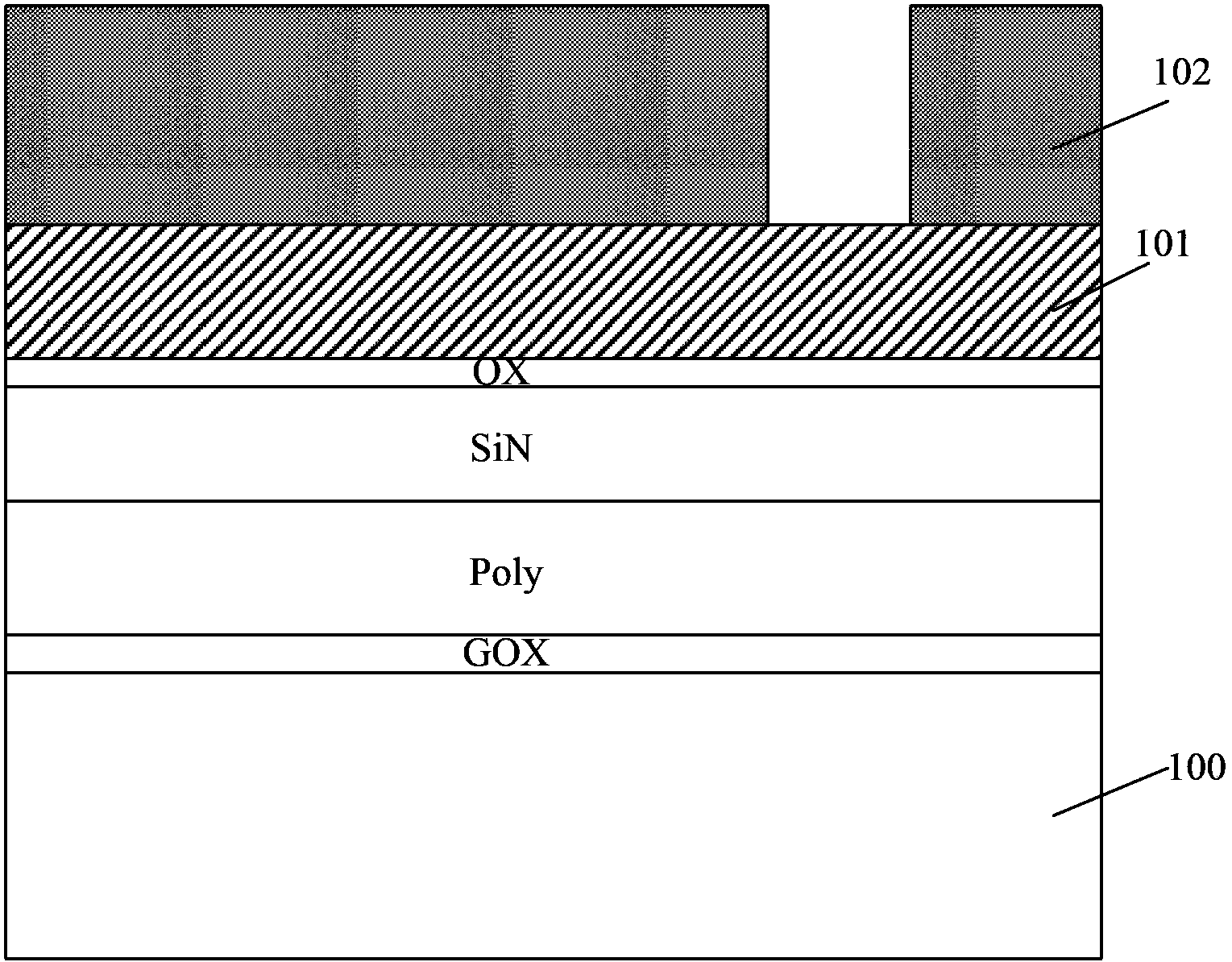

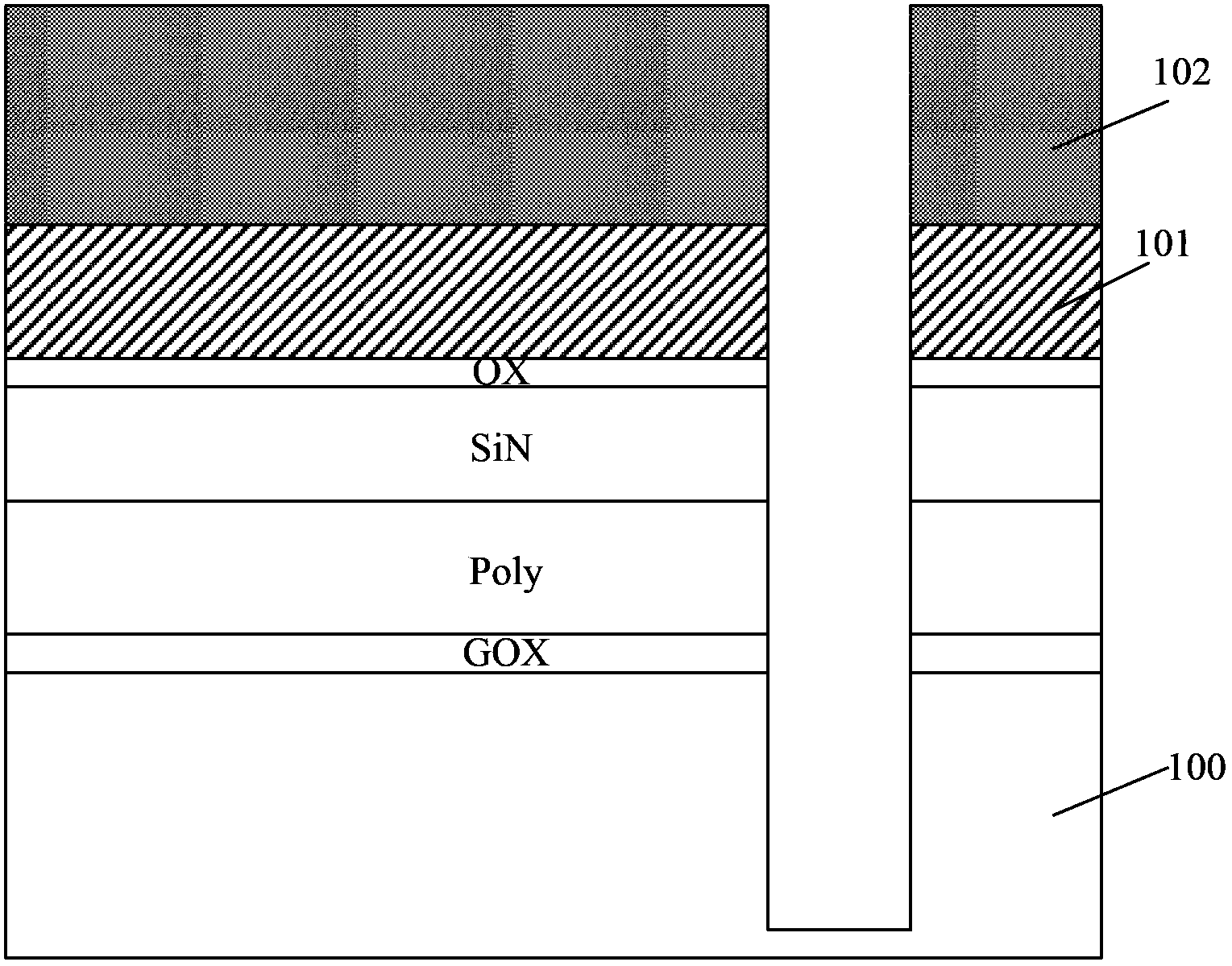

Manufacturing method for semiconductor device

ActiveCN103794557APrecise sizeSmall sizeSemiconductor/solid-state device manufacturingEngineeringSemiconductor device modeling

The invention discloses a manufacturing method for a semiconductor device. A semiconductor substrate having multiple deposited films is provided in advance, a first bottom antireflective layer and a first patterning photo-resistive glue layer are formed at a surface of the deposited films, and the first patterning photo-resistive glue layer defines an active region of a peripheral circuit; the first patterning photo-resistive glue layer is taken as a mask, and the semiconductor substrate is etched to a predetermined depth to form a groove; after the first bottom antireflective layer and the first patterning photo-resistive glue layer are removed, first oxidation layers are deposited in the groove and the surface of the deposited films; APF, DARC, a second bottom antireflective layer and a second patterning photo-resistive glue layer are formed at surfaces of the first oxidation layers, and the second patterning photo-resistive glue layer defines an active region of a unit array; the second patterning photo-resistive glue layer is taken as a mask, and APF is etched; the APF is taken as a sacrificial layer employing an SADP method to form an oxidation line having a predetermined width; the oxidation line is etched to the predetermined depth of the semiconductor substrate. The manufacturing method has the simplified technology.

