Progressive die of side plate of rocking chair underframe

A progressive die and chassis technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of large amount of raw materials for side panels, unstable product size, low utilization rate of raw materials, etc., and reduce the cutting of edge material. The effect of process, size accuracy and product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

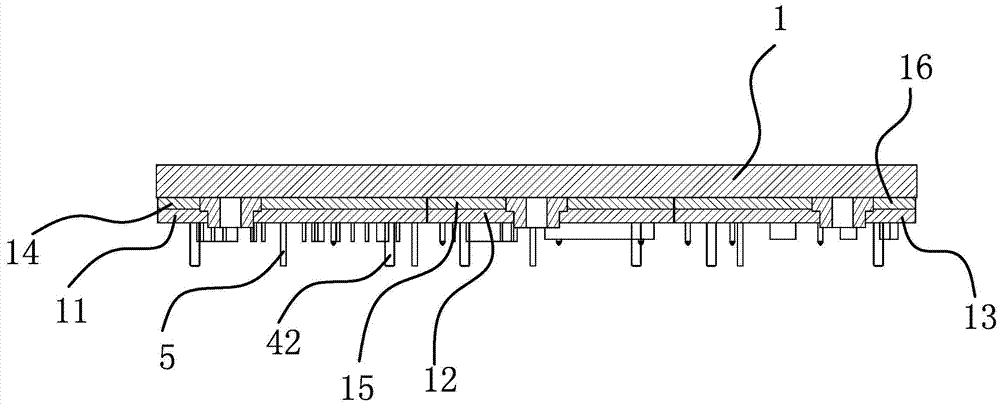

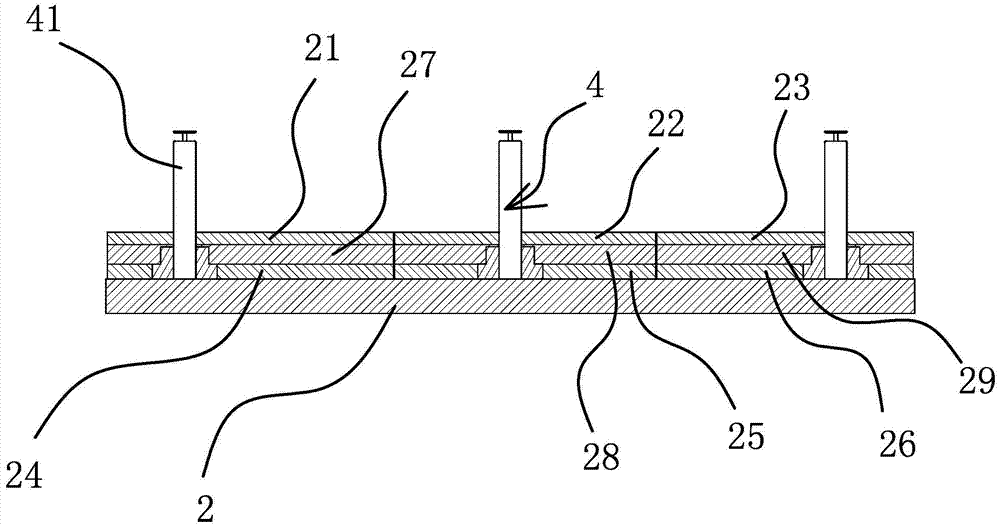

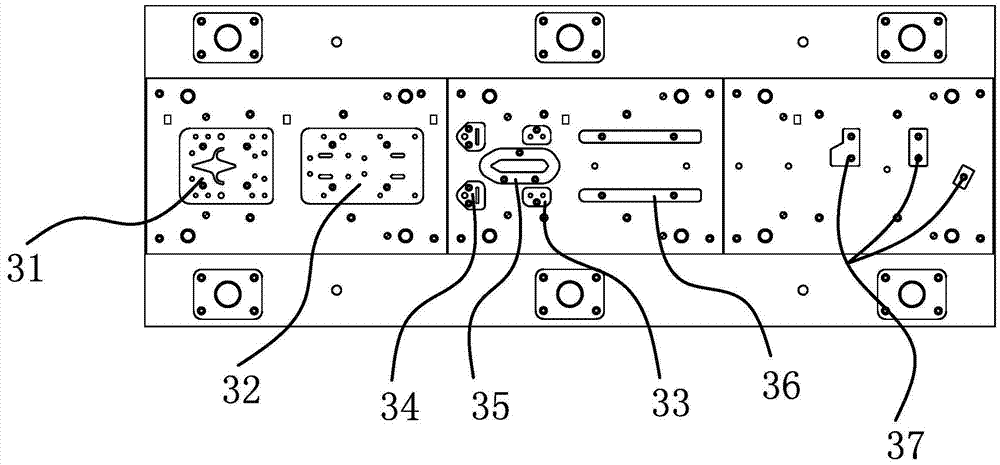

[0025] Such as figure 1 , figure 2 with image 3 As shown, a progressive die for the side plate of the bottom frame of a rocking chair includes an upper die base 1 and a lower die base 2, and a guide post 4 arranged between the upper die base 1 and the lower die base 2, the lower end of the upper die base 1 The first splint 11, the second splint 12 and the third splint 13 are arranged in sequence, and the upper end of the lower mold base 2 is provided with the first stripping plate 21, the second stripping plate 22 and the third stripping plate respectively corresponding to the first splint 11, the second splint 12 and the third splint 13. 23. Plywood one 11 is provided with punching insert one 31 and punching insert tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com