Rotation necking-down device

A technology of necking and adjusting devices, which is applied in the field of rotary necking devices for pen material necking in the pen-making industry, which can solve the problems of rough surface, affecting the writing quality of the pen tip, and increasing the cost, so as to achieve smooth surface and uniform force on the pipe fittings , to avoid the effect of local stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

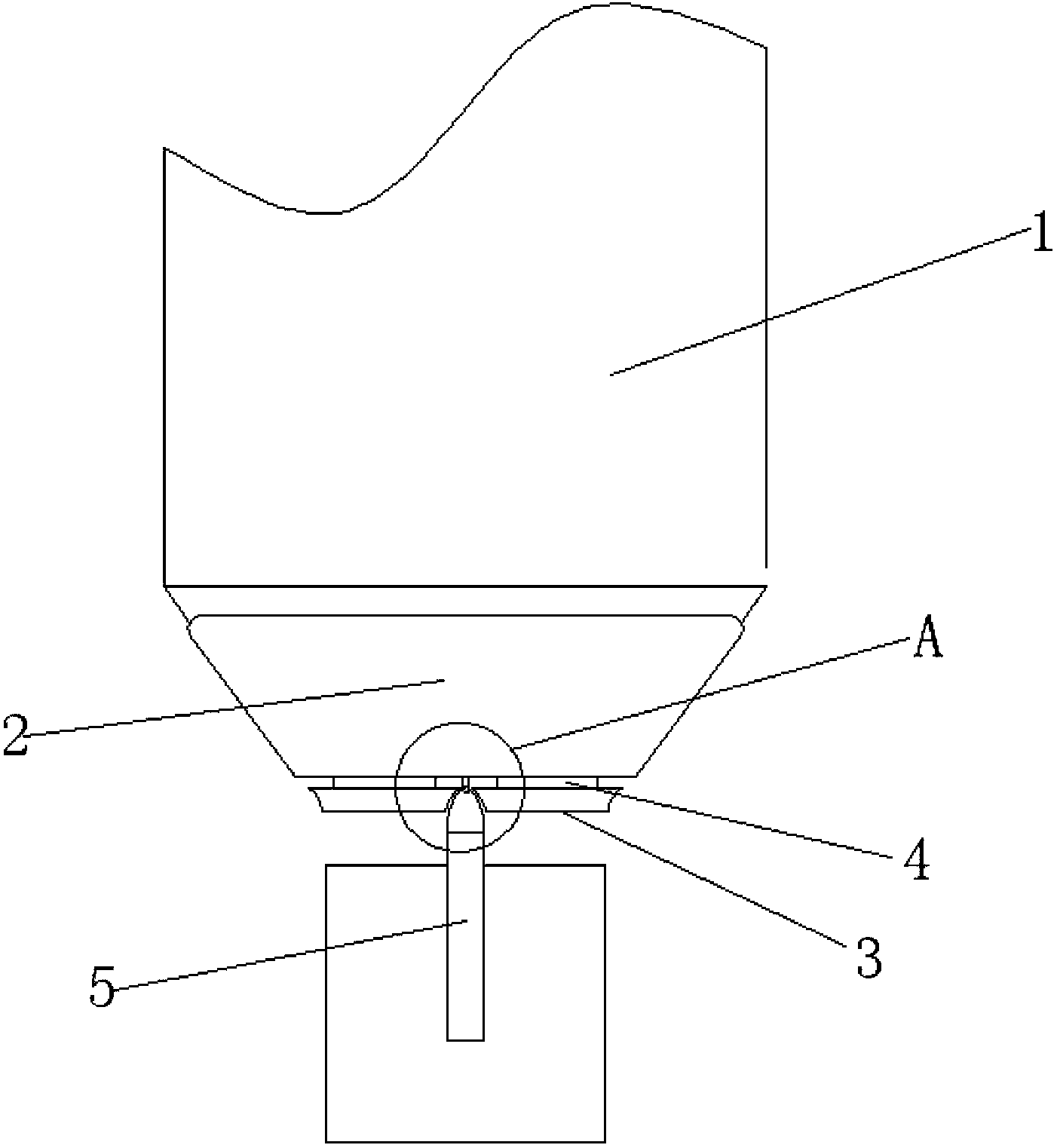

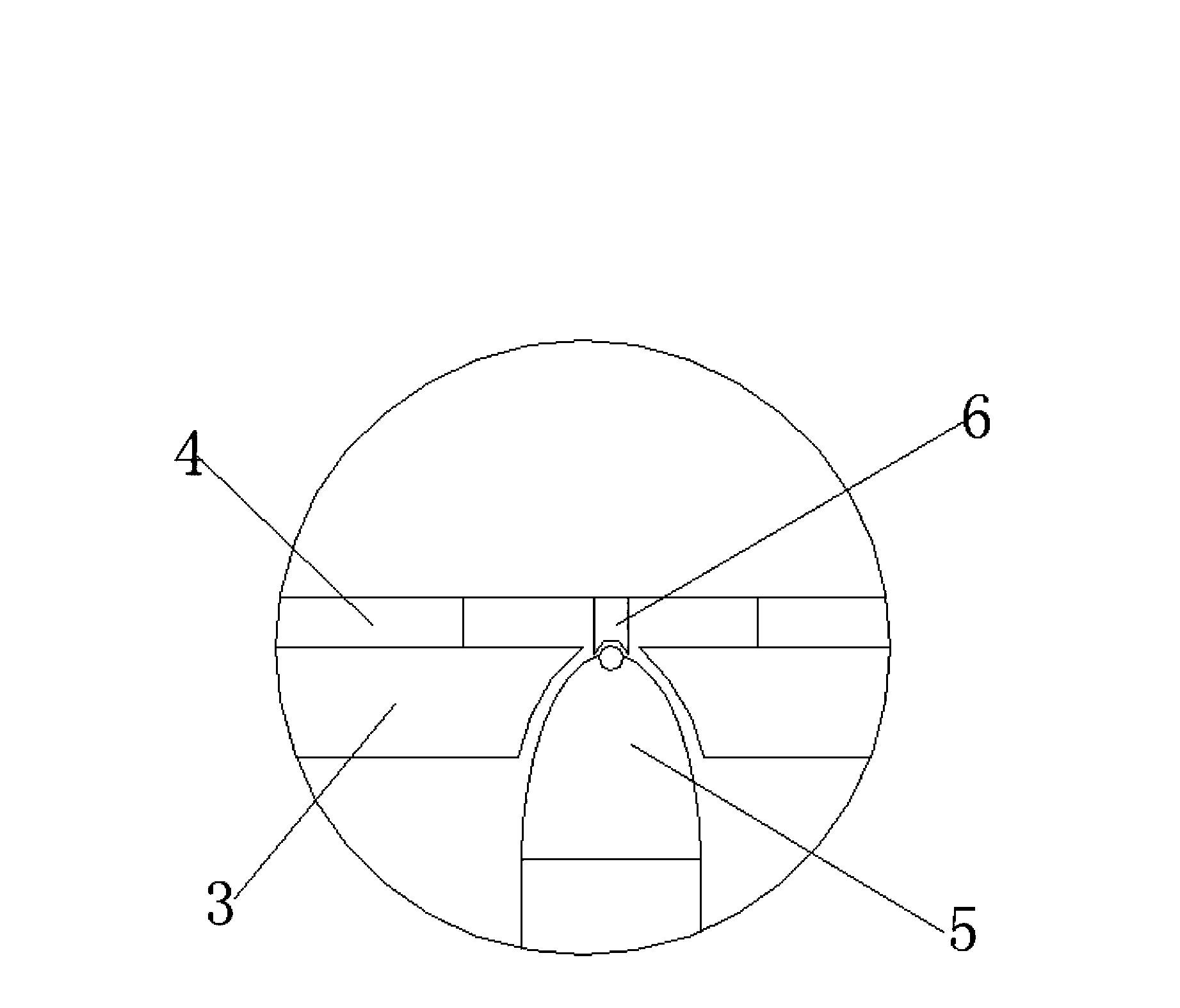