Owner:SEMICON MFG INT (SHANGHAI) CORP

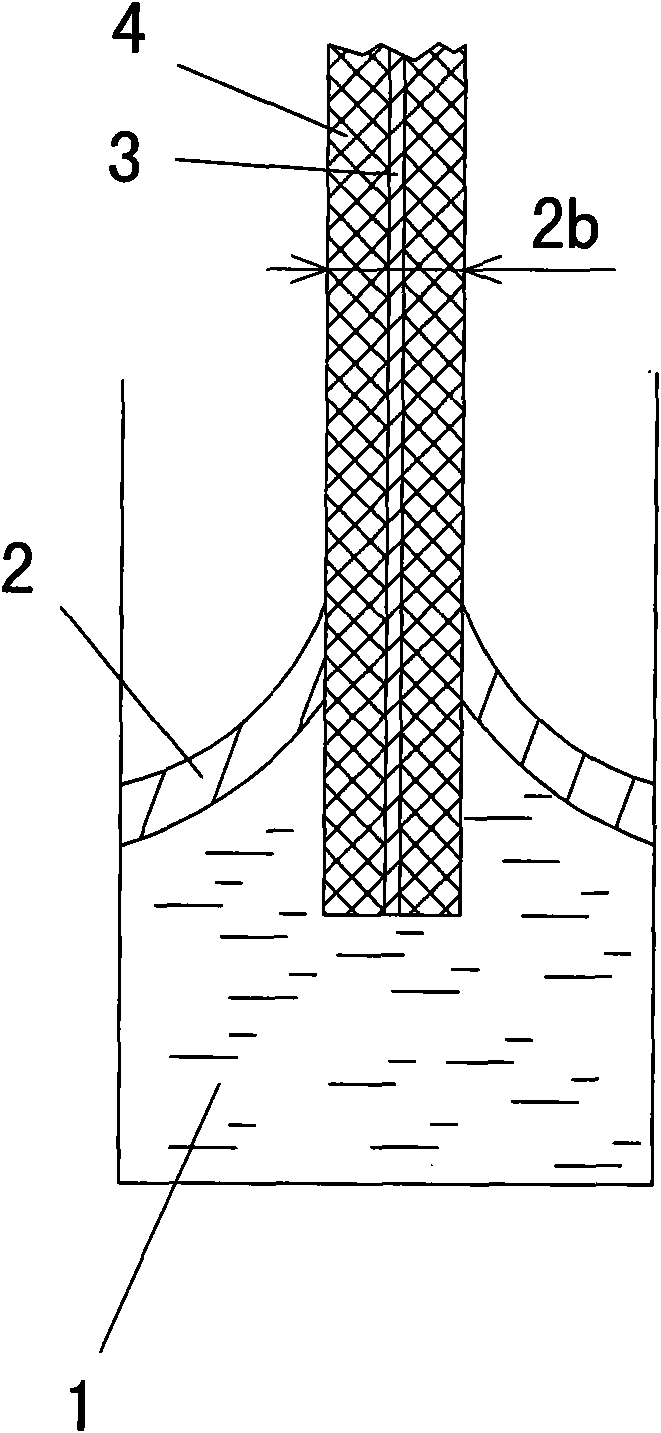

Quartz product preparation apparatus

The invention discloses a quartz product preparation apparatus. The quartz product preparation apparatus comprises a blowtorch, a hearth, and a deposition bench; the blowtorch is arranged at a top ofthe hearth, the deposition bench is arranged below the blowtorch, an air-flow guiding apparatus is arranged at an outlet of the hearth, which is used for guiding high-temperature gas to form lateral air flow. The air-flow guiding apparatus is added at a specific position, influence of SiO2 dust and water vapor on surface of a quartz material in the hearth can be removed, and adsorption is reduced,so that the surface of the quartz material has a flat appearance.

Owner:YANGTZE OPTICAL FIBRE AND CABLE JOINT STOCK LIMITED COMPANY

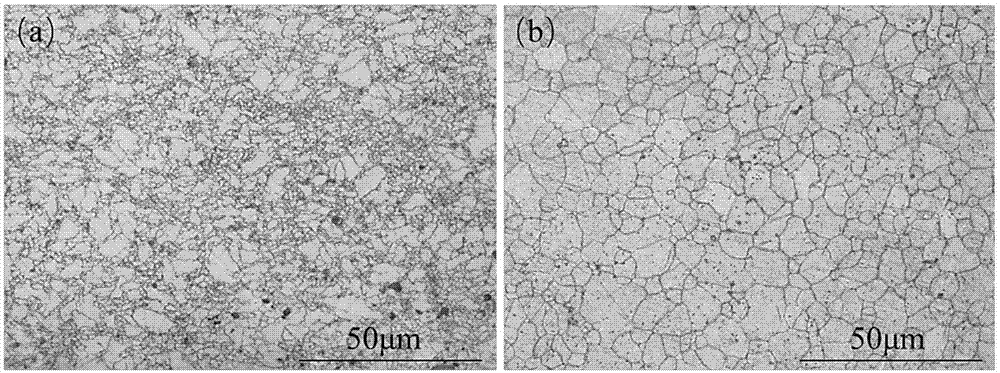

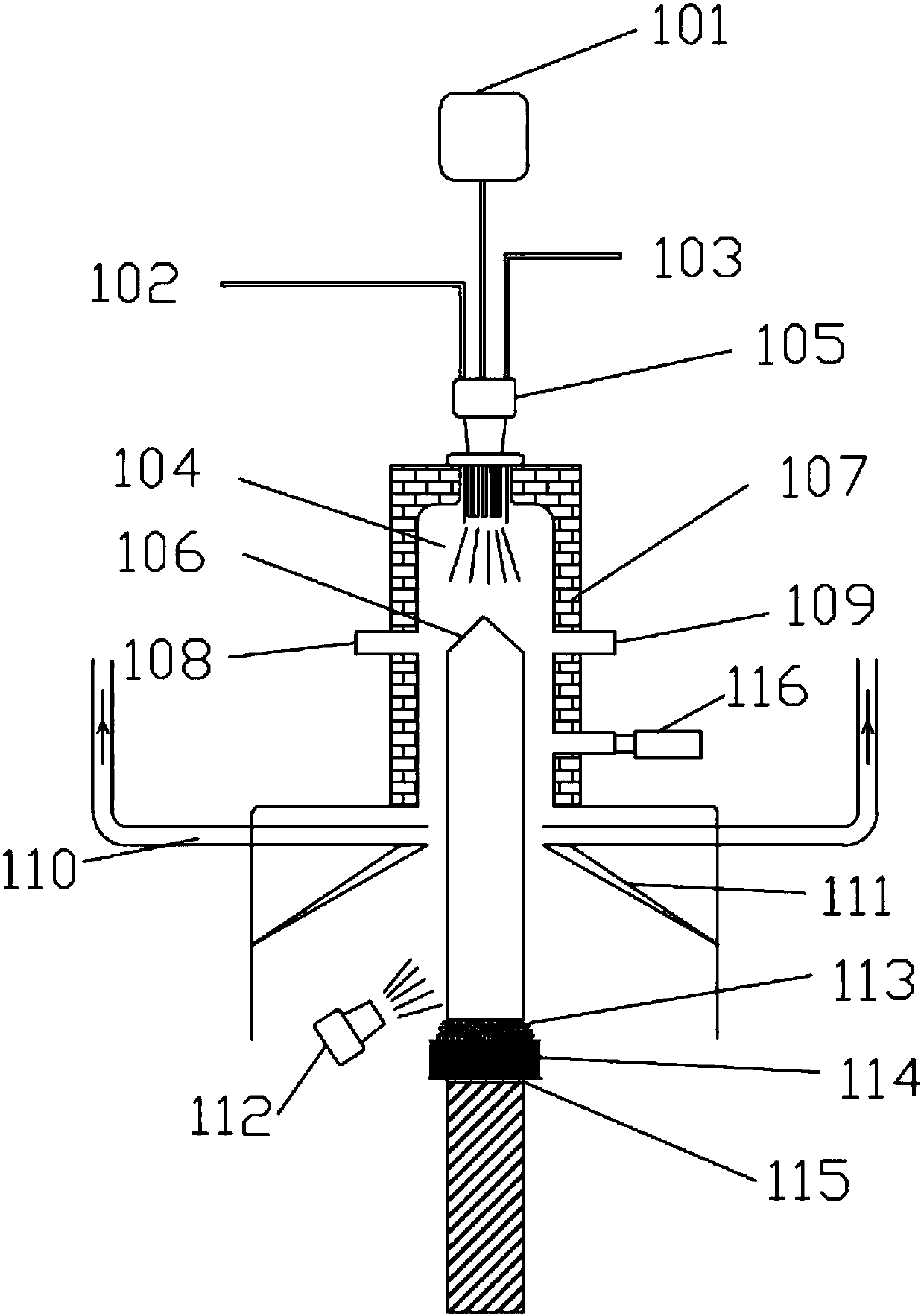

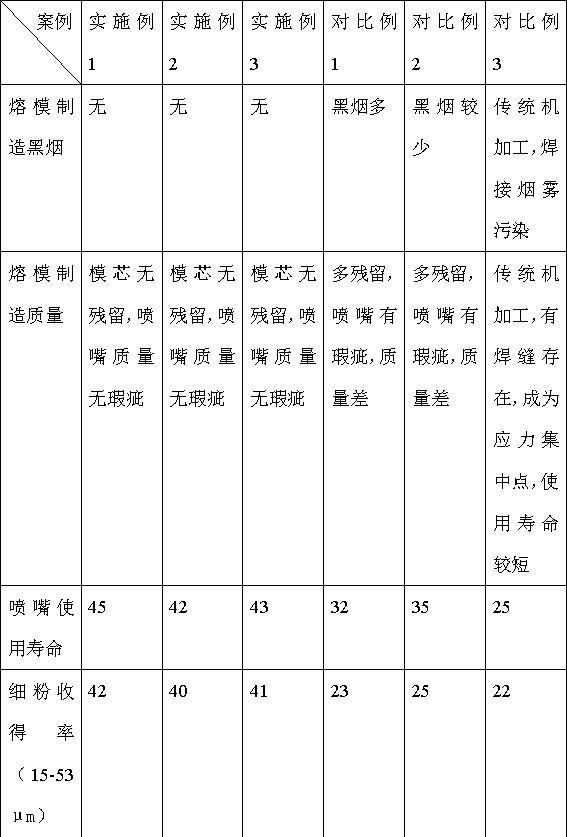

Preparation method of high-strength and high-toughness stainless steel powder for selective laser melting additive manufacturing