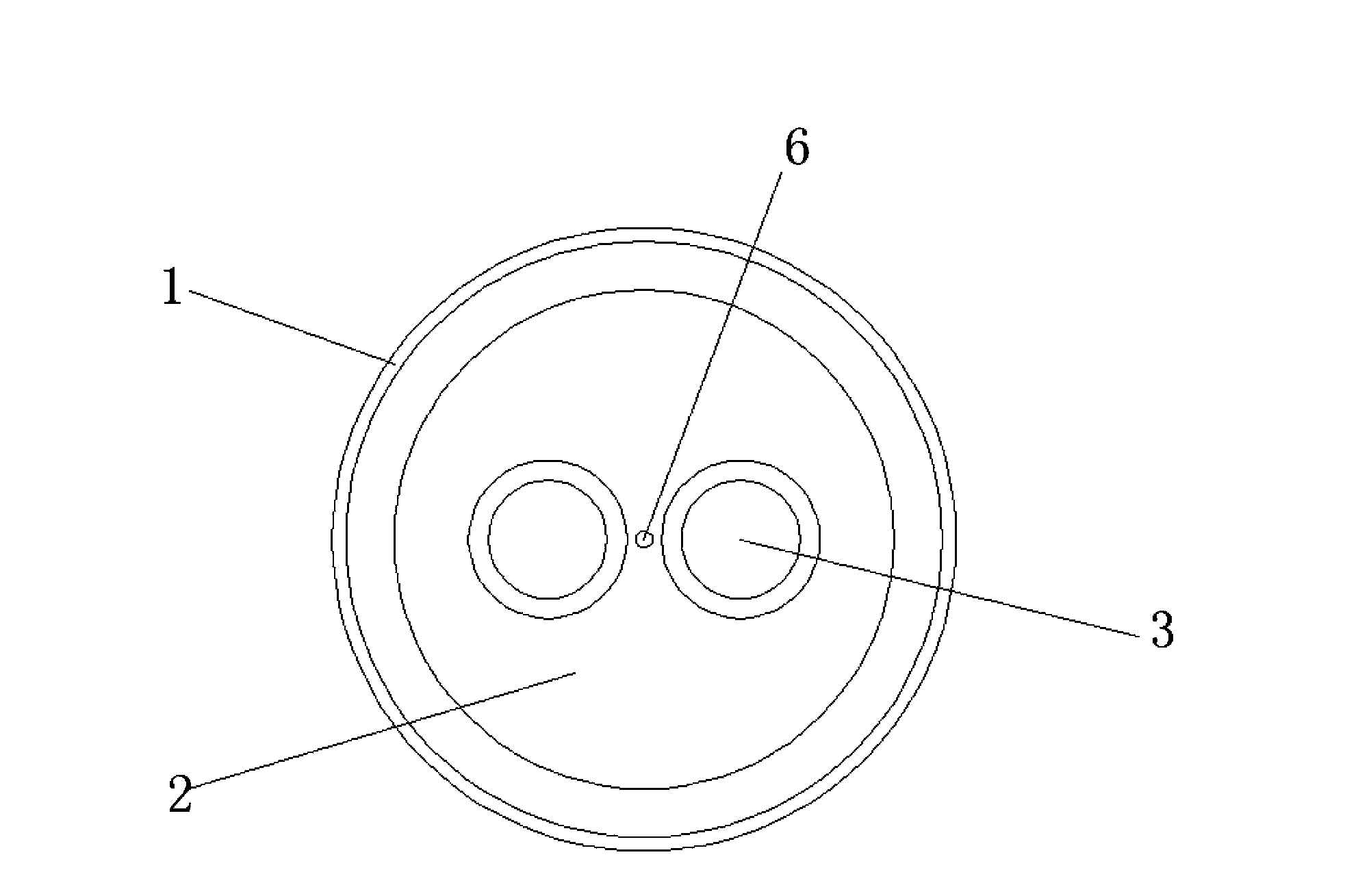

[0017] Such as figure 1 , figure 2 with image 3 As shown, a rotary necking device is characterized in that it includes a power head 1, a base 2 and at least two discs 3, and the power head can rotate along its own axis driven by an external power device based on the direction of use. and move up and down, the upper end of the base is detachably fixed on the lower end of the power head, corresponding to each disk, an adjustment device 4 is provided, the upper end of the adjustment device is positioned and fixed on the lower end of the base, the adjustment device The lower end is fixedly connected to the upper end of the disk, the adjustment device can adjust the disk axially and radially along the power head, the disks are located on the same plane and arranged centered on the axis of the power head, The disc is in the shape of a rounded table with a certain radian concave toward the center on the peripheral side, and the disc can rotate along its own axis. During the shrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com