PendingCN114012101APrecise sizeThe preparation process is environmentally friendlyAdditive manufacturing apparatusTransportation and packagingTundishPolystyrene

The invention relates to a preparation method of high-strength and high-toughness stainless steel powder for selective laser melting additive manufacturing. The method comprises the following steps: S1, selecting composite components for burdening, carrying out vacuum induction heating melting, continuously refining till that a molten pool stops bubbling and furnace burden is completely cleared after molten steel is completely cleared, pouring the molten metal into a tundish heat preservation crucible, and flowing into a supersonic gas atomizing nozzle (self-made) through a flow guide pipe; S2, introducing high-pressure inert argon, forming a supersonic airflow, and atomizing the supersonic airflow into fine metal liquid drops; S3, enabling the liquid drops to become particles under surface tension in the air and to be rapidly cooled and solidified into a metal powder, and collecting the metal powder; and S4, screening according to requirements. According to the method, a reasonable component proportion is adopted, a gas atomizing nozzle is prepared from an environment-friendly polystyrene powder, the problem of black smoke is eliminated, complete dewaxing is achieved through a segmented dewaxing method, the service life is long, and the yield of powder meeting the requirement in the prepared metal powder is high; and the powder fluidity is good, and the performance of a test piece prepared through selective laser melting is obviously improved.

Owner:SHANXI CHEM RES INST

Jewelry and production process thereof

PendingCN108185596AHighlight gloss and light releasePrecise sizeJewelleryManufacturing engineeringNumerical control

The invention discloses jewelry and a production process thereof. The jewelry comprises a pendant body and precious stone, wherein an embedding assembly is arranged at the upper part of the pendant body; the precious stone is fixed on the pendant body through the embedding assembly. The jewelry can prevent the precious stone from falling off from the pendant body; clothes cannot be hooked; skin cannot be injured through being hooked by the pendant body; the luster degree and the light release degree of the precious stone can be shown to the maximum degree, so that the precious stone achieve aneffect of floating on the base; the diamond looks bigger and more brilliant; jewelry meets the requirements of a customer on the gold purity. According to the production process, the CNC (computerized numerical control) technology is used for replacing the complicated edge shoveling work procedure after the manual artificial position nailing in the prior art; the product neatness degree and the efficiency are optimized; the problems of nonuniform length and nonuniform thickness of the product are solved; the frequently occurring problems of incorrect position, out of roundness and the like due to manual operation are solved; through the process technology improvement and creation, the technical flow process is changed; the cost such as the labor cost and the production time is greatly reduced.

Owner:中科国金股份有限公司

Method for processing boards by dividing log

InactiveCN106625883AReduce mistakesPrecise sizeFeeding devicesCircular sawsSmooth surfaceWood processing

The invention relates to the field of wood processing, in particular to a method for processing boards by dividing a log. The method for processing the boards by dividing the log comprises the following steps that (1) the log is divided into multiple boards at a time through a multi-blade log saw, and the multiple boards are driven through driving rollers; (2) each board transversely enters an automatic breaking machine so as to be transversely cut at a time, so that a plurality of fixed-length boards are obtained; (3) one flaw piece of each fixed-length board can be made into a smooth surface through a single-blade saw, and excessive flow piece restraining treatment is conducted by making a 90-degree right angle be formed between each fixed-length board and the cutting edge; (4) each board subjected to excessive flaw piece restraining is made to pass through a quadruple breaking machine so as to be transversely cut at a time, and thus a plurality of fixed-length square boards can be processed at a time; and (5) each fixed-length square board is made to pass through an automatic squaring machine, so that remaining flaw pieces of the square boards are trimmed into smooth surfaces, 90-degree right angles are formed, and thus the boards of specified specifications are obtained. According to the method for processing the boards by dividing the log, reasonable mechanical equipment are provided for all procedures, automatic feeding and discharging are achieved through a machine, and errors of the boards obtained through sawing are few or are avoided; and the dimension is accurate, consumption is reduced, the processing efficiency is high, labor is saved, and labor intensity is low.

Owner:王瀚

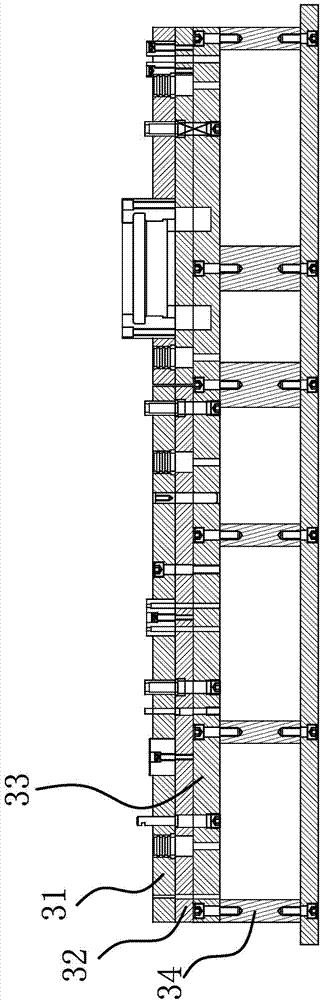

Progressive die of side plate of rocking chair underframe

The invention provides a progressive die of a side plate of a rocking chair underframe, and belongs to the technical field of dies. The progressive die solves the technical problems that an existing die of a side plate of an existing rocking chair underframe is low in production efficiency and the like. The progressive die of the side plate of the rocking chair underframe comprises an upper die base, a lower die base and a guide column between the upper die base and the lower die base, the lower end of the upper die base is sequentially provided with a first clamping plate, a second clamping plate and a third clamping plate, the upper end of the lower die base is provided with a first supporting plate, a second supporting plate and a third supporting plate, the first supporting plate, the second supporting plate and the third supporting plate correspond to the first clamping plate, the second clamping plate and the third clamping plate respectively, the first clamping plate is sequentially provided with a first punching insert and a second punching insert, the second clamping plate is sequentially provided with a first waste cutter insert, a second waste cutter insert, a third punching insert and a pier hole insert, and the third clamping plate is provided with a product cutter. The progressive die has the advantages of being high in efficiency, saving production cost and the like.

Owner:ZHEJIANG FEILI TECH

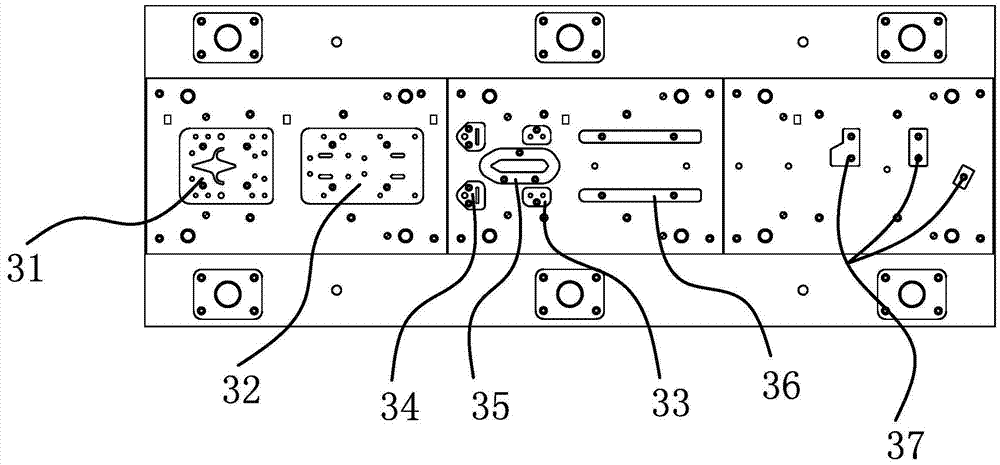

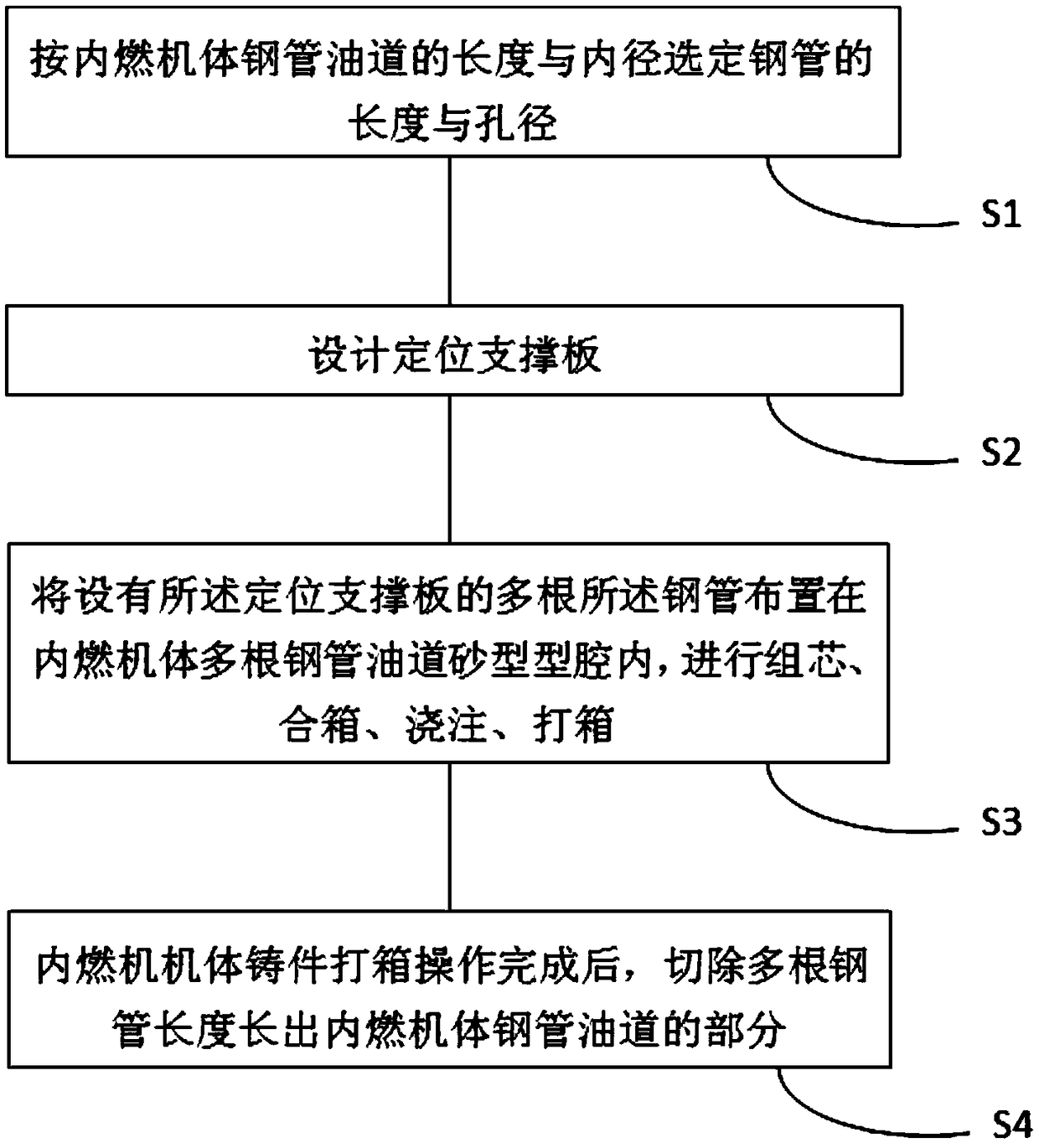

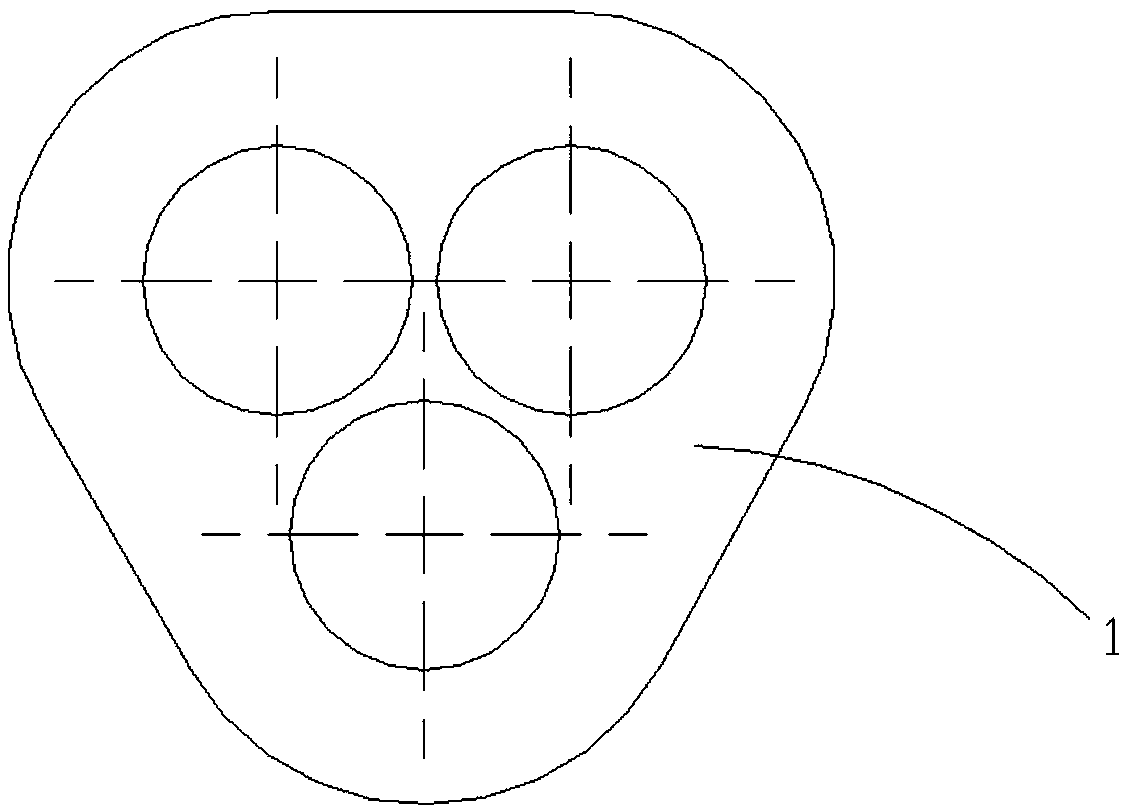

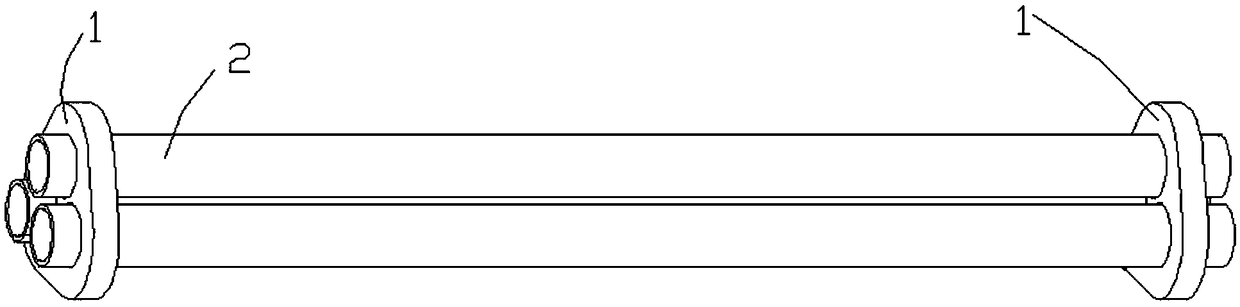

Inlay casting method for multiple steel pipe oil ducts of internal combustion engine body

ActiveCN109047724APrecise sizeSmall center offsetExternal combustion engineInternal combustion engine

The invention relates to the field of casting of internal combustion engine bodies, in particular to an inlay casting method of multiple steel pipe oil ducts of an internal combustion engine body. Theinlay casting method comprises the following steps that S1, the length and diameters of steel pipes are selected according to the length and inner diameter of the steel pipe oil ducts of the internalcombustion engine body; S2, a positioning and supporting plate is designed; S3, the multiple steel pipes provided with the positioning and supporting plate are arranged in sand mold cavities of the multiple steel pipe oil ducts of the internal combustion engine body, and then core assembling, mold assembling, casting and mold disassembling are conducted; and S4, after mold disassembling of castings of the internal combustion engine body is completed, the portions, stretching out of the steel pipe oil ducts of the internal combustion engine body, of the multiple steel pipes are cut off. By adoption of the method, the multiple steel pipe oil ducts, meeting requirements, of the internal combustion engine body can be directly obtained, the size of the oil ducts is accurate, the center offsetis small, uniform wall thicknesses and small deformation of the oil ducts are ensured, and the quality of the castings of the internal combustion engine body is improved.

Owner:四川共享铸造有限公司

Casting production process for belt wheel casting

The invention discloses a casting production process for a belt wheel casting; the casting production process disclosed by the invention comprises the steps of manufacturing a mould, manufacturing a sand mould, setting a core, pouring and carrying out subsequent operation in sequence; the casting production process disclosed by the invention is characterized in that the step of manufacturing the sand mould comprises filling the mould by moulding sand, compacting the moulding sand to complete a mould, and simultaneously, setting an air inflation hole in the completed mould; a step of smelting is set between the step of setting the core and the step of pouring; the step of smelting comprises selecting materials according to the casting at first, adding alloy elements into molten iron, inoculating after discharging molten iron, and then, pouring; and the step of pouring comprises injecting molten iron into a cavity and pouring to obtain the belt wheel casting. By means of the casting production process disclosed by the invention, the problems of being more in process and high in workload in processing of the belt wheel casting in the prior art are solved; the production efficiency is increased; the quality defect due to the fact that the belt wheel is processed unqualifiedly is avoided; the utilization rate of raw materials is high; the production cost is reduced; the cast belt wheel is precise in size and unnecessary to machine; and thus, the quality of the casting is effectively ensured.

Owner:QINGDAO HEDELONG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